Patents

Literature

119 results about "Fiberglass reinforced plastic grating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs. It is used in a variety of applications including walkways and overhead platforms. FRP grating is a structural product that can be weight-bearing between spans.

High temperature resistant paint for glass fibre reinforced plastic grille

ActiveCN1552784AImprove adhesionExtended protection periodFireproof paintsEpoxy resin coatingsHigh resistanceFiberglass reinforced plastic grating

A refractory paint for the grate made of glass fibre reinforced plastics contains component A and component B, which are proportionally mixed before used. Said component A is prepared from organosilicon resin modified organic resin, high-temp stable pigment and filler, flame retarding-smoke inhibiting agent, coupling agent, solidifying promoter, and UV absorbing or shielding assistant. Said component B is polyurethane solidifying agent containing NCO. Its advantages are high resistance to high temp (900 deg.C) and weatherability and low smoke density at high temp.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

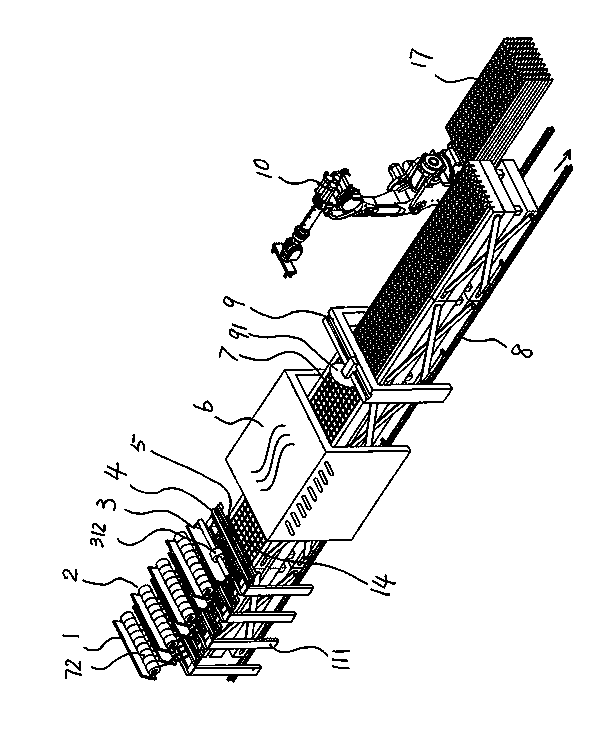

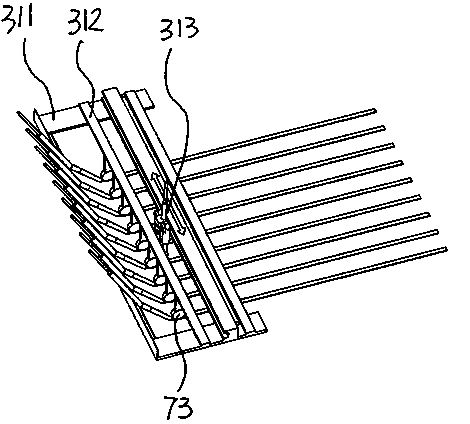

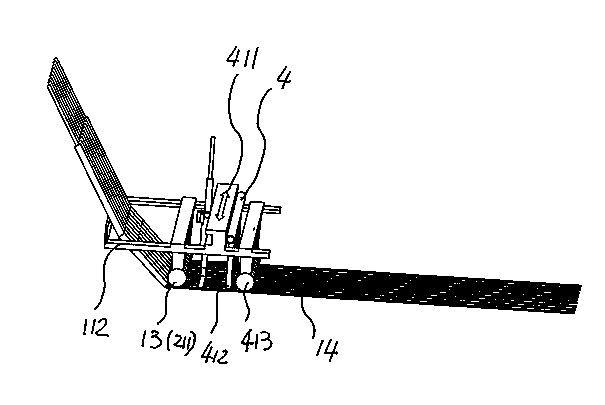

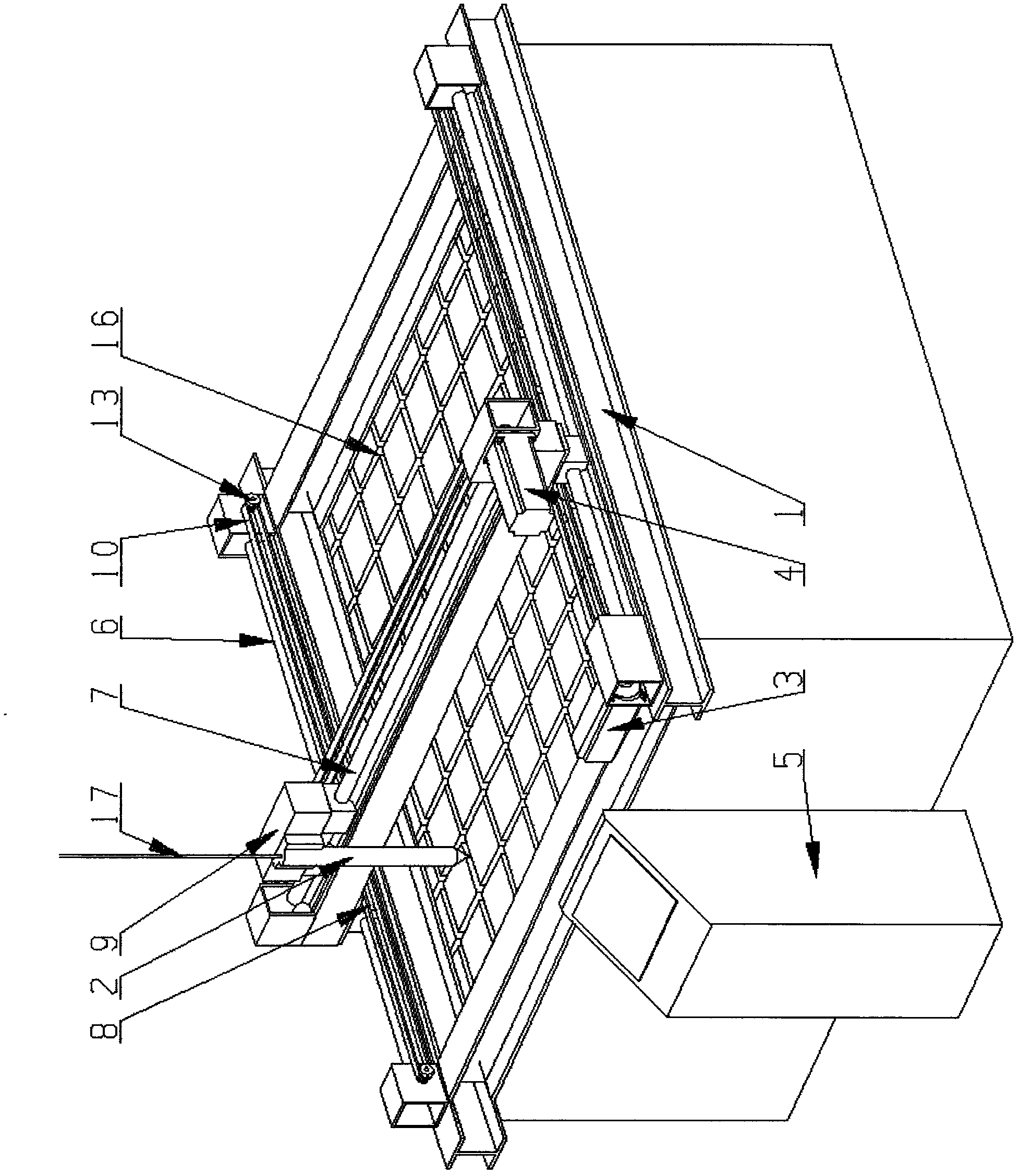

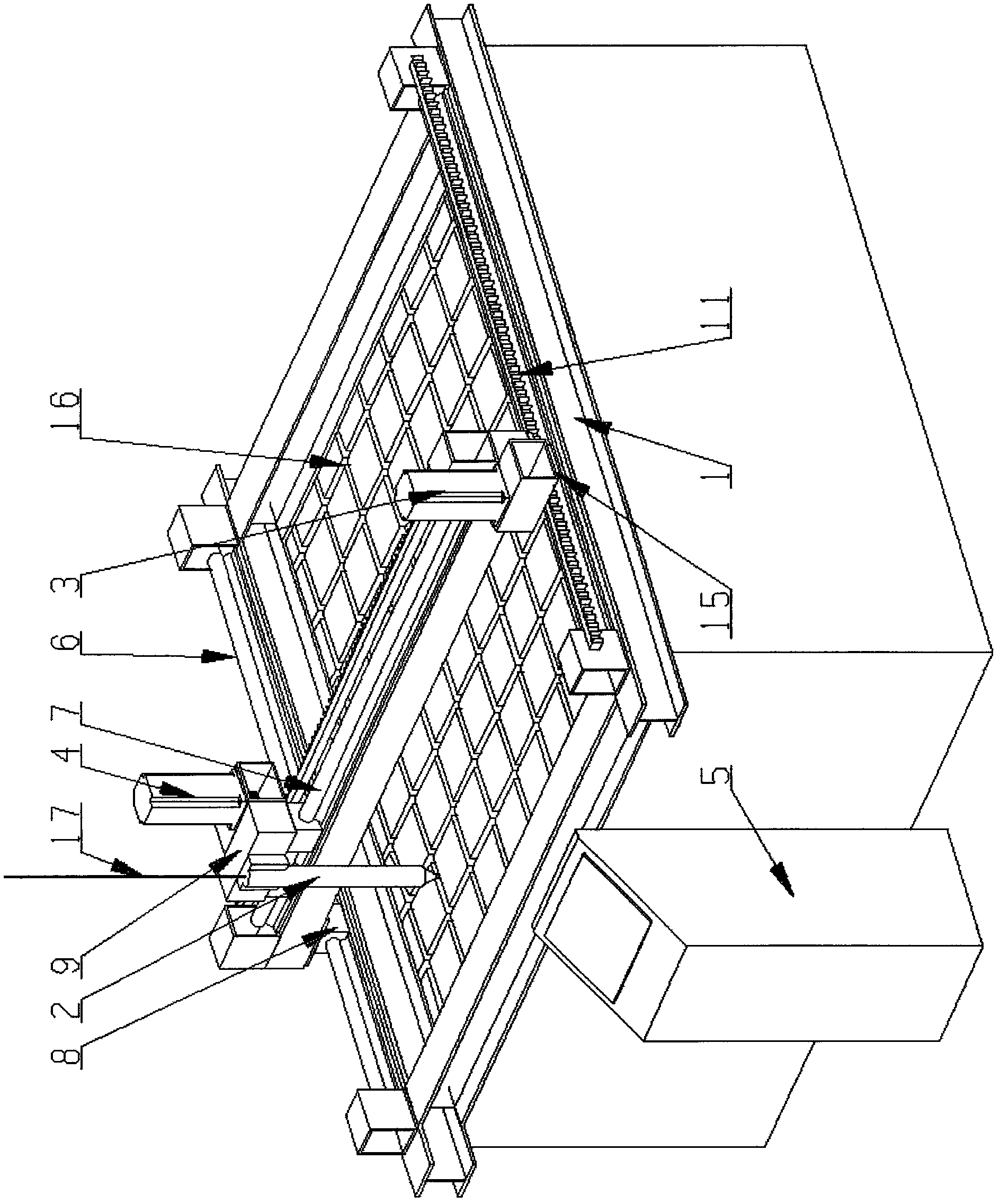

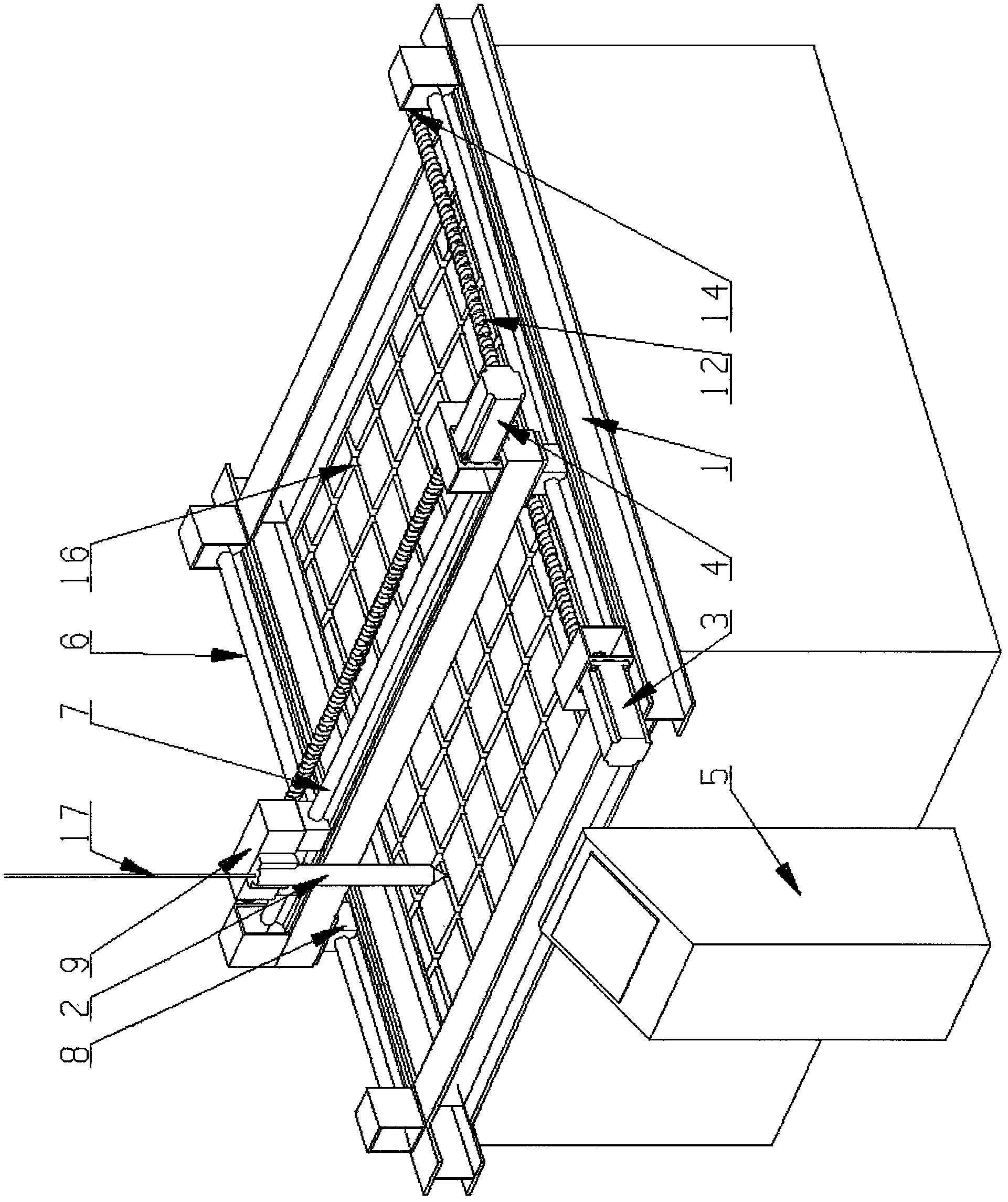

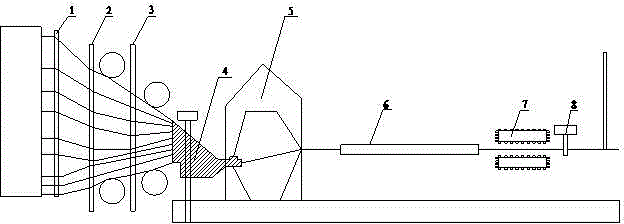

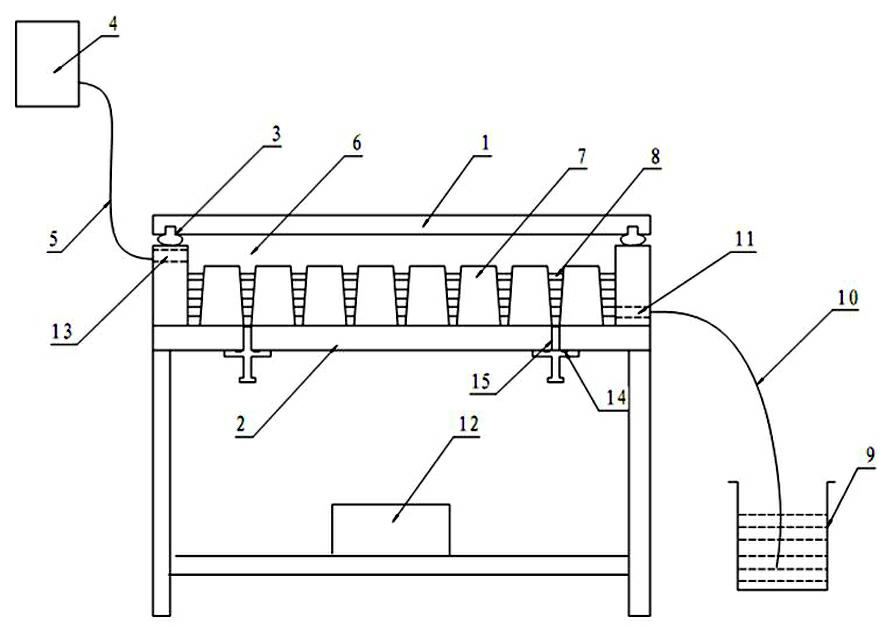

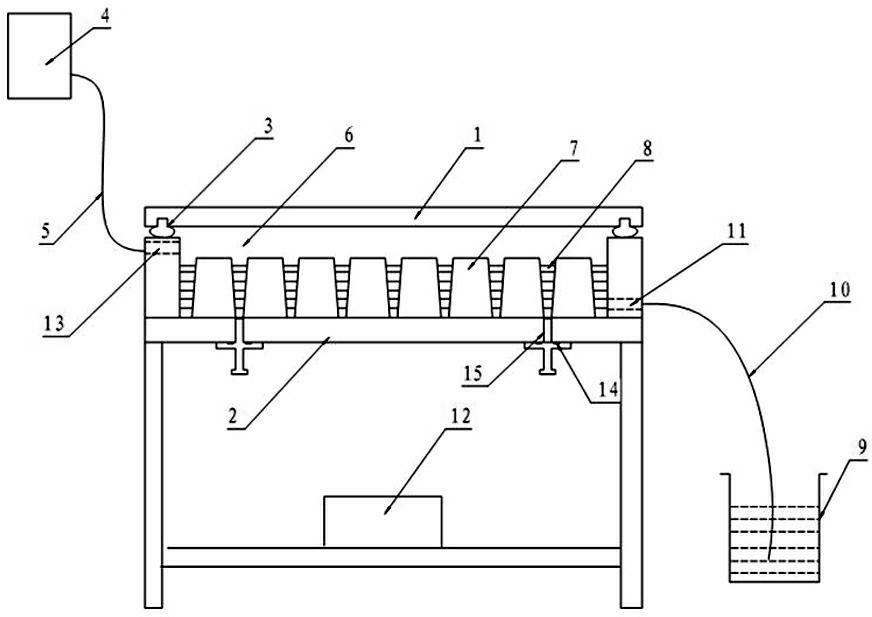

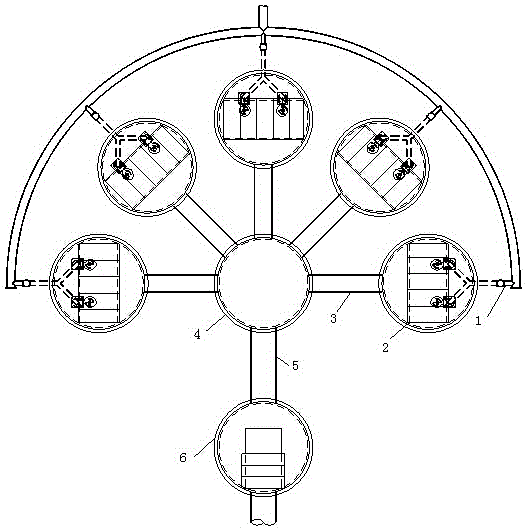

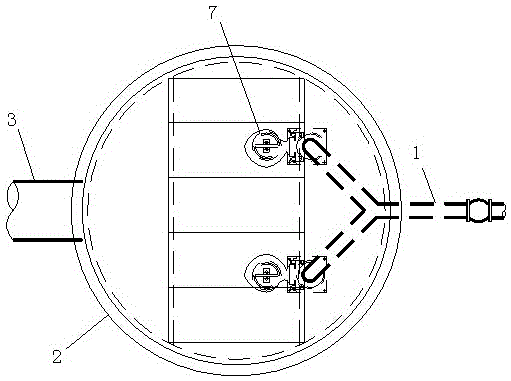

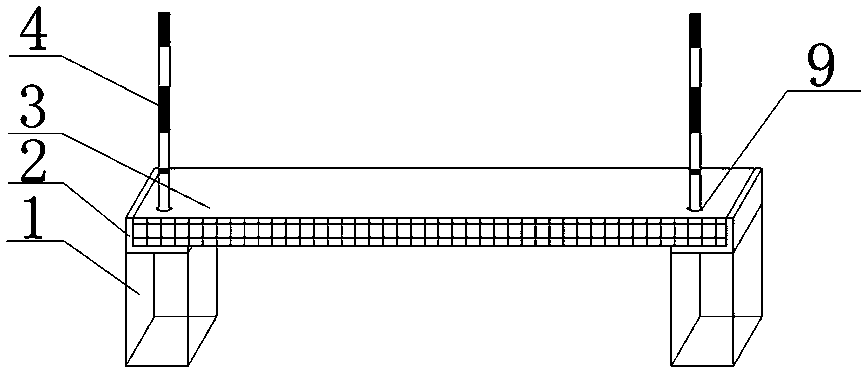

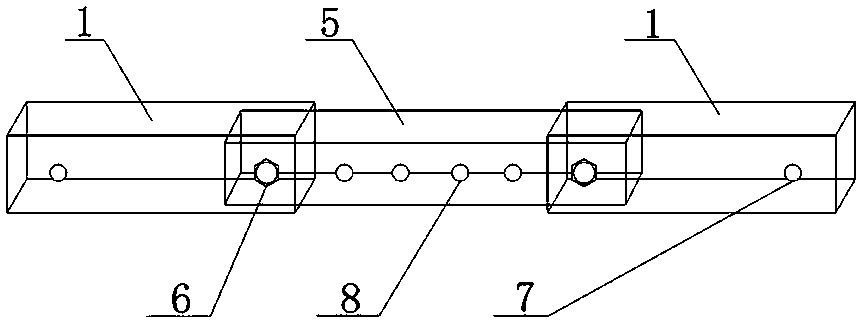

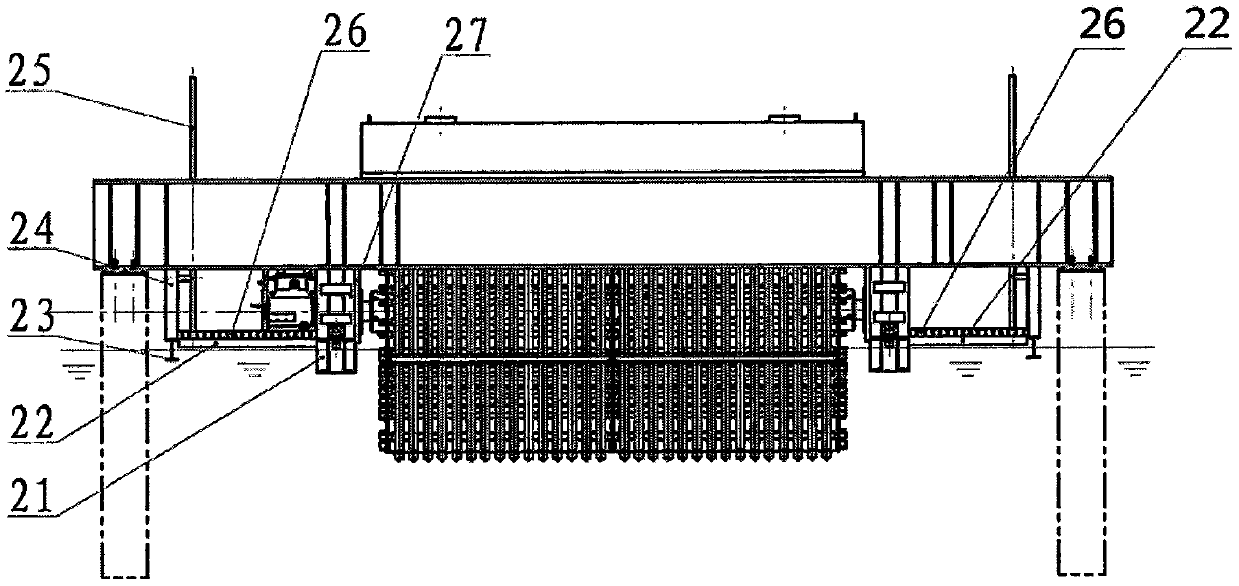

Automatic continuous production device for fiber reinforced plastic gratings

