Patents

Literature

2242 results about "Compressive resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

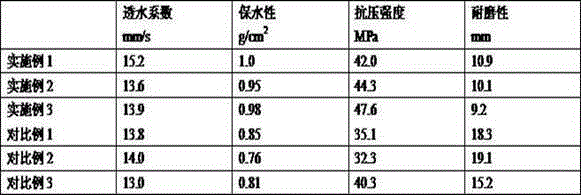

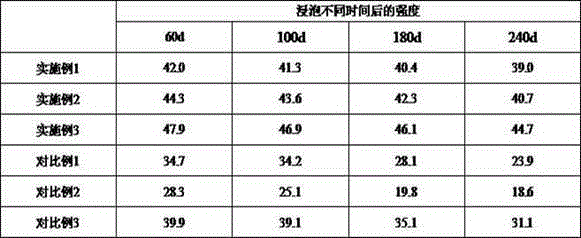

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

Lightweight leveling mortar

The invention discloses a lightweight leveling mortar material for a variety of wall surfaces and floors inside and outside buildings, and the lightweight leveling mortar material comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive. The lightweight leveling mortar material is a single-component dry-mixed material produced by a factory and can be used on a construction site by only adding water for stirring. The lightweight leveling mortar has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional mortar to be plastered on a variety of wall surfaces and floors of buildings and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

Environment-friendly type alkali-free liquid accelerator for sprayed concrete and preparation method thereof

The invention belongs to the technical field of building materials, and in particular relates to an environment-friendly alkali-free liquid quick-setting agent used for shotcrete and a method for preparing the same. The alkali-free liquid quick-setting agent is a light green viscous liquid prepared from aluminum sulfate, sodium fluoride, triethanolamine and polyacrylamide, wherein the aluminum sulfate and the sodium fluoride are main quick-setting components, the aluminum sulfate can significantly reduce the initial setting time of cement, while the sodium fluoride can significantly shorten the final setting time of the cement, promote the formation of a hydrate structure, and improve the shear strength of the concrete and the binding power of a reinforcing steel bar. The triethanolamine shortens the setting time of the concrete to csertain extent and greatly improves the 1d compressive strength of mortar, and the polyacrylamide is an organic tackifying component to improve the thickness of a primarily sprayed layer, improve the bond strength between the concrete and a substrate, reduce the rebound loss in the spraying process, and save materials. The environment-friendly alkali-free liquid quick-setting agent has the advantages of wide source of raw materials, low cost, simple production method, and high production efficiency, and is suitable for industrial mass production.

