Terminal alkenyl nonsaturated polyether and purpose thereof

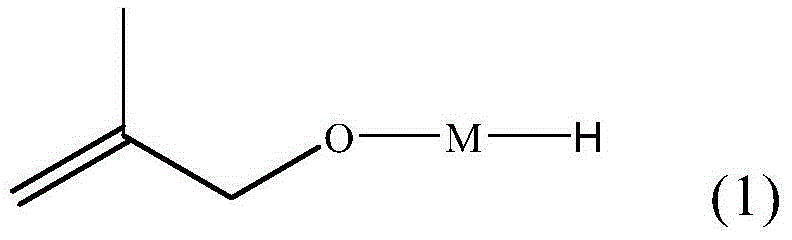

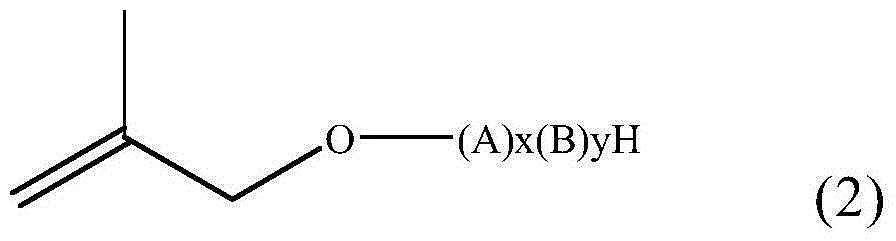

An unsaturated, ethylenically-terminated technology, used in the preparation of polycarboxylate superplasticizers and ethylenically-terminated unsaturated polyethers, can solve the problems affecting the application performance of methallyl ether, high polyethylene glycol content, and polyether. The problem of increasing ethylene glycol content, etc., can improve the steric hindrance effect, improve the dispersion effect, and increase the double bond retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In the preparation process of the polyether of the present invention, the alkoxylation reaction is carried out under the catalysis of a basic catalyst. The basic catalyst used can be any catalyst used in the existing alkoxylation reaction, and its analogue or modified product can also be used.

[0067] In one embodiment of the preparation process of the polyether of the present invention, the basic catalyst can be alkaline earth metal compounds and alkali metal compounds, including but not limited to alkaline earth metal oxides, alkali metal carbonates, alkaline earth metal hydroxides, alkali metal Hydroxides, alkaline earth metal alkoxides and alkali metal alkoxides, especially alkali metal C1-C4 alkoxides. The above catalysts may be used alone or in combination of two or more.

[0068] In a preferred embodiment, basic catalysts include, but are not limited to, hydroxides, oxides, hydrides, and alkoxides of sodium, potassium, rubidium, cesium, calcium, and magnesium. ...

Embodiment 1

[0080] Weigh 119.4g of methallyl alcohol and 1.3g of solid potassium methylate catalyst into the reactor, start stirring, heat to 80°C, then evacuate the reactor to 5kPa and fill the vacuum with nitrogen, repeat vacuuming and filling with nitrogen Vacuum three times.

[0081] Then make the reaction kettle warm up to 100°C, then start to add propylene oxide, control the reaction temperature at 140°C, and the reaction pressure is 0.4MPa, when 192.3g of propylene oxide has been added, keep the temperature in the still at 140°C 0.8 hours. Then add ethylene oxide, control the reaction temperature at 140°C, and the reaction pressure is 0.4MPa. After adding 2188.3g of ethylene oxide, keep the temperature in the kettle at 140°C for 0.5 hours, then neutralize with acetic acid to pH 5.0-7.0, and cooled to room temperature to obtain terminal ethylenically unsaturated PE type polyoxyalkyl ether A1.

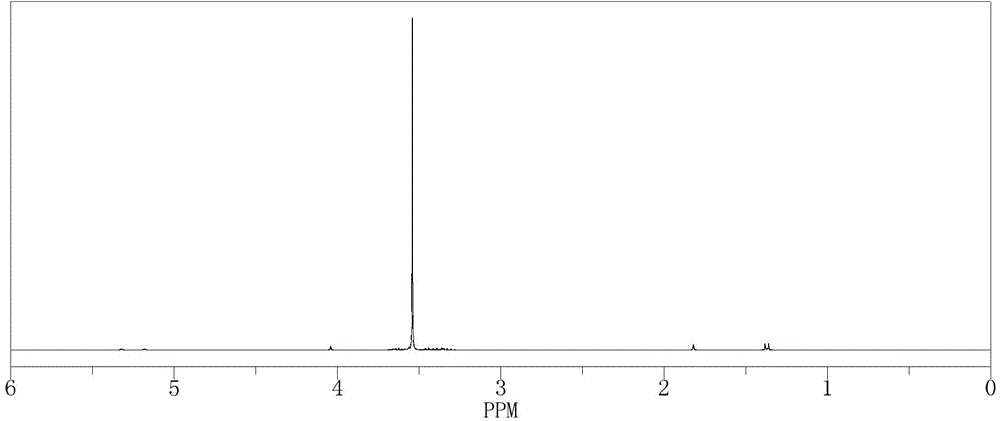

[0082] According to GPC analysis (30 ℃, with polyethylene glycol as the standard produc...

Embodiment 2

[0087] Weigh 63.1g of methallyl alcohol and 1.6g of solid potassium methylate catalyst into the reactor, start stirring, heat to 80°C, then evacuate the reactor to 5kPa and fill the vacuum with nitrogen, repeat vacuuming and filling with nitrogen Vacuum three times.

[0088]Then make the reaction kettle warm up to 100°C, then start to add propylene oxide, control the reaction temperature at 130°C, and the reaction pressure is 0.4MPa, when 508.4g of propylene oxide has been added, keep the temperature in the still at 130°C 0.8 hours. Then add ethylene oxide, control the reaction temperature at 130°C, and the reaction pressure is 0.4MPa. After adding 1928.5g of ethylene oxide, keep the temperature in the kettle at 130°C for 0.5 hours, then neutralize with acetic acid to pH 5.0-7.0, and cooled to room temperature to obtain terminal ethylenically unsaturated PE type polyoxyalkyl ether A2.

[0089] According to GPC analysis (30° C., using polyethylene glycol as a standard product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com