Patents

Literature

364 results about "Chemically strengthened glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemically strengthened glass is a type of glass that has increased strength as a result of a post-production chemical process. When broken, it still shatters in long pointed splinters similar to float glass. For this reason, it is not considered a safety glass and must be laminated if a safety glass is required. However, chemically strengthened glass is typically six to eight times the strength of float glass.

Down-drawable, chemically strengthened glass for cover plate

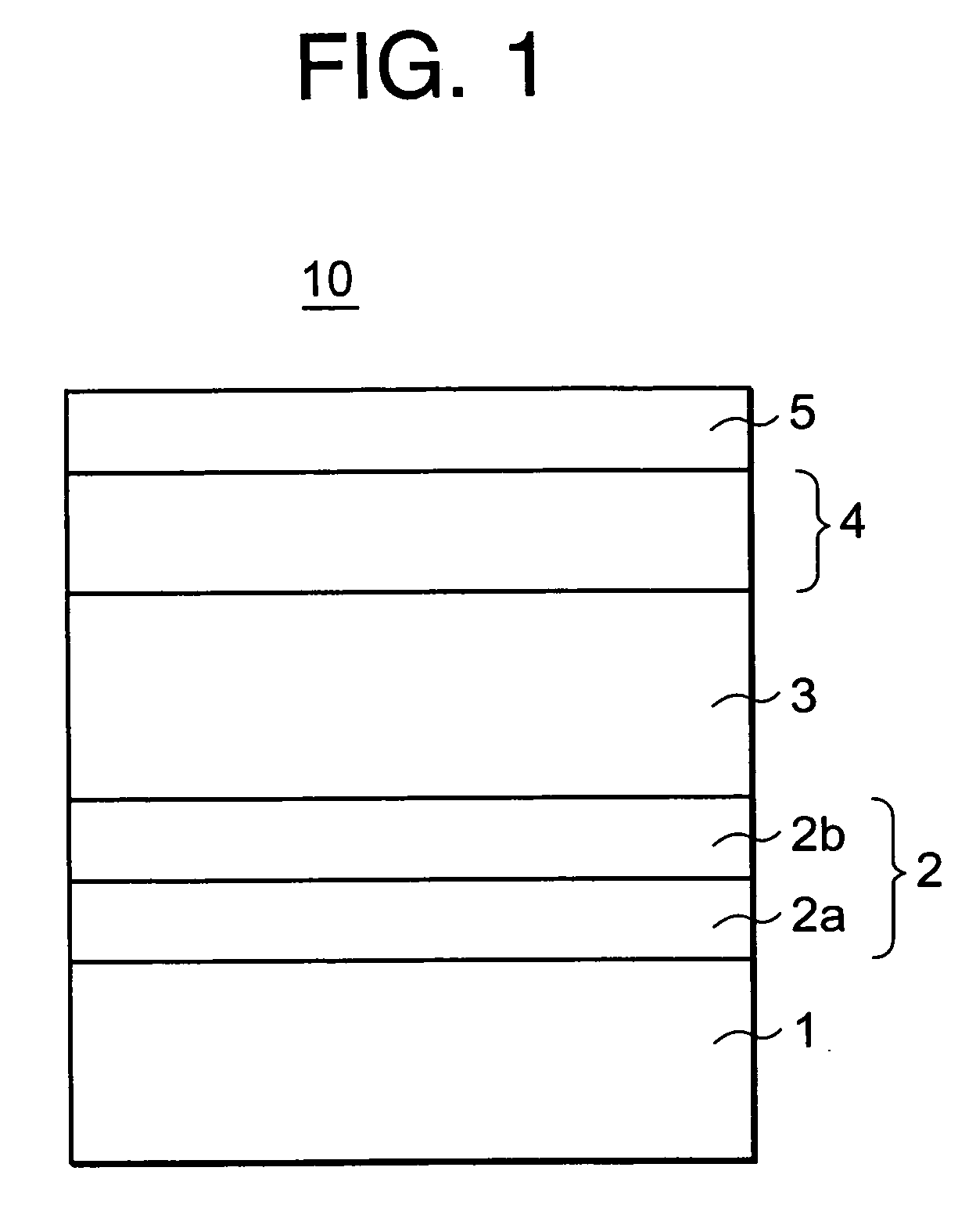

An alkali aluminosilicate glass that is chemically strengthened and has a down-drawable composition. The glass has a melting temperature less than about 1650° C. and a liquidus viscosity of at least 130 kpoise and, in one embodiment, greater than 250 kpoise. The glass undergoes ion exchange at relatively low temperatures to a depth of at least 30 μm.

Owner:CORNING INC

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

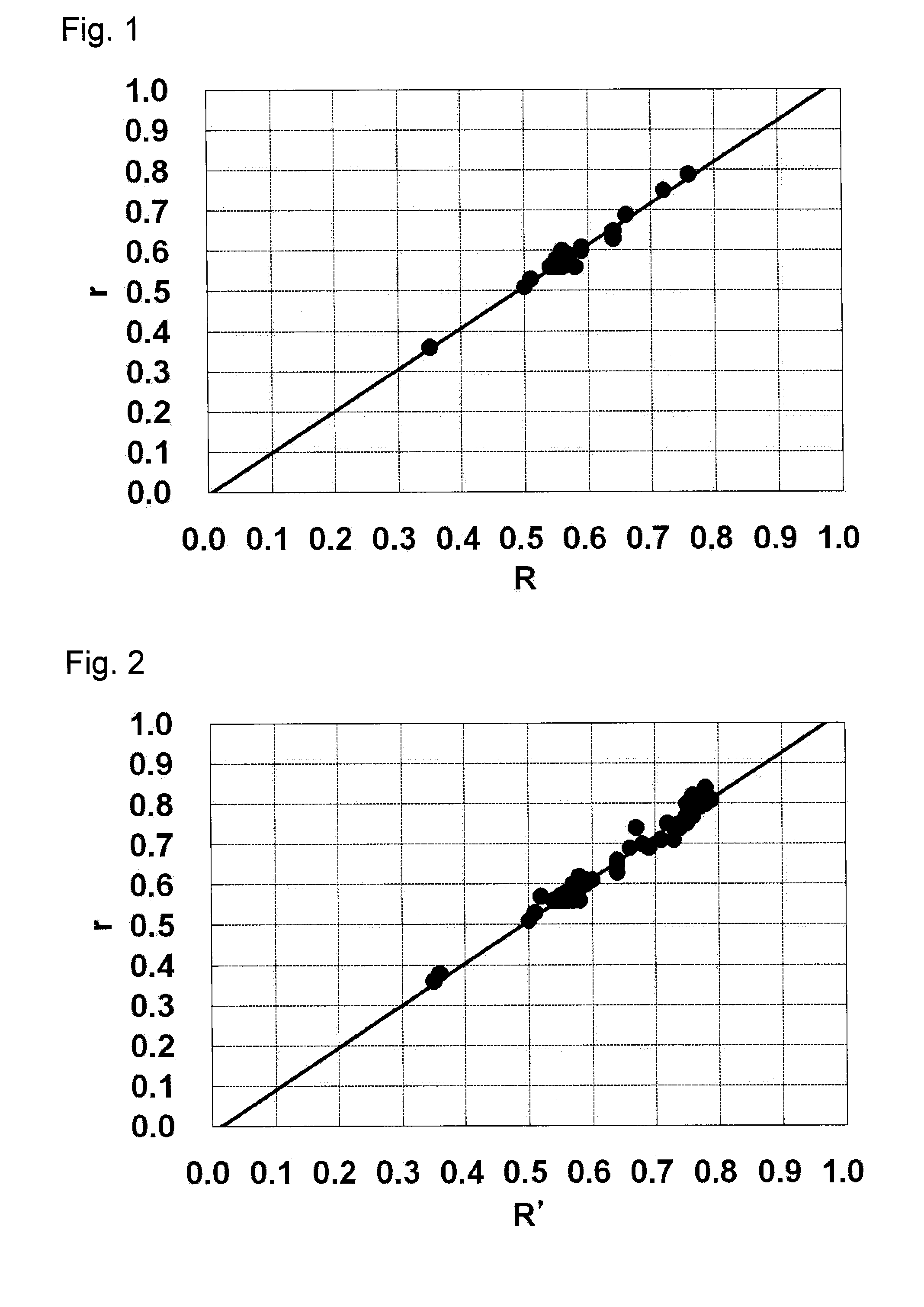

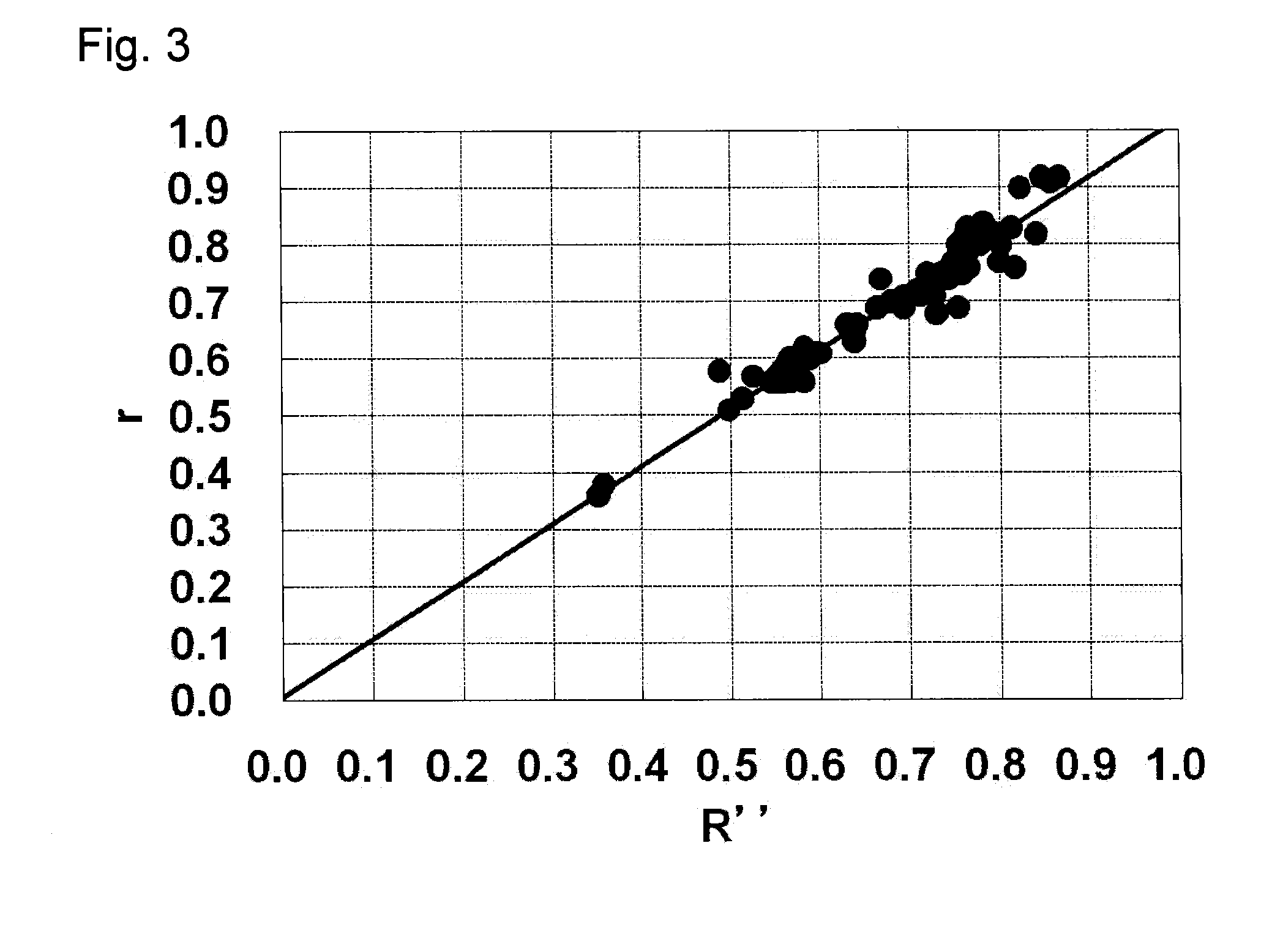

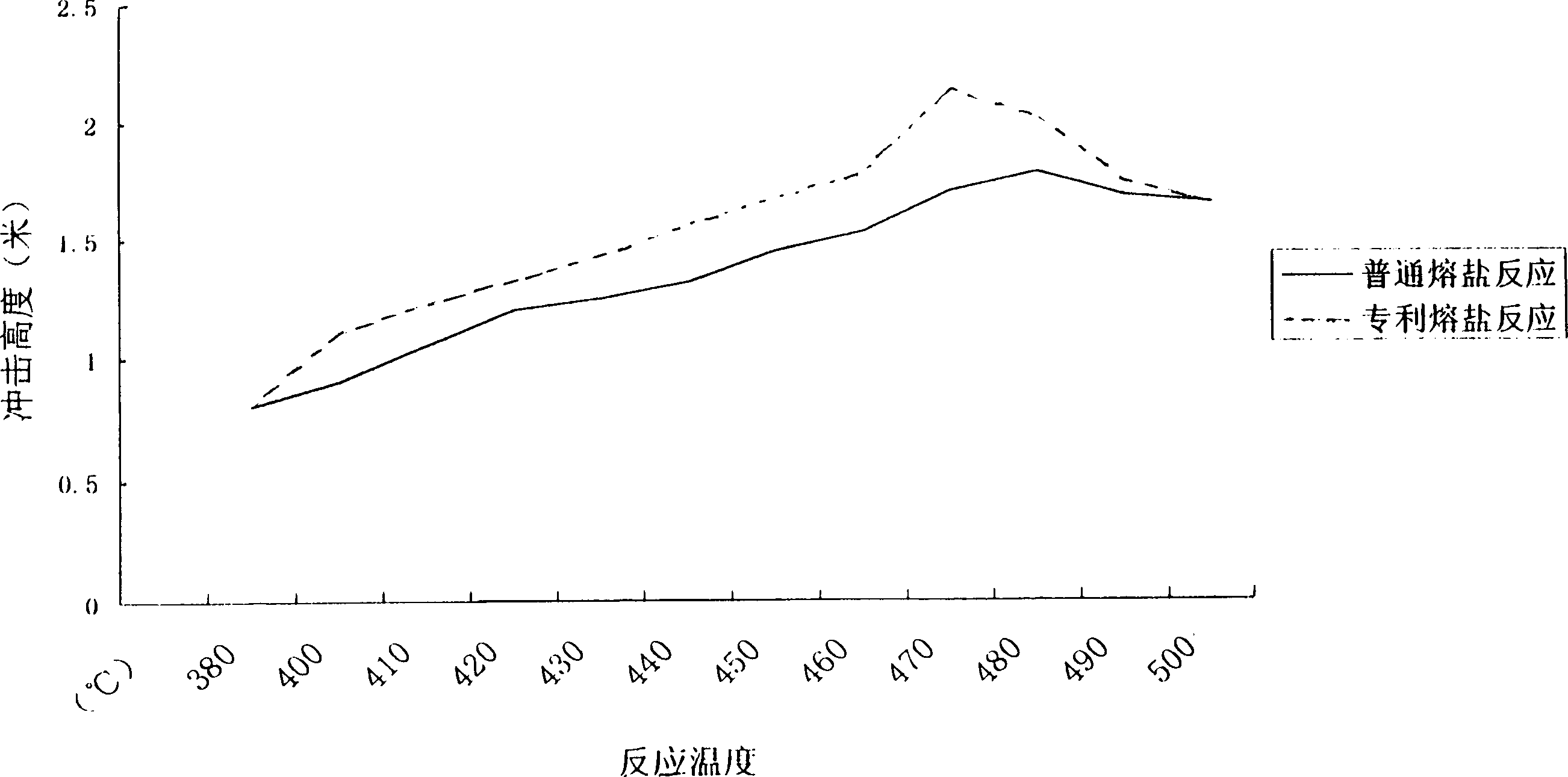

Method for producing chemically tempered glass

To provide a method for producing chemically tempered glass, whereby frequency of replacement of the molten salt can be reduced. A method for producing chemically tempered glass, which comprises repeating ion exchange treatment of immersing glass in a molten salt, wherein the glass comprises, as represented by mole percentage, from 61 to 77% of SiO2, from 1 to 18% of Al2O3, from 3 to 15% of MgO, from 0 to 5% of CaO, from 0 to 4% of ZrO2, from 8 to 18% of Na2O and from 0 to 6% of K2O; SiO2+Al2O3 is from 65 to 85%; MgO+CaO is from 3 to 15%; and R calculated by the following formula by using contents of the respective components, is at least 0.66:R=0.029×SiO2+0.021×Al2O3+0.016×MgO−0.004×CaO+0.016×ZrO2+0.029×Na2O+0×K2O−2.002

