Colorized conductive glass-fiber reinforced plastic grille and manufacturing method thereof

A technology of glass fiber reinforced plastics and grids, applied in the direction of conductive adhesives, epoxy resin glue, adhesive types, etc., can solve the problem that the surface conductive layer does not have anti-skid function, the grid has poor electrical conductivity, and the anti-static effect is poor, etc. problem, to achieve lasting and stable electrical conductivity and anti-static performance, stable and reliable product quality, good anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

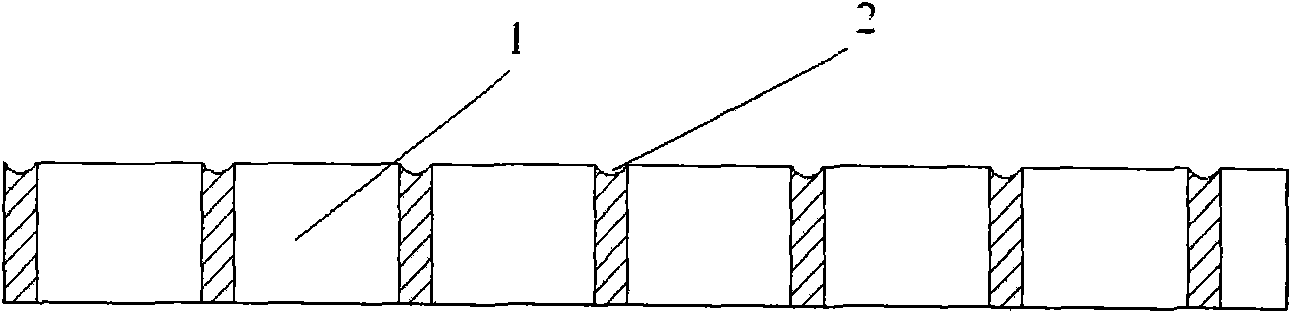

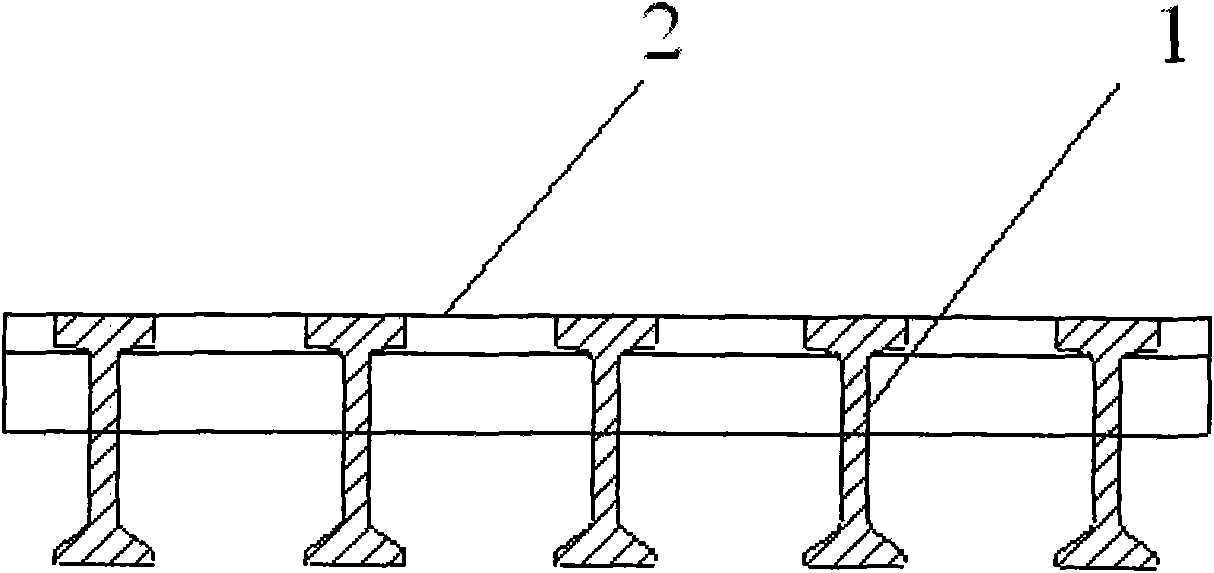

[0035] Refer to attached figure 1 , the colored FRP grid with conductive function of the present invention comprises a glass fiber reinforced plastic grid 1, and an upper surface conductive layer 2 solidified with it; the conductive layer 2 of the present embodiment is a concave layer, and adopts Molding in-mold production method. The conductive adhesive in the conductive layer 2 is a cured product of m-benzene type unsaturated resin, appropriate amount of metal powder, accelerator, curing agent, and pigment paste. The content of components in the conductive adhesive of this embodiment is: 59.1% of isophthalic unsaturated resin, 39.6% of metal powder, 0.24% of accelerator, 0.47% of curing agent, and 0.59% of pigment paste. A method for producing the above-mentioned FRP grating with conductive function, comprising the following steps:

[0036] ① Prepare the m-benzene type unsaturated resin mixture according to the process regulations, pour the resin mixture into the mold, app...

Embodiment 2

[0044] Refer to attached figure 1 , the colored FRP grid with conductive function of the present invention comprises a glass fiber reinforced plastic grid 1, and an upper surface conductive layer 2 solidified with it; the conductive layer 2 of the present embodiment is a concave layer, and adopts Molding in-mold production method. The conductive adhesive of the conductive layer 2 is a cured product of m-benzene type unsaturated resin, appropriate amount of metal powder, accelerator, curing agent, and pigment paste. The content of the components in the conductive adhesive of this embodiment is: 38.53% isophthalic unsaturated resin, 57.81% metal powder, 0.96% accelerator, 1.54% curing agent, and 1.16% pigment paste. A method for producing the above-mentioned FRP grating with conductive function, comprising the following steps:

[0045] ① Prepare the m-benzene type unsaturated resin mixture according to the process regulations, pour the resin mixture, apply glass fiber yarn, ap...

Embodiment 3

[0053] Refer to attached figure 1 , the colored FRP grid with conductive function of the present invention comprises a glass fiber reinforced plastic grid 1, and an upper surface conductive layer 2 solidified with it; it is produced by molding, and the conductive layer 2 of the present embodiment is a Sand layer. The conductive adhesive of the conductive layer 2 is a cured product of epoxy resin, appropriate amount of metal powder, curing agent, and pigment paste. The content of each component in the conductive adhesive of this embodiment is: 41.5% of epoxy resin, 41.5% of metal powder, 16.6% of curing agent, and 0.4% of pigment paste. The method for producing the above-mentioned fiberglass grating with conductive function comprises the following steps:

[0054] ① According to the process regulations, the isophthalic resin grid body is produced;

[0055] ②Grind the surface of the grille to the specified height;

[0056] ③ Preparation of epoxy resin conductive adhesive;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com