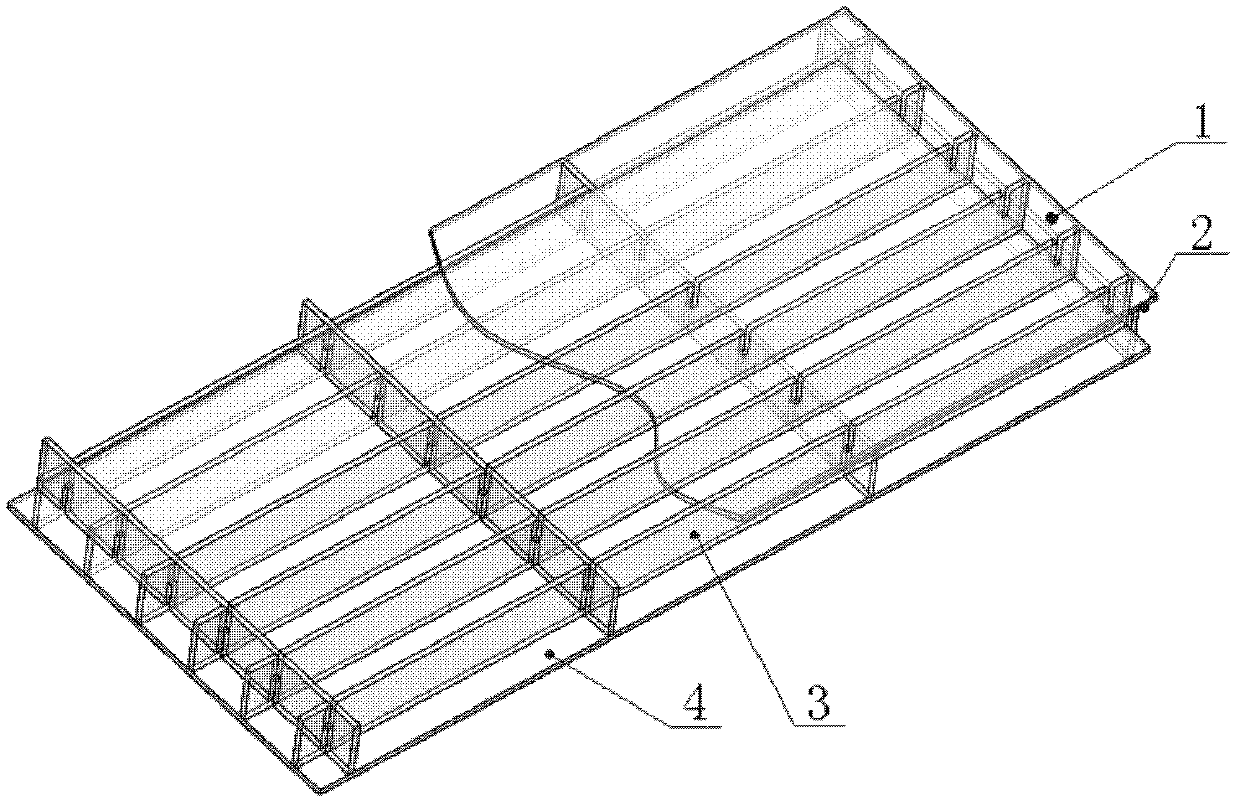

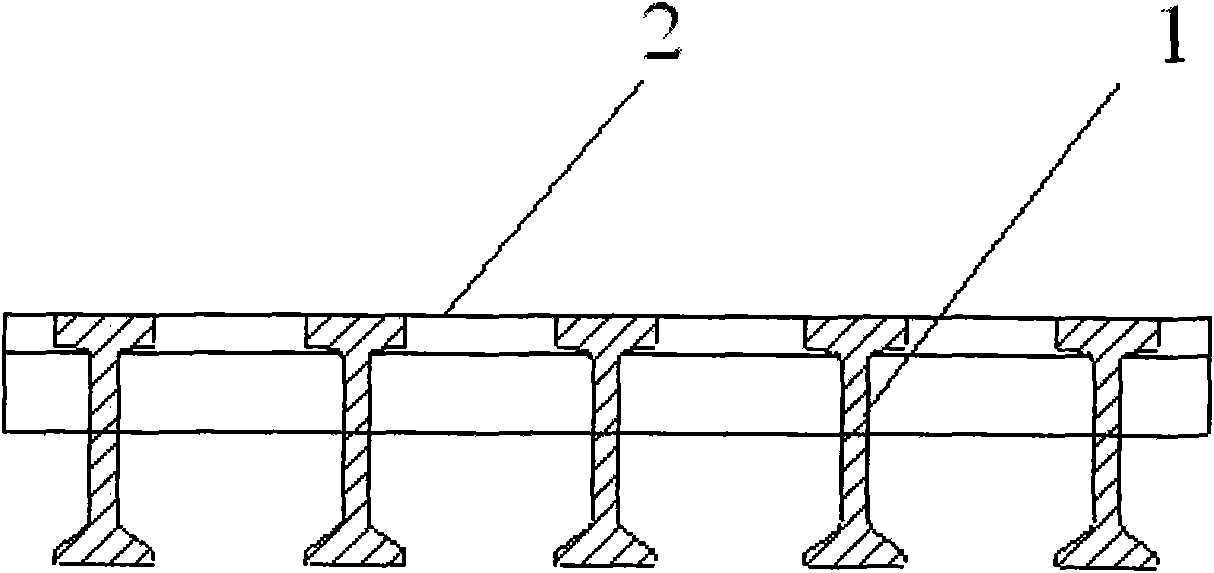

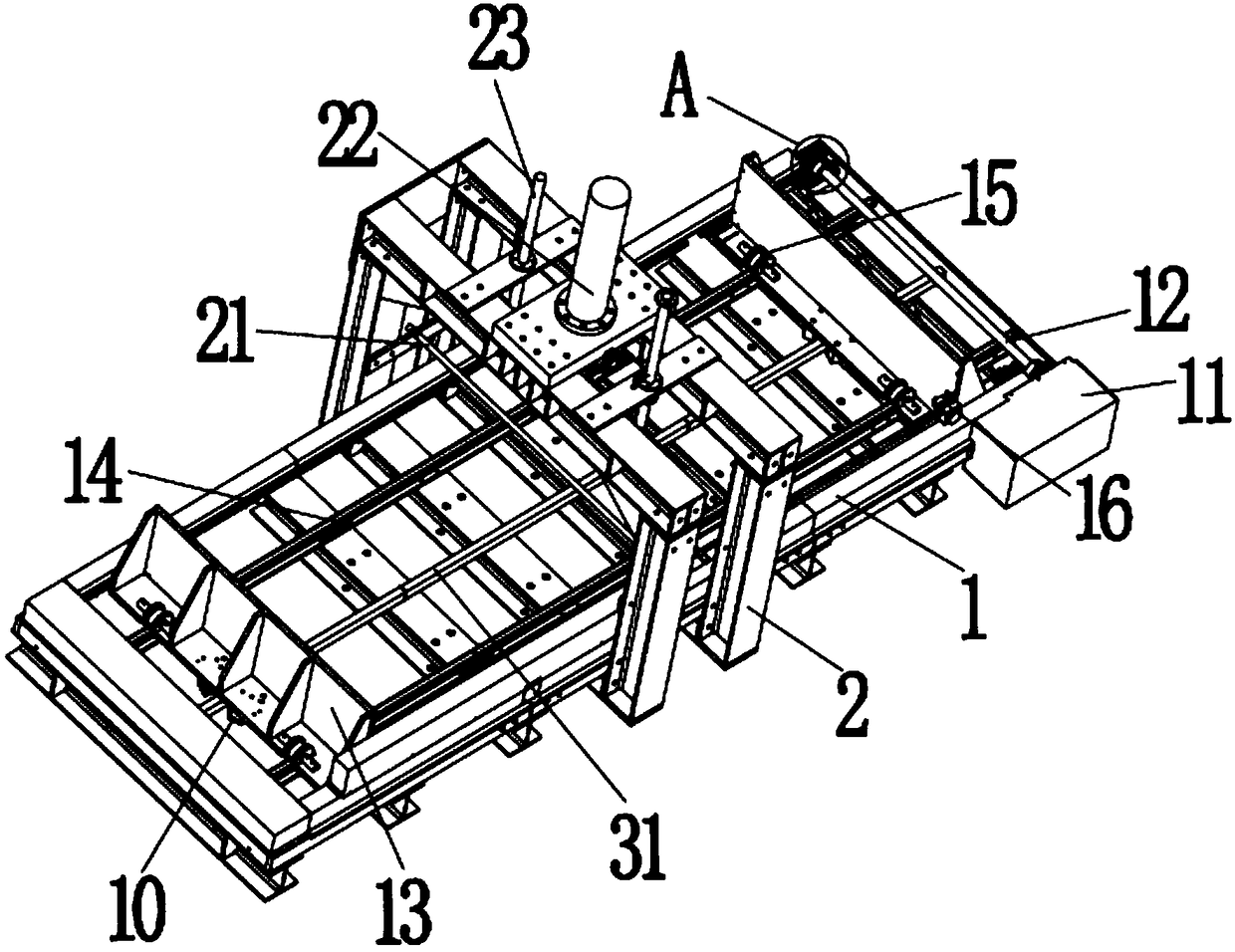

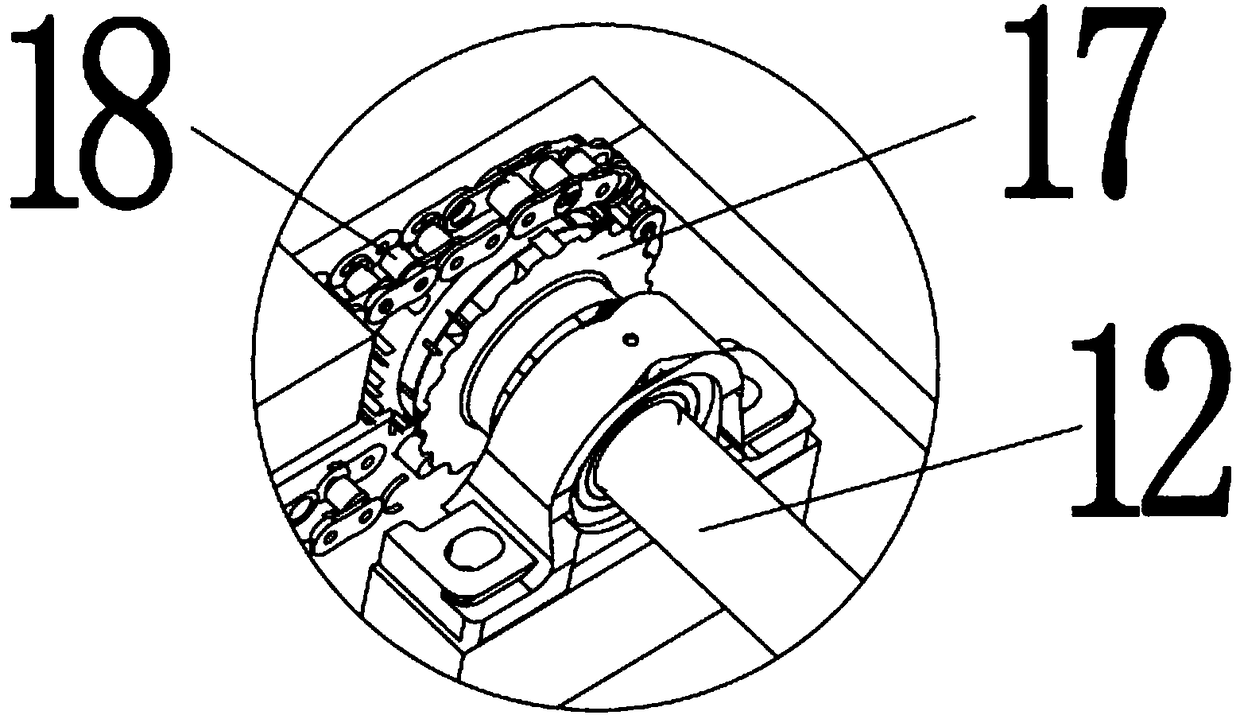

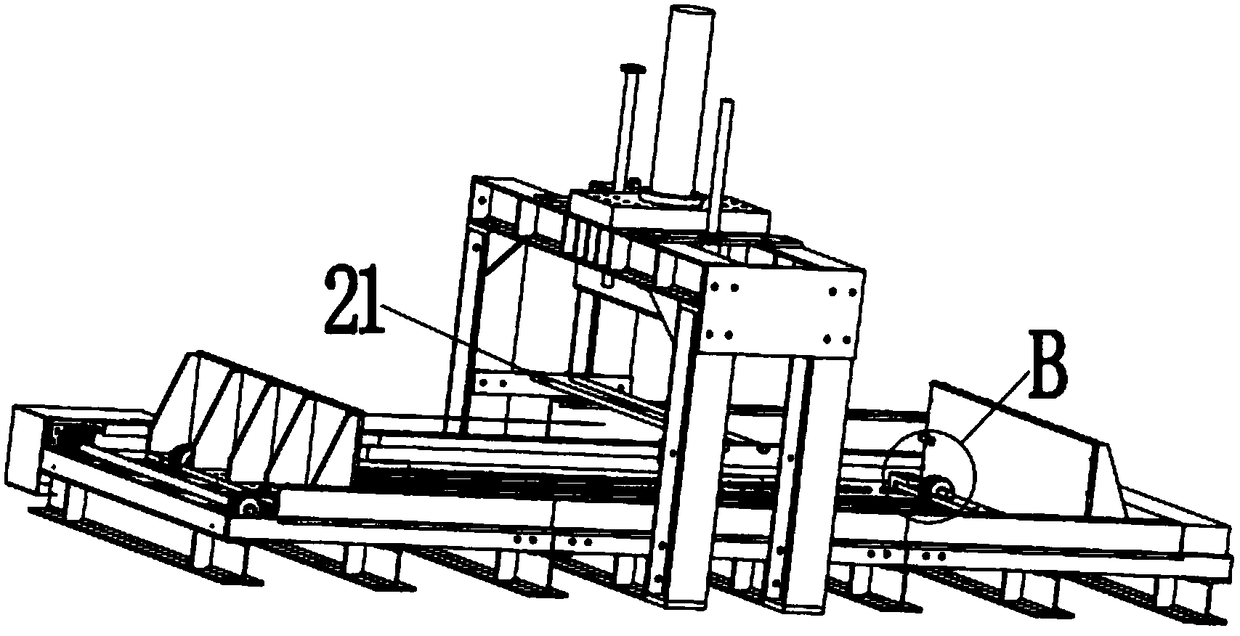

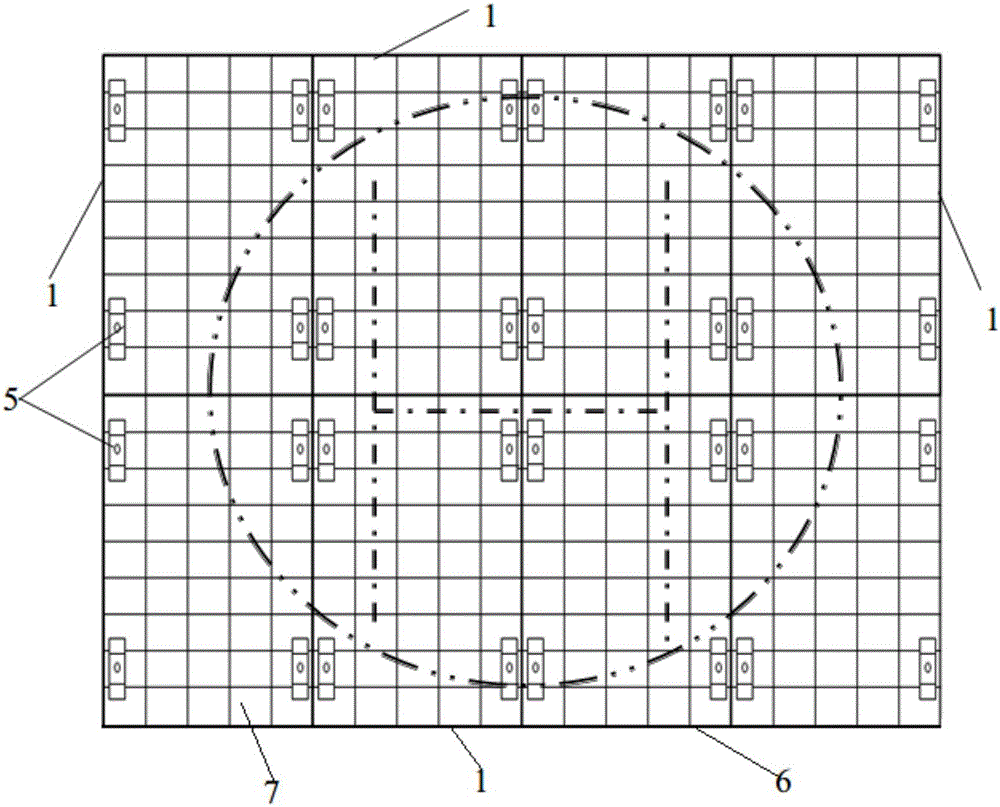

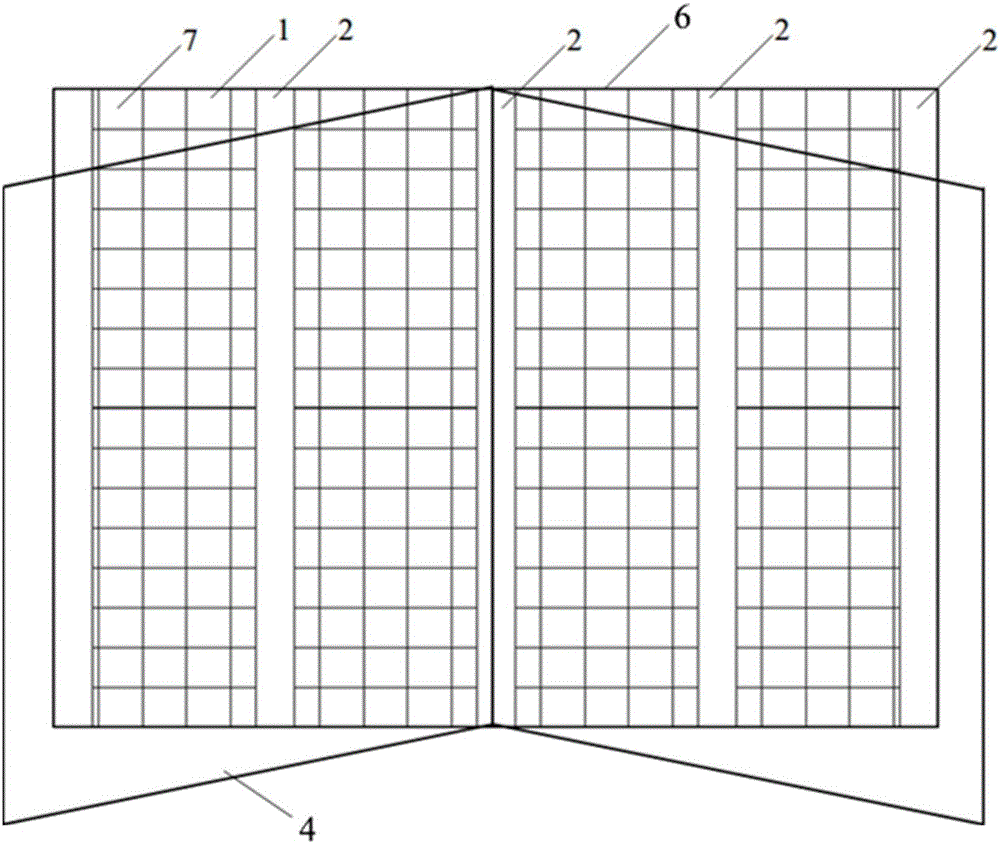

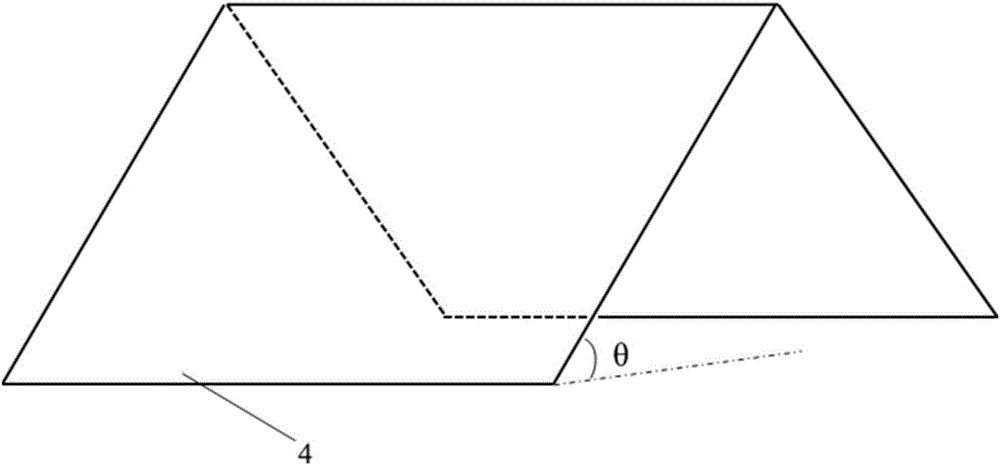

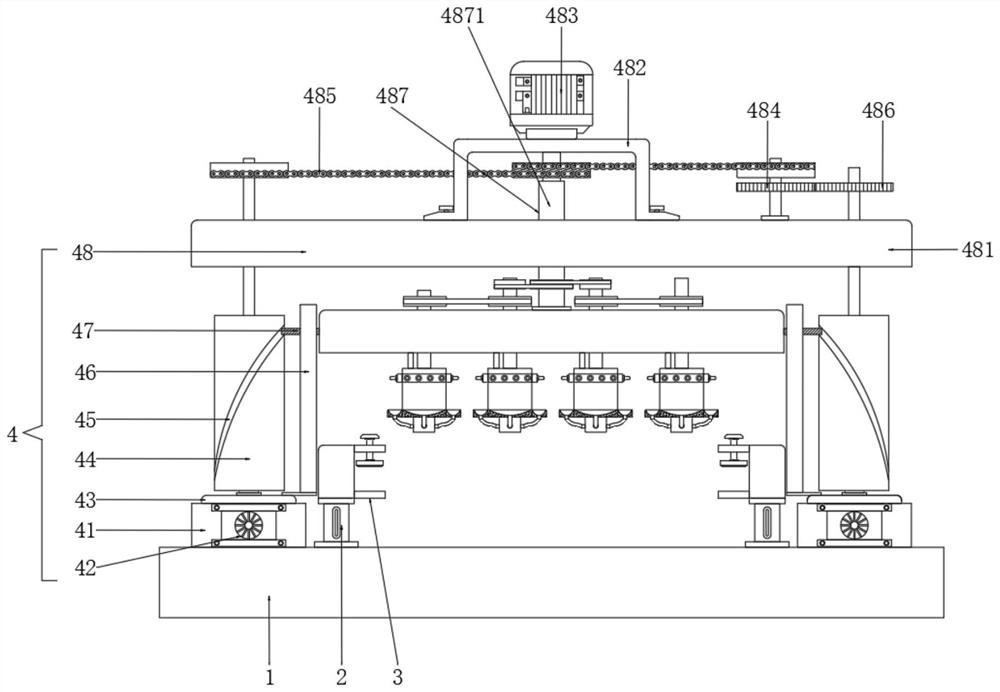

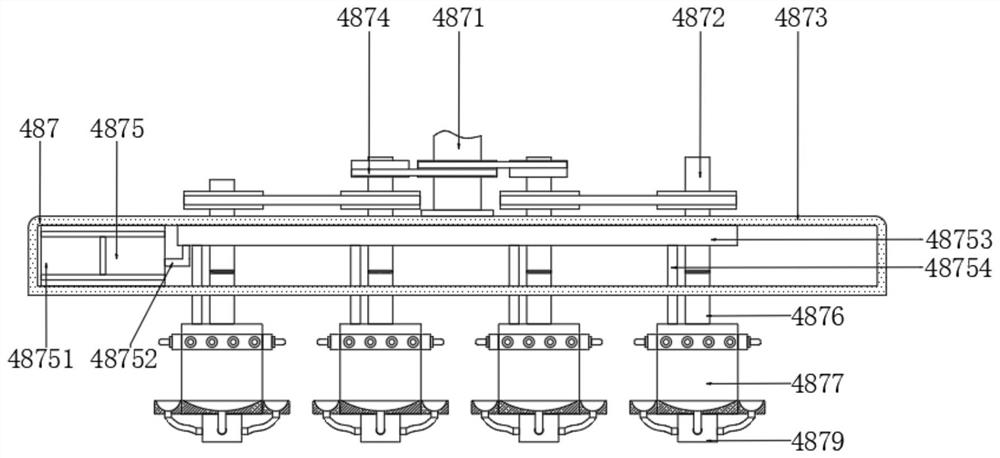

The invention belongs to the technical field of fiber reinforced plastic grating production equipment, and particularly discloses an automatic continuous production device for fiber reinforced plastic gratings. The device structurally comprises a laying mechanism, a solidification mechanism, a grating cutting mechanism, a carrying mechanism and a mold plate which are arranged sequentially, wherein the grating cutting mechanism is used after demolding of a mold; and the mold plate is arranged in a supporting bracket and driven to move by a power mechanism and comprises longitudinal slots and horizontal slots. By means of the device, continuous production of the fiber reinforced plastic gratings can be realized, and the production efficiency is improved; and longitudinal fiber reinforced plastic fiber in the prepared grating is long fiber with integral uniform specification, and mechanical laying, glue filling and compaction are adopted, so that the product quality of the gratings is remarkably improved.

Owner:JIZHOU ZHONGYI FRP TECH CO LTD +1

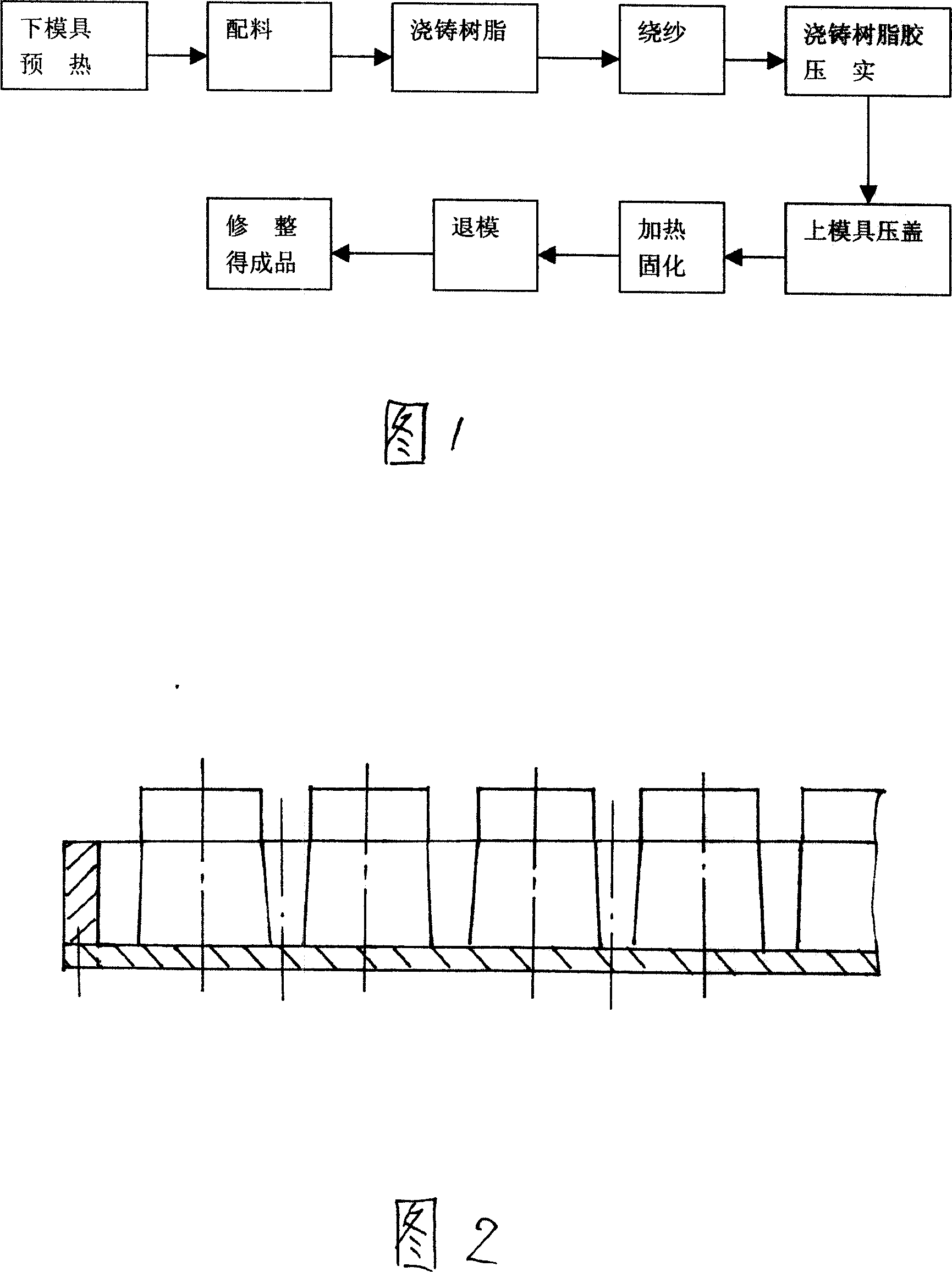

Moulded glass fibre reinforced plastic grille and manufacturing method thereof

InactiveCN101131032AGood adhesionHigh strengthCovering/liningsBuilding componentsGlass fiberHigh intensity