Owner:ASAHI GLASS CO LTD

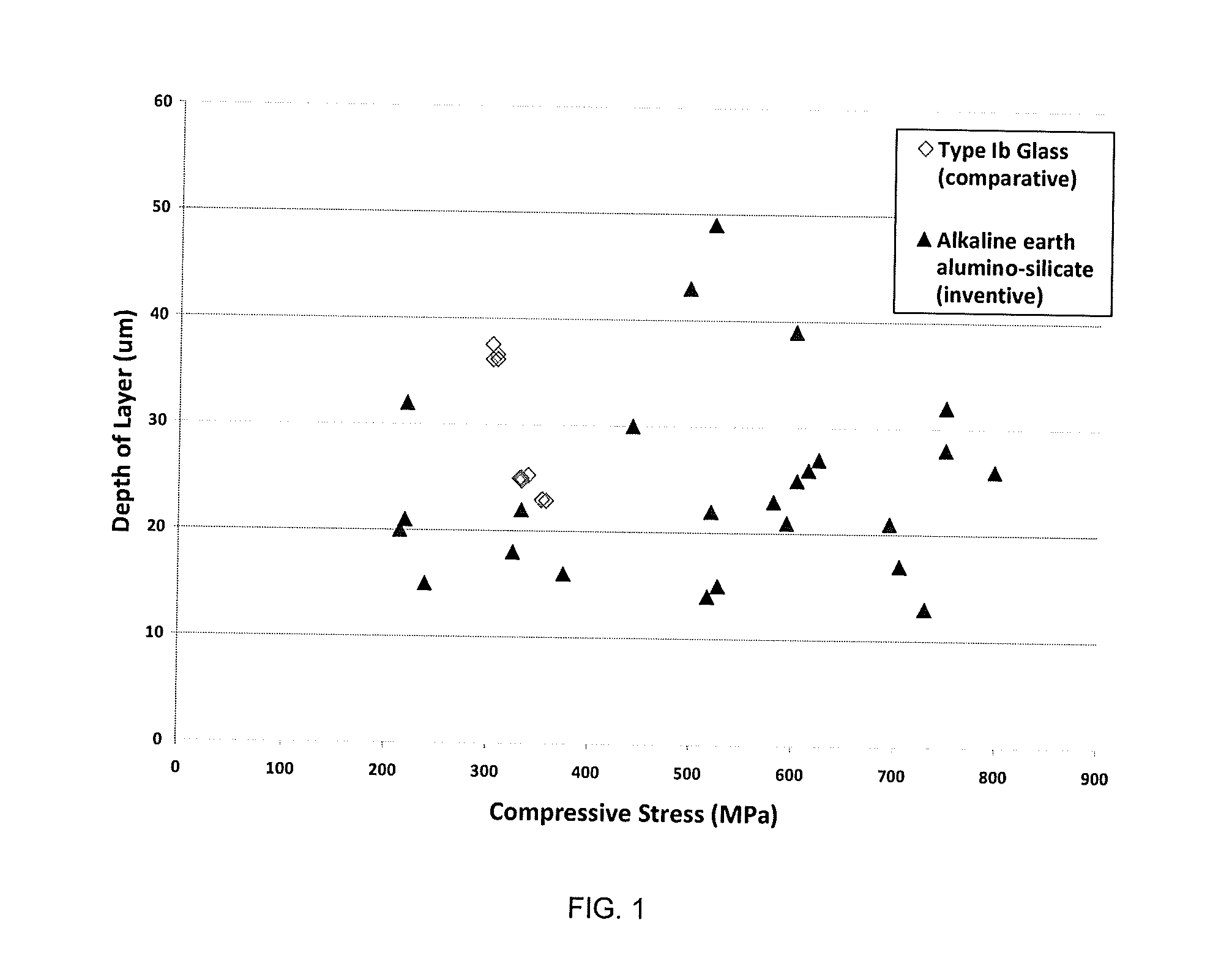

Alkaline earth alumino-silicate glass compositions with improved chemical and mechanical durability

