Patents

Literature

53results about How to "High heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon steel water-soluble environment-friendly super thick insulating coating and preparation method thereof

ActiveCN102746725AHigh solid contentGood heat resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventWater soluble

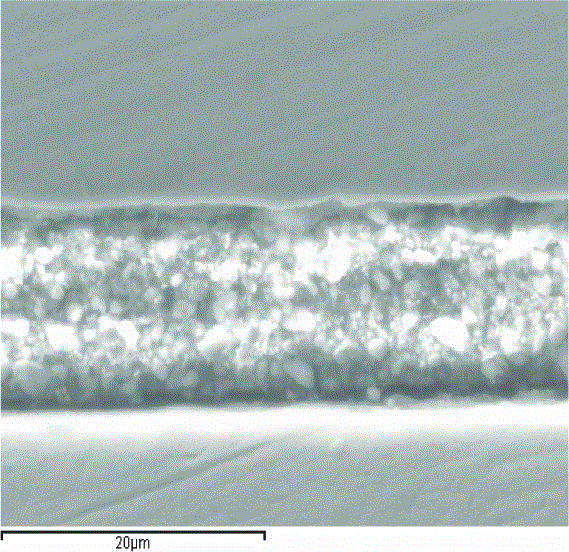

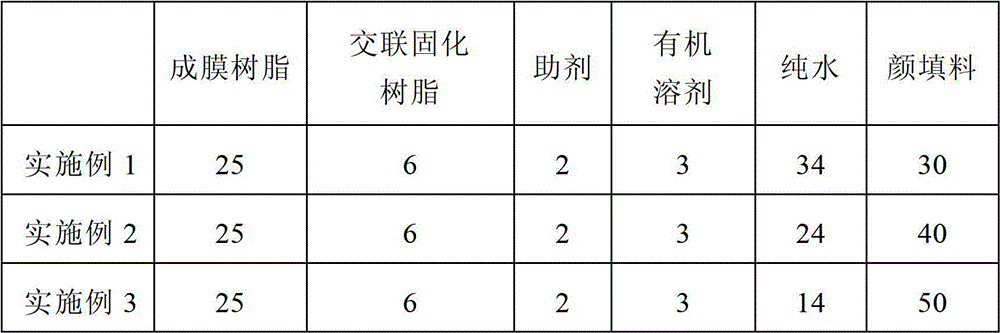

A silicon steel water-soluble environment-friendly super thick insulating coating and a preparation method thereof. The insulating coating comprises the following components, by weight percentage: 10-60% of organic resin containing film-forming resin and crosslinking curing resin; 0.1-5% of inorganic pigment; 28-60% of filler; additives including 0.1-4% of wetting agent, 0.1-4% of dispersing agent, 0.1-1% of defoaming agent in and 0.1-1% of pH regulator; 1-15% of organic solvent; and the balance of pure water. The present invention provides a chrome-free C6 water-soluble environment-friendly coating with low VOC emission. The coating has high solid content and inorganic filler content (solid no less than 60%, inorganic filler content no less than 40%, GB / T 1725-2007), excellent surface insulation performance no less than1500 ohm.cm<2> / tablet (ASTM A717), good attachment (grade class A, phi 10mm rod, GB / T 2522-2007), low lamination heat compression rate, and good corrosion resistance, and is suitable for silicon steel processed with clipping and stamping by large and medium-sized motors.

Owner:BAOSHAN IRON & STEEL CO LTD

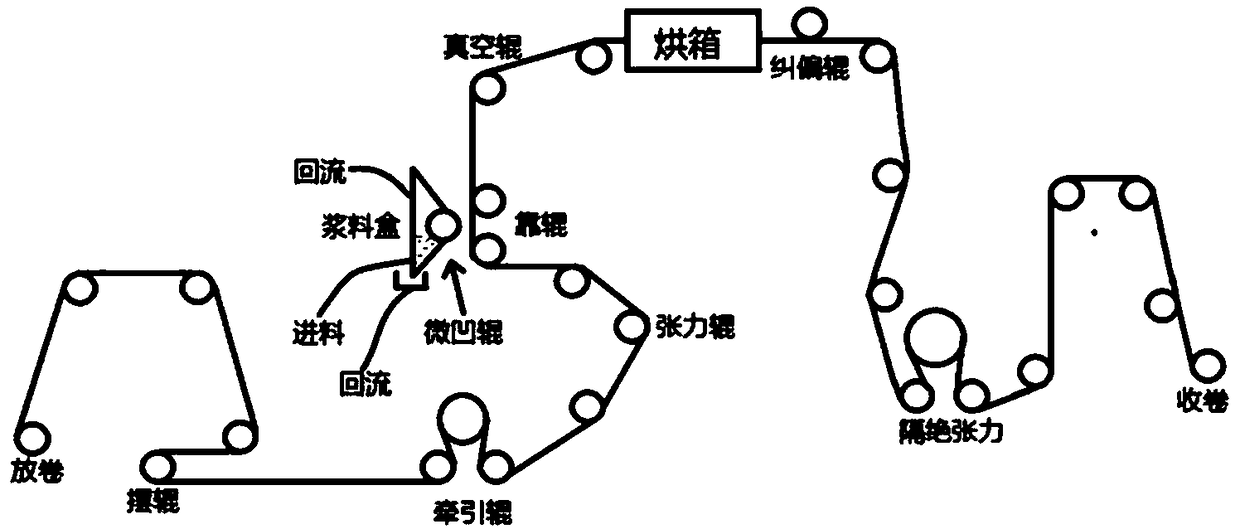

Composite diaphragm as well as preparation method and application thereof

InactiveCN104064713ALarge specific surface areaImprove thermal stabilitySecondary cellsCell component detailsSolventWater soluble

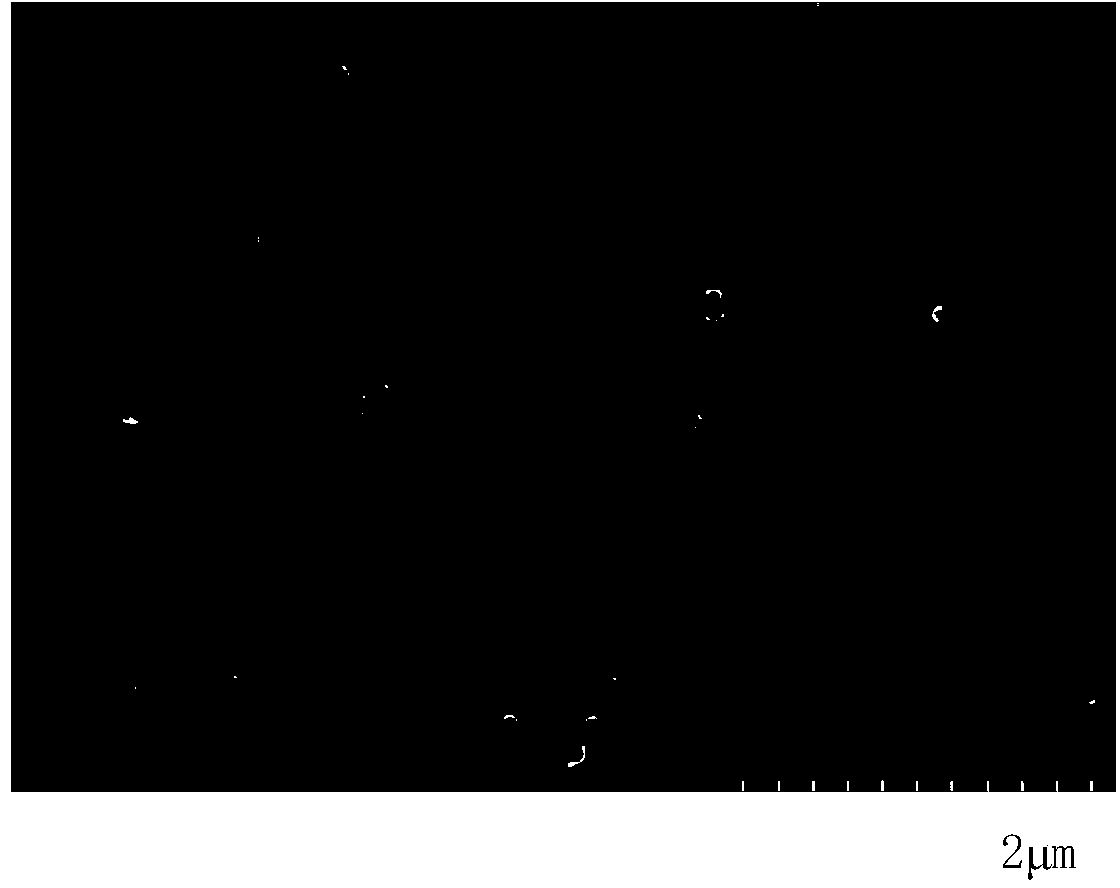

The invention provides a composite diaphragm as well as a preparation method and application thereof, and relates to a lithium ion battery. The composite diaphragm comprises a base diaphragm material; a protective layer coats the surface of the base diaphragm material and adopts a water-soluble bonding agent; a solvent used by slurry of the protective layer is water. The preparation method of the composite diaphragm comprises the steps of (1) evenly mixing inorganic particle powder, the water-soluble bonding agent and the solvent to obtain mixed powder; and (2) coating the single or double surfaces of a common commercially available diaphragm with the mixed powder obtained in the step (1) by a film applicator, carrying out vacuum drying, and removing the solvent to obtain the composite diaphragm, wherein the thickness of the composite diaphragm can be adjusted by controlling the concentration of the slurry and the parameters of the film applicator. The composite diaphragm can be applied to the preparation of a secondary battery and can be used for replacing an existing ceramic diaphragm, wherein the secondary battery comprises but not limited to a lithium ion battery.

Owner:XIAMEN UNIV +1

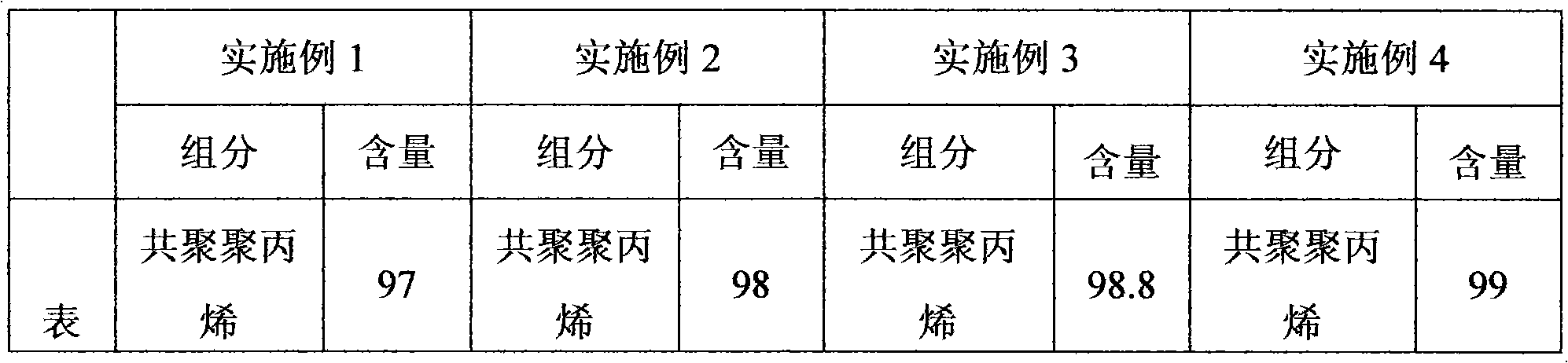

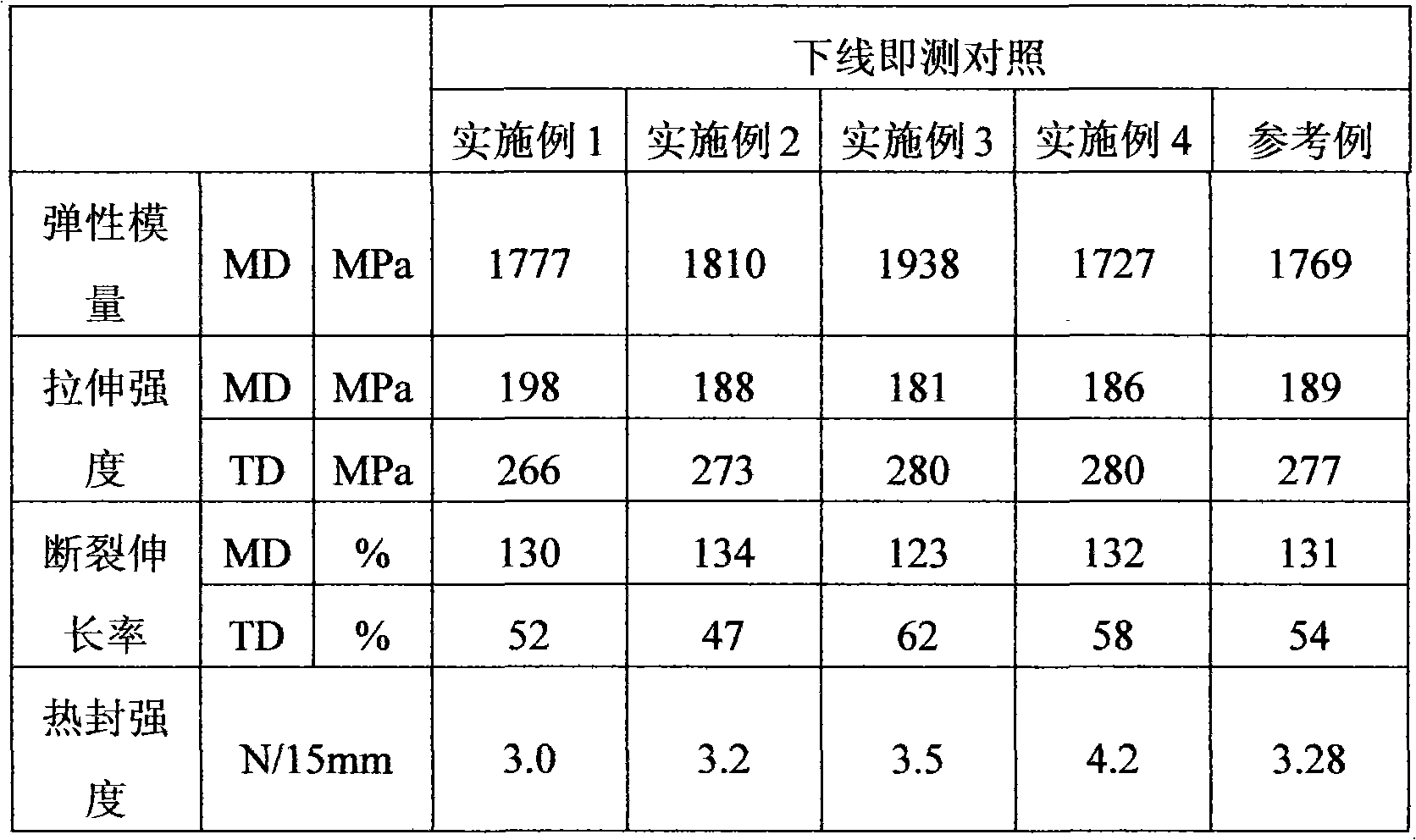

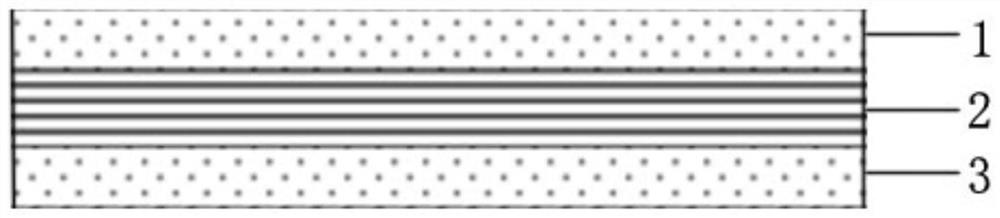

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

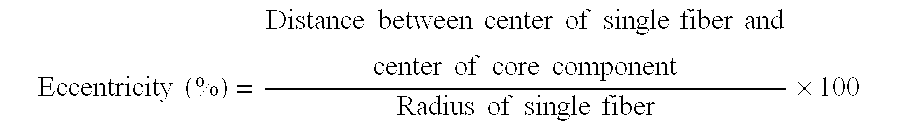

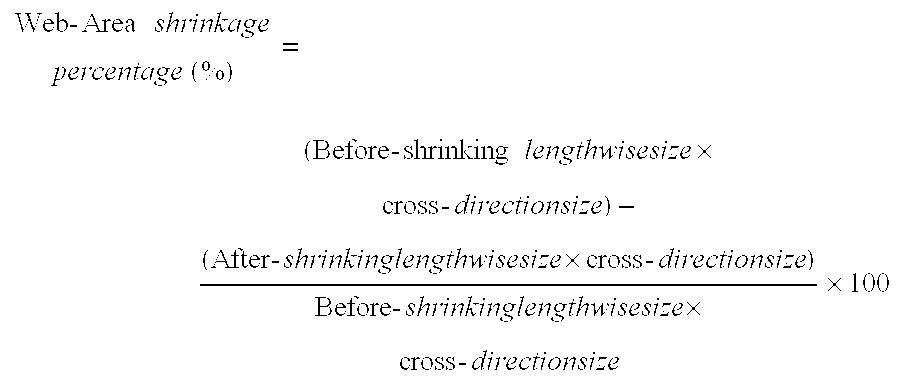

Potential crimping composite fiber and method for production thereof, and fiber aggregate, and nonwoven fabric

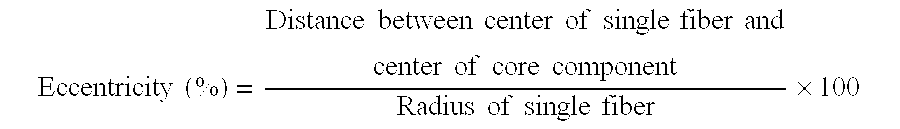

ActiveUS20070014987A1Facilitated to develop crimpHigh heat shrinkageSynthetic resin layered productsMelt spinning methodsSingle fiberDry heat

A latently crimpable conjugate fiber is constructed using a first component containing an ethylene-α-olefin copolymer polymerized with a metallocene catalyst and a second component formed from a thermal plastic polymer having a melting point T2 higher than a melting point T1 of the first component, such that the first component is exposed with an exposed length of at least 20% relative to a peripheral length of the fiber, and which fiber has a single fiber dry heat shrinkage percentage of at least 50%, which is determined according to JIS-L-1015 (dry heat shrinkage percentage) at 100° C. under an initial tension of 0.018 mN / dtex (2 mg / d) for 15 minutes and a single fiber dry heat shrinkage percentage of at least 15%, which is determined under the same condition under an initial tension of 0.450 mN / dtex (50 mg / dtex) for 15 minutes. The latently crimpable conjugate fiber develops crimps and has thermal adhesiveness at a low temperature.