Owner:TONGJI UNIV

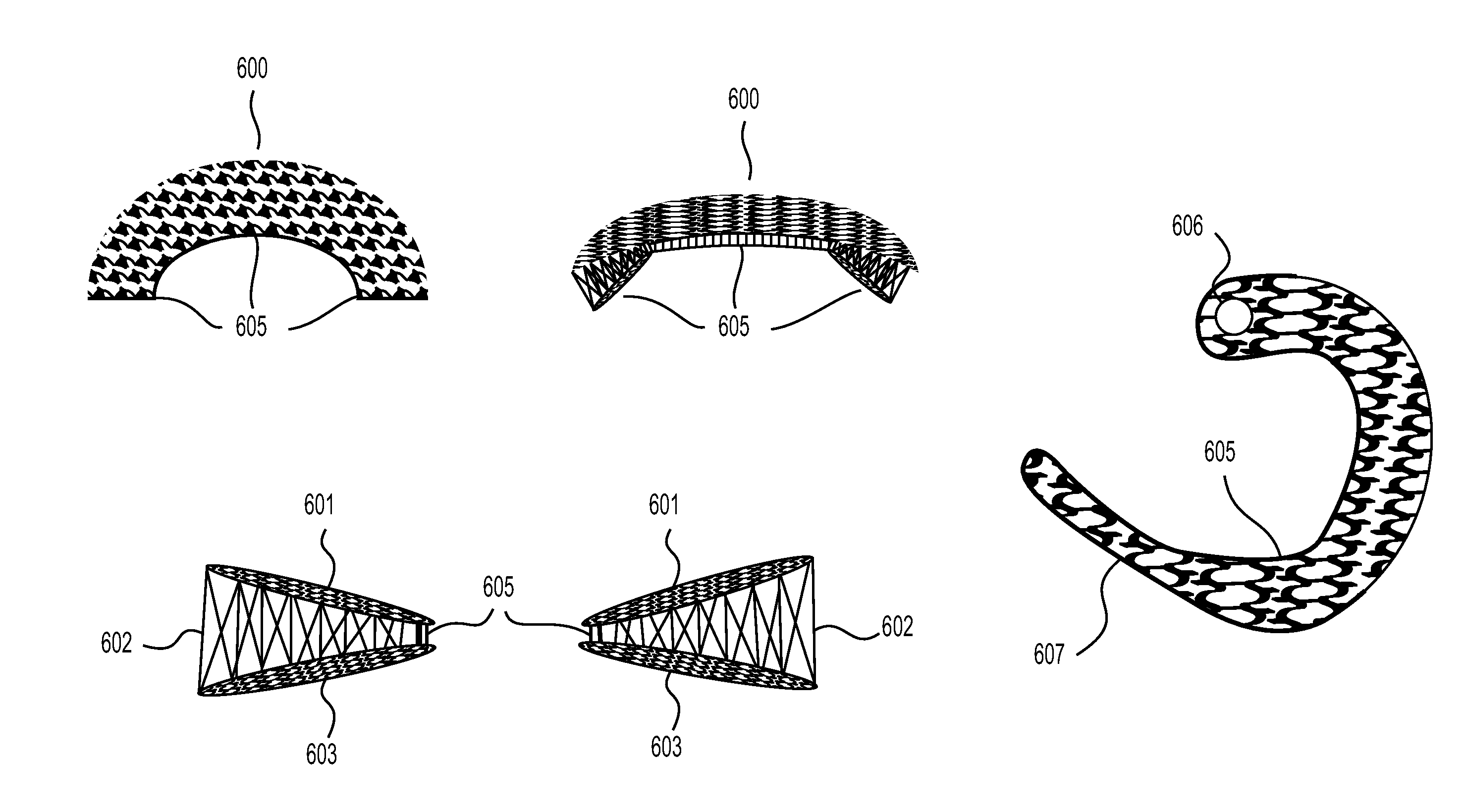

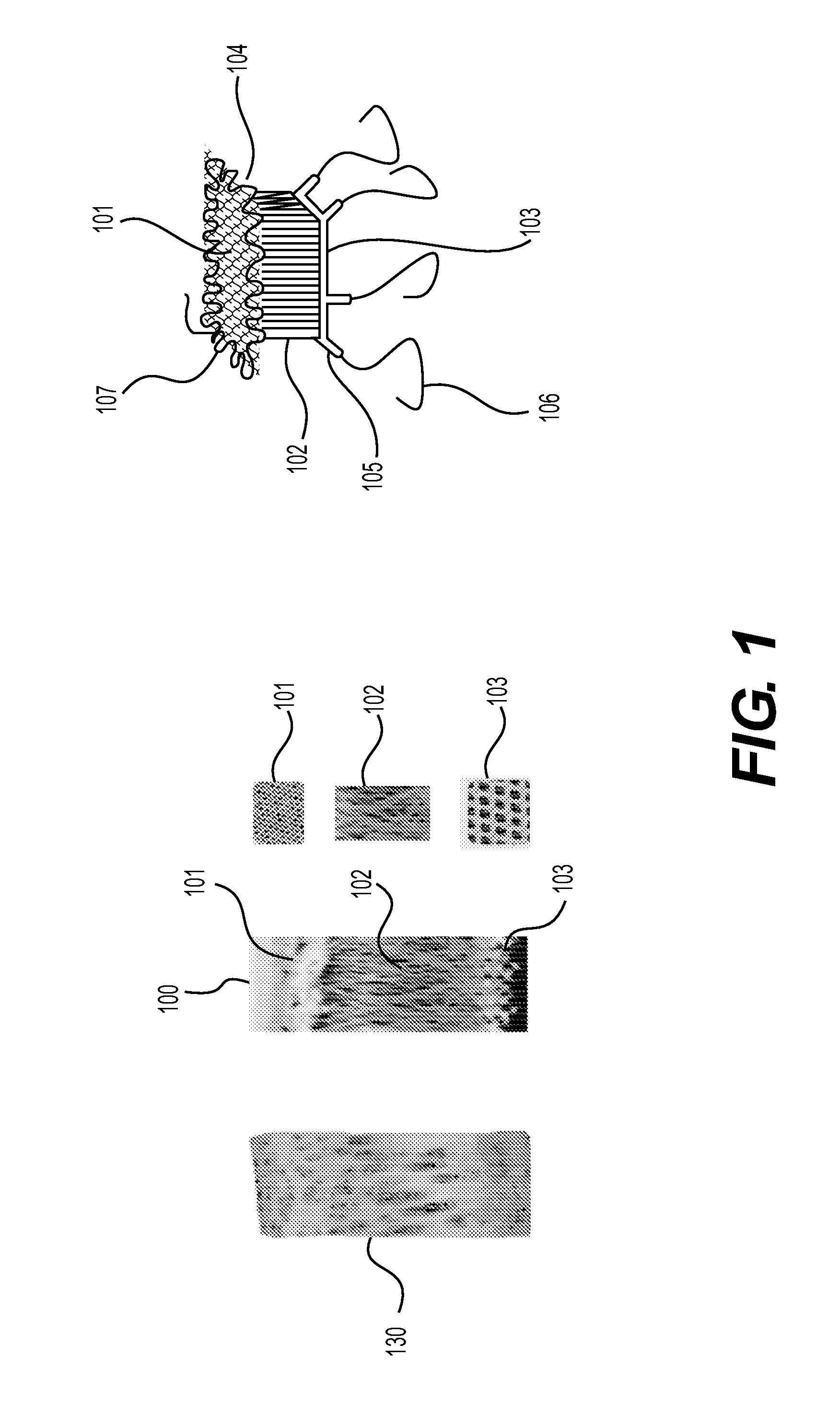

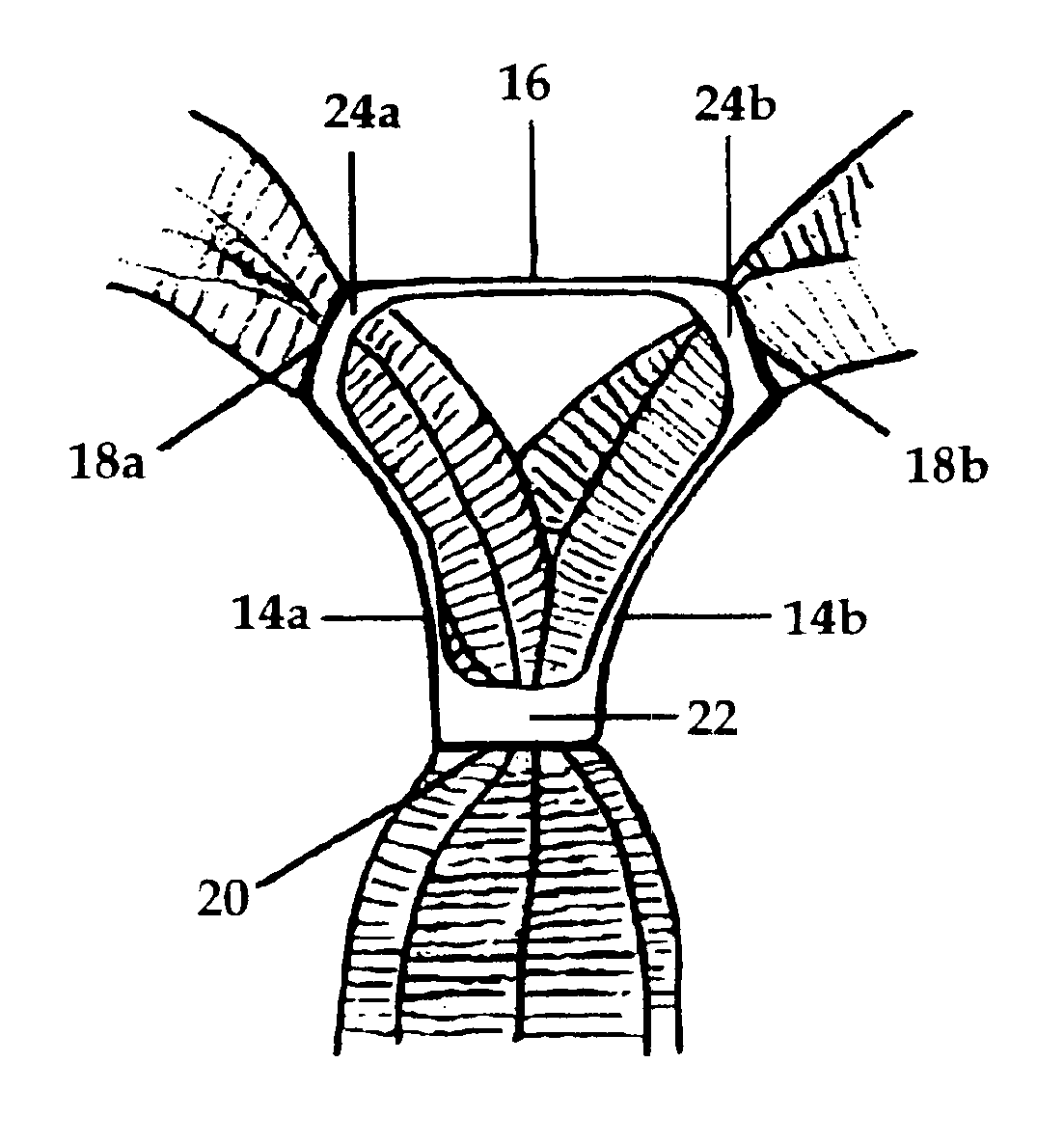

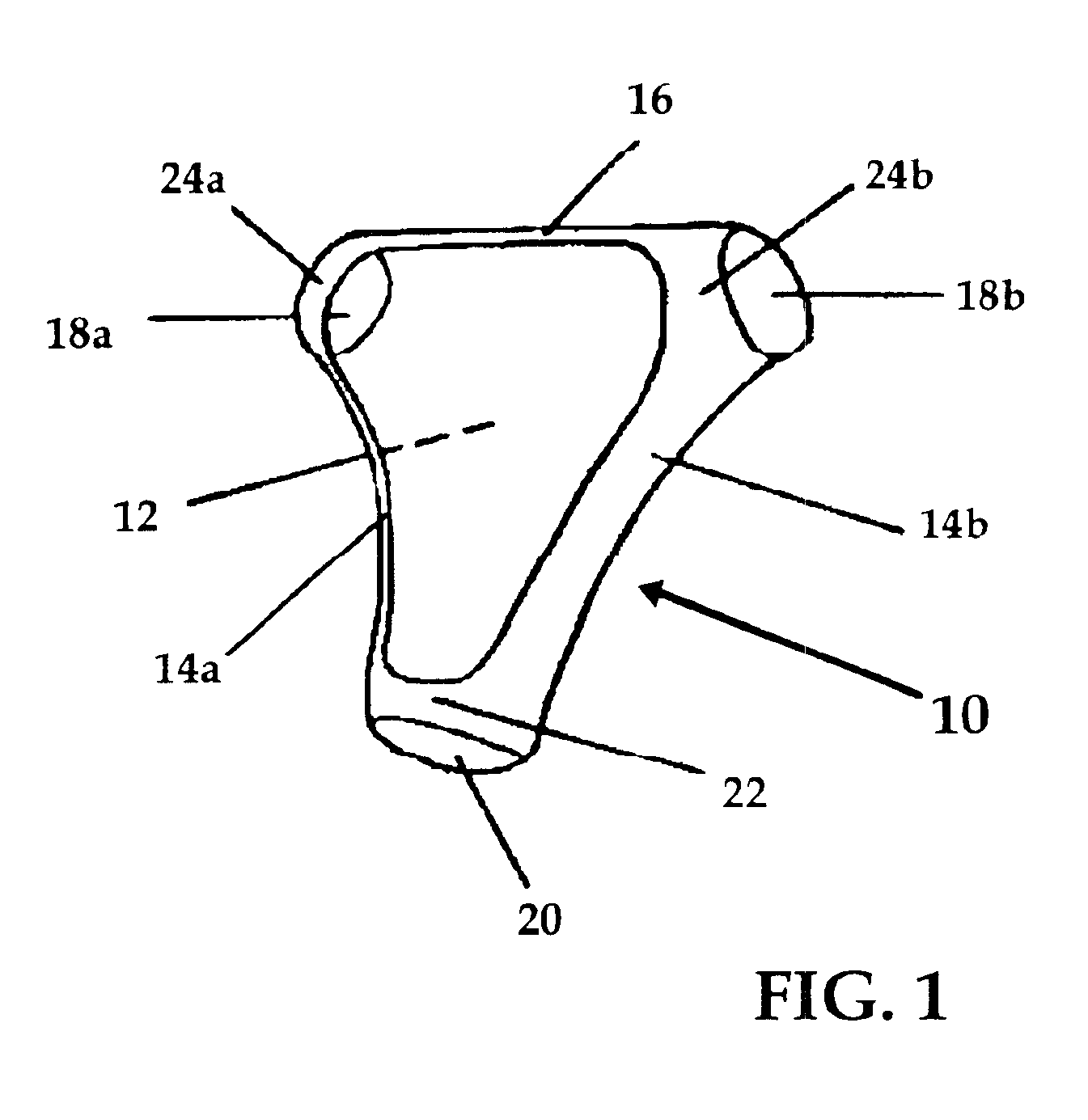

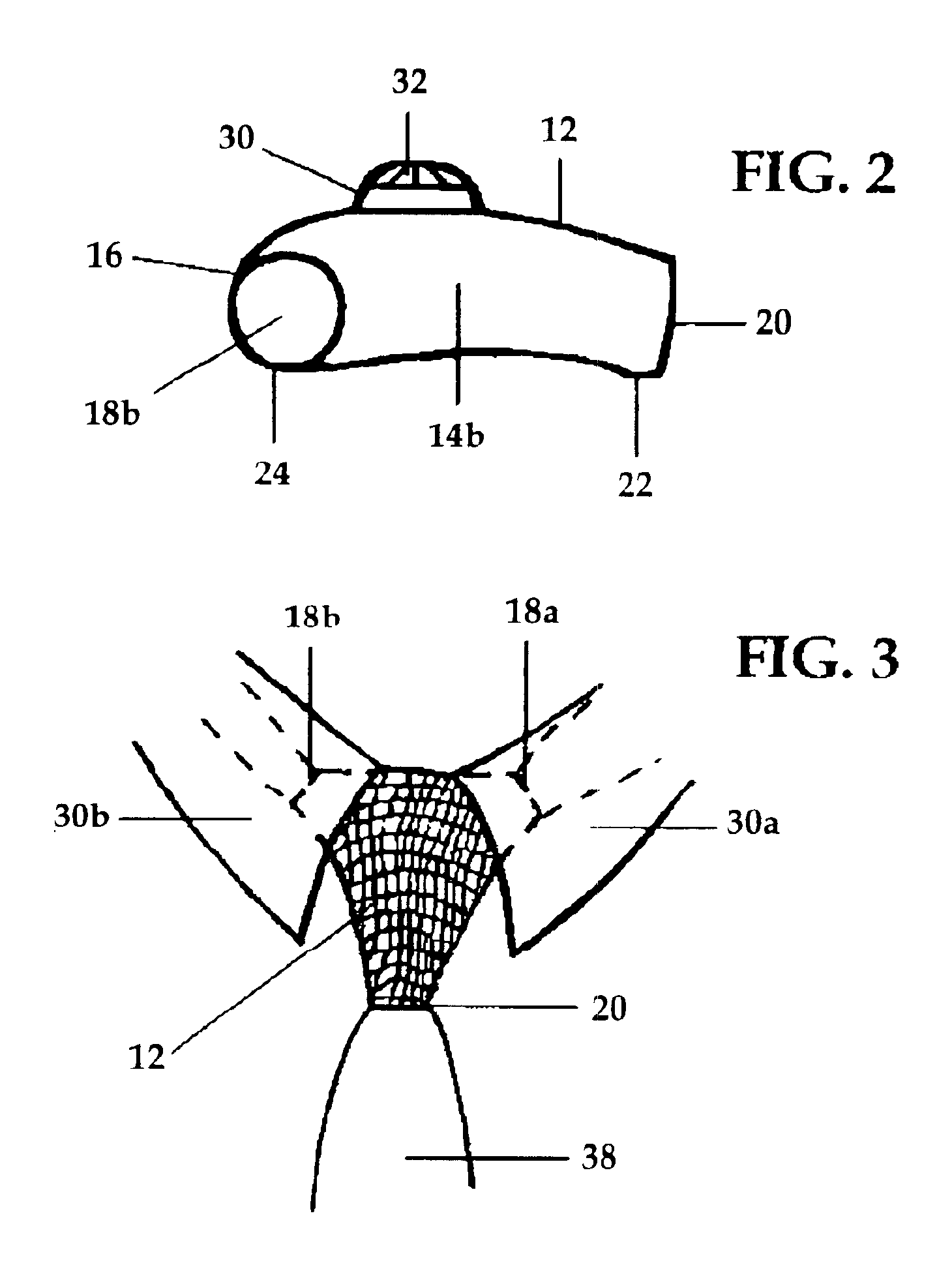

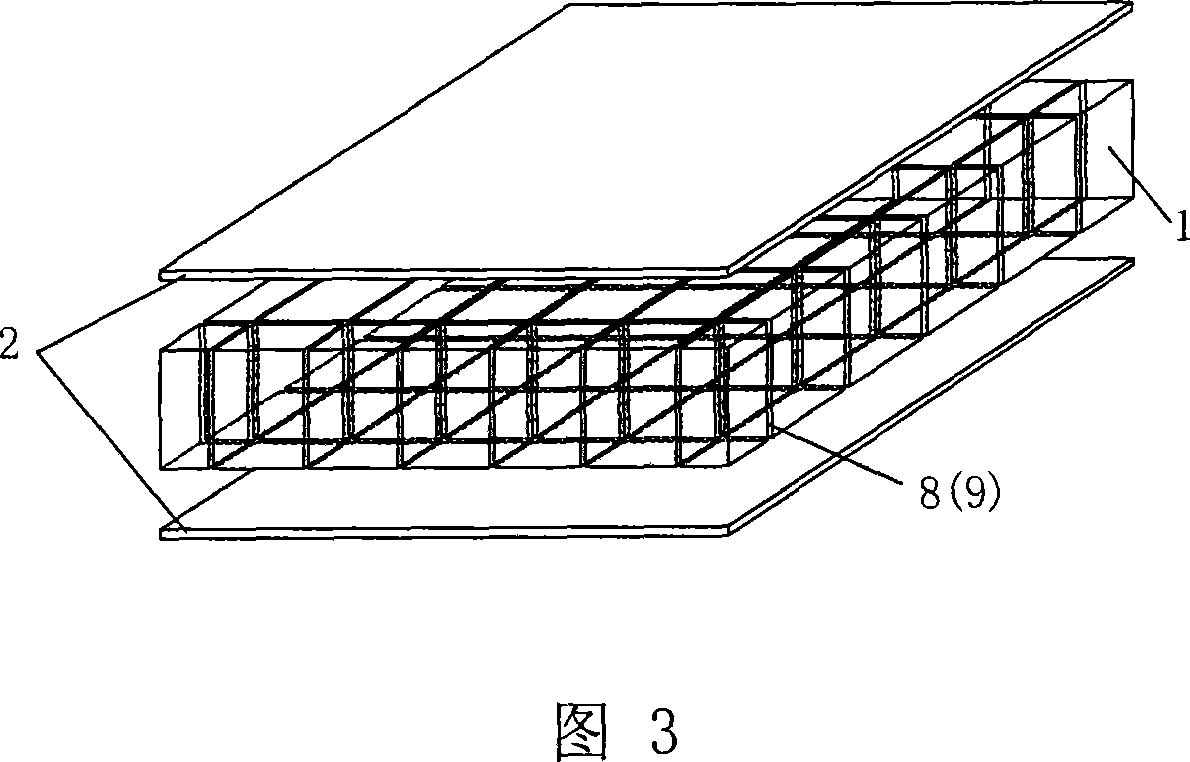

Implantable Devices for Musculoskeletal Repair and Regeneration

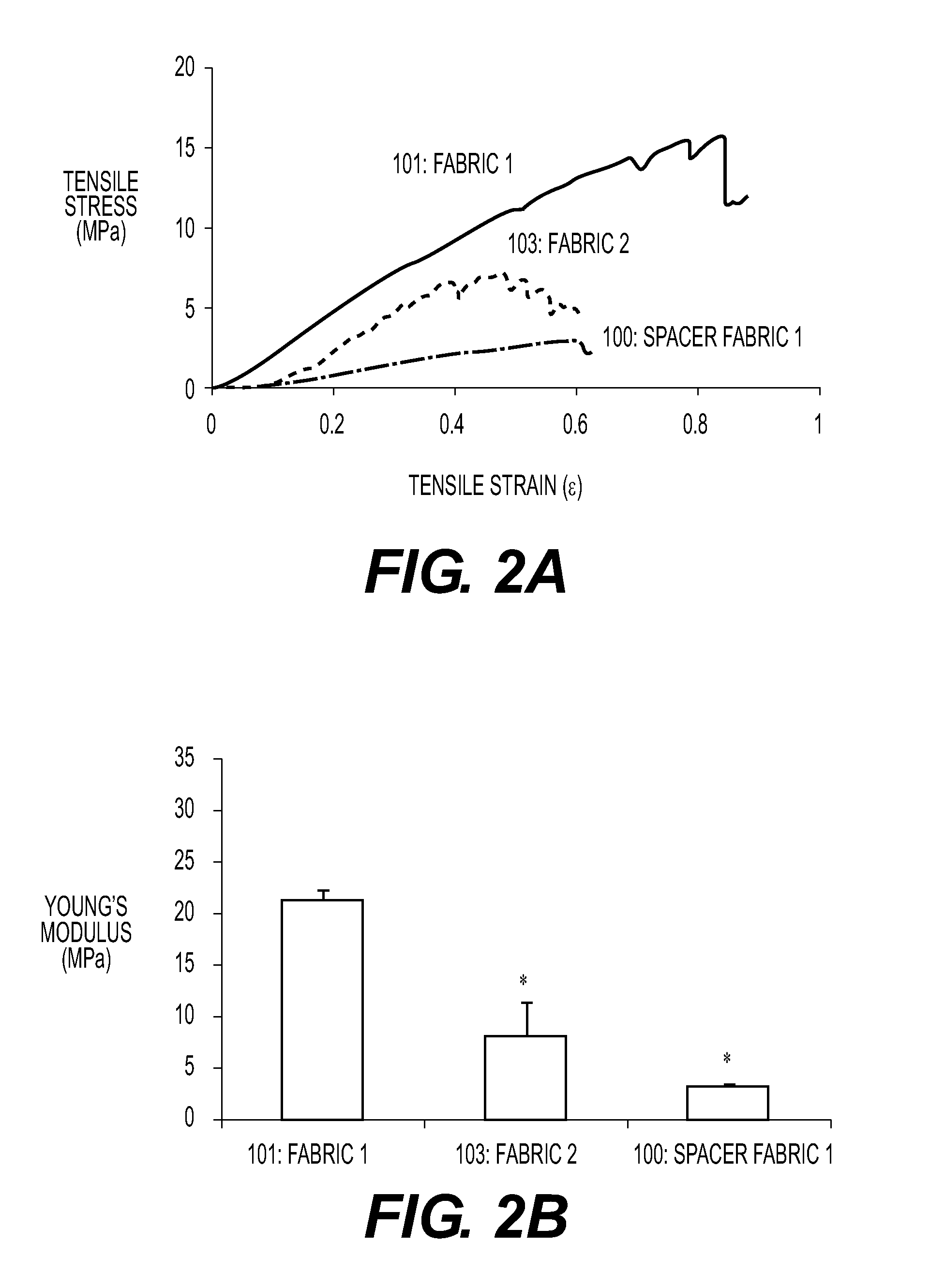

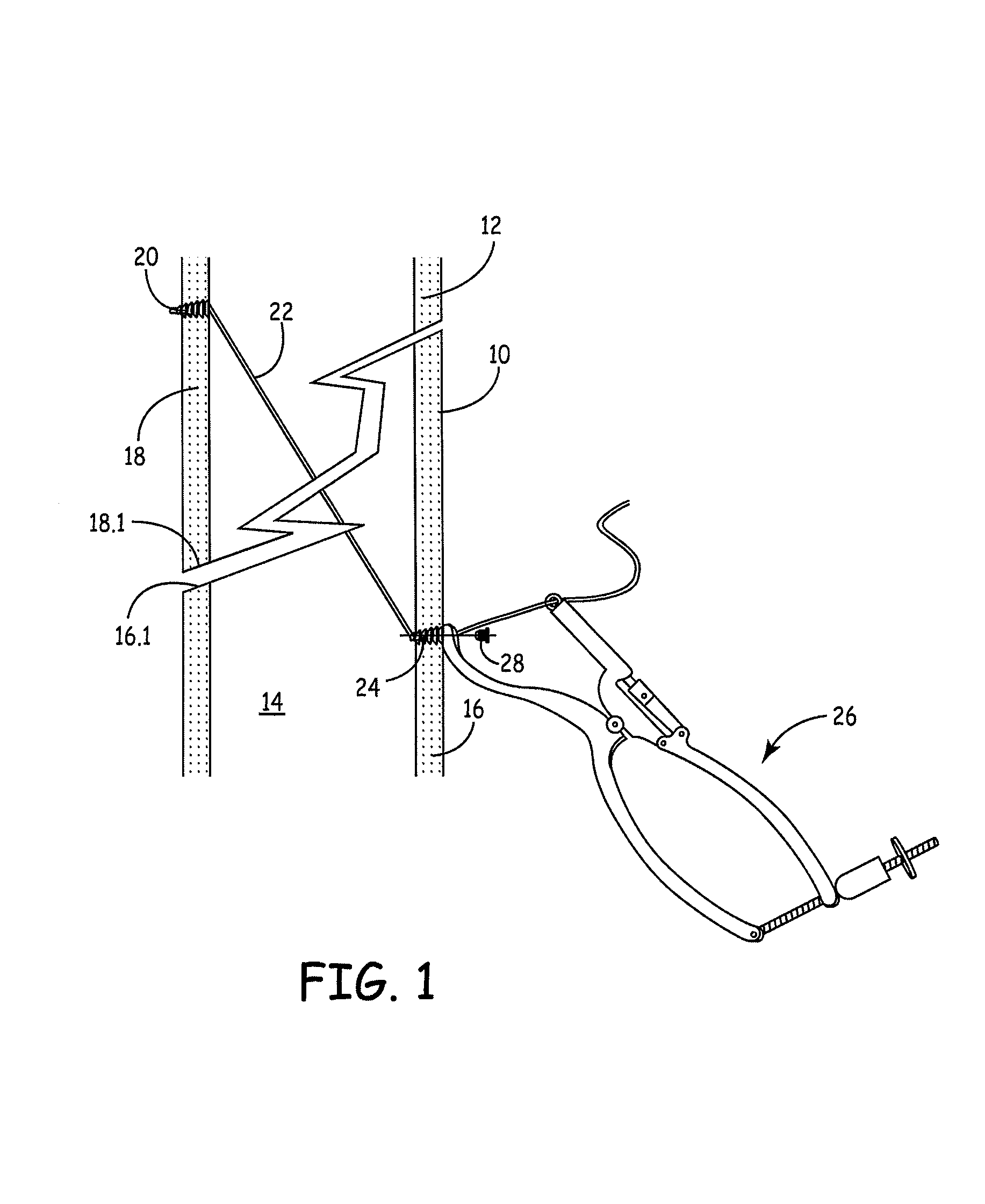

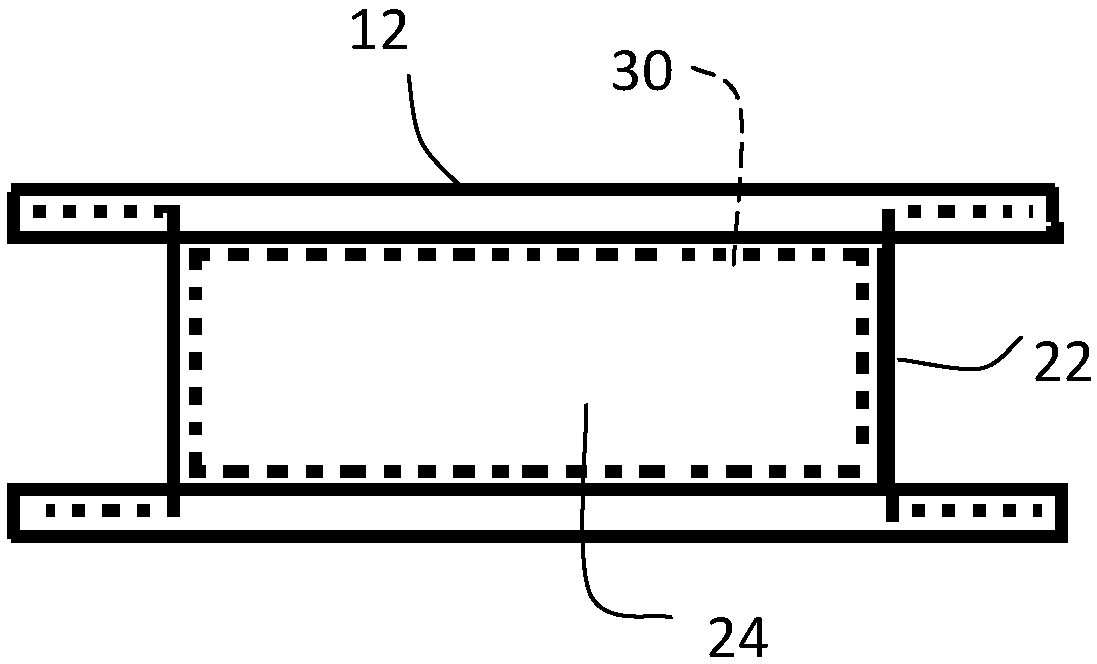

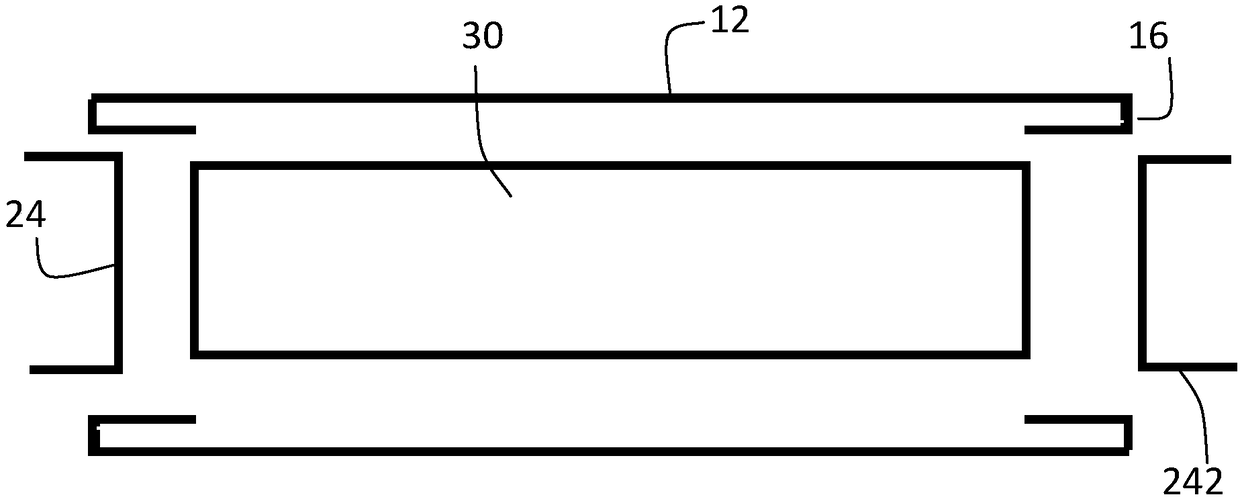

This application describes an implantable device for tissue repair comprising at least two fabrics with interconnecting spacer elements transversing, connecting, and separating the fabrics, forming the device. Some embodiments have fixation points which can be an extension of at least one of the fabrics. The implantable device allows modification of the two fabrics having varying constructions, chemistries, and physical properties. The spacer elements create a space between the two fabrics, which can be used for the loading of biological materials (peptides, proteins, cells, tissues), offer compression resistance (i.e. stiffness), and compression recovery (i.e., return to original dimensions) following deformation and removal of deforming load. The inclusive fixation points of the fabrics are designed to allow for fine adjustment of the sizing and tension of the device to promote integration with the surrounding tissues as well as maximize the compressive resistance. The fixation points can include either the first fabric, the second fabric, or the combination of both fabrics. This device is suitable for soft and hard tissue regeneration or replacement with a preference for musculoskeletal tissues including but not limited to cartilage (including hyaline (referred to as articular, e.g. cartilage on the ends of long bones), fibrous (e.g. meniscus or intervertebral discs), elastic (e.g. ear, epiglottis)), bone, muscle, tendon, ligament, and fat.