The present invention relates to one kind of molded GRP grille and its production process, and features that the molded GRP grille is produced with resin as basic material, and through adding proper amount of promoter and curing agent and glass fiber as reinforcing material, molding and curing. The resin may be one of three kinds of resin, including vinyl resin, etc; the promoter is cobalt isozincate in 0.5-3 wt% of resin; and the curing agent is butanone peroxide in 0.5-3 wt% of resin. The molded GRP grille has high strength and easy edge trimming.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

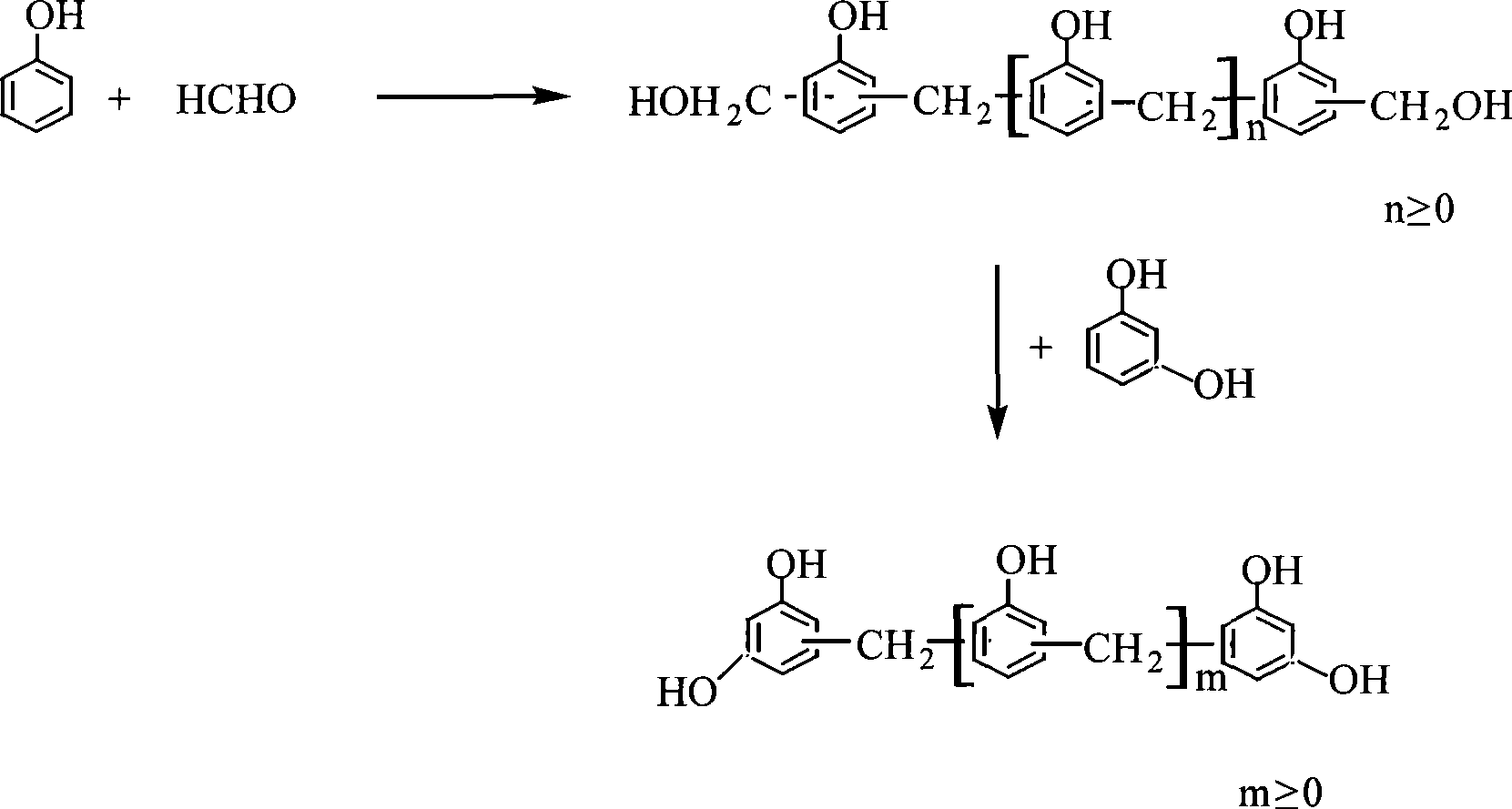

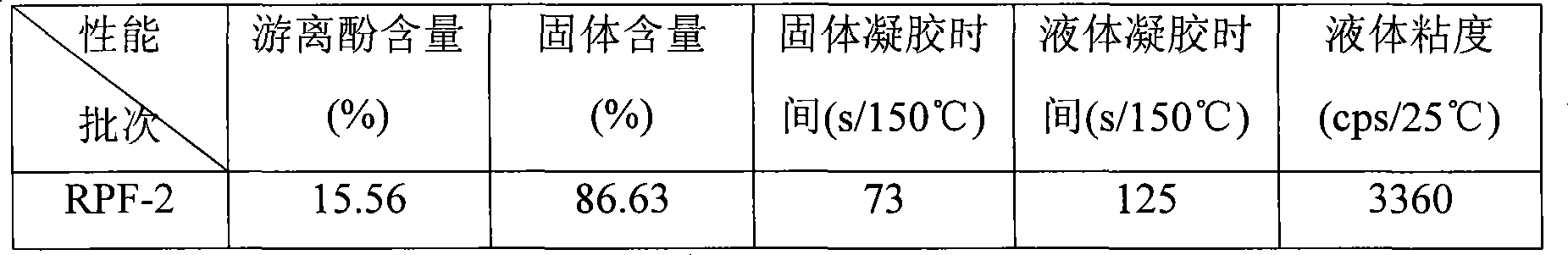

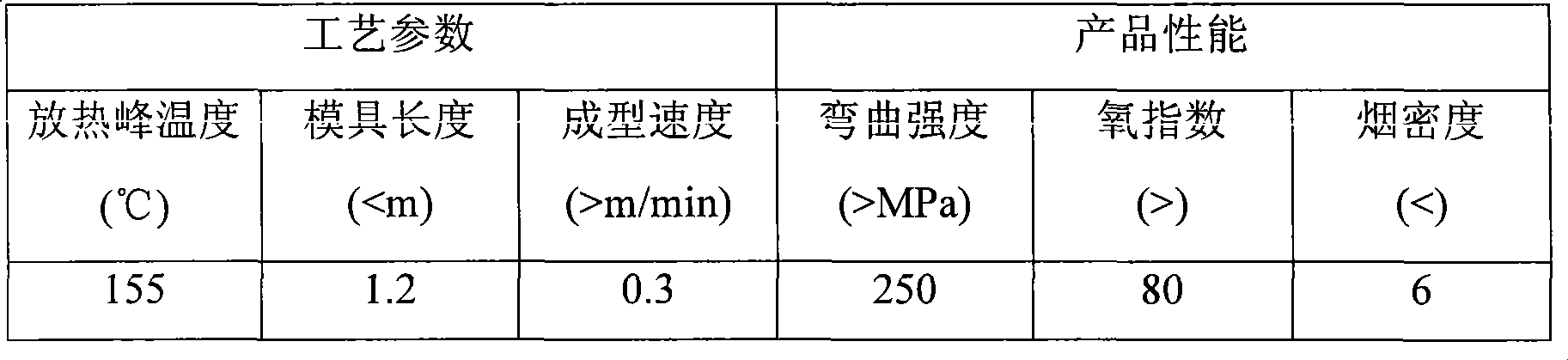

Thermosetting rapid curing phenolic resin and preparation method thereof

The invention discloses thermosetting rapid setting phenolic resin and a method for preparing the same. The phenolic resin composite comprises a phenol raw material containing resorcin, an aldehyde raw material and a catalyst containing bivalent zinc salt and an alkali catalyst, wherein the weight of the resorcin against the weight of the phenol raw material is between 5 and 30 percent. For the thermosetting phenolic resin, the exothermal peak temperature is 155 DEG C, the viscosity at the room temperature(25 DEG C) is between 3, 000 and 4, 000cps, the storage period is over 2 months, and the gel time at a temperature of 150 DEG C is between 120 and 200 seconds. By adopting the thermosetting phenolic resin prepared by the invention, glass steel gratings used for platforms, floors, trench covers and the like can be prepared by utilizing the rapid forming process such as the pulling-extrusion and the like; and the glass steel gratings can be used for offshore petroleum drilling platform, and the like.