Owner:CORNING INC

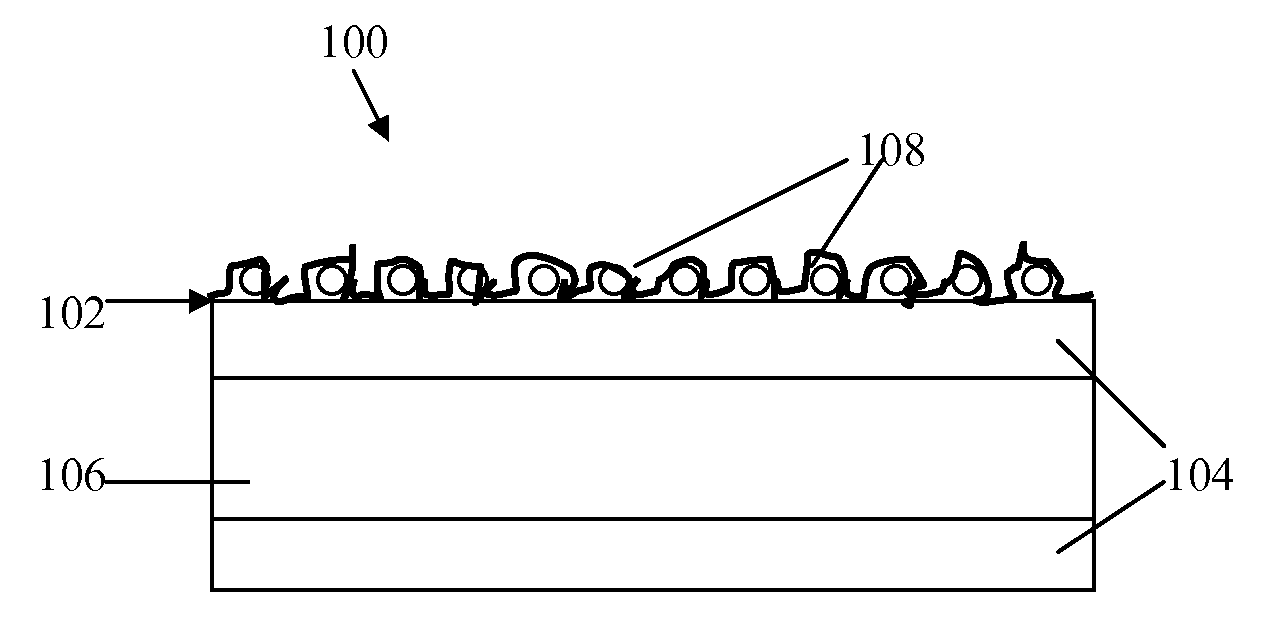

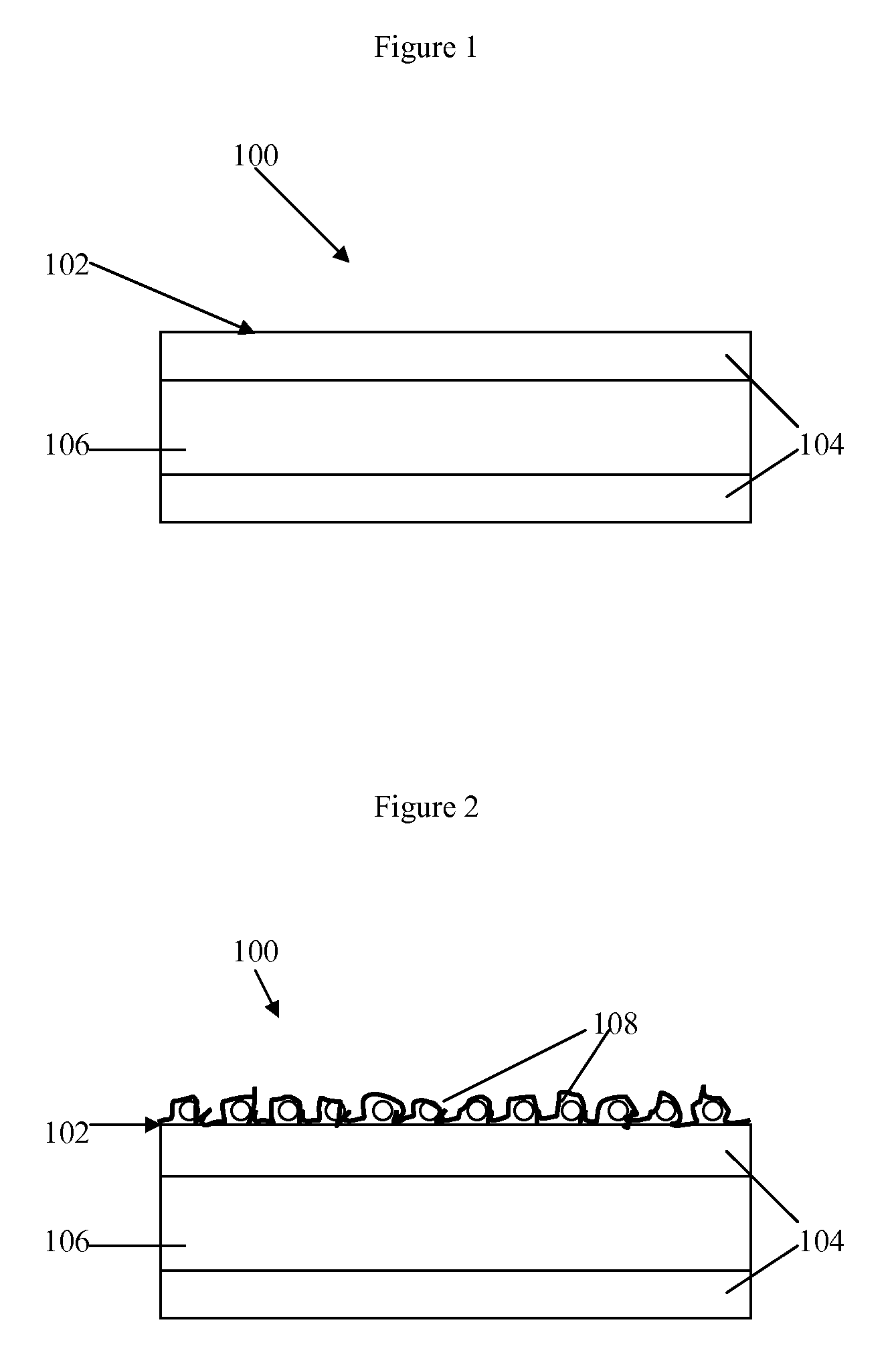

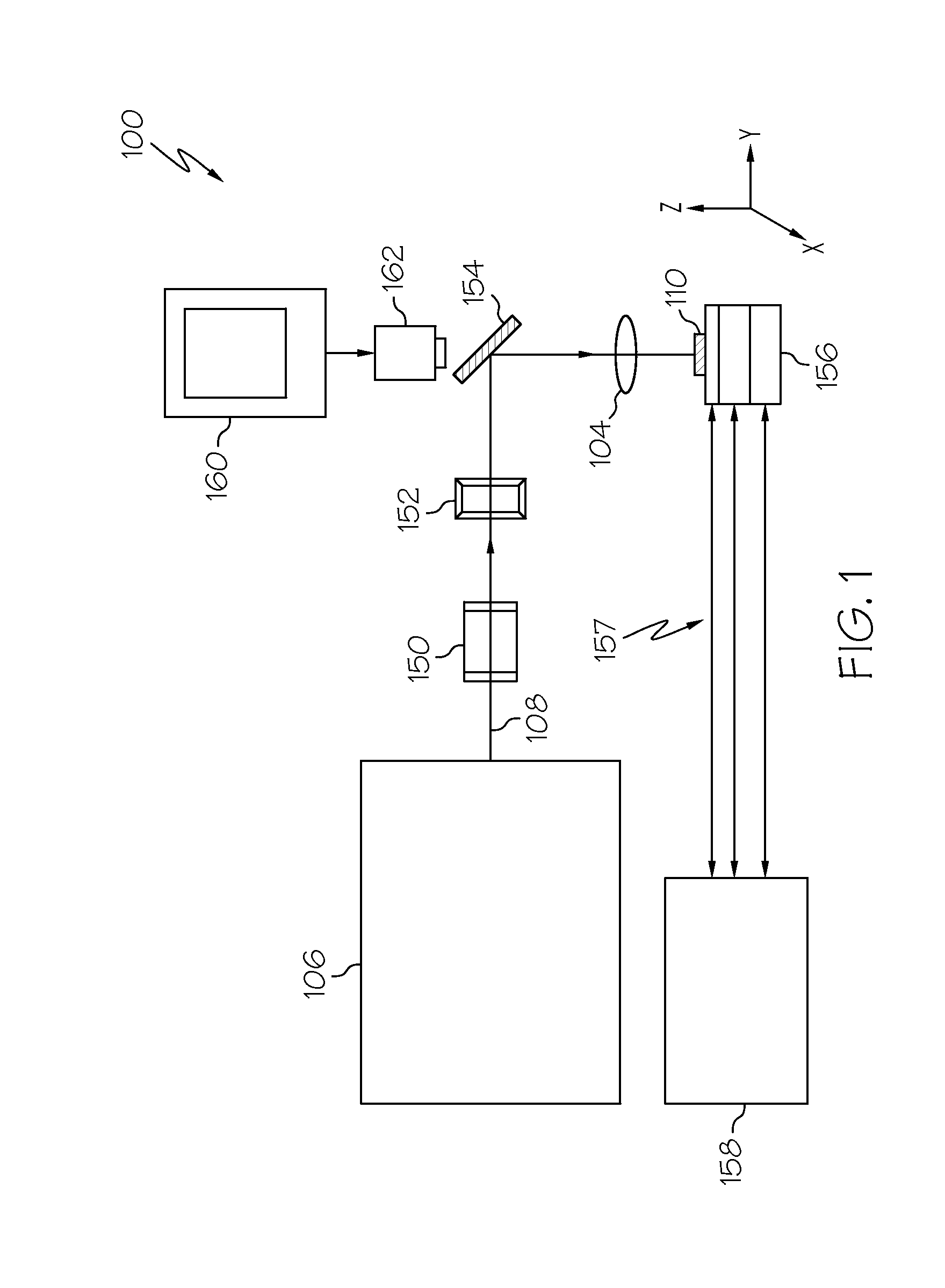

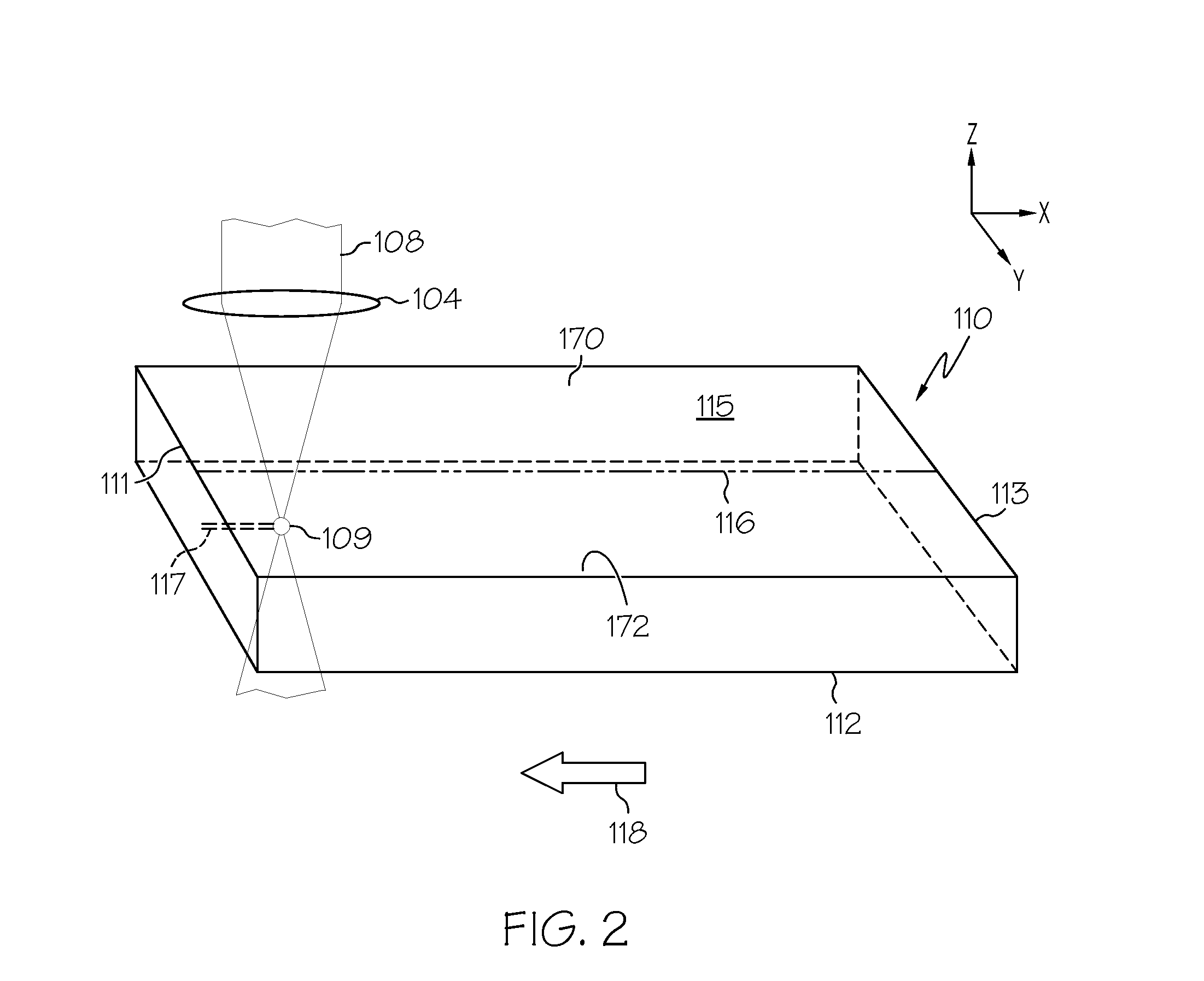

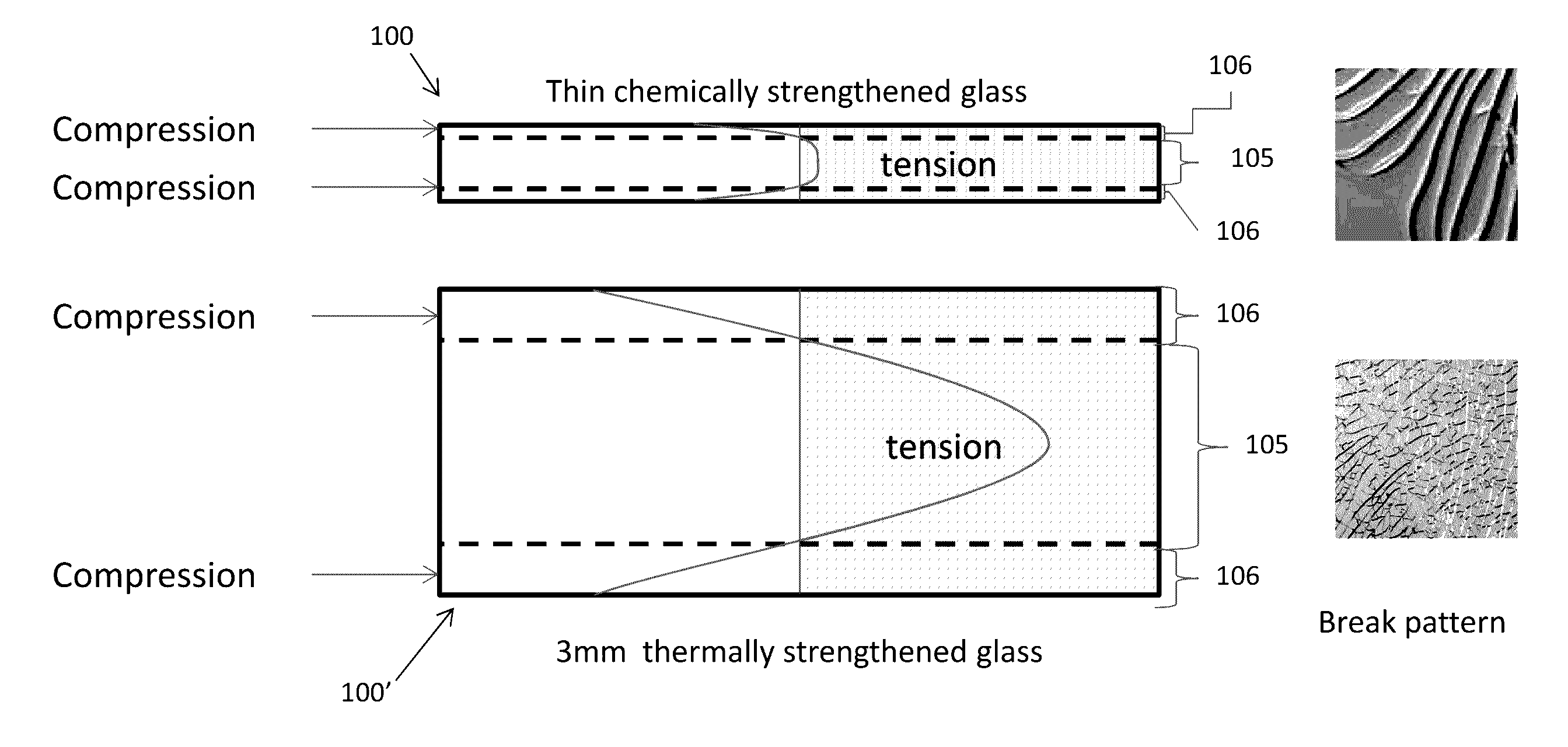

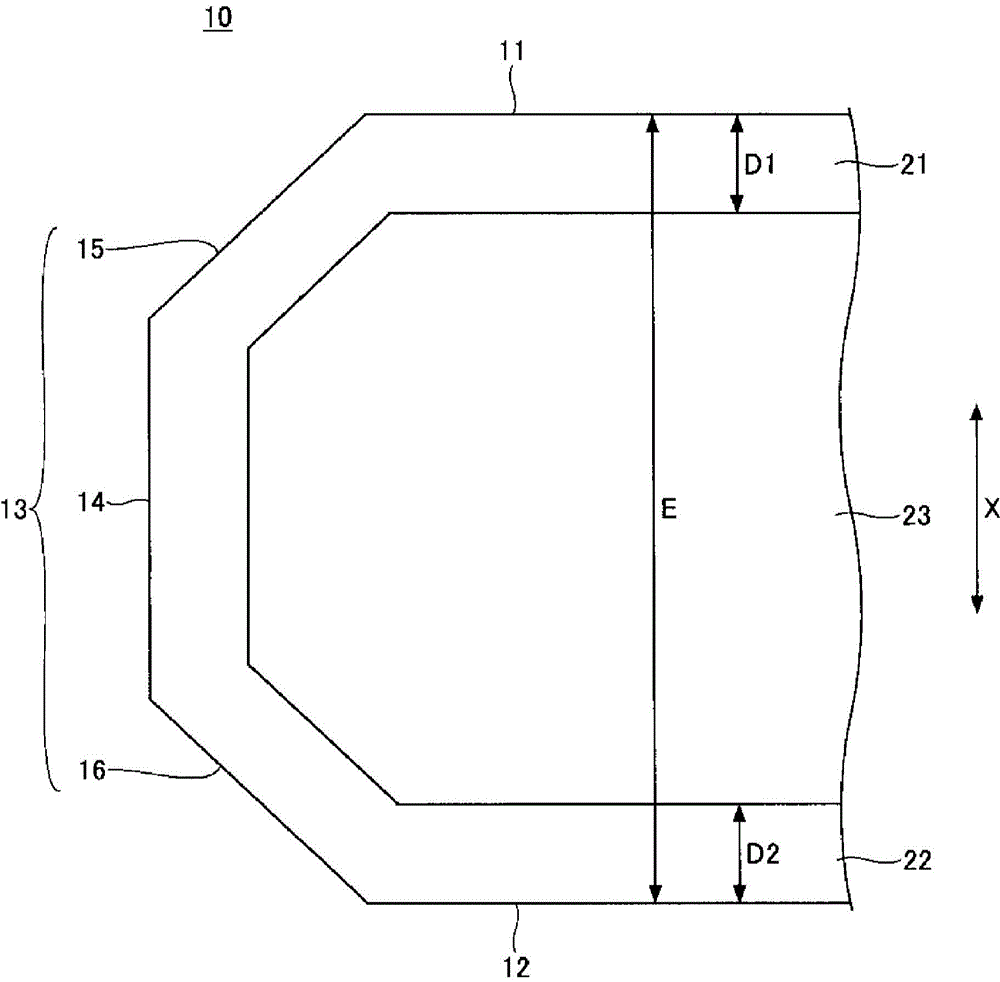

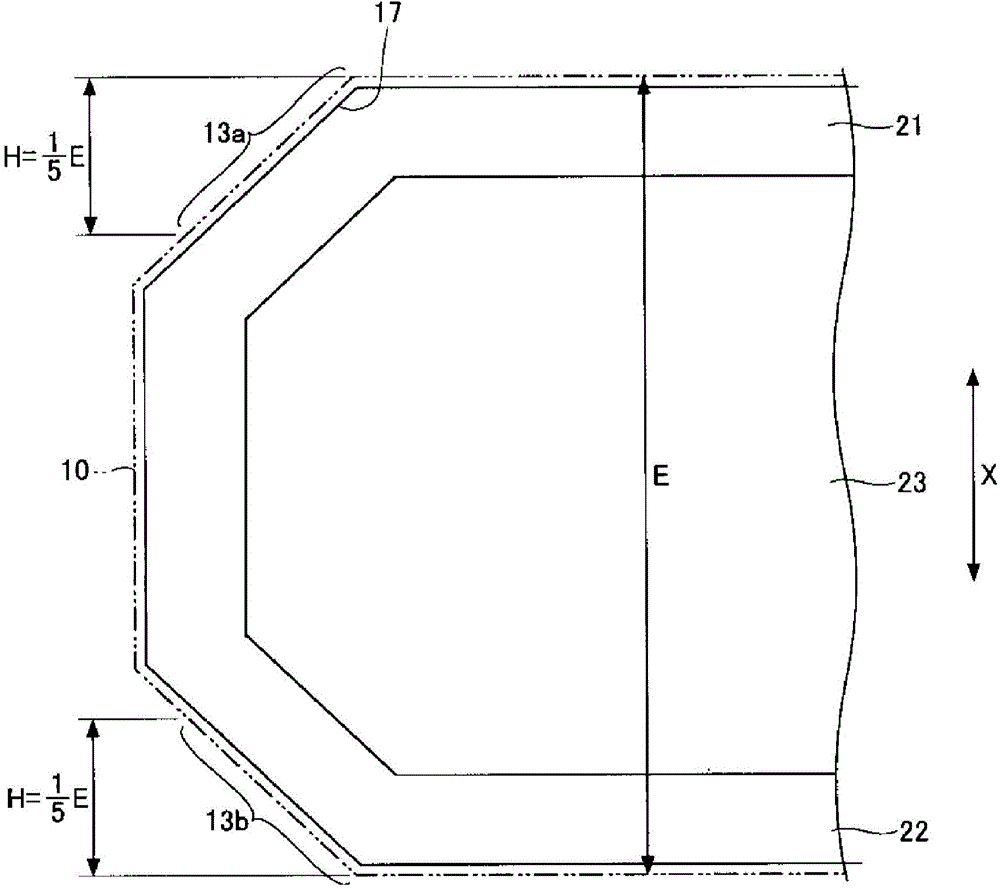

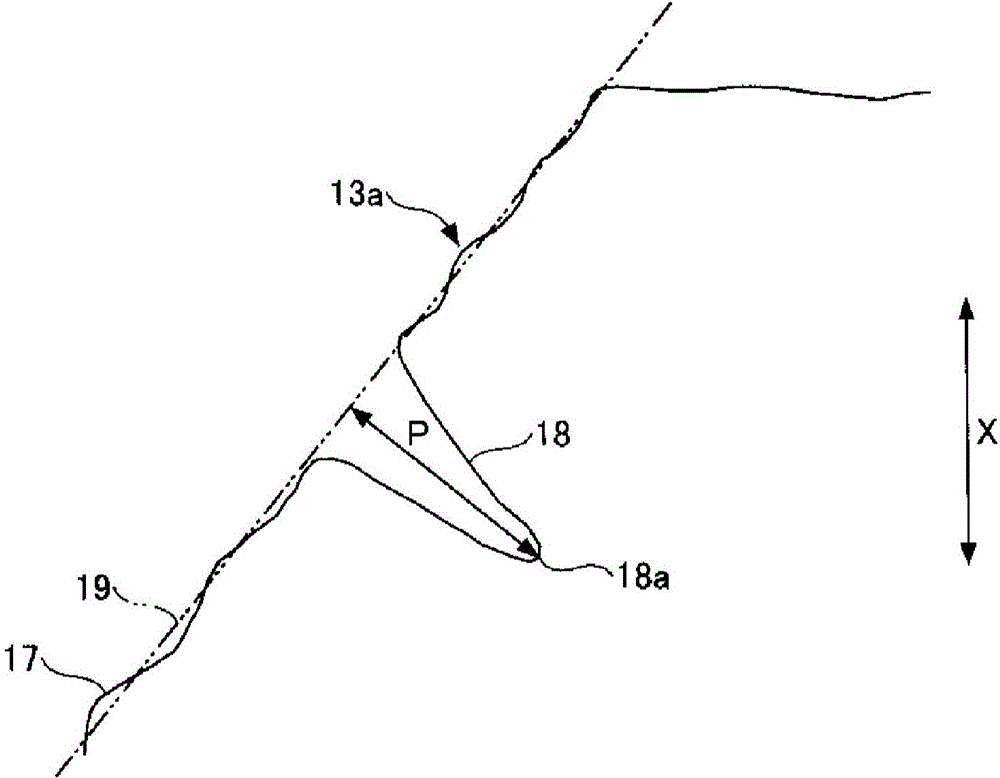

Methods for laser cutting articles from ion exchanged glass substrates

ActiveUS20120145331A1Increase the tensile stressGlass reforming apparatusGlass severing apparatusIon exchangeLaser cutting