Owner:MCCULLEN SETH

Method for preparing environment-friendly water permeable bricks by using iron tailings

InactiveCN103204698AImprove performanceSimple production processCeramicwareCarbide siliconCompressive resistance

The invention discloses a method for preparing environment-friendly water permeable bricks by using iron tailings, belonging to the field of comprehensive utilization of iron tailing resources and construction ceramic materials. The method is characterized in that through taking iron tailings as basic aggregates and introducing a certain amount of waste broken glass, an environment-friendly water permeable brick with excellent performance is prepared. The method comprises the following process steps of raw material crushing, ball milling, material dispensing, mixing, drying, molding, sintering, cutting and grinding. The dispensed material comprises the following ingredients in percentage by weight: 30-60% of iron tailings powder, 5-15% waste glass powder, 15-30% of clay, 15-24% of quartz, 5-15% of potash feldspar, and 0.25-1.5% of silicon carbide. The prepared water permeable brick is high in compressive strength, good in abrasion resistance and excellent in water permeability, and accords with national related standards of water permeable bricks, therefore, the method creates a new way for the high-technology and high value-added application of iron tailing resources.

Owner:UNIV OF SCI & TECH BEIJING +2

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS20130216802A1Improve insulation effectImprove barrier propertiesSolid waste managementWallsThermal insulationRebar

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

Alkali-activated cementing material and preparation method thereof

InactiveCN104446045ABroaden the way of resource utilizationIncrease consumptionCement productionLiquid waterAlkali activated

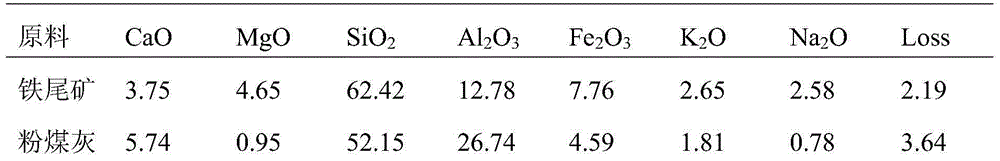

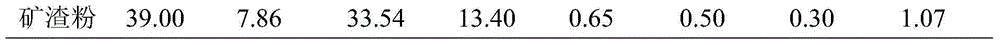

The invention relates to an alkali-activated cementing material prepared from siliceous iron tailings and a preparation method of the alkali-activated cementing material. The preparation method comprises the following steps: 1) proportionally and evenly mixing siliceous iron tailing powder, coal ash and slag powder together to obtain iron tailing powder-coal ash-slag powder compound powder; 2) mixing liquid water glass with water to obtain an alkali activating agent solution; 3) adding the alkali activating agent solution to the compound powder and stirring evenly to obtain an alkali-activated cementing material paste; 4) injecting the alkali-activated cementing material paste into a die for vibrating molding and maintaining under a normal temperature condition until knockout, thereby obtaining an alkali-activated cementing material net paste test piece; and 5) performing steam curing on the alkali-activated cementing material net paste test piece. The alkali-activated cementing material has the beneficial effects that the alkali-activated cementing material hardened paste has excellent mechanical properties, the 3d compressive strength of the optimal proportion of the hardened paste is greater than 60MPa and the 28d compressive strength of the hardened paste is greater than 80MPa.

Owner:WUHAN UNIV OF TECH

Internal cord fixation device

InactiveUS7410489B2Prevent and reduce particulate sheddingProvide resistanceSuture equipmentsInternal osteosythesisCompressive resistanceBone prosthesis

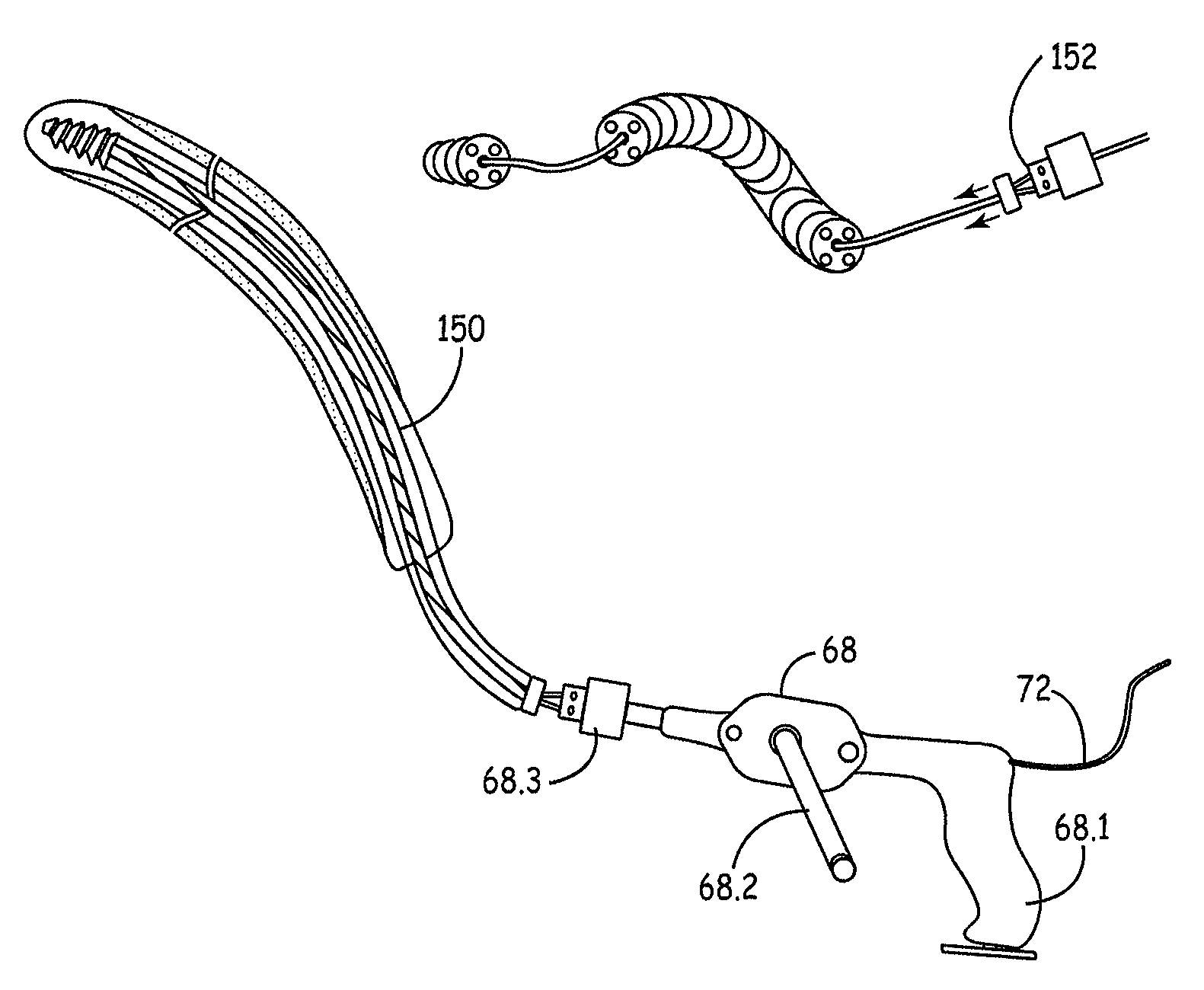

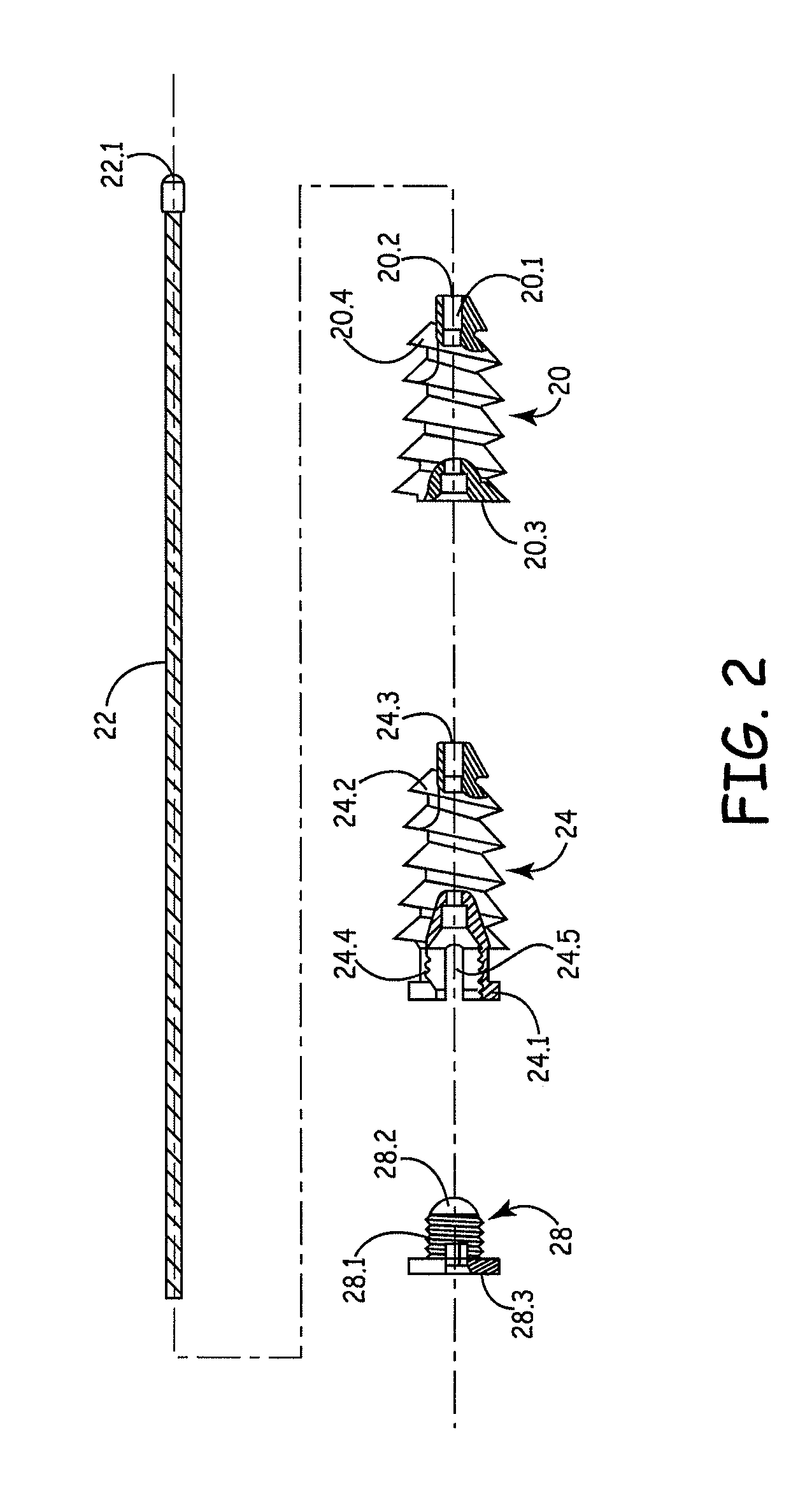

Methods and apparatuses for fixing a bone fragment or a bone prosthesis onto a bone. To affix a bone fragment to the bone, an internal fastener is attached from within the interior of the bone to a bone fragment with a length of flexible, inelastic cord extending within the bone interior and attached to the fastener and passing outwardly through an opening in a second bone fragment. An axially rigid tubular support may be placed along the cord to reduce particulate shedding, to reduce ingrowth of bone into the cord, to provide compressive resistance to the cable, or to deliver antibiotics or other pharmaceuticals. The fastener and cord are so positioned as to draw respective fracture surfaces together to reduce the fracture when the cord is pulled outwardly of the opening in the second bone fragment. A second fastener desirably is attached to the bone opening, this fastener including an open bore to receive the cord and a lock to secure the cord to this fastener and maintain the cord under tension.