Owner:北京玻钢院复合材料有限公司

Numerical control paver for glass steel grid fiber

InactiveCN102602009ARealize fully automatic layingLaying speed is fastFiberFiberglass reinforced plastic grating

The invention relates to the technical field of mechanical equipment, in particular to a numerical control automatic device for paving a fiber when a glass steel grid is produced. The invention aims at providing a numerical control automatic fiber paver which can complete liberate the expensive labor on a fiber paving link when the glass steel grid is produced, and is high in production efficiency, stable in product quality, and raw material-saving. The paver comprises a main frame, a fiber conduit, high-speed servo motors and a special numerical control system. The main frame comprises a Y-axis formed by two parallel guide rails and an X-axis formed by a gantry type guide rail, wherein the X-axis is further provided with a dolly which can slide along with the axial direction, and a fiber conduit is arranged on the dolly. A set of driving system is respectively arranged on the Y-axis and the X-axis. The main frame is fixed above a glass steel grid mould, and the two servo motors are connected with the special numerical control system. Only by inputting the relevant data such as the size and the like through the special numerical control system, the paver can be used for automatically paving the fiber, so that the production cost can be saved in many ways, and the product quality can be improved.

Owner:毛英旭

Method for manufacturing corrosion-resistant and flame-retardant glass steel grid through pultrusion profile production system

ActiveCN104890262AManufacturing flexibilityIncrease productivityCoatingsGlass fiberFiberglass reinforced plastic grating

The invention discloses a method for manufacturing a corrosion-resistant and flame-retardant glass steel grid through a pultrusion profile production system. The method comprises the following steps: glass fiber filaments are leaded into a guide system; and unsaturated polyester resins, a flame retardant, an antiaging agent, a curing agent, an accelerant and a reduction inhibitor are formed to flame-retardant resin mixed liquid for filling in an impregnation device with the mass proportion of 100: 10-30: 3-5: 1-2: 2-3: 0.5-1.5, then enter a molding system for dipping, enter a heating curing device for curing, are cooled and demolded to enter a reciprocating traction device for towing, and enter a cutting device for cutting and finishing to obtain a product. The method can flexibly manufacture according to the production requirements, adopts a continuous production process to cut according to a specified dimension, and is high in production efficiency, stable, safe and reliable.

Owner:江苏澳兰德新材料科技有限公司

Anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating

The invention discloses an anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating which is prepared from, by weight, 50-150 parts of UPR, 20-60 parts of vinylite, 5-15 parts of epoxy resin, 2-5 parts of expandable graphite, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydrate, 2-6 parts of talcum powder, 1-4 parts of quartz powder, 2-5 parts of ceramic powder, 3-5 parts of glass fiber, 1-4 parts of benzotriazole, 1-6 parts of a BYK-W940 wetting dispersant, 2-8 parts of a BYK-W985 wetting dispersant, 1-4 parts of ammonium polyphosphate, 3-9 parts of a BYK-S6665 adding agent, 1-4 parts of a BYK-S740 adding agent, 1-5 parts of an KH-560 silane coupling agent, 2-5 parts of a curing agent and 3-6 parts of an accelerant. The anti-flaming anti-corrosion modified UPR glass fiber reinforced plastic grating has excellent anti-corrosion and anti-flaming properties.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

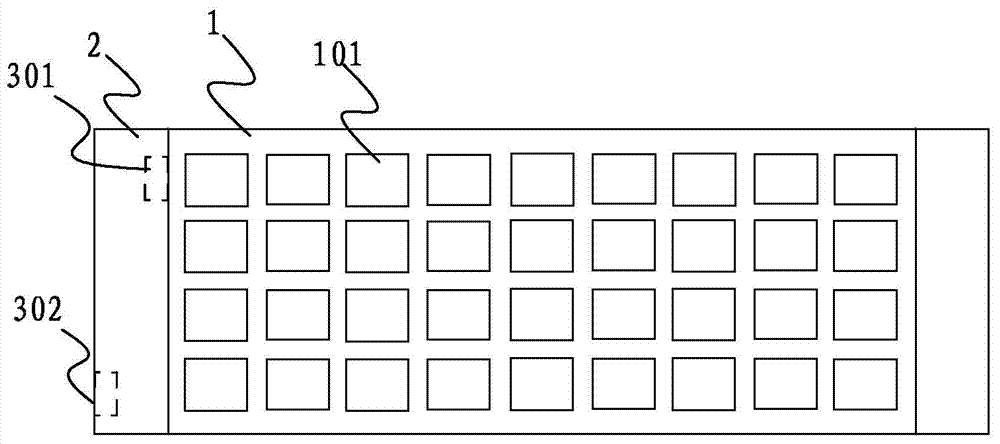

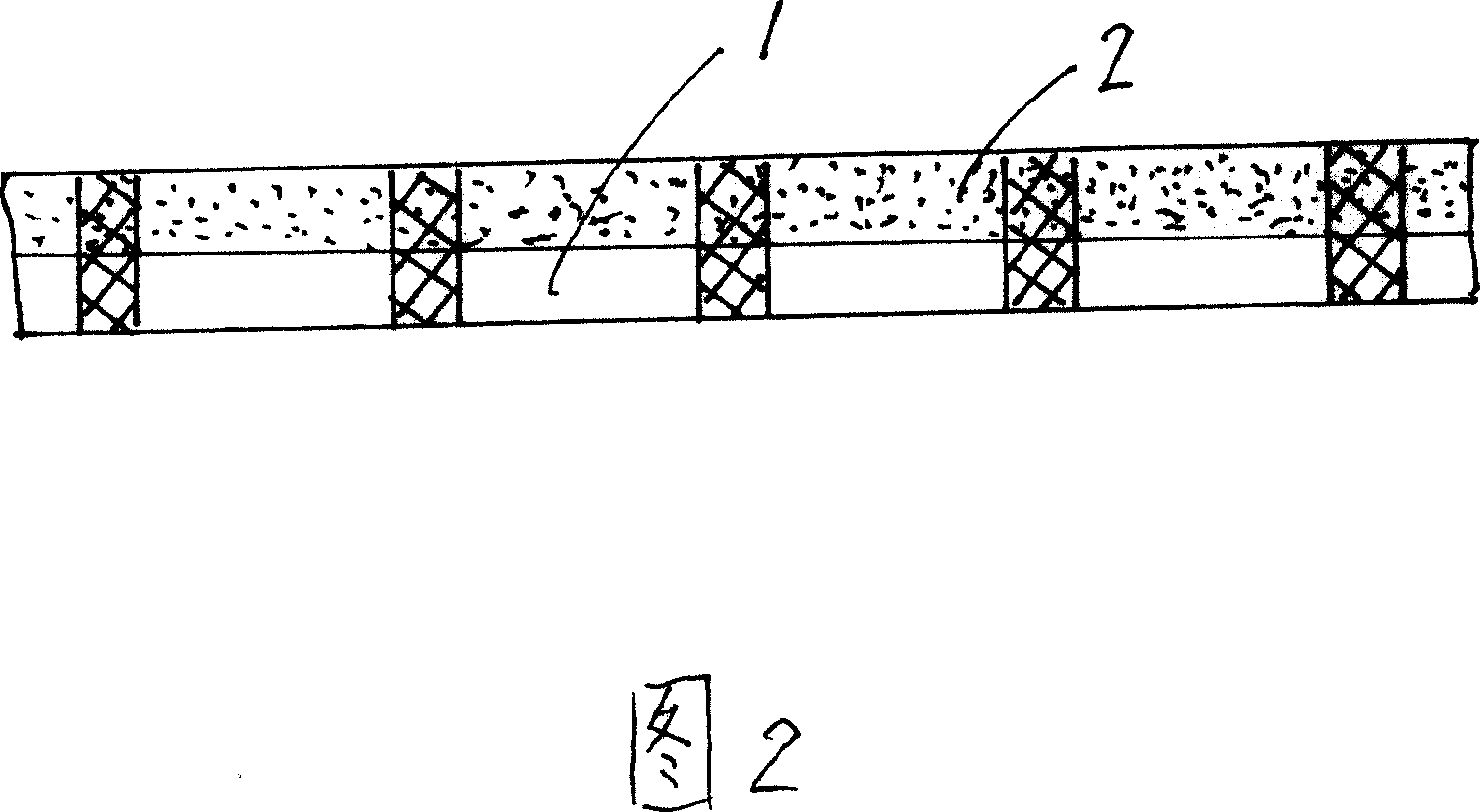

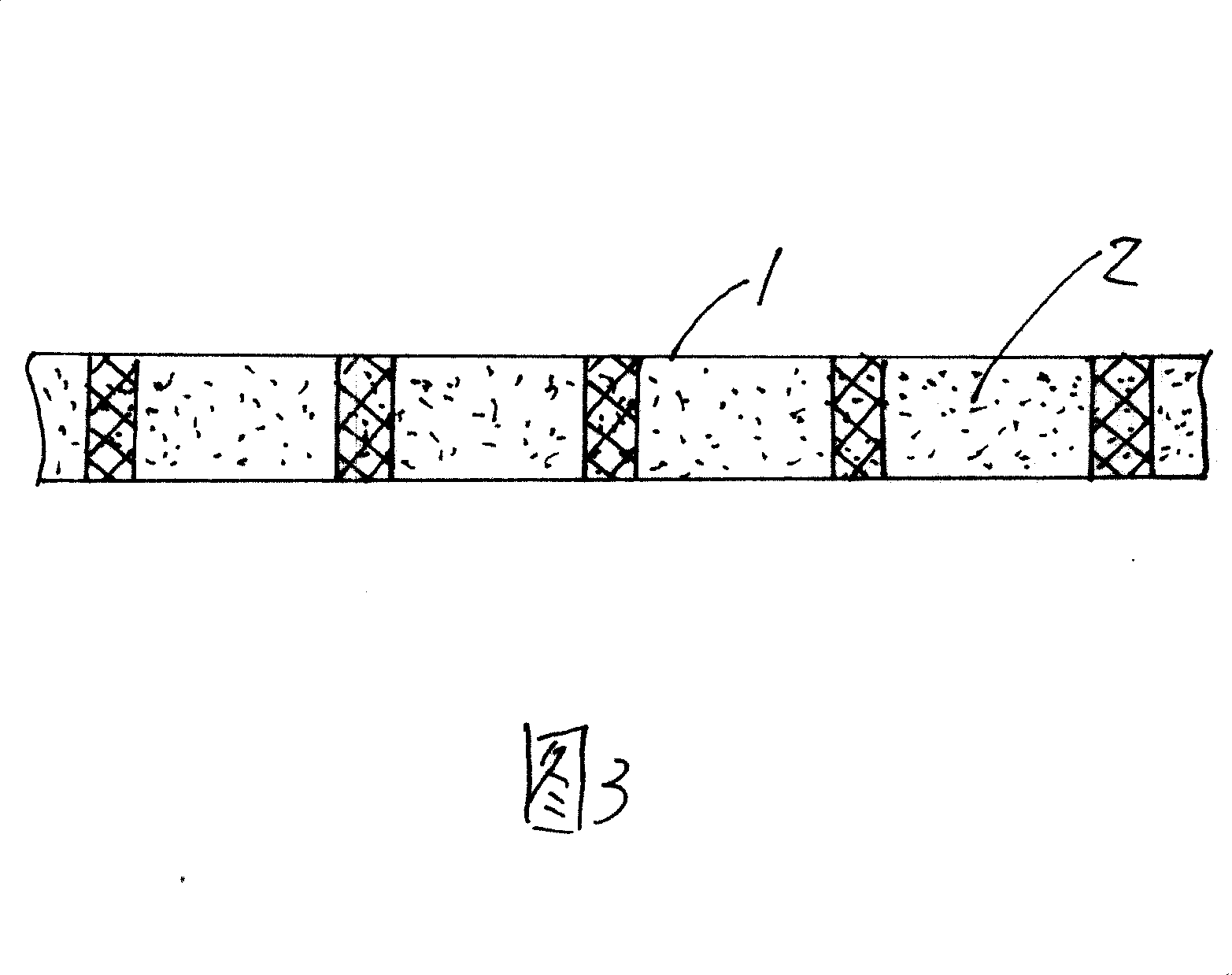

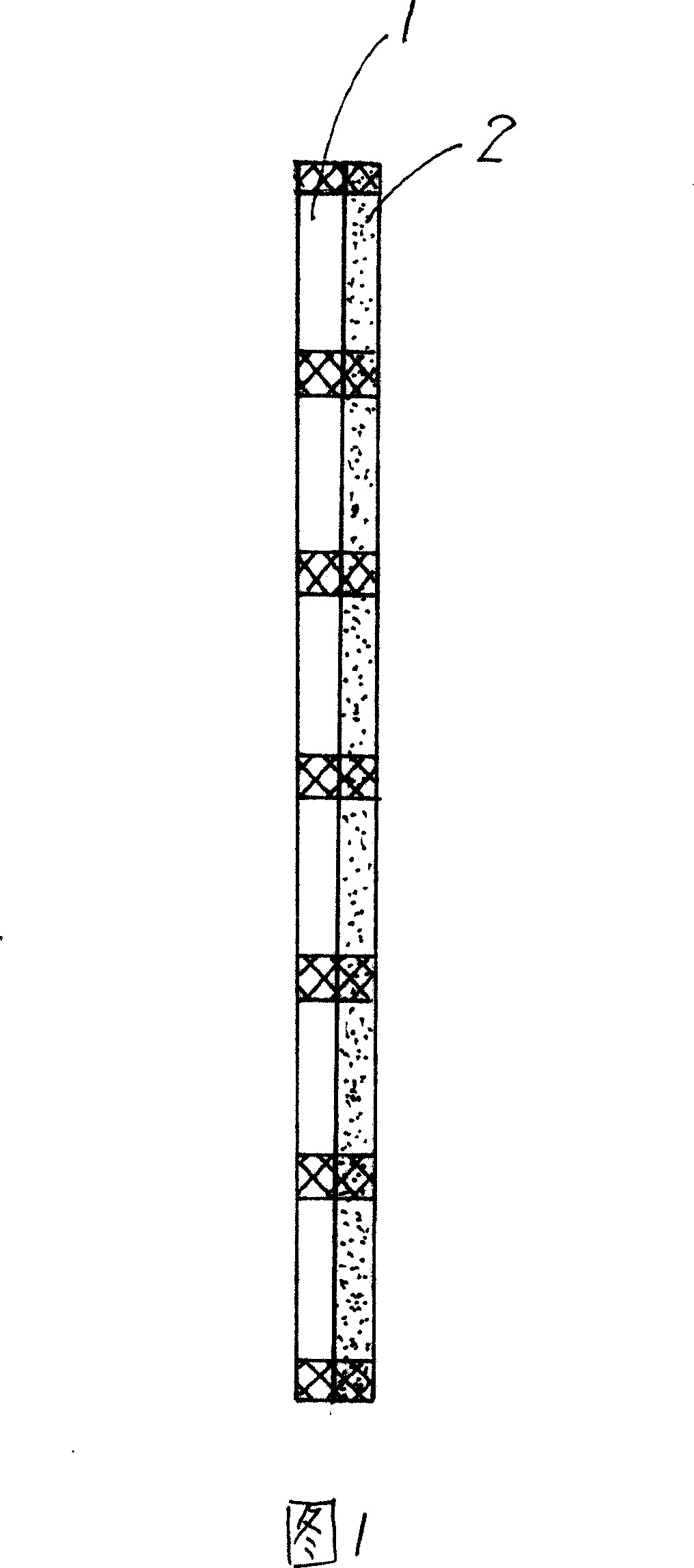

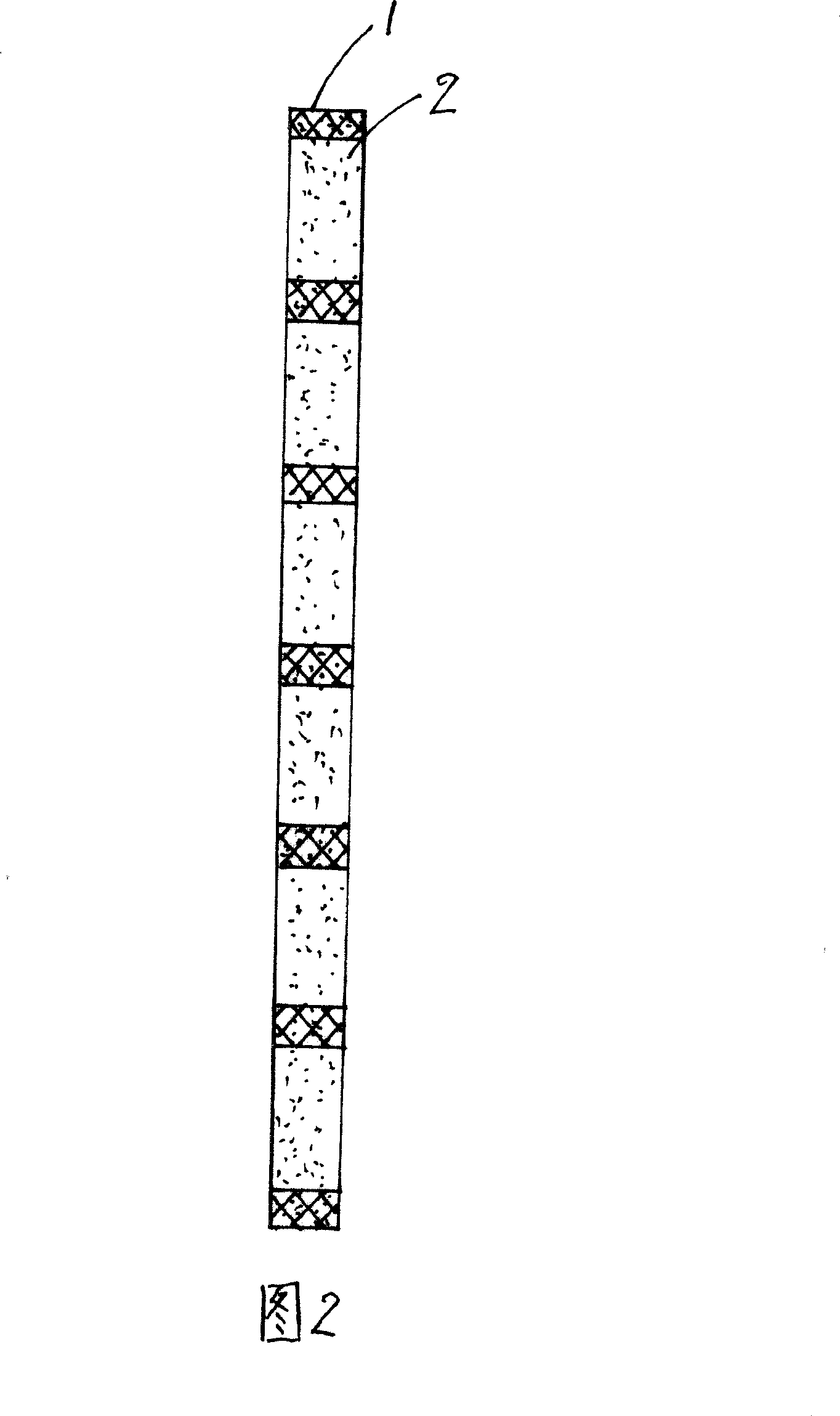

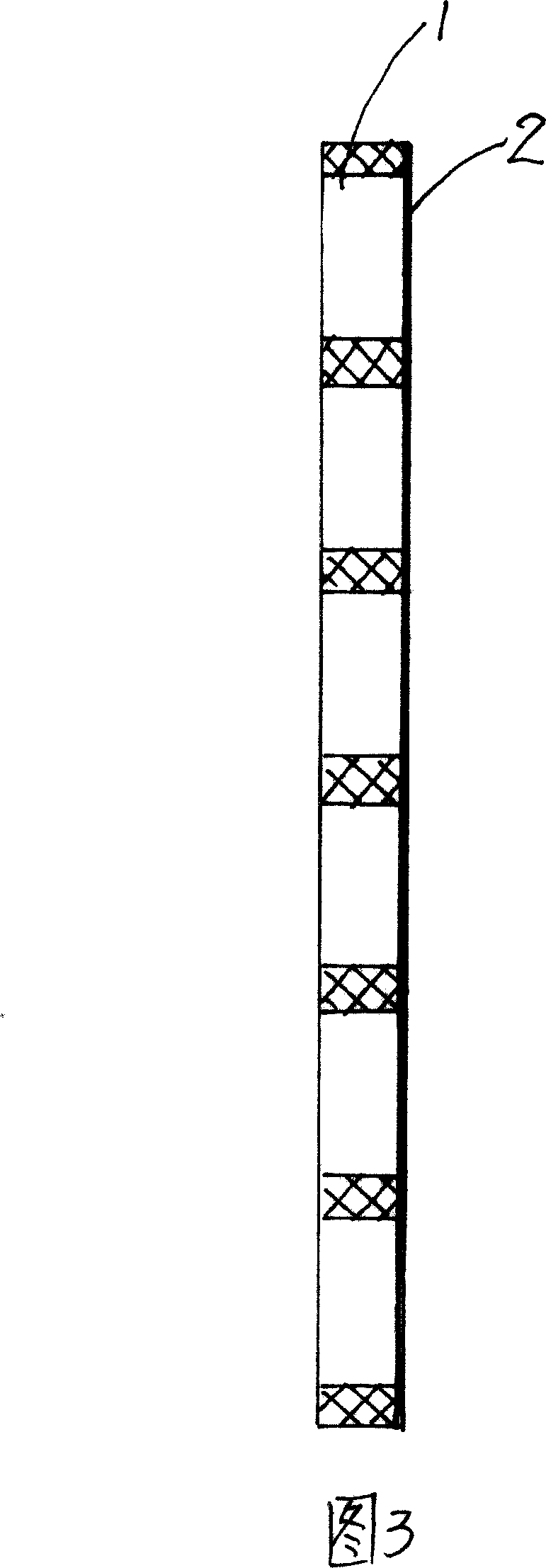

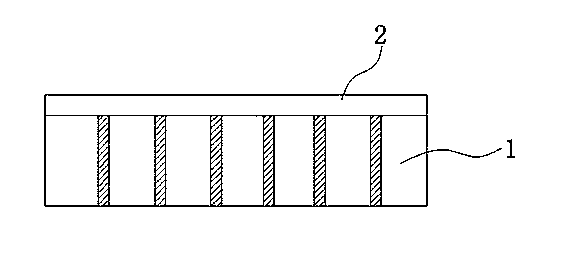

Glass fiber reinforced plastic grating hollow plate and production method thereof