Owner:DAIWABO HOLDINGS CO LTD

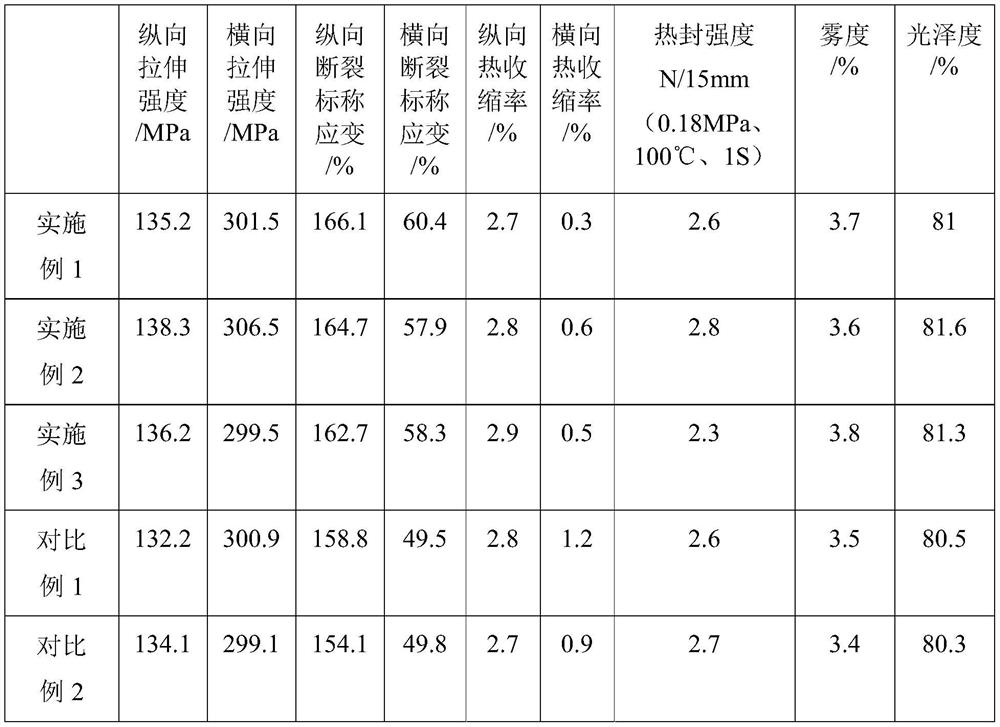

Biaxially oriented polypropylene high-modulus film master batch and production process thereof

The invention discloses biaxially oriented polypropylene high-modulus film master batch and a production process thereof. The biaxially oriented polypropylene high-modulus film master batch comprises the following components in percentage by mass: 50-60% of homo-polypropylene, 0-50% of an erectness enhancer, 0.2-1.0 of an antioxidant, 0.5-5% of cage-shaped polyhedral oligomeric silsesquioxane with a grain size of 0.5-10nm. According to the biaxially oriented polypropylene high-modulus film master batch disclosed by the invention, hydrogenated petroleum resin and the cage-shaped polyhedral oligomeric silsesquioxane cooperatively enhance the erectness, so that the erectness of the BOPP film is effectively improved; meanwhile, the BOPP film has the characteristics of low haze and high glossiness, can meet the using requirements of high-speed automatic packaging equipment, and is positive in practical significance.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

