Patents

Literature

33results about How to "Has fast hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

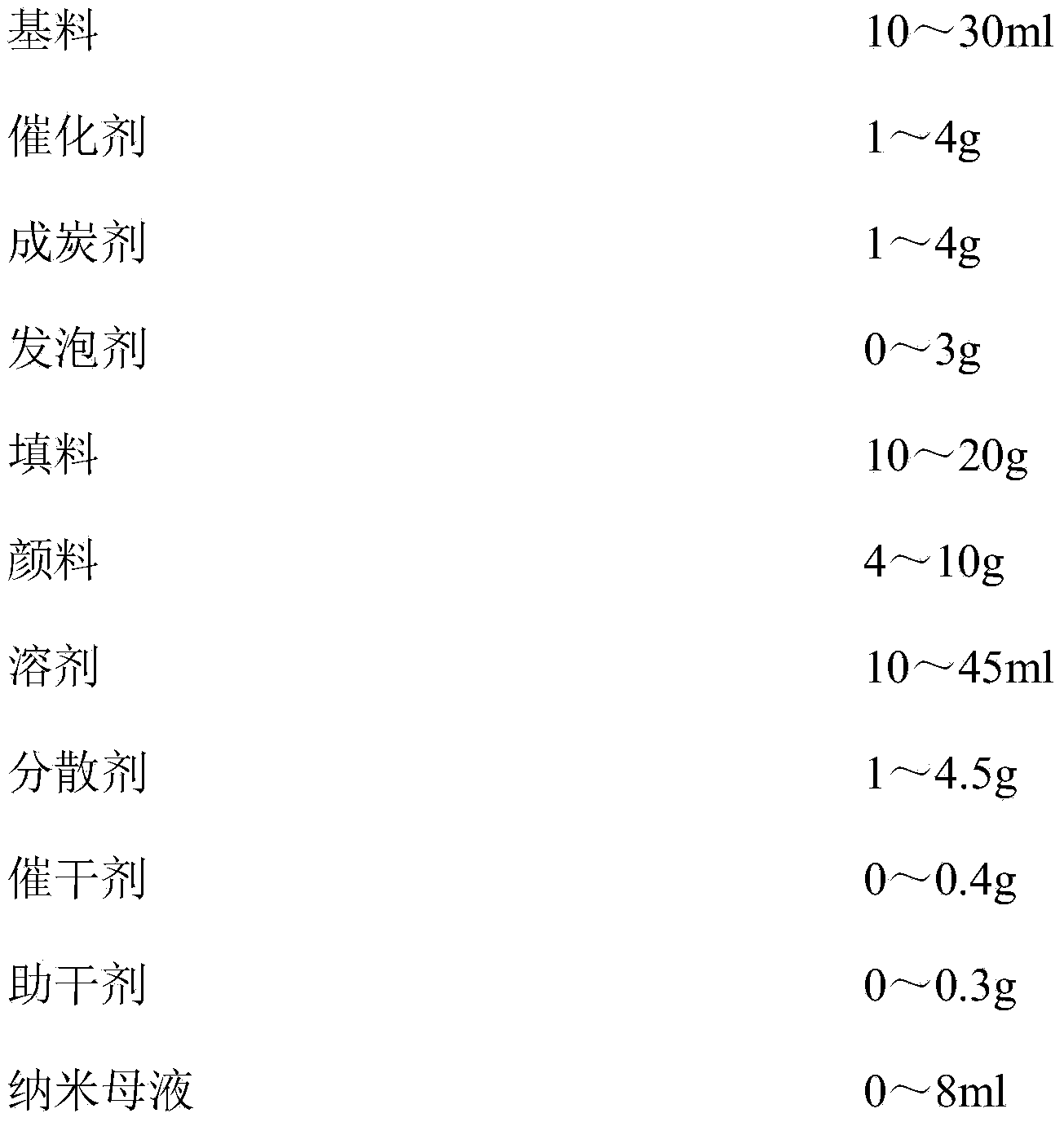

Fire-retardant coating with photo-catalytic performance and preparation method thereof

The invention discloses a fire-retardant coating with photo-catalytic performance and a preparation method thereof, belonging to the field of fire-retardant coatings. The coating comprises a base material, a catalyst, a charring agent, a foaming agent, a filler, a pigment, a solvent, a dispersant, a drier, a drying aid, a nano mother solution and the like, wherein the base material is aluminum dihydrogen phosphate, the catalyst is ammonium polyphosphate, the charring agent is pentaerythritol, the foaming agent is melamine, the filler is ultra-fine slag powder, the pigment is Cu-La / TiO2, the solvent is water, the dispersant is a BYK180 polymeric dispersant, the drier is lead oxide, the drying aid is zinc powder, and the nano mother solution is a nano SiO2 mother solution. The fire-retardant coating disclosed by the invention reduces the environment pollution to the maximum extent by using industrial waste residues as the filler; meanwhile, the coating has a function of realizing photocatalytic degradation of formaldehyde gas under a visible light source to endow conventional fire-retardant coatings with a brand-new function, and the fire-retardant coating accords with the development trend of national green ecological building materials.

Owner:镇江新智生物科技有限公司

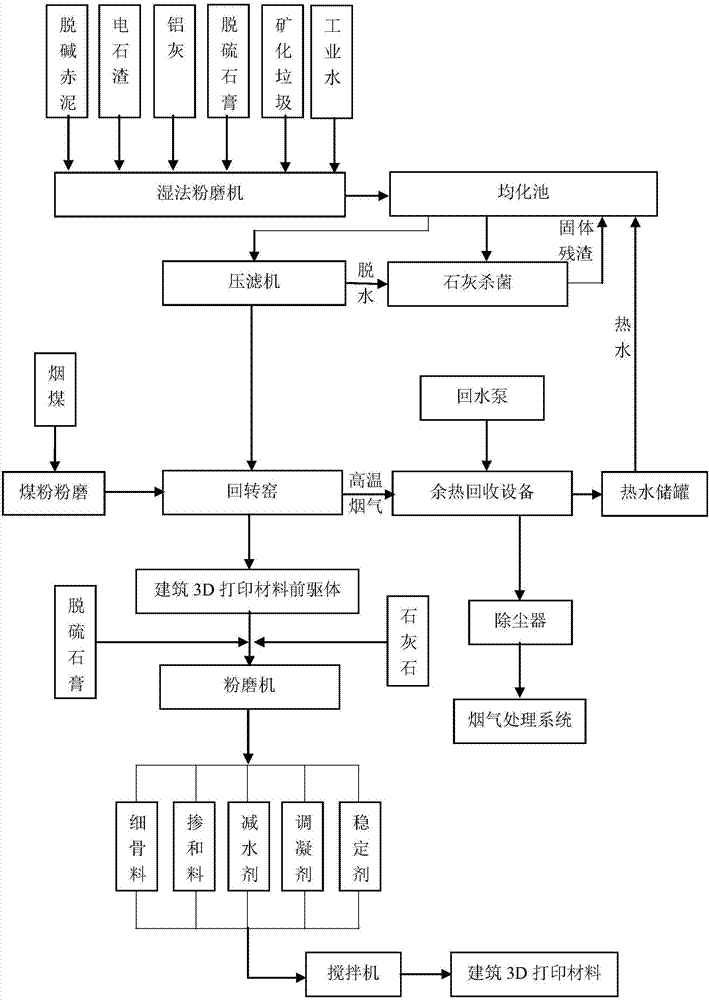

System and method for preparing building 3D printing material by using municipal waste and industrial solid waste