ActiveCN103286994AStable structureImprove adhesionSynthetic resin layered productsLaminationGlass fiberGrating

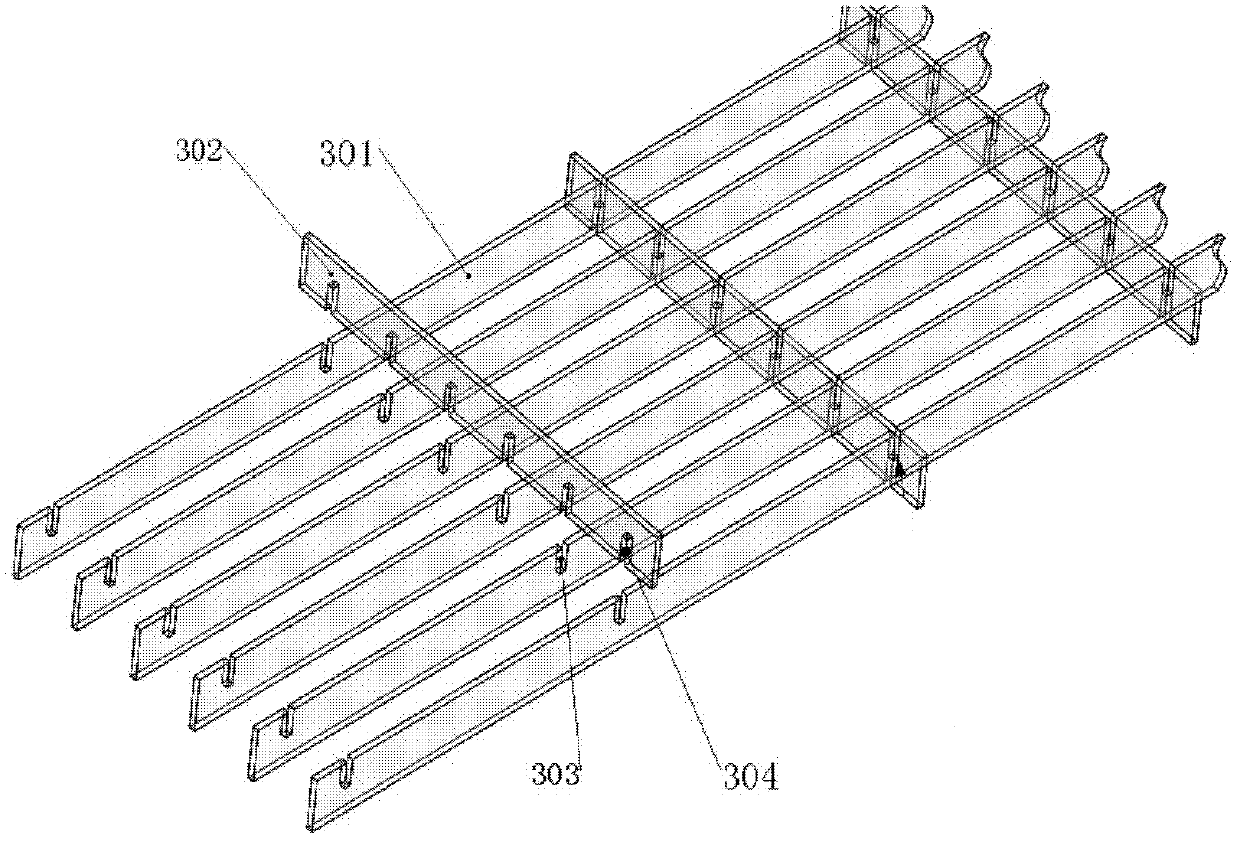

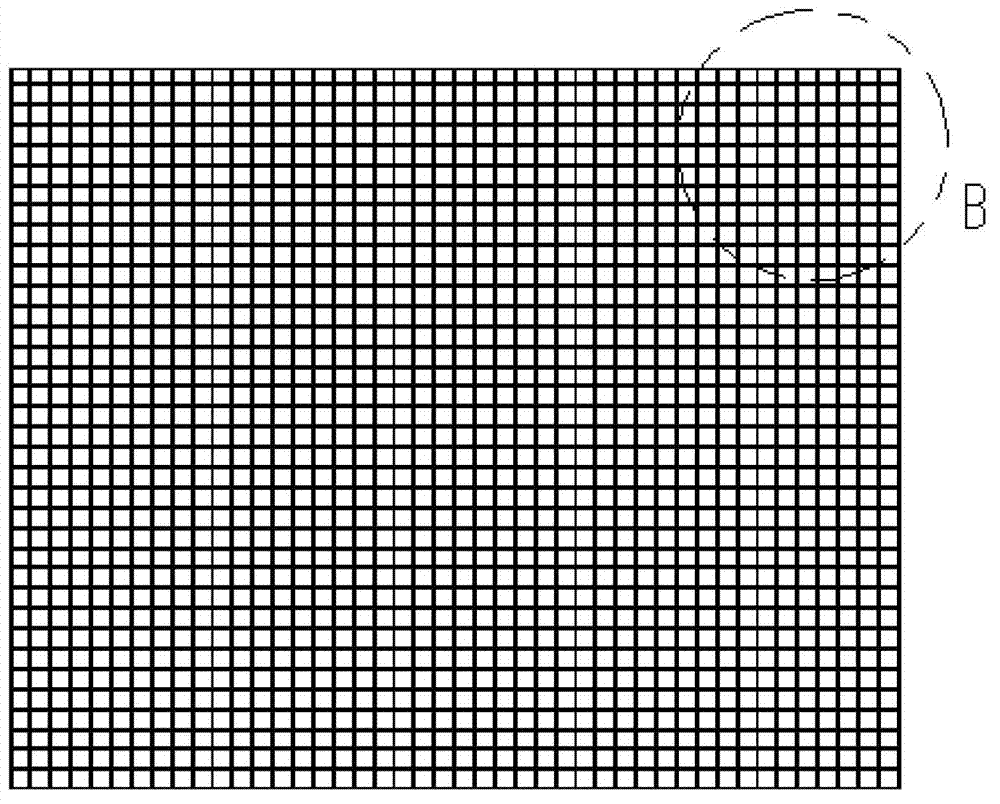

The invention belongs to the technical field of plates for building containment, and specifically relates to a glass fiber reinforced plastic grating hollow plate and a production method of the glass fiber reinforced plastic grating hollow plate. The glass fiber reinforced plastic grating hollow plate comprises an outside plate, a grating and an inside plate, the grating comprises a longitudinal rib plate and a cross diaphragm plate in latticed structure. The production method comprises the steps of preparing the grating, preparing the inside plate and bonding the grating, preparing the outside plate and bonding the grating and the inside plate, and cutting. The technical problems that the existing glass fiber reinforced plastic hollow plate is easily subjected to the cross shearing strength damage parallel to a panel, the existing glass fiber reinforced plastic production method is low in production efficiency and bad in product stability, are solved. The glass fiber reinforced plastic grating hollow plate provided by the invention is stable in structure, secure in bonding and strong in cross anti-shearing ability. The production method provided by the invention is capable of adopting the intermittent production process to manufacture one by one, and adopting the continuous production process to cut according to the specified size, the production efficiency is high and the product is stable.

Owner:秦皇岛耀华新材料有限公司

High-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille

InactiveCN105907070AExtended service lifeImprove high temperature resistanceTemperature resistanceUnsaturated polyester

The invention discloses a high-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille. The fiberglass-reinforced plastic grille is prepared from the raw materials in parts by weight: 50-150 parts of modified unsaturated polyester resin, 20-60 parts of phenol-formaldehyde resin, 5-15 parts of acrylic acid modified alkyd resin, 2-5 parts of silicon carbide, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydroxide, 2-6 parts of talcum powder, 1-4 parts of paraffin, 2-5 parts of zinc oxide, 3-5 parts of fiberglass, 1-4 parts of hydroxy silicone oil, 1-6 parts of wetting dispersant BYK-W940, 2-8 parts of anti-aging agent D, 1-4 parts of ammonium polyphosphate, 2-5 parts of hydroxyethyl methacrylate, 1-5 parts of tin dibutyl dilaurate, 1-4 parts of dicumyl peroxide, 3-5 parts of propenyl ether glycol peroxide, 1-5 parts of silane coupling agent KH-570, 2-5 parts of methylethyl ketone peroxide and 3-6 parts of cobalt naphthenate. The fiberglass-reinforced plastic grille disclosed by the invention has excellent high-temperature resistance and corrosion resistance.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

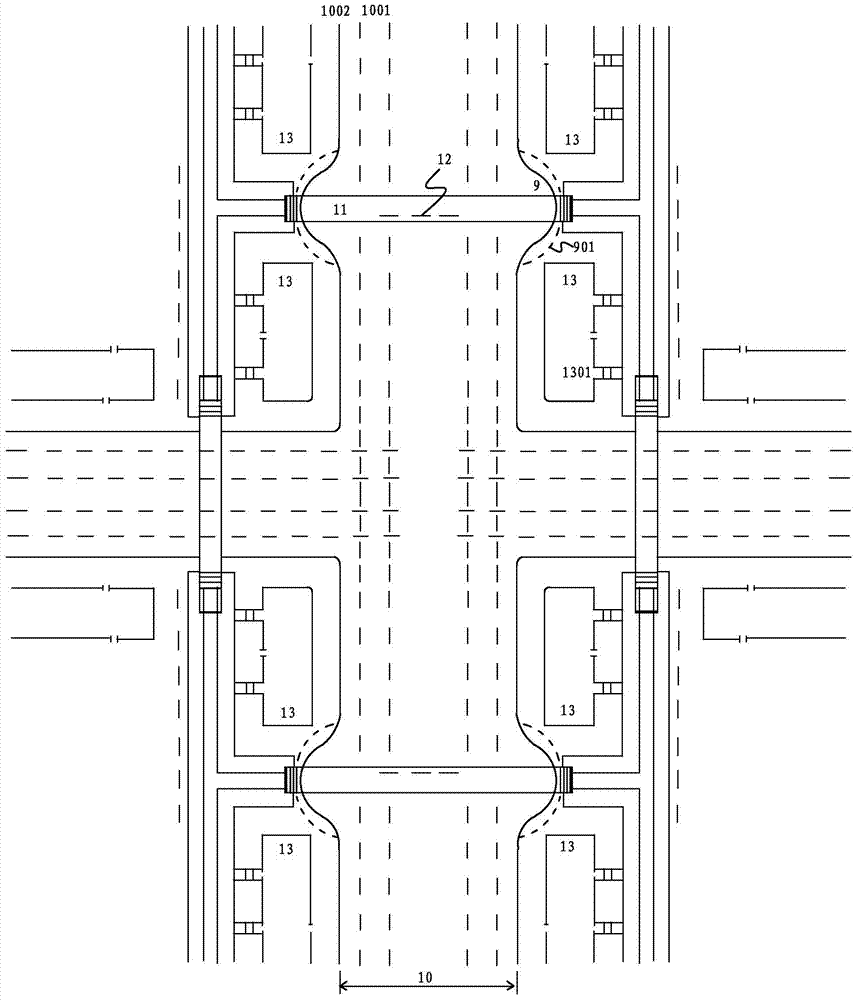

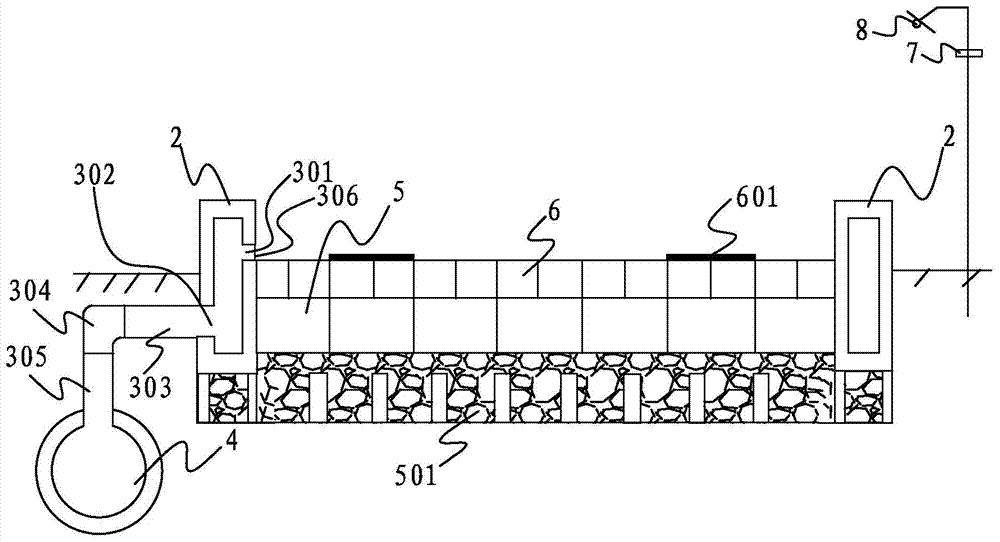

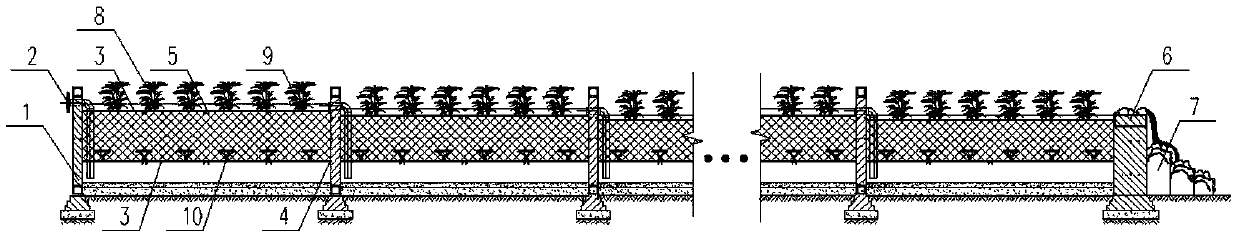

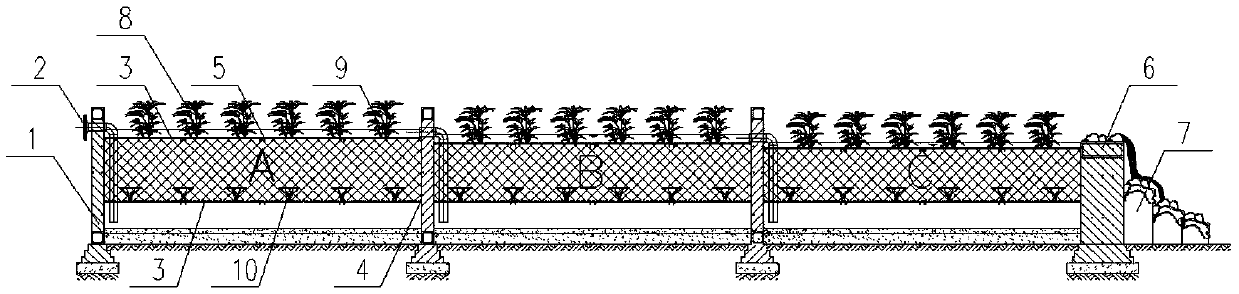

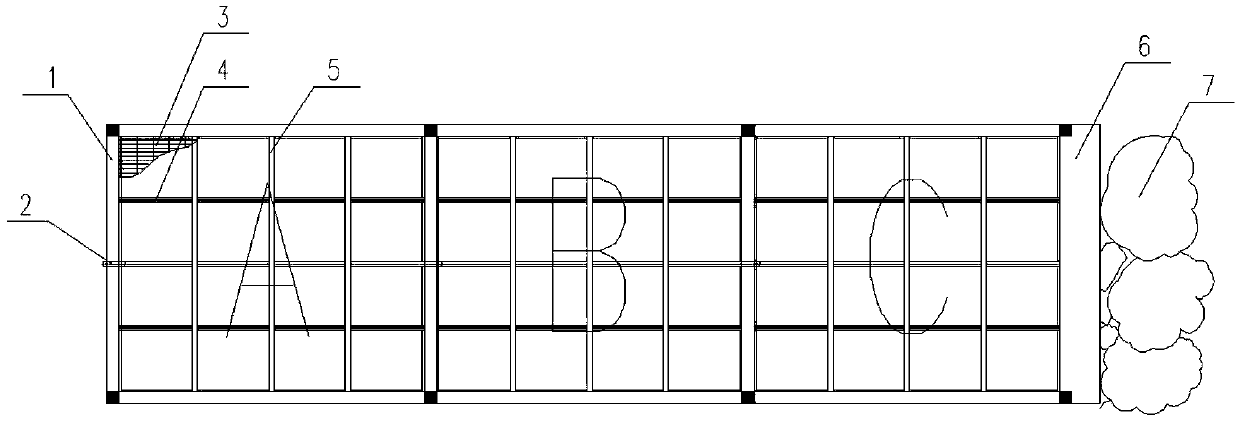

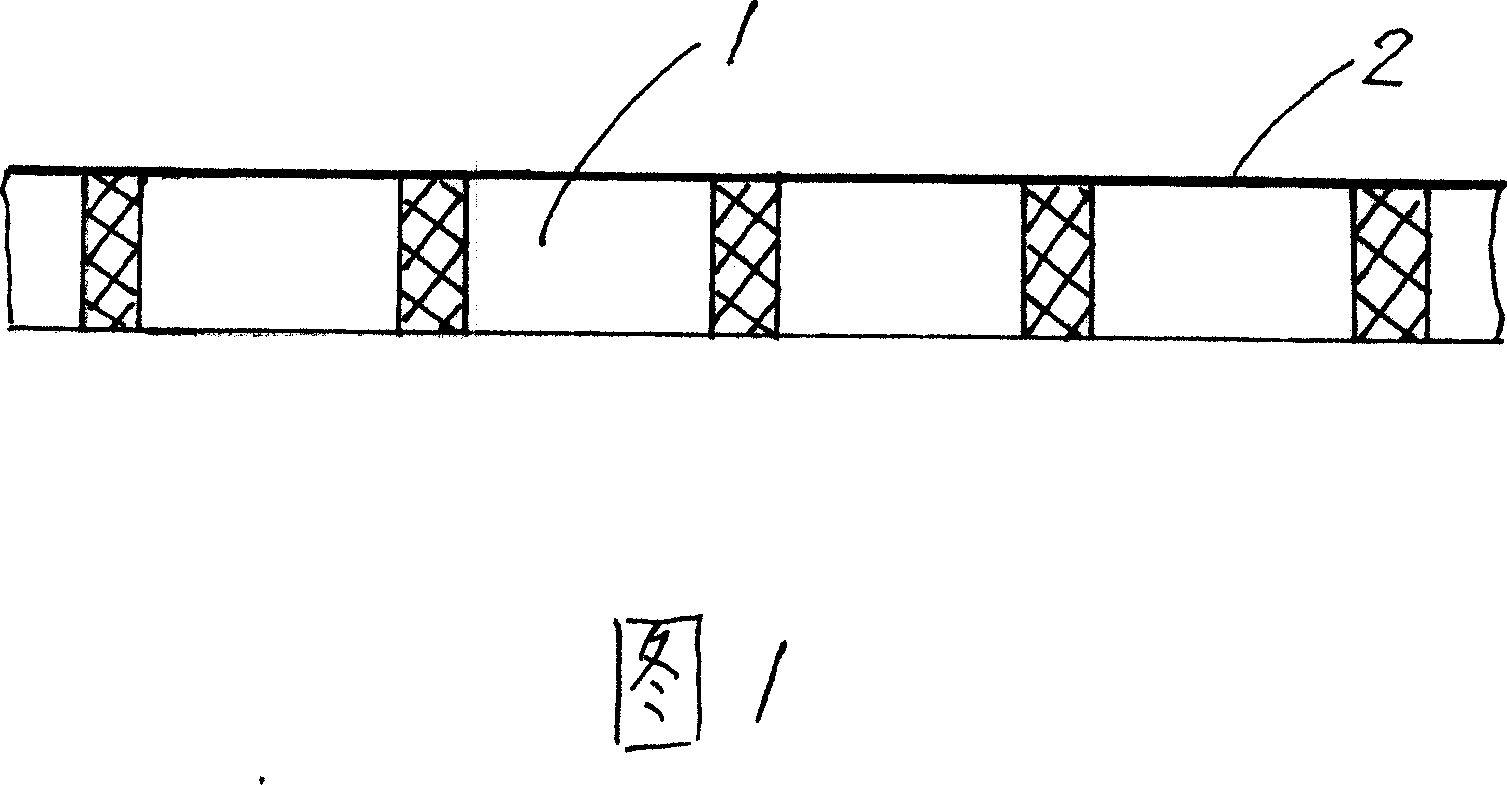

Assembled dedicated pedestrian street, pavement method of pedestrian street and design method of pedestrian street

The invention discloses an assembled dedicated pedestrian street, a pavement method and a design method of the pedestrian street, and aims at solving the problem that historical sidewalks in towns and countries, especially streets in old towns, are seriously damaged. The assembled dedicated pedestrian street comprises a street body, matched equipment and a drainage system in an assembling manner, wherein inside a geosynclines, a glass fiber reinforced plastics grid plate bottom and glass fiber reinforced plastics square tube curbs at two sides form a bottom plate to form a bottom plate groove; a medium sand layer, a common permeable brick roadbed, a permeable rubber rick and a rubber blind road brick pavement are arranged inside the groove to form the street body; inner and outer outfalls are formed at two sides of each curb; an inner opening is attached to the pavement; an outer opening is connected with an underground glass fiber reinforced plastics drainage pipeline through a branch pipe to form the drainage system. Table and chair facilities can be manufactured into artware to be fixed on the bottom plate. The pedestrian street is not overhauled, change old parts with new parts, and broadened or dismantled according to the requirements, and all components can be recovered and processed to be recycled, so that the life cycle cost is low. The assembled dedicated pedestrian street can be arranged on the outer surfaces of residential and commercial buildings at the sides of urban and rural public transport roads and highways, streets, parks, fields and other pedestrian floors in a paving manner.

