High-elasticity and high-toughness gel micro-nano particle and preparation method thereof

A micro-nano-particle and high-toughness technology, applied in the field of high-elasticity and high-toughness gel micro-nano particles and their preparation, can solve the problems of low mechanical strength of the gel system, poor ability to control cracks, poor stability, etc., and achieve mechanical strength. Low, the inhibition stability is poor, the operation is feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

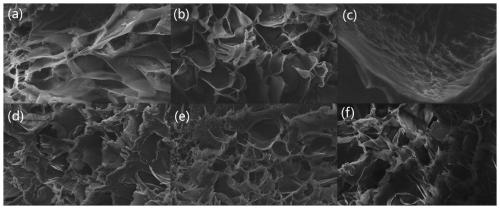

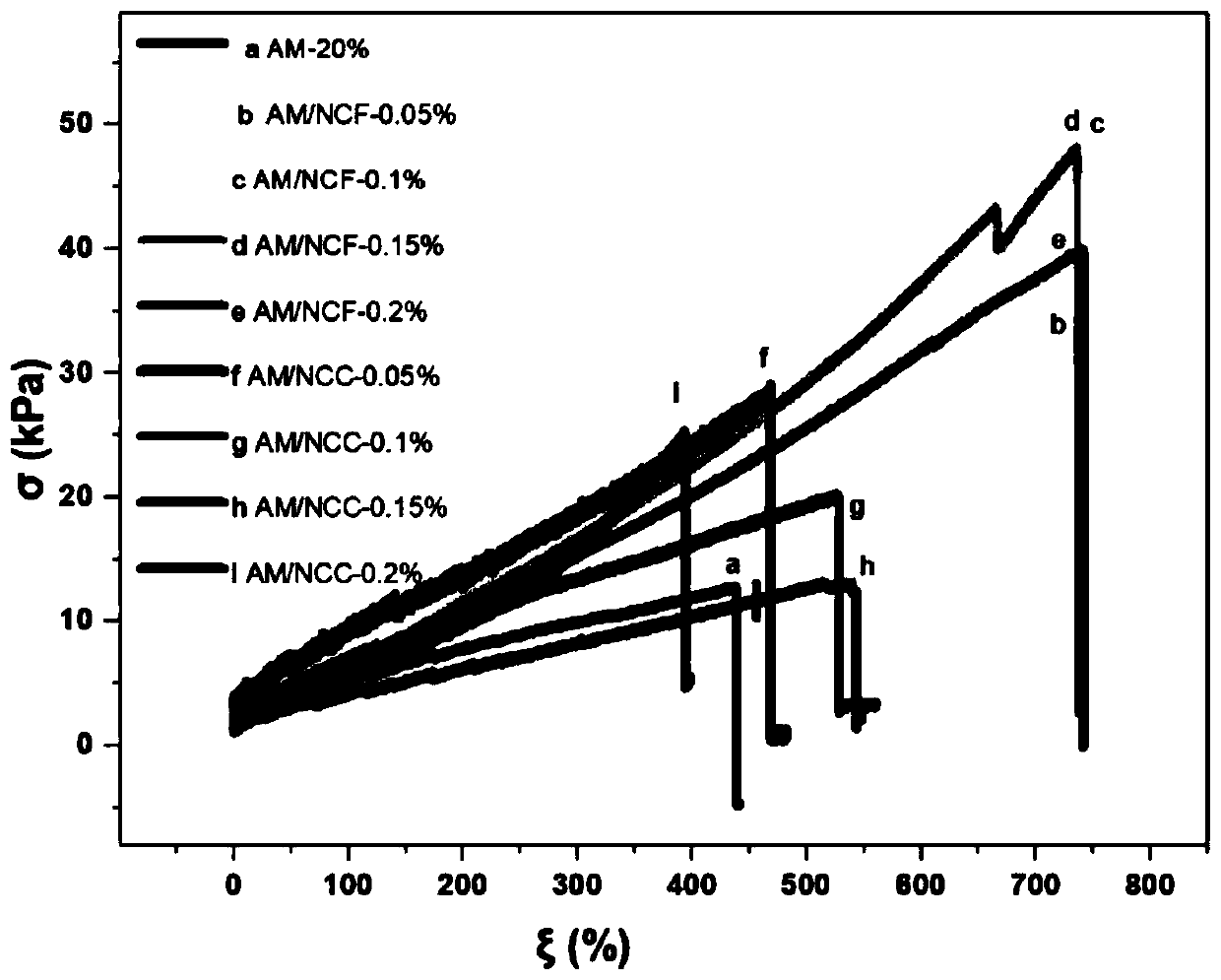

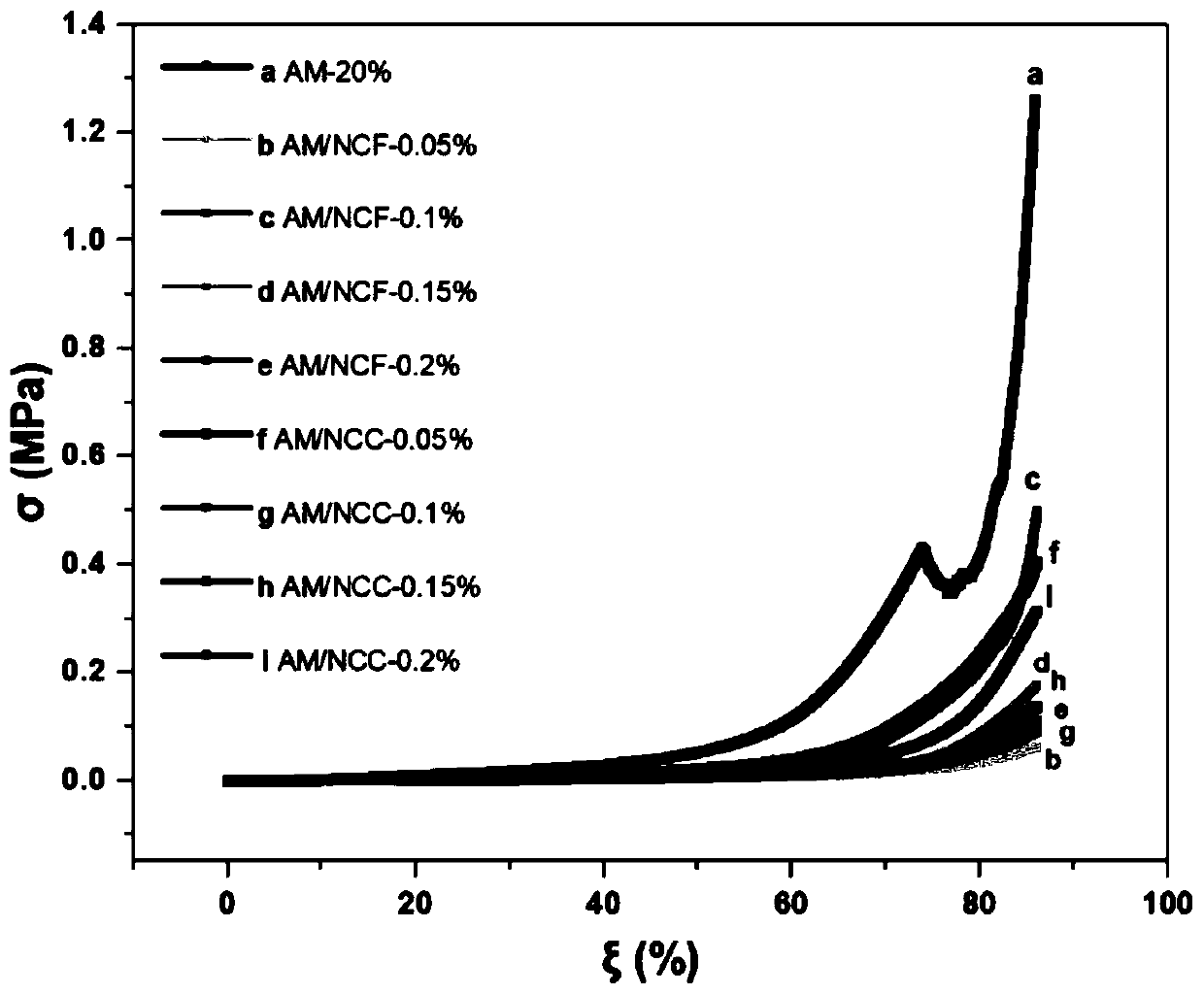

[0026] A highly elastic and high toughness gel micro-nano particle includes the following components: 20 g of acrylamide monomer, 0.1 g of cellulose nanofibrils, 0.06 g of polyethylene glycol 400, 0.2 g of ammonium persulfate and 100 mL of deionized water.

[0027] The preparation method of the above-mentioned high elasticity and high toughness gel micro-nano particles includes the following steps:

[0028] Disperse and activate the cellulose nanofibrils at high speed for 10 minutes and place them in deionized water. Stir and mix for 20 minutes to obtain a cellulose suspension. Then add the acrylamide monomer to the cellulose suspension. After stirring for 20 minutes, add polyethylene glycol 400 , Continue to stir for 5 minutes to obtain the cellulose mixture; place the cellulose mixture in a 70℃ water bath, open the nitrogen bottle, and pour continuous nitrogen into the mixture. Under the protection of nitrogen, add ammonium persulfate at 70°C. ℃ water bath conditions, fully react...

Embodiment 2

[0030] A high-elasticity and high-toughness gel micro-nano particle comprises the following components: 20 g of acrylamide monomer, 0.1 g of cellulose nanocrystals, 0.06 g of polyethylene glycol 400, 0.2 g of ammonium persulfate and 100 mL of deionized water.