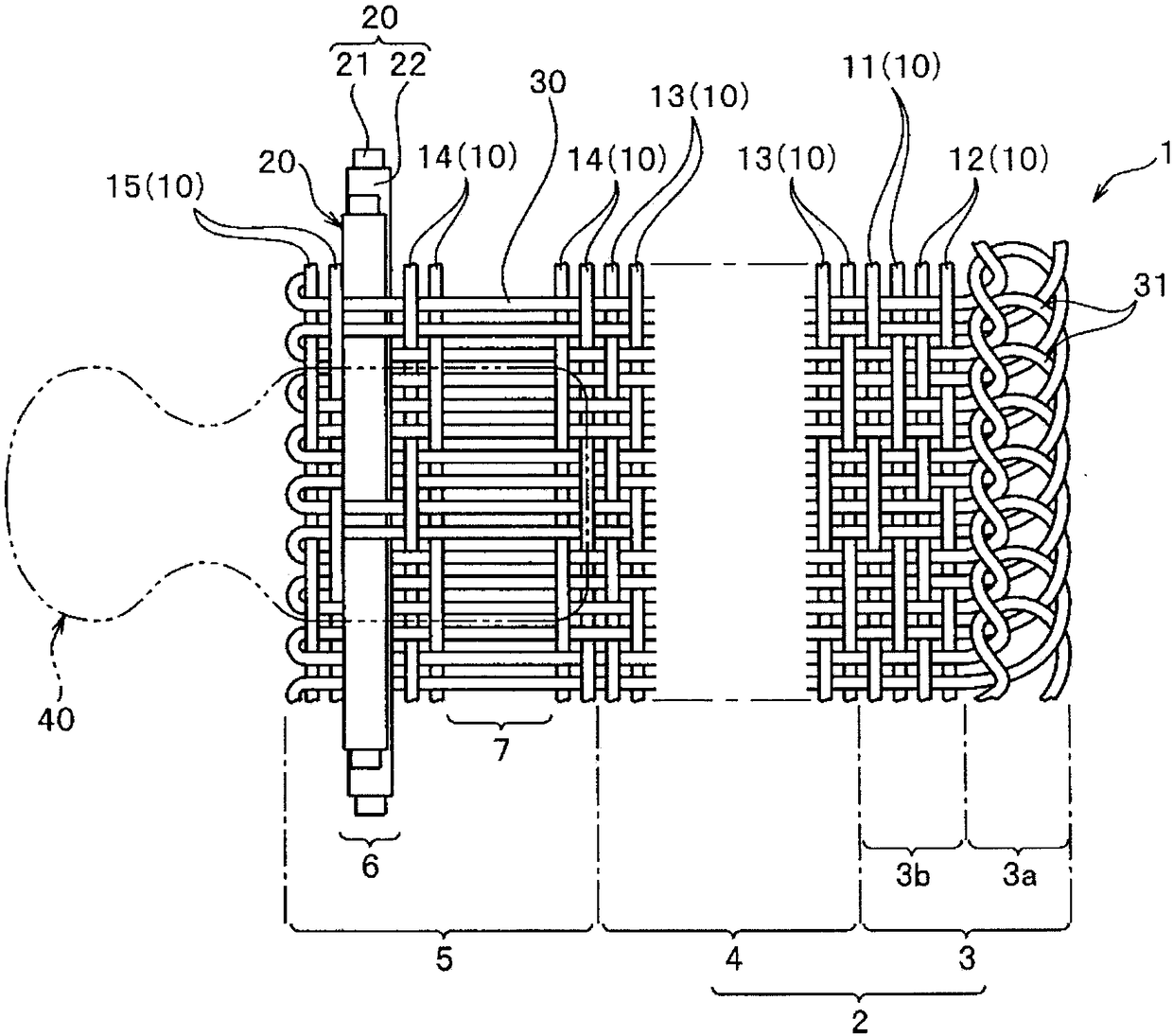

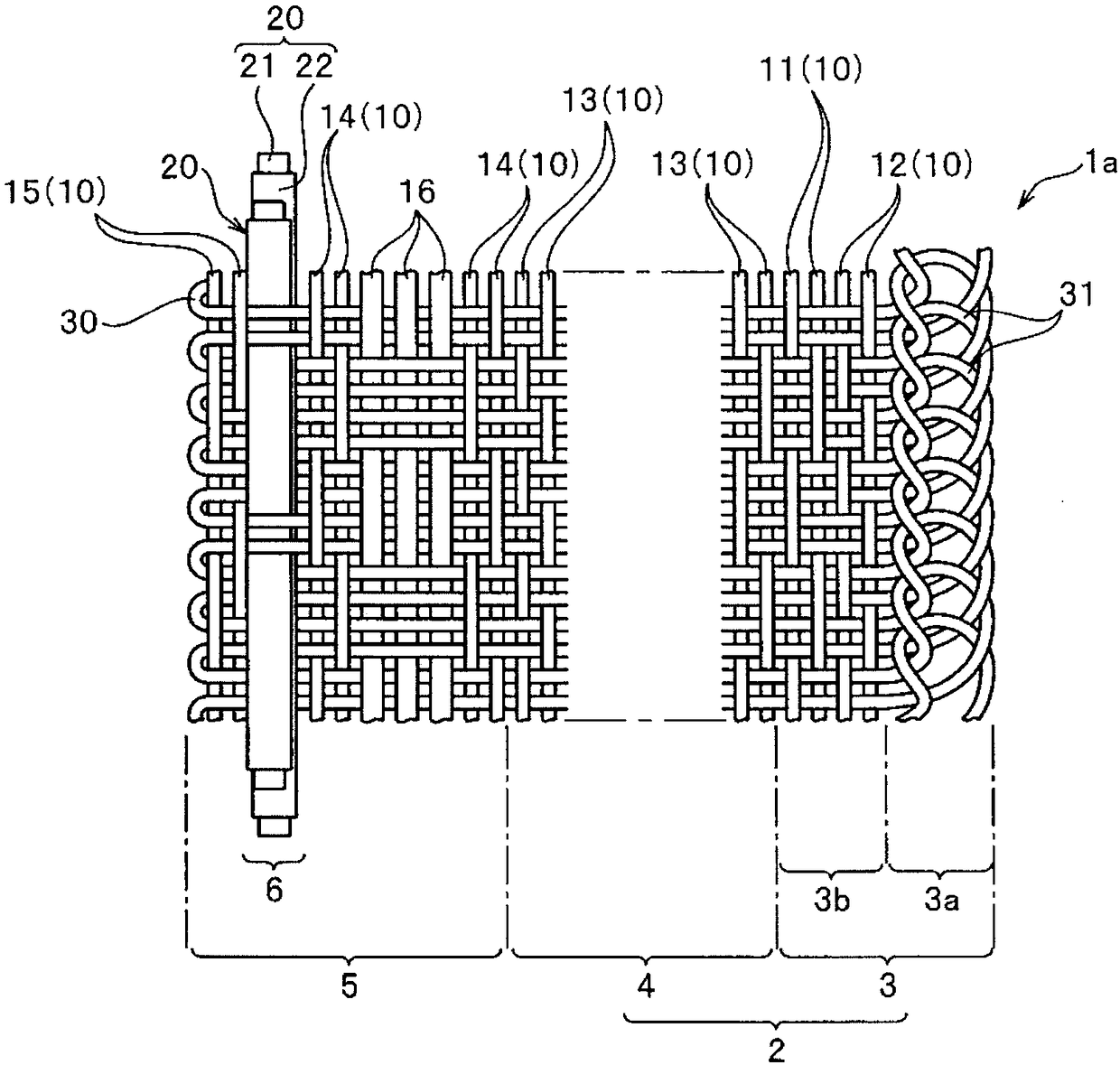

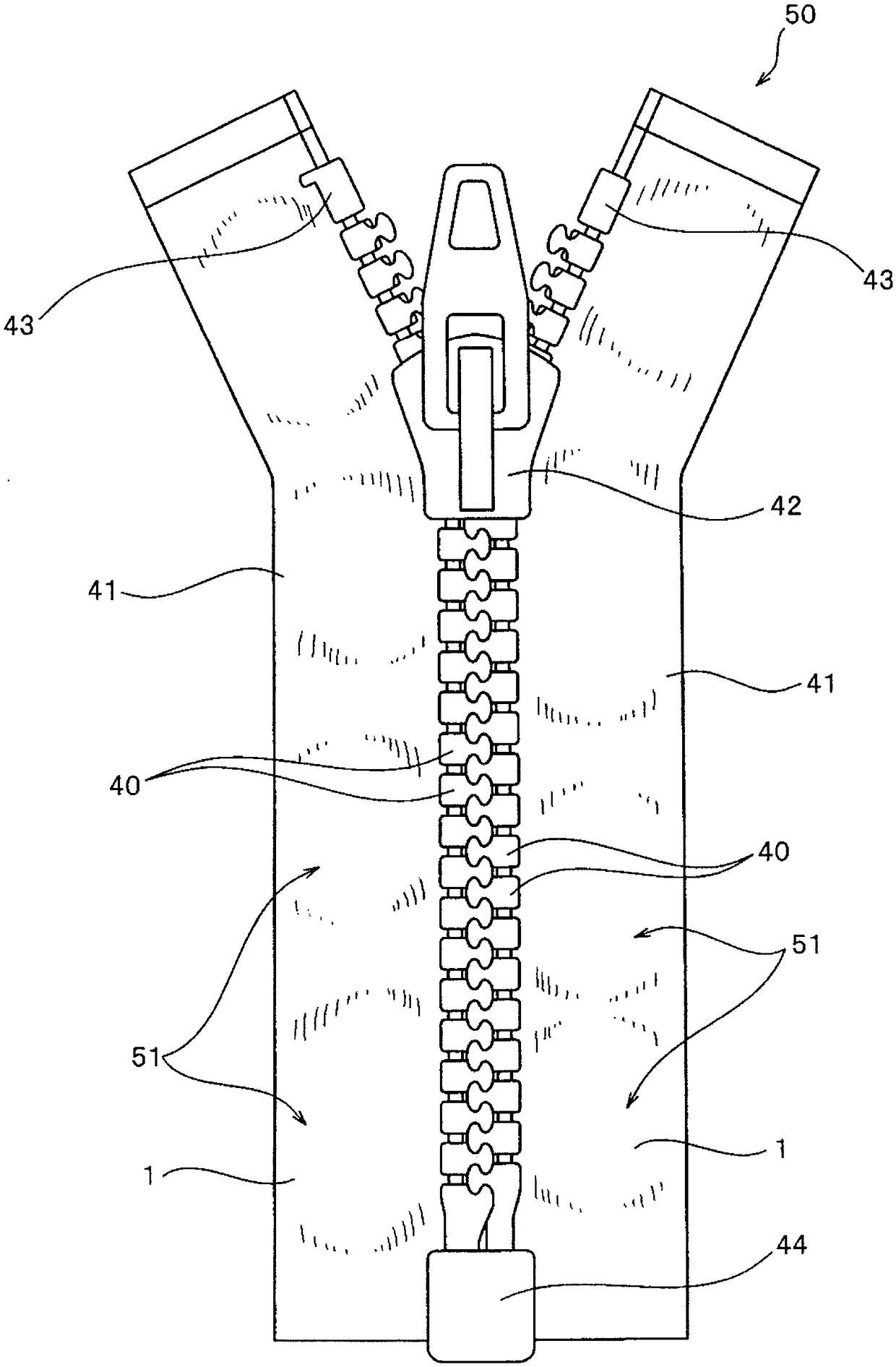

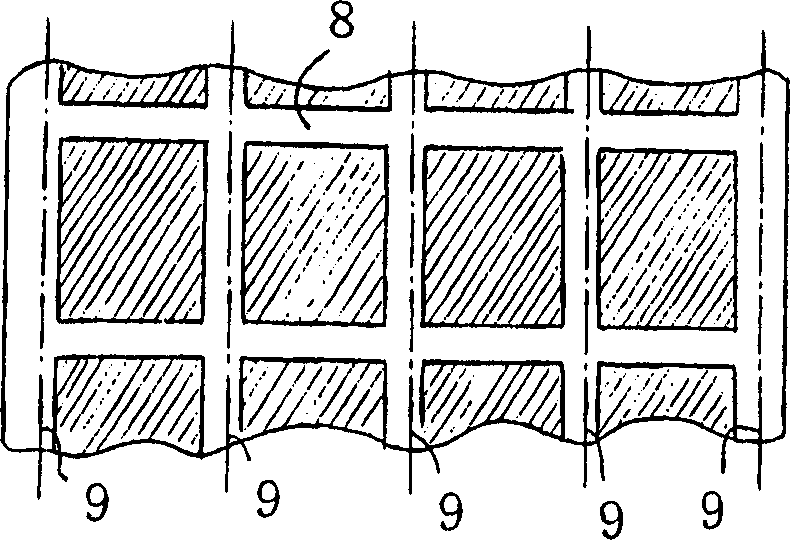

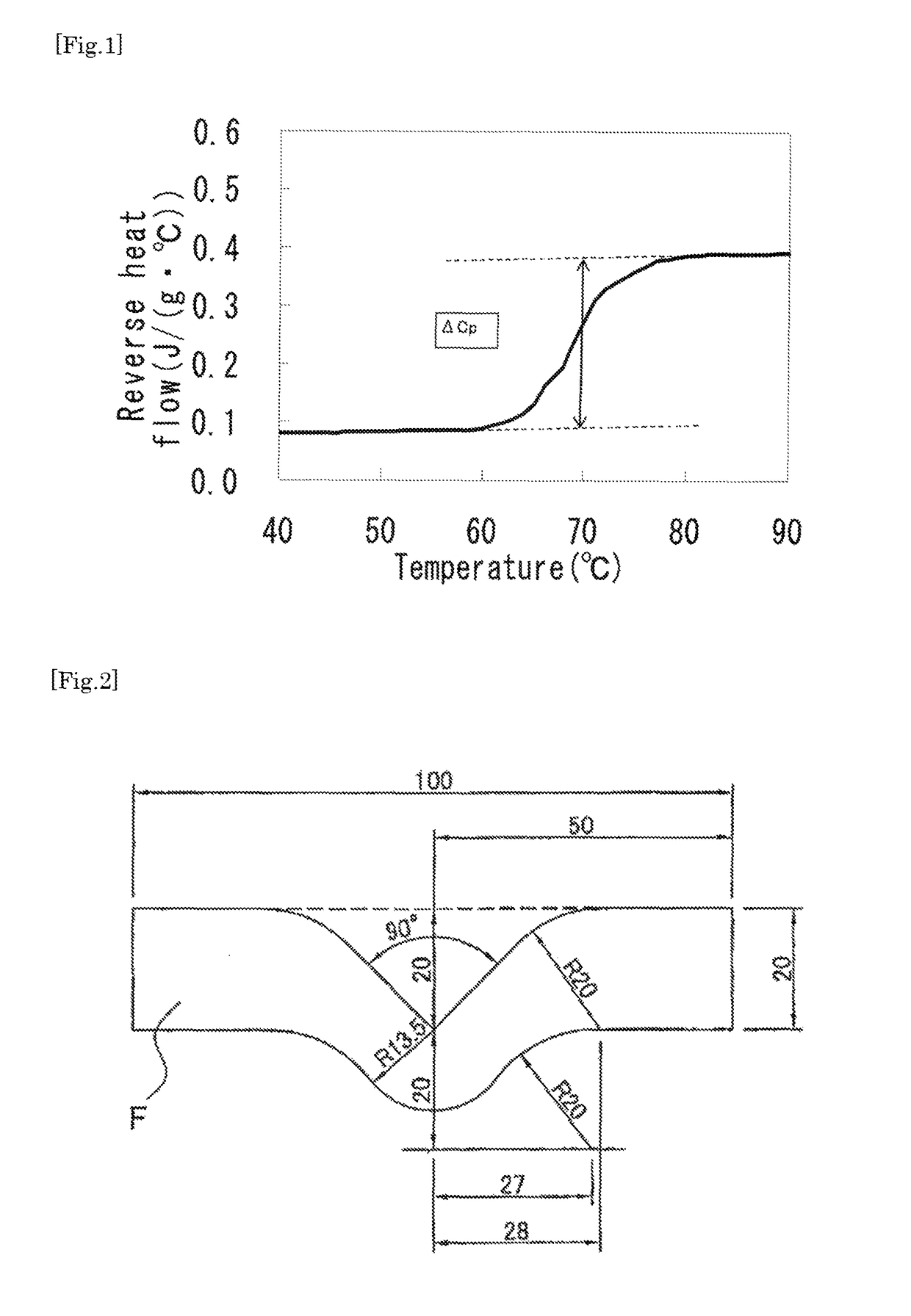

Zipper belt and zipper chain belt

The invention provides a zipper belt and a zipper chain belt, which can prevent reverse wrinkles when a zipper is woven to a product. Moreover, the problems caused by wrinkles in the zipper in the steps such as dyeing, delivering, injection moulding, and the like, are solved. The provided zipper belt (1,1b) comprises a belt main body (2) and a chain installation part (5) provided with a core rope(20). The belt main body (2) comprises an ear part (4) containing a plurality of warps (10) and a basic part (4) arranged between the ear part (3) and the chain installation part (5). The warps (10) of the basic part (4) are arranged in a more released state, compared with the at least one of the warps of the ear part (3) and the core rope (20).

Owner:YKK CORP

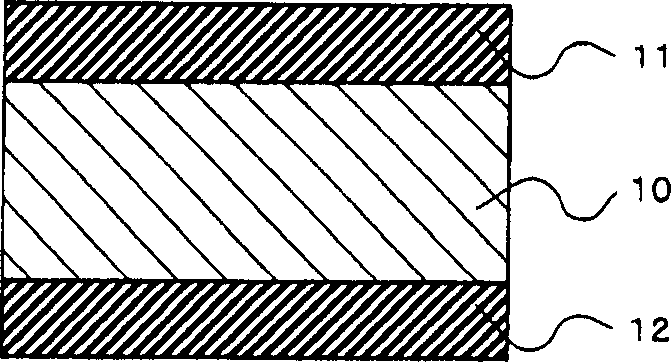

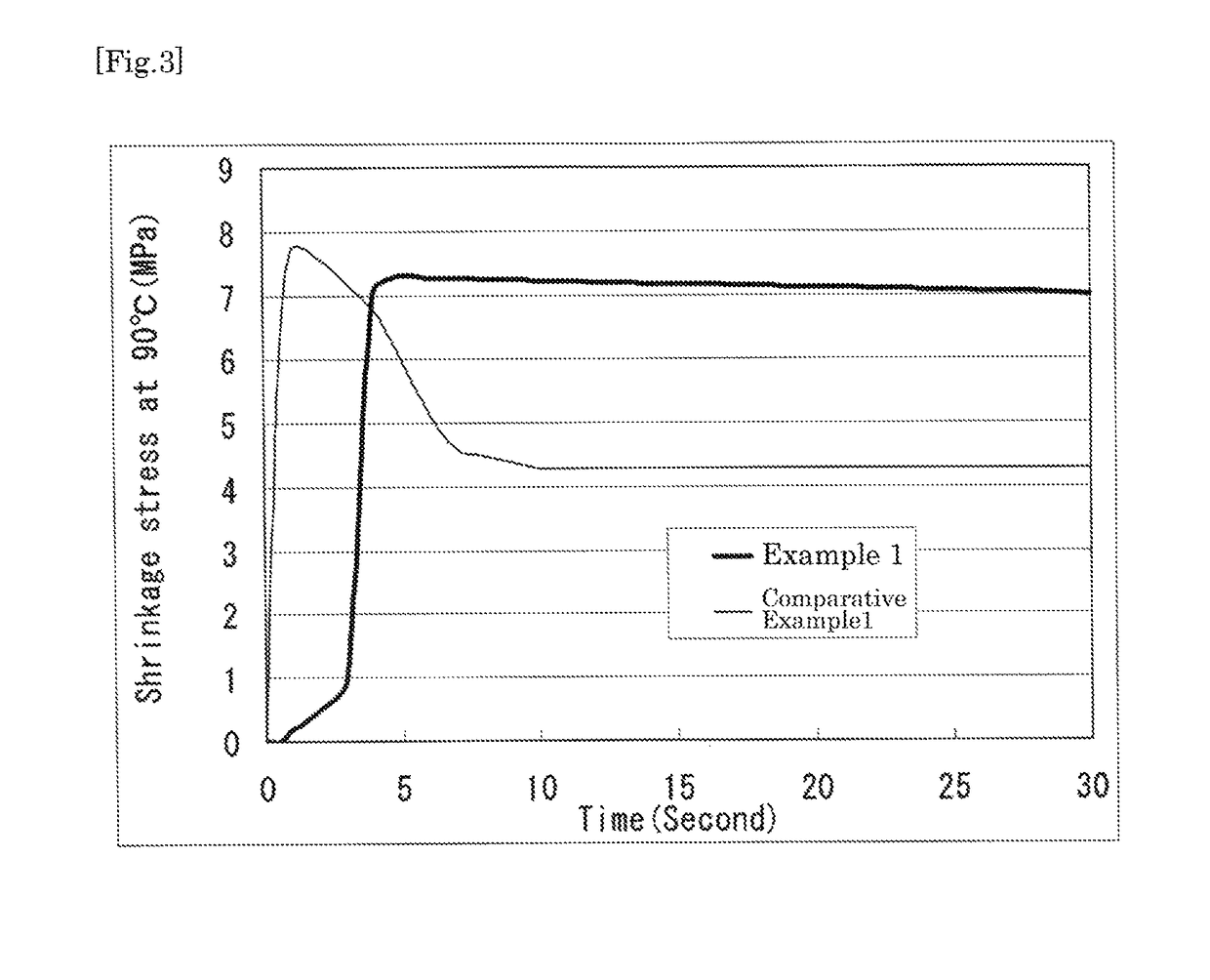

Multilayer heat-shrinkable film and containers fitted with labels made from the film through heat shrinkage

ActiveCN1802252AHigh transparencyImprove heat resistanceStampsSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

A multilayer heat-shrinkable film which is constituted of at least three layers comprising two surface layers made of a resin composition comprising 55 to 95% by mass of a cyclic olefin resin and 45 to 5% by mass of linear low-density polyethylene and an interlayer made of a resin composition comprising 95 to 55 % by mass of a propylene / alpha-olefin random copolymer or a resin composition containing this copolymer as the main component and 5 to 45% by mass of a cyclic olefin resin and which exhibits a crosswise heat shrinkage of 50% or above when immersed in water at 90 DEG C for 10 seconds and a lengthwise tear propagation strength of 800 to 350mN. This multiplayer heat-shrinkable film has a low specific gravity, does not cause on heat shrinkage whitening due to the staining with fingerprints, and is excellent in heat-shrinkage characteristics and perforation characteristics, thus being suitable for labels.