Owner:DAOS

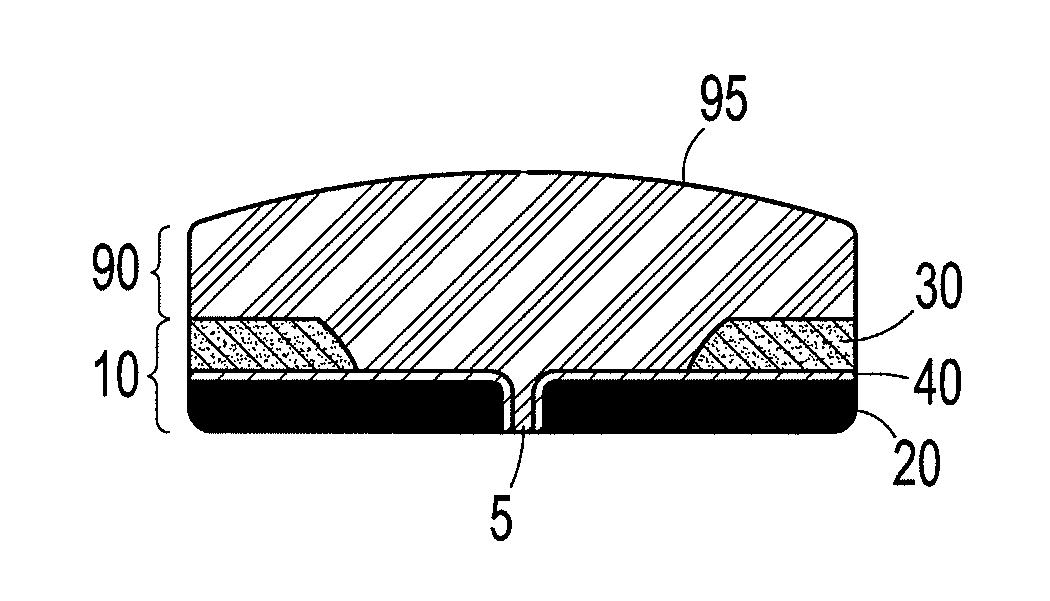

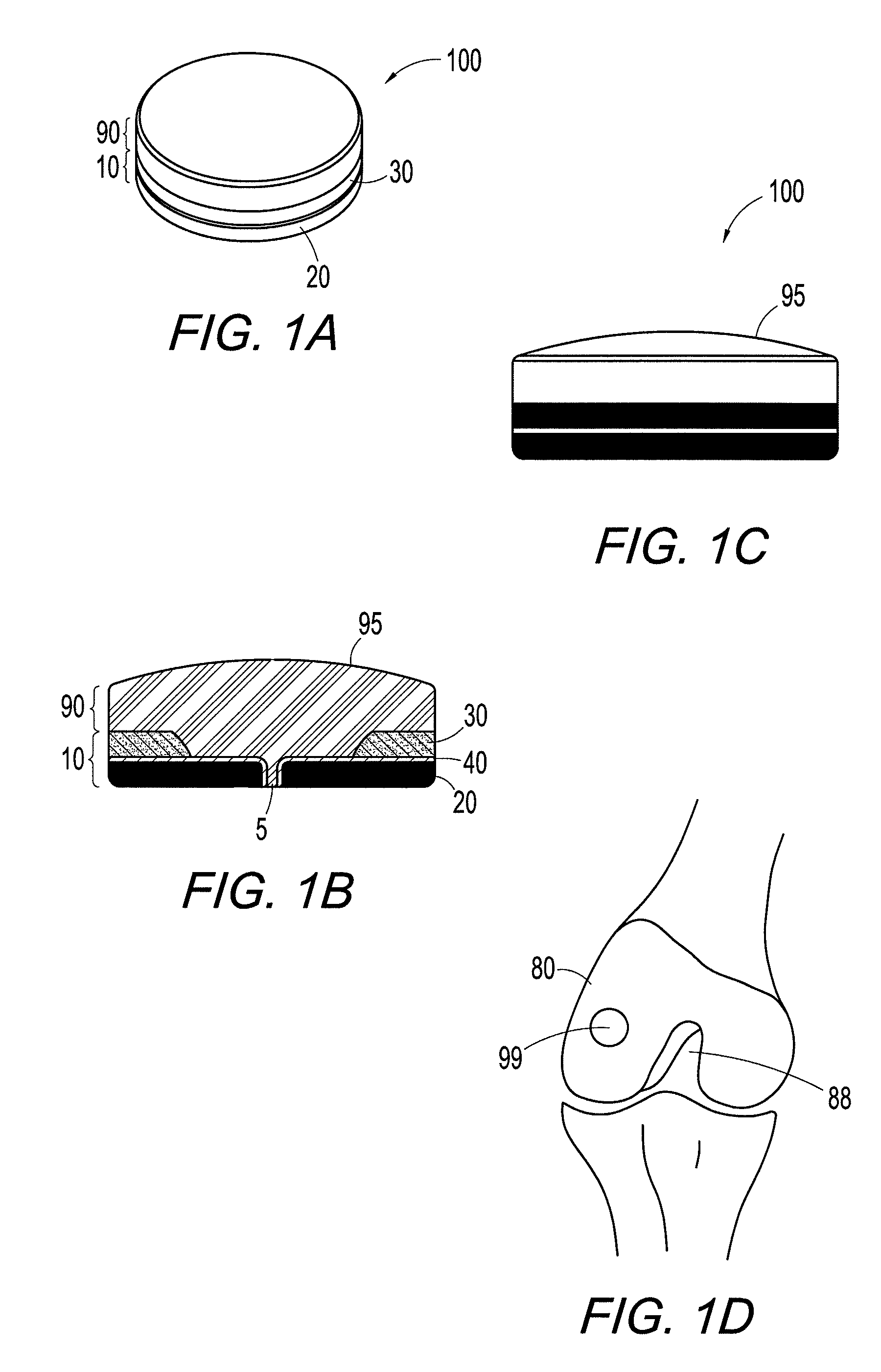

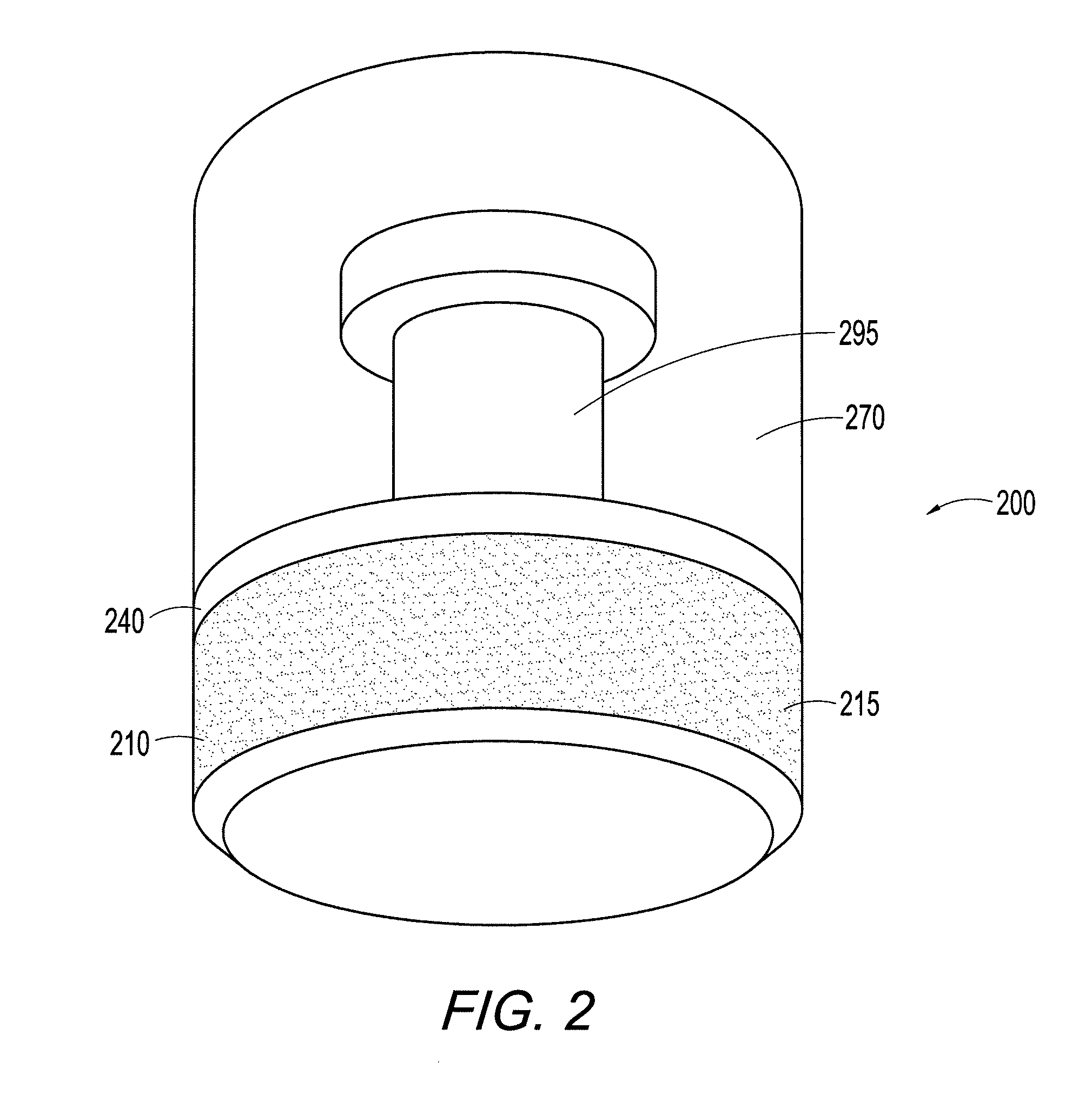

Hybrid polymer/metal plug for treating chondral defects

Osteochondral implants for repair of chondral defects and providing bone fixation through bone ongrowth and / or ingrowth. The implant is provided with a base allowing for bone ongrowth and / or ingrowth and a top attached to the base, the top being formed of a material having a compressive resistance similar to that of the cartilage. The material of the top is polycarbonate urethane, for example. The base may comprise a porous substrate for bony ingrowth formed of metal or PEEK and having a pattern porosity about similar to the porosity of cancellous bone. One side of the top attaches to the base for stability, and the other side of the top forms a surface for articulating with the opposing cartilage surface of the joint.

Owner:ARTHREX

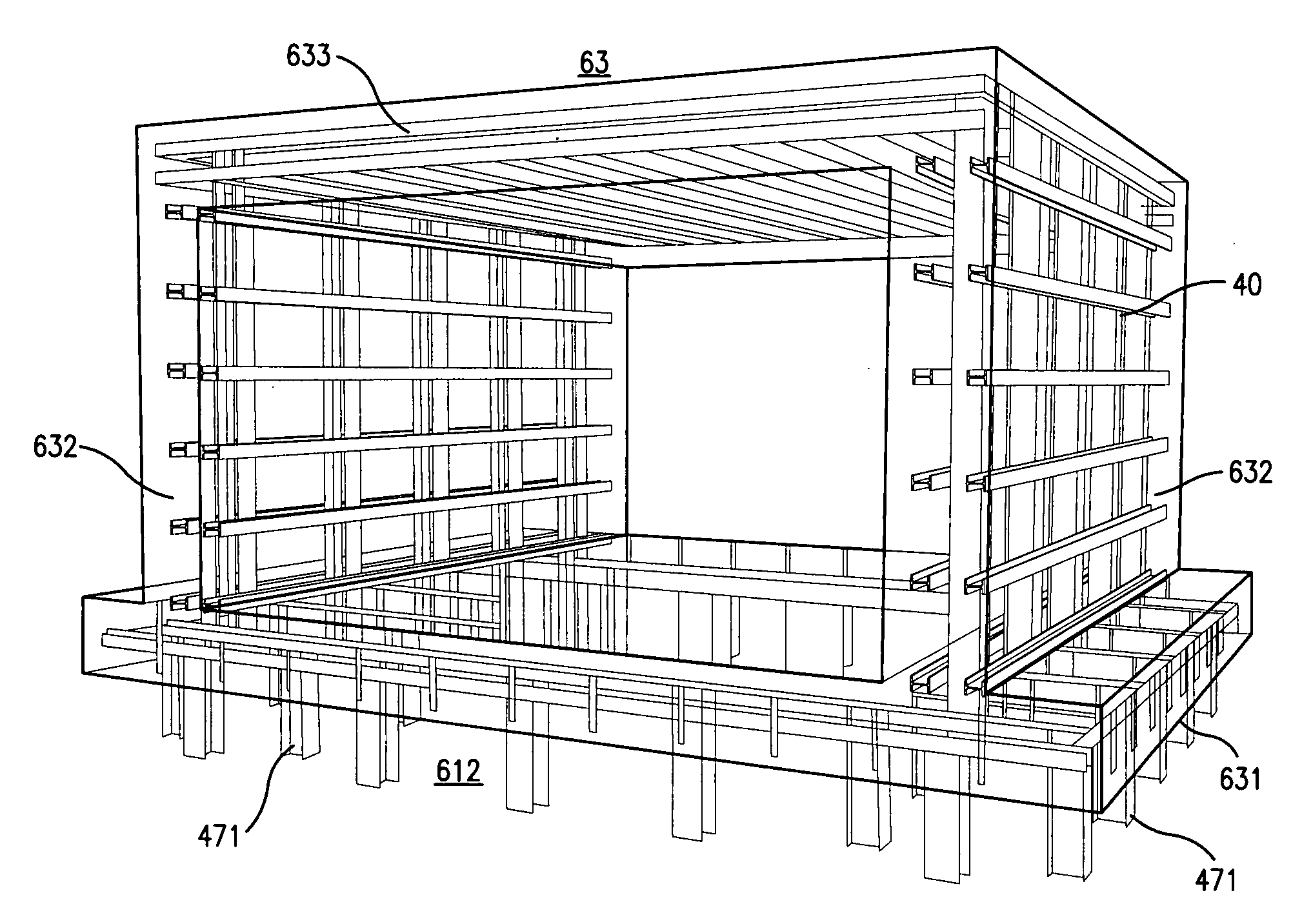

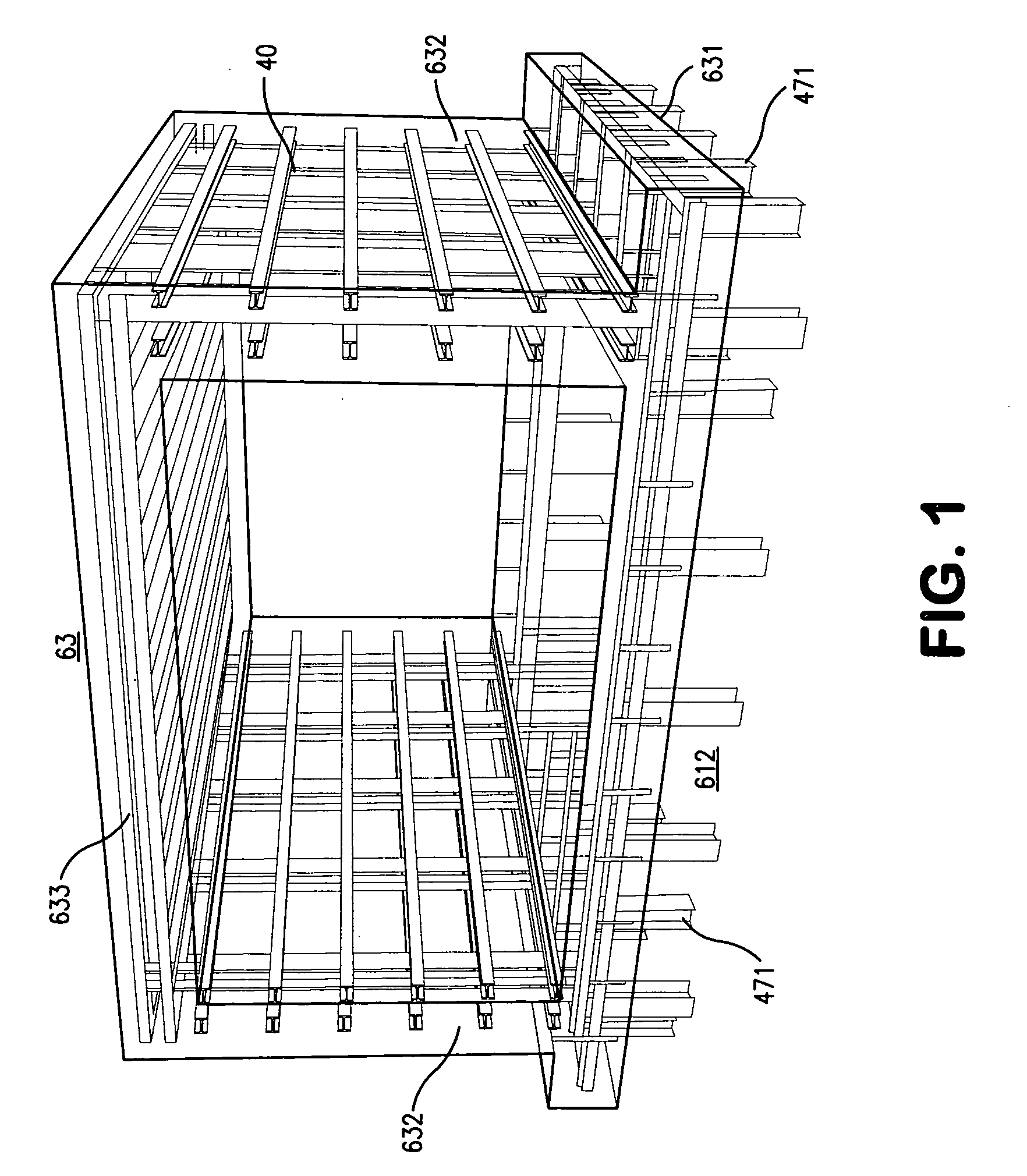

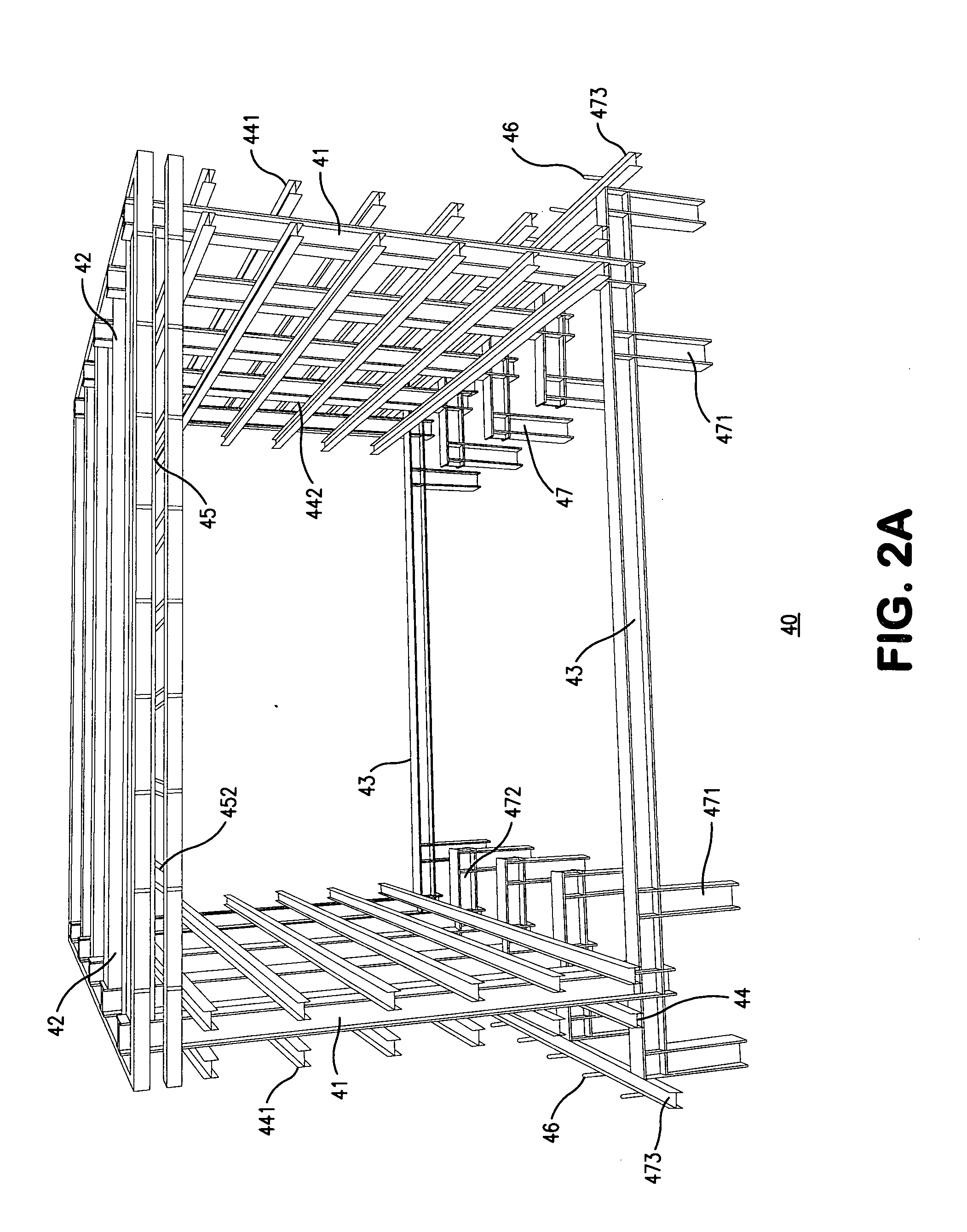

Modular construction mold apparatus and method for constructing concrete buildings and structures

ActiveUS20110011018A1Easy constructionSimpler and safer and economicalConstruction materialWallsSteel frameCompressive strength

A modular steel-framed construction mold apparatus comprised of a plurality of contiguous foundation, cavity wall and roof deck void spaces defined and formed by assemblies of interlocking encasement panels and connectors integrally attached to a structural steel grillage for accepting, containing, and shaping wet concrete fill, a method for forming, casting, and encasing monolithic composite concrete and steel buildings and structures in situ using said mold apparatus, and a permanently encased monolithic composite concrete and steel structure constructed by employing the foregoing modular mold apparatus and method of concrete construction. The structural steel grillage supports the encasement assemblies before and during the casting process, becoming fully embedded within the cast concrete, and provides tensile strength complementing the compressive strength of concrete fill. The panelized encasement assemblies remain in place following casting protecting and insulating the resulting composite concrete and steel buildings and structures.