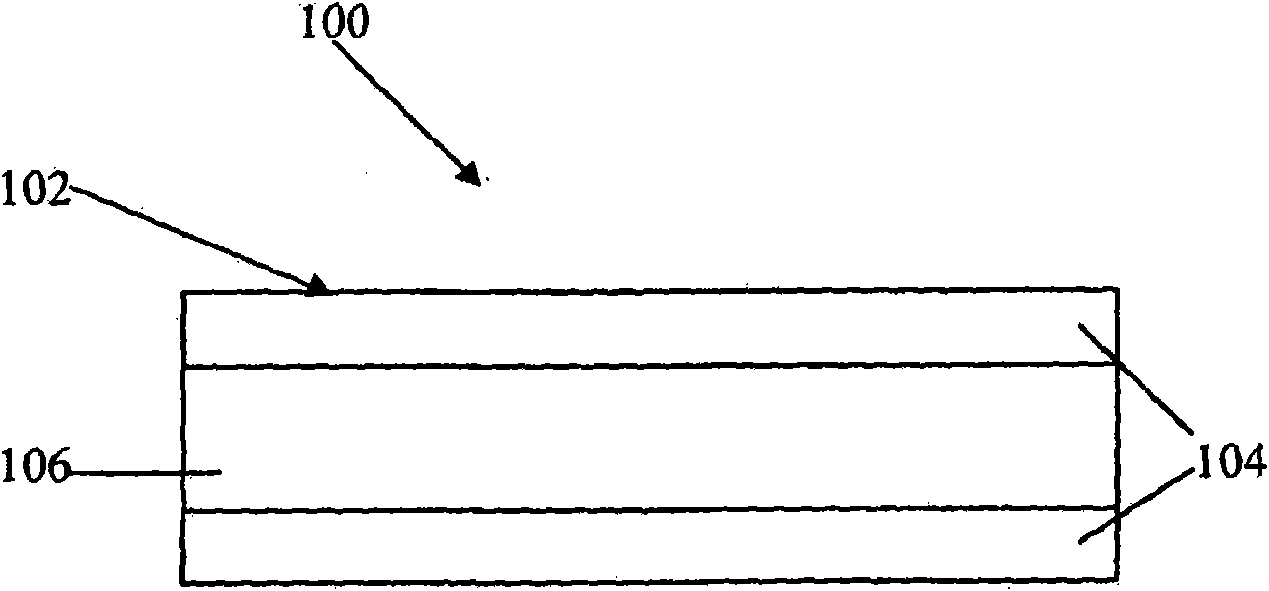

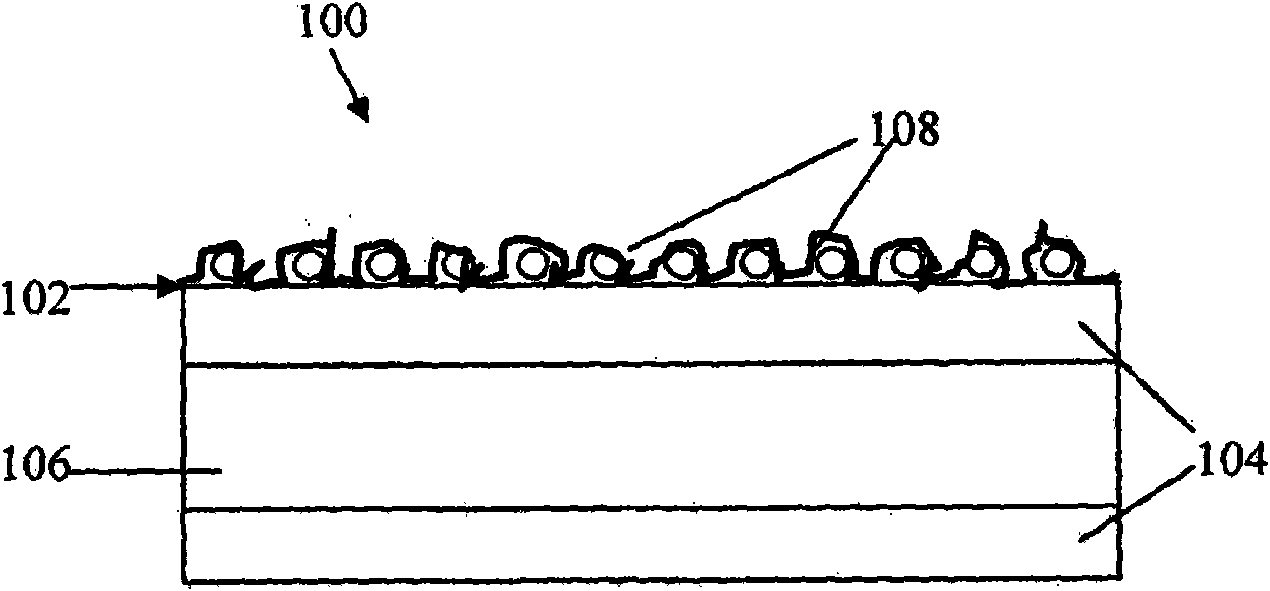

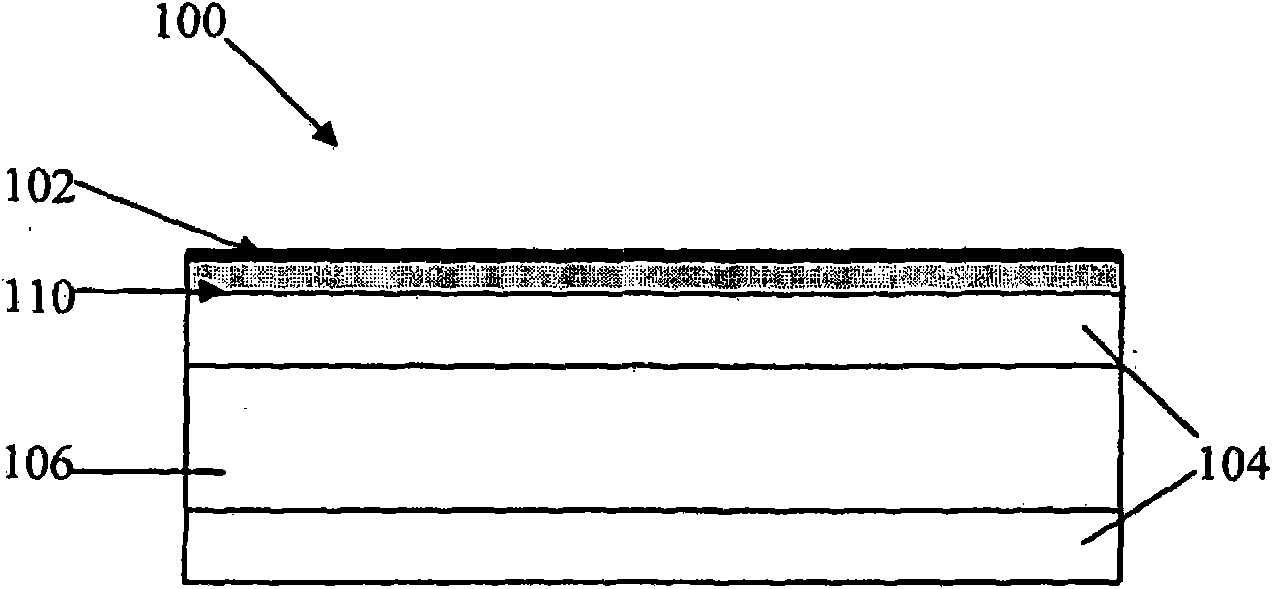

A method of cutting an article (172) from a chemically strengthened glass substrate (110) includes generating a pulsed laser beam (108) from a laser source (106). The pulsed laser beam (108) may have a pulse duration of less than about 1000 fs and an output wavelength such that the chemically strengthened glass substrate (110) is substantially transparent to the pulsed laser beam (108). The pulsed laser beam (108) may be focused to form a beam waist (109) that is positioned in the same horizontal plane as an inner tensile region (124) of the chemically strengthened glass substrate (110). The beam waist (109) may be translated in a first pass along a cut line (116), wherein the beam waist (109) traverses an edge (111) of the chemically strengthened glass substrate. The beam waist (113) may then be translated in a second pass along the cut line (116) such that a crack (119) propagates from the edge (113) along the cut line (116) ahead of the translated beam waist (109) during the second pass.

Owner:CORNING INC

Glass substrate, chemically strengthened glass substrate and cover glass, and method for manufactruing the same

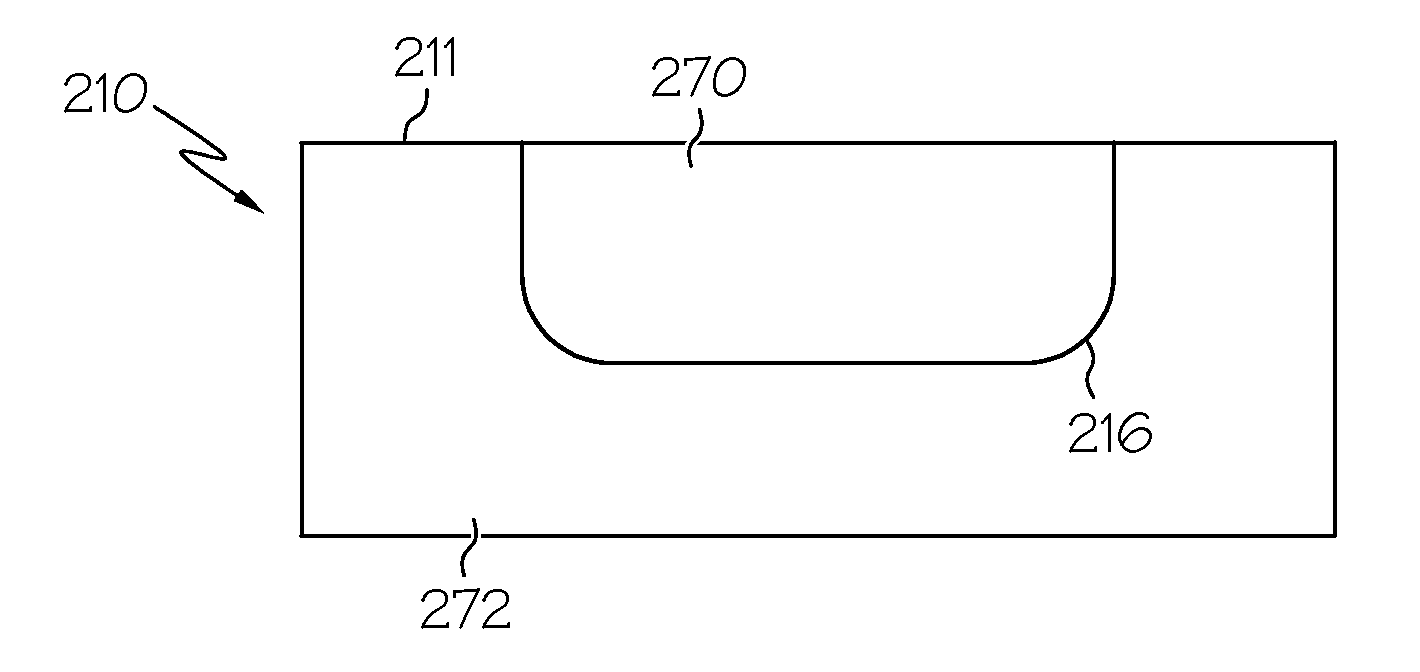

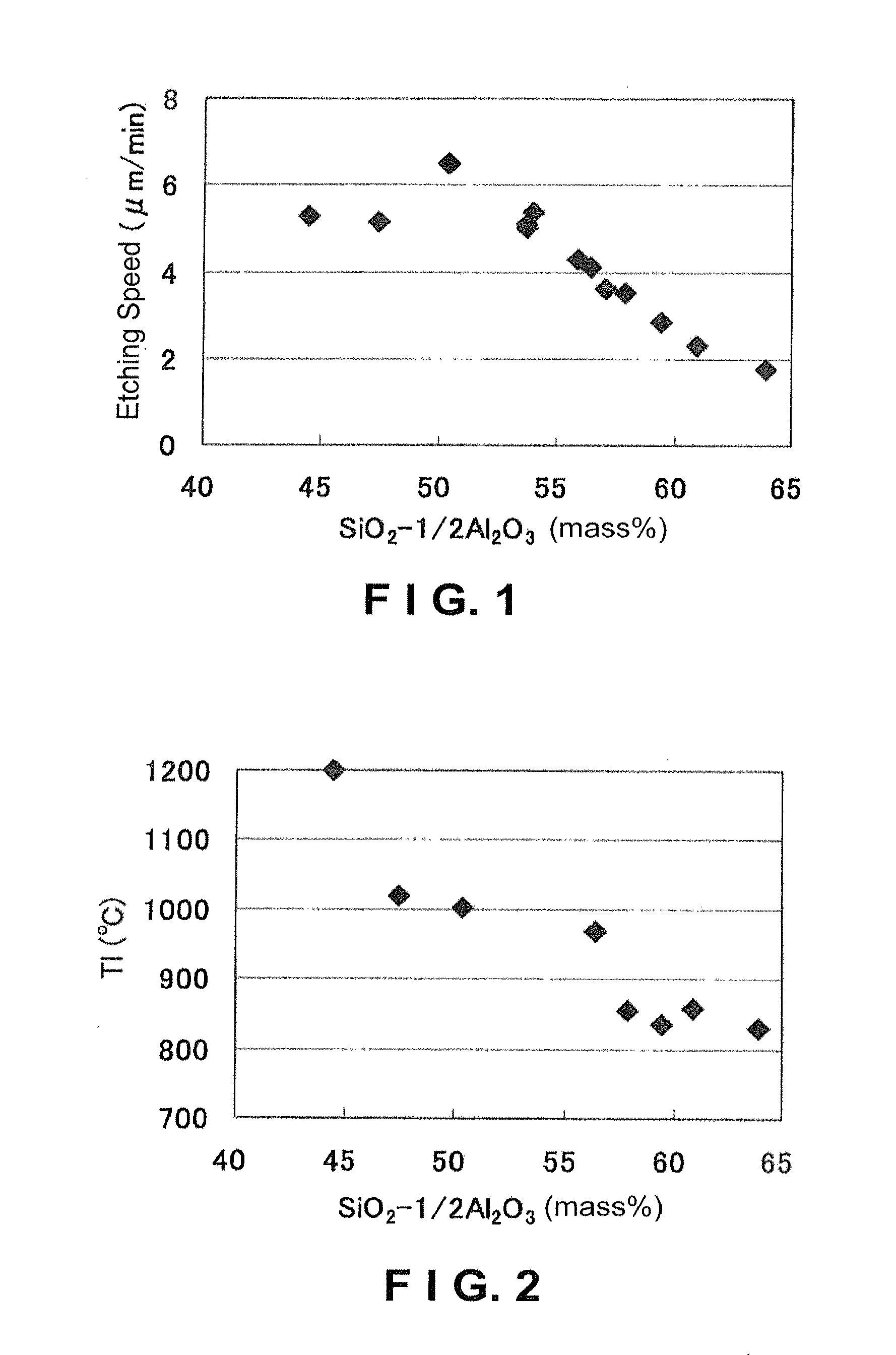

InactiveUS20120052275A1Etching speed is fastIncrease productionGlass drawing apparatusGlass forming apparatusCover glassChemistry

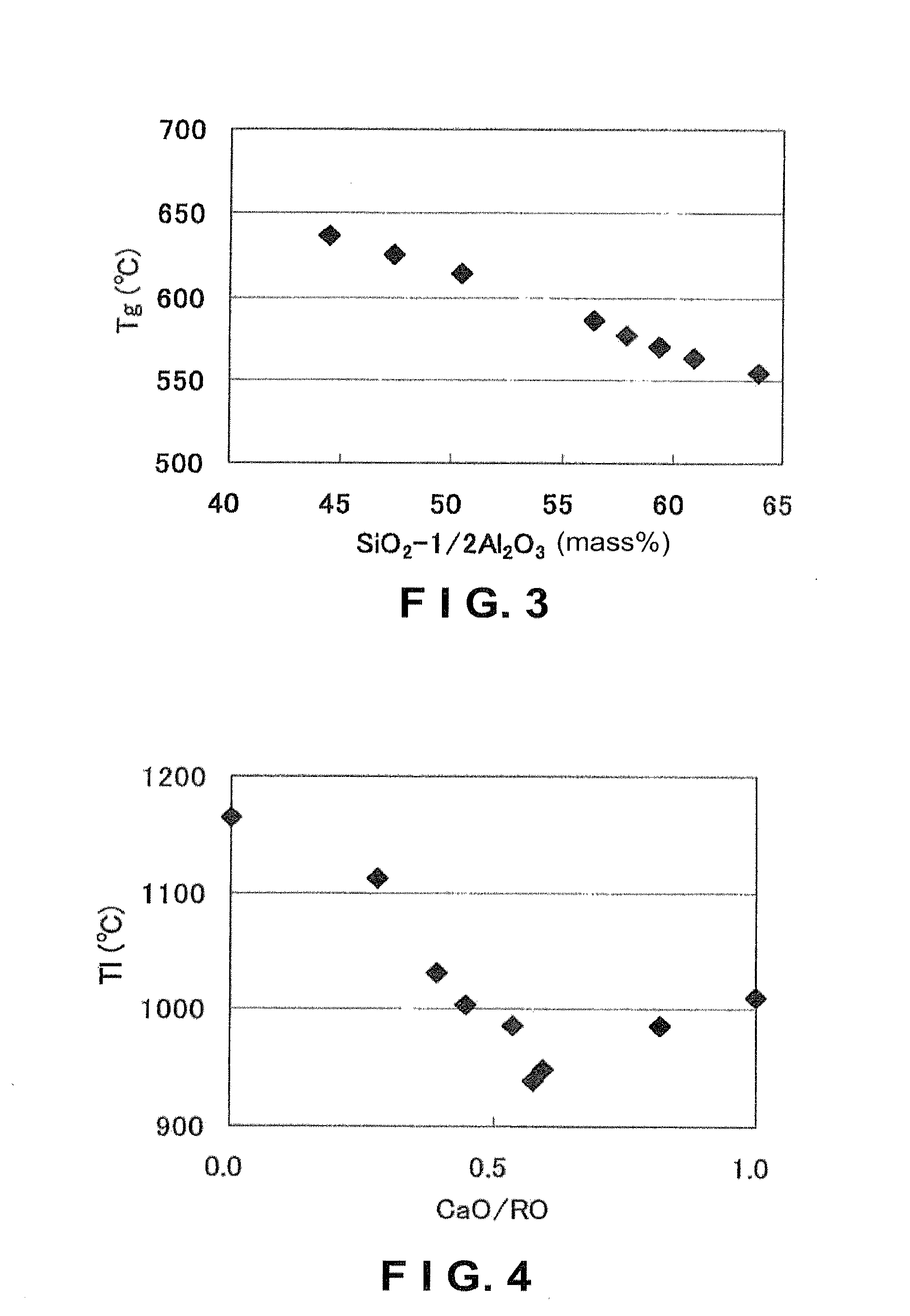

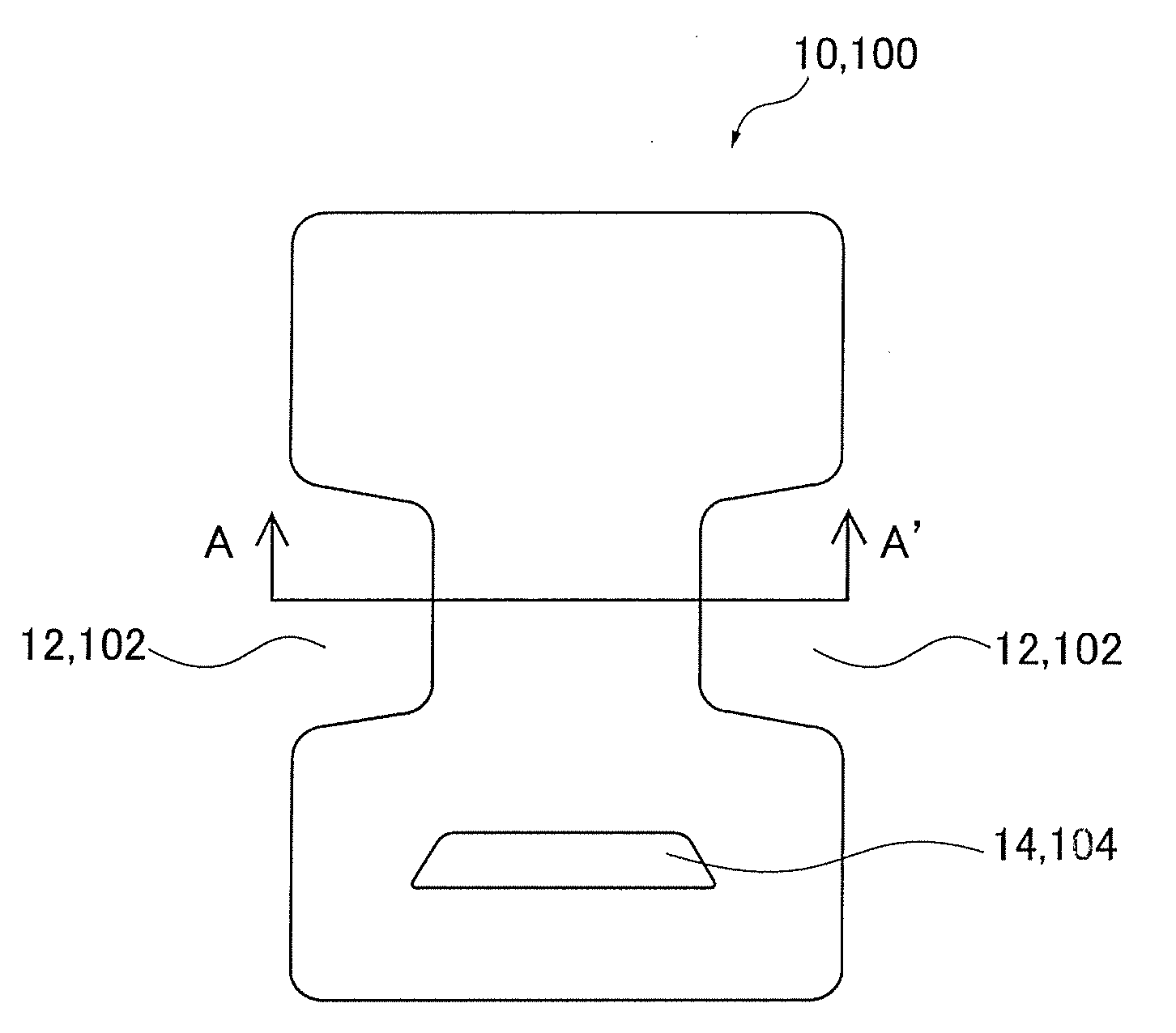

Provided is a cover glass having a down-drawable composition including, in mass percent: 50%-70% SiO2, 5%-20% Al2O3, 6%-20% Na2O, 0%-10% K2O, 0%-10% MgO, above 2%-20% CaO, and 0%-4.8% ZrO2 wherein, (i) 46.5%≦(SiO2−½Al2O3)≦59%, (ii) 0.3<CaO / RO, where RO represents a total mass percent of one or more compounds selected from the group consisting of MgO, CaO, SrO and BaO included in the glass substrate, (iii) SrO+BaO<10%, (iv) 0≦(ZrO2+TiO2) / SiO2)<0.07, and (v) 0≦B2O3 / R12O<0.1, where R12O represents a total mass percent of one or more compounds selected from the group consisting of Li2O, Na2O and K2O included in the glass substrate.

