Composite concrete agent

A composite agent and concrete technology, which is applied in the field of additives and concrete composite agents, can solve problems such as small compressive strength grades and fractures, and achieve the effects of improving slump, wide sources, and saving cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

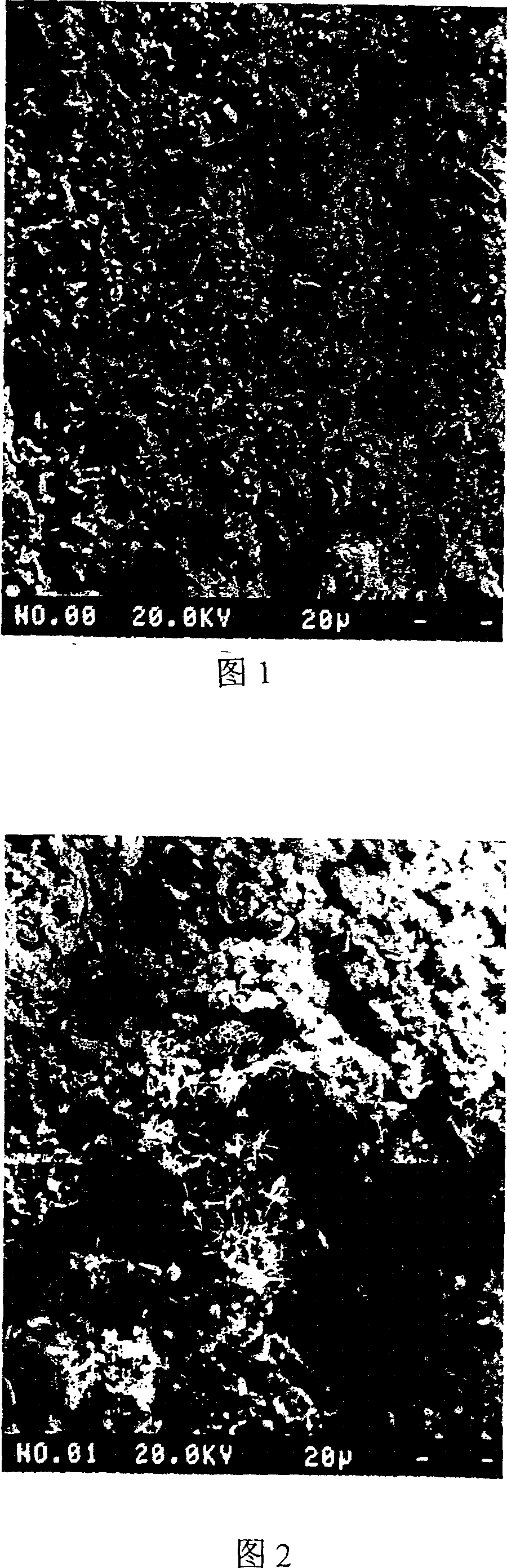

Image

Examples

Embodiment 1

[0011] Example 1: Take the construction of a bearing column for a large-scale workshop of a factory building as an example

[0012] Concrete composite agent, composed of the following raw materials in weight percentage: 50% silicon dioxide, 35% fluorspar, 5.5% sodium cetylbenzenesulfonate, 8.7% hydroxycarboxylic acid, aliphatic hydroxysulfonate high-efficiency water reducer 0.8%. Firstly, silicon dioxide, fluorspar, and sodium cetylbenzenesulfonate are firstly ground by Raymond Mill respectively, mixed in proportion and then secondly ground by ball mill, and the obtained powdery mixture is passed through a standard with a fineness of 400 mesh. Sieve, then add hydroxycarboxylic acid and aliphatic hydroxysulfonate high-efficiency water reducer to the above powder mixture, stir evenly, pass through a standard sieve with a fineness of 400 mesh, and the sieve residue is less than 5% to be the finished product.

[0013] The original design concrete of the bearing column is C50 grad...

Embodiment 2

[0014] Example 2: Taking the anti-vibration foundation of large-scale equipment poured in a certain workshop as an example

[0015] Concrete composite agent, composed of the following raw materials in weight percentage: 49% silicon dioxide, 40% fluorspar, 5% sodium cetylbenzenesulfonate, 5.5% hydroxycarboxylic acid, aliphatic hydroxysulfonate high-efficiency water reducer 0.5%. Firstly, silicon dioxide, fluorspar, and sodium cetylbenzenesulfonate are firstly ground by Raymond Mill respectively, mixed in proportion and then secondly ground by ball mill, and the obtained powdery mixture is passed through a standard with a fineness of 400 mesh. Sieve, then add hydroxycarboxylic acid and aliphatic hydroxysulfonate high-efficiency superplasticizer to the above powder mixture, stir evenly, pass through a standard sieve with a fineness of 400 mesh, and the finished product with a sieve residue of less than 5%.

[0016] When in use, the concrete composite agent prepared above is adde...

Embodiment 3

[0017] Embodiment 3: Take the construction of a mine shaft as an example in a certain mine

[0018] Concrete composite agent, composed of the following raw materials in weight percentage: 55% silicon dioxide, 32% fluorspar, 7.5% sodium cetylbenzenesulfonate, 4.5% hydroxycarboxylic acid, aliphatic hydroxysulfonate high-efficiency water reducer 1%. Firstly, silicon dioxide, fluorspar, and sodium cetylbenzenesulfonate are firstly ground by Raymond Mill respectively, mixed in proportion and then secondly ground by ball mill, and the obtained powdery mixture is passed through a standard with a fineness of 400 mesh. Sieve, then add hydroxycarboxylic acid and aliphatic hydroxysulfonate high-efficiency superplasticizer to the above powder mixture, stir evenly, pass through a standard sieve with a fineness of 400 mesh, and the finished product with a sieve residue of less than 5%.

[0019] The length of the wellbore is 620m-670m, and it needs to pass through the sub-viscous powder fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com