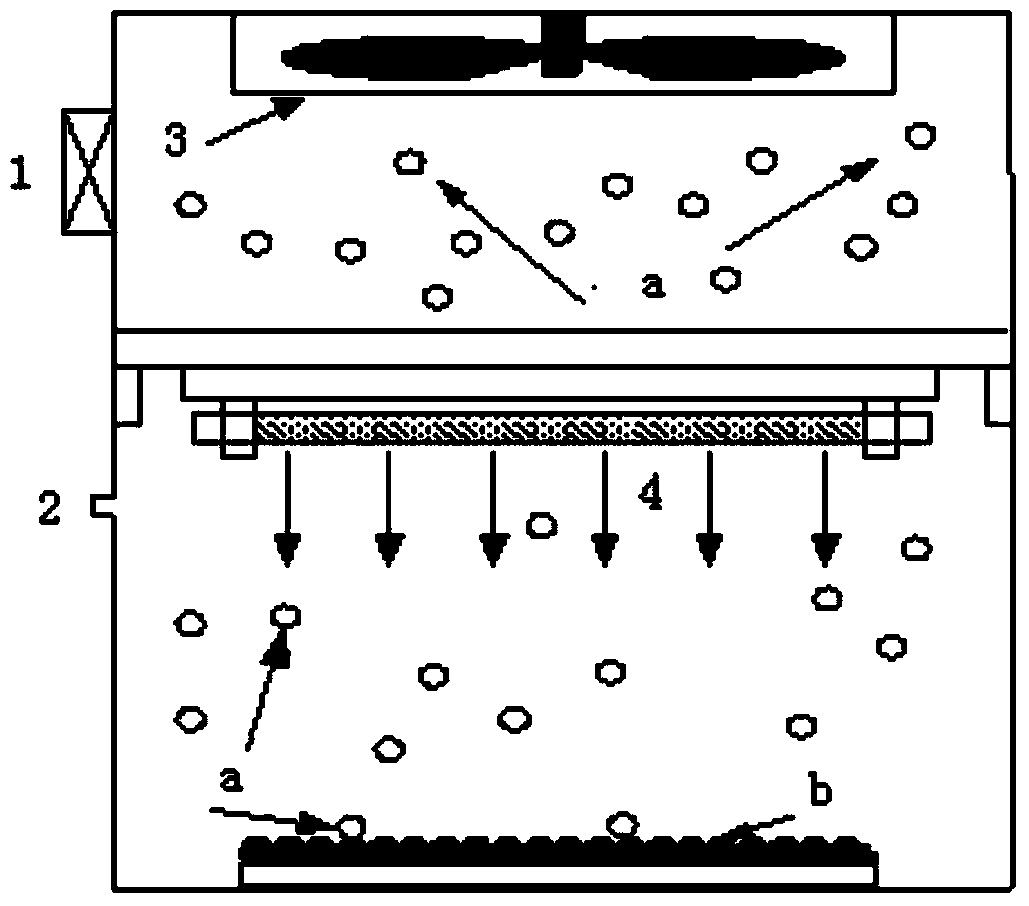

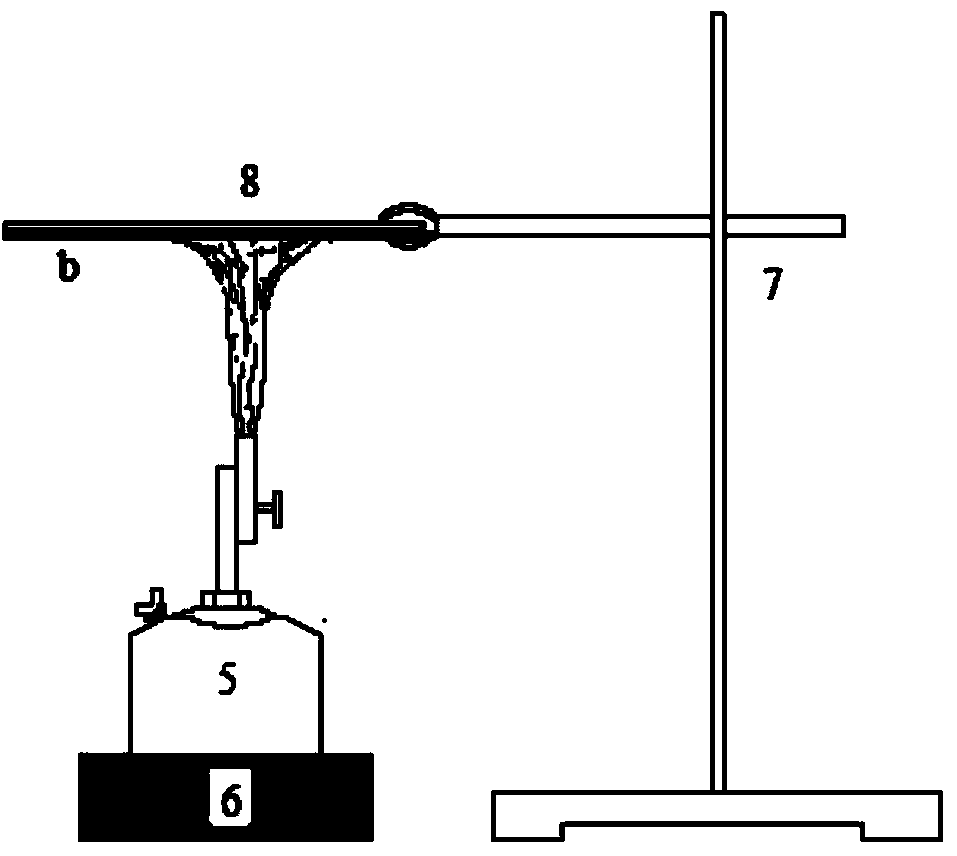

ActiveCN106904924ALow costReduce energy consumptionAdditive manufacturing apparatusSolid waste managementDry weightRed mud

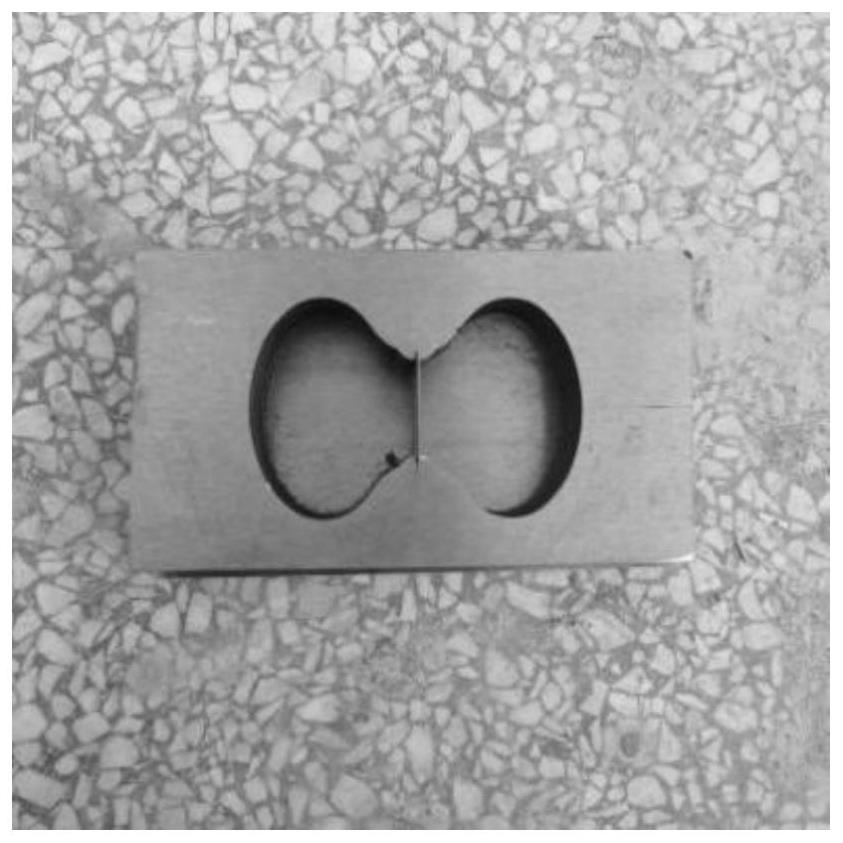

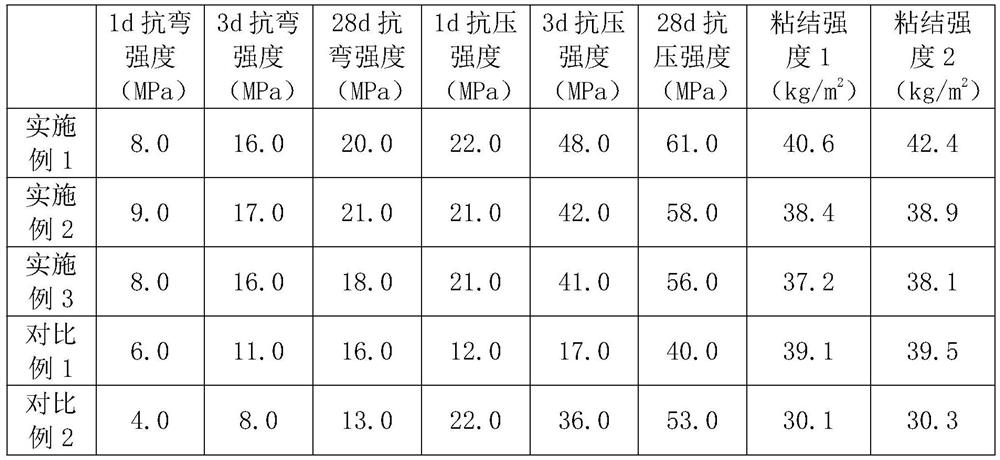

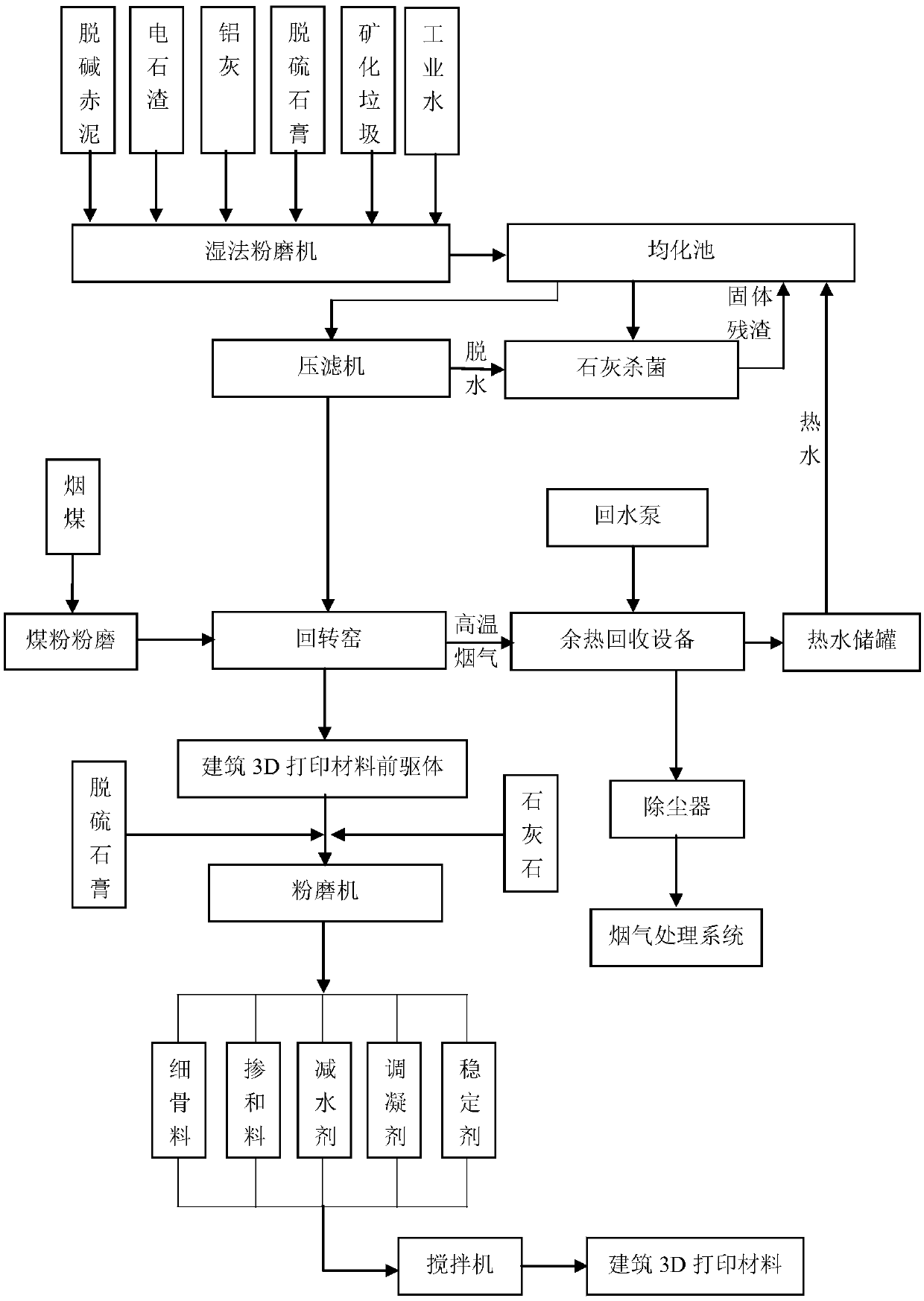

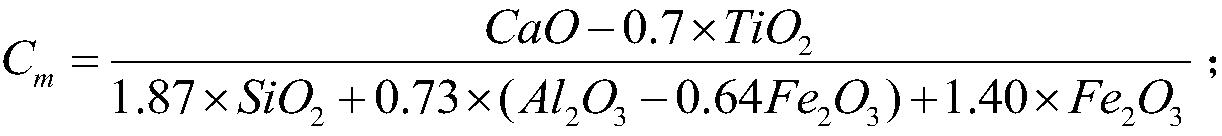

The present invention discloses a system and a method for preparing a building 3D printing material by using municipal waste and industrial solid waste. The system comprises a homogenization pool, a wet powder mill, a filter press, a rotary kiln, a powder mill and a hot water storage tank. According to the method, wet sludge produced from an urban sewage treatment plant is directly mixed with mineralized garbage, red mud, desulfuration gypsum, carbide slag and industrial water to form a mixed solution without dewatering, a dry weight ratio of the wet sludge to the mineralized garbage to the red mud to the desulfuration gypsum to the carbide slag in the mixed solution is 5-10:5-10:15-30:10-20:30-60, the solid-liquid ratio in the mixed solution is maintained at 1:3-1:4, the mixed solution is sequentially subjected to wet milling, homogenization treatment and alkali removing, the homogenization treatment temperature is 60-70 DEG C, the homogenized material is subjected to mechanical pressure filtration dehydration, and the filtered material is subjected to high temperature calcination to obtain the building 3D printing material precursor.

