Thermosetting rapid curing phenolic resin and preparation method thereof

A phenolic resin and phenolic technology, which is applied in the field of thermosetting fast-curing phenolic resin and its preparation, and can solve the problems of single curing time and molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

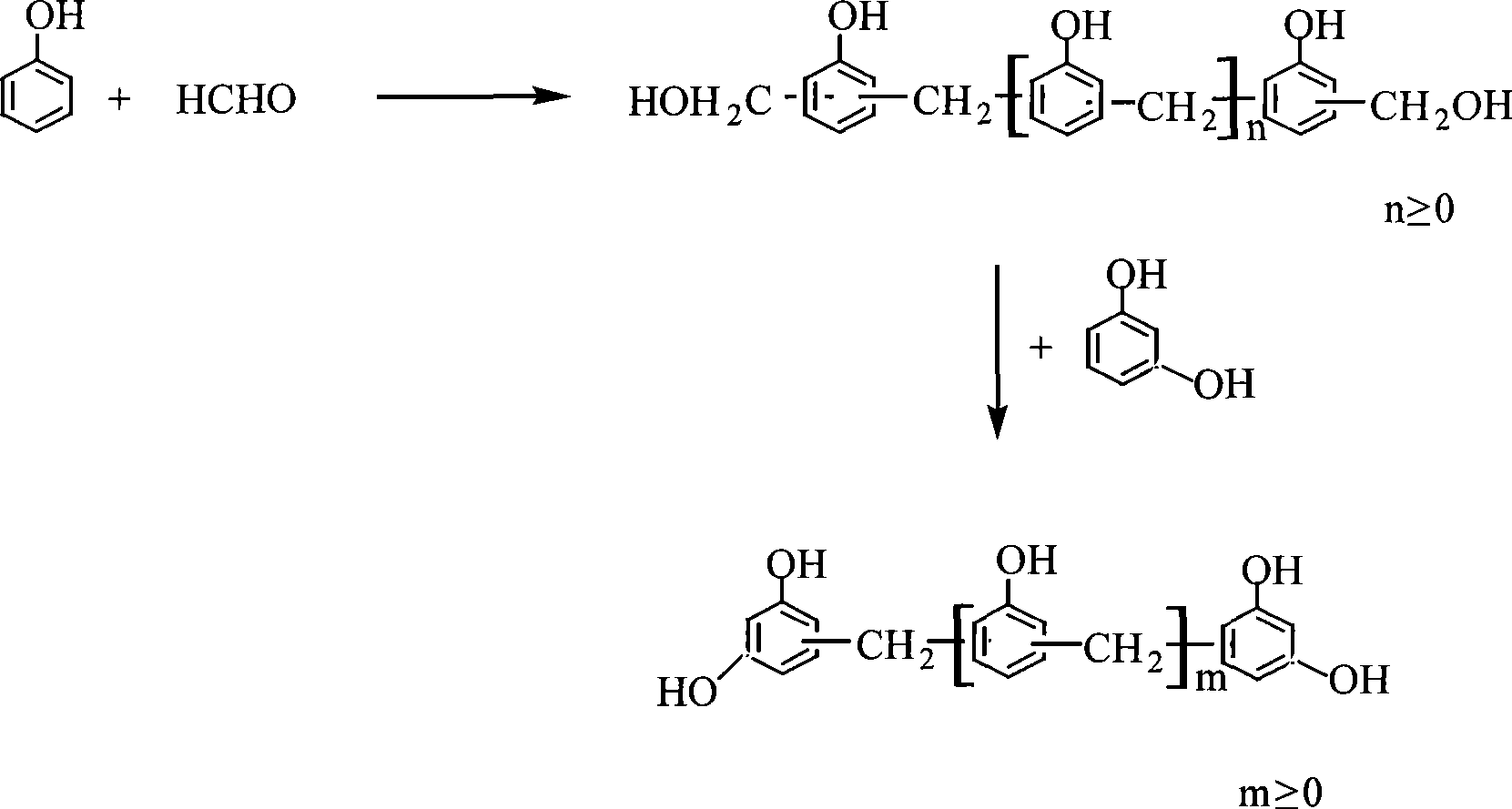

Method used

Image

Examples

preparation example Construction

[0058] A specific preparation method is:

[0059] For example, a mixture of phenol and resorcinol is used as the phenolic raw material (wherein the weight percentage of resorcinol is 5 to 30%), and formaldehyde, acetaldehyde, butyraldehyde and / or a mixture thereof are used as the aldehyde raw material According to the molar ratio of phenolic raw materials and aldehyde raw materials is 1:0.5~0.8, put phenolic raw materials (excluding resorcinol) and aldehyde raw materials into the reactor, and then add divalent metal zinc salt to adjust the system The pH of the solution is 4~7, stir, slowly raise the temperature to 80~90°C and react for 40~60min; cool down to 60~80°C, add 0.8~1.5mol of aldehyde raw materials (relative to 1mol of phenolic raw materials), adjust with lye The pH value of the solution is 8-9, and the reaction is continued at 90°C for 60-80 minutes; finally, an appropriate amount of resorcinol is added to the solution system, the temperature is lowered to 60-80°C, a...