Owner:GUNZE LTD +1

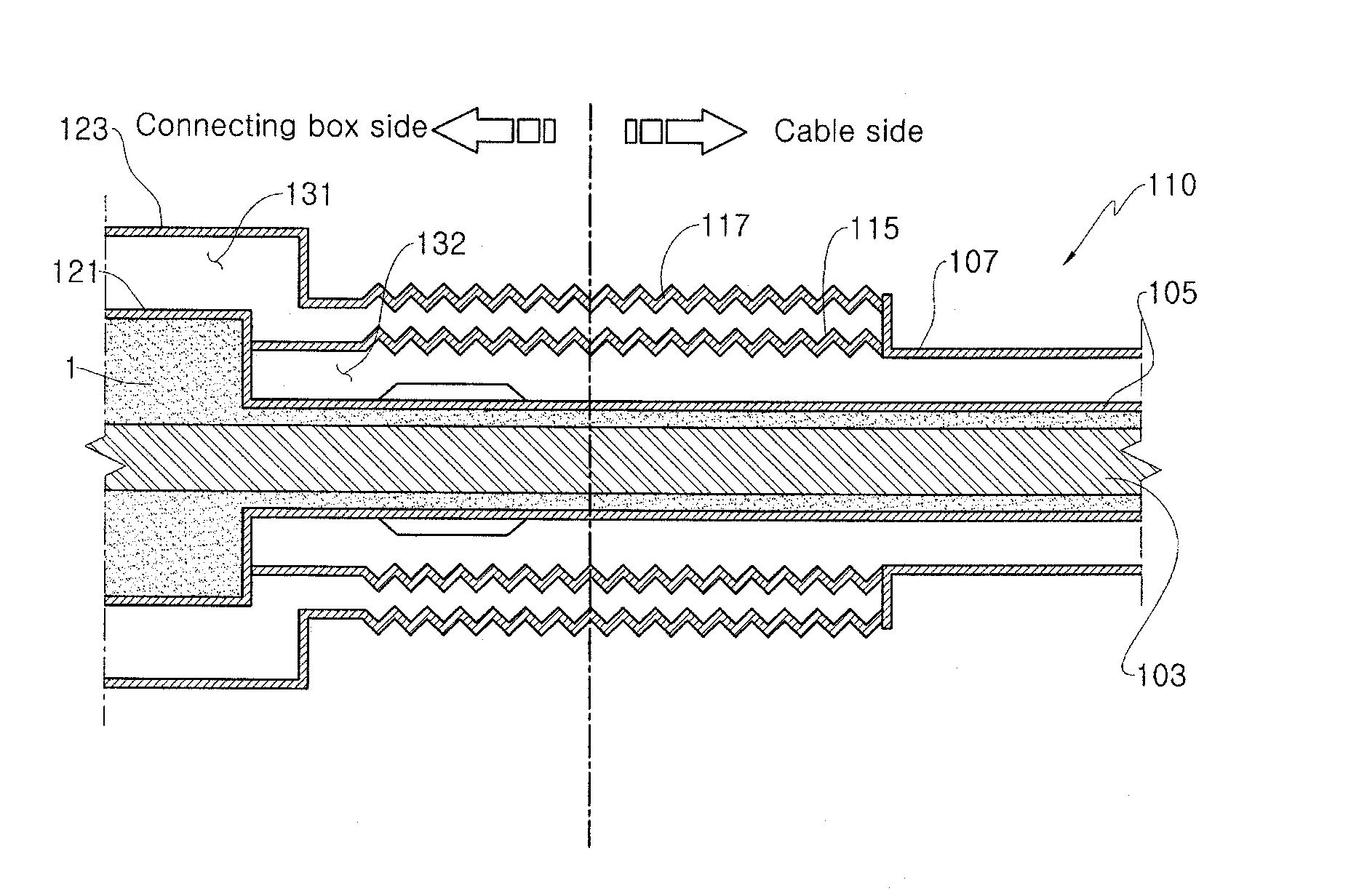

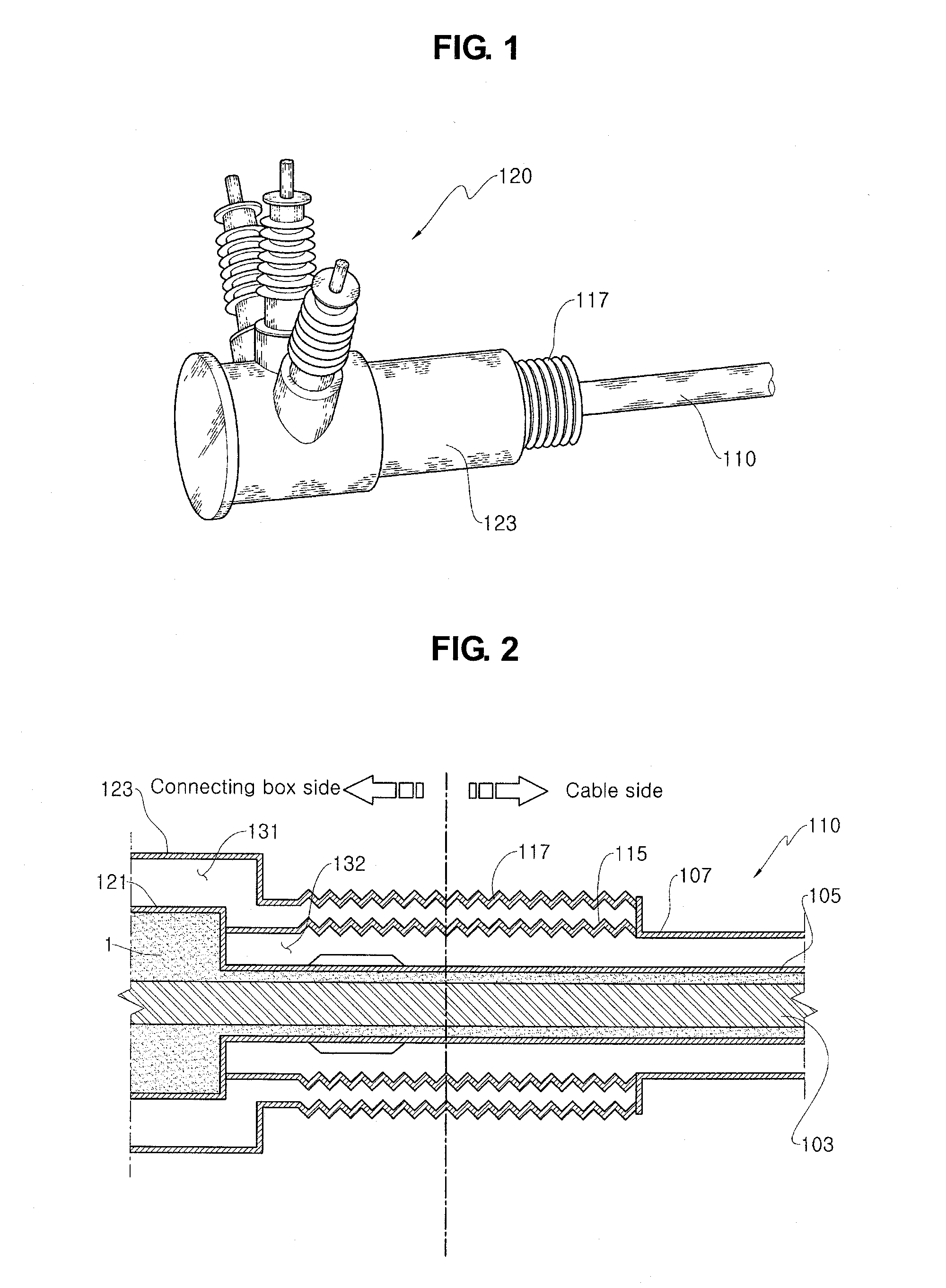

Cryostat of superconducting cable

InactiveUS20100199689A1Spatial separationHigh heat shrinkageSuperconductors/hyperconductorsInsulated cablesEngineeringLiquid nitrogen

A cryostat of a superconducting cable disclosed herein includes an inner metallic tube filled with liquid nitrogen and extended along the circumference of a core, an outer metallic tube surrounding the circumference of the inner metallic tube at a distance, a cooling vessel of a terminal connecting box connected to the inner metallic tube and filled with liquid nitrogen, an insulation tube surrounding the circumference of the cooling vessel at a distance, an inner bellows tube connecting an end of the outer metallic tube to the cooling vessel, and an outer bellows tube spaced apart from the inner bellows tube and connecting the end of the outer metallic tube to the insulation tube.

Owner:LG CABLE LTD (KR)

Heat-shrinkable polyolefin film

InactiveCN1488492AHigh heat shrinkageEasy to industrializeSynthetic resin layered productsFlat articlesVitrificationPolyolefin

Owner:TOYOBO CO LTD

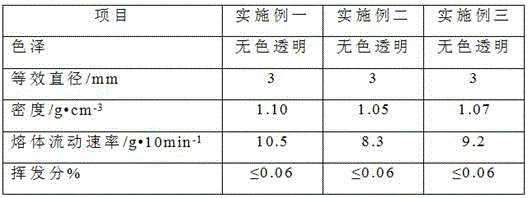

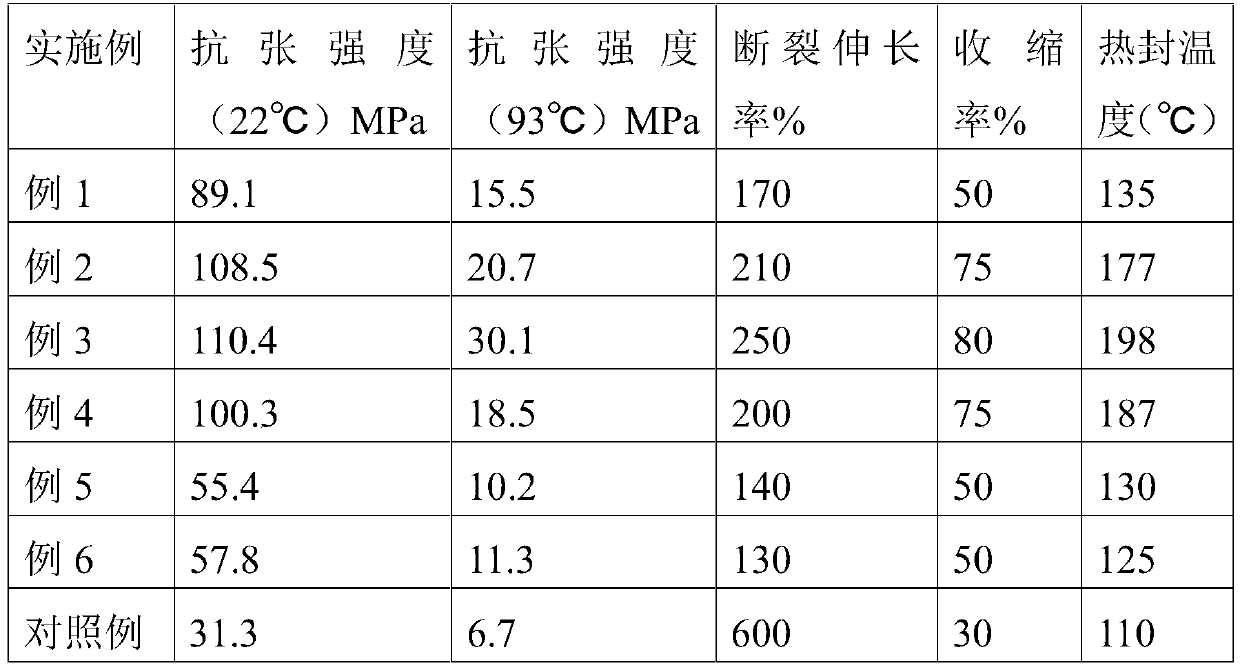

Biaxially oriented poly lactic acid (BOPLA) thermal contraction type film for high-speed automatic packaging machine, and preparation method of BOPLA thermal contraction type film

ActiveCN104592724ABroaden molecular weight distributionReduce forceFlat articlesSilane couplingThermal contraction

The invention relates to a biaxially oriented poly lactic acid (BOPLA) thermal contraction type film for a high-speed automatic packaging machine. The film comprises the following components: high molecular weight polylactic resin, low molecular weight polylactic resin, nanoscale inorganic filler and a silane coupling agent, wherein the mass ratio of the high molecular weight polylactic resin to the low molecular weight polylactic resin is equal to (1-20): 1, the dosage of the nanoscale inorganic filler is 0.6-1.2% of that of the total polylactic resin, and the dosage of the silane coupling agent is 0.1-2% of that of the inorganic filler; a preparation method of the BOPLA thermal contraction type film for the high-speed automatic packaging machine comprises the steps of evenly mixing all the components according to the content, carrying out melt extrusion, casting a sheet by curtain coating, and preparing the BOPLA thermal contraction type film by adopting a biaxially oriented method. The BOPLA thermal contraction type film has the beneficial effects that the BOPLA thermal contraction type film prepared by the technical scheme is low in friction coefficient, good in heat seal performance, high in hot-shrinkage rate and excellent in mechanical property, so that the requirements for the thermal contraction type film used for the automatic packaging machine can be met.

Owner:常州钟恒新材料股份有限公司

Method for producing two-way stretching polypropylene film for cigarette by pipe soaking method

The production process of polypropylene film includes the following steps: mixing polypropylene resin and functional mother material in certain ratio, co-extruding in extruder to form initial tubular film; fast cooling of the initial tubuler film; preheating at 260-400 deg.c in a stove; transverse blowing to expand for 5.0-8.0 times at 300-510 deg.c in a stove; longitudinal stretching for 6.5-8.0 times at 135-150 deg.c; wind cooling, winding, cutting rewinding and re-cutting. Compared with available plain drawing process, the present invention has the advantages of small covered area, less investment and high heat shrinkage of the product.

Owner:海南日新酒店管理有限公司

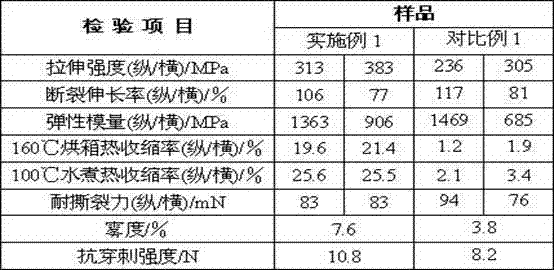

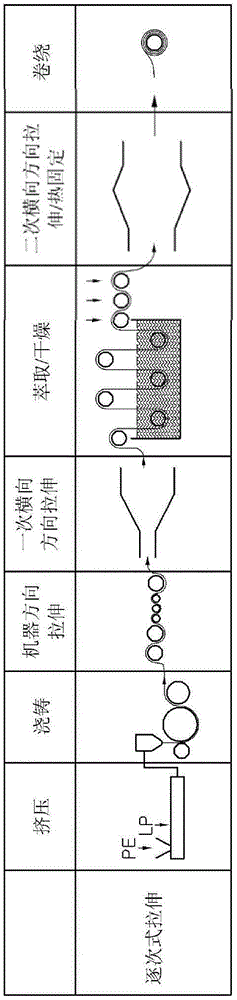

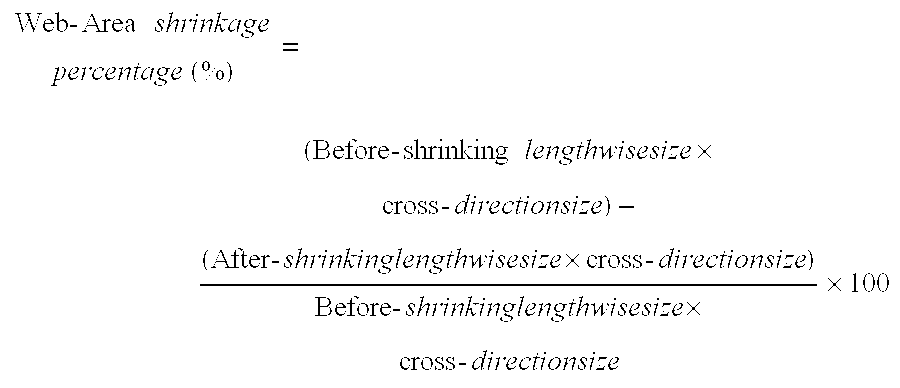

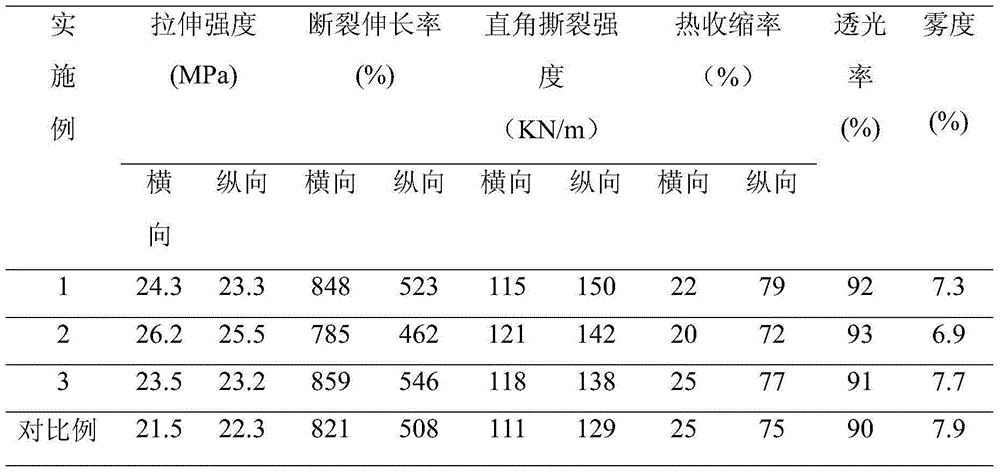

Production process of thermal contraction two-way stretch polyamides film

The invention discloses a production process of a two-way stretch polyamides (BOPA) film, which comprises the following steps of enabling the polyamides (PA) masterbatch to be fused and extruding a formed film out through a three-extrusion extruder; cooling and shaping to obtain coarse products of PA thin films; enabling the coarse products of the PA thin films to respectively conduct longitudinal stretch and transverse stretch, and rolling to obtain products. Each index of the BOPA film produced by using the method meets national food safety standards, and can not only effectively separate oxygen as a general BOPA film, but also have high heat contractibility rate. Experimental data indicate that the thermal contraction two-way stretch polyamides film is boiled in water at the temperature of 100 DEG C for 30 minutes, longitudinal contractibility rate and transverse contractibility rate are both not lower than 10%, and product appearance of food packages prepared by using the BOPA film is still smooth and free of puckering after high temperature sterilization.

Owner:FSPG HI TECH

Anti-ultraviolet PET film and preparation method thereof

The invention discloses an anti-ultraviolet PET film and a preparation method thereof. The anti-ultraviolet PET film comprises the following raw materials by weight part: PET polyester chip, vinyl organic silicon resin, conductive polymer resin, a silane coupling agent, toluene, butanone, a first ultraviolet absorbent, a second ultraviolet absorbent, an anti-scratch agent, an anti-blocking agent, an oily nano-titanium dioxide dispersion agent, a thioxanthone photoinitiator, glycerol, an antioxidant, and calcium stearate. The anti-ultraviolet PET film provided by the invention has the characteristics of good heat sealability, high heat shrinkage, easy recovery and good mechanical properties, contains ultraviolet absorbents, and can absorb ultraviolet. Also the ultraviolet absorbents are difficult to migrate, thus greatly prolonging the timeliness of the anti-ultraviolet function. The anti-ultraviolet PET film provided by the invention can be used for making anti-ultraviolet heat-insulating film products, can be used for ultraviolet protection of automobiles, constructions and the like, effectively blocks the harmful ultraviolet encountered in daily life, and avoids the damage of ultraviolet to the human body.

