All-solid-waste water permeable brick as well as preparation method and application thereof

A technology of permeable bricks and water reducers, applied in the field of all-solid waste permeable bricks and their preparation, can solve the problems of large thickness, unfavorable sustainable development, high energy consumption of Portland cement production, etc., and achieve simple process and good water permeability , the effect of improving the overall mechanical properties and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

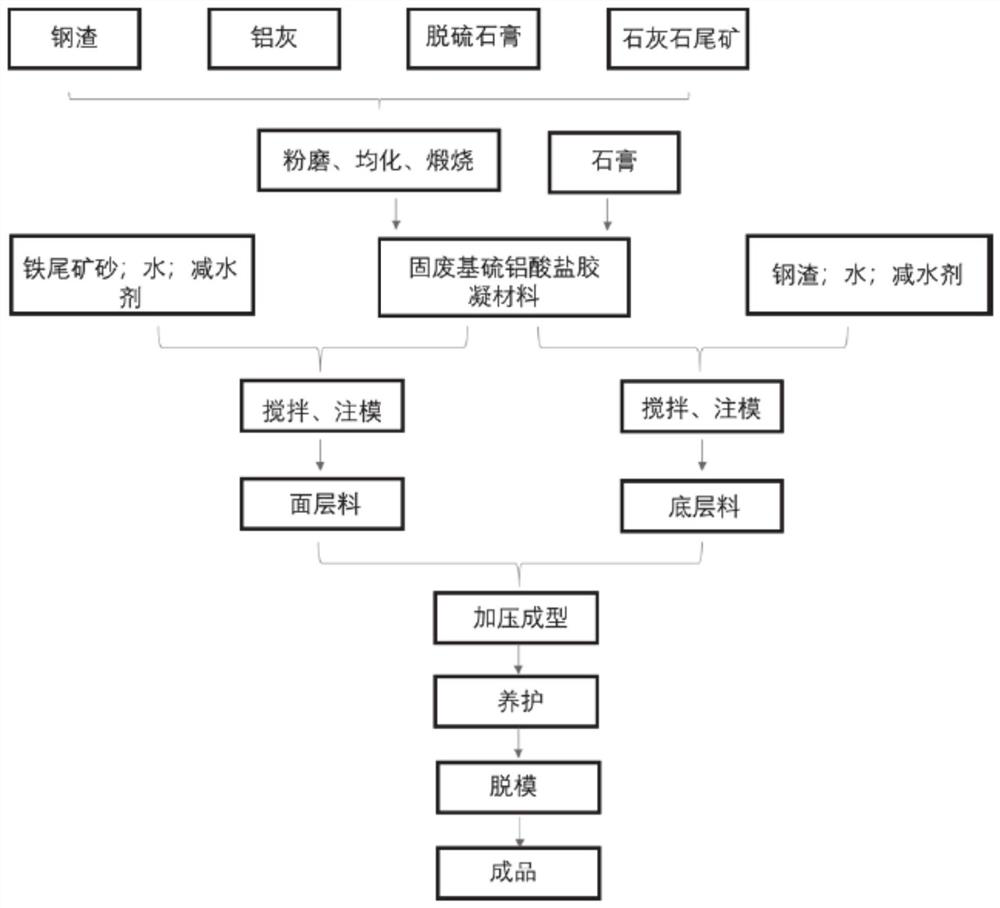

[0041] In a second aspect of the present invention, a method for preparing the above-mentioned all-solid waste permeable brick is provided, which includes:

[0042] Preparation of the bottom layer of the permeable brick: Dry mix the solid waste-based sulfoaluminate cementitious material and steel slag in proportion, then add water and water reducer to mix evenly to form a dry and hard mixture, and spread it into the mold for initial pressure to become a permeable brick bottom layer;

[0043] Preparation of the surface layer of permeable bricks: Use a mortar mixer to evenly mix solid waste-based sulfoaluminate cementitious materials, iron tailings sand, and water to make fabrics, and then evenly spread them on the pressed bottom layer, and finally press them into shape;

[0044] The permeable brick samples were cured for 28 days under the conditions of temperature 20±0.5°C and humidity 98%.

[0045] Preferably, the thickness of the bottom layer of the permeable brick is 50-60m...

Embodiment 1

[0050] Preparation of solid waste-based sulfoaluminate cementitious material:

[0051] Steel slag 25%, aluminum ash 22.39%, desulfurized gypsum 30.20%, carbide slag 22.39%, the raw materials after grinding and homogenization were calcined at 1220°C in the kiln, and the holding time was 30min to obtain solid waste-based sulphoaluminate cement Clinker, the obtained solid waste-based sulphoaluminate cement clinker is ground with 4% desulfurized gypsum to prepare solid waste-based sulphoaluminate cementitious material, which has the characteristics of early strength, fast hardening, low cost and environmental protection .

Embodiment 2

[0053] An all-solid waste permeable brick consists of the following components by weight: 15 parts of solid waste-based sulfoaluminate cementitious material; bottom layer aggregate: 80 parts of steel slag; surface layer aggregate: 8 parts of iron tailings; water-binder ratio 0.33; The water reducer accounts for 0.2 parts of the cementitious material;

[0054] A small brick machine is used for layered compression molding. The sample size is 200mm×200mm×60mm, the thickness of the bottom layer is 55mm, and the thickness of the surface layer is 5mm. First use a forced mixer to dry mix solid waste-based sulphoaluminate cementitious materials and steel slag with a particle size of 5.0mm to 20.0mm for 60s, add water and water reducer and mix evenly for 120s to form a dry and hard mixture, and then pave to the appropriate position in the mold, and finally pressed into the bottom layer of the permeable brick according to the designed molding parameters. At the same time, use a mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com