Owner:SHANDONG UNIV

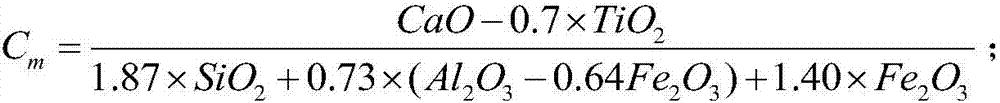

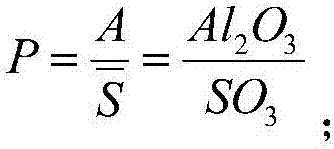

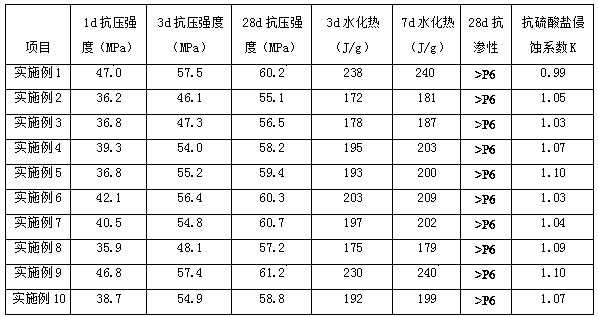

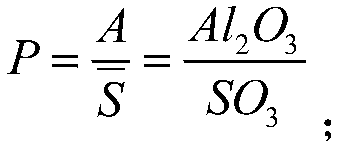

White sulphoaluminate cement and preparing method thereof

The invention provides white sulphoaluminate cement. The white sulphoaluminate cement comprises the following raw materials in parts by weight: 65-90 parts of white sulphoaluminate cement clinker, 0-20 parts of dolomite, 5-15 parts of gypsum, 0-5 parts of white silicate cement clinkers, 0-10 parts of slag and 0-2 parts of retarder. The white sulphoaluminate cement has the characteristics of rapid hardening, early strength, high strength and the like, and the clinkers also have the characteristics of low forging temperature, energy saving, environment-friendliness and the like. The invention further provides a preparing method for the white sulphoaluminate cement.

Owner:SINOMA INT ENG

Low alkali high-strength cement

The invention relates to a low-alkali high-strength cement comprising the following clinker components (by weight parts), C4A3S 20-30 parts, C2S 20-30 parts, C3S 15-30 parts, CaSO4 5-15 parts, C4AF 5-10 parts, C3A 2-5 parts, the cement may also contain CaCO3 5-10 parts or / and SiO2 t-10 parts as additives.

Owner:王红

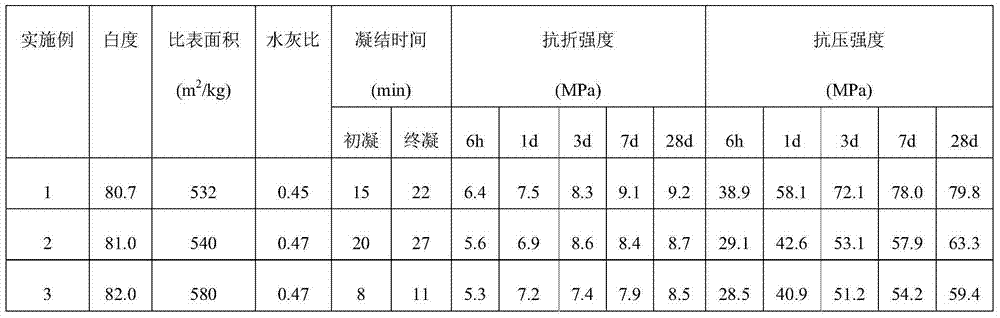

System and method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste

ActiveCN106866006ASolve the shortcomings of productionSolve the problem of difficult utilization of solid wasteClinker productionFiltrationRed mud

The invention discloses a system and a method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste. The system consists of an organic wastewater pool, a homogenizing pool, a wet powder mill, a pressure filter, a rotary kiln and an indirect heat exchanger. The method includes: mixing dealkalized red mud, carbide slag, aluminum ash, desulfurized gypsum and a part of organic wastewater to obtain a mixed solution, which has a water content of 60%-70% (mass), then conducting wet pulverizing on the mixed solution, and subjecting the wet pulverized material to homogenizing treatment so as to obtain a slurry, and performing mechanical pressure filtration dehydration to obtain a slurry, concentrating another part of organic wastewater, then sending the concentrated organic wastewater and the slurry into the rotary kiln and performing high-temperature calcination to obtain a sulphoaluminate clinker, and spraying pulverized coal into the rotary kiln during high-temperature calcination to combust organic waste in the pulverized coal and slurry and organic waste in the concentrated wastewater. The system and method realize comprehensive utilization of industrial solid waste and organic wastewater and zero-pollution emission.

Owner:SHANDONG UNIV

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

Ferronickel slag magnesium phosphate binding material and application thereof

InactiveCN106630924AHigh yieldGuaranteed physical and mechanical propertiesSolid waste managementPorosityMagnesium phosphate

The invention discloses a ferronickel slag magnesium phosphate binding material and application thereof. The binding material is prepared from 6-12 parts of ferronickel slag, 12-25 parts of dead burned magnesia, 3-12 parts of phosphate and 1-10 parts of retarder. The ferronickel slag magnesium phosphate binding material is used in structural members requiring high strength in early age period and rush-repair work. The ferronickel slag magnesium phosphate binding material has the advantages of achieving rapid hardening and early strengthening, and being high in strength and small in shrinkage deformation, the interior structure is more compact, the porosity is low, and the durability including water tolerance is improved. Moreover, according to the ferronickel slag magnesium phosphate binding material, innocent treatment of the ferronickel slag is achieved, high-efficiency resource utilization of industrial waste residues is promoted, and on the premise that the mechanical properties of the binding material is guaranteed, the consumption of dead burned magnesia is reduced, the consumption of a non-renewable resource, namely magnesite, and energy loss are reduced, the production cost of the magnesium phosphate binding material is decreased, and therefore, economic benefits and environmental benefits are remarkable.

Owner:HOHAI UNIV

High-iron sulfoaluminate cement clinker and preparation method of same

InactiveCN109020274ASmall shrinkageMake up for drying shrinkageCement productionCalcium in biologyPolymer science

The invention discloses a high-iron sulfoaluminate cement clinker and a preparation method of same. The high-iron sulfoaluminate cement clinker includes, by mass, 45-70% of a calcium material, 5-40% of an aluminum material, 5-30% of an iron material, and 5-15% of a gypsum material. The clinker has mineral composition of: 35-55% of C4A3S, 20-35% of C2S and 15-25% of C4AF. In the invention, the cement clinker is prepared from low-grade calcium material, gypsum material and the like being raw materials, so that the product is higher than ordinary Portland cement in both early strength and later strength; due to the specific mineral composition, the cement clinker is low in overall hydration heat and has a good volume stability.