Owner:肖桂芬

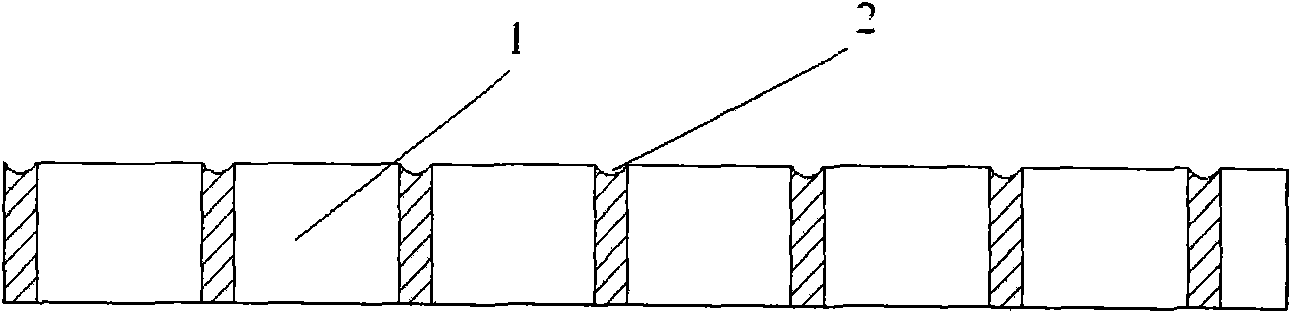

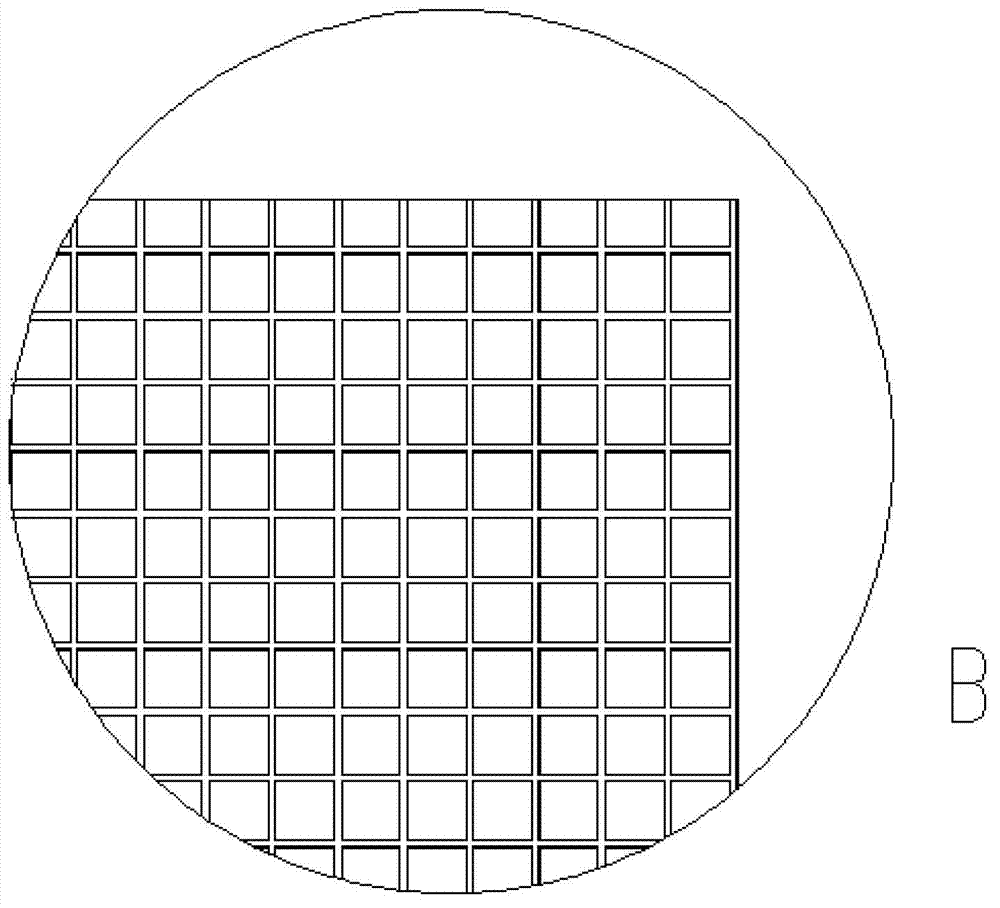

Fiberglass-reinforced plastic grid forming method and special forming mold thereof

The invention discloses a fiberglass-reinforced plastic grid forming method and a special forming mold thereof. The process comprises the following steps of: carrying out manual dry winding on fiberglass yarn bundles under certain conditions, injecting resin to the mold cavity of a mold, and forming. The process is realized by adopting the special forming mold. The special mold mainly comprises an upper mold and a lower mold, wherein a core mold is arranged in the lower mold, a resin inflow hole is arranged on the sidewall of the lower mold, a sealing ring is arranged at a demolding top hole, a vacuumizing hole is arranged at the highest point of the lower mold, the vacuumizing hole is in diagonal arrangement with a resin suction port, and a vibration motor is arranged at the bottom of the mold holder of the lower mold. According to the invention, a method combing vacuumizing with vibrating is adopted, thus the formed grid has good compact effect and the service life of the grid is prolonged; the process adopts a sealed manner, does not discharge volatile substances and is environmentally friendly; and as compared with an opened mold manner for manufacturing the grid, the process has the advantages of greatly saving manpower and reducing labor intensity.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Colorized conductive glass-fiber reinforced plastic grille and manufacturing method thereof

InactiveCN101551058ASolve the problems of poor conductivity and poor anti-static effectSolve the problem of not having anti-skid functionElongated constructional elementsEpoxy resin adhesivesGlass fiberFirming agent

The invention relates to a colorized conductive glass-fiber reinforced plastic grille and a manufacturing method thereof. The colorized conductive glass-fiber reinforced plastic grille is characterized by comprising a glass-fiber reinforced plastic grille and an upper-surface conductive layer which is integrated with the glass-fiber reinforced plastic grille and leads the grille to obtain a certain capability of conducting current and dissipating electrostatic charge. The upper-surface conductive layer of the grille can be in concave type or sanding type. The conductive glue in the conductive layer is condensate of resin and right amount of metal powders, accelerant, firming agent and pigment paste; as a right amount of metal powders are added in the resin, by using the conductive property of metal powders, the produced glass-fiber reinforced plastic grille can achieve better conductive performance and static-free effective; meanwhile, by using the properties and different colors of resin and metal, the glass-fiber reinforced plastic grille can be produced to match different surroundings; and the integration of resin and metal widens the application scope of the glass-fiber reinforced plastic grille.

Owner:SUZHOU GRATING

Method and die for manufacturing glass fiber reinforced plastic gratings based on vacuum technology, and grating

InactiveCN103042699AFinal product manufactureWind motor componentsGlass fiberFiberglass reinforced plastic grating

The invention provides a method and a die for manufacturing glass fiber reinforced plastic gratings based on a vacuum technology, and a grating. The method comprises the following steps of: respectively coating a gel coat layer on the lower surface and side face of a groove of a female die of a grating; sequentially laying glass bundles according to the shape of the groove of the female die, wherein the number of laying layers is not less than five; buckling a male die on the female die, and sealing the joint of the male die and the female die; carrying out vacuumization on the male die and the female die which are subjected to sealing; closing a vacuum pump and keeping a sealing state; guiding resins from a vessel to an injection base on the female die; and after the resins are completely cured, carrying out heat emission on the resins so as to form a solid. The method, die and grating disclosed by the invention has the beneficial effects that an integral design is adopted, and the one-step molding of products can be implemented just through carrying out cutting according to required sizes, thereby simplifying the production process; the anti-corrosion performance is improved; the weight of the grating is reduced, and just accounts for 1 / 4 of the weight of a steel-structured grating in the same specification; the roughness of the inner surface is improved; and the processing cost is low, and the price of the grating accounts for 1 / 3 of the price of a steel wire mesh in the same specification.

Owner:EULIKIND TIANJIN TECH

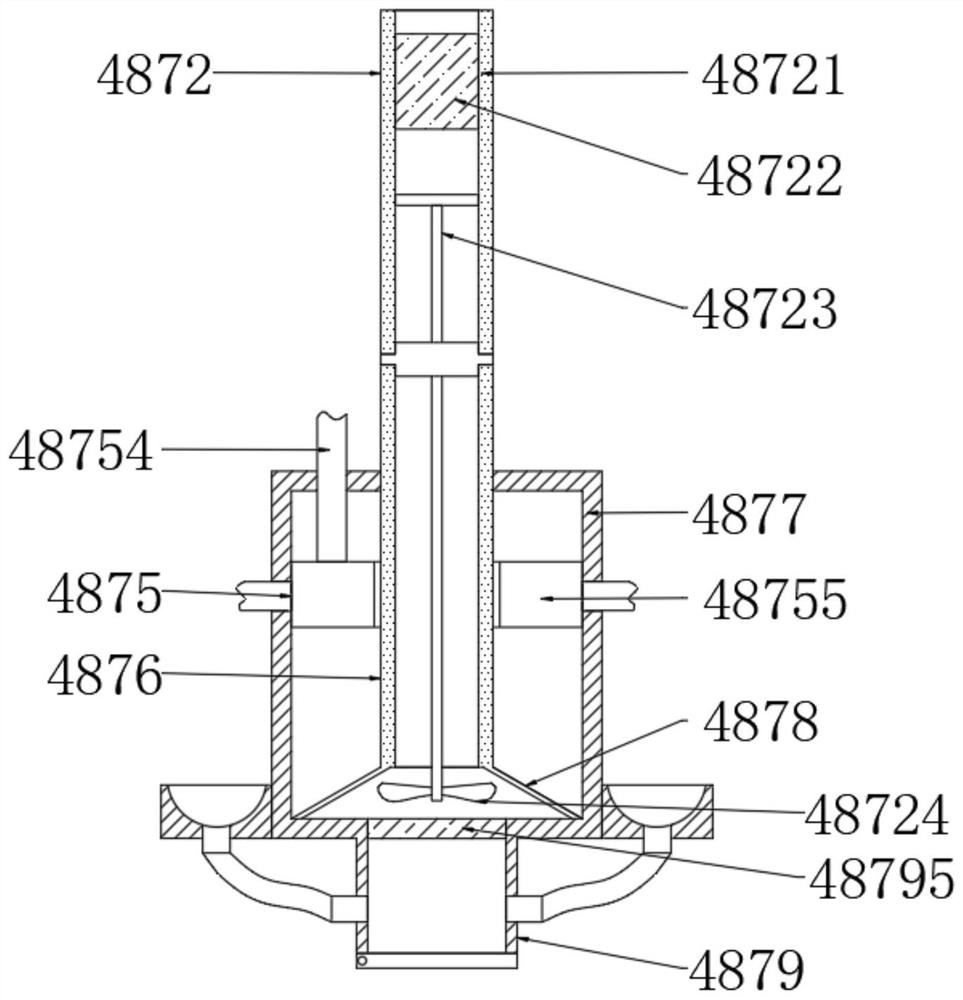

Drop-aeration water treatment system

InactiveCN105502822ADeep water purificationIncrease or decrease volumeWater aerationMultistage water/sewage treatmentWater treatment systemGrating

The invention provides a drop-aeration water treatment system which comprises a microorganism filter pool and a drop dam. The microorganism filter pool comprises multiple stages of microorganism filter beds which are connected in series and provided with water inlet pipes at water inlets. The microorganism filter bed at the head end is connected with a water inlet pump. The microorganism filter bed at the tail end is connected with the drop dam. Each microorganism filter bed comprises carrier filler, an upper tempered glass grating plate covering the carrier filler, a floating bed arranged on a water body above the upper tempered glass grating plate, aeration nozzles laid blow the carrier filler, and a lower tempered glass grating plate arranged below the aeration nozzles. The system integrates biological and ecological processing, reoxygenation and the landscape effect, and is good in treatment effect and suitable for river channel water bodies.

Owner:NANJING FRONTIER ENVIRONMENTAL TECH

Glass fiber reinforced plastics grille with conducting function and manufacturing method thereof

InactiveCN101131039AImprove conductivityFast curingConstruction materialElongated constructional elementsFiberGlass fiber

The present invention relates to one kind of conductive GRP grille and its production process, and features that the conductive GRP grille is produced with resin as basic material, glass fiber as reinforcing material, proper amount of carbon powder as conducting material, curing agent butanone peroxide, and promoter cobalt isozincate. The conductive GRP grille has high conducting performance, and may be in preventing static electricity, earthing, electromagnetic shielding and other fields.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

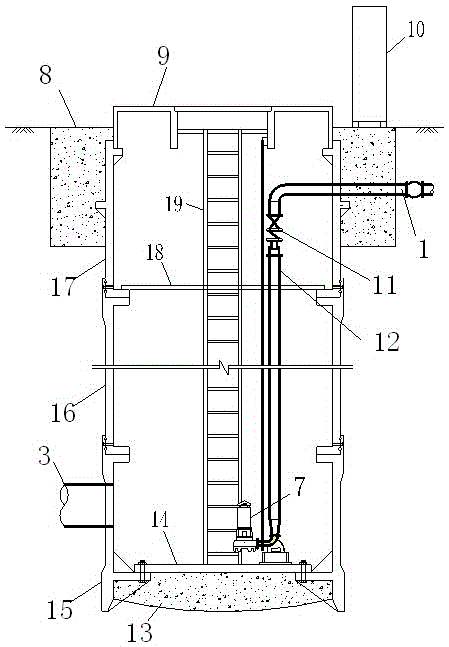

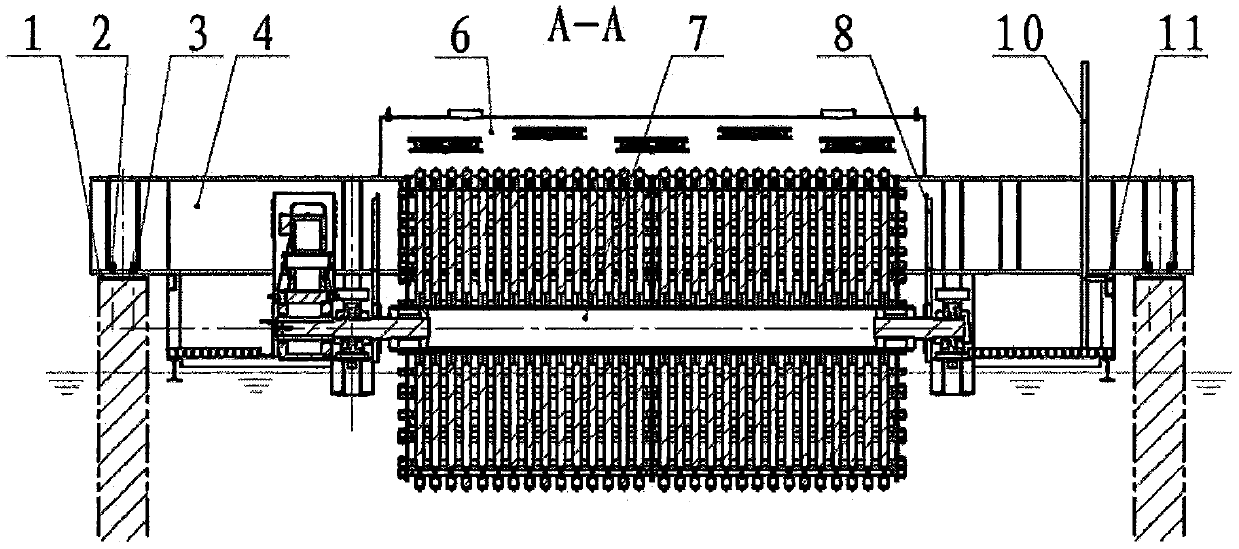

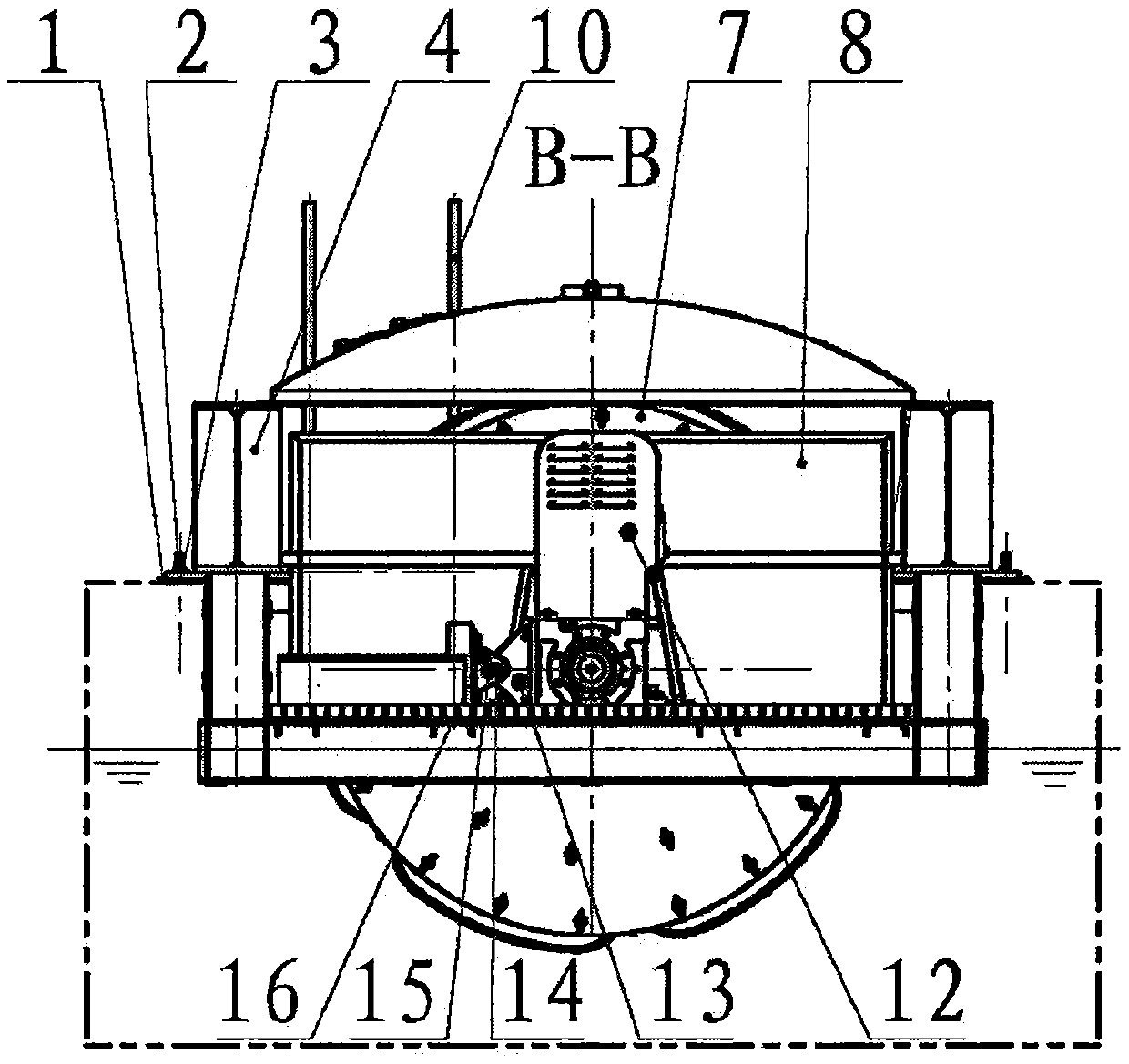

Glass reinforced plastic open caisson modularization pump station capable of being quickly constructed and construction method thereof

InactiveCN105089145AHigh degree of standardizationFast constructionSewerage structuresCaissonsFiberglass reinforced plastic gratingBuilding construction

The invention discloses a glass reinforced plastic open caisson modularization pump station capable of being quickly constructed and a construction method thereof. The glass reinforced plastic open caisson modularization pump station comprises glass reinforced plastic pump room wells which are communicated with a glass reinforced plastic distribution well through distribution pipes, and the glass reinforced plastic pump room wells are communicated with a glass reinforced plastic grille well through a water inlet pipe; the bottoms of the glass reinforced plastic pump room wells are provided with draining pumps, and the draining pumps are connected with water outlet pressure pipes. The construction method of the glass reinforced plastic open caisson modularization pump station comprises the steps that glass reinforced plastic shafts from industrialized production are assembled into a well body at the construction site, the well body is sunk to the design elevation by adopting a drop shaft sinking method, and after bottom sealing by concrete is completed at the bottom of the well body, a lass reinforced plastic bottom plate is installed; after bottom sealing is completed, other equipment, pipelines and a well lid are installed, and therefore construction of a single small glass reinforced plastic pump room well pump station is completed; then the multiple glass reinforced plastic pump room wells are connected to the glass reinforced plastic distribution well through the distribution pipes as needed and connected with the glass reinforced plastic grille well through the water inlet pipe, and then the pump station with the larger scale is formed.