Owner:JOHNSON FR +1

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

Heat insulation and sound insulation material for flour and its preparing method

InactiveCN1749203ASolve the technical problems of non-wettingRealize inorganic modificationSolid waste managementHeat proofingFiberPolymer adhesive

The heat insulating and sound insulating material for floor consists of cement as cementing material, polystyrene foam grain, flyash boulder and other light aggregate. It is new type of building function material compounded through surface modification of polystyrene foam grain, raising construction performance and adhesion with polymer adhesive and water maintaining agent, toughening with polymer fiber and other measures. The preparation process includes surface modification of polystyrene foam grain, and mixing the materials via stirring. The heat insulating and sound insulating material for floor has good placeability, good construction performance, high adhesion strength, high pressure resistance, high heat insulating performance, high sound isolating performance, etc.

Owner:CHONGQING UNIV

Cementing casing strings in deep water offshore wells

InactiveUS20020005287A1Meet the requirementsFluid removalFlushingCompressive resistanceWell cementing

The present invention provides improved compositions and methods for cementing casing strings in deep water offshore formations penetrated by well bores. The methods are basically comprised of the steps of preparing a cement composition comprised of hydraulic cement, water, an environmentally degradable water reducing and dispersing additive, an environmentally degradable set retarding additive and an environmentally degradable compressive strength and set accelerating additive.

Owner:HALLIBURTON ENERGY SERVICES INC

Machine-spraying-type plastering gypsum mortar and preparation technology thereof

ActiveCN104961423ASolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthMaterials science

The invention relates to machine-spraying-type plastering gypsum and a preparation technology thereof and belongs to the technical field of building materials. The machine-spraying-type plastering gypsum is characterized by being prepared from the following raw materials: 200-400 parts of gypsum, 10-60 parts of cement, 520-650 parts of fine aggregate, 80-160 parts of heavy calcium powder, 2-4 parts of redispersible emulsion powder, 2-4 parts of hydroxypropyl methyl cellulose ether, 0.15-0.25 part of an air entraining agent, 5-10 parts of expanded perlite, 0.3-0.8 part of a gypsum retarder and 200-300 parts of water. The machine-spraying-type plastering gypsum is applicable to being directly sprayed to a wall surface by adopting a mortar spraying machine, both time and labour are saved, construction efficiency can be improved, and cost is reduced; bonding performance with the wall surface is good, rebounce is not caused, anti-sagging performance is good, both bonding strength and compressive strength can meet requirements, and cracking of a wall body can be reduced; and usage amount of gypsum is low, and cost can be effectively reduced.

Owner:新疆荣高鸿骏新材料技术有限公司

Necktie knot simulator

A necktie knot simulator closely resembling the shape of a necktie knot. Generally consisting of a one piece body with three properly dimensioned, fully enclosed circular apertures, one at the upper right, one at the upper left, and one at the base to provide both a means to thread a necktie through the necktie knot simulator and compressive resistance. The back side of the necktie knot simulator is predominantly open to allow wearer access to the necktie while threading it through the invention. The front surface of the necktie knot simulator can easily be modified to include inlays, logos, patterns or even precious and semi-precious gemstones.

Owner:DICKENS BART

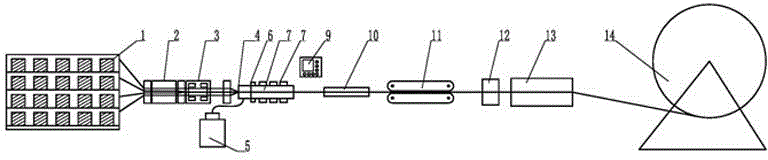

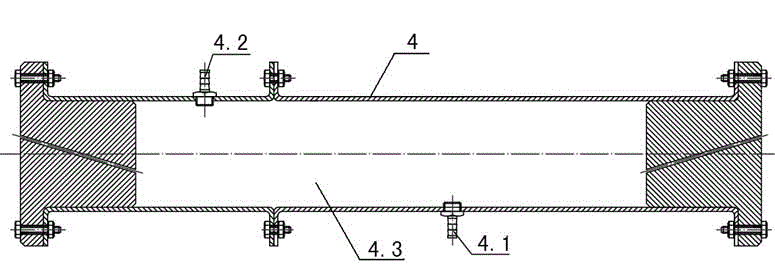

Open-shelf underwater detecting robot mechanism

InactiveCN101797968AImprove scalabilitySimple structureUnderwater equipmentFault toleranceCompressive resistance

The invention aims at providing an open-shelf underwater detecting robot mechanism. The mechanism comprises a robot main body, an environment perception device, a movement perception device and a movement executing device; wherein the robot main body comprises a frame (2), a buoyancy material (11) and a compressive resistance cabin (1), the environment perception device comprises an ultrasound thickness tester (14), a front view sonar (12) and an underwater glimmer camera (15), the movement perception device comprises an optical fiber compass (6) and a depthometer (7), the movement executing device comprises a left main propeller (17), a right main propeller (10), a rear side propeller (8), a rear vertical propeller (9), a front side propeller (3) and a front vertical propeller (4), a two-degree of freedom holder (13) and a headlamp (16). The invention is simple in structure, operation is flexible and reliable, adaptability is strong; and the mechanism thereof has strong expandability, is easy to assemble and has certain fault tolerance.

Owner:HARBIN ENG UNIV

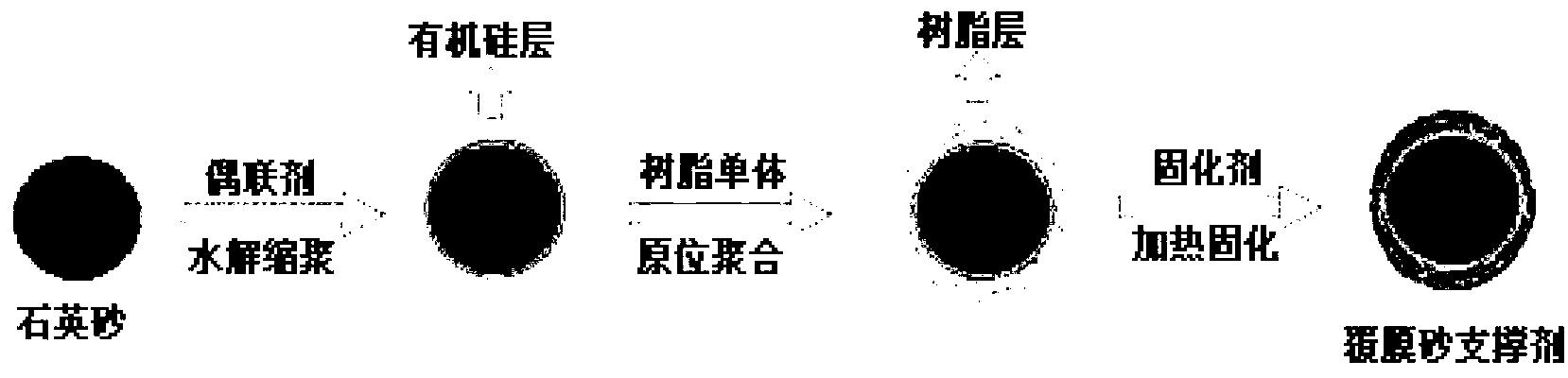

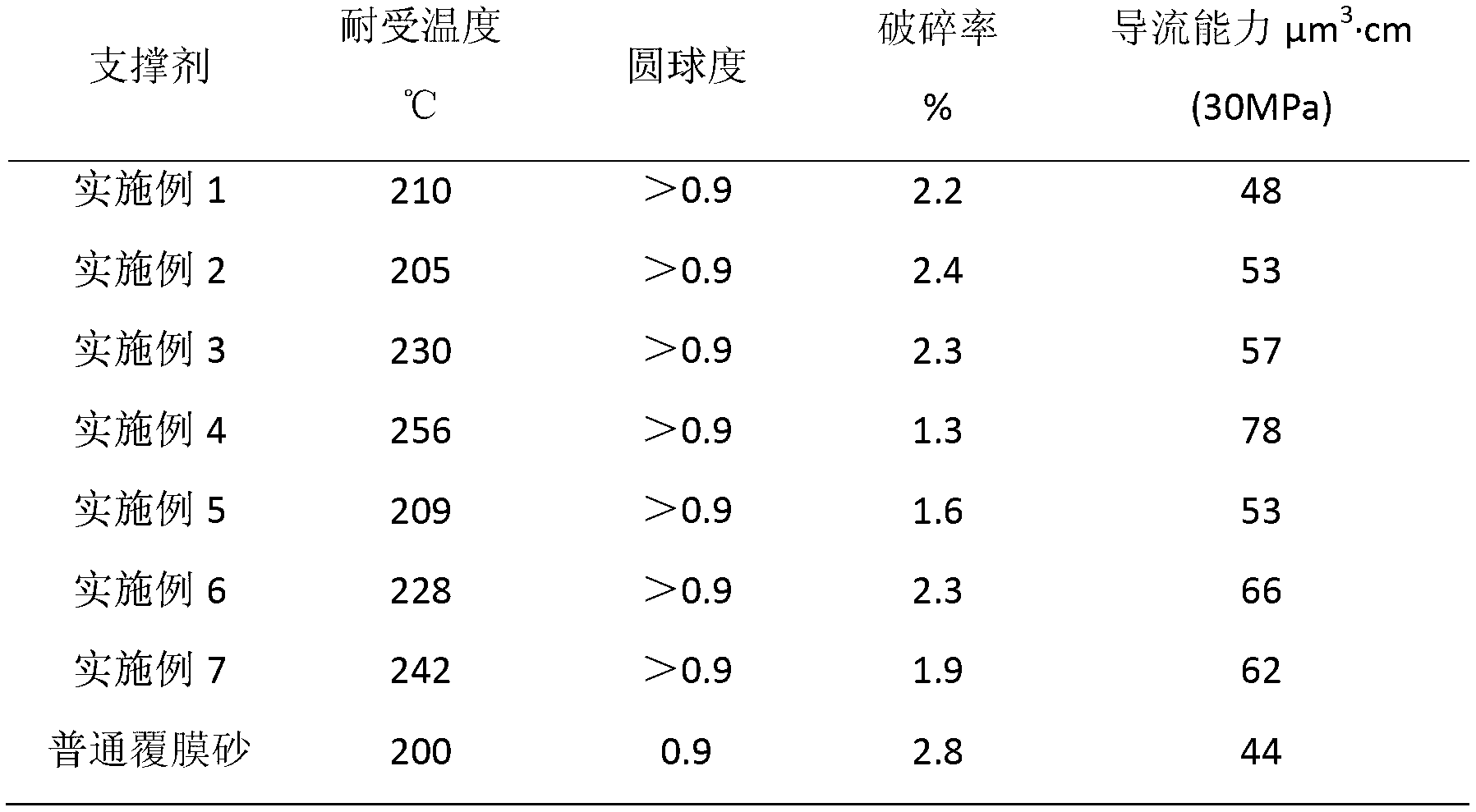

Heat-resistant high-strength precoated sand fracturing propping agent and preparation method thereof

ActiveCN103194205AImprove heat resistanceHigh compressive strengthFluid removalCompressive resistancePolymer science

The invention relates to a heat-resistant high-strength precoated sand fracturing propping agent and a preparation method thereof. The heat-resistant high-strength precoated sand fracturing propping agent comprises the following components by mass ratio: resin-coating quartz sand, a curing agent and a dispersing agent in a mass ratio of 9:1:1. The preparation method comprises the following steps: (1) carrying out hydrophobic treatment on the quartz sand surface utilizing a silane coupling agent; (2) preparing the resin-coating quartz sand through an in situ polymerization method; and (3) adding the resin-coating quartz sand, the curing agent and the dispersing agent into a container according to the mass ratio of 9:1:1, stirring at 80 DEG C to disperse for 1h, curing at 120 DEG C for 2h and curing at 180 DEG C for 1h so as to obtain the heat-resistant high-strength precoated sand fracturing propping agent. By utilizing the preparation method, a fusing coating technology with high energy consumption and poor precoating effect is avoided, and the obtained precoated sand fracturing propping agent has good heat resistance and high compressive strength.

Owner:PETROCHINA CO LTD +1

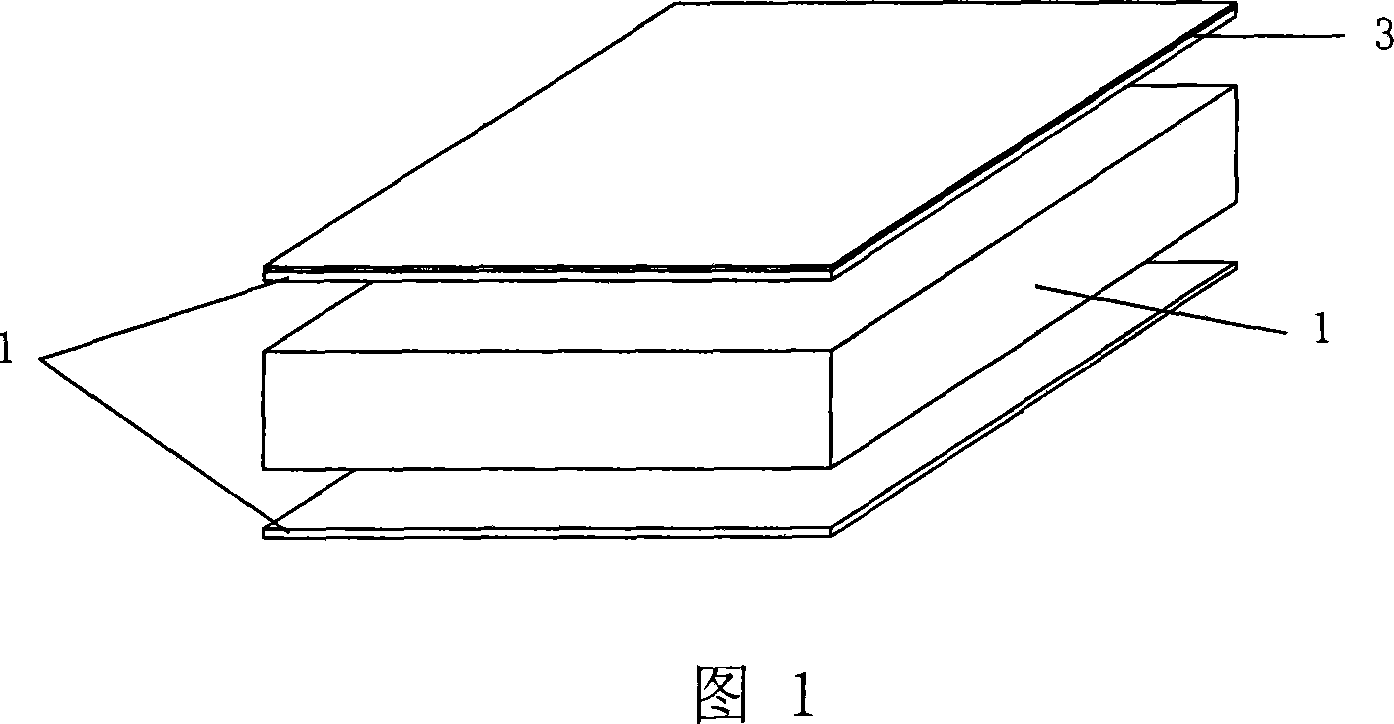

Composite material road tie plate and assembling technique

The invention relates to a composite road backing plate, comprising core material (1), faceplates (2) solidified by fiber cloth layer and resin and set at two sides of the core material (1) and non-skidding coating (3) set at the upper surface of faceplate (2). It is characterized in that the structure of connecting edges of backing plate can adopt male-female connecting edge, iron chain or canvas and so on. The invention can be used in building and repairing of urgent road in civil and national engineering. It is provided with light weight, high intensity, big rigidity, corrosion resistance, anti-stripping, convenient and quick assembly, repeatable usage, no damage for field environment and industrial production. Because the invention is made of light wood or foam core material and resin matrix fiber faceplate and resin column or resin web plate so on are formed on the core material, abilities of compressive resistance and shear resistance are improved while because adjacent backing plates are connected by canvas, iron chain or male-female connecting edge, the road for vehicle are assembled quickly.