Owner:GUANGDONG SHANG XIN NEW MATERIALS CO LTD

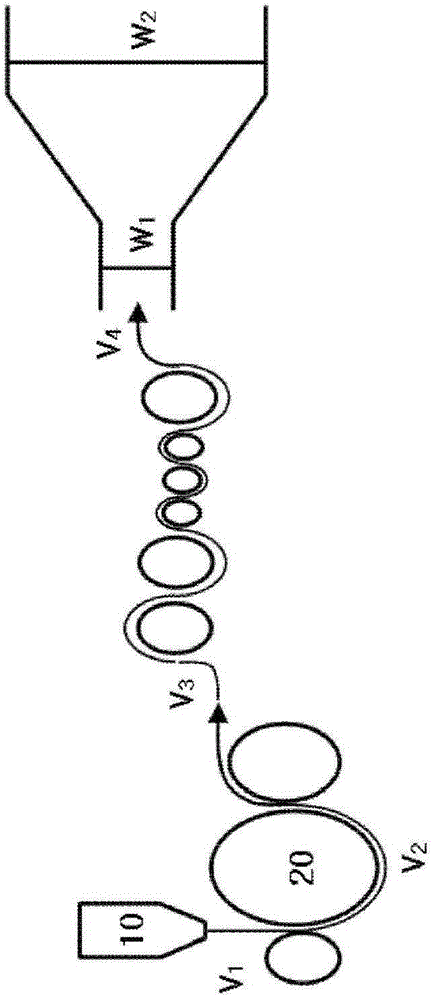

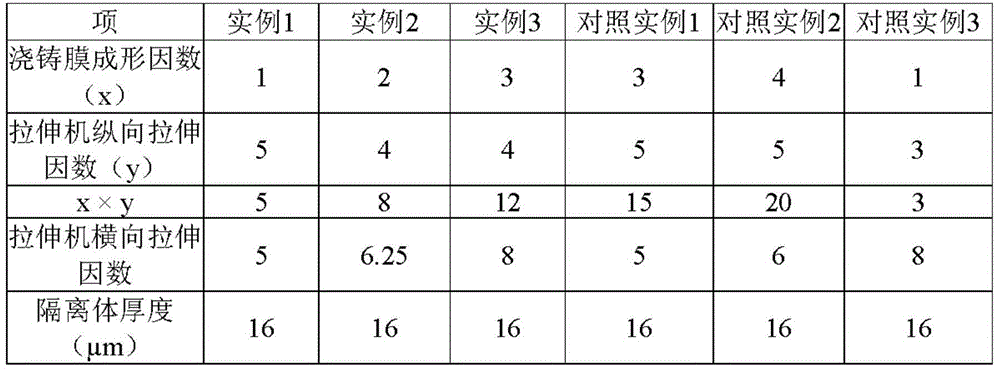

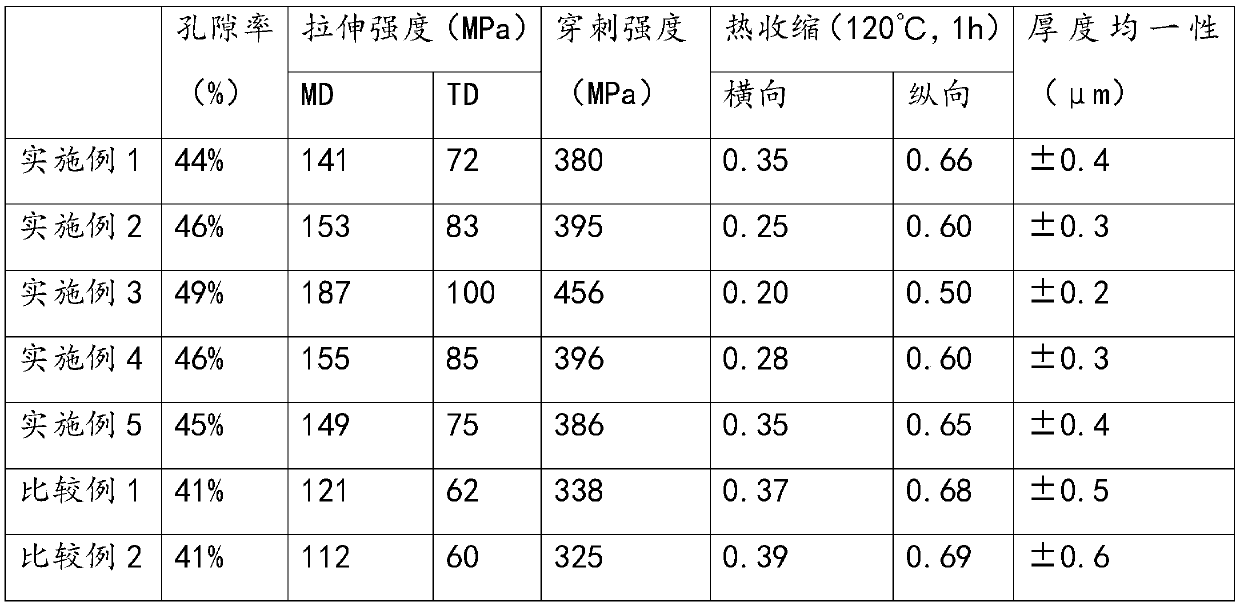

Method for producing separation membrane, and said separation membrane and battery using same

InactiveCN104871342AHigh tensile strengthHigh heat shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufacturePolyolefinElectrical battery

The present invention relates to a method for producing a polyolefin-based porous separation membrane and, more particularly, to a method for producing a separation membrane having improved tensile strength and thermal shrinkage rate by adjusting the stretching factor of a base film during the casting and stretching processes of a separation membrane production process. Also, the present invention relates to a polyolefin-based porous separation membrane having a small difference in tensile strength between the longitudinal direction and the transverse direction of the separation membrane, excellent tensile strength, and improved thermal shrinkage rate and improved puncture strength. Further, the present invention relates to an electrochemical battery of which the dimensional stability under heat and tension is improved using the separation membrane.

Owner:SAMSUNG SDI CO LTD

Latently crimpable conjugate fiber and production method of the same, and fiber assembly, and nonwoven

ActiveUS7670677B2Facilitated to develop crimpHigh heat shrinkageSynthetic resin layered productsMelt spinning methodsSingle fiberCopolymer

A latently crimpable conjugate fiber is constructed using a first component containing an ethylene-α-olefin copolymer polymerized with a metallocene catalyst and a second component formed from a thermal plastic polymer having a melting point T2 higher than a melting point T1 of the first component, such that the first component is exposed with an exposed length of at least 20% relative to a peripheral length of the fiber, and which fiber has a single fiber dry heat shrinkage percentage of at least 50%, which is determined according to JIS-L-1015 (dry heat shrinkage percentage) at 100° C. under an initial tension of 0.018mn / dtex (2mg / d) for 15 minutes and a single fiber dry heat shrinkage percentage of at least 15%, which is determined under the same condition under an initial tension of 0.450mN / dtex (50mg / dtex) for 15 minutes. The latently crimpable conjugate fiber develops crimps and has thermal adhesiveness at a low temperature.

Owner:DAIWABO HOLDINGS CO LTD

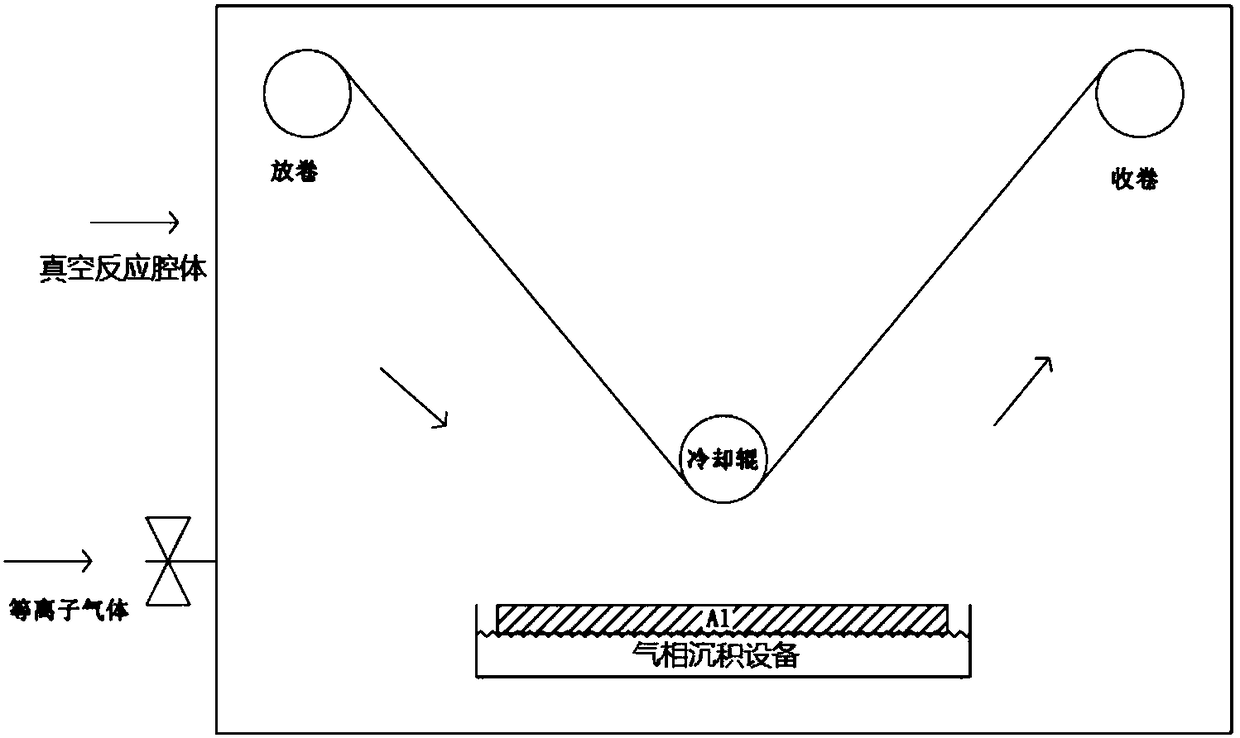

Preparation method of lithium ion battery diaphragm, lithium ion battery diaphragm and lithium ion battery

InactiveCN109004159AGuaranteed Uniformity and ConsistencyLow heat shrinkageSecondary cellsCell component detailsChemistryLithium electrode

The invention belongs to the technical field of lithium ion batteries and relates to a preparation method of a lithium ion battery diaphragm, a lithium ion battery diaphragm and a lithium ion battery.The preparation method of the invention comprises the following steps: fixing a base material in an unwinding mechanism in a vacuum reaction chamber, and introducing optional coating material plasmagas into the vacuum reaction chamber; The coating material is vaporized into a vacuum reaction chamber by vapor deposition equipment, and the coating material is deposited on the base material by a vapor deposition method; the base material with the coating material deposited on the surface is stored in the winding mechanism; A cooling roller is also arranged between the unwinding mechanism and the winding mechanism, and the cooling roller is located above the vapor deposition equipment. The thickness of the coating is greatly reduced compared with the traditional process, the coating has goodair permeability and uniformity; The equipment has high cleanliness, the quantity of impurities introduced is greatly reduced, and the slurry does not need to be prepared, which can reduce the environmental pollution; and The coating has no additive and excellent thermal stability and oxidation resistance are achieved in a high temperature and high pressure system.

Owner:CHANGZHOU XINGYUAN NEW ENERGY MATERIAL CO LTD

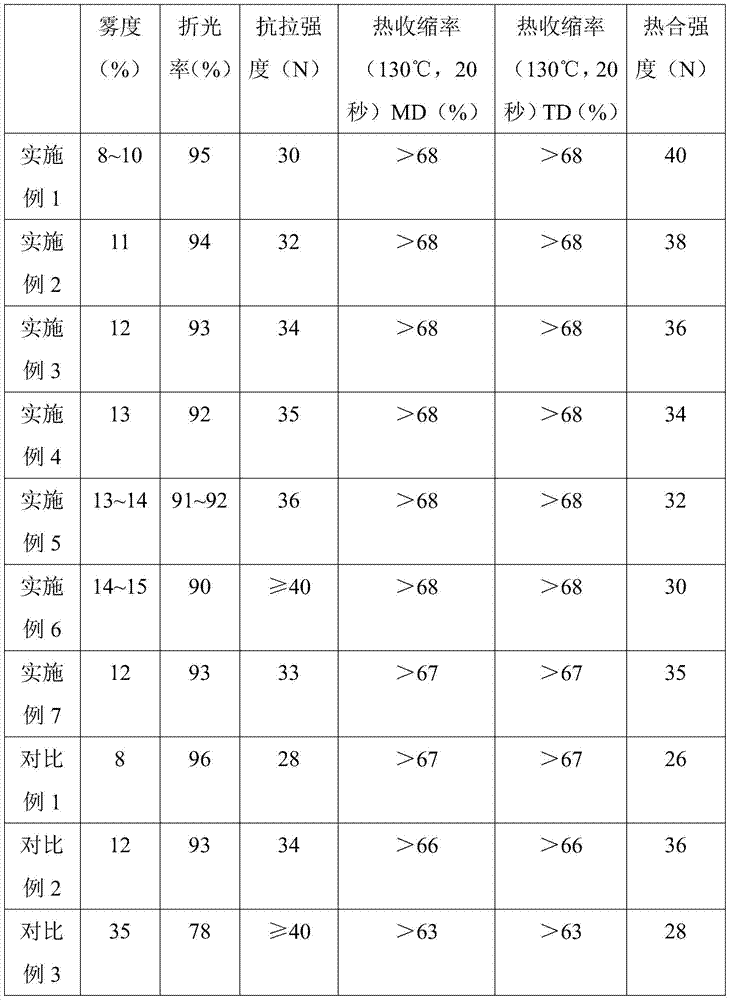

High-transparency and high-strength heat shrinkage film

InactiveCN106965511ASimple recipeSave raw materialsSynthetic resin layered productsDomestic articlesHigh densityRefractive index

The present invention discloses a high-transparency and high-strength heat shrinkage film, which comprises an inner layer, an outer layer and a middle layer, wherein the inner layer and the outer layers respectively comprise, by weight, more than or equal to 50% of mLLDPE and less than or equal to 50% of LLDPE, the melt indexes of mLLDPE and LLDPE are less than or equal to 0.5 g / 10 min, and the densities of mLLDPE and LLDPE are greater than or equal to 0.920 g / cm<3>. According to the present invention, the inner layer and the outer layer only comprise mLLDPE and LLDPE, and do not use auxiliary agents and other polyethylene materials, such that the formula is simple, and the raw materials are saved; and by using mLLDPE having low melting index and high density and LLDPE having low melting index and high density, the heat shrinkage film has advantages of high tensile strength (more than 30 N), good transparency (the mist degree is 8-15%), good heat-sealing strength (the heat-sealing strength of the existing heat shrinkage film is about 20-25 N while the heat shrinkage film of the present invention is 30-40 N), and good refractive index (more than 90%).

Owner:杭州德雅包装有限公司

Polyethylene/ polypropylene/ polypropylene three-layer co-extrusion upward bowing film and preparation method thereof

InactiveCN105150648AIncreased tensile elongation at breakHigh tear strengthSynthetic resin layered productsLaminationPolypropyleneBinding force

The invention provides a polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film and a preparation method thereof and belongs to the technical field of high molecular materials. The polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film and the preparation method solve the problems that existing PP melt is low in intensity, and it is difficult to keep transparency after blending and toughening are conducted. The inner layer and the outer layer of the upward blowing film are ethylene blender, and the middle layer is propylene random copolymer. The invention further provides the preparation method of the polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film. The propylene random copolymer is selected to serve as the middle layer of the upward blowing film, the tensile elongation yield and the tearing strength of the PP film can be effectively improved, proper models of PE and PP are blended to serve as the inner layer and the outer layer, the compatibility of the middle layer of the PP film and the PE of the inner layer and the outer layer can be increased, the binding force among layers is improved, the stripping phenomenon among layers is avoided, the transparency of PP can be kept, and the hot-shrinkage rate of multiple layers of films is raised.