Owner:HOYA CORP +1

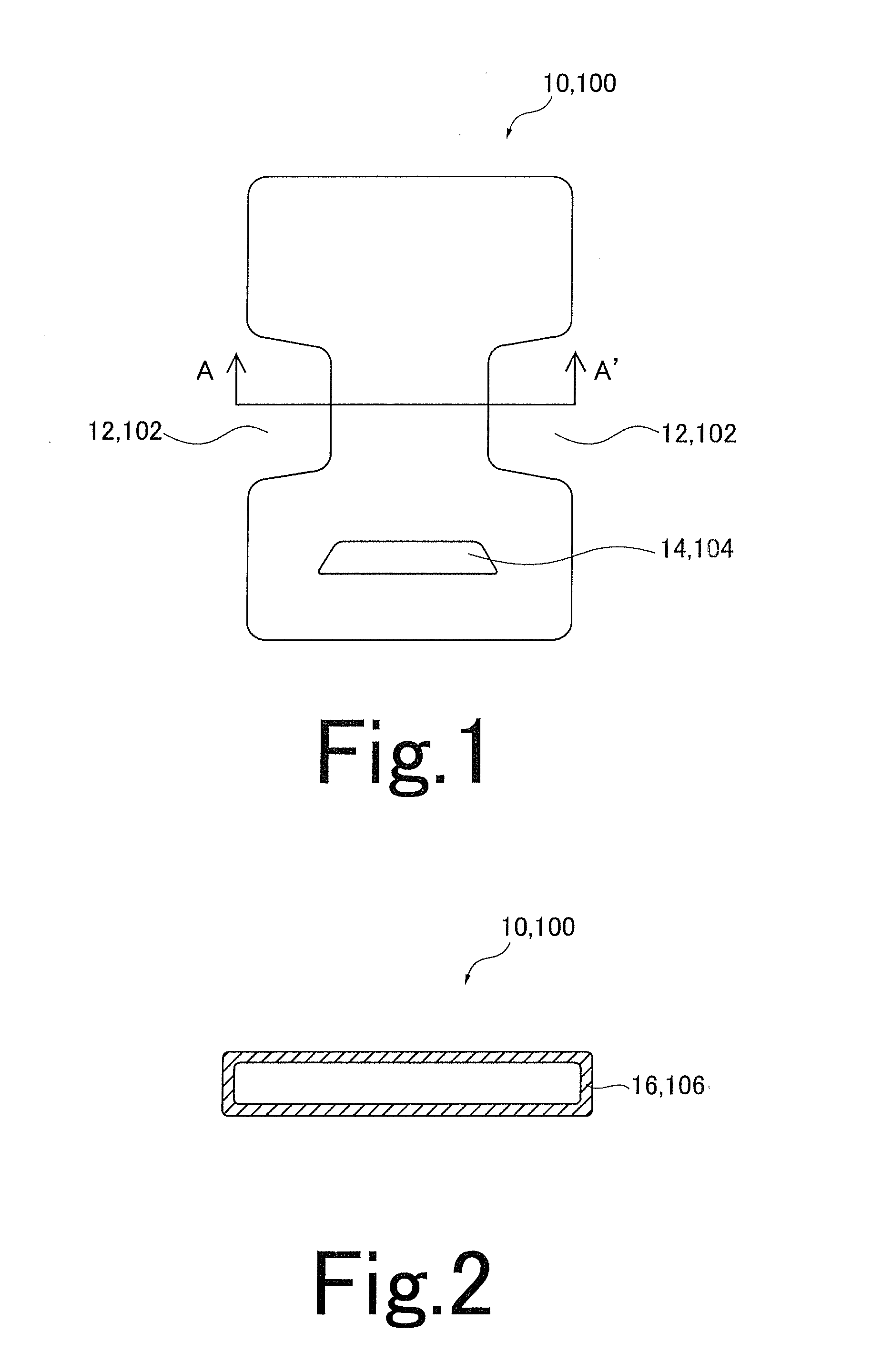

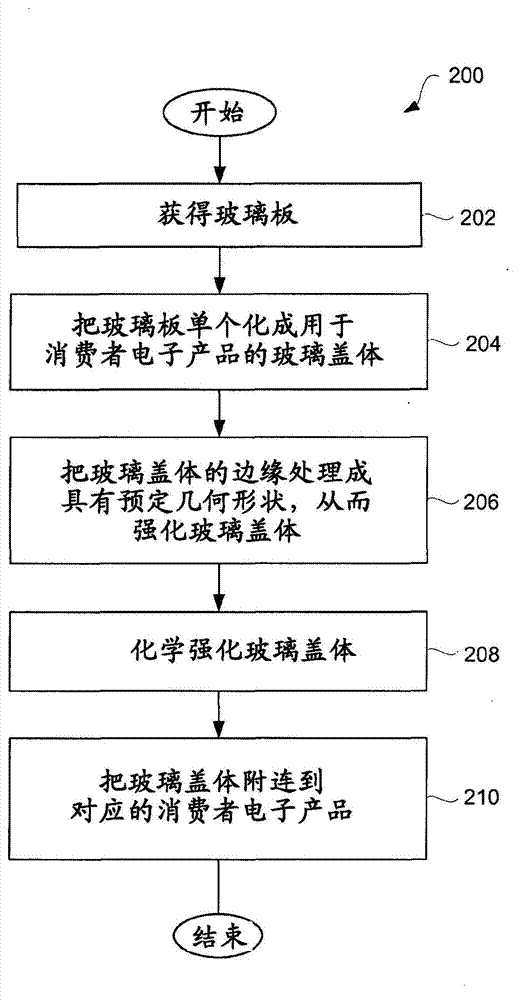

Cover glass and method for producing cover glass

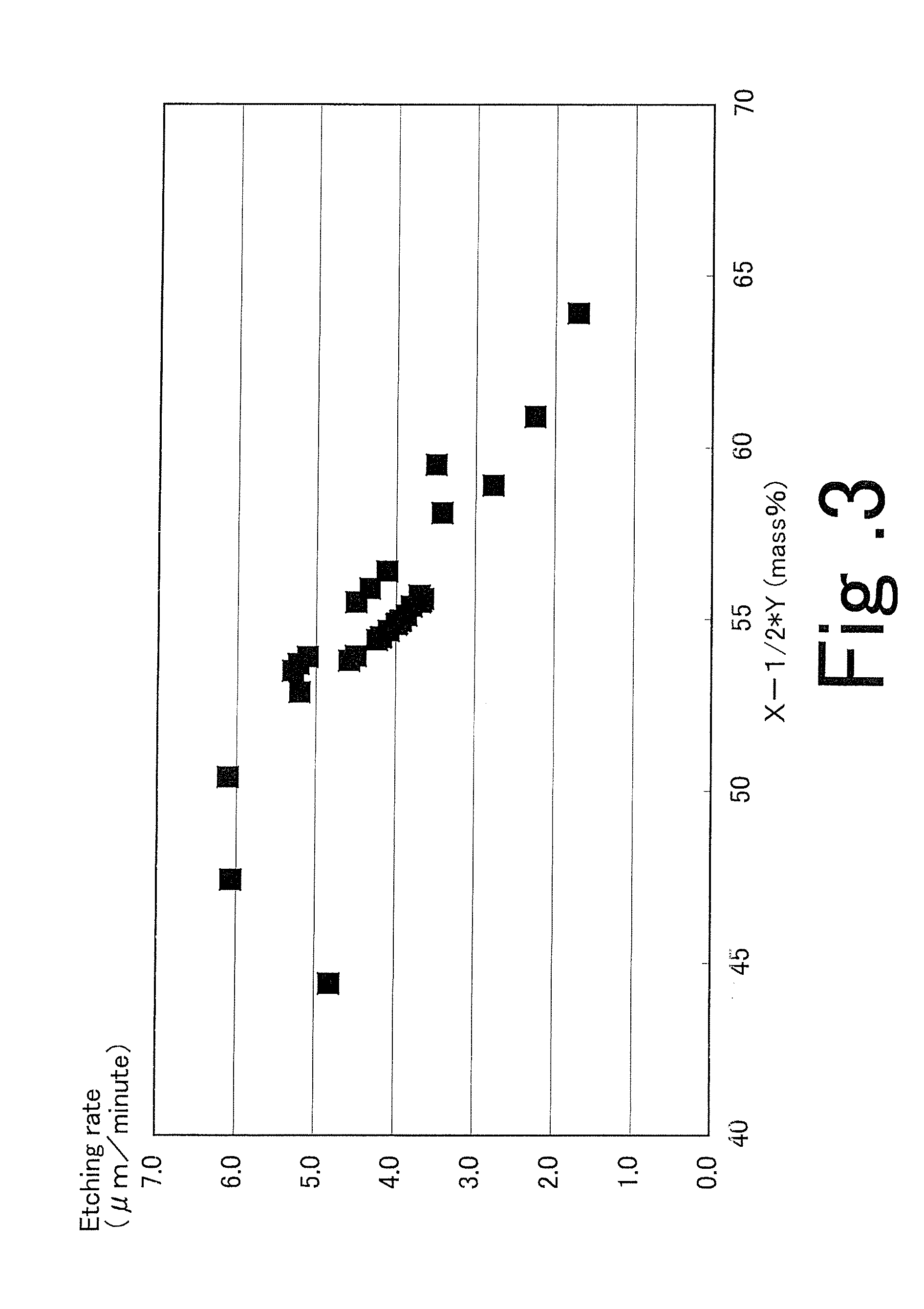

The disclosed cover glass is produced by etching a glass substrate that has been formed by a down-drawing process, and chemically strengthening the glass substrate to provide the glass substrate with a compressive-stress layer on the principal surfaces thereof. The glass substrate contains, as components thereof, 50% to 70% by mass of SiO2, 5% to 20% by mass of Al2O3, 6% to 30% by mass of Na2O, and 0% to less than 8% by mass of Li2O. The glass substrate may also contain 0% to 2.6% by mass of CaO, if necessary. The glass substrate has an etching characteristic in which the etching rate is at least 3.7 μm / minute in an etching environment having a temperature of 22° C. and containing hydrogen fluoride with a concentration of 10% by mass.

Owner:AVANSTRATE INC +1

Down-drawable chemically strengthened glass for information storage devices

ActiveUS20140356576A1Synthetic resin layered productsGlass forming apparatusMaterials scienceInformation storage

Described herein are various glass compositions, glass articles, and information storage devices that comprise the glass articles as substrates therefor, along with methods for their manufacture and use.

Owner:CORNING INC

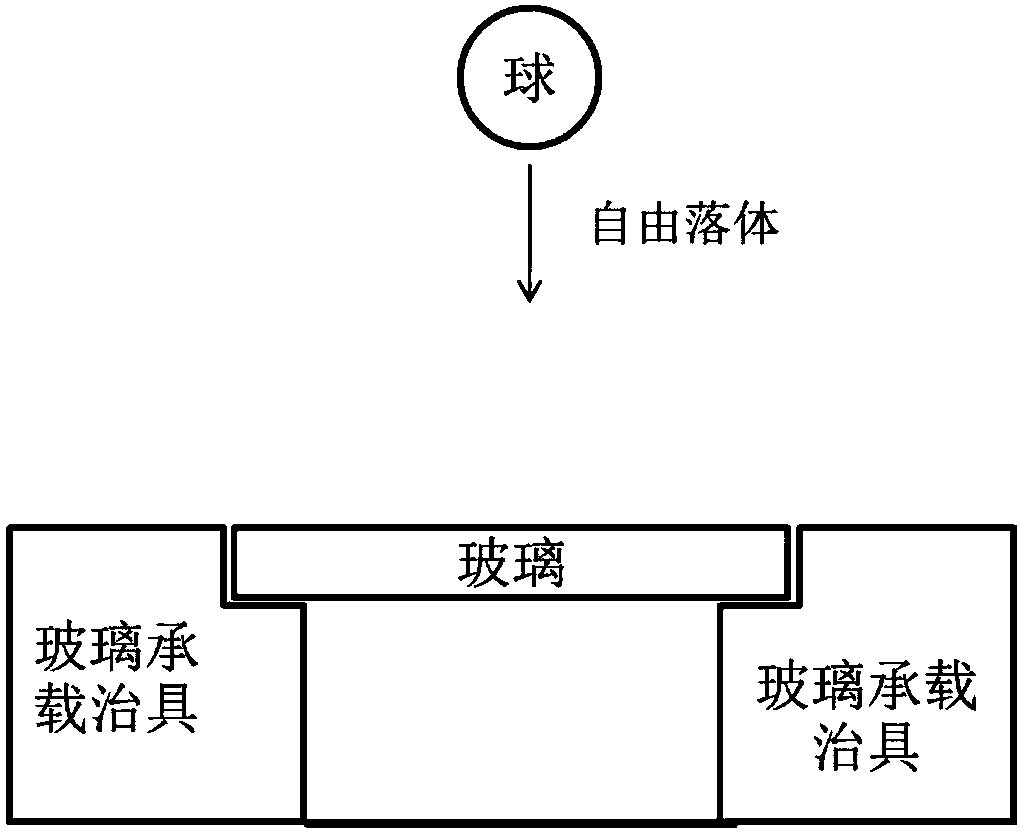

Chemical strengthening treatment method of magnetic disk glass substrate

InactiveUS20070039353A1Low priceLiquid surface applicatorsBase layers for recording layersCompound (substance)Materials science

Chemical strengthening treatment is performed by first providing a granular chemical strengthening salt so as to prevent spread in atmosphere at the time of introduction of chemical strengthening salt in a treating vessel, introducing the chemical strengthening salt in a treating vessel, melting the chemical strengthening salt into molten chemical strengthening salt and bringing a glass disc into contact with the molten chemical strengthening salt. The granular chemical strengthening salt is, for example, one obtained by forming of a powdery chemical strengthening salt material into grains. A chemically strengthened glass substrate for magnetic disk can be obtained through the process of carrying out chemical strengthening treatment of magnetic disk glass substrates. A magnetic disk can be obtained by forming at least a magnetic layer on the chemically strengthened glass substrate for magnetic disk.

Owner:HOYA CORP

Laser cutting strengthened glass

Methods for cutting strengthened glass are disclosed. The methods can include using a laser. The strengthened glass can include chemically strengthened, heat strengthened, and heat tempered glass. Strengthened glass with edges showing indicia of a laser cutting process are also disclosed. The strengthened glass can include an electrochromic film.