Owner:JIAHUA SPECIAL CEMENT

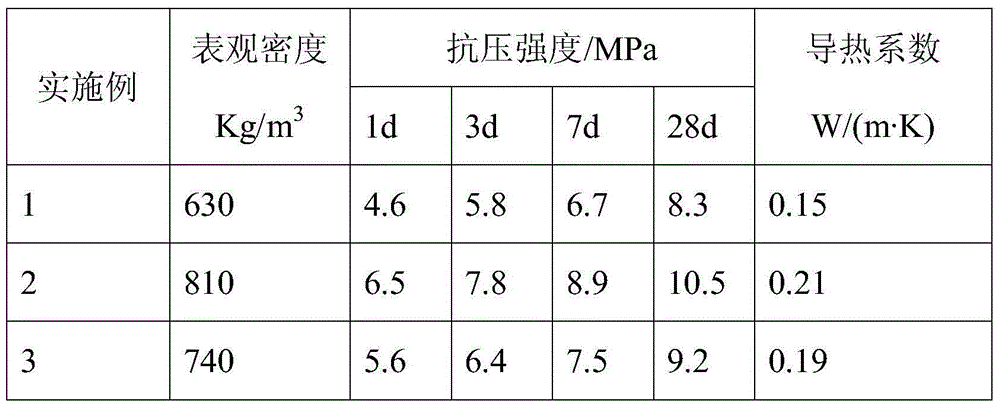

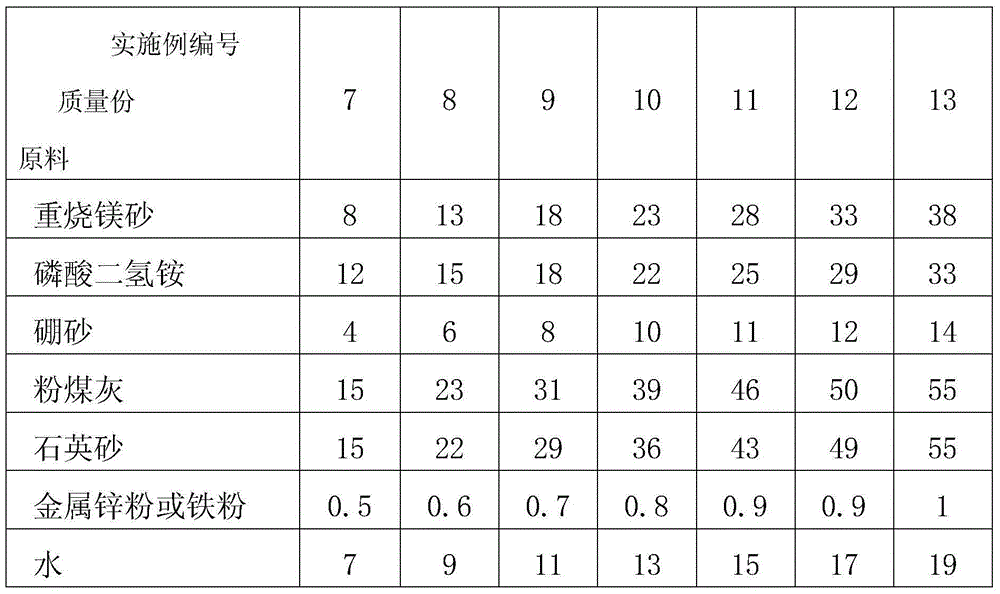

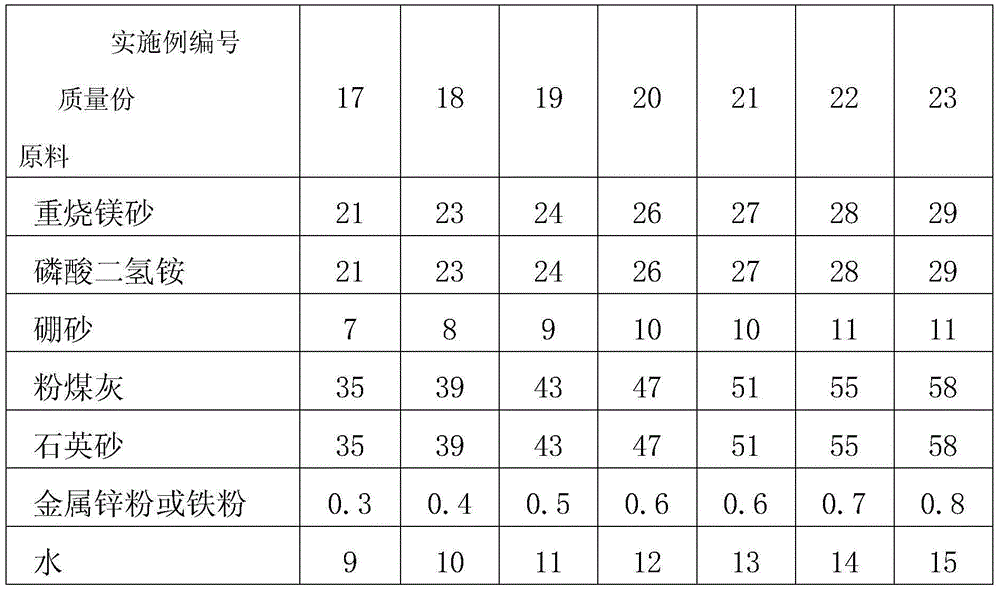

Magnesium phosphate cement-base porous material and preparation method thereof

InactiveCN104556954AGood acid and alkali corrosion resistanceGood insulation performanceCeramicwareMagnesium orthophosphatePowder mixture

The invention discloses a magnesium phosphate cement-base porous material and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking the following raw materials in parts by mass: 5-40 parts of dead burnt magnesite, 10-35 parts of ammonium dihydrogen phosphate, 2-15 parts of borax, 10-60 parts of fly ash, 10-60 parts of quartz sand, 0.3-1 part of metallic zinc or iron powder and 5-20 parts of water; uniformly mixing the dead burnt magnesite, ammonium dihydrogen phosphate, borax, fly ash, quartz sand and metallic zinc or iron powder to obtain a powder mixture; adding the powder mixture into a container with a stirring device, adding water while starting time keeping, stirring slowly for 15-30 seconds, stirring quickly for 1.5-3 minutes, stopping stirring for 15 seconds, and stirring quickly for 3-5 minutes to obtain a slurry; and forming the slurry, and curing to obtain the magnesium phosphate cement-base porous material. The porous material disclosed by the invention has the advantages of early strength, quick hardening, favorable acid / alkali attack resistance, favorable thermal-insulation property, low carbon and environment friendliness, and is mainly used as a thermal-insulation material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

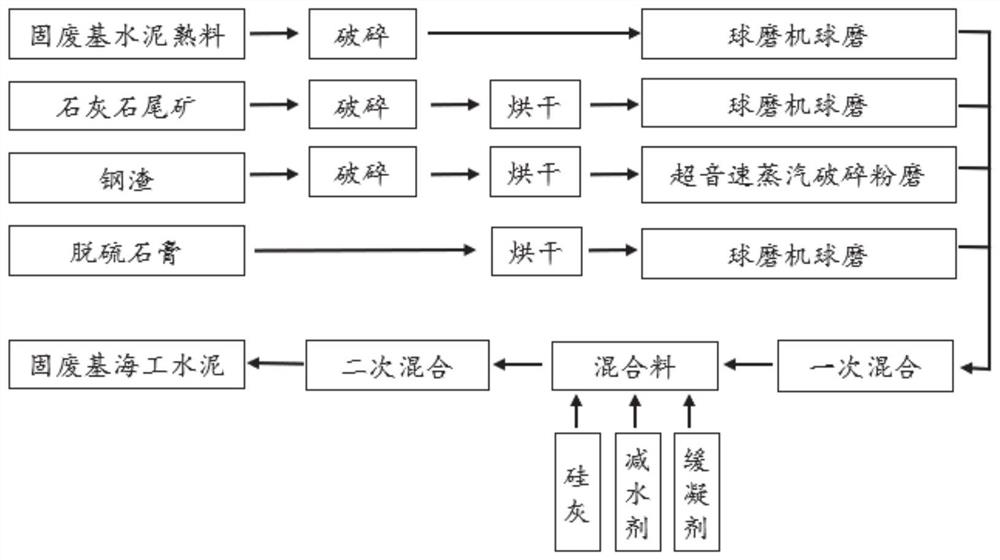

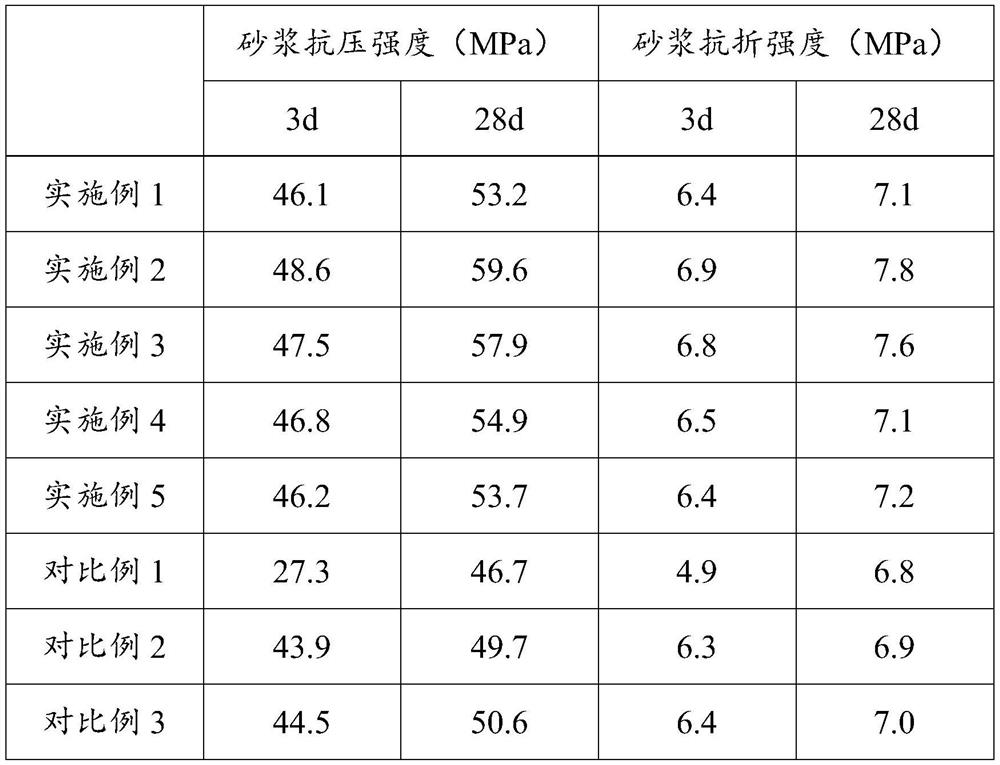

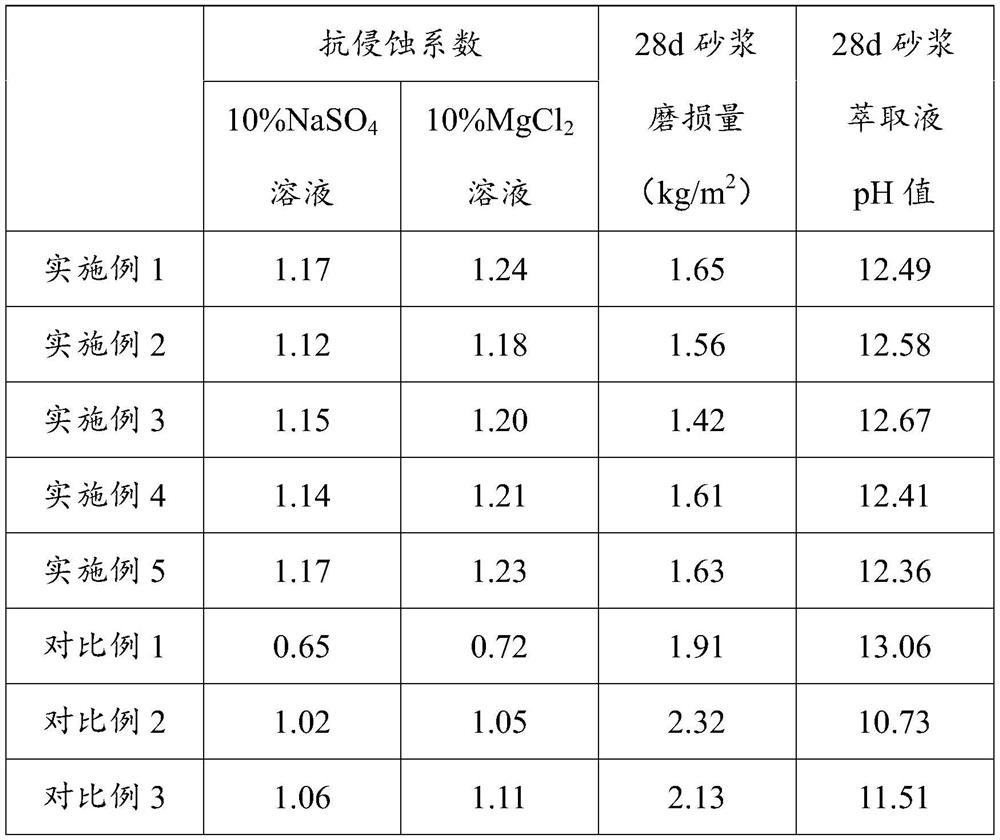

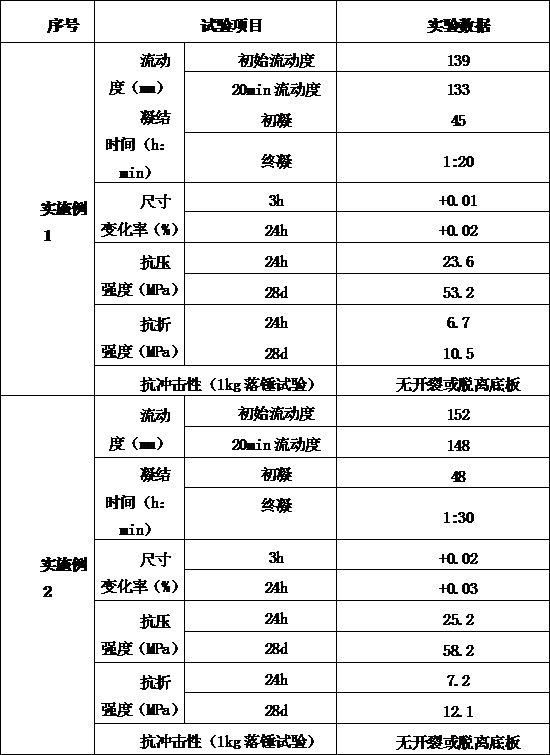

Solid-waste-based high-iron sulphoaluminate maritime work cementing material as well as preparation method and application thereof

The invention belongs to the resource recycling industry, and relates to comprehensive utilization of solid wastes, in particular to a solid-waste-based high-iron sulphoaluminate maritime work cementing material as well as a preparation method and application thereof. The high-iron sulphoaluminate cement is prepared from the following raw materials in parts by mass: 70 to 80 parts of solid waste-based high-iron sulphoaluminate cement clinker, 5 to 10 parts of desulfurized gypsum, 5 to 10 parts of limestone tailings, 10 to 20 parts of steel slag, 0.15 to 0.2 part of water reducing agent, 0.05 to 0.1 part of retarder and 2 to 4 parts of silica fume. The concrete has the characteristics of quick hardening, early strength, high strength, high compactness, high permeability resistance and the like, is particularly resistant to seawater erosion, has excellent seawater erosion resistance and carbonization resistance, and can effectively prolong the durability of marine concrete engineering.