Owner:公主岭华美塑料制品有限公司

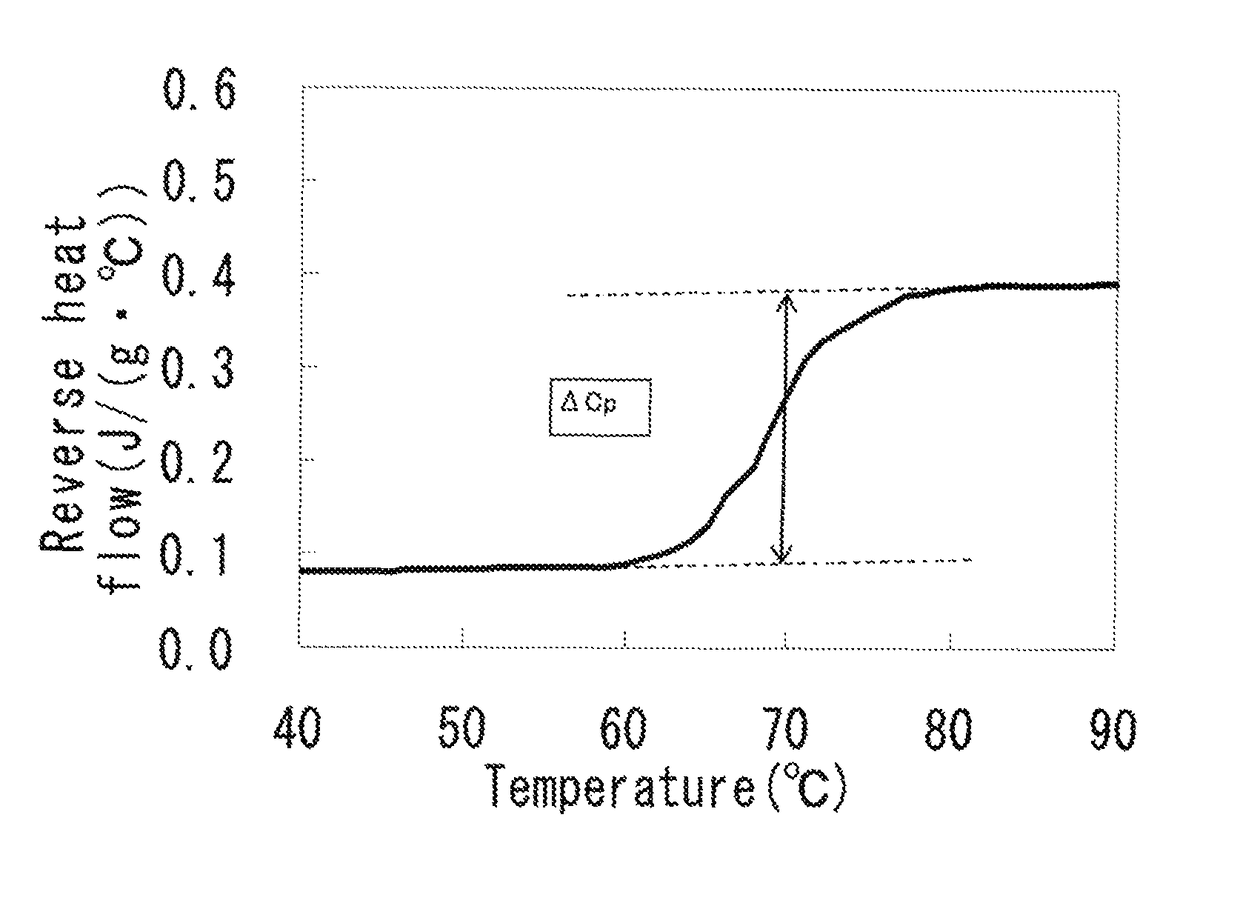

Heat-shrinkable polyester film and package

ActiveUS10035335B2High heat shrinkageEffective installationContainer decorationsLevel indicationsBreaking strengthPolyester

The invention provides a heat shrinkable polyester film which has (1) a hot-water heat shrinkage of not less than 55% and not more than 90% in a main shrinking direction of the film when dipped in hot water at 98° C.; (2) a hot-water heat shrinkage of not less than −5% and not more than 12% in a direction orthogonal to the main shrinking direction of the film when dipped in hot water at 98° C.; (3) a difference in specific heat capacity ΔCp between at a lower and a higher temperature than Tg of not less than 0.1 J / (g·° C.) and not more than 0.7 J / (g·° C.) when a reverse heat flow is measured with a temperature modulated DSC; and (4) a tensile breaking strength of not less than 70 MPa and not more than 150 MPa in the direction orthogonal to the main shrinking direction of the film.

Owner:TOYOBO CO LTD

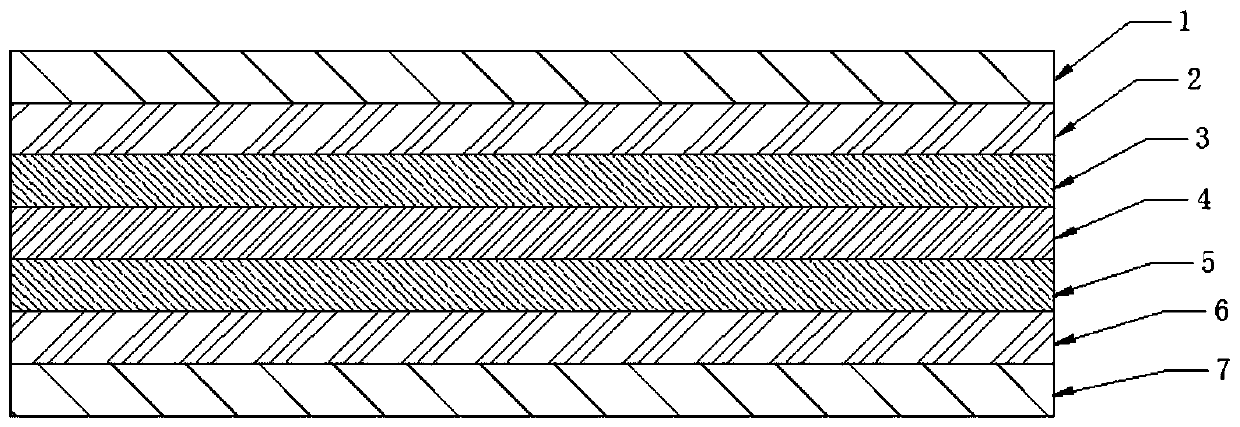

High-barrier puncture-resistant irradiation crosslinking type multilayer heat shrinkage film and preparation method thereof

InactiveCN110920185AStrong resistance to deformationHigh tensile strengthSynthetic resin layered productsDomestic containersPolymer scienceTotal thickness

The invention discloses a high-barrier puncture-resistant irradiation crosslinking type multilayer heat shrinkage film. The multilayer heat shrinkage film comprises a first PE film layer, a first adhesive film layer, a first PA film layer, a middle EVOH film layer, a second PA film layer, a second adhesive film layer and a second PE film layer which are formed through coextrusion; the total thickness of the multilayer heat shrinkage film is 30-200 [mu]m, and the respective thickness of the first PE film layer and the second PE film layer is 5-40% of the total thickness; and the respective thickness of the first adhesive film layer and the second adhesive film layer is 2-10% of the total thickness, the respective thickness of the first PA film layer and the thickness of the second PA film layer is 2-15% of the total thickness, and the thickness of the EVOH film layer is 2-10% of the total thickness. The provided multilayer heat shrinkage film has high barrier properties and excellent puncture resistance.

Owner:JIANGYIN BAOBO PACKING

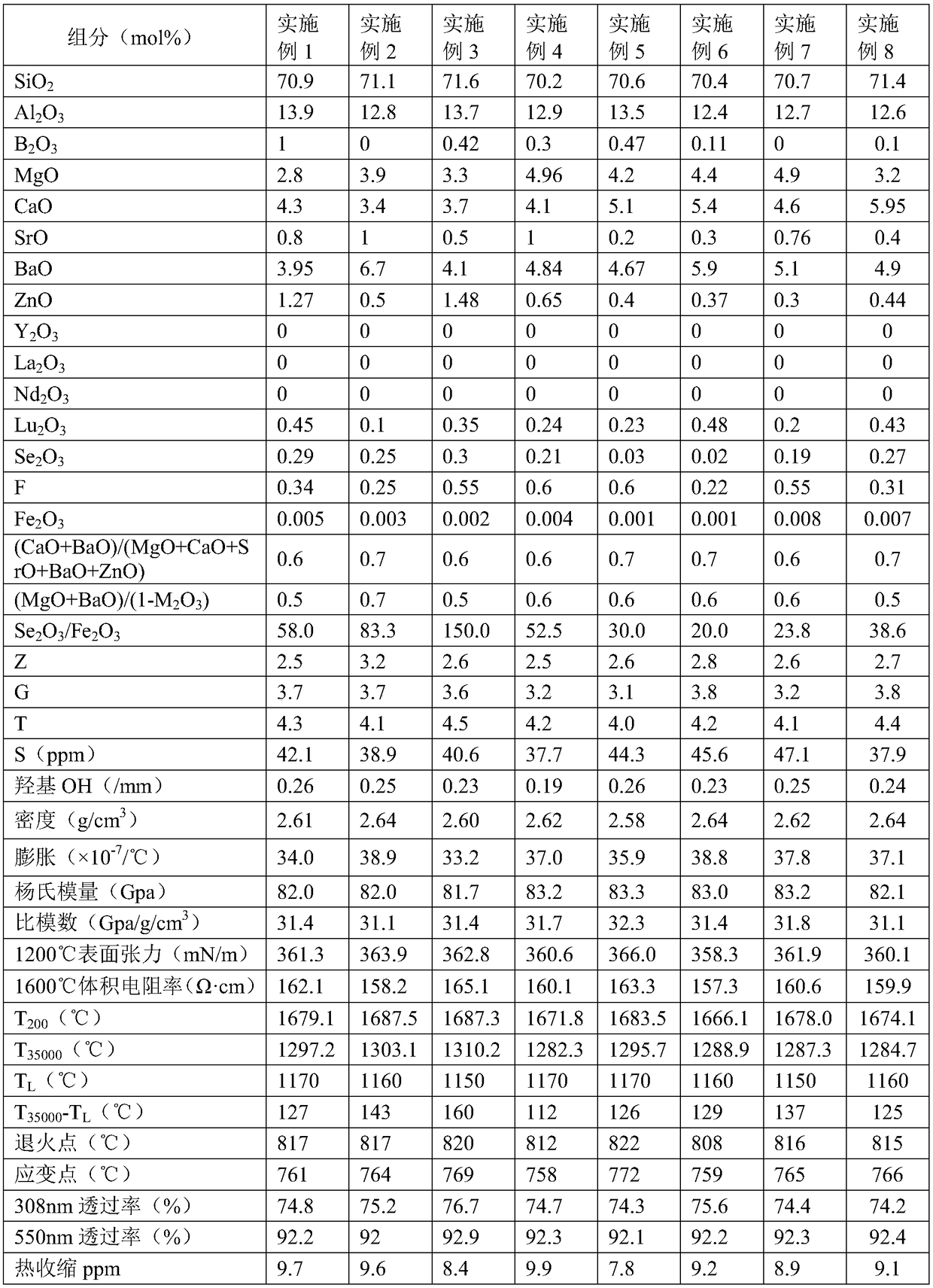

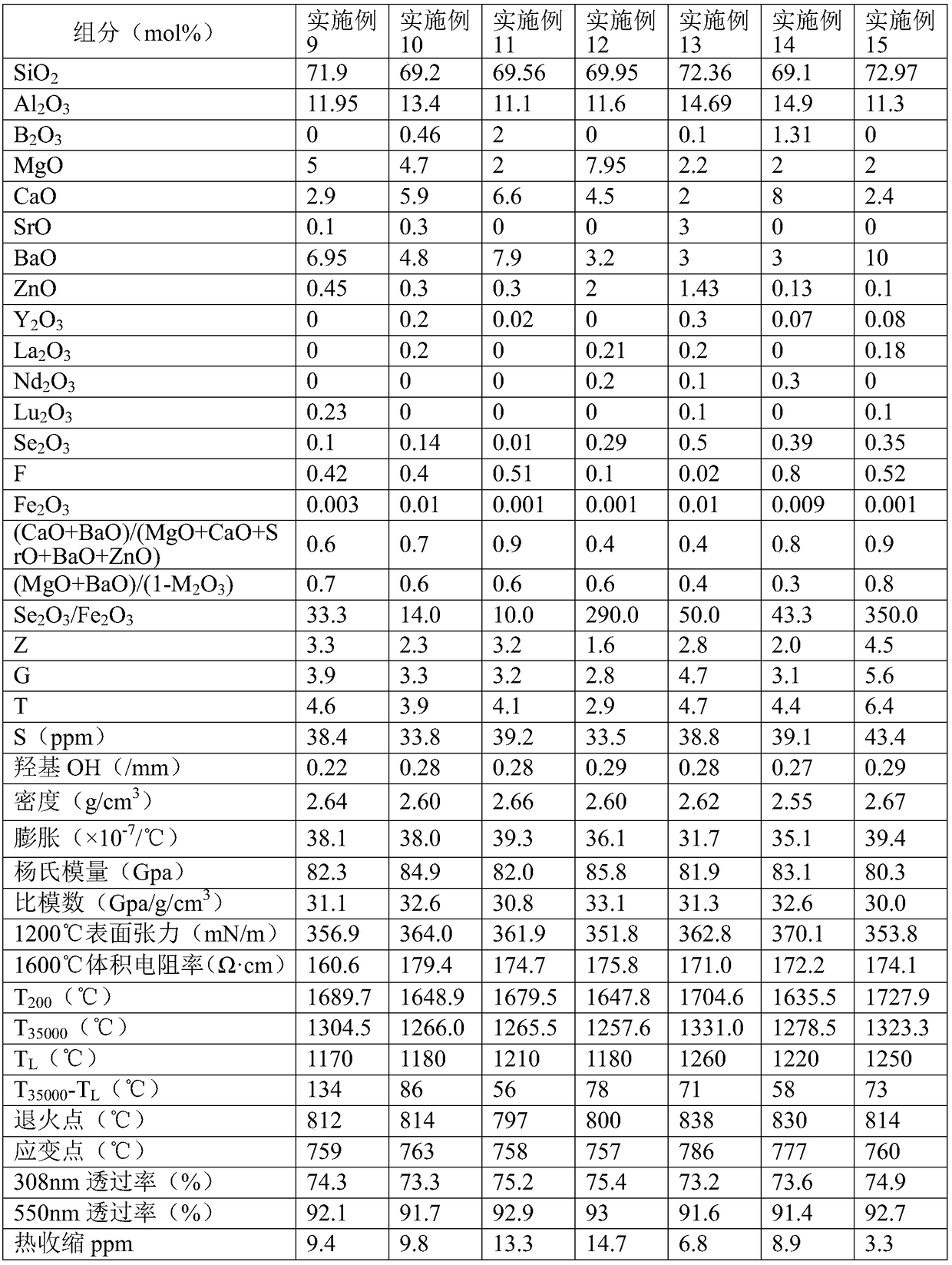

Non-alkali aluminium silicate glass as well as preparation method and application thereof

The invention relates to the field of glass manufacturing, and discloses non-alkali aluminium silicate glass as well as a preparation method and application thereof. When the non-alkali aluminium silicate glass is at a temperature of 1600 DEG C, electrical resistivity of glass melt is lower than or equal to 200 Ohm.cm; when viscosity of the non-alkali aluminium silicate glass is 35000 poises, thecorresponding temperature T35000 is greater than or equal to 1250 DEG C; when the viscosity of the non-alkali aluminium silicate glass is 1013 poises, the corresponding annealing point is greater thanor equal to 790 DEG C. The non-alkali aluminium silicate glass provided by the invention has relatively low density and relatively high elastic modulus, good thermal stability and a relatively low thermal shrinkage rate; and the non-alkali aluminium silicate glass has a high penetration rate at 308 nm and / or 550 nm, and is suitable for large industrial production.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Cross-linked heat shrinkable film with flame retardant effect and preparation method thereof

InactiveCN110406127AAvoid the disadvantages of excessive smoke generationImprove flame retardant performanceOther domestic articlesCross-linkPolymer science

The invention discloses a preparation method of a cross-linked heat shrinkable film with a flame retardant effect. The method comprises the following steps of: adding raw materials of an outer layer,a core layer and an inner layer, respectively melting and plasticizing, and obtaining a composite material by coextruding the layers; performing primary inflation on the composite material to obtain afilm bubble, and cooling and shaping the film bubble to form a film tube; drawing the film tube to an electron accelerator, and crosslinking linear molecular chains of the film tube through electronirradiation; preheating the cross-linked film tube, carrying out bidirectional stretching, and then carrying out secondary inflation on the film tube; and shaping the film tube subjected to secondaryinflation after being cooled by an air ring and subjected to heat treatment, and obtaining the cross-linked heat shrinkable film with the flame retardant effect by trimming and rolling. An organic flame retardant and an inorganic flame retardant are compounded, so that the flame retardant effect is improved, the defects that the smoke amount of the organic flame retardant is too large in the combustion process and the like are avoided, and the phenomenon that the affinity with the cross-linked heat shrinkable film is poor due to the fact that too much inorganic flame retardant is added, and the processing and mechanical properties are poor is avoided.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

