Polyethylene/ polypropylene/ polypropylene three-layer co-extrusion upward bowing film and preparation method thereof

A three-layer co-extrusion and polyethylene technology, which is applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as difficulty in maintaining transparency and low PP melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

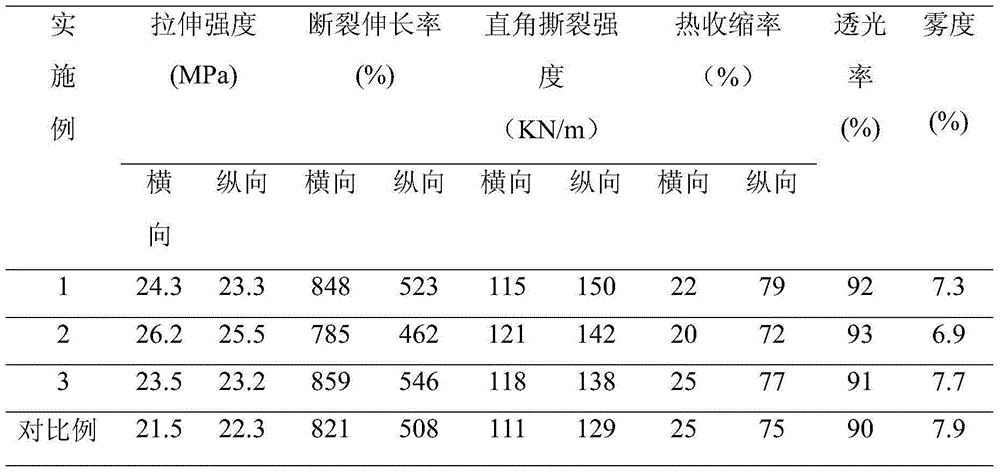

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of a polyethylene / polypropylene / polyethylene three-layer co-extrusion blown film, comprising:

[0034] The propylene random copolymer is added to the middle layer extruder hopper of the three-layer co-extrusion blown film machine, and then the inner layer ethylene blend and the outer layer ethylene blend are respectively added to the three-layer co-extrusion blown film machine In the hopper of the extruder for the inner and outer layers, the upper blowing method is used to blow the film into a film to obtain a polyethylene / polypropylene / polyethylene three-layer co-extruded upper blown film.

[0035] The set temperature of the three-layer co-extrusion film blowing machine is preferably: outer zone 1: 180-210°C, outer zone 2: 180-210°C, outer zone 3: 185-215°C, outer zone 4: 190- 220°C, outer five zones: 190-220°C; middle one zone: 180-210°C, middle two zone: 180-210°C, middle three zone: 185-215°C, middle four zone...

Embodiment 1

[0038] The invention provides a high-strength heat-shrinkable polyethylene / polypropylene / polyethylene three-layer co-extruded blown film, the composition and mass ratio of the formula are as follows:

[0039] 30 parts of special resin for outer layer PE blown film (7042:1018:100Ac=4:3:3);

[0040] Middle layer K8303 (PP:PE=7:3) 40 parts;

[0041] 30 parts of special resin for inner layer PE blown film (7042:1018:100Ac=3:3:4).

[0042] In the hoppers of the three extruders, the outer layer, the middle layer, and the inner layer, add the outer layer PE blown film special resin, the middle layer K8303, and the inner layer PE blown film special resin according to the above ratio, and use the upper blowing method to blown into a film to obtain polyethylene / polypropylene / Polyethylene three-layer co-extrusion blown film. The set temperature of the film blowing machine for three-layer co-extruded PE / PP / PE blown film is outer zone 1: 180-210℃, outer zone 2: 180-210℃, outer zone 3: 1...

Embodiment 2

[0045] The invention provides a high-strength heat-shrinkable polyethylene / polypropylene / polyethylene three-layer co-extruded blown film, the composition and mass ratio of the formula are as follows:

[0046] 25 parts of special resin for outer layer PE blown film (7042:1018:100Ac=4:3:3);

[0047] Middle layer K8303 (PP:PE=7:3) 50 parts;

[0048] 25 parts special resin for inner layer PE blown film (7042:1018:100Ac=3:3:4).

[0049] In the hoppers of the three extruders, the outer layer, the middle layer, and the inner layer, add the outer layer PE blown film special resin, the middle layer K8303, and the inner layer PE blown film special resin according to the above ratio, and use the upper blowing method to blown into a film to obtain polyethylene / polypropylene / Polyethylene three-layer co-extrusion blown film. The set temperature of the film blowing machine for three-layer co-extruded PE / PP / PE blown film is outer zone 1: 180-210℃, outer zone 2: 180-210℃, outer zone 3: 185-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com