Owner:SHANDONG UNIV

Multi-component concrete composite repair mortar

InactiveCN111875322AImprove liquidityGood self-compactnessStructural engineeringUltimate tensile strength

The invention belongs to the technical field of prefabricated building application, and particularly discloses multi-component concrete composite repair mortar, which is prepared from the following multiple mixtures according to a certain proportion: a cementing material, a mineral admixture, a plastic expanding agent and a functional additive; when multi-component concrete composite repair mortaris prepared from dry powder composed of the cementing material, the mineral admixture, the plastic expanding agent and the functional additive, the multi-component concrete composite repair mortar isprepared by stirring the dry powder and water according to the ratio of 0.11-0.16. The multi-component concrete composite repair mortar disclosed by the invention has the beneficial effects of good fluidity, strong self-compaction, high early strength, micro-expansion in volume, no collapse in later strength and good durability, and has the advantages of quick setting, quick hardening and strongconstruction adaptability.

Owner:江苏智信达建筑科技有限公司

High corrosion resistant marine cement cementing material and preparation method thereof

The invention relates to the construction field, and in particular relates to a high corrosion-resistant marine cement cementing material and a preparation method thereof, and the high corrosion-resistant marine cement cementing material comprises 20-25 parts of wollastonite; 80-100 parts of sulphoaluminate cement; 30-50 parts of nano-like hydrotalcite; 20-30 parts of fiber; 80-100 parts of coralreef sand; 50-60 parts of polyacrylamide; 20-30 parts of modified acrylic emulsion and 10-15 parts of additives; the invention aims to overcome the defects of the prior art and provide the high corrosion-resistant marine cement cementing material and the preparation method thereof. The high corrosion-resistant marine cement cementing material has the characteristics of good mechanical strength, durability and corrosion resistance, improved bending strength, improved cement density, better flocculation property, capability of reducing friction resistance between liquids, excellent impermeability, quick hardening, early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

High-toughness epoxy composite grouting material capable of being constructed at low temperature and preparation method thereof

The invention relates to a high-toughness epoxy composite grouting material capable of being constructed at low temperature and a preparation method thereof. The epoxy composite grouting material comprises a component A, a component B and a component C, the component A comprises an epoxy emulsion, a styrene-butadiene emulsion and a defoaming agent; the component B comprises a curing agent, a cosolvent and water; and the component C comprises modified cement powder, a coagulant, a retarder, a powder water reducer, alkali-resistant glass flakes and quartz sand. The three components are uniformly mixed and stirred according to a certain proportion and sequence for use. The defects that an existing epoxy mortar grouting material is poor in low-temperature constructability and a common cement-based grouting material is low in early strength are overcome, a waterborne epoxy rapid curing system is combined with a special cementing material, the grouting material has the advantages of being good in groutability and rapid in hardening and early strength under the low-temperature condition, and the grouting material is safe and environmentally friendly. Meanwhile, after being hardened, the material is high in toughness and good in impact resistance and corrosion resistance, and can be widely applied to the fields of building repair and reinforcement, duct grouting, secondary grouting and the like.

Owner:安徽瑞和新材料有限公司 +2

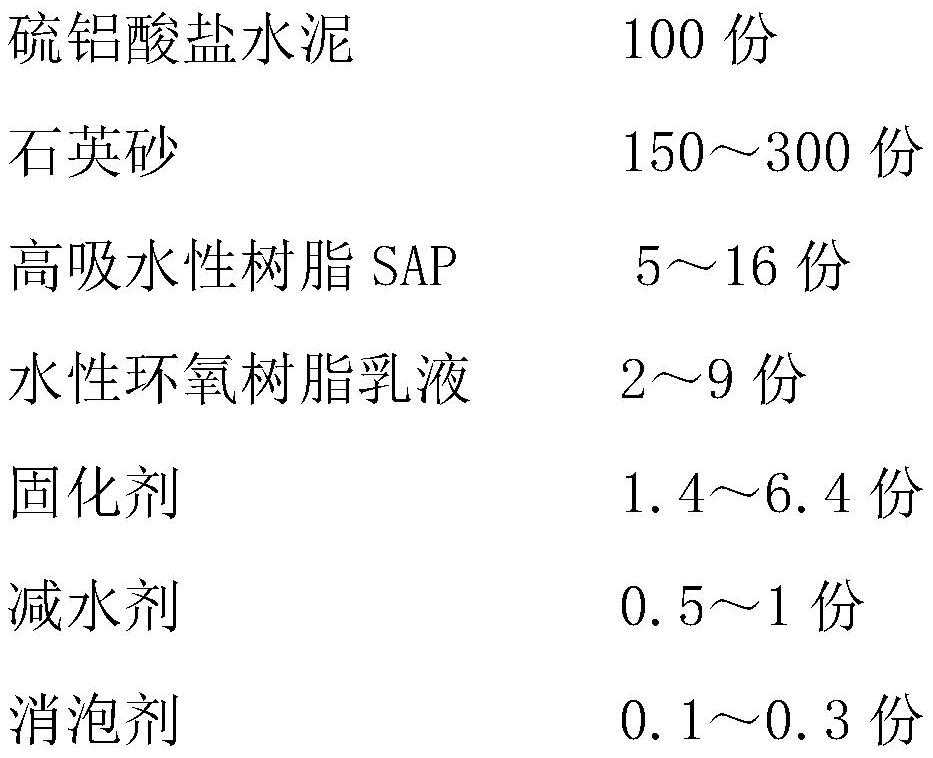

High-impermeability cement-based repairing mortar with crack self-sealing function and preparation method

