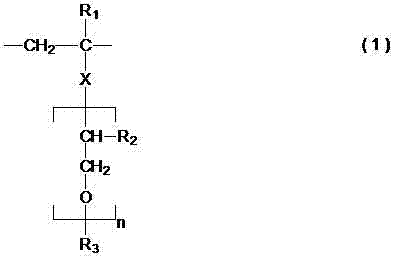

Polyether amine modified poly carboxylic acid superplasticizer and preparation method thereof

A superplasticizer and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve problems such as harsh conditions and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Add 700.0g of water, 700.0g of A-1, 100.0g of B-2 and 20.0g of ammonium persulfate into a 2000ml four-necked flask equipped with a stirrer, a thermometer and a dropping device, and stir to raise the temperature to 50°C. At the same time, add 100.0g reducing agent aqueous solution (obtained by dissolving 10.0g L-ascorbic acid and 10.0g 3-mercaptopropionic acid in 80.0g water) and 380.0g monomer aqueous solution (obtained by dissolving 200.0g B-1 in 180.0g water) respectively. ), the dropping time was controlled at 240 minutes and 210 minutes respectively, and the reaction temperature was controlled at 50-55°C. After the dropwise addition, keep the temperature at 50-55°C for about 60 minutes to complete the polymerization reaction to obtain a carboxylic acid-based polymer, which is designated as PAE-1, and its weight-average molecular weight is 13,800 by GPC.

[0067] Add 200.0g of carboxylic acid-based polymer PAE-1 and 156.4g of C-1 into a 1000ml four-neck flask equippe...

Embodiment 2

[0069] Add 450.0 g of water and 450.0 g of A-2 into a 2000 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 80°C. At the same time, 100.0g aqueous initiator solution (obtained by dissolving 20.0g ammonium persulfate in 80.0g water), 100.0g aqueous solution of chain transfer agent (obtained by dissolving 15.0g 3-mercaptopropionic acid in 85.0g water) and 900.0g mono Body aqueous solution (obtained by dissolving 500.0g B-1 and 50.0g B-3 in 350.0g water), the dropping time was controlled at 240 minutes, 210 minutes and 210 minutes respectively, and the reaction temperature was controlled at 78-82°C. After the dropwise addition, keep the temperature at 78-82°C for about 60 minutes to complete the polymerization reaction to obtain a carboxylic acid-based polymer, which is denoted as PAE-2, and its weight-average molecular weight is 8700 by GPC test.

[0070] Add 200.0g of carboxylic acid-based polymer PAE-2 and...

Embodiment 3

[0072] Add 690.0g of water, 800.0g of A-3 and 10.0g of 35% hydrogen peroxide into a 2000ml four-necked flask equipped with a stirrer, a thermometer and a dropping device, and stir to raise the temperature to 60°C. At the same time, 100.0g reducing agent aqueous solution (obtained by dissolving 5.0g L-ascorbic acid and 10.0g thioglycolic acid in 85.0g water) and 400.0g monomer aqueous solution (obtained by dissolving 200.0g B-1 in 200.0g water) were added dropwise, dropwise The adding time was controlled at 240 minutes and 210 minutes respectively, and the reaction temperature was controlled at 60-65°C. After the dropwise addition, keep the temperature at 60-65°C for about 60 minutes to complete the polymerization reaction to obtain a carboxylic acid-based polymer, which is designated as PAE-3, and its weight-average molecular weight is 18,000 as measured by GPC.

[0073] Add 200.0g of carboxylic acid-based polymer PAE-3 and 36.2g of C-2 into a 1000ml four-neck flask equipped w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com