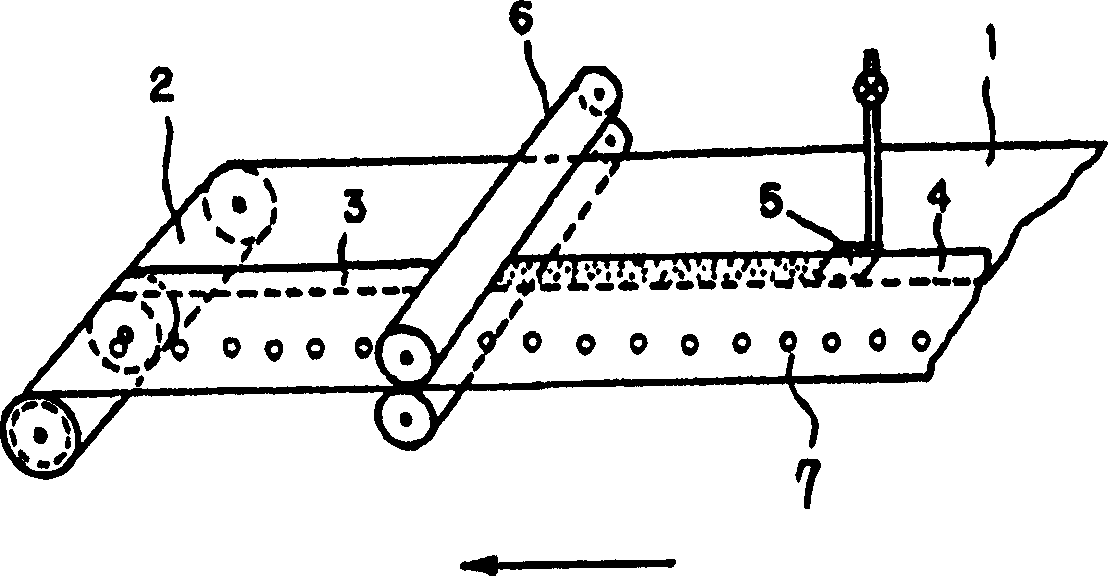

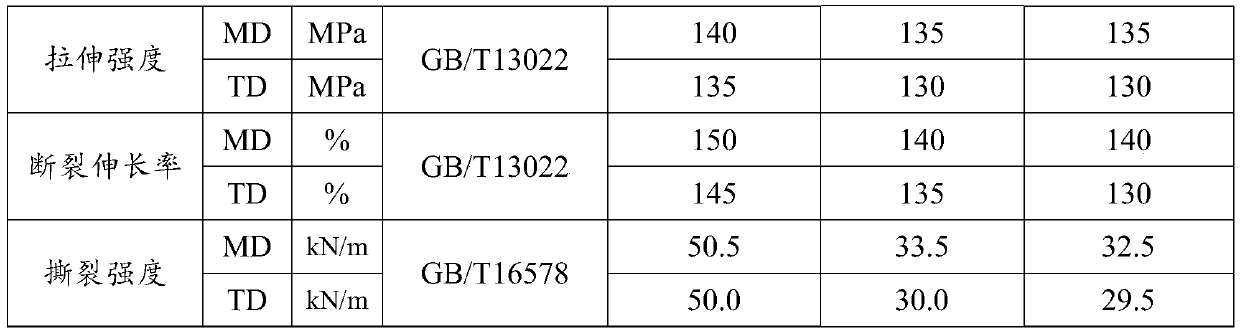

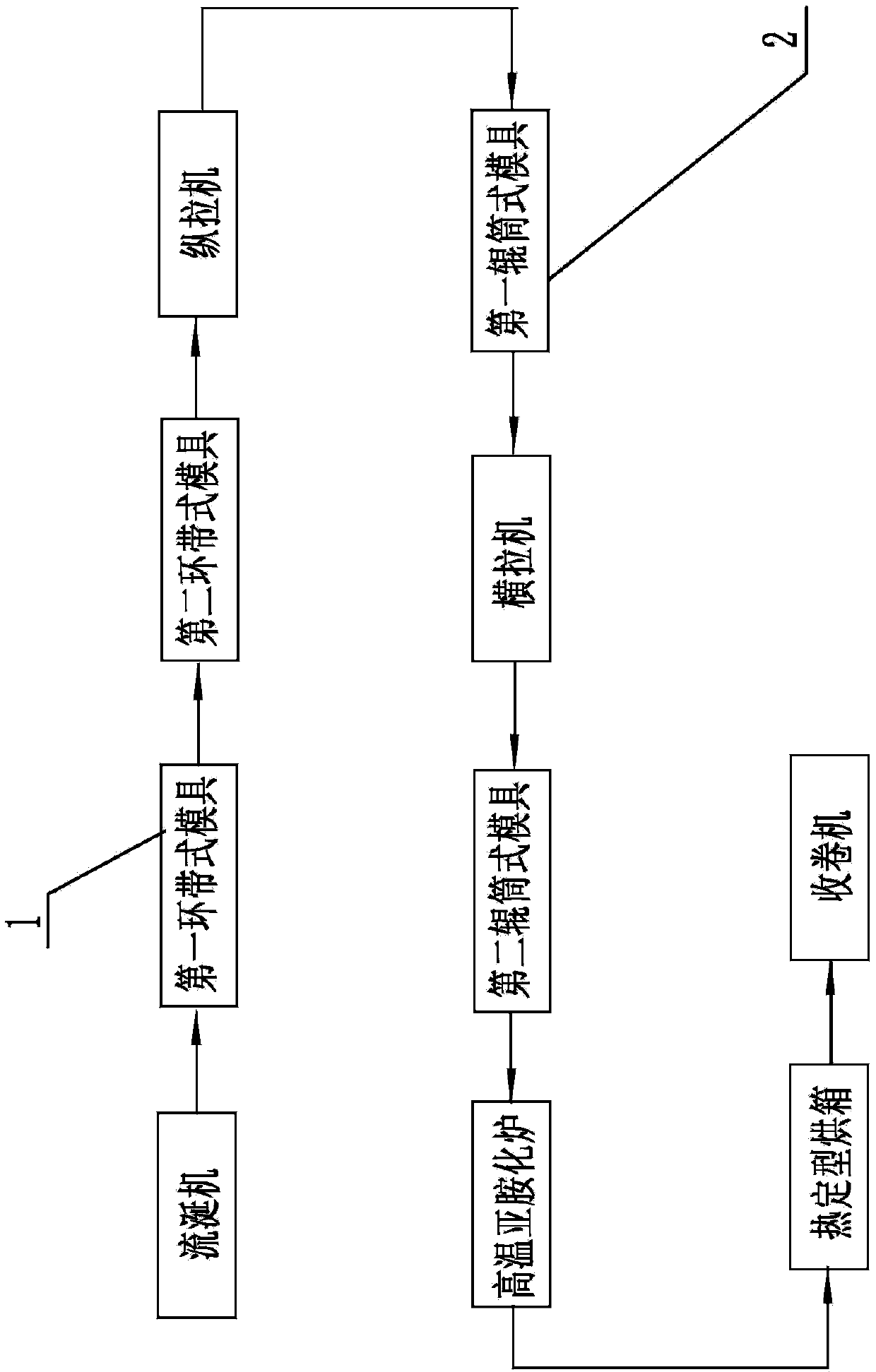

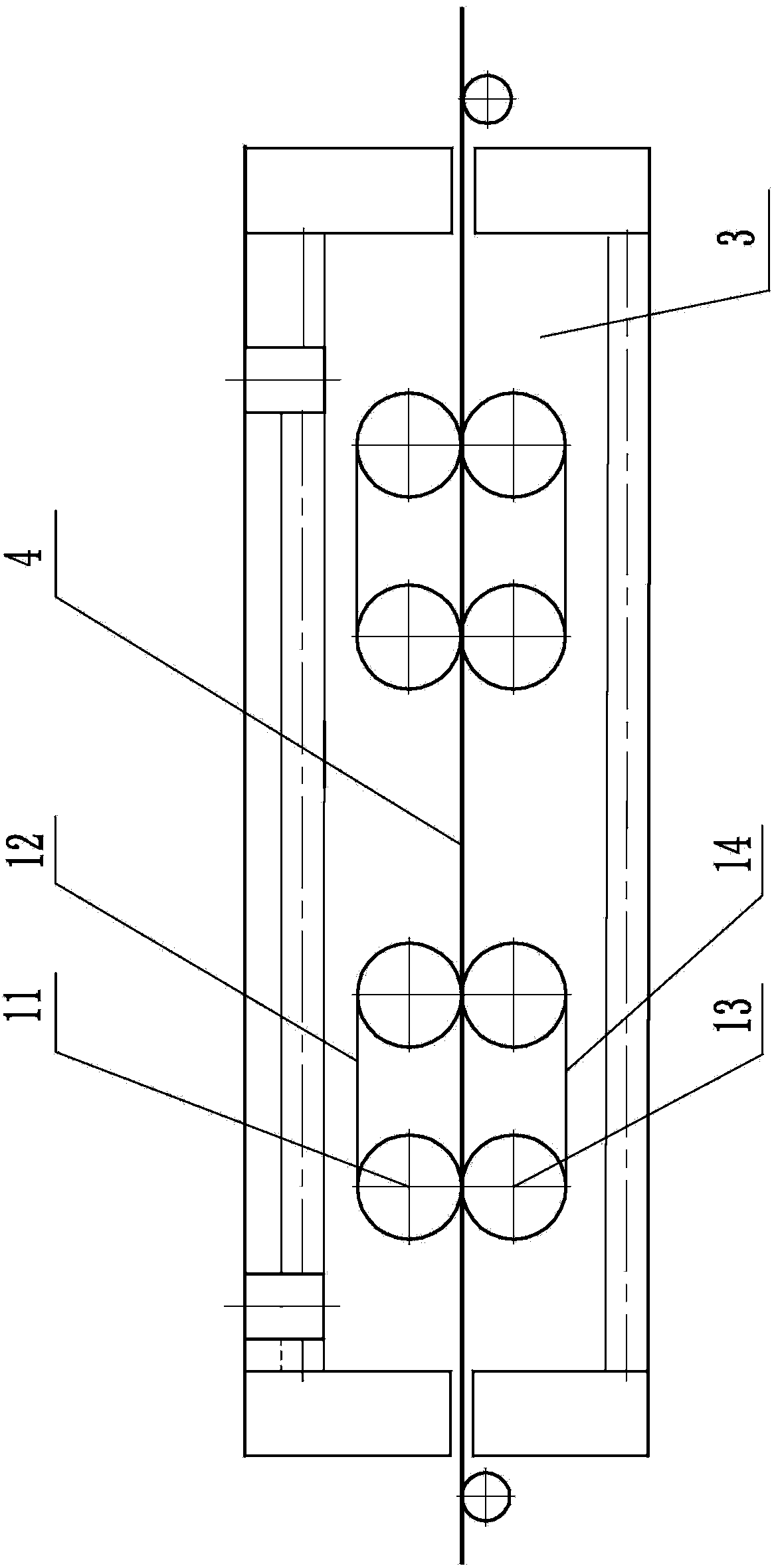

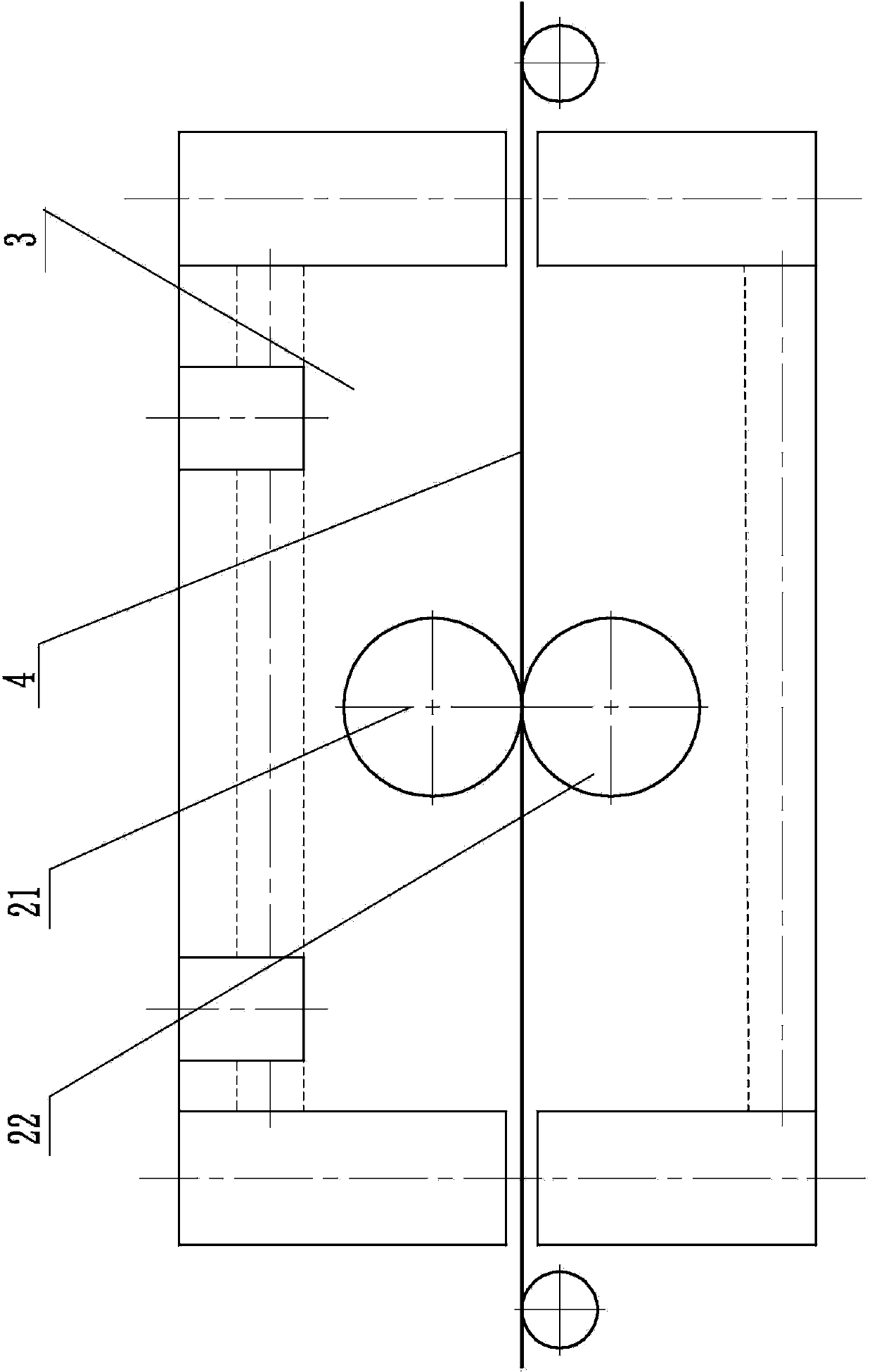

Method for improving physical properties of polyimide film and polyimide film production line

ActiveCN104191635AGood physical propertiesImprove flatnessFlat articlesProduction lineHeat conducting

The invention relates to a method for improving physical properties of a polyimide film and a polyimide film production line. According to the method, a polyamide acid film obtained by casting is rolled for one to three times and then enters a drawing process; during rolling, the content of a solvent in the polyamide acid film is 30-100 percent; after longitudinal drawing and / or transverse drawing, the polyamide acid film is also rolled for one to three times; during rolling, the temperature is 50-180 DEG C. On the production line, one to three rolling moulds are arranged behind a casting machine, and one to three rolling moulds are arranged behind a drawing machine. The rolling moulds are roller type moulds or endless belt type moulds, each roller type mould comprises two same rolling rollers respectively positioned on and below the film, and each endless belt type mould comprises an upper rolling steel belt and a lower rolling steel belt which are the same and respectively encircle two rollers. The rolling moulds are positioned in a rolling oven, and / or a circulation channel is formed in each roller and used for receiving heat-conducting media. The method significantly improves the thickness uniformity, surface quality and roller smoothness of a following-up polyimide film product. The polyimide film production line is simple in structure and easy to implement.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Modified organic silica gel having color changing function

InactiveCN104877620ARealize the effect of photosensitive and temperature sensitiveRealized the transformation of general organic silicone adhesive into a light-sensitive and temperature-sensitive effectNon-macromolecular adhesive additivesAluminateAdhesive

The invention discloses a modified organic silica gel having a color changing function. The modified organic silica gel is prepared from the following components in percentage by mass: 40-70wt.% of thermochromic powder, 15-50wt.% of organic silicon adhesive, 15-50wt.% of hydroxypolyorganosiloxane, 20-55wt.% of dibutyl tin diacetate, 0.1-2.0wt.% of aluminate, 0.05-1.0wt.% of antioxidant and 0.1-1wt.% of calcium stearate. According to the modified organic silica gel having the color changing function, the formula is improved, and the thermochromic powder is added to the organic silicon adhesive to enable the organic silicon adhesive to have the light sensing and temperature sensing effects, and the formation of dead zones under hard light irradiation can be avoided. The modified organic silica gel having the color changing function is good in heat sealability, high in thermal shrinkage, easy to recover, and good in mechanical properties.