Owner:JIAXING PLANNING & RES INST

Fluorescent glass fibre reinforced plastic grille and manufacturing method thereof

InactiveCN101131031AHas a luminous functionAdapt to the requirements of different occasionsCovering/liningsBuilding componentsGlass fiberFiber

The present invention relates to one kind of fluorescent GRP grille and its production process, and features that the fluorescent GRP grille includes grille comprising resin as basic material and glass fiber as reinforcing material and fluorophor cured in the resin. The resin may be one of three kinds of resin, including vinyl resin, etc; and the fluorophor is mixture of fluorescent powder, promoter and curing agent added into resin. Owing to the light accumulating and light emitting functions of fluorescent powder, the fluorescent GRP grille can emit light in night.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

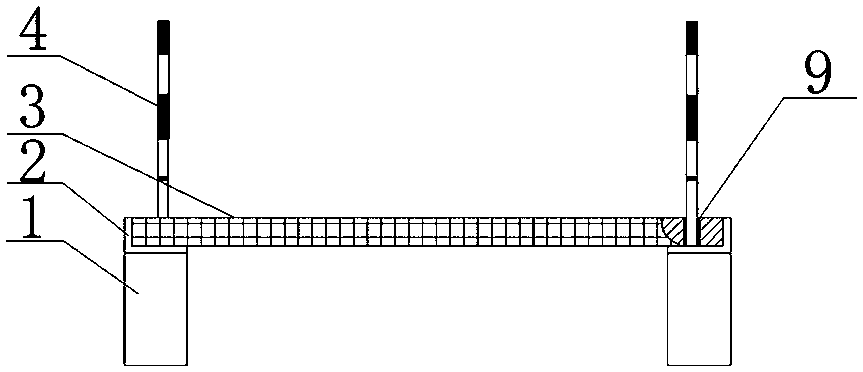

Retractable ditch trestle bridge

InactiveCN109322240AImprove installation efficiencyHigh strengthPortable bridgeBridge structural detailsGlass fiberBridge deck

The invention discloses a retractable ditch trestle bridge, and relates to the technical field of bridges. The retractable ditch trestle bridge structurally comprises two steel beams, through holes Aare formed in both ends of the steel beams, the two steel beams are connected through a casing pipe, through holes B are formed in the casing pipe, the steel beams and the casing pipe are fixed through the through holes A and through holes B with limit bolts, and the length of the steel beams can be adjusted through the casing pipe and the limit bolts; and limited angle steel is fixed to the steelbeams, the steel beams are fixed to a bridge deck through the limit angle steel, inserting openings are separately formed in both sides of the bridge deck, vertical railings are separately inserted into the inserting openings, and horizontal railings are fixed to the vertical railings. The retractable ditch trestle bridge has the beneficial effects that finished glass fiber reinforced plastic products are adopted for on-site assembly, the installation work efficiency of the ditch trestle bridge is improved, inspection is convenient, and the defects of time consumption, labor consumption, difficult movement, non-durability and the like in the installation of a steel trestle bridge on a current construction site can be effectively overcome; and glass fiber reinforced plastic grilles are adopted for the bridge deck, and the glass steel grilles have the advantages of corrosion resistance, light weight, high strength, aging resistance, flame retardance, better comprehensive economic benefits, low installation cost and the like.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

Fiber reinforced plastic grid with automatic luminescence function, and production process thereof

InactiveCN103468015AGood automatic lighting functionThe problem of delaying rapid subsidenceFiberYarn

The present invention discloses a fiber reinforced plastic grid with an automatic luminescence function, and a production process thereof. The fiber reinforced plastic grid comprises a grid body, wherein the grid body is prepared by adopting a resin as a substrate and adopting glass fiber yarns as a reinforcing material. The fiber reinforced plastic grid is characterized in that the grid body is a luminescence body. The production process comprises: according to a certain ratio, adding luminescence powder, a sedimentation resistance agent, an accelerator and a curing agent to a resin glue to prepare a mixing raw material, uniformly stirring the mixing raw material, uniformly injecting the uniformly stirred mixing raw material into a special mold cavity, uniformly and alternately paving glass fiber yarns into the special mold cavity according to the vertical and horizontal direction while applying external force to make the glass fiber yarns and the mixing raw material completely infiltrate, repeatedly the previous step, carrying out heating curing, and demolding. According to the present invention, after the used resin and the luminescence powder are mixed, the luminescence powder can not settle in the resin so as not to form the layered special structure form. With the production process, the problem that the effect is not significant due to easy sedimentation of the luminescence powder in the resin is solved.

Owner:南通时瑞塑胶制品有限公司

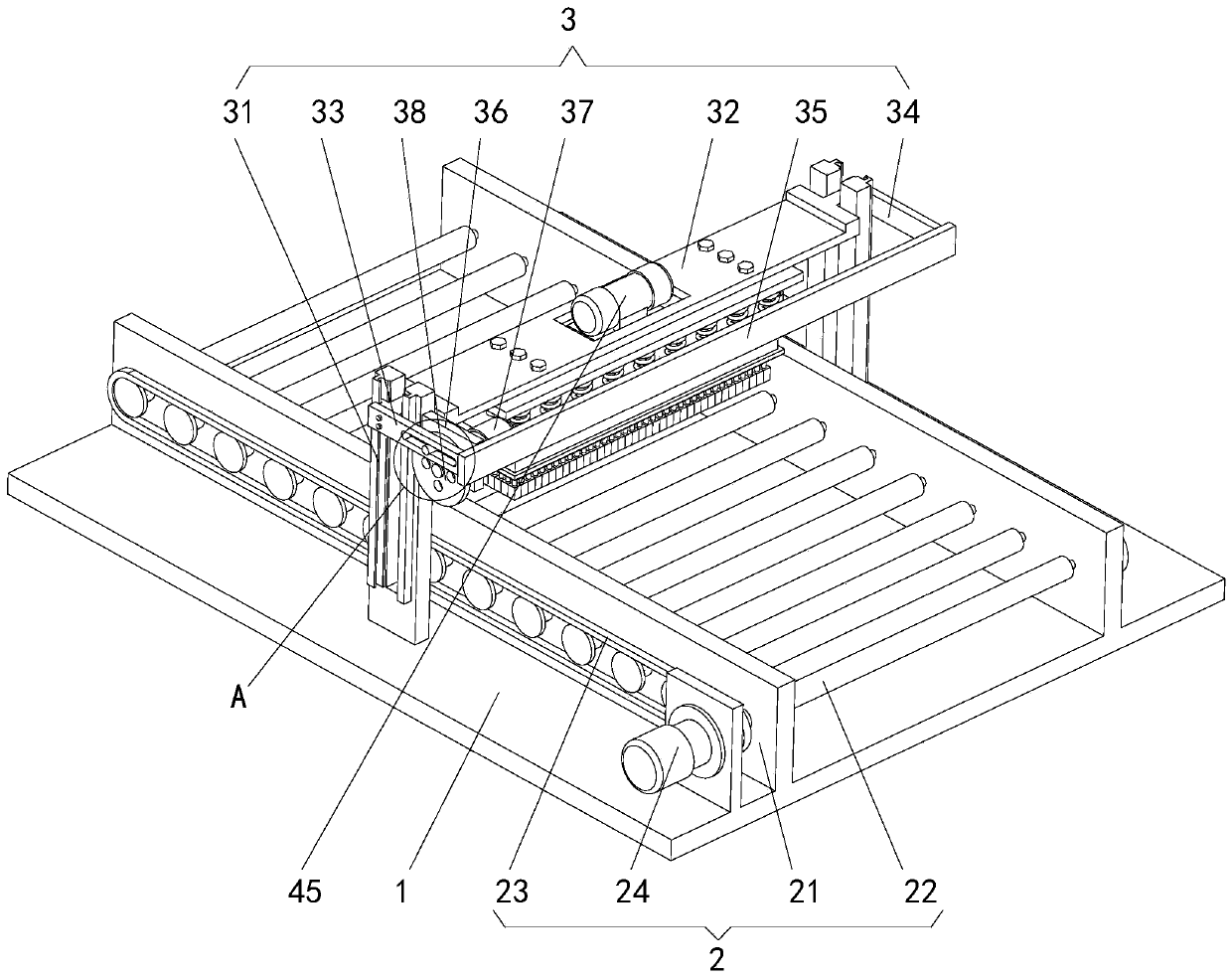

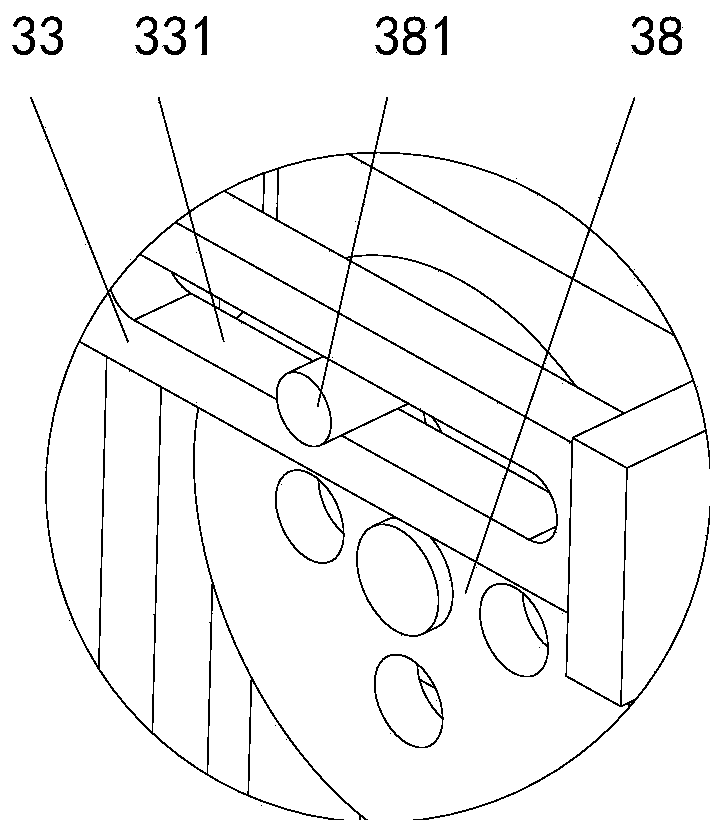

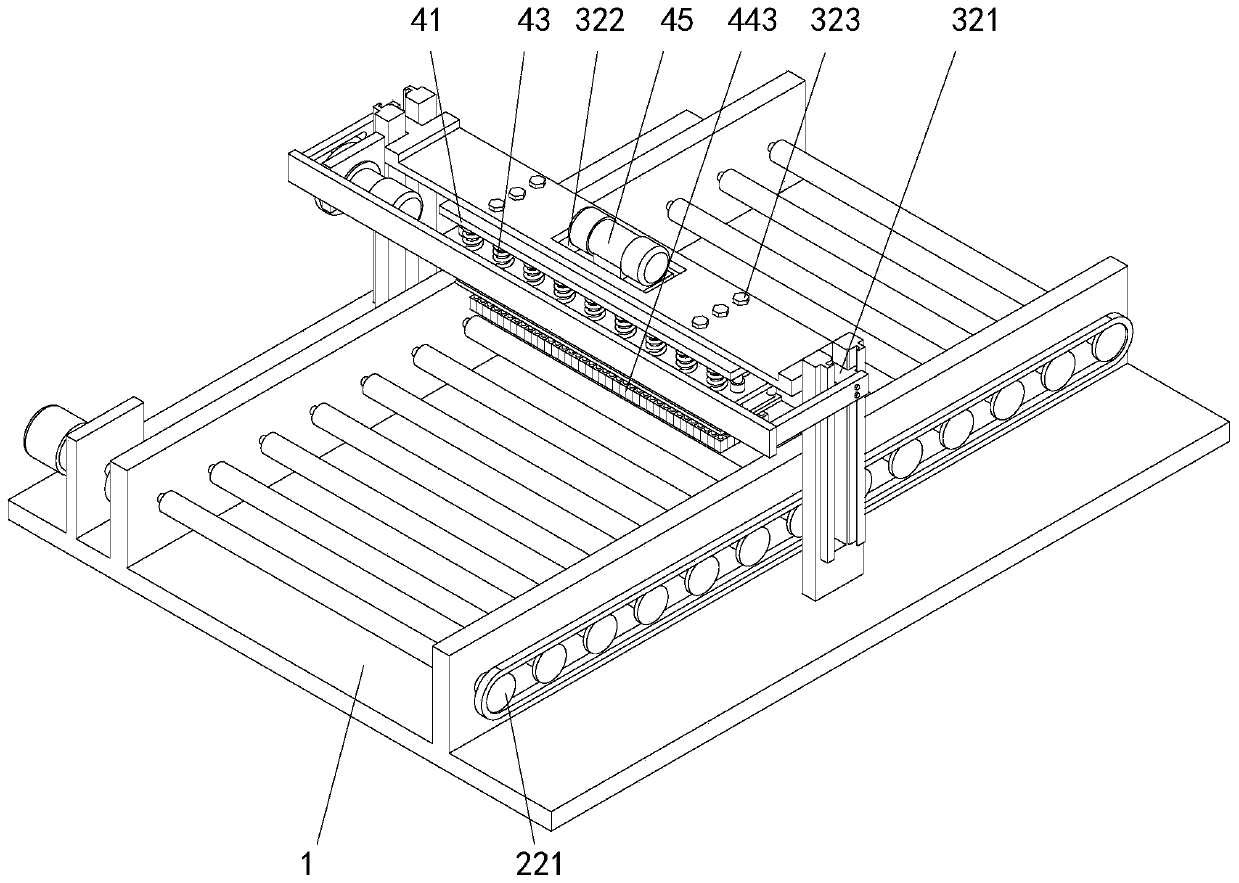

Quick surface cleaning device for secondary use of fibre reinforced plastic grille composite plate

ActiveCN110871179AQuick clean upTargetedCleaning using toolsCleaning using liquidsSurface cleaningEngineering

The invention relates to a quick surface cleaning device for secondary use of a fibre reinforced plastic grille composite plate. The cleaning device comprises a bottom plate, a roller type conveying device which is arranged on the bottom plate and is used for conveying a plate, a reciprocating lifting mechanism arranged on the bottom plate and a cleaning mechanism arranged on the reciprocating lifting mechanism; the cleaning mechanism is positioned above the roller type conveying device; and the cleaning device provided by the invention can perform secondary use quick cleaning on the fibre reinforced plastic grille composite plate, can realize automatic quick cleaning, can greatly reduce the amount of cleaning water, and meets the requirements on cleaning different models of fibre reinforced plastic grille plates.

Owner:浙江亿钛数控机械有限公司

High-performance glass-fiber-reinforced plastic grid

The invention discloses a high-performance glass-fiber-reinforced plastic grid which comprises the following components in parts by weight: 10-30 parts of glass fiber, 2-4 parts of titanium dioxide, 5-10 parts of unsaturated polyester resin, 20-25 parts of epoxy resin, 1-2 parts of antistatic agent, 5-10 parts of filler, 2-5 parts of mica, 1-4 parts of talcum powder and 2-5 parts of thickener. The grid has the advantage of scientific and reasonable formula; the added mica, asbestos and glass fiber can effectively enhance the wear-resistant effect of the grid; and the added titanium dioxide can effectively enhance the stability of the grid, and prolongs the service life of the grid due to the high strength.

Owner:太仓市华强玻璃钢五金厂

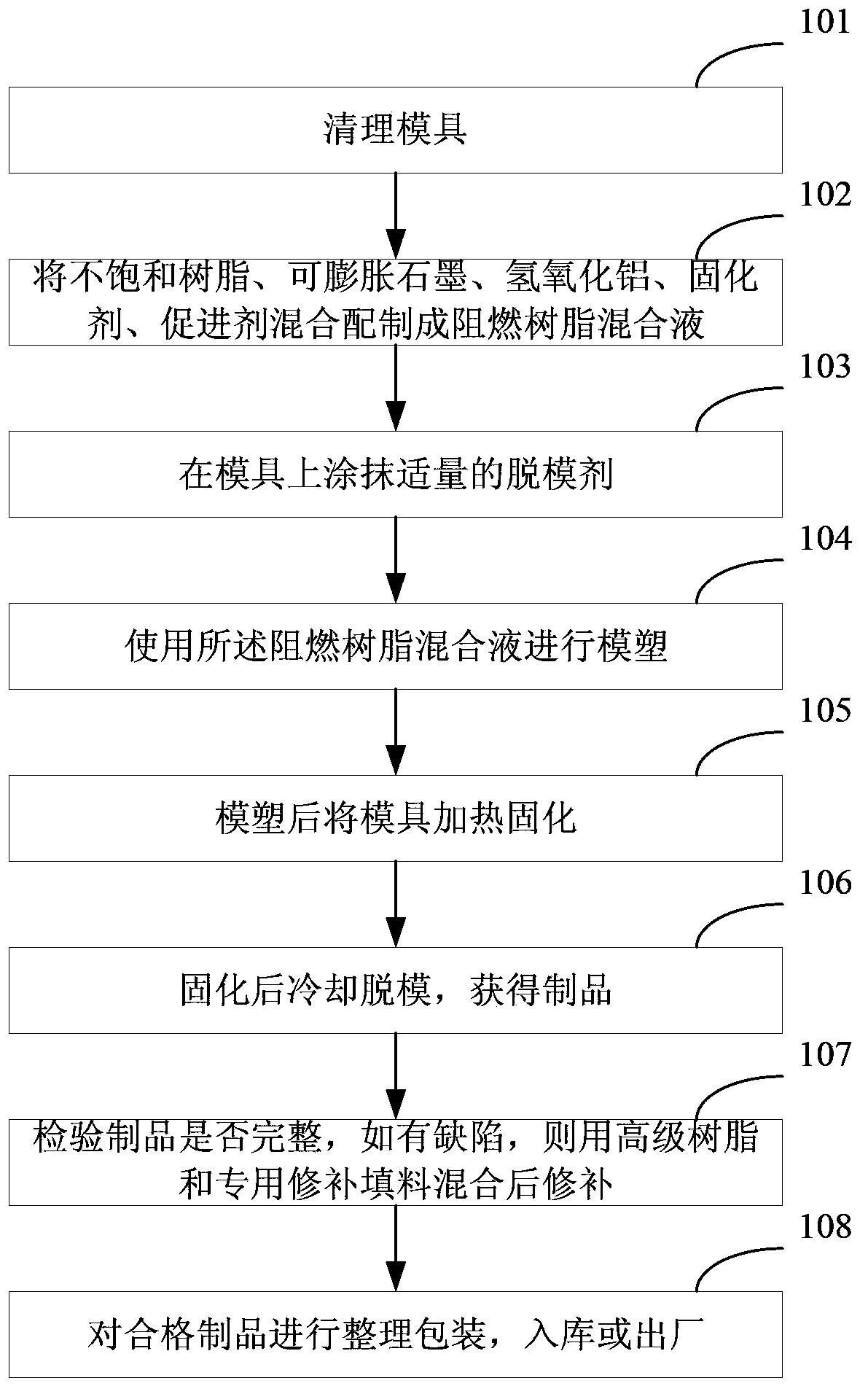

Production method of flame-retardant high-strength fiberglass-reinforced-plastic grid

The invention discloses a production method of a flame-retardant high-strength fiberglass-reinforced-plastic grid. The production method comprises: mixing an unsaturated resin, expandable graphite, aluminium hydroxide, a curing agent and a promoter to prepare a flame-retardant resin mixed liquor; coating a mold lubricant on a mold; performing molding with the flame-retardant resin mixed liquor; performing heat-curing on the mold after molding; and cooling and demolding after curing to obtain a product. By using expandable graphite with excellent flame retardancy, the production method of the fiberglass-reinforced-plastic grid helps to reduce smog and harmful gases generated by combustion of the conventional fiberglass reinforced plastics, and improving flame retardation of the fiberglass reinforced plastic; by raising the processing temperature of the flame-retardant material, the production method helps to guarantee the original mechanical properties; and also the performances of heat insulation, anticorrosion and weatherability are improved.