Owner:KINESTRAL TECH

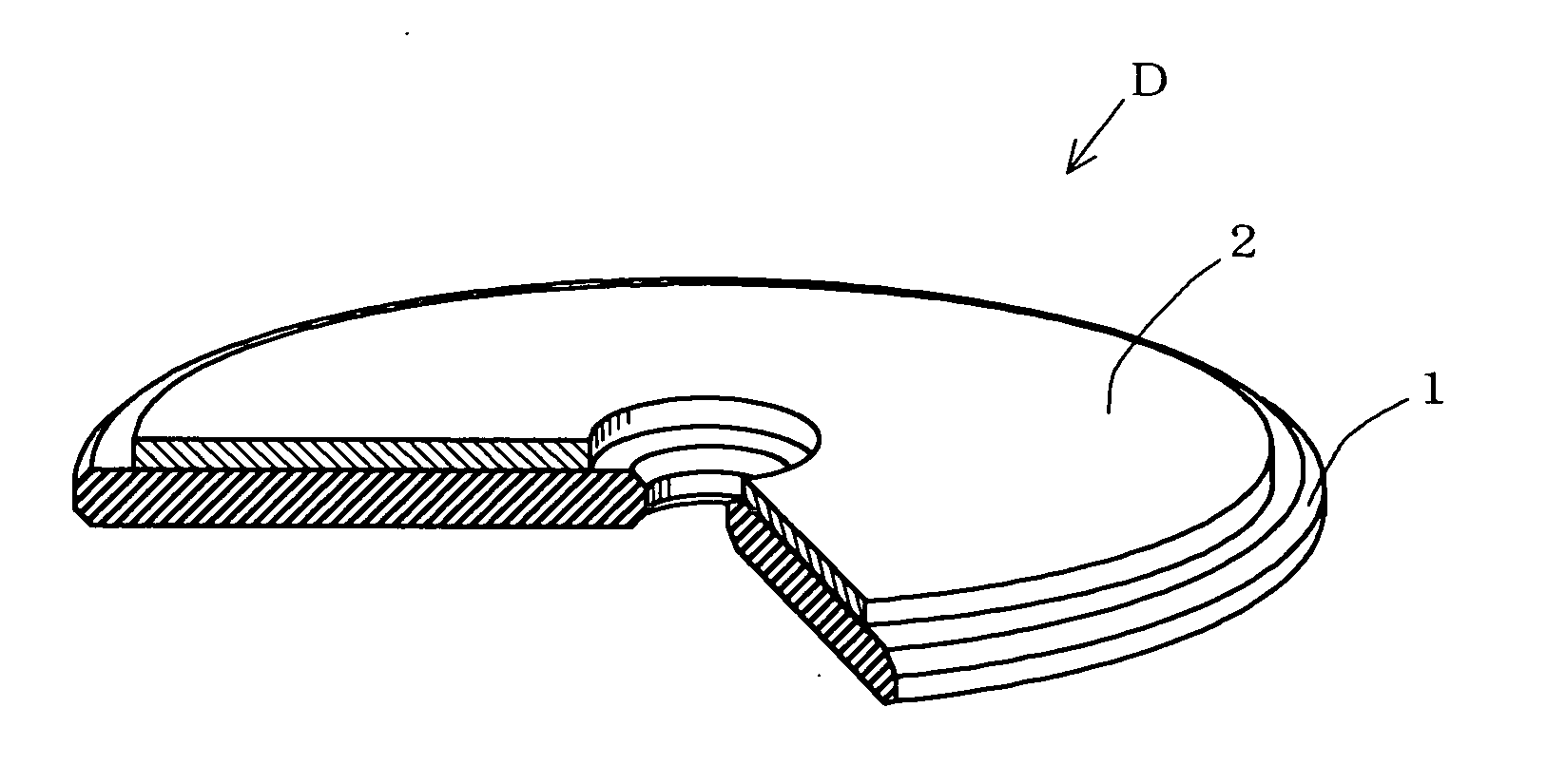

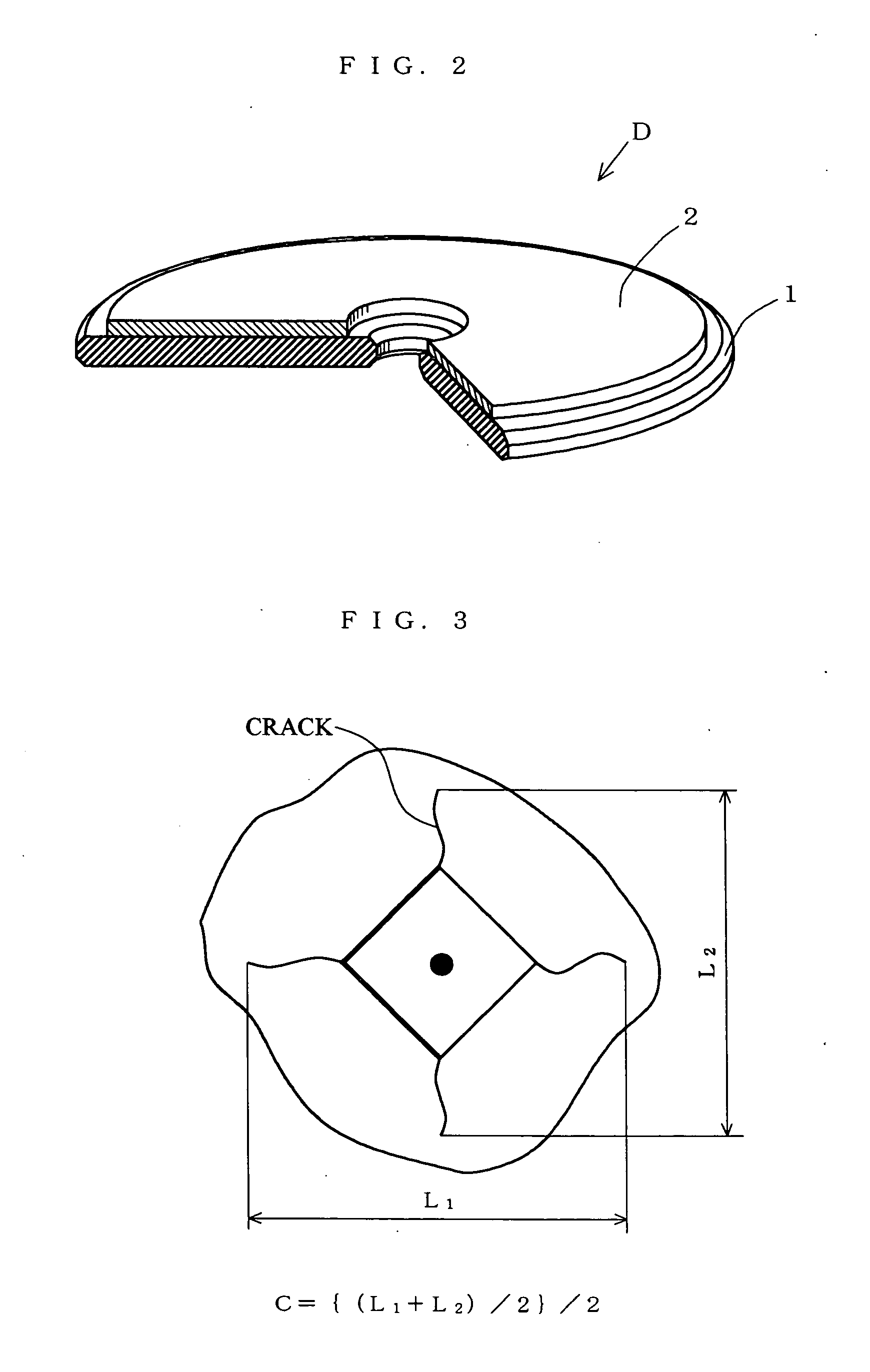

Glass substrate for an information recording medium and information recording medium employing it

InactiveUS20050096210A1Improve yieldIncreased durabilityMagnetic materials for record carriersBase layers for recording layersEdge surfaceRecording layer

A chemically strengthened glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, wherein a strengthened layer formed by chemical strengthening exists on the outer edge surface and on the inner edge surface but substantially not on a surface on which an information recording layer is formed.

Owner:HOYA CORP

Method for producing chemically tempered glass, and glass for chemical tempering

InactiveUS20120264585A1High strengthDevitrification resistance can be poorDigital data processing detailsNon-linear opticsCompound (substance)Toughened glass

To provide a method for producing chemically tempered glass, whereby the chemical tempering can be done at a low temperature and in a short time. A method for producing chemically tempered glass, which comprises chemically tempering glass for chemical tempering, comprising, as represented by mole percentage based on the following oxides, from 60 to 75% of SiO2, from 5 to 15% of Al2O3, from 1 to 12% of MgO, from 0 to 3% of CaO, from 0 to 3% of ZrO2, from 10 to 20% of Li2O, from 0 to 8% of Na2O and from 0 to 5% of K2O, and having a total content R2O of Li2O, Na2O and K2O of at most 25%, and a ratio Li2O / R2O of the Li2O content to R2O of from 0.5 to 1.0.

Owner:ASAHI GLASS CO LTD

Method for producing chemically tempered glass, and glass for chemical tempering

InactiveUS20140364298A1High strengthDigital data processing detailsNon-linear opticsPhotochemistryChemically strengthened glass

A Glass for chemical tempering, which includes, as represented by mole percentage based on the following oxides, from 60 to 75% of SiO2, from 5 to 15% of Al2O3, more than 7 and at most 12% of MgO, from 0 to 3% of CaO, from 0 to 3% of ZrO2, from 10 to 20% of Li2O, from 0 to 8% of Na2O and from 0 to 5% of K2O, and has a total content R2O of Li2O, Na2O and K2O of at most 25%, and a ratio Li2O / R2O of the Li2O content to R2O of from 0.5 to 1.0.

Owner:ASAHI GLASS CO LTD

Dual stage ion exchange for chemical strengthening of glass

A method of chemically strengthening a glass. The method includes ion exchange of the glass in a first bath, followed by immersion in the second bath. The first bath is diluted with an effluent ion. The second bath has a smaller concentration of the effluent ion than the first bath. The method provides a compressive stress at the surface of the glass that is sufficient to arrest flaws introduced by contact forces at the surface of the glass while having sufficiently deep compressive depth-of-layer for high reliability.

Owner:CORNING INC

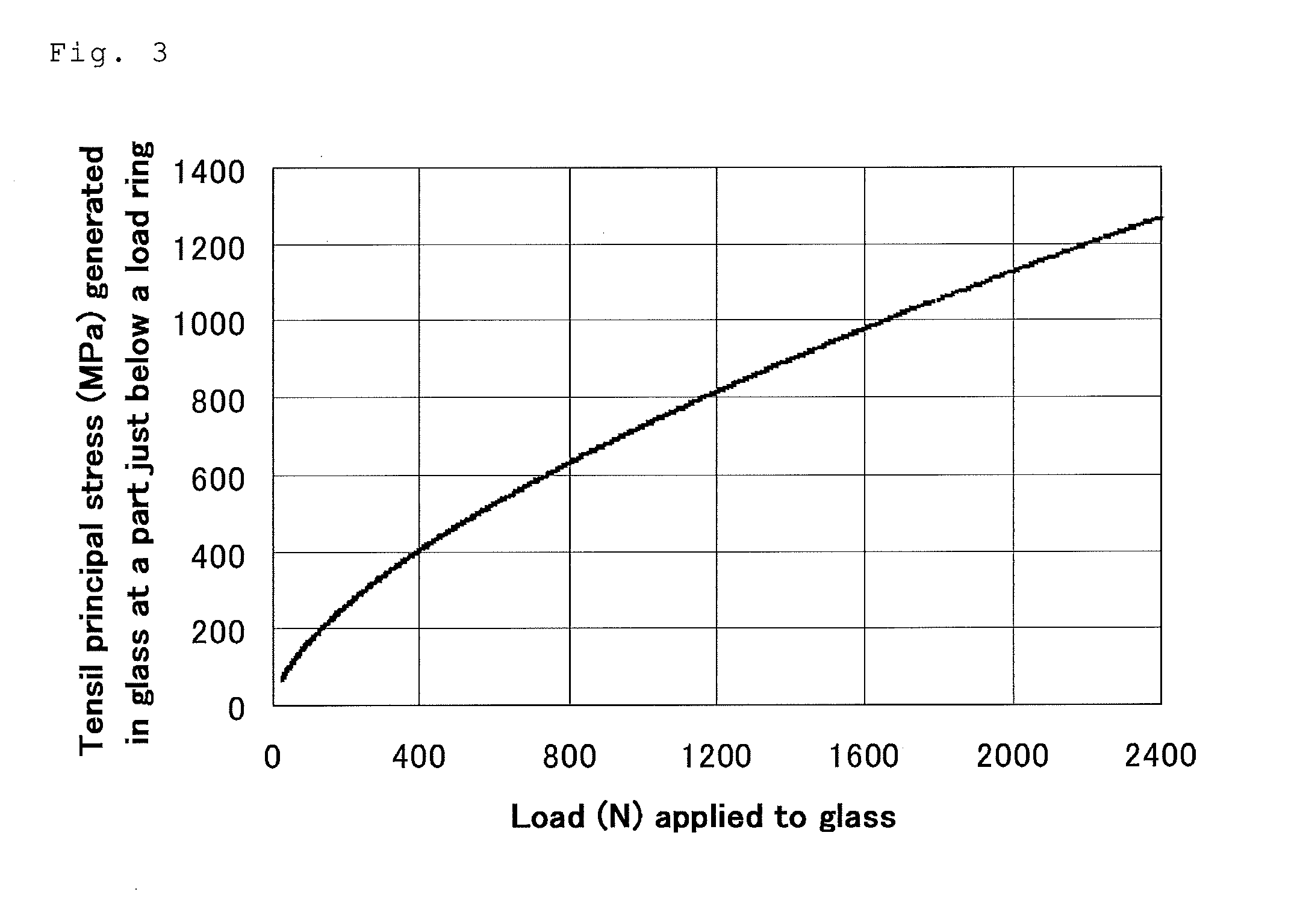

Cover glass for display device, and manufacturing method for same

InactiveUS20140227525A1High mechanical strengthHigh strengthGlass/slag layered productsDisplay deviceIon exchange

The present invention aims to provide a cover glass for display devices, made of soda-lime glass, excellent in cutting easiness and reliability of surface strength. The cover glass for display devices of the present invention includes a chemically strengthened glass, and has a compressive stress layer having a depth of 6 to 15 μm.In the cover glass, a shape parameter determined in accordance with JIS R 1625 (1996) based on analysis of a facture stress of the cover glass measured by a coaxial double ring test is not less than 7, and strength of the cover glass when a cumulative fracture probability is 1% is not less than 450 MPa.The glass plate before the ion exchange is made of soda-lime glass.

Owner:CENT GLASS CO LTD

Chemically strengthened glass, substrate for information recording medium and information recording medium

InactiveUS20060216552A1High strengthImprove recording densityMagnetic materials for record carriersBase layers for recording layersFlexural strengthRecording layer

A glass for use in chemical reinforcement for use in a substrate of an information recording medium, having a composition comprising, denoted as mol %: SiO247 to 70% Al2O31 to 10%(where the total of SiO2 and Al2O3 is 57 to 80%)CaO2 to 25%BaO1 to 15%Na2O1 to 10%K2O0 to 15%(where the total of Na2O and K2O is 3 to 16%)ZrO21 to 12%MgO0 to 10%SrO0 to 15%(where the ratio of the content of CaO to the total of MgO, CaO,SrO, and BaO is greater than or equal to 0.5)ZnO0 to 10%(where the total of MgO, CaO, SrO, BaO, and ZnO is 3 to 30%)TiO20 to 10%and the total content of the above-stated components is greaterthan or equal to 95%.A glass for use in chemical reinforcement for use in the substrate of an information recording medium employed in a perpendicular magnetic recording system, in which the glass exhibits the glass transition temperature is greater than or equal to 600° C. A substrate for use in an information recording medium consisting of the above glass and being chemically reinforced. A substrate for an information recording medium consisting of a chemically reinforced glass having a glass transition temperature of greater than or equal to 600° C. and exhibiting a bending strength following heating for two hours at 570° C. of greater than or equal to 15 kgf / mm2. An information recording medium comprising an information recording layer on the above substrate for an information recording medium. The present invention provides glass having both high thermal resistance and high strength, a substrate for use in information recording media comprised of this glass, and an information recording medium employing such a substrate.

