Cross-linked heat shrinkable film with flame retardant effect and preparation method thereof

A technology of heat shrinkable film and flame retardant, which is applied to other household appliances, etc., can solve the problems of fast burning and poor flame retardant effect of heat shrinkable film, so as to improve the heat shrinkage rate, avoid excessive smoke generation, and achieve good Effect of Heat Shrinkage Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In one embodiment of the present invention, a method for preparing a cross-linked heat-shrinkable film with a flame-retardant effect comprises the following steps:

[0029] Add the raw materials of the outer layer, core layer and inner layer, melt and plasticize them separately, and obtain the compound material through co-extrusion layer;

[0030] The composite material is blown once to obtain a film bubble, and the film bubble is cooled and shaped to form a film tube;

[0031] The membrane tube is pulled to the electron accelerator, and the linear molecular chains of the membrane tube are cross-linked by electron irradiation;

[0032] The cross-linked film tube is preheated and biaxially stretched, and then the film tube is blown twice after biaxial stretching;

[0033] The film tube after secondary inflation is cooled by an air ring and heat-treated, then shaped, trimmed and rolled to obtain the cross-linked heat-shrinkable film with flame-retardant effect.

[0034]...

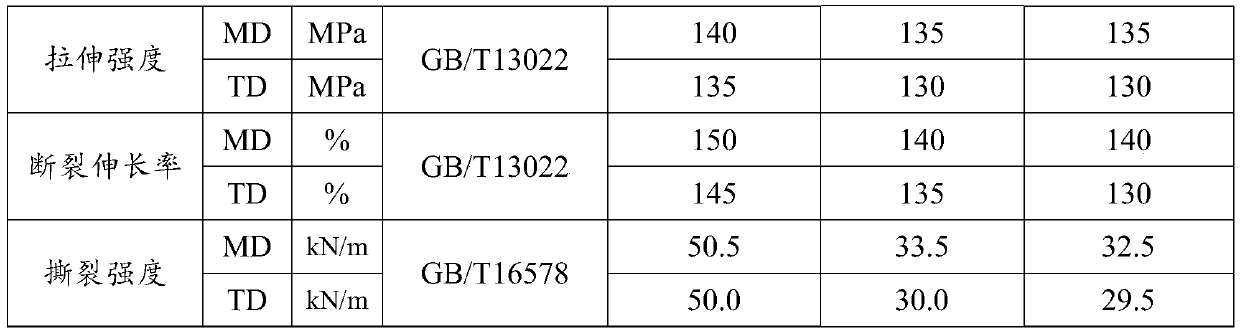

Embodiment 1

[0051]Add outer layer raw materials: 56% low-density polyethylene, 34% ethylene-octene copolymer, 3% silicone anti-blocking agent, 2% erucamide slip agent, 3% surfactant-type antistatic agent masterbatch, 1% flame retardant (coated red phosphorus 75%, ammonium polyphosphate 25%) and 1% N,N-methylenebisacrylamide crosslinking initiator, core material: 30% Low-density polyethylene, 53% flame retardant (coated red phosphorus 75%, ammonium polyphosphate 25%), 6% erucamide slip agent, 8% N,N-methylene bisacrylamide Co-initiator and 3% surfactant-type antistatic agent masterbatch, inner layer raw materials: 56% low-density polyethylene, 34% ethylene-octene copolymer, 3% silicone anti-blocking agent, 2% Erucamide slip agent, 3% surfactant-type antistatic agent masterbatch, 1% flame retardant (coated red phosphorus 75%, ammonium polyphosphate 25%) and 1% N,N-methylene The bisacrylamide crosslinking initiator is melted and plasticized separately, and the composite material is obtained...

Embodiment 2

[0057] Add outer layer raw materials: 36% low-density polyethylene, 35% ethylene-octene copolymer, 3% diatomaceous earth anti-blocking agent, 1% oleic acid amide slip agent, 2% surfactant type anti-blocking agent Static agent masterbatch, 20% flame retardant (70% aluminum hydroxide, 30% tricresyl phosphate) and 3% diisocyanate crosslinking initiator, core material: 53% low density polyethylene, 30% Flame retardant (70% aluminum hydroxide, 30% tricresyl phosphate), 6% oleic acid amide slip agent, 8% diisocyanate crosslinking initiator and 3% surfactant-type antistatic agent masterbatch , Inner material: 36% low-density polyethylene, 35% ethylene-octene copolymer, 3% diatomaceous earth anti-blocking agent, 1% oleic acid amide slip agent, 2% surfactant anti-blocking agent Static agent masterbatch, 20% flame retardant (70% aluminum hydroxide, 30% tricresyl phosphate) and 3% diisocyanate crosslinking initiator, melt and plasticize respectively, and obtain composite material through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com