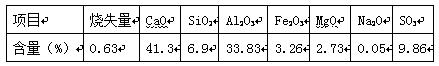

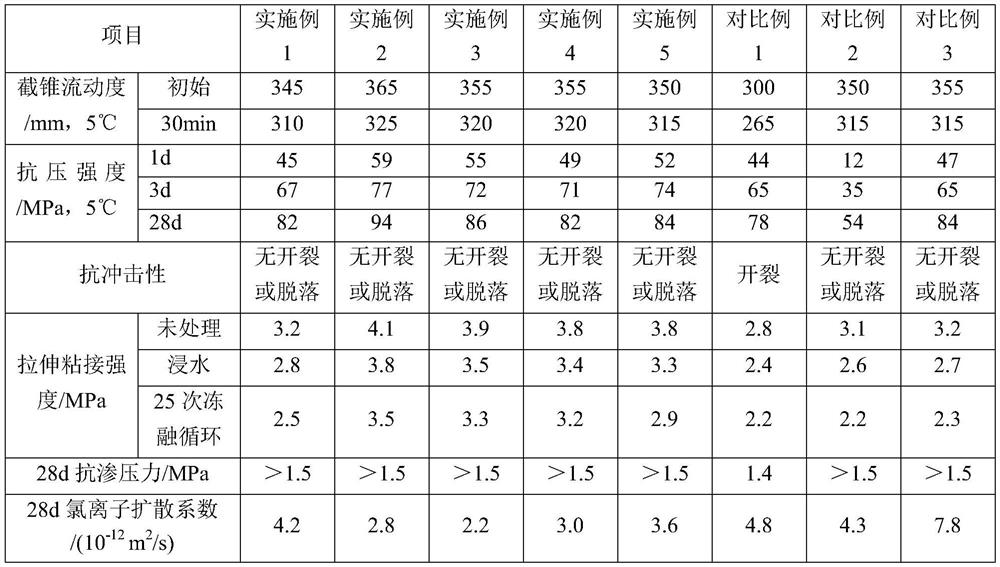

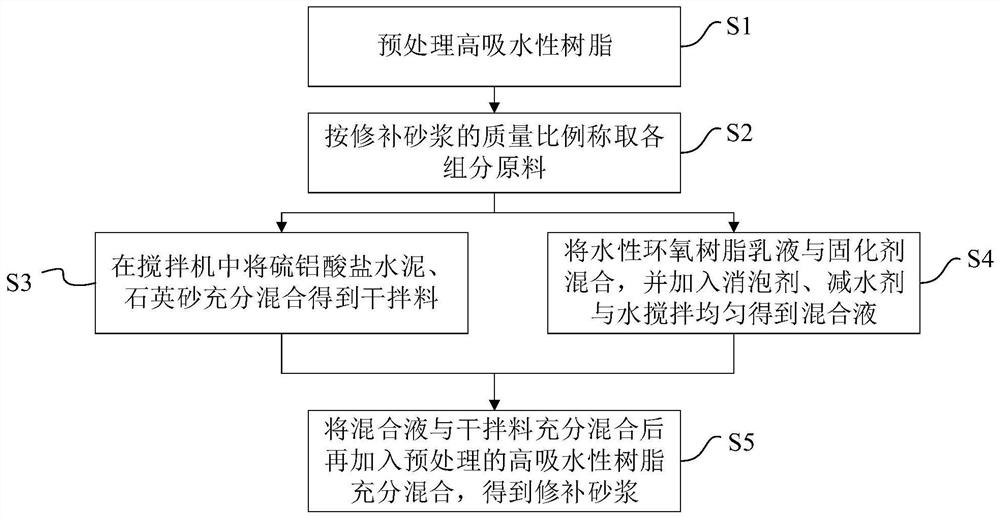

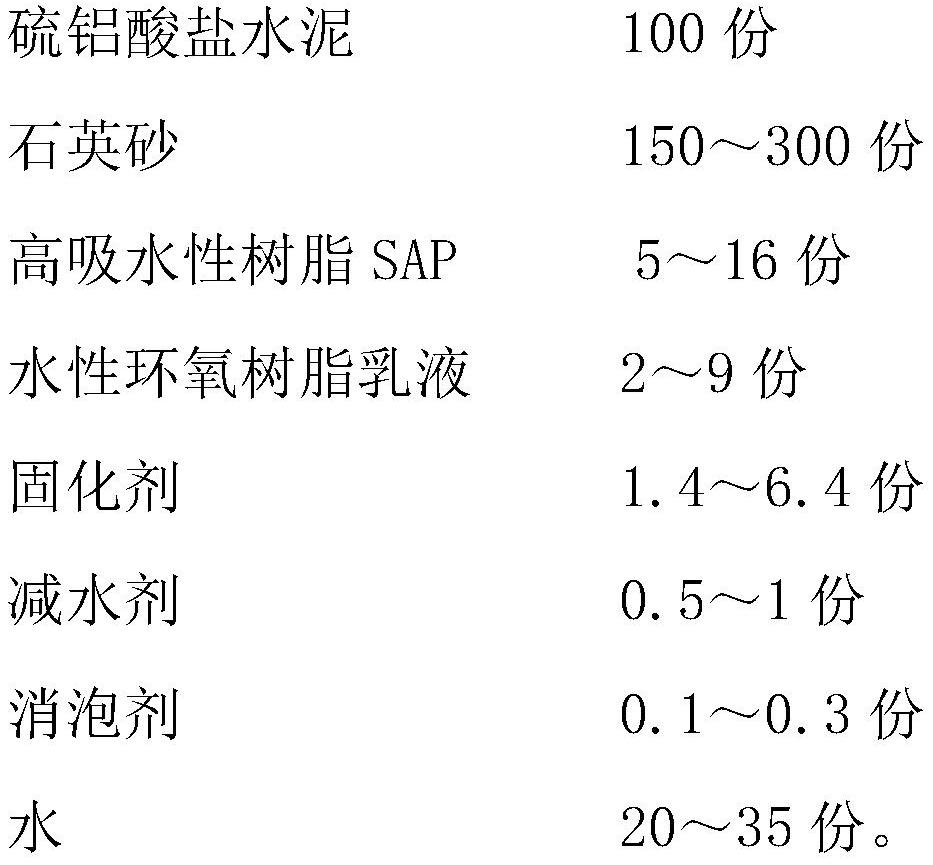

The invention relates to high-impermeability cement-based repair mortar with a crack self-sealing function and a preparation method, and is suitable for the technical field of building materials. The repair mortar is prepared from the following components in parts by mass: 100 parts of sulphoaluminate cement, 150 to 300 parts of quartz sand, 5 to 16 parts of super absorbent resin SAP, 2 to 9 parts of waterborne epoxy resin emulsion, 1.4 to 6.4 parts of curing agent, 0.5 to 1 part of water reducing agent, 0.1 to 0.3 part of defoaming agent and 20 to 35 parts of water. The super absorbent resin needs to be pretreated by adopting a high-concentration calcium salt solution before being used. The cement-based repairing mortar provided by the invention not only has a good bonding effect with matrix concrete, but also has a crack self-sealing function when underground water permeates, so that a good anti-permeability effect is achieved, and the repairing efficiency of underground engineering concrete under high-water-content geology can be effectively improved.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Method for recycling magnesium oxysulfate building material waste based on magnesite tailings and product

The invention belongs to the technical field of building waste recycling, particularly relates to a method for recycling magnesium oxysulfate building material waste based on magnesite tailings, and further discloses a product prepared from the waste. According to the method for recycling the magnesium oxysulfate building material waste based on the magnesite tailings, magnesium oxysulfate building materials are heated and activated by a flue, performances of gel materials of the magnesite tailings are assisted, the compressive strength of a prepared building material product reaches 42.5MPa or more, a softening coefficient reaches up to 0.9 or more, and the product has the advantages of high strength and good water resistance, rapidness in hardening, easiness in strength and the like andcan be used for repairing materials. The product is uniform in quality, stable in performance and long in service life, main materials of the product include more than 95% of the waste, the recyclingrate of the magnesium oxysulfate building material waste can reach 90%, the method is economical and environmentally friendly, energy is saved, emission is reduced, the magnesium oxysulfate building material waste is recycled, waste accumulation of low-grade magnesite tailings is treated, magnesium sulfate produced by waste acid is used and the like.

Owner:辽宁科大中驰镁建材科技有限公司 +1

Plastering gypsum formula

The invention discloses a plastering gypsum formula, which comprises the following materials in weight percent: desulfurized gypsum and calcium carbonate (with a ratio of 8:2), 5 percent of fine sand screened out by a 0.8mm mesh screen, 1.8 thousandths of hydroxypropyl methylcellulose, 1 thousandth of polyvinyl alcohol, 1 thousandth of lignocellulose, 3 thousandths of gypsum retarder, 0.15 thousandths of guar gum and 2 thousandths of slaked lime, all of which are mixed uniformly. The plastering gypsum produced by the formula is convenient and fast in construction, gelates automatically, has a unique self-breathing function, is colorless, odorless, non-radioactive and noise-absorbing, does not shrink and crack, can meet the function requirements of building partitions, is economical and practical, is an ideal choice for high-rise and middle and low rise building walls and decoration and fitment, and has the advantages of high strength, rapid hardening, fire protection, earthquake resistance, heat resistance, heat insulation, sound insulation, high cementation, no empty drum, construction success in one time, convenient operation and the like; not only project quality is improved but also project period is shortened, and better comprehensive benefits are obtained.

Owner:朔州市润臻新技术开发有限公司

High-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster and preparation method thereof

InactiveCN110342890AFast setting and hardeningHigh flexural and compressive strengthAluminiumSilicate Cement

The invention discloses a high-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster, and belongs to the technical field of self-leveling mortar. The high-strength cement-based self-leveling mortar prepared by desulfurization calcium plasteris prepared from the following raw materials in parts by weight: 18 to 28 parts of desulfurized calcium plaster, 30 to 37 parts of aluminate cement, 5 to 6 parts of Portland cement, 35 to 39 parts of natural siliceous sand, 0.7 to 0.8 part of water reducing agent, and 0.01 part of thickener. The invention further discloses apreparation method of thehigh-strength cement-based self-leveling mortar prepared by the desulfurization calcium plaster. According to the high-strength cement-based self-leveling mortar prepared bythe desulfurization calcium plaster and the preparation method thereof, the performance characteristics of the desulfurized calcium plaster, high-alumina cement, and the ordinary Portland cement are fully utilized respectively, the prepared cement-based self-leveling mortar has the characteristics that the setting and hardening speeds are fast, fracture resistance and crush resistanceof early andlater periods are high, wear resistance is good,the surface is not prone to being pulverized, and impact performance is good; the plasterin the desulfurized calcium plaster is not subjected to treating processes such as pressure filtration and drying, so that the dispersion effect of the desulfurized plasterin cement slurry is better, the production cost is lowered, new approaches are provided forpreparation of cement-based self-leveling mortar and resource utilization of desulfurizedcalcium plaster,and economic and environmental benefits are good.

