Concrete water-proof additive

A technology for concrete and additives, applied in the field of concrete additives, can solve the problems of high construction cost, high construction difficulty and complexity, and achieve the effects of improving slump and gripping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

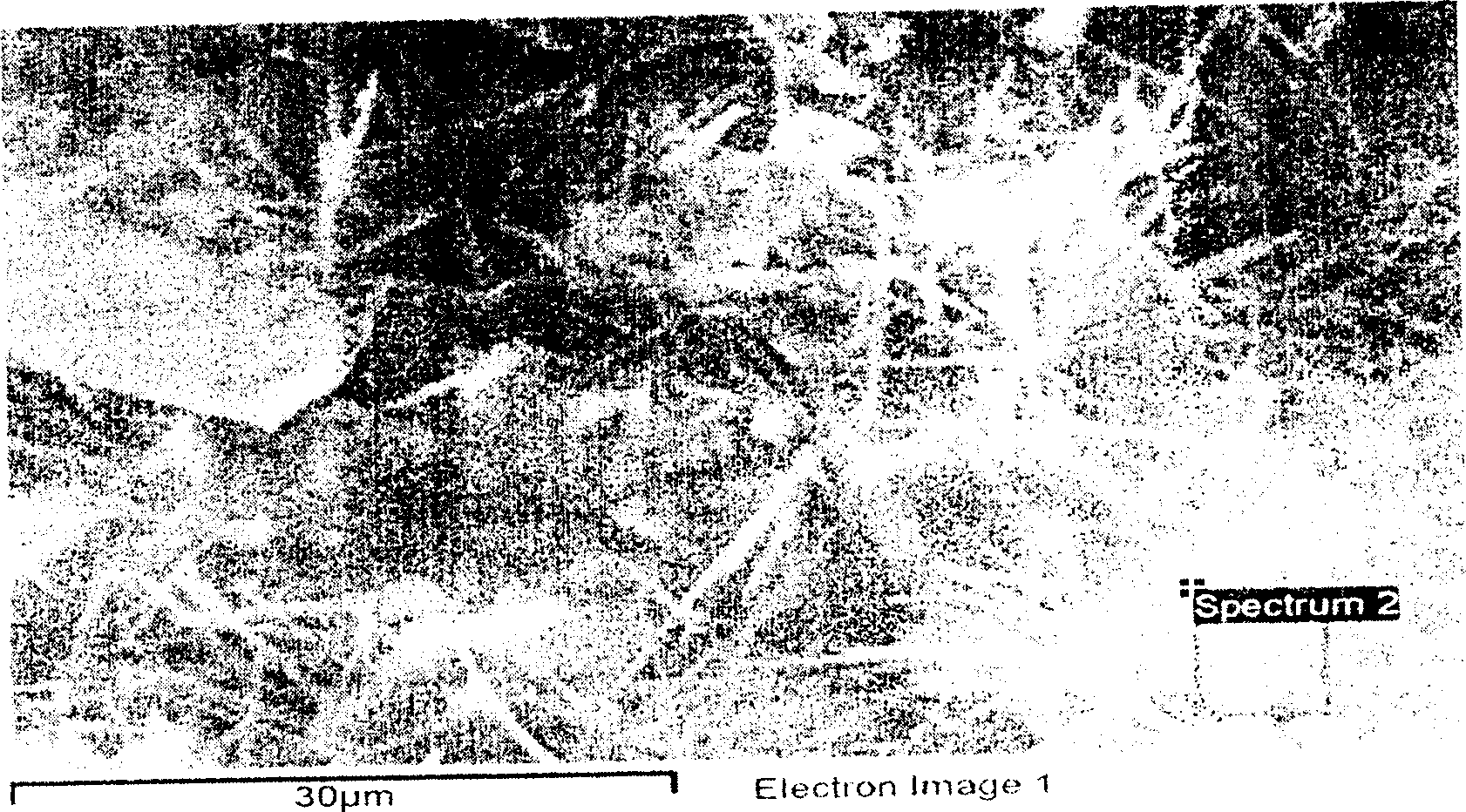

Image

Examples

Embodiment 1

[0020] Embodiment 1: Take the construction of a mine shaft as an example.

[0021] The concrete waterproof additive is composed of the following components and weight ratio: 75% of silicon dioxide, 6% of hydroxy carboxylate, 15% of aluminum sulfate, and 4% of dispersant. The above components are mixed and ground, passed through a standard sieve with a fineness of 300 mesh, and the obtained powder is the concrete waterproof additive.

[0022] The dispersant is selected from industrial grade pull-off powder.

[0023] The hydroxycarboxylate is selected from LHG polymerized hydroxycarboxylate produced by Yichuan Pingping Chemical Building Materials Research Institute, Luoyang City, Henan Province.

[0024] Said waterproof additive is added in conventional concrete with 8% of cement consumption (weight).

[0025] A certain mine constructs 3 shafts with a minus 630 meters, and the present invention is used in No. 3 wells. Design concrete strength C30, impermeability S12. The abo...

Embodiment 2

[0037] The concrete waterproof additive is composed of the following components and weight ratio: 85% of silicon dioxide, 4% of hydroxy carboxylate, 8% of aluminum sulfate, and 3% of dispersant. The above components are mixed and ground, passed through a standard sieve with a fineness of 300 mesh, and the obtained powder is the concrete waterproof additive.

[0038] The dispersant is selected from sodium 12-16 alkylbenzene sulfonate.

[0039] The hydroxycarboxylate is selected from LHG polymerized hydroxycarboxylate produced by Yichuan Pingping Chemical Building Materials Research Institute, Luoyang City, Henan Province.

[0040] Said waterproof additive is added in conventional concrete with 10% of cement consumption (weight).

[0041] The underground coal bunker section of a certain mine is 150 meters long, with an upper mouth diameter of 6 meters, a middle diameter of 15 meters, and a lower mouth diameter of 6 meters, in the shape of a shuttle. After being built with conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com