Machine-made sand regulator and preparation method thereof

A sand conditioner and mechanism technology, applied in the field of building materials, can solve the problems of poor working performance and low strength of concrete, and achieve the effects of high water reduction rate, good compatibility and prolonging construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

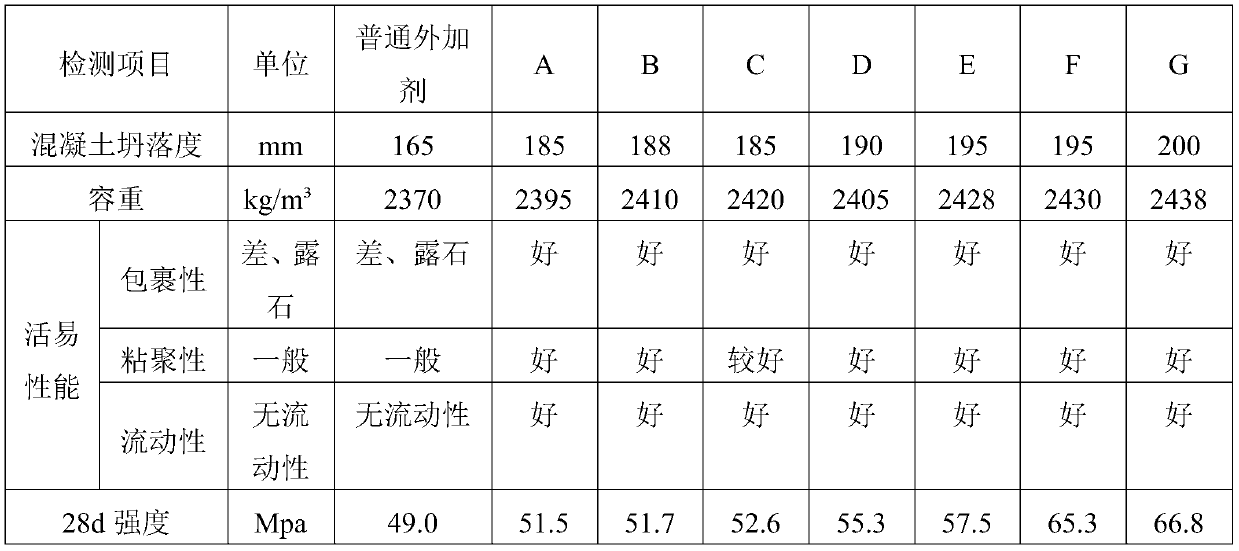

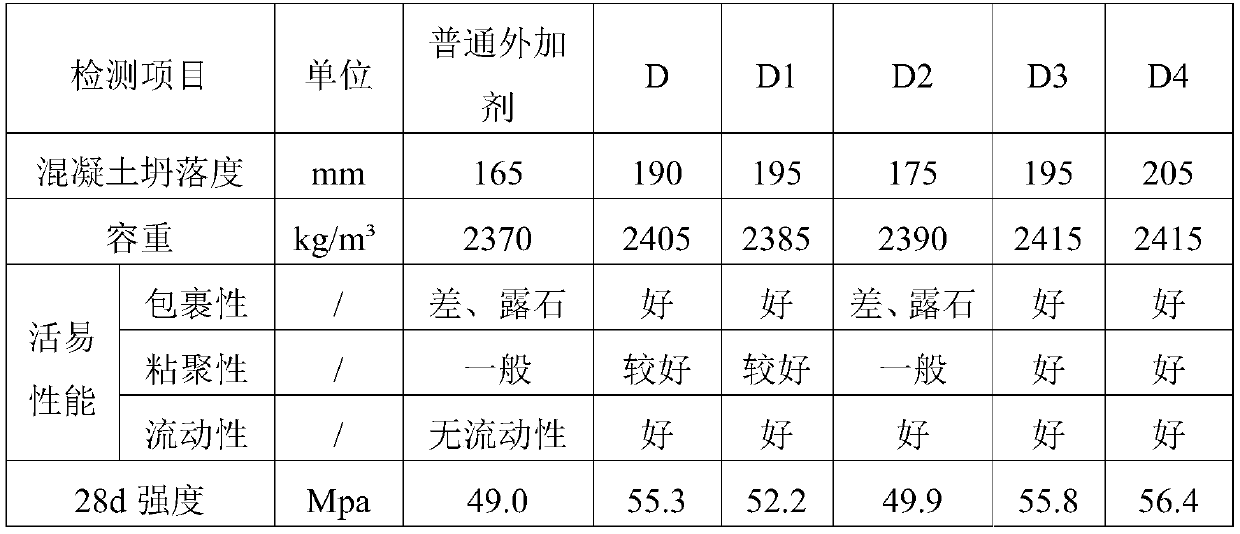

Examples

Embodiment 1

[0039] This example provides a machine-made sand regulator, which contains the following components by mass percentage:

[0040] Polycarboxylic acid water reducing agent 1%, glue reducing agent 5%, early strength agent 3%, air-entraining agent 0.01%, polyether defoaming agent 0.05%, dense repair agent 0.4%, viscosity thixotropic agent 0.05%, the rest The amount is water.

[0041] Among them, the water reducing rate of the polycarboxylic acid water reducing agent is greater than 25%. The solid content of the polycarboxylic acid water reducing agent is 35-45%.

[0042] The gum reducing agent is triethanolamine. The early strength agent is calcium formate. The air-entraining agent is polyether phosphate. The polyether defoamer is emulsified silicone oil. The dense repair agent is polyacrylonitrile fiber. The viscosity thixotropic agent is talc.

Embodiment 2

[0044] This example provides a machine-made sand regulator, which contains the following components by mass percentage:

[0045] Polycarboxylic acid water reducer 5%, glue reducer 10%, early strength agent 10%, air-entraining agent 0.5%, polyether defoamer 0.8%, compact repair agent 3.5%, viscosity thixotropic agent 2%, and the rest The amount is water.

[0046] Among them, the water reducing rate of the polycarboxylic acid water reducing agent is greater than 25%. The solid content of the polycarboxylic acid water reducing agent is 35-45%.

[0047] The gum reducing agent is diethanol monoisopropanolamine. The early strength agent is Yuanming powder. The air-entraining agent is sodium lauryl sulfate. The polyether defoamer is emulsified silicone oil. The dense repair agent is polyacrylonitrile fiber. The viscosity thixotropic agent is molasses.

Embodiment 3

[0049] This example provides a machine-made sand regulator, which contains the following components by mass percentage:

[0050] Polycarboxylic acid water reducer 3%, glue reducer 7%, early strength agent 6%, air-entraining agent 0.3%, polyether defoamer 0.4%, compact repair agent 1.7%, viscosity thixotropic agent 1%, and the rest The amount is water.

[0051] Among them, the water reducing rate of the polycarboxylic acid water reducing agent is greater than 25%. The solid content of the polycarboxylic acid water reducing agent is 35-45%.

[0052] The gum reducing agent is triethanolamine. The early strength agent is Yuanming powder. The air-entraining agent is polyether phosphate. The polyether defoamer is emulsified silicone oil. The dense repair agent is polyacrylonitrile fiber. The viscosity thixotropic agent is molasses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com