Owner:YANCHENG INST OF TECH

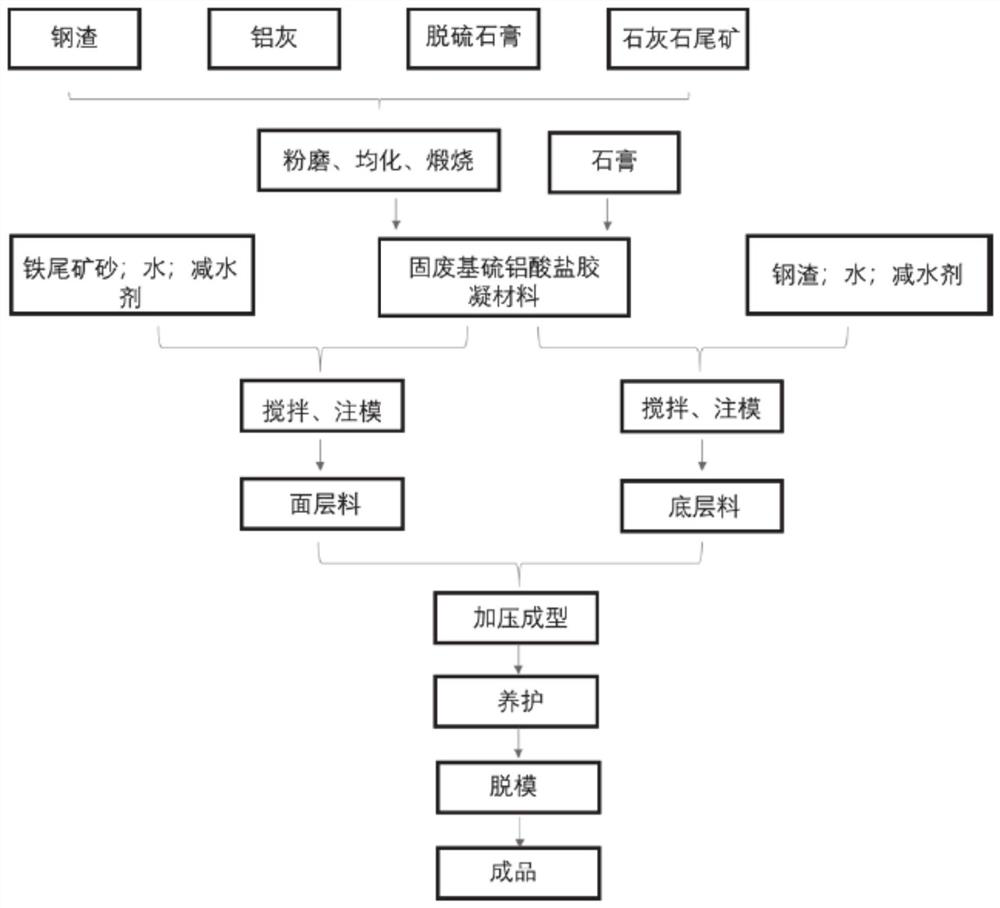

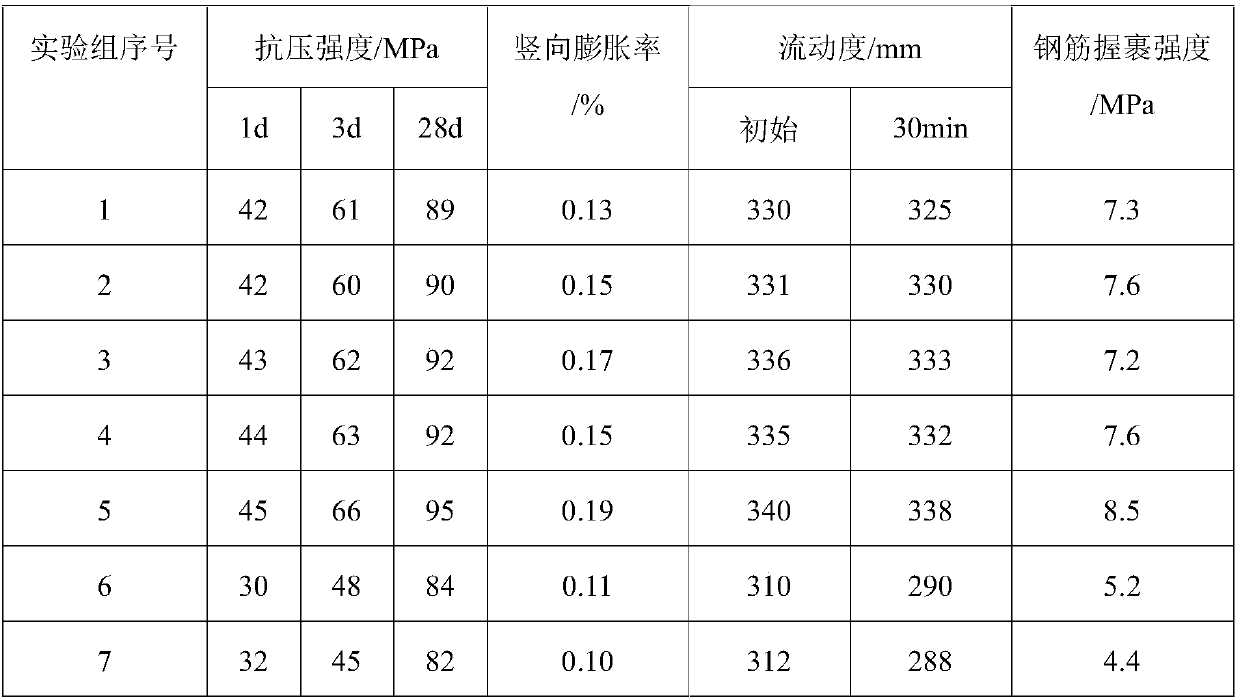

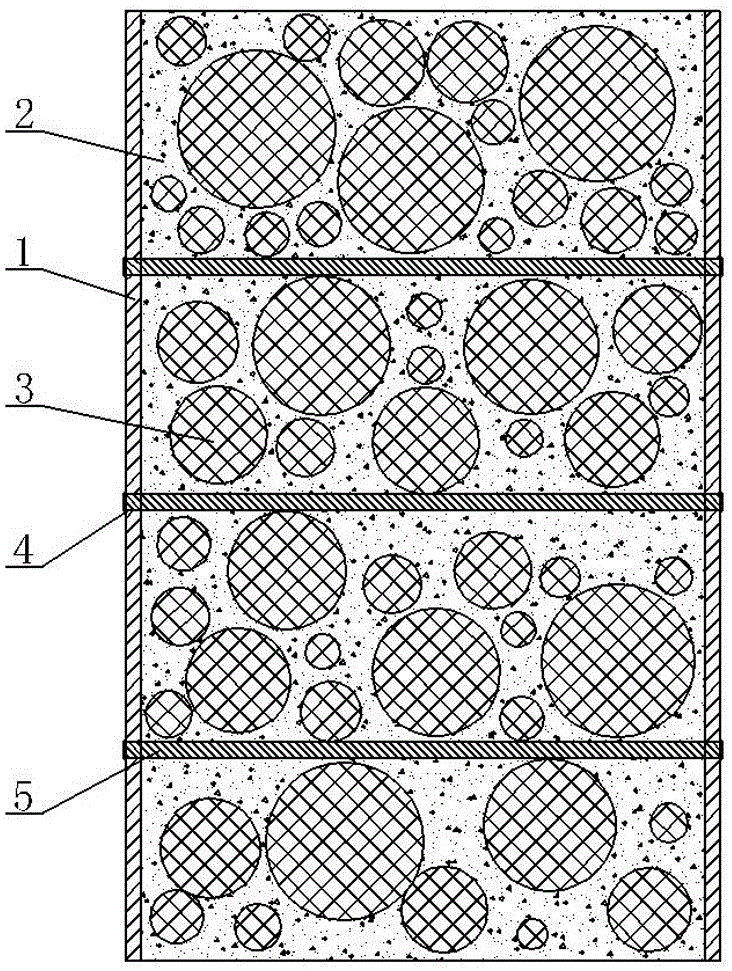

All-solid-waste water permeable brick as well as preparation method and application thereof

PendingCN113582635AEarly strengthHas fast hardeningSingle unit pavingsCeramicwareAluminateCompressive resistance

The invention relates to the technical field of water permeable bricks, in particular to an all-solid-waste water permeable brick and a preparation method and application thereof. The water permeable brick comprises a bottom layer and a surface layer, wherein the bottom layer comprises the following raw materials in parts by mass: 15-22 parts of a solid waste-based sulphoaluminate cementing material, 70-80 parts of steel slag, a water-cementitious material ratio of 0.33, and 3-4.4 parts of a water reducing agent; and the surface layer is prepared from the following raw materials in parts by mass: 15-22 parts of a solid waste-based sulphoaluminate cementing material, 8-10 parts of iron tailing sand, a water-cementitious material ratio of 0.33 and 3-4.4 parts of a water reducing agent. The solid waste-based sulphoaluminate cementing material and the steel slag are compounded, so that the compressive strength of the water permeable brick is improved, and the water permeability of the water permeable brick can be ensured to be good. The wear resistance and the freezing resistance of the water-permeable brick reach the standards of the water-permeable brick, iron tailing sand is selected as aggregate in the surface layer, and the iron tailing sand is compounded with a solid waste-based sulphoaluminate cementing material, so that the water permeability is improved, water can more easily penetrate through the surface layer to reach the bottom layer of the water-permeable brick, and the penetrated water can more easily penetrate through the base layer. All solid waste raw materials are adopted, the process is simple, and cost is low.

Owner:山东高速材料技术开发集团有限公司

Fireproof coating for tunnels

The invention discloses a fireproof coating for tunnels. The fireproof coating comprises the following raw materials in parts by weight: 5-70g of high-alumina cement, 5-70g of ordinary Portland cement, 1-10g of redispersible rubber powder, 9-32g of expanded perlite, 7-33g of expanded vermiculite, 5-15g of hollow beads, 15-35g of light calcium carbonate, 2-12g of bentonite, 2-9g of sepiolite, 1-10gof aluminum silicate fibers, 4-25g of a flame retardant smoke inhibitor, 2-15g of aluminum hydroxide, 3-10g of magnesium hydroxide and 2-10g of sodium tetraborate. According to the invention, throughnon-inflammability and low thermal conductivity of the material and heat absorption performance of the material in a coating layer, the heat rising speed of steel bars is delayed, fire resistance isimproved, the fire resistance limit is enhanced, and bonding strength between the coating and inner walls of the tunnels is enhanced. Fire prevention treatment is effectively carried out in the tunnel, loss caused by external fire is reduced, and repair cost is reduced.

Owner:天津安盛达防火材料有限公司

Grouting material for sound barrier backboard

InactiveCN107602006AHas fast hardeningGood adhesionNoise reduction constructionPre stressingHeat stability

The invention relates to the technical field of building materials and provides a grouting material for a sound barrier backboard. The grouting material comprises the following raw materials (by weight): 15-25 parts of Portland cement, 30-40 parts of fly ash, 50-70 parts of building rubbish, 10-15 parts of water and 0.61-1.08 parts of additives. The grouting material has advantages of wide sourcesof raw materials, high utilization rate of solid wastes, low cost, rapid hardening, early strength, slight expansion, strong bonding force, good heat stability and the like, and can be used as a binder for bonding or reinforcement of engineering equipment. The sound barrier backboard is provided with multiple reinforcing holes. after the backboard is maintained to design strength, the backboard is tensioned with pre-stress steel bars or steel strands, and then the grouting material is injected to glue the pre-stress steel bars or steel strands with the sound barrier backboard as a whole. Thus, the sound barrier backboard is safe and stable and durable.

Owner:SICHUAN SHUANGTIE TECH CO LTD

A method and product for recycling magnesium oxysulfide building material waste based on magnesite tailings

ActiveCN109896824BSolving Recycling ProblemsHigh compressive strengthCompressive resistanceRepair material

The invention belongs to the technical field of recovery and reuse of construction waste, and in particular relates to a method for recycling magnesium oxysulfide building material waste based on magnesite tailings, and further discloses the obtained product. The present invention is based on the method of reusing magnesium oxysulfide building material waste from magnesite tailings, by heating and activating the magnesium oxysulfide building material waste through a flue, supplemented by the performance of magnesite tailings gel material, to obtain building material products The compressive strength reaches above 42.5MPa, the softening coefficient is as high as above 0.9, and has the advantages of high strength and good water resistance; and it has the characteristics of fast hardening and early strength, and can be used for repair materials; at the same time, the product quality is uniform, the performance is stable, and the service life Long, the main material in the product is composed of more than 95% body waste, and its waste recycling rate can reach 90%, which is economical and environmentally friendly, energy saving and emission reduction, and at the same time solves the recycling of magnesium building material waste and the disposal of low-grade magnesite tailings Accumulation, the use of magnesium sulfate in the production of waste acid, etc.

Owner:辽宁科大中驰镁建材科技有限公司 +1

Steel pipe gypsum mortar and waste concrete combined column and preparation method thereof

The invention discloses a steel pipe gypsum mortar and waste concrete combined column. The steel pipe gypsum mortar and waste concrete combined column is characterized by comprising a steel pipe, and gypsum mortar and a waste concrete block which are filled into the steel pipe, wherein the two ends of the steel pipe are sealed by end plates; a plurality of tamping holes are arrayed on a side wall of the steel pipe; a plurality of longitudinal steel bars are uniformly distributed in the circumference of the inner wall of the steel pipe. The invention further discloses a method for preparing the steel pipe gypsum mortar and waste concrete combined column. The steel pipe gypsum mortar and waste concrete combined column prepared by the invention has the characteristics of rapid hardening and early strengthening, and can rapidly reach a bearing capability; the strength of a member is mainly provided by a waste concrete block framework, so that the material cost can be reduced; furthermore, the gypsum mortar is only used as a cementing material and a joint filling material, and the outer part is restrained by the steel pipe, so that the determination of a weak interface between the gypsum mortar and the waste concrete block can be weakened, and the strength and ductility of the member are greatly improved.

Owner:苏州三佳交通工程有限公司

Interface joint material based on industrial solid waste and preparation method thereof

The invention discloses an interface joint material based on industrial solid waste and a preparation method thereof, and relates to the field of interface joint materials for buildings. The concrete comprises the following raw materials in parts by weight: 80-130 parts of Portland slag cement, 80-130 parts of metakaolin, 80-130 parts of industrial solid waste, 25-35 parts of sodium silicate, 8-12 parts of alkali, 30-36 parts of acrylate, 1-3 parts of a trivinyl ether compound, 1-3 parts of inorganic sulfite, 1-3 parts of persulfate, 3-6 parts of a water reducing agent and 60-80 parts of water. The interface joint material based on the industrial solid waste is suitable for concrete interfaces with different components, is good in cohesiveness and high in strength, and has the advantages of being capable of being pumped, rapid in hardening, early in strength, micro in expansion and high in ductility. According to the invention, the industrial solid waste is doped, so that the utilization rate of the industrial solid waste in the joint material for the building is increased, and the joint material has important significance on recycling of the industrial solid waste.