Owner:HOYA CORP

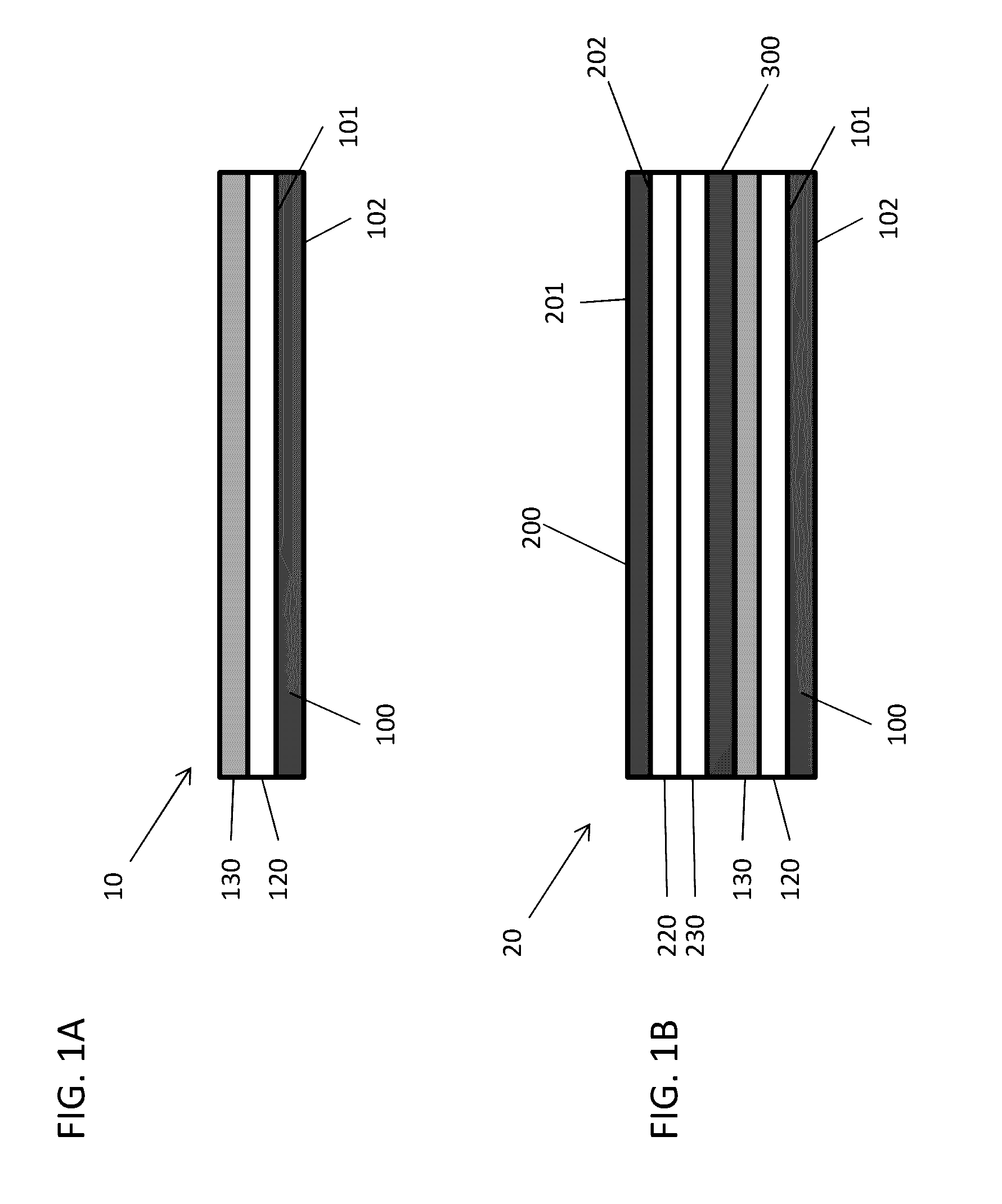

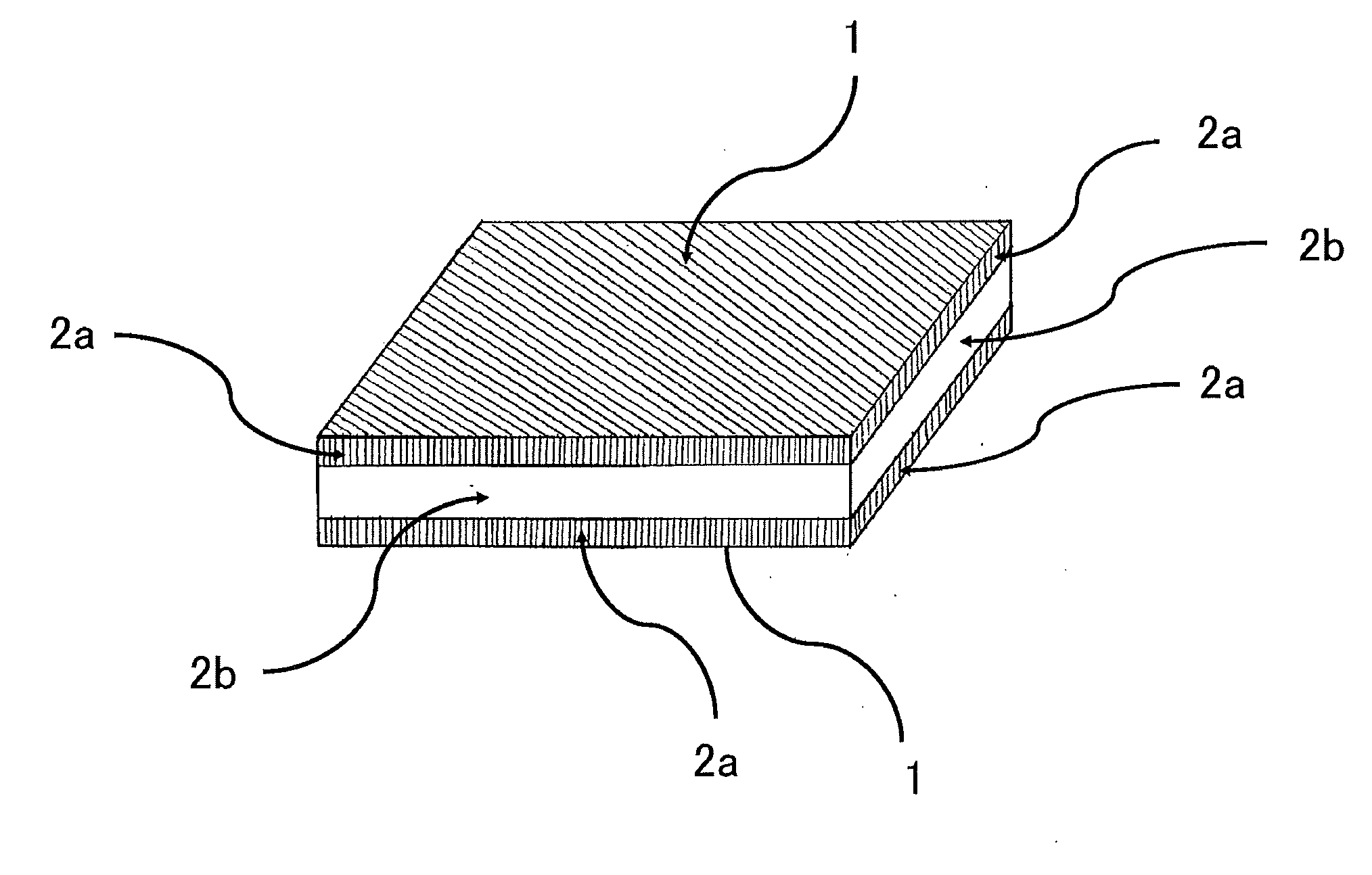

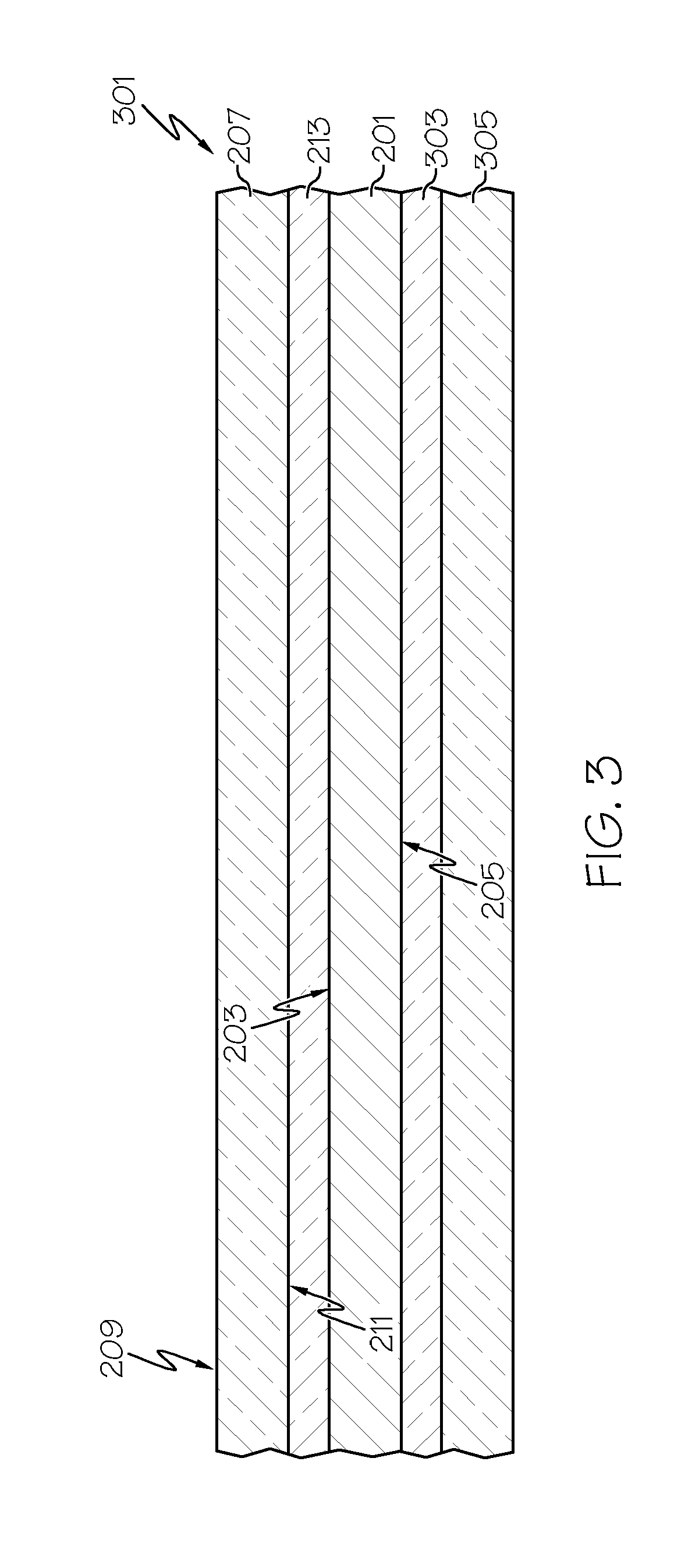

Glass/metal laminated structures and methods of manufacturing laminated structures

ActiveUS20150246507A1Lamination ancillary operationsDecorative surface effectsMetal sheetGlass sheet

Laminated structures comprise a metal sheet including a first face and a second face with a thickness of from about 0.5 mm to about 2 mm extending between the first face and the second face. The laminated structure further includes a first chemically strengthened glass sheet including a thickness of less than or equal to about 1.1 mm and a first interlayer attaching the first chemically strengthened glass sheet to the first face of the metal sheet. In further examples, methods of manufacturing a laminated structure comprise the steps of laminating with a metal sheet and a first chemically strengthened glass sheet together with an interlayer.

Owner:CORNING INC

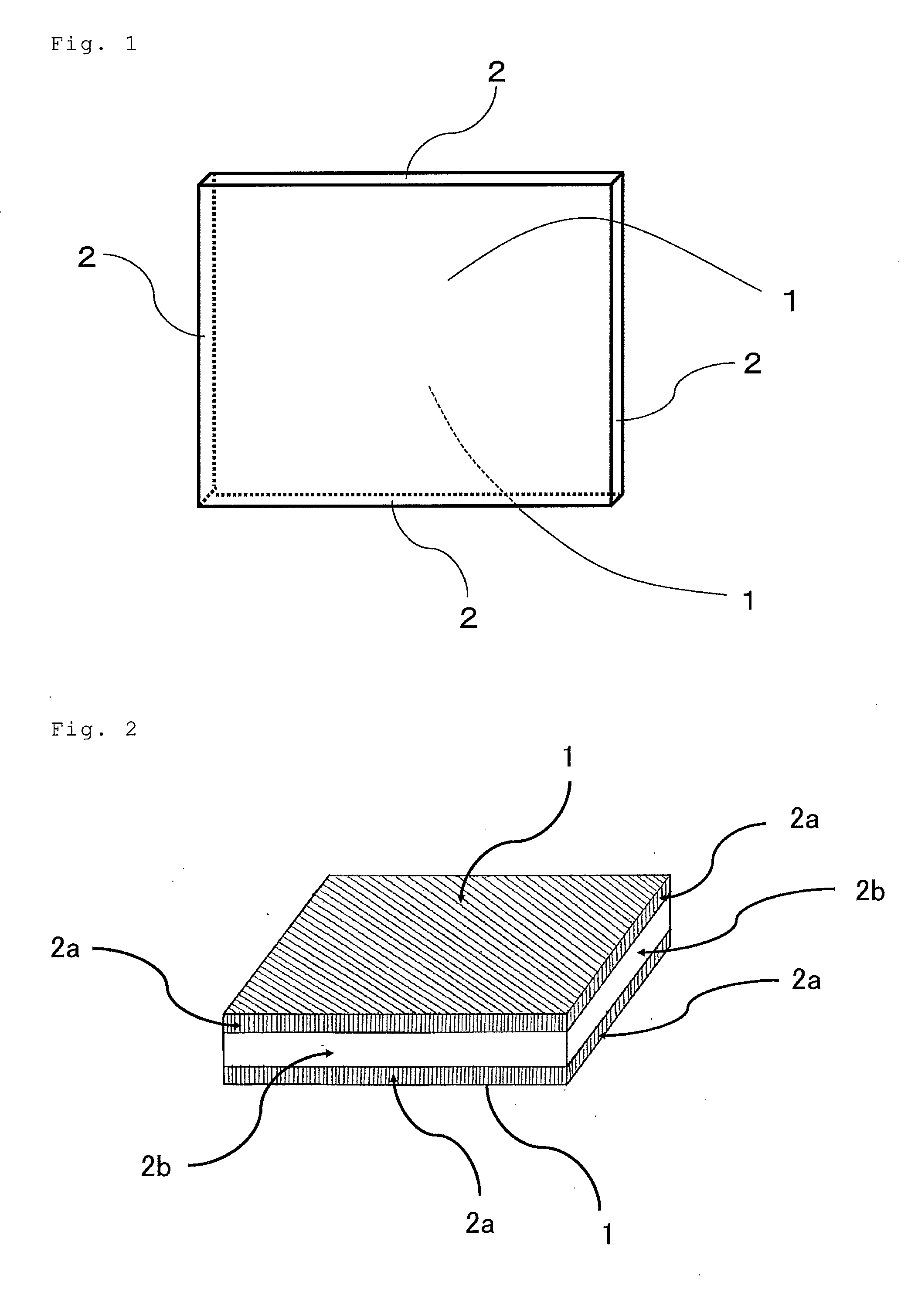

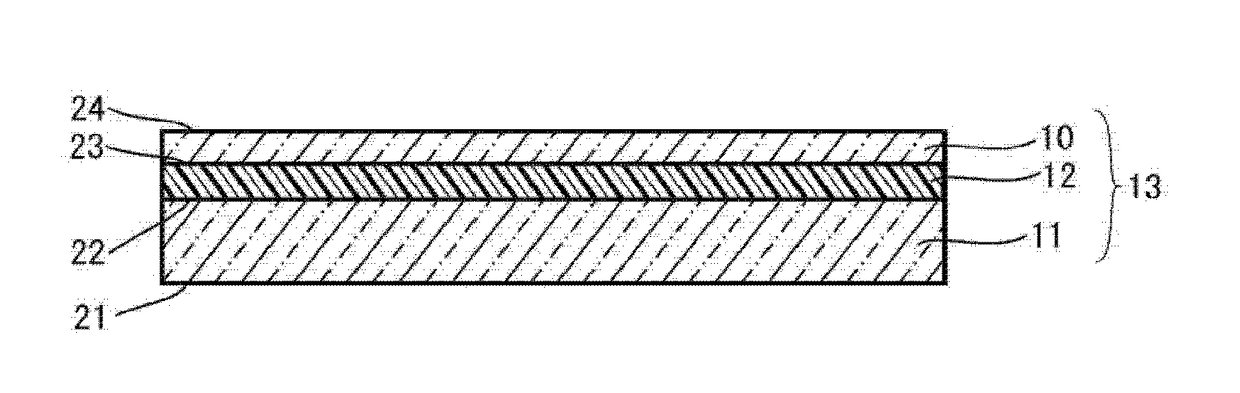

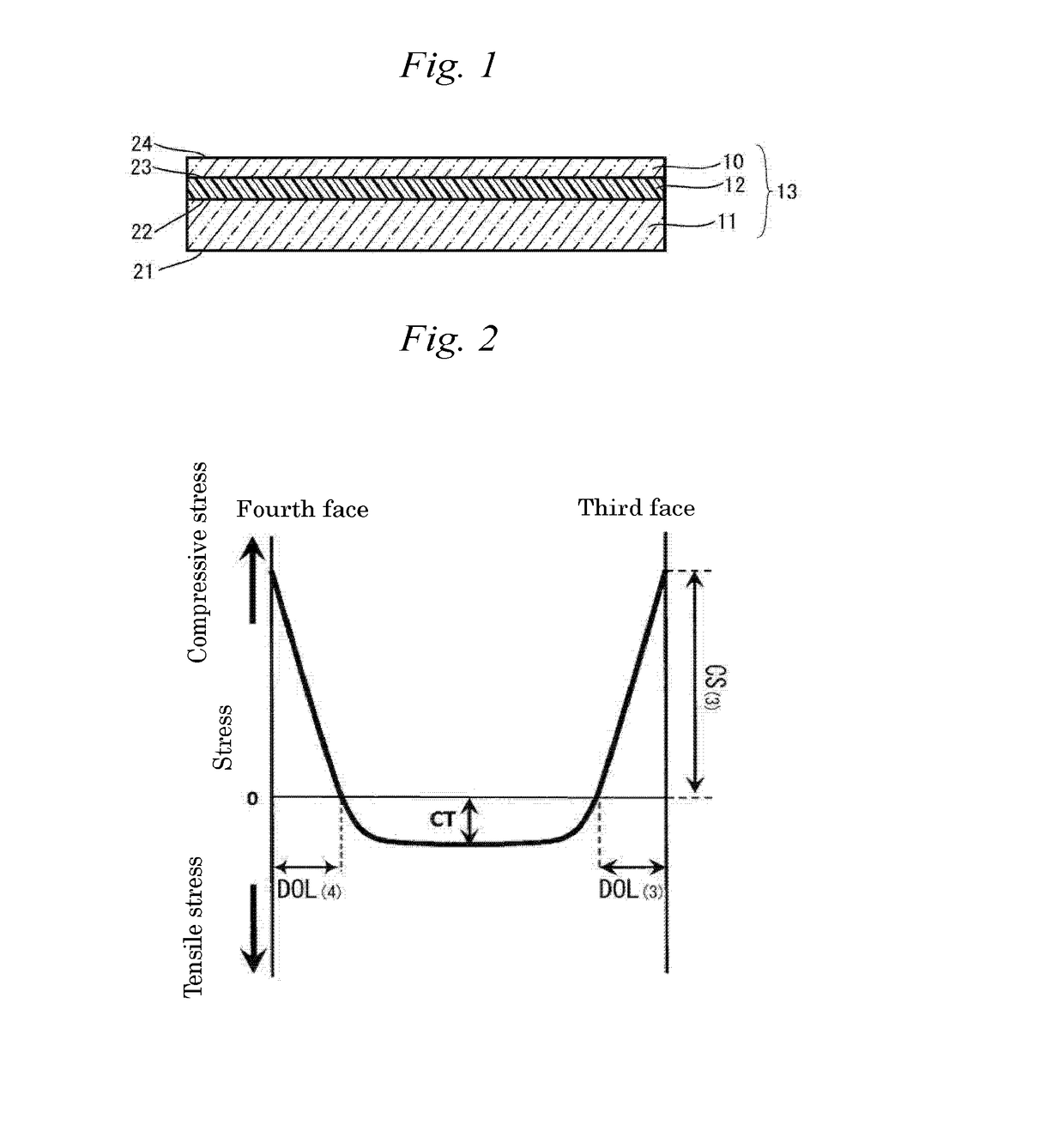

Laminated glass

InactiveUS20170066223A1Easy to visually identifyVehicle componentsGlass/slag layered productsEngineeringGlass sheet

The present invention relates to a laminated glass including a first glass plate, a second glass plate and an intermediate layer provided between the first glass plate and the second glass plate, in which the first glass plate has a first face and a second face opposing the first face, the second glass plate has a third face and a fourth face opposing the third face, the intermediate layer is provided between the second face and the third face, the second glass plate is a chemically-strengthened glass, and in the second glass plate, when a compressive stress on the third face is denoted as CS(3), a tensile stress generated in an interior of the second glass plate is denoted as CT, a thickness of the second glass plate is denoted as t, a depth of the compressive stress on a side of the third face is denoted as DOL(3) and a depth of a compressive stress on a side of the fourth face is denoted as DOL(4), CS(3) / [CT2×{t−(DOL(3)+DOL(4))}] is greater than 1.1 MPa−1×mm−1.