Owner:NANJING UNIV OF TECH

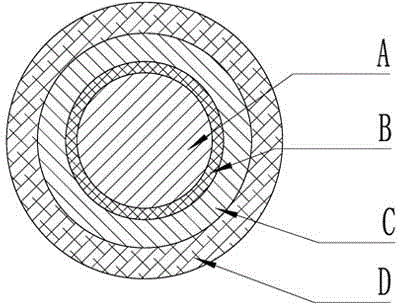

Multilayer compound eccentric-wear-preventing continuous sucker rod and manufacturing device and method thereof

ActiveCN104060944AAccelerated corrosionImprove partial wear resistanceDrilling rodsLayered productsEpoxyManufacturing technology

The invention relates to a multilayer compound eccentric-wear-preventing continuous sucker rod and a manufacturing device and a manufacturing method thereof. The sucker rod is characterized in that one section or several sections of the external surface of a fiber reinforced resin matrix composite rod body are respectively covered with a thermosetting wear layer; each thermosetting wear layer is made from one of polyurethane, a fluorocarbon coating, modified epoxide resin, vinylester resin, unsaturated polyester and phenolic resin; by adopting a manufacturing technology of multilayer composite winding and pultrusion or weaving and pultrusion, an internal layer of longitudinal fibers, an intertwining layer or a weaving layer and an external layer of longitudinal fibers are formed from interior to exterior in sequence; the manufactured rod body has a continuous length of 0-5000m. The sucker rod has the beneficial effects that the radial strength and the axial compressive strength are enhanced; the corrosion resistance and the eccentric wear resistance of the thermosetting wear layers are improved by 30%; the maximum temperature tolerance of the thermosetting wear layers is up to 190 DEG C; meanwhile, the bonding between an sucker rod body and each thermosetting wear layer is greater in length and quite high in strength, so that the slippage and the layering of an eccentric-wear-preventing layer from the surface of the sucker rod in the normal operation of an oil well are avoided.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

High-strength diamond saw blade

The present invention is a high-strength diamond saw blade, which includes a substrate and a diamond cutter head. The substrate of the diamond saw blade includes the following components by weight: 28-37 parts of copper powder, 0-5 parts of aluminum powder, and 2-6 parts of tin powder , 2-4 parts of zinc powder, 5-8 parts of rare earth, 15-18 parts of titanium powder, 11-15 parts of nickel powder, 8-12 parts of cobalt powder, 1-3 parts of manganese powder, 0-1 part of phosphorus powder, silicon 1-3 parts of vanadium powder, 0.2-0.9 parts of vanadium powder, 2-5 parts of silver powder, 2-6 parts of molybdenum powder, 0.1-2 parts of tungsten powder, 0.5-3 parts of chromium powder, and the rest are iron and unavoidable impurities; diamond The cutter head of the saw blade includes the following components by weight: copper powder 35‑40 parts, tin powder 8‑11 parts, zinc powder 1‑2 parts, titanium powder 6‑10 parts, diamond 13‑18 parts, iron powder 9‑ 14 parts, nickel powder 1-5 parts, rare earth 1-4 parts, tungsten powder 1-3 parts. The invention can effectively improve the cutting performance of the diamond saw blade, and has high strength, high wear resistance, firmness and durability, great pressure resistance and low cost.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

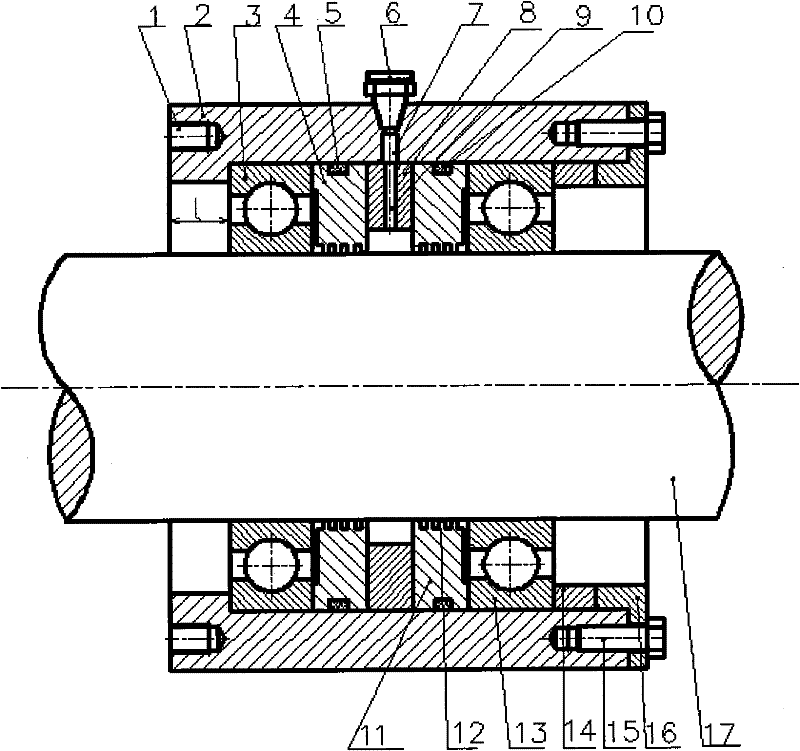

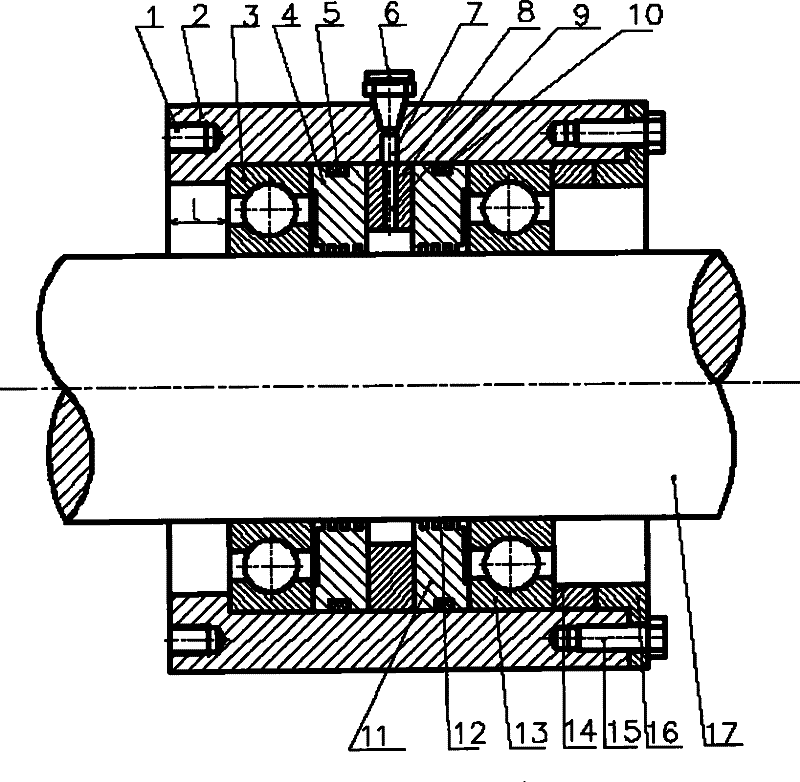

Sealing device with evenly distributed magnetic liquid

The invention relates to a sealing device with evenly distributed magnetic liquid, which belongs to the sealing field of mechanical engineering. The sealing device comprises a sealing assembly formed by installing a left bearing, a left pole shoe with a rubber sealing ring, a permanent magnet, a right pole shoe with a rubber sealing ring and a right bearing together. The space between the internal surface of the permanent magnet and the external surface of an axle is between 5 mm and the height of pole teeth to ensure that magnetic liquid successfully inflows into the clearance between the pole teeth and the axle under the action of magnetic field force, the width center of the permanent magnet is radially provided with a through hole, a through hole with tapered threads is arranged on the position of a casing, the width between the through hole and the left surface is l plus the width of the left bearing plus the width of the left pole shoe with the rubber sealing ring plus half of the width of the permanent magnet, a pipe head is connected in the through hole with tapered threads, and the sealing assembly is filled with air to ensure each pole tooth of the pole shoe to be distributed with the magnetic liquid, thereby the compressive resistance of the device is improved, and the service life of the device is prolonged.

Owner:BEIJING JIAOTONG UNIV

Modified recycled aggregates and preparation method therefor

ActiveCN109608077AReasonable ratioReduce hydrothermalizationSolid waste managementPorosityGlass fiber

The invention belongs to the technical field of reclaimed concrete and discloses a preparation method for modified recycled aggregates. The method comprises the step of soaking recycled aggregates ina modification solution for 1 to 3 hours, wherein the modification solution comprises the ingredients in parts by weight: 60-80 parts of water glass with a mass concentration of 5%, 5-10 parts of silane coupler, 10-20 parts of silicone resin and 5-10 parts of kaolin. Prepared modified reclaimed concrete has relatively low porosity. The invention further discloses reclaimed concrete. The reclaimedconcrete comprises the following ingredients in parts by weight: 250-300 parts of cement, 80-130 parts of fly ash, 50-85 parts of mineral powder, 685-735 parts of sand, 646-874 parts of gravels, 202-398 parts of the modified recycled aggregates, 140-175 parts of water, 5-9 parts of water reducer and 10-15 parts of glass fibers. The prepared reclaimed concrete still has relatively high compressivestrength under the condition that a large volume of reclaimed concrete is utilized.

Owner:中建西部建设北方有限公司

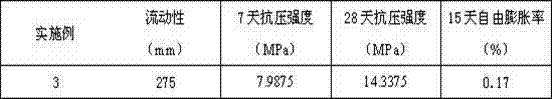

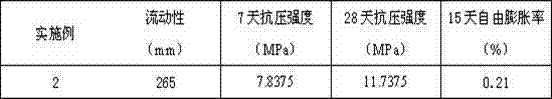

Cementing materials with micro-expansion effect for mine filling

The invention relates to a method of using industrial waste residues, such as steel slag, blast furnace slag, and the like as main raw materials to produce a mine cementation filling material with a micro-expansion effect, which belongs to the field of environmental protection and mine filling. Aiming at the difficult problems that the cement amount required for cemented filling is large, filling cost is high, filling materials are easy in bleeding and difficult in roof-contacted filling at present, the invention provides a cementing material, which uses 30%-80% of the steel slag mixed with 15%-60% of slag and 5%-15% of desulfurized gypsum to be as an activator to form a hydraulic cementing material in a mixing way, and the hydraulic cementing material completely replaces cement as a cementing agent. The steel slag-slag full-tailing mine filling material which is prepared by the cementing material has micro-expansibility and good fluidity, compressive strength after 28 days can reach high up to 14.3Mpa, and the performance requirement of mine filling and roof-contacted filling on the compressive strength can be satisfied.

Owner:UNIV OF SCI & TECH BEIJING

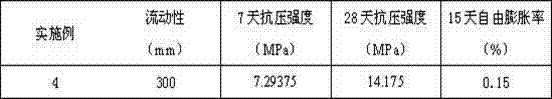

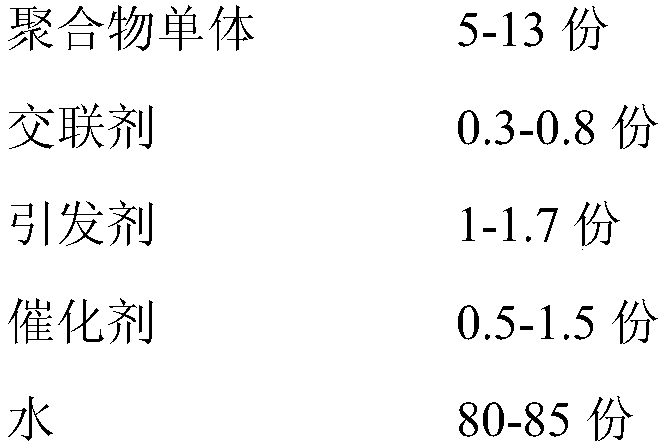

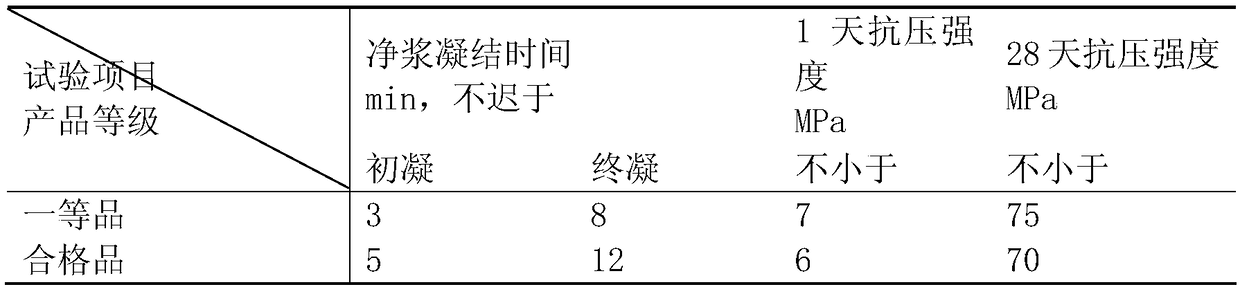

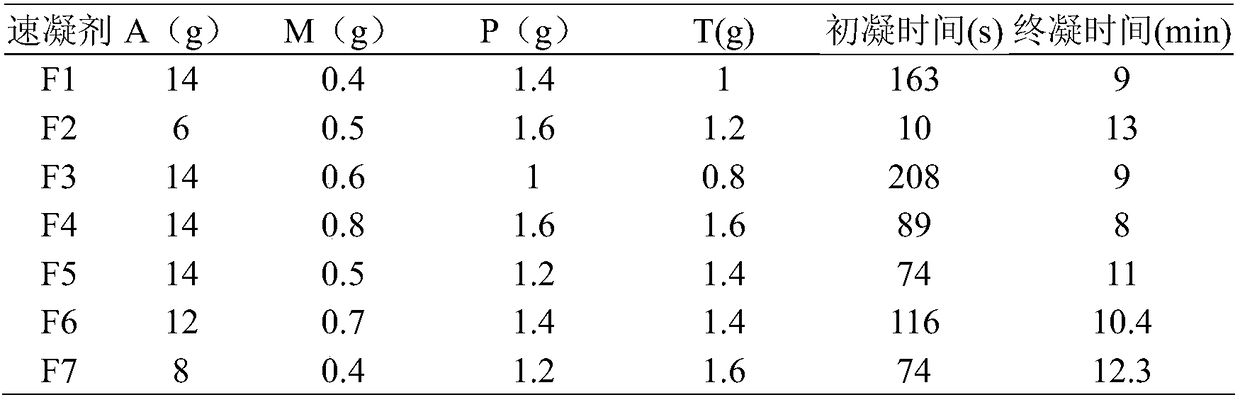

Organic low-alkali setting accelerator capable of forming interpenetrating network structure as well as preparation method thereof

The invention relates to an organic low-alkali setting accelerator capable of forming an interpenetrating network structure. A hydration product formed through cement hydration as well as a macromolecular polymer form the interpenetrating network structure, so that the quick setting effect is achieved. The setting accelerator comprises the following components in parts by weight: 5 to 13 parts ofa polymer monomer, 0.3 to 0.8 part of a crosslinking agent, 1 to 1.7 parts of an initiator, 0.5 to 1.5 parts of a catalyst and 80 to 85 parts of water. The setting accelerator has the advantages of adjustable setting time, high tolerance on environment change and raw material change, high adaptability on different types of cement and the like; regardless of the aqueous solution doping mode or thepowder doping and stirring and water adding stirring mode, the quick setting characteristic of quickly forming the interpenetrating network structure can be performed. The organic-inorganic interpenetrating network structure obviously improves the toughness of a cement-based material and mainly manifests in that the crack resistance is improved and the breaking strength is improved. The initial setting time and the final setting time of the cement with the setting accelerator as well as the 28-day compressive strength meets the requirement of the national standard, and high adaptability on a water reducer is achieved.