Owner:浙大宁波理工学院

A kind of waterless gunpowder and preparation method thereof

The invention provides an anhydrous taphole clay, which uses high-alumina aggregate, corundum, silicon carbide, boron nitride, pitch and coke as main raw materials, through the synergistic combination of additives soft clay and tar, through batching, mud grinding and It is prepared after forming; the parts by weight of the main raw materials and additives are: high alumina aggregate 20~24, corundum 23~24, silicon carbide 20~25, boron nitride 3~5, pitch 6~8, coke 8 ~10 parts, soft clay 5~8, tar 14~15; The present invention also provides a kind of preparation method of anhydrous gunpowder, at first raw material is stirred evenly to obtain mixed raw material; Milled at 55°C for 40~50? min; then transfer the milled mud to the molding machine, extrude the mud from the squeeze port at 55~65°C, divide the block according to 5~7kg per piece, and carry out no less than 10 times of throwing mud process, make. The anhydrous taphole clay prepared by the invention has high strength, good volume stability, strong slag resistance and erosion resistance, and good opening performance.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Low alkali high-strength cement

The invention relates to a low-alkali high-strength cement comprising the following clinker components (by weight parts), C4A3S 20-30 parts, C2S 20-30 parts, C3S 15-30 parts, CaSO4 5-15 parts, C4AF 5-10 parts, C3A 2-5 parts, the cement may also contain CaCO3 5-10 parts or / and SiO2 t-10 parts as additives.

Owner:王红

Tile adhesive and preparation method thereof

InactiveCN107502241ACompact structureInterface transition zone enhancementNon-macromolecular adhesive additivesMacromolecular adhesive additivesSludgeSlurry

The invention provides a tile adhesive. The tile adhesive is prepared from components of raw materials in parts by weight as follows: 20-40 parts of heavy metal sludge, 5-10 parts of methylethylcellulose ether, 5-10 parts of methyl hydroxypropyl cellulose ether, 8-28 parts of starch ether, 30-50 parts of an acrylic pressure-sensitive adhesive solution and 3-10 parts of triterpenoid saponins. The tile adhesive has the advantages of rapid hardness, early strength, high strength and small shrinkage deformation; by means of the adhesive, the mechanical performance and the durability of a slurry-aggregate interface can be improved.

Owner:东莞市西牛建材科技有限公司

System and method for utilizing municipal waste and industrial solid waste construction 3D printing materials

ActiveCN106904924BIncrease added valueReduce control difficultyAdditive manufacturing apparatusSolid waste managementSlagRed mud

The present invention discloses a system and a method for preparing a building 3D printing material by using municipal waste and industrial solid waste. The system comprises a homogenization pool, a wet powder mill, a filter press, a rotary kiln, a powder mill and a hot water storage tank. According to the method, wet sludge produced from an urban sewage treatment plant is directly mixed with mineralized garbage, red mud, desulfuration gypsum, carbide slag and industrial water to form a mixed solution without dewatering, a dry weight ratio of the wet sludge to the mineralized garbage to the red mud to the desulfuration gypsum to the carbide slag in the mixed solution is 5-10:5-10:15-30:10-20:30-60, the solid-liquid ratio in the mixed solution is maintained at 1:3-1:4, the mixed solution is sequentially subjected to wet milling, homogenization treatment and alkali removing, the homogenization treatment temperature is 60-70 DEG C, the homogenized material is subjected to mechanical pressure filtration dehydration, and the filtered material is subjected to high temperature calcination to obtain the building 3D printing material precursor.

Owner:SHANDONG UNIV

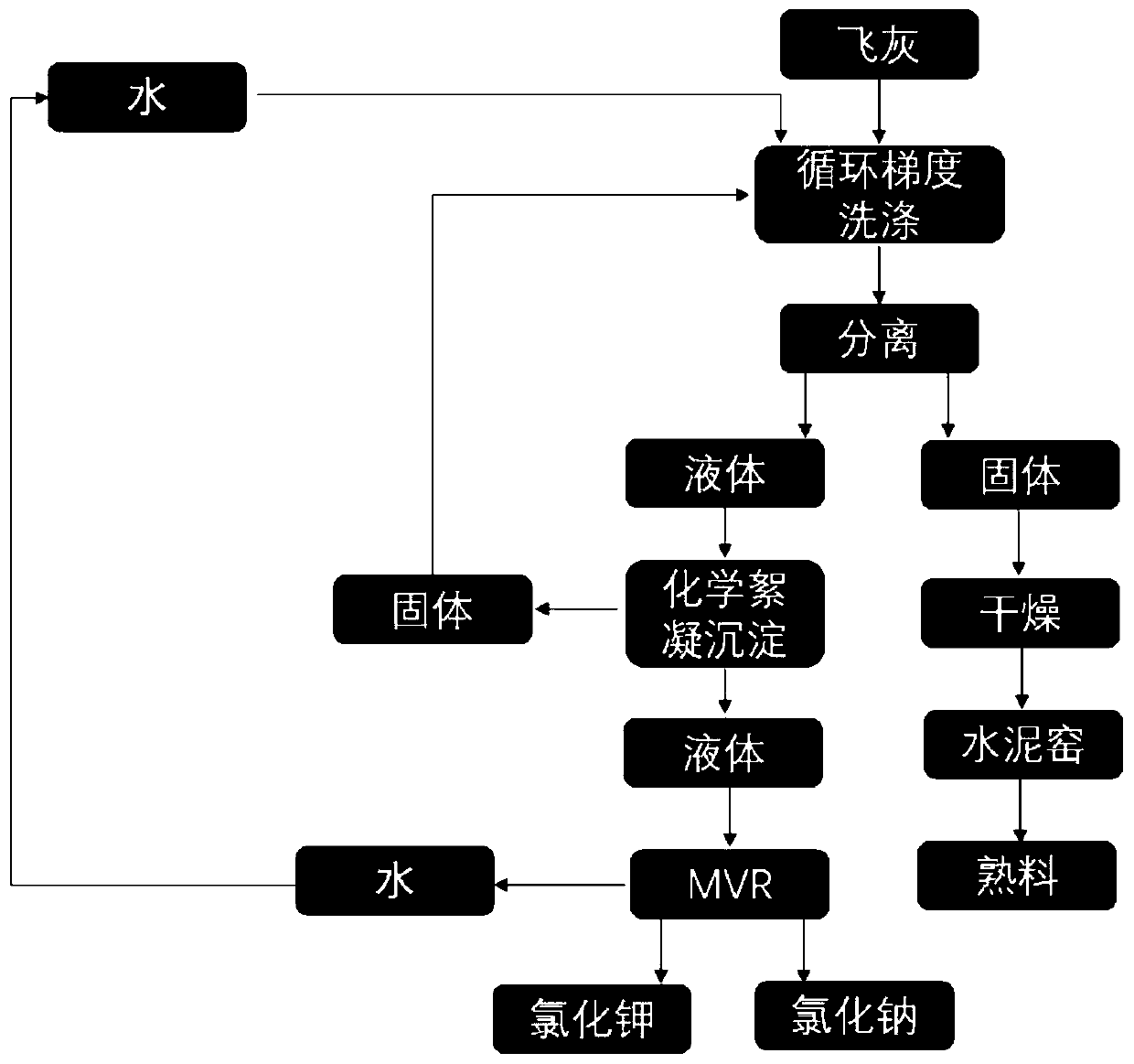

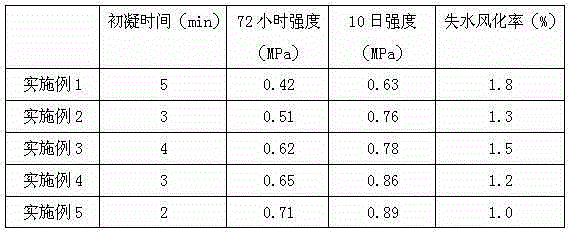

A resource utilization method of waste incineration fly ash and industrial solid waste

ActiveCN108483958BRealize resource utilizationTo achieve the purpose of dealing with fly ashCement productionAluminateClinker (waste)

The invention relates to a method for performing resource utilization on garbage incineration fly ash and industrial solid waste. The method comprises the following steps: 1) performing pretreatment on the garbage incineration fly ash: mixing the garbage incineration fly ash and water, repeatedly washing the garbage incineration fly ash for three times, performing magnetic stirring while washing,filtering after washing, obtaining wet fly ash after filtering, drying at 100 DEG C for 2 hours and grinding the dried product for future use; 2) preparing raw material balls from raw materials such as fly ash, desulfurized gypsum and aluminum ash which are pretreated in the step 1), calcining, and cooling at room temperature to obtain clinker; and 3) crushing, grinding and sieving the calcined clinker in the step 2), and adding the gypsum to obtain a sulfur aluminate cementing material. By the method, the garbage incineration fly ash can be treated completely and the problem of secondary pollution caused by treatment on the garbage incineration fly ash is effectively avoided.

Owner:SHANDONG UNIV

A super high water filling material

The invention discloses an ultrahigh water filling material. The ultrahigh water filling material consists of a component A and a component B, wherein the component A comprises calcium sulphoaluminate, calcium aluminate, calcium carbonate, sodium carbonate, polyacrylamide and sodium carboxymethyl cellulose; the component B comprises calcium sulfate, calcium oxide, meta-aluminate and calcium chloride; and the meta-aluminate in the component B is sodium meta-aluminate or calcium meta-aluminate. In the ultrahigh water filling material, the component A comprises 45 to 75wt% of calcium sulphoaluminate, 15 to 45wt% of calcium aluminate, 2 to 8wt% of calcium carbonate, 2 to 8wt% of sodium carbonate, 0.5 to 2wt% of polyacrylamide and 0.5 to 2wt% of sodium carboxymethyl cellulose, the component B comprises 70 to 90wt% of calcium sulfate, 8 to 25wt% of calcium oxide, 1 to 5wt% of meta-aluminate and 1 to 3wt% of calcium chloride, and the weight ratio of the component A to the component B is (0.5-2):1. The ultrahigh water filling material provided by the invention has the advantages of short initial setting time and high and stable strength after condensation. The ultrahigh water filling material provided by the invention is non-toxic, odorless, pollution-free, safe and environment-friendly.

Owner:HEBEI ZHUSHENG BUILDING MATERIALS SCI & TECH DEV

Mortar capable of consolidating polluted soil

The invention discloses mortar capable of consolidating contaminated soil. The mortar is prepared from the following components in parts by weight: 50-70 parts of high-alumina cement, 8-10 parts of modified sodium bentonite, 8-10 parts of silica gel, 8-10 parts of a high-molecular polymer and 6-10 parts of a heavy metal ion chelating agent, the preparation method comprises the following steps: preparing modified sodium bentonite: crushing and homogenizing bentonite raw ore, and screening to obtain bentonite with the mesh number of 50-100 meshes; and uniformly mixing the 50-100-mesh bentonite with the sodium modifying agent and the modification additive, adding water, stirring to obtain a mixture, stacking, aging and drying the mixture to obtain the modified bentonite. In order to solve the problem that heavy metal ions are easy to dissolve out, three substances, namely bentonite, silica gel and a heavy metal ion chelating agent, are selected, and through the combined action of the three substances, the heavy metal ions can be firmly fixed and prevented from being dissolved out. In addition, the high-alumina cement is selected, so that the problem that heavy metal ions are dissolved out due to non-corrosion resistance is relieved to a certain extent.

Owner:广东碧通百年科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com