Owner:WUXI ZHONGXING IND ADHESIVE TAPE

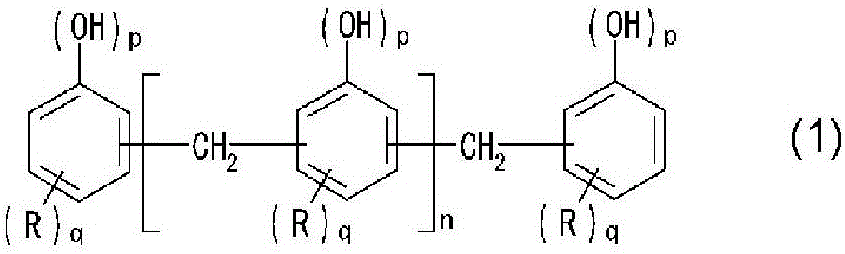

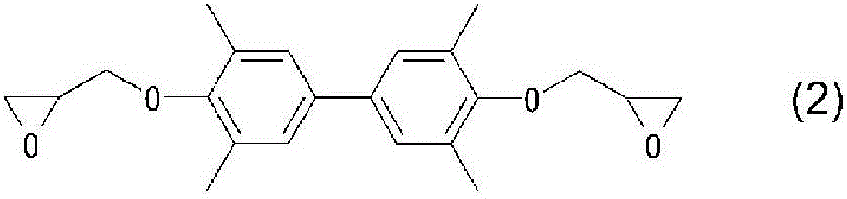

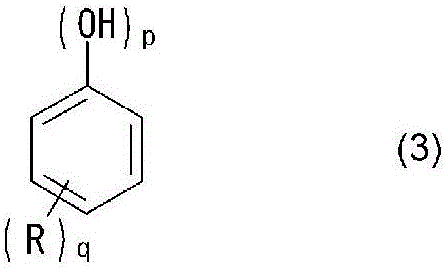

Phenolic resin, epoxy resin containing the phenolic resin, cured product of the epoxy resin composition, and semiconductor device having the cured product

ActiveCN106133017AHigh thermal expansionHigh heat shrinkageSemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

The phenol resin of the present invention is represented by general formula (1). The phenolic resin imparts to a cured product, which is produced from the phenolic resin, an epoxy resin represented by general formula (2) and a curing accelerator, a thermal expansion coefficient of 1.5% or more at temperatures above 40DEG C and below 180DEG C. The phenolic resin is preferably the one which can impart to the cured product a storage elastic modulus of 15 MPa or more at 250DEG C Preferably,

Owner:UBE IND LTD

Heat-shrinkable polyester-based film

Owner:TOYOBO CO LTD

Wet diaphragm and preparation process thereof

InactiveCN111477814AExtended service lifeSmall particle sizeCell seperators/membranes/diaphragms/spacersNanoceramicAnti oxidant

The invention discloses a wet-process diaphragm and a preparation process thereof. The wet-process diaphragm comprises the following components: polyethylene, a pore-forming agent, an antioxidant andnano ceramic powder, wherein the mass mixing ratio of the polyethylene to the pore-forming agent is 1:1-1:5.5, and the mass of the antioxidant and the mass of the nano ceramic powder account for 0.1%-1% of the mass of the polyethylene. By adjusting the formula and preparation process of the product, the finally prepared diaphragm has the advantages of high-power discharge resistance, long servicelife and high safety performance.

Owner:泰州衡川新能源材料科技有限公司

Multi-layer co-extrusion high-temperature-resistant BOPP (biaxially-oriented polypropylene) film and preparation method thereof

PendingCN114434912AImprove wear resistanceHigh heat shrinkageFlexible coversWrappersCalcium silicateGlass fiber

The invention belongs to the field of film preparation, and discloses a multi-layer co-extrusion high-temperature-resistant BOPP film and a preparation method thereof. The film sequentially comprises an upper high-temperature-resistant layer, a core layer and a lower high-temperature-resistant layer, based on the total weight of the upper high-temperature-resistant layer or the lower high-temperature-resistant layer, the raw materials of the upper high-temperature-resistant layer and the raw materials of the lower high-temperature-resistant layer respectively and independently comprise 20-55% of a high-temperature-resistant polymer, 5-25% of glass fibers, 1-15% of calcium silicate, 15-40% of co-polypropylene, 0.1-1.0% of a thermal curing agent, 0.1-1.0% of a cross-linking agent, 0.1-1.0% of an anti-adhesion agent and 0.3-0.5% of an antioxidant. The high-temperature-resistant polymer and the calcium silicate are compounded on the upper high-temperature-resistant layer and the lower high-temperature-resistant layer through a technology for preparing the film through multi-layer co-extrusion, so that the heat resistance of the BOPP film is greatly improved, and the prepared film has excellent mechanical strength, high wear resistance and high thermal shrinkage rate.

Owner:安徽维龙新材料科技有限公司

Preparation technology for uvioresistant modified PET film coating liquid

The invention discloses a preparation technology for uvioresistant modified PET film coating liquid, which is characterized by comprising the following steps of: 1, preparing 15-50wt.% of conducting polymer resin, 15-50wt.% of silane coupling agent, 20-55wt.% of vinyl organic silicon resin, 0.1-2.0wt.% of glycerin, 0.05-1.0wt.% of antioxygen, 0.1-1wt.% of calcium stearate and 30-40wt.% of ultraviolet light absorber into slurry, wherein the ultraviolet light absorber is chlorinated benzotriazole type ultraviolet light absorber; 2, heating slurry in the step 1, wherein the heating temperature is 80-120 DEG C and the heating time is 10-30S. According to the preparation technology, the formula is improved, and the problem that in the prior art the PET film is colored that the visual effect is influenced is solved by adopting the method of mixing the ultraviolet light absorber with the PET functional layer master batch and then heating to melt.

Owner:WUXI ZHONGXING IND ADHESIVE TAPE

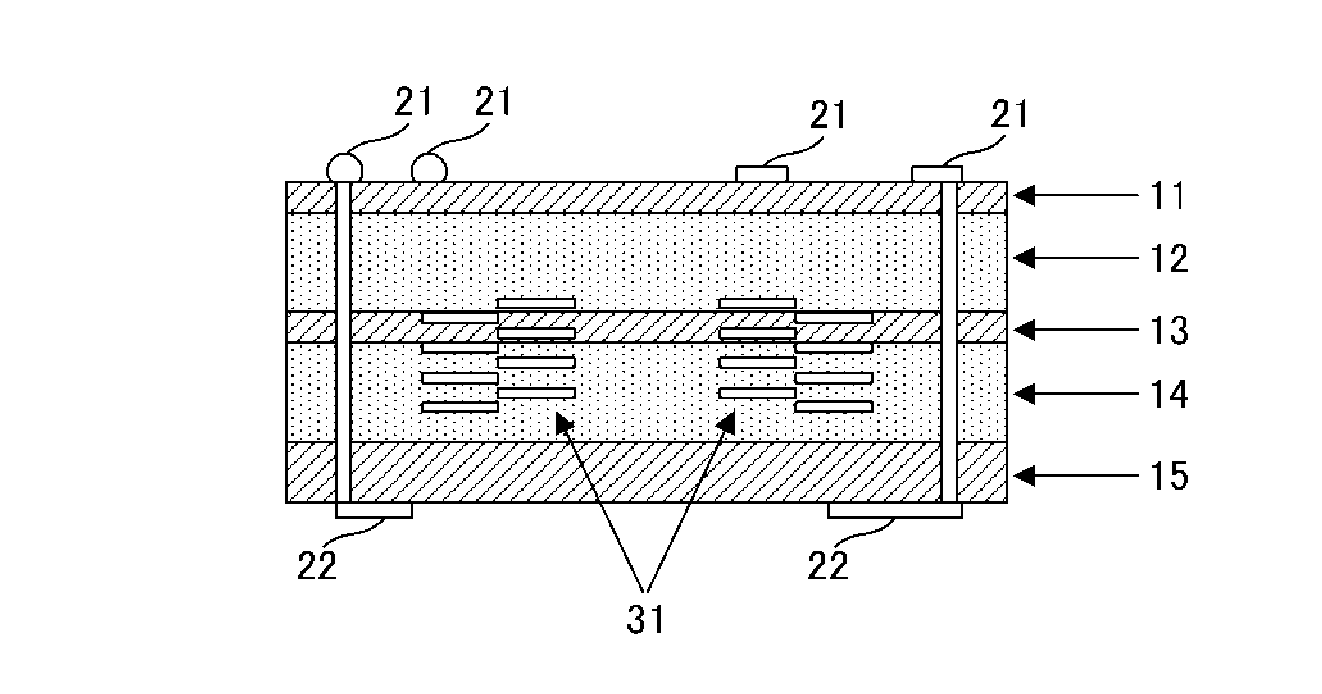

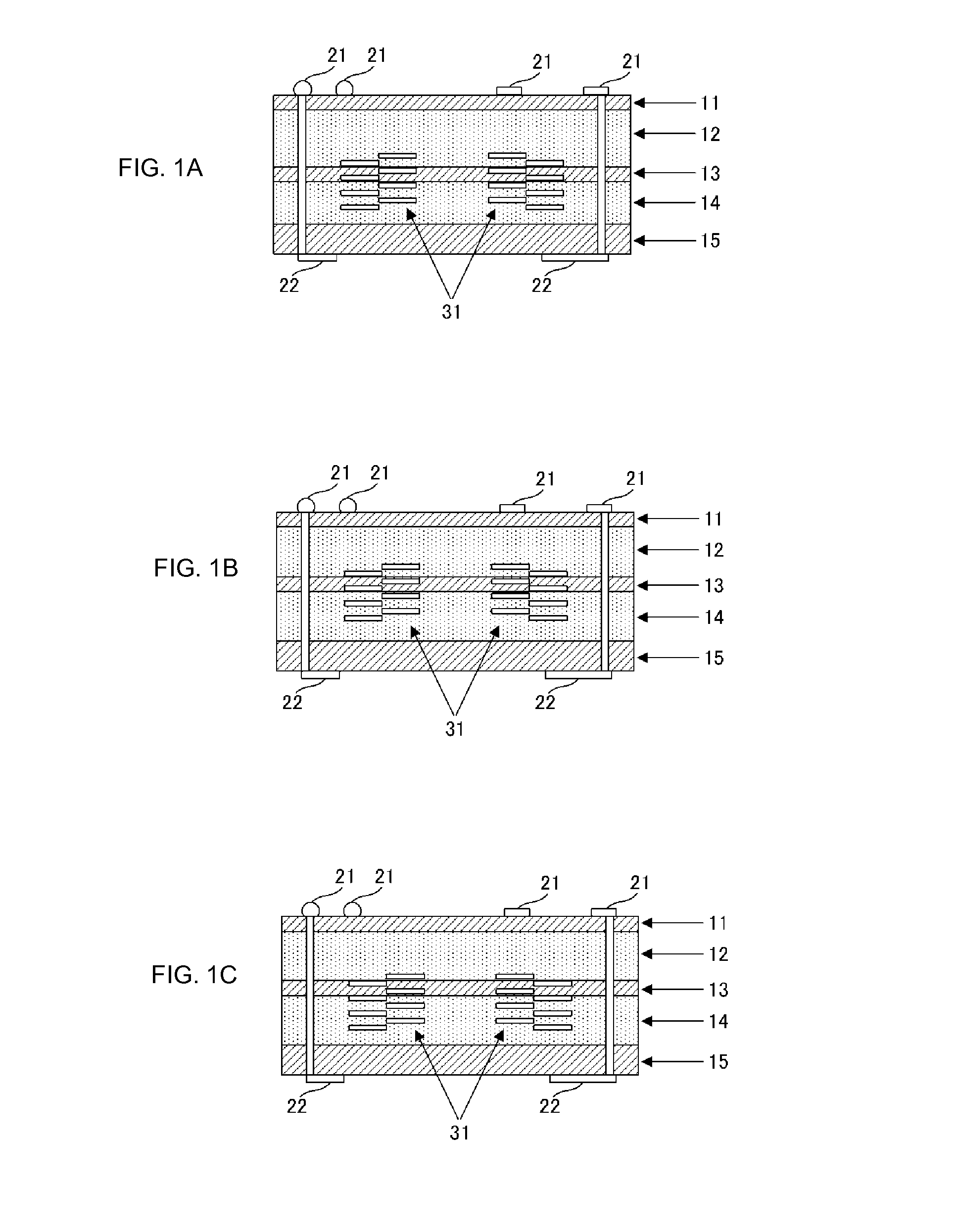

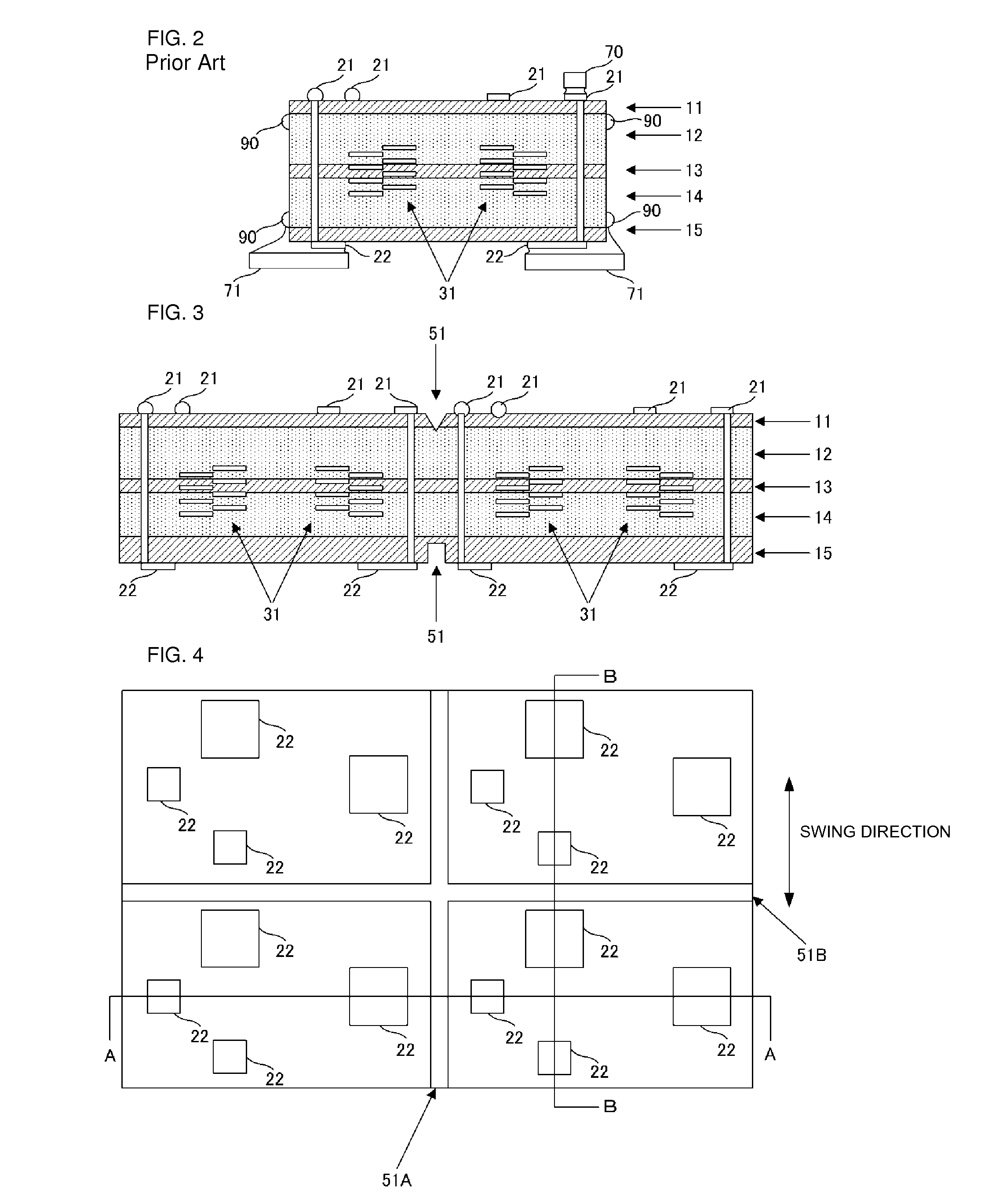

Laminated inductor element and manufacturing method thereof

ActiveUS9129733B2Improve flatnessPrevent unintended short circuitsTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite layerInductor

A laminated inductor element is configured to prevent warpage of the entire element with a structure in which a non-magnetic ferrite layer on an upper surface side is reduced in thickness to achieve a reduction in height of the entire element, a non-magnetic ferrite layer on a lower surface side is increased in thickness to be thicker than the non-magnetic ferrite layer so as to prevent a metal component diffused from a magnetic ferrite layer from coming into electrical contact with a land electrode of a mounting substrate, and an inductor is disposed toward the lower surface side across a non-magnetic ferrite layer.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com