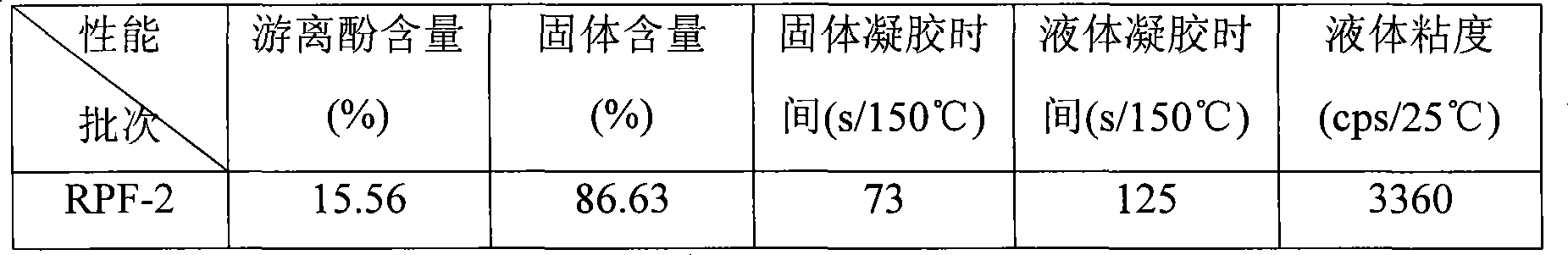

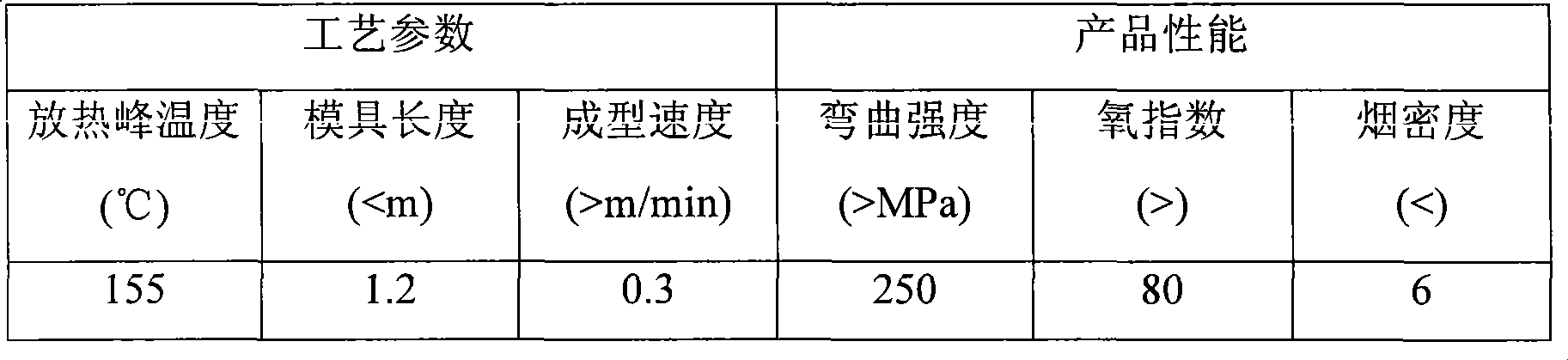

Embodiment 1

[0062] The molar ratio of phenol to aldehyde is 1:1.5, put 254kg of phenol and 146kg of formaldehyde with a concentration of 37% (weight) into the reactor, and add a zinc acetate solution with a concentration of 30% (weight) and a weight of 20kg. , stir, slowly heat up to 85-95°C, keep the reaction for 40-60min, at this time the pH value of the solution is between 4-7; add 220kg of formaldehyde, and add a sodium hydroxide solution with a concentration of 20% and a weight of 10kg , adjust the pH value of the solution between 8 and 9, control the temperature between 85 and 95°C, and continue to react for 60 to 80 minutes; then cool down to 60 to 80°C, add 16.5kg of resorcinol, and continue to keep warm React for 90 to 150 minutes, and the pH value of the solution is between 9 and 10 at this time; finally, vacuum dehydration at 45 to 75 ° C, and the gel time of the reactant is 70 to 75 s measured by the iron plate wire drawing method. Add 50kg of ethylene glycol at about 50°C, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com