Chemically strengthened glass with high safety stress and testing method

A technology for strengthening glass and safety stress, which is applied in glass tempering, glass manufacturing equipment, force/torque/power measuring instruments, etc., to achieve low production cost, good scratch resistance, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

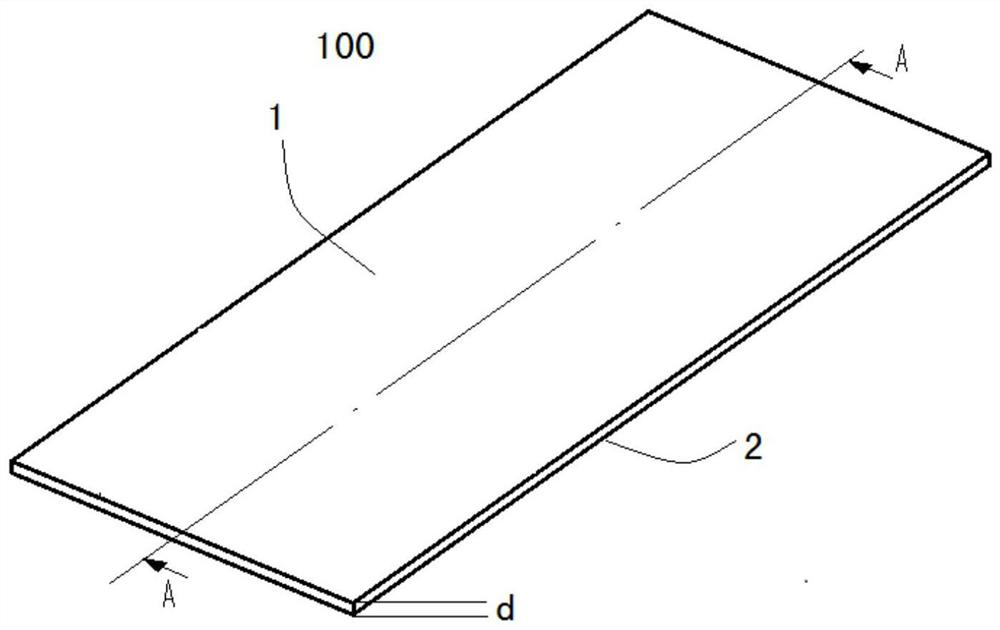

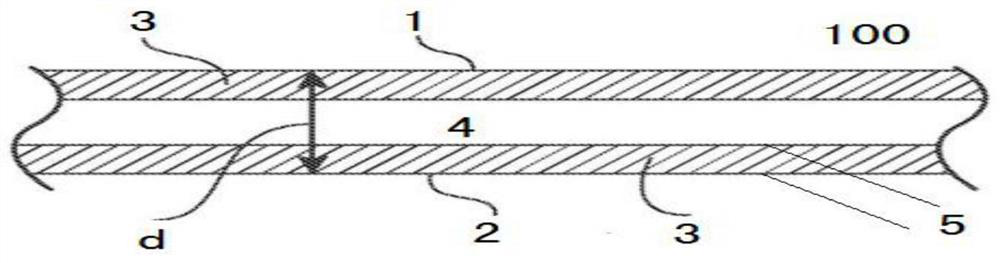

Image

Examples

Embodiment 1

[0077] Embodiment 1: A kind of preparation method of chemically strengthened glass with high safe compressive stress, comprises the following steps:

[0078] S1: Firstly, accurately weigh according to the ratio of the glass substrate (see Table 1), and then mix the raw materials thoroughly, then heat them at a high temperature of 1630°C for 4 hours to melt them to obtain molten glass.

[0079] S2: Cast the molten glass into a preheated stainless steel mold, then put it into an annealing furnace, and perform a long-term gradient annealing around the annealing point to eliminate the internal stress of the glass. After the annealed glass brick is finished, the six sides are cut to obtain a glass brick with a suitable size, and then the wire cutting machine, CNC engraving machine, and flat grinding and polishing machine are used for size precision cutting, flat grinding, and edge sweeping to obtain the precursor glass plate;

[0080] S3: preheating the precursor glass obtained in...

Embodiment 2~5

[0084] Adopt the same method as in Example 1 to obtain the precursor glass plate, the difference is: (1) the formula of the glass substrate is different (Table 1); (2) the test results are different (see Table 2)

[0085] Table 1

[0086]

[0087] Note: "-" means that the component is not contained in the precursor glass.

[0088] Table 2

[0089]

[0090] table 3

[0091]

[0092] Note: "-" indicates that the glass product has not been subjected to this step.

[0093] The results show that, referring to Table 2, the drop height of the whole machine for the impact strength of Examples 1 to 5 of the present invention is between 1.2 and 1.8 m. Finally, the glass damage state is observed, and only 2-3 cracks are extended instead of stars. Explosion, avoiding the influence of external force on the destructive state to the greatest extent. The strengthened glass is fixed with a Vickers diamond drill bit and a guide rail to ensure that the drill bit impacts the glass su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com