Owner:ASAHI GLASS CO LTD

Glass for cathode-ray tube, strengthened glass, method for the production thereof and use thereof

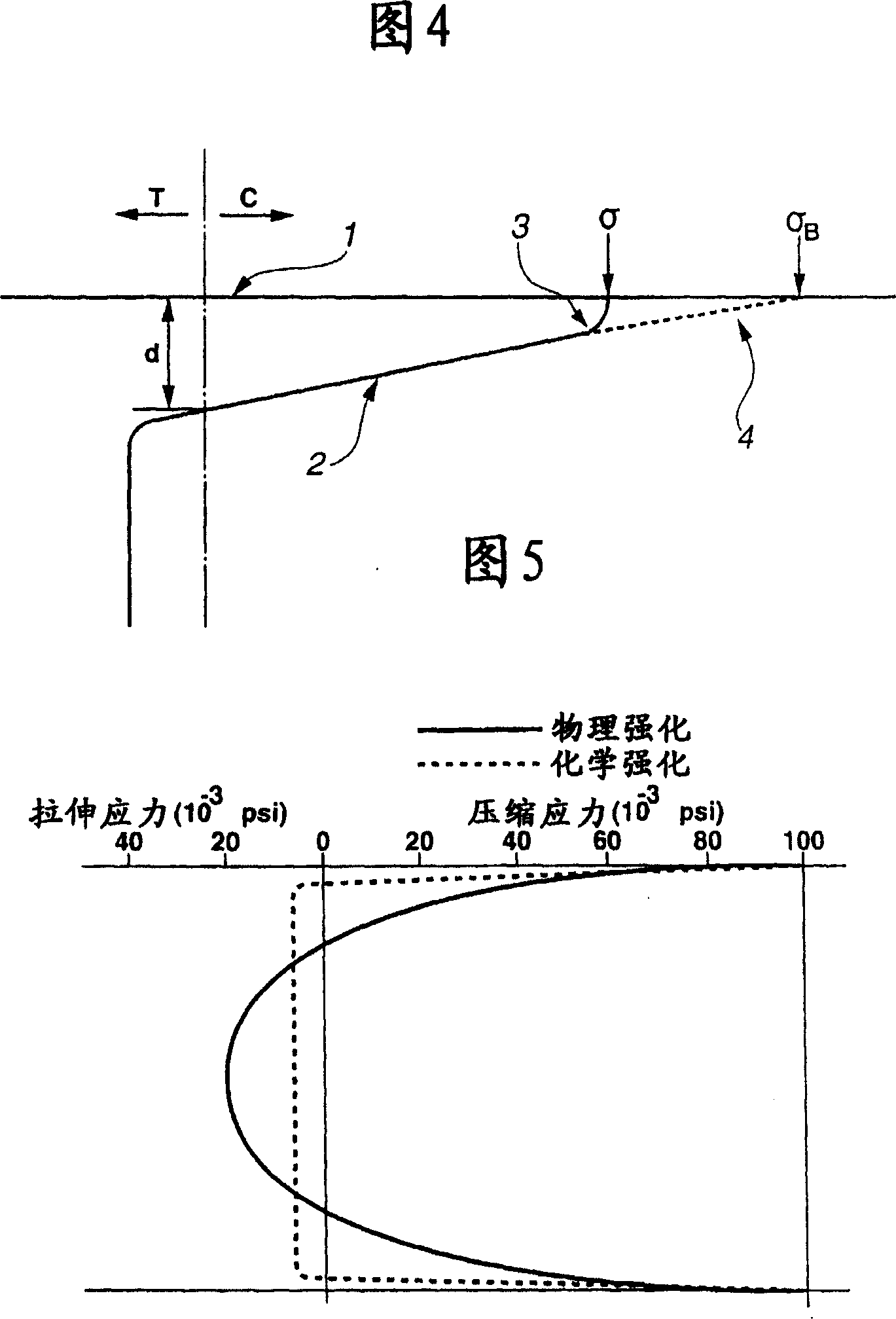

InactiveUS20010049327A1High strengthImprovement factorCathode-ray/electron-beam tube vessels/containersAlkali metal oxidePhysical chemistry

Disclosed are a glass for a cathode ray tube which glass can be decreased in thickness and weight, a glass panel for a cathode ray tube, a cathode ray tube and methods for producing them. Further disclosed are a strengthened glass having a high bending strength and a thick stress-strain layer, a glass for a display which glass is made of the strengthened glass, particularly, a glass panel for a cathode ray tube and a cathode ray tube. The present invention provides (1) a glass for a cathode ray tube which glass is made of a chemically strengthened glass and has a Young's modulus of at least 90 GPa, (2) a glass for a cathode ray tube, which is a chemically strengthened glass from a matrix glass which comprises SiO2, Al2O3, an alkali metal oxide, SrO and ZrO2 and has an Al2O3 content of more than 4% by weight but not more than 20% by weight and an SrO content of 5 to 20% by weight, and (3) a strengthened glass formed by chemical strengthening of a physically strengthened matrix glass at a temperature lower than the strain temperature of the matrix glass.

Owner:HOYA CORP

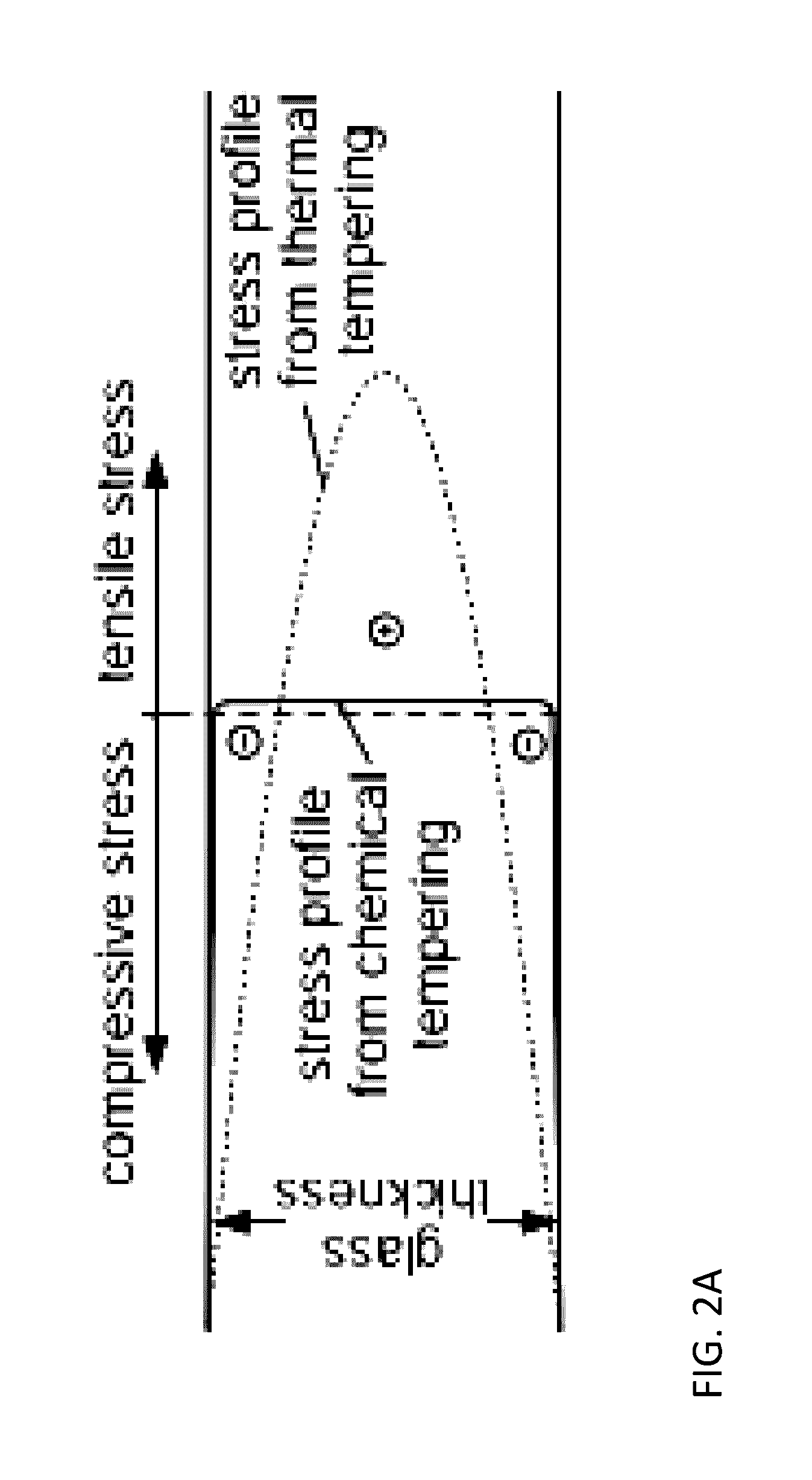

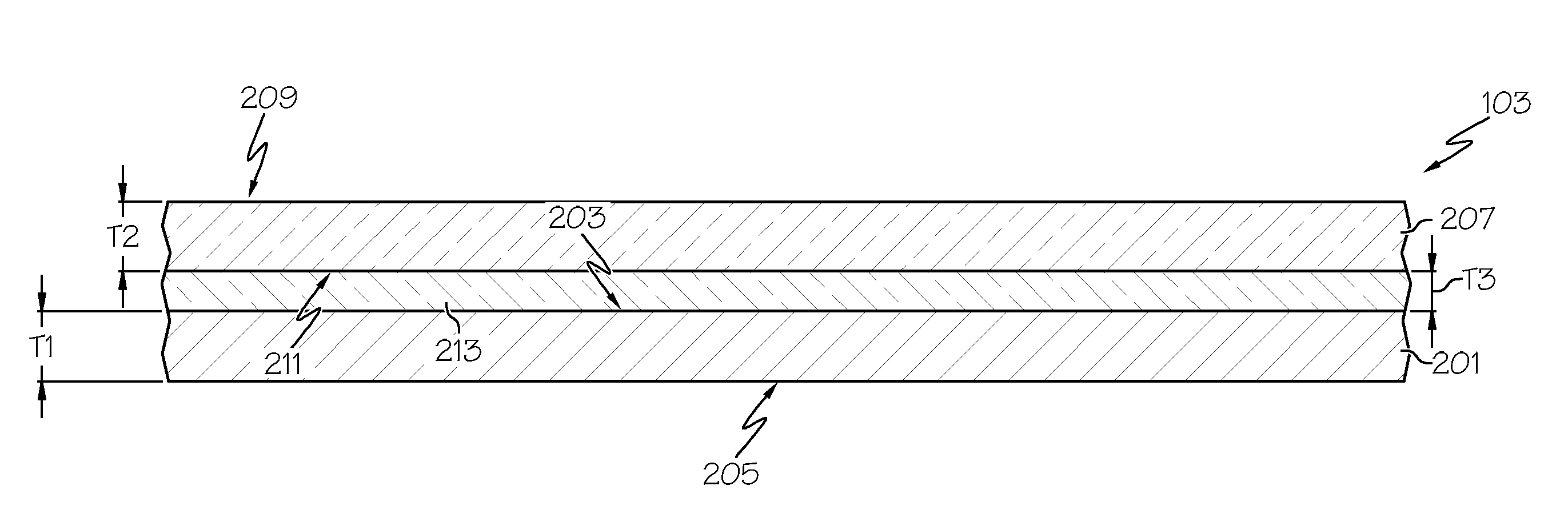

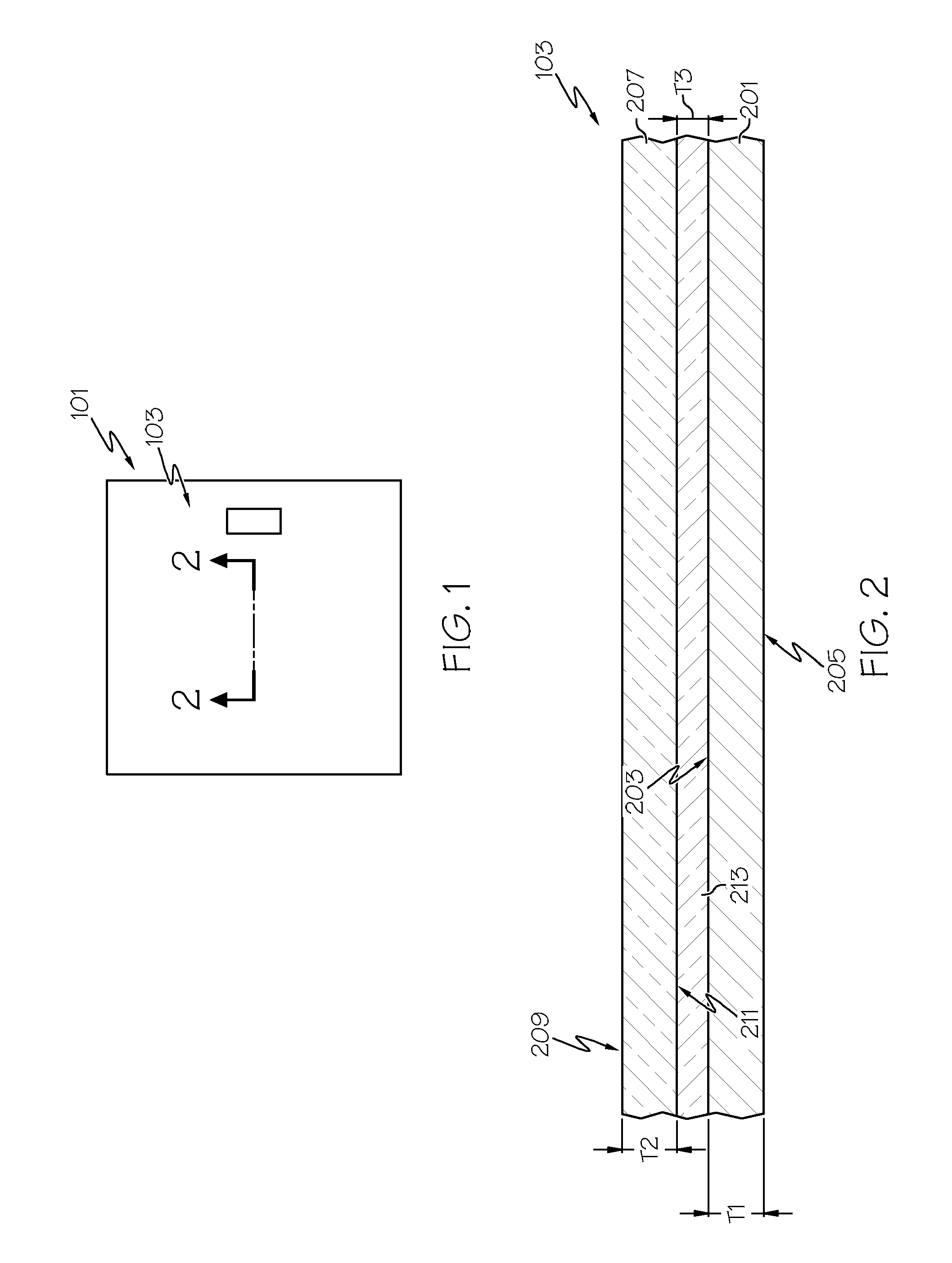