Owner:BEIJING UNIV OF TECH

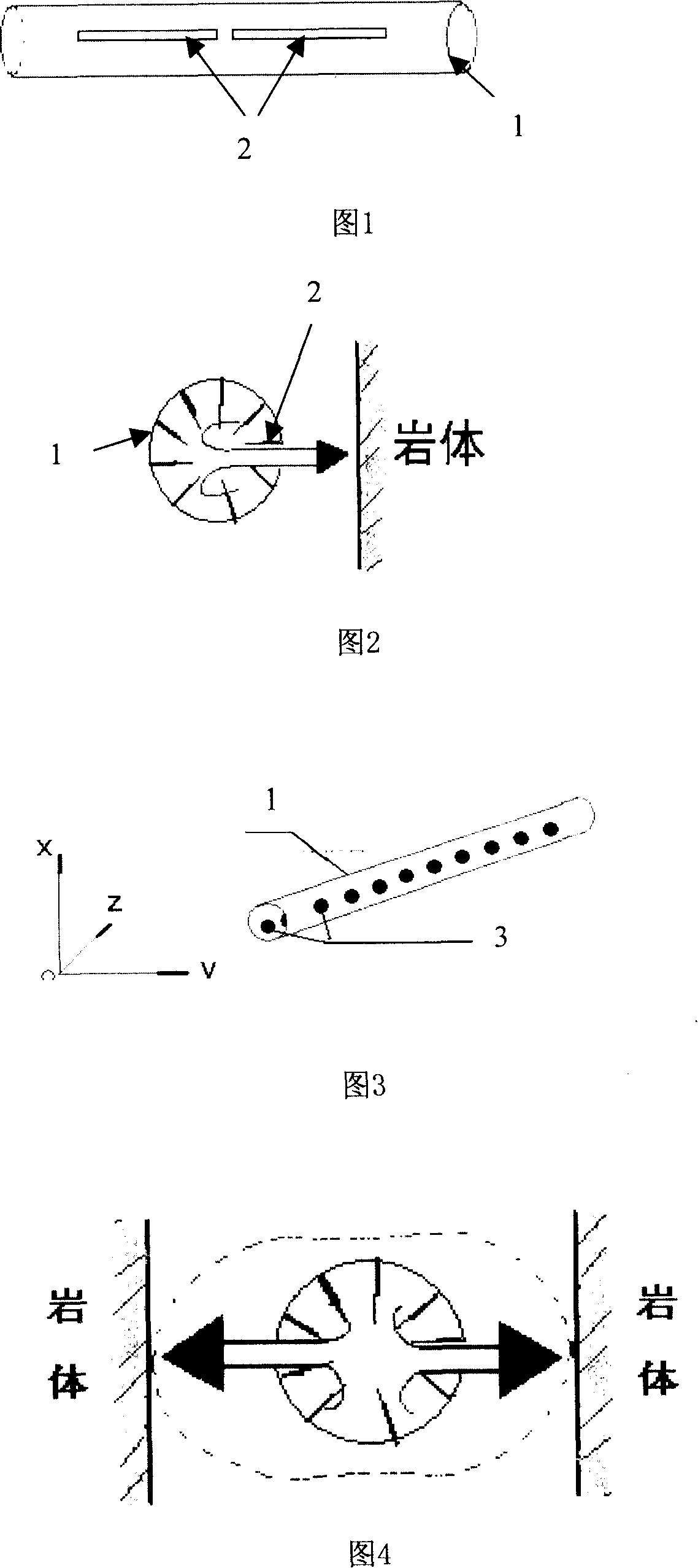

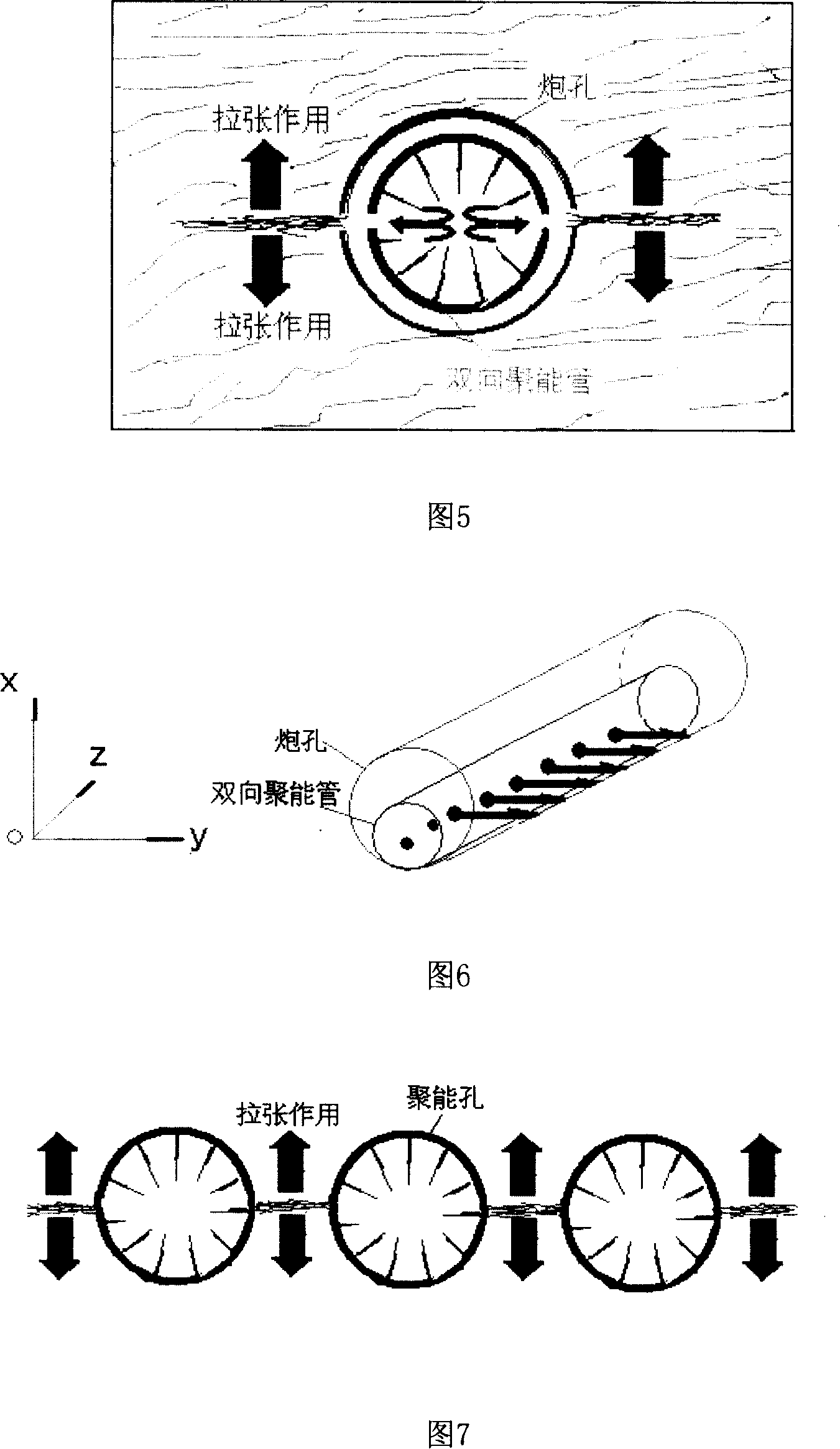

Bidirectional energy gathering tension shaping blasting cartridge

The invention relates to a bidirectional energy-accumulating tension forming blasting pipe, belonging to the energy-accumulating blasting device field. The conventional energy-accumulating blasting is to use the energy-accumulating device to linearly accumulate energy (such as ABS slotted pipe), and the detonation shock wave releases energy along the cutting joint of the energy-accumulating device, which generates the linear impact pressure action on hole wall and results in that the substance to be exploded generates the vertical radial crack surface along a blast hole. At present, the invention is mainly applied to the directional blasting of soft rock. If the substance to be exploded has the high compressive strength, the effect is limited. Due to the adoption of a PVC pipe and the bidirectional energy-accumulating hole, the invention generates the tension action on the substance to be exploded when blasting, which thereby can fully use the characteristic of that the tensile strength is far less than the compressive strength in order to generate the tension forming blasting effect. Therefore, the invention is far better than the conventional energy-accumulating blasting in forming effect, peripheral hole mark rate, explosive consumption, blast hole drilling volume, overbreak volume and other aspects.

Owner:何满潮

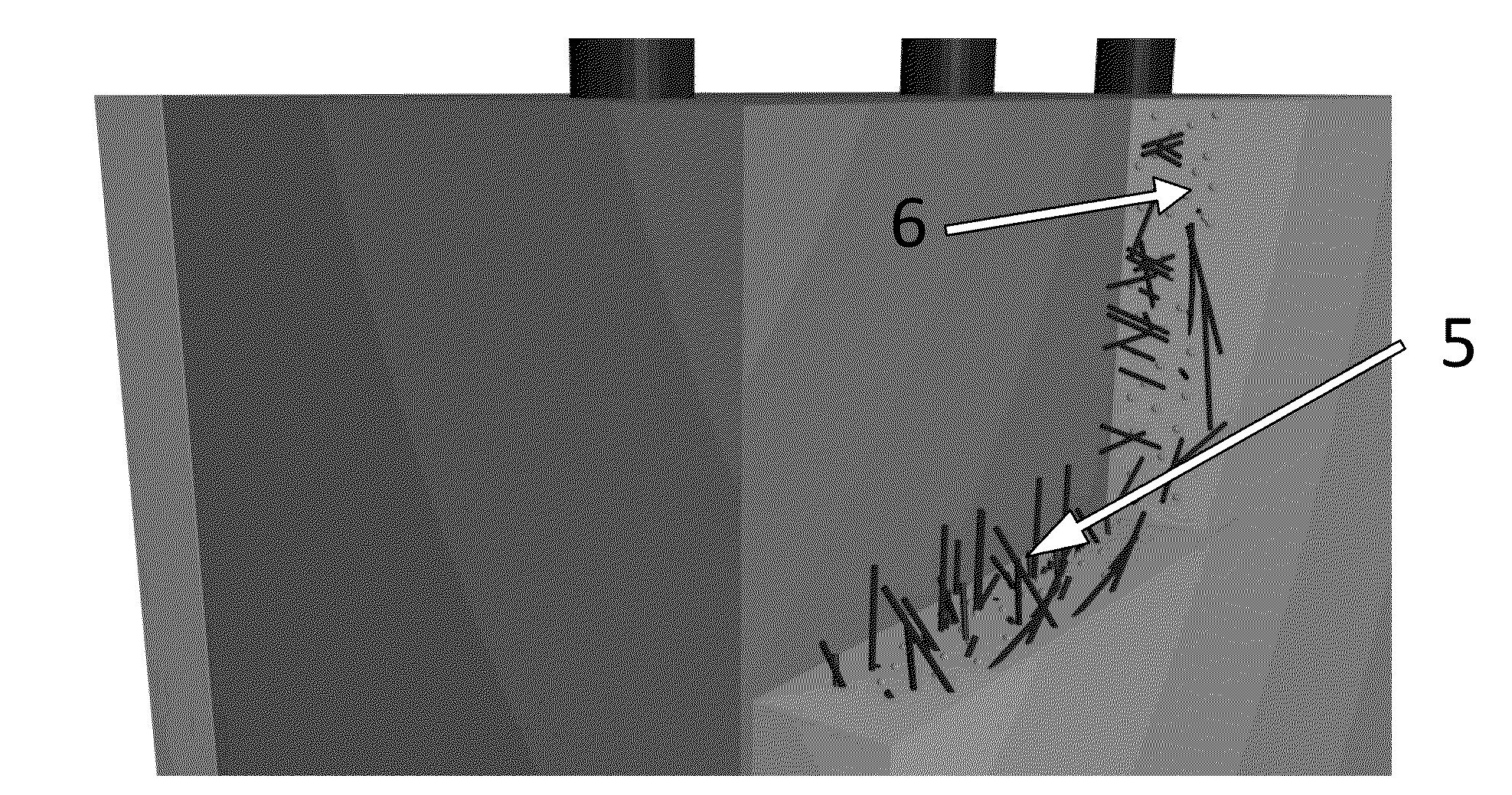

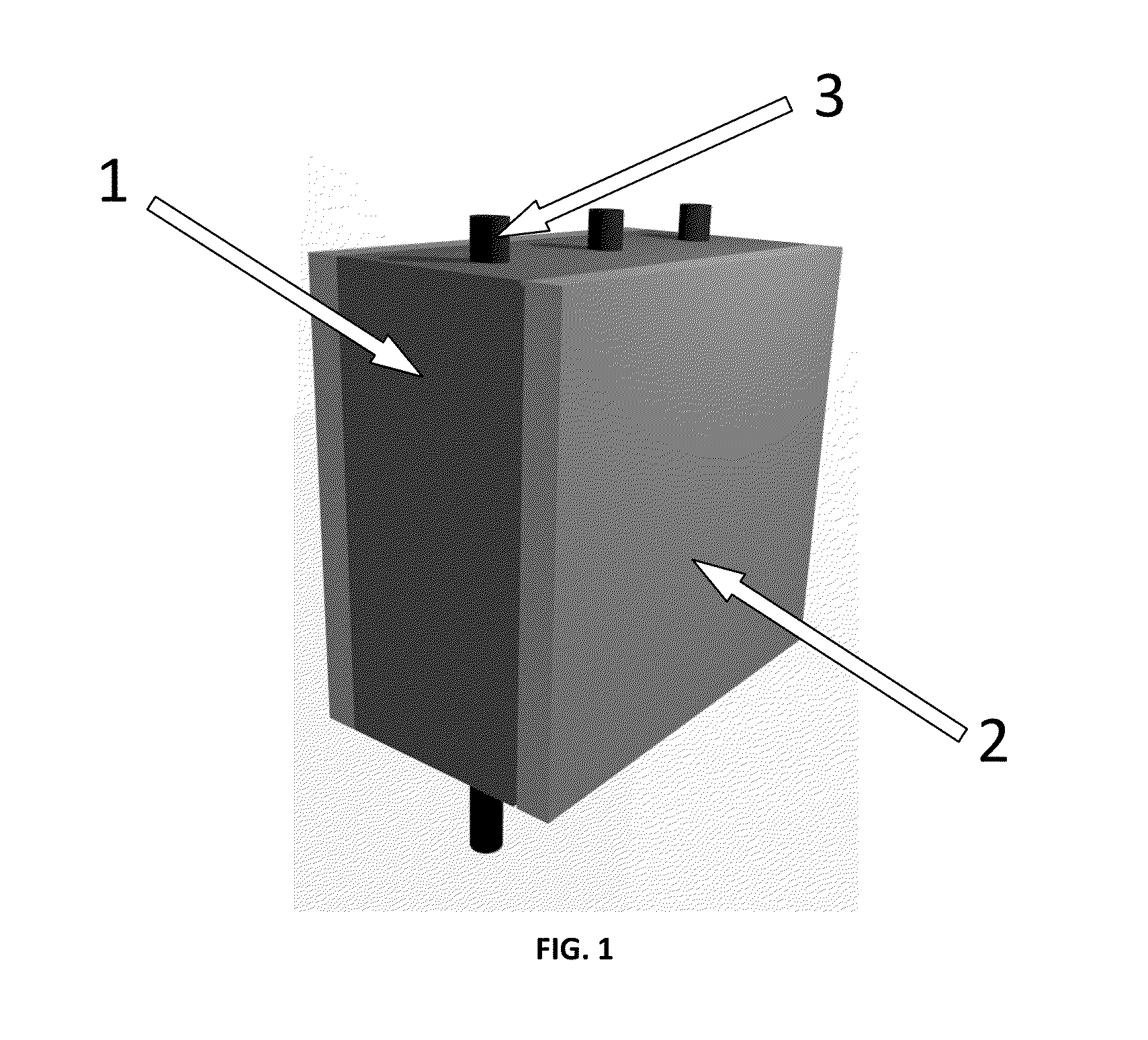

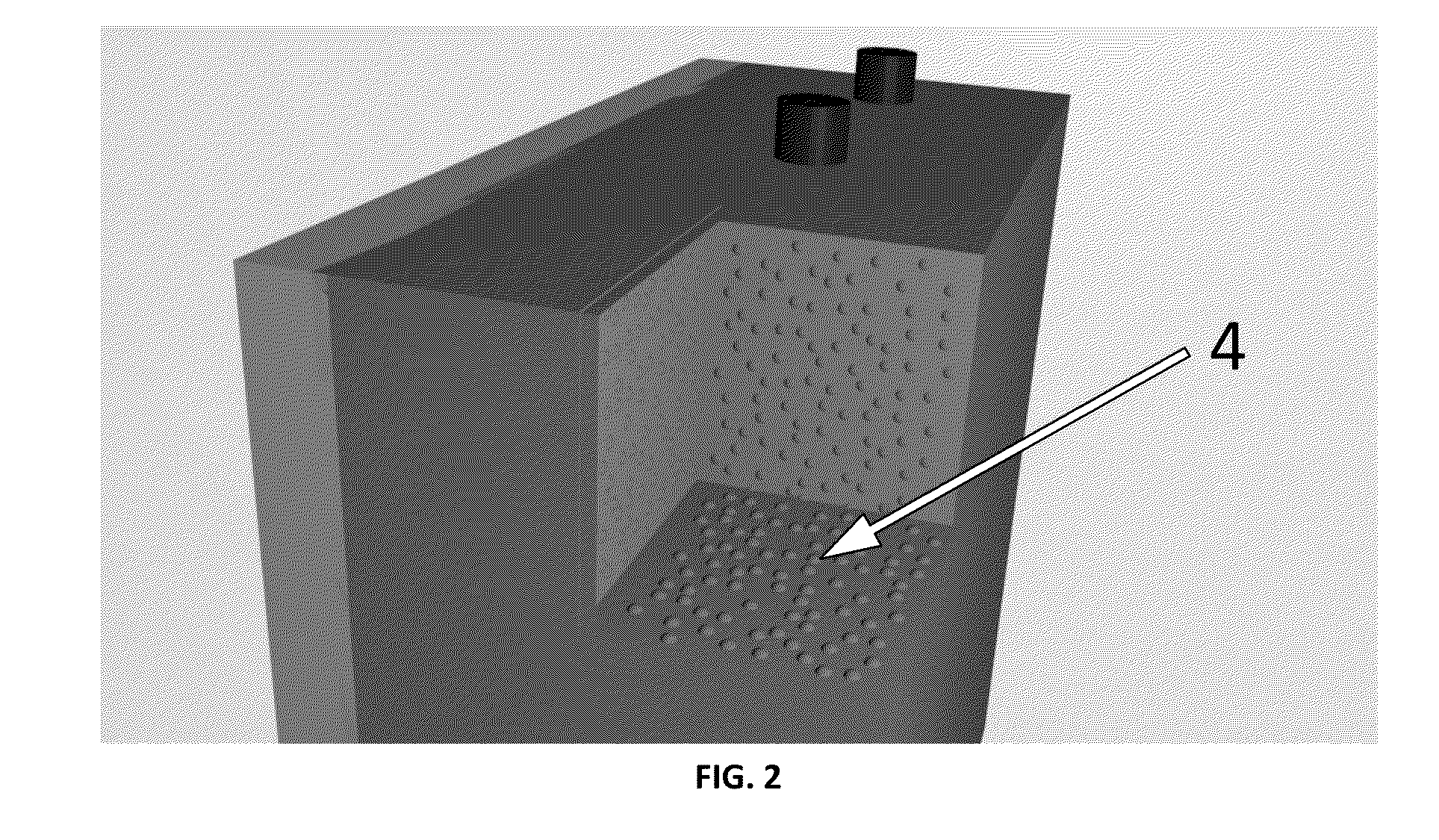

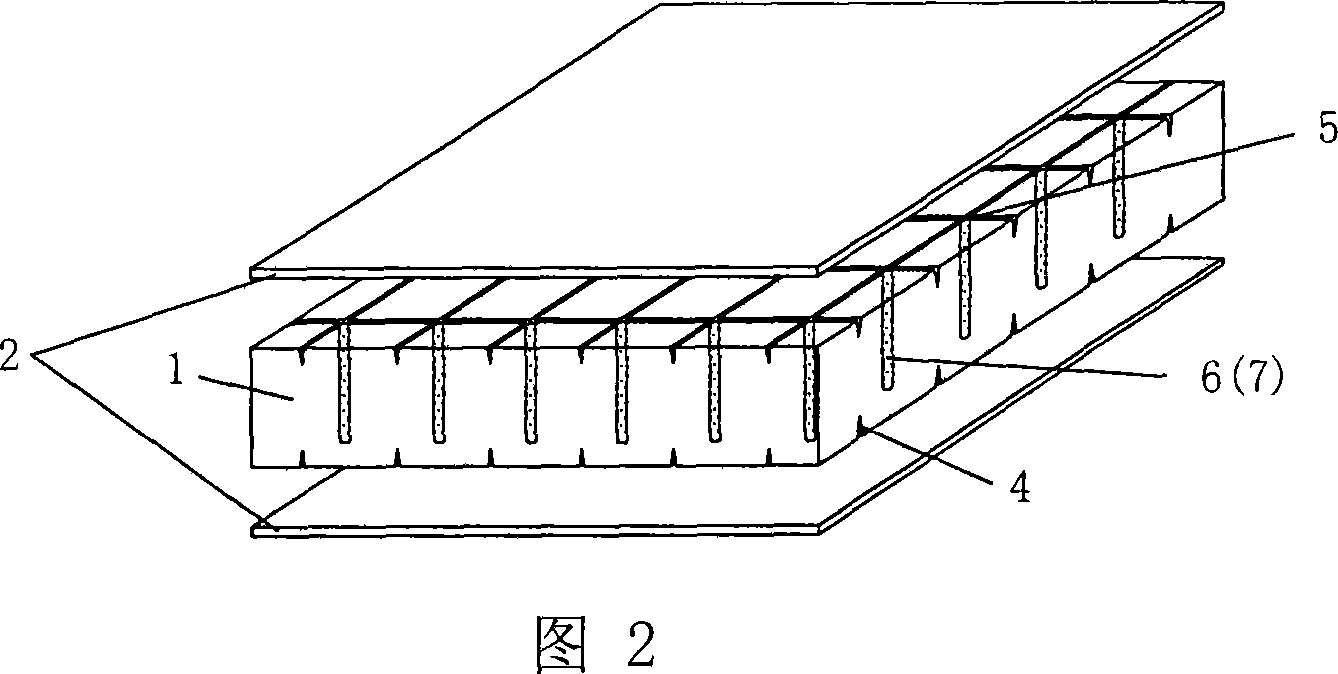

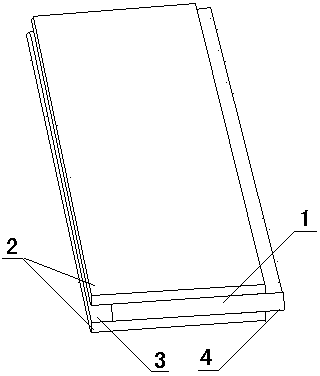

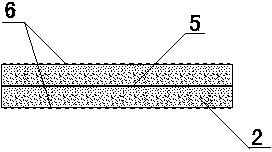

Composite engaging-type thermal-insulation wall plate composed of rigid polyurethane foam and reinforced foamed concrete