[0031] The preparation method of the above-mentioned high elasticity and high toughness gel micro-nano particles includes the following steps:

[0032] The cellulose nanocrystals were dispersed and activated at high speed for 10 minutes and then placed in deionized water, stirred and mixed for 20 minutes to obtain a cellulose suspension, and then acrylamide monomer was added to the cellulose suspension. After stirring for 20 minutes, polyethylene glycol 400 was added. Continue stirring for 5 minutes to obtain the cellulose mixture; place the cellulose mixture in a 70℃ water bath, open the nitrogen bottle, and pour continuous nitrogen into the mixture. Under nitrogen protection, add ammonium persulfate at 70℃. Under water bat...

Embodiment 3

[0034] A high-elasticity and high-toughness gel micro-nano particle includes the following components: 10g of acrylamide monomer, 0.1g of cellulose nanofibrils, 0.03g of N,N-methylenebisacrylamide, 0.1g and 100mL of ammonium persulfate Deionized water.

[0035] The preparation method of the above-mentioned high elasticity and high toughness gel micro-nano particles includes the following steps:

[0036] Disperse and activate the cellulose nanofibrils at high speed for 10 minutes and place them in deionized water. Stir and mix for 20 minutes to obtain a cellulose suspension. Then add the acrylamide monomer to the cellulose suspension. After stirring for 20 minutes, add N, N- Methyl bisacrylamide, continue to stir for 5 minutes to obtain the cellulose mixture; place the cellulose mixture in a 70℃ water bath, open the nitrogen bottle, and pour continuous nitrogen into the mixture. Under nitrogen protection, add Ammonium sulfate, fully reacted in a water bath at 70℃ under nitrogen atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Tensile elongation at break | aaaaa | aaaaa |

| Tensile elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com