Biaxially oriented polypropylene high-modulus film master batch and production process thereof

A biaxially oriented, polypropylene technology, applied in the field of masterbatch for biaxially oriented polypropylene high-modulus film, can solve the problems of increasing secondary production process, easy thermal and oxygen aging and discoloration, increasing production cost, etc., to save Production process, the effect of reducing the high temperature friction coefficient and improving the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 55wt% homopolypropylene (2020S produced by Formosa Plastics Ningbo, melt flow rate 3g / 10min, Vicat softening point 150°C), 40wt% C9 hydrogenated petroleum resin (R-1125 produced by Eastman, USA, Ring and ball softening point 125°C), 0.2wt% antioxidant 1010, cage polysilsesquioxane 4.8wt% put in the mixer and stir for 10min, then put the mixture into the hopper of the extruder, extrude The temperature of each section of the machine is between 170 and 210°C, and the screw speed is 150 r / min. After the melt is extruded, it is cooled and formed in the water tank, and it is drawn to the pelletizer for pelletizing and drying.

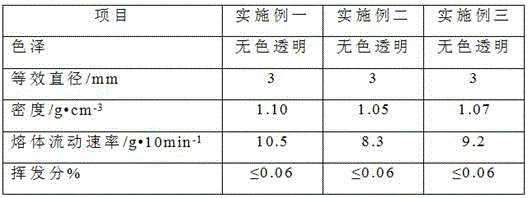

[0034] The physical and chemical properties of the prepared masterbatch are shown in Table 1.

Embodiment 2

[0036] Weigh 55wt% of polypropylene (2020S produced by Formosa Plastics Ningbo, with a melt flow rate of 3g / 10min and a Vicat softening point of 150°C), 44.3wt% of C9 hydrogenated petroleum resin (R-1125 produced by Eastman, Global softening point 125°C), 0.2wt% antioxidant 1010, 0.5wt% cage polysilsesquioxane, put them in the mixer and stir for 10 minutes, then put the mixture into the hopper of the extruder, and the extruder The temperature of each section is between 170 and 210°C, the screw speed is 150r / min, the melt is extruded and cooled in the water tank for molding, and then pulled to the pelletizer for pelletizing and drying.

[0037] The physical and chemical properties of the prepared masterbatch are shown in Table 1.

Embodiment 3

[0039]Weigh 55wt% of polypropylene (2020S produced by Formosa Plastics Ningbo, with a melt flow rate of 3g / 10min and a Vicat softening point of 150°C), 42wt% of C9 hydrogenated petroleum resin (R-1125 produced by Eastman in the United States, global softening point 125 ℃), 0.2wt% of antioxidant 1010, cage polysilsesquioxane 2.8wt% were placed in the mixer and stirred for 10 minutes, then the mixture was put into the hopper of the extruder, and each extruder The temperature of the section is between 170 and 210°C, the screw speed is 150r / min, the melt is extruded, cooled and formed in the water tank, and then pulled to the pelletizer for pelletizing and drying.

[0040] The physical and chemical properties of the prepared masterbatch are shown in Table 1.

[0041] Table 1 Physicochemical properties of booster stock

[0042]

[0043] The masterbatch prepared in the examples is added to polypropylene to prepare a BOPP film. The film has a three-layer structure. The upper surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com