InactiveCN104110093AImprove stress resistanceImprove impact resistanceBuilding componentsCompressive resistanceFoam concrete

The invention relates to a composite engaging-type thermal-insulation wall plate composed of rigid polyurethane foam and reinforced foamed concrete. The wall plate includes a rigid polyurethane foam plate (1) and reinforced foamed concrete plates (2). The wall plate is characterized in that the rigid polyurethane foam plate (1) is employed as a middle layer of the thermal-insulation wall plate. Both the two sides of the rigid polyurethane foam plate (1) are provided with the reinforced foamed concrete plates (2). The rigid polyurethane foam plate (1) and the reinforced foamed concrete plates (2) on the two sides of the rigid polyurethane foam plate (1) are integrated completely. An engaging opening (3) is disposed at one side of the wall plate and an engaging tenon (4) is arranged at an opposite side of the wall plate to form the composite thermal-insulation wall plate. A rebar grid (5) is disposed inside each reinforced foamed concrete plate. Two surfaces of each reinforced foamed concrete plate are provided with fiber grids (6). According to the invention, a compressive resistance of the thermal-insulation wall plate is increased; a weight of a building wall is reduced by 50-70%; a shock resistance of the building wall is enhanced; and mechanized assembly in a construction site is achieved.

Owner:山东鲁盾保温材料有限公司

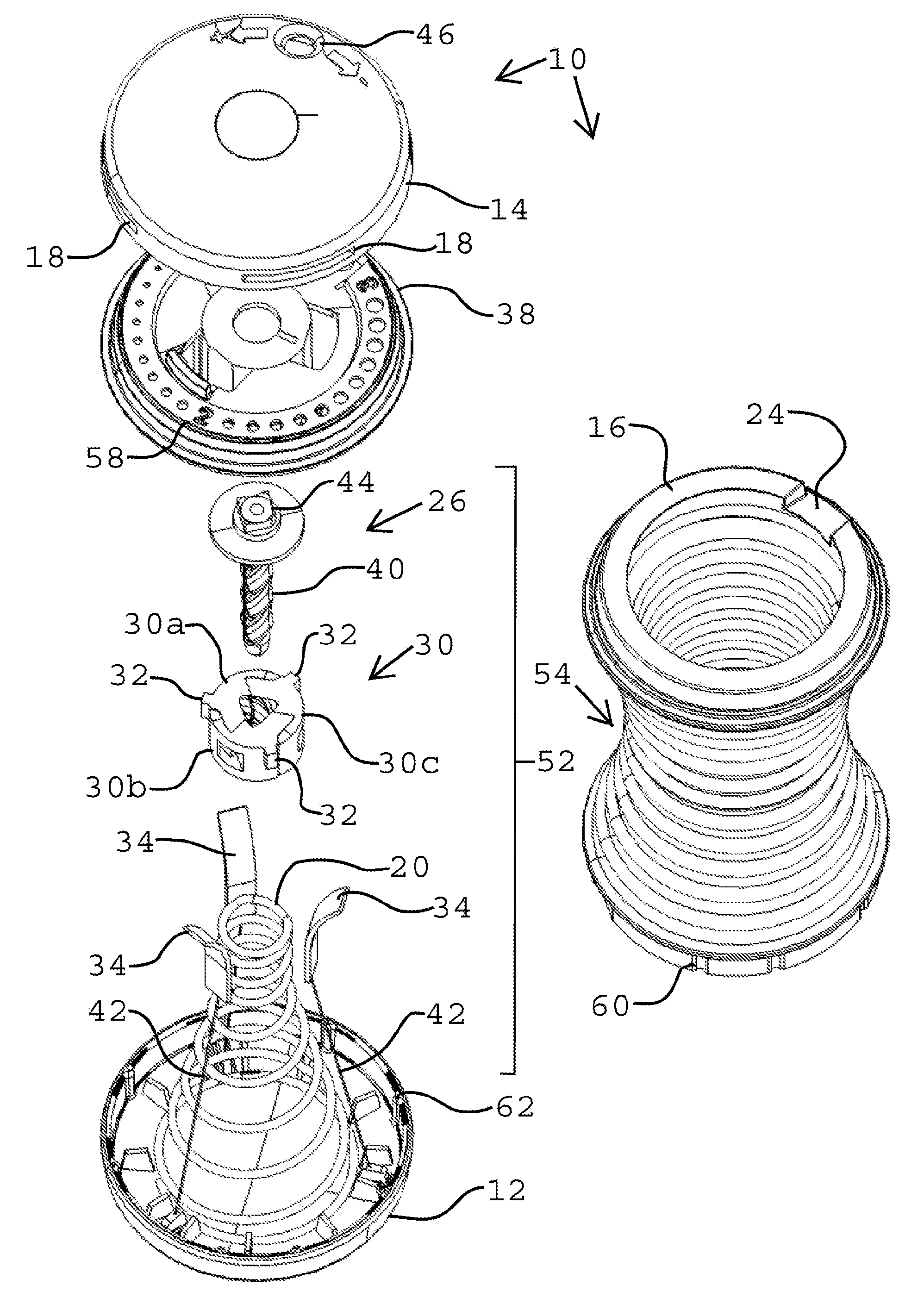

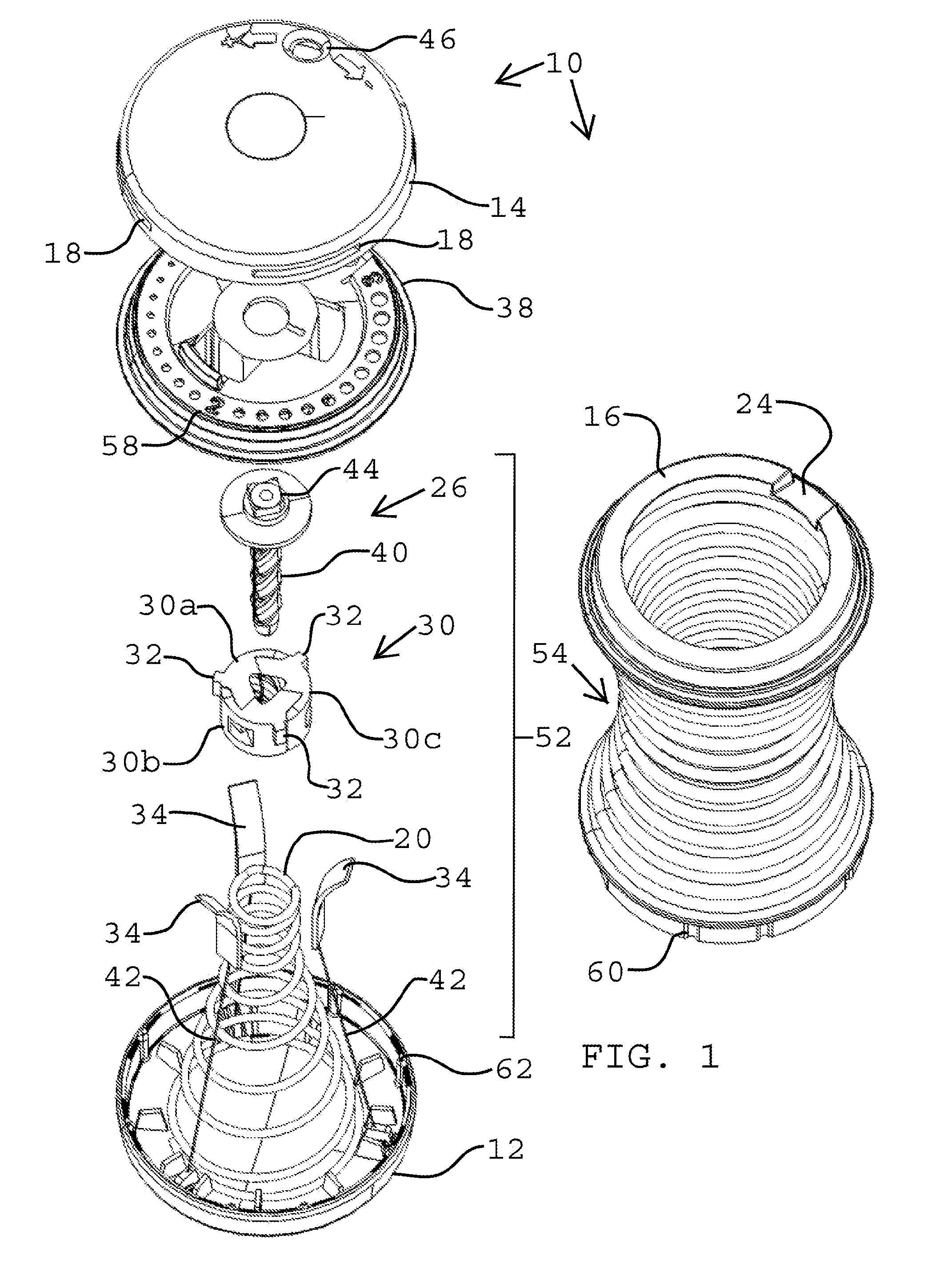

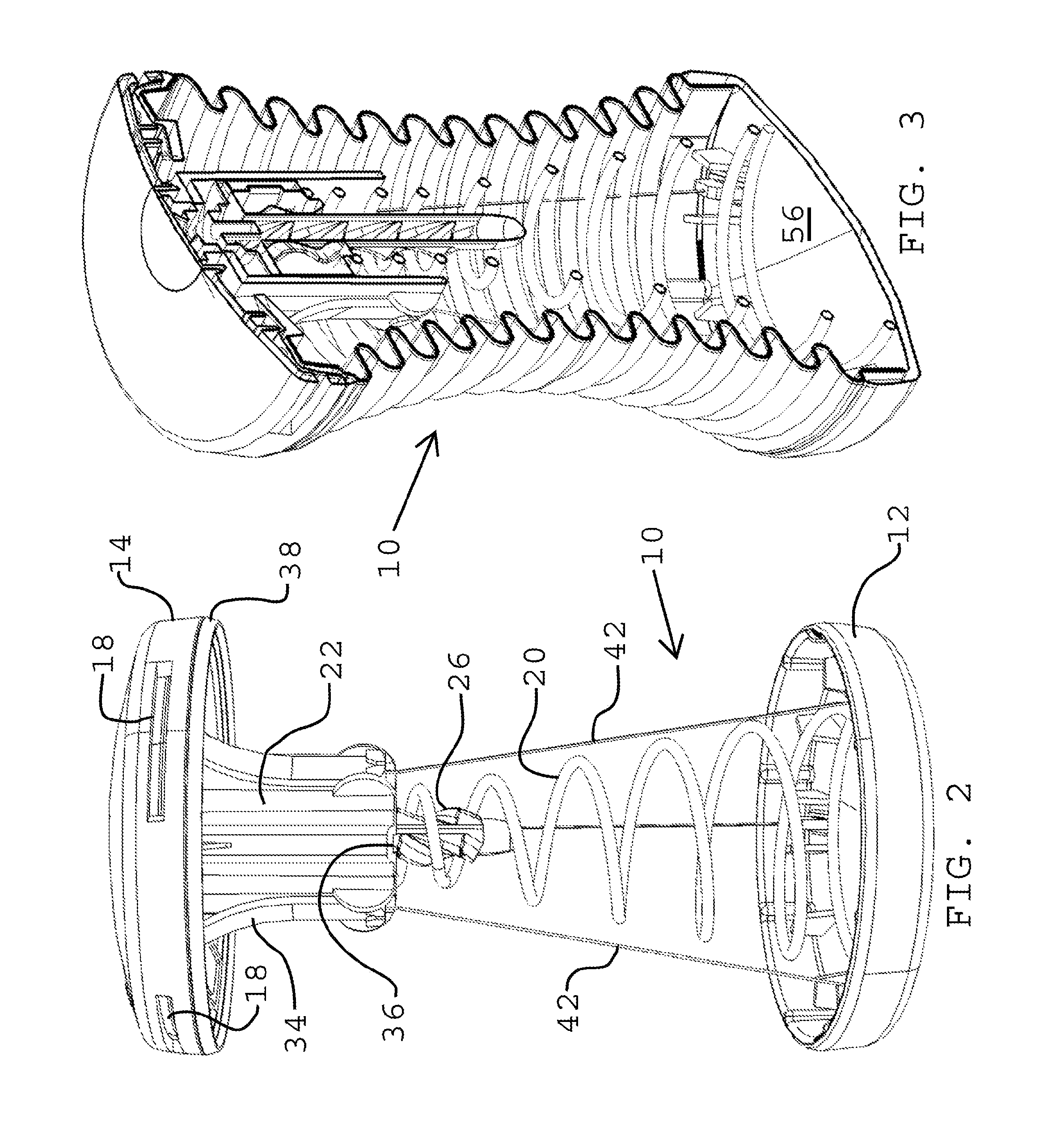

Compressive Resistance Means and Exercise Device

InactiveUS20120214650A1Permit of resistance levelMinimal force requirementResilient force resistorsCompressive resistanceBiomedical engineering

An exercise device (10) is provided with a twist cap (14) spaced apart from a base cap (12) with a resistance assembly (52) therebetween. The resistance assembly (52) includes a spring (20), a rotating member (26) that rotates with the twist cap (14), and a translating member (30) threadably engaged to the rotating member (26) and configured to variably deform the spring (20) due to rotation of the twist cap (14) in order to adjust the resistance level. An annularly pleated sidewall (16) and a vent means (18) may be included to provide a further resistance means. The exerciser compresses the twist cap (14) towards the base cap (12) to experience both compressive and bending resistance.

Owner:JAHNS HENNER

Graphene enhanced type carbon fiber composite pantograph pan and manufacturing technology thereof

InactiveCN106433037AImprove conductivityImprove impact toughnessRailway vehiclesPower current collectorsEpoxyFiber

The invention discloses a graphene enhanced type carbon fiber composite pantograph pan and a manufacturing technology thereof. The graphene enhanced type carbon fiber composite pantograph pan contains the following components in parts by weight: 1-5 parts of graphene, 30-40 parts of novolac epoxy, 40-50 parts of carbon fiber cloth, 1-5 parts of graphite powder, 1-5 parts of wollastonite powder and 3-7 parts of toughening agent. The pantograph pan manufactured according to the invention has the advantages of high electrical conductivity, specific resistance below 3.60 micro omega-m, high impact toughness, notched bar impact strength above 5.00J / cm2, high hardness, high abrasive resistance, shore hardness above 67, high strength compressive strength above 75MPa, capability of meeting the running requirements of common trains and high-speed rails, capability of effectively solving the problem of the dependence on import of the pantograph pan for Chinese high-speed rail and capability of realizing replacement of the imported products with the autonomously produced products.

Owner:张道松

Composite concrete agent

The invention discloses a concrete complexing agent as additive in the architectural material technical domain, which comprises the following parts: 48-55% silica, 27.5-45% fluorite, 2.5-8% sodium cetylsulfate, 4-9% hydroxy carboxyl acid and 0.5-1% aliphatic hydroxy sulfonate high-effective dehydragent. The complexing agent improves particle bond of concrete aggregate, which saves cement quantity by 10-20%.

Owner:王衡

Fireproofing and heat-insulating adhesive

ActiveCN109021837AEasy to prepareReduce investmentNon-macromolecular adhesive additivesClimate change adaptationCombustionSandwich board

The invention discloses a fireproofing and heat-insulating adhesive. The fireproofing and heat-insulating adhesive comprises, 100 parts of a saturated magnesium sulfate solution, 100 parts of magnesium oxide, 100-500 parts of water, 0.05-20 parts of a curing modifier, 0.05-40 parts of a waterproof modifier, 10-70 parts of a flame retardant and 0.5-50 parts of a flame retardant synergist. The fireproofing and heat-insulating adhesive is used for the fireproof coating modification of a polystyrene foam board, so the fireproofing and heat-insulating adhesive penetrates into the polystyrene foam board in order to achieve the purpose of uniform coating modification. A color steel sandwich board produced from the polystyrene fireproofing and thermal-insulating board has the advantages of high bending strength, high compressive strength, good tolerance, good combustion performance, and no collapse in fire scenes.

Owner:应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com