Owner:天长市蓝天复合材料有限公司

High hardness and ultraviolet resistant modified unsaturated polyester resin fiber reinforced plastic grid

The invention discloses a high hardness and ultraviolet resistant modified unsaturated polyester resin fiber reinforced plastic grid. The raw materials include: modified unsaturated polyester resin, diphenylmethane bismaleimide, hydroquinone type liquid crystal bismaleimide, styrene, carbon nanotube, nano calcium carbonate, nano alumina, organic modified montmorillonite, ceramic powder, glass fiber, benzotriazole, a BYK-W940 wetting dispersant, methyl ethyl ketone peroxide, poly nano titanium dioxide ammonium, cobalt naphthenate, a BYK-S740 assistant, a silane coupling agent KH-560, a curing agent and an accelerator. The fiber reinforced plastic grid provided by the invention has high hardness and strong ultraviolet resistance.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

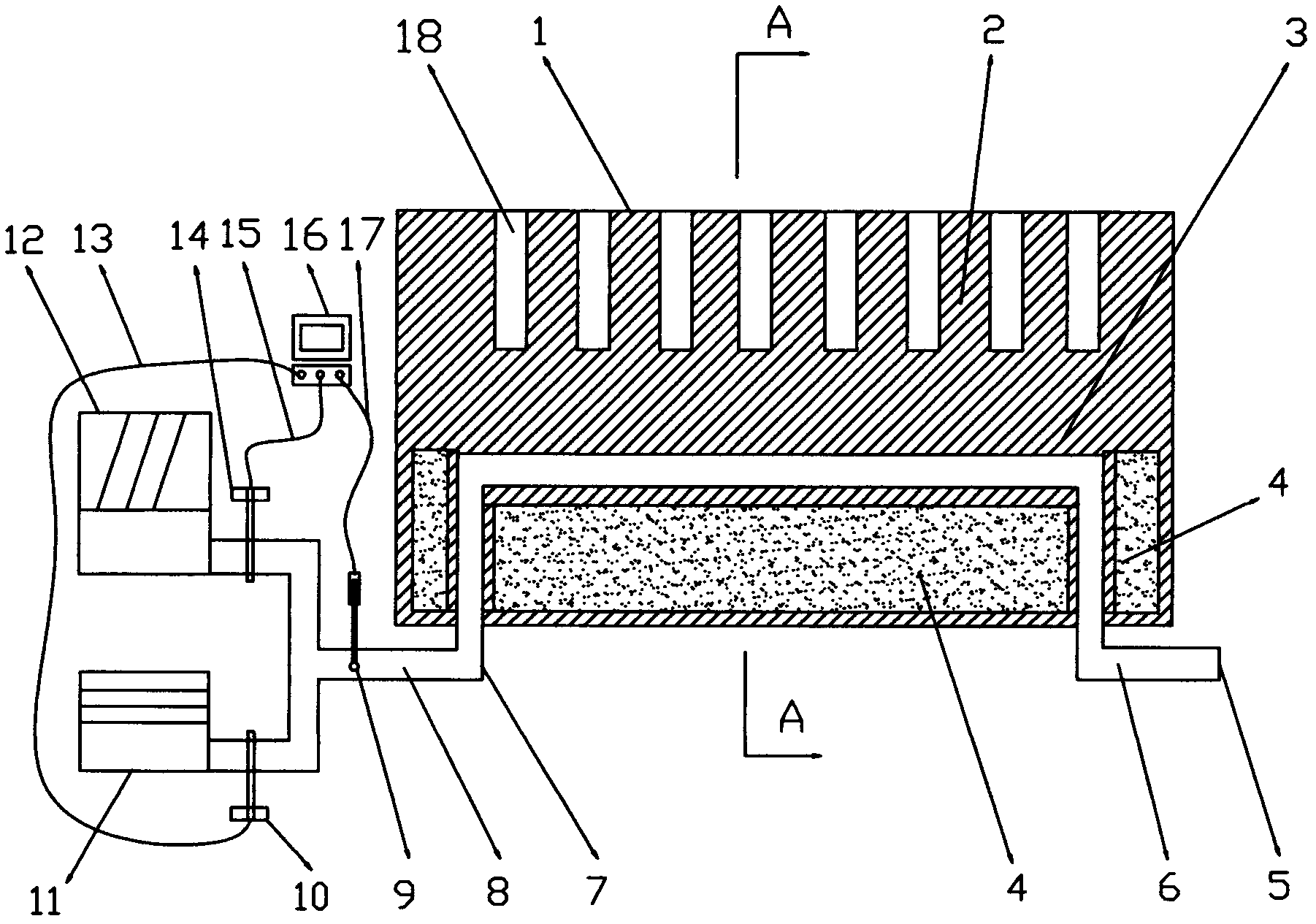

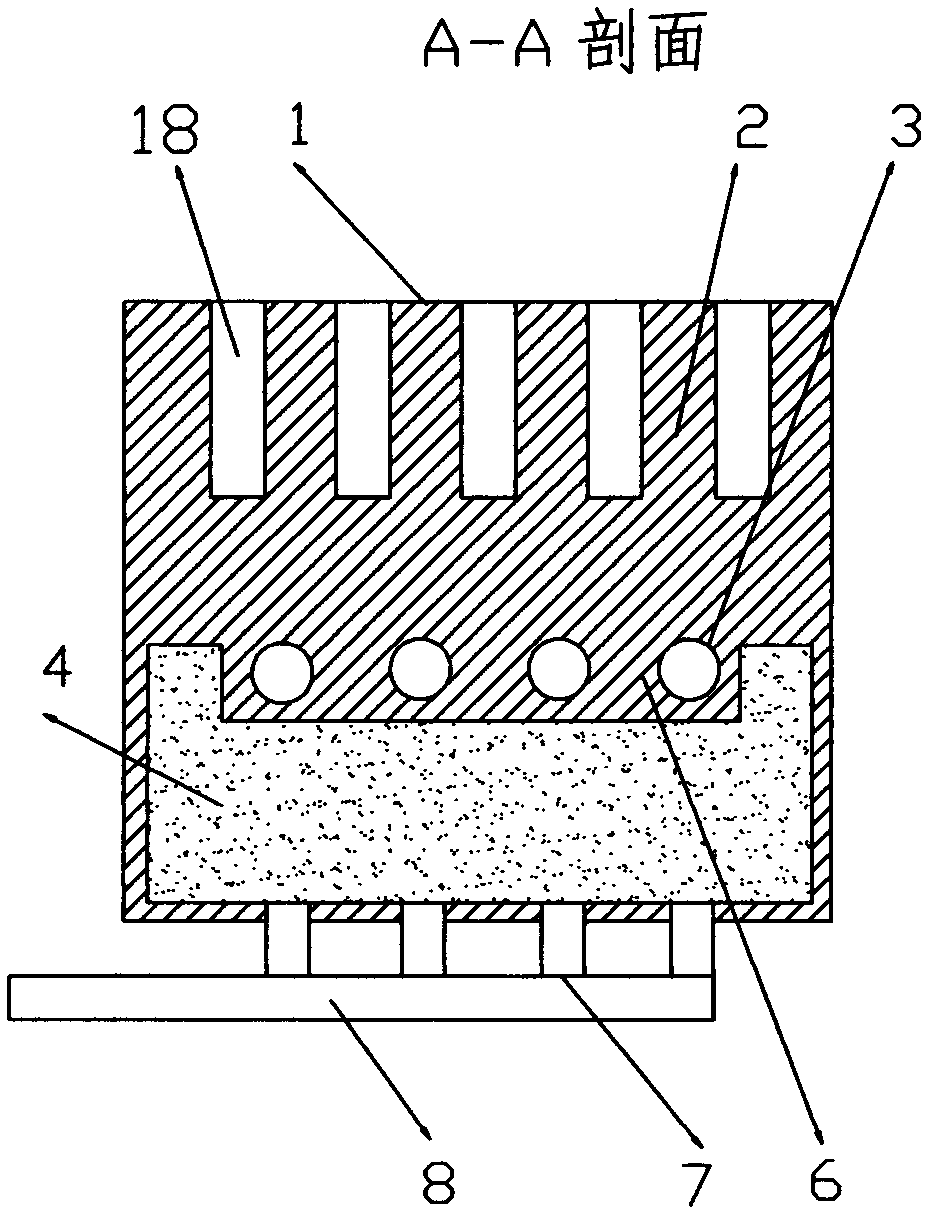

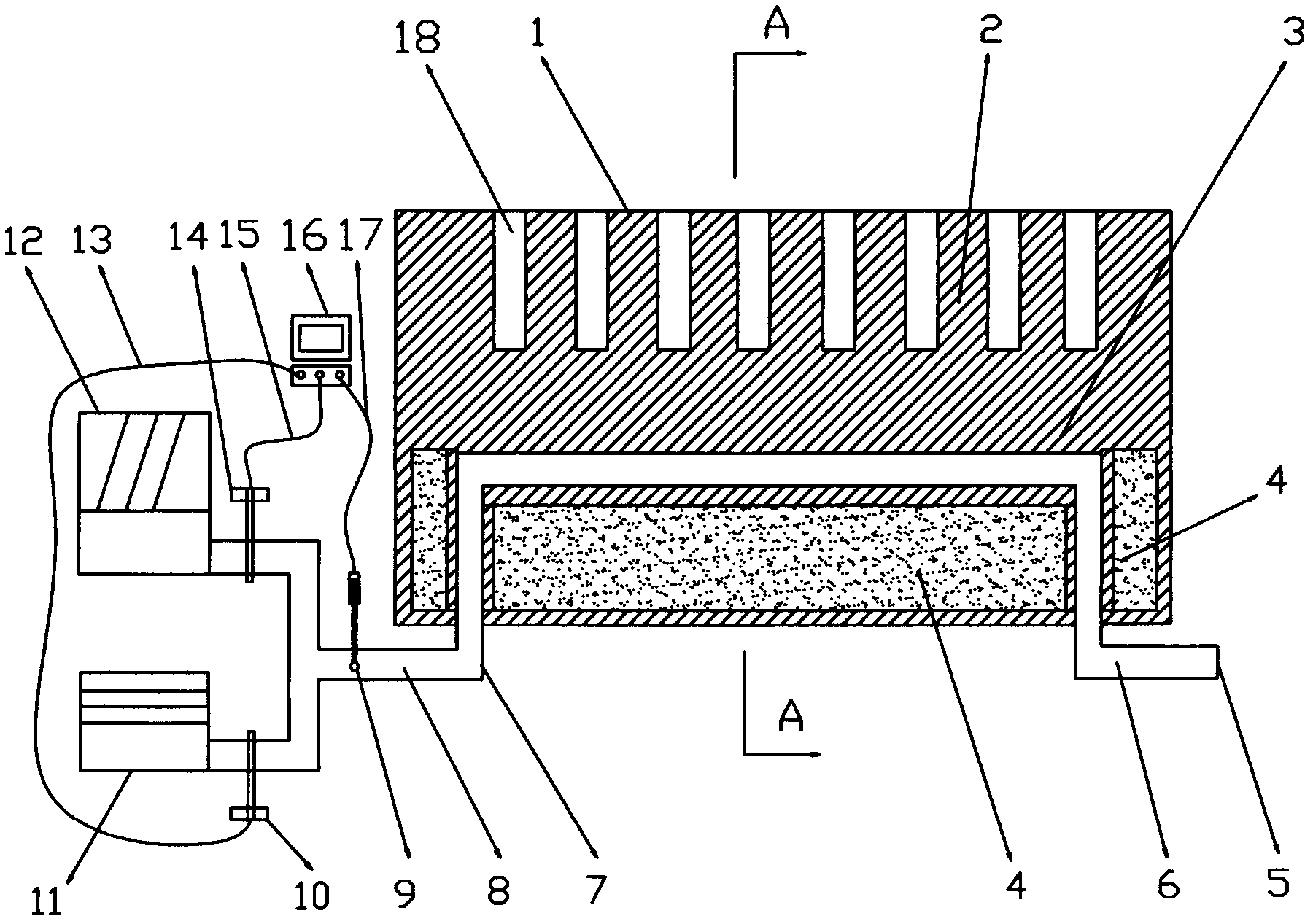

Molding mold for glass fiber reinforced plastic grate

The invention provides a molding mold for a glass fiber reinforced plastic grate, which comprises a molding template, a temperature control chamber, a warming pipeline, a heat preservation layer and other parts, wherein the temperature control chamber is arranged below or on the lower portion of the molding template, the warming pipeline and the heat preservation layer are arranged in the temperature control chamber, the heat preservation layer is wrapped on the left side, the right side and the lower side of the warming pipeline, and the heat preservation layer is made of inflaming retarding plastics or noncombustible mineral wool. Outlets and inlets of the warming pipeline are arranged below the temperature control chamber, and all the inlets are connected with the same bus pipe which is connected with a temperature measurement instrument. A heat source device is a solar energy device and a conventional coal furnace or oil furnace device which are connected in parallel and respectively connected with a valve A and a valve B. The temperature measurement instrument is connected with a control system through a signal line, and the control system is respectively connected with the two valves and controls opening and closing of the two valves through a control line. The molding mold for the glass fiber reinforced plastic grate adopts a pipeline, heat preservation layer and template integrated design and is compact in structure, good in heat preservation effect and small in energy consumption. In addition, the molding mold can adopt a self-control system and is high in automation degree and production efficiency and low in labor intensity.

Owner:于忠志

High-strength glass fiber reinforced plastic grating material

The invention discloses a high-strength glass fiber reinforced plastic grating material. The glass fiber reinforced plastic grating material is prepared from the following components in parts by weight: 10 to 20 parts of phenolic resin, 5 to 10 parts of unsaturated polyester resin, 10 to 15 parts of vinyl resin, 2 to 8 parts of calcium carbonate, 2 to 8 parts of aluminum hydroxide, 1 to 5 parts of glass beads, 2 to 6 parts of ceramic powder, 5 to 10 parts of BYK-W985 wetting dispersant, 3 to 10 parts of silica powder, 5 to 15 parts of macromolecule toughening agent and 3 to 10 parts of fire retardant. A preparation technology disclosed by the invention is simple and has the advantages of environmental friendliness and no pollution in a preparation process; the prepared glass fiber reinforced plastic grating material has excellent flame retardance, corrosion resistance, wear resistance and high temperature resistance and meanwhile has the characteristics of high strength, high toughness and long service life.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

Load testing machine

PendingCN108398332APrevent inflowMeet production requirementsMaterial strength using tensile/compressive forcesGratingShell molding

The invention relates to a load testing machine which comprises a luggage carrier and a testing frame. The testing frame is matched with the luggage carrier. A moving component and two moving bracketsare arranged on the luggage carrier, the two moving brackets are separately positioned at two ends of the luggage carrier; the moving component controls the two moving brackets to move in the opposite directions at the same time; a lifting component, a pressure sensor and a pressing shovel are arranged on the testing frame, the pressure sensor is positioned between the lifting component and the pressing shovel, the lifting component is matched with the pressing shovel, the pressing shovel is matched with a sample on each moving bracket. The load testing machine adopting the scheme is mainly used for detecting the mechanical properties of linear load test and uniformly distributed load test of composite products such as a plastic glass steel grating, a glass steel grating cover plate, a glass steel grating plate, a pultrusion glass steel grating, a pultrusion glass steel profile and acrylic artificial marbles, meets production requirements, and prevents substandard composite products from flowing into markets.

Owner:苏州拓博机械设备有限公司

Anticorrosive flame-retardant treatment process for glass fiber reinforced plastic grid

ActiveCN104985830AIncrease productivityAdvanced production technologySilicon dioxideUnsaturated polyester

The invention discloses an anticorrosive flame-retardant treatment process for a glass fiber reinforced plastic grid. The anticorrosive flame-retardant treatment process comprises the following steps: mixing unsaturated resin, a curing agent, a plasticizer, a diluent and a modifier to prepare resin mixed liquor, injecting the resin mixed liquor into a liquor storage tank, transmitting glass fiber filaments into the unsaturated resin storage tank by a guide mechanism for being sufficiently soaked, heating and curing the soaked glass fiber filaments, and taking out the glass fiber filaments after de-molding the glass fiber filaments; placing a glass fiber reinforced plastic semi-finished product on a workbench, then coating a layer of unsaturated polyester resin on the surface of the glass fiber reinforced plastic semi-finished product, immediately coating a layer of melamine resin cover on the unsaturated polyester resin and then coating a silicon dioxide wear-resisting layer on the melamine resin cover; placing the glass fiber reinforced plastic semi-finished product, upper and lower surfaces of which are adhered, into a hot press to carry out hot-pressing; and cutting and trimming glass fiber reinforced plastics subjected to the hot-pressing, and checking and warehousing a finished product. The anticorrosive flame-retardant treatment process is high in production efficiency, fireproof and flame-retardant, wear-resisting and efficient, advanced in production process and capable of resisting ageing and prolonging the service life.

Owner:江苏澳兰德新材料科技有限公司

Heliport

The invention discloses a heliport which is installed on a top of a building and comprises fiberglass grating plates, a fixing plate, a supporting device and an air inducing device. The plurality of fiberglass grating plates are fixedly connected with the fixing plate through buckling pieces, and a heliport body is formed. The heliport body is rectangular or square. The surface of the heliport body is basically flat. A plurality of water and air discharging holes are evenly distributed in the heliport body. The supporting device is fixedly connected with the lower portion of the fixing plate, the air inducing device is fixedly connected with the fixing plate arranged in the middle of the heliport body, the supporting device penetrates through the air inducing device and then is fixedly connected with a roof, and the air inducing device is used for inducing air generated in the landing process of a helicopter to the outer side of the heliport body. The heliport is good in antiskid performance, high in corrosion resistance, attractive in appearance, convenient to install, low in cost, firm in fixation and stable in landing.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

Finish machining treatment machine for producing and manufacturing glass fiber reinforced plastic grating plate

ActiveCN112223611ATo achieve the effect of deburringNot easy to damageDispersed particle filtrationGlass fiberReciprocating motion

The invention discloses a finish machining treatment machine for producing and manufacturing a glass fiber reinforced plastic grating plate in the technical field of glass fiber reinforced plastic grating plate production. The machine comprises a base and a treatment adjusting assembly. Clamp main bodies with the same structure are symmetrically arranged at the tops of two sets of supporting columns. The treatment adjusting assembly comprises longitudinal sliding rails fixed to the left side and the right side of the top of the base, connecting rotating shafts are movably arranged at the topsof two sets of sliding blocks through bearings correspondingly, and spiral grooves with the heads and the tails closed are symmetrically formed in the outer walls of two sets of rotating columns. According to the finish machining treatment machine for producing and manufacturing the glass fiber reinforced plastic grating plate, the treatment adjusting assembly is arranged, a burr removing assemblyis arranged in the treatment adjusting assembly, a dry ice granulator is started, in the vertical reciprocating motion process, dry ice particles are sprayed out through spray heads on the peripheryto spray and polish the inner walls of rectangular grids on the glass fiber reinforced plastic grating plate, the burr removing effect is achieved by means of the characteristic of dry ice heat transfer, the surfaces of the inner walls of the rectangular grids in the glass fiber reinforced plastic grating plate are prevented from being scratched and rubbed while the glass fiber reinforced plasticgrating plate is not likely to be damaged, and the machining quality of the glass fiber reinforced plastic grating plate is improved.

Owner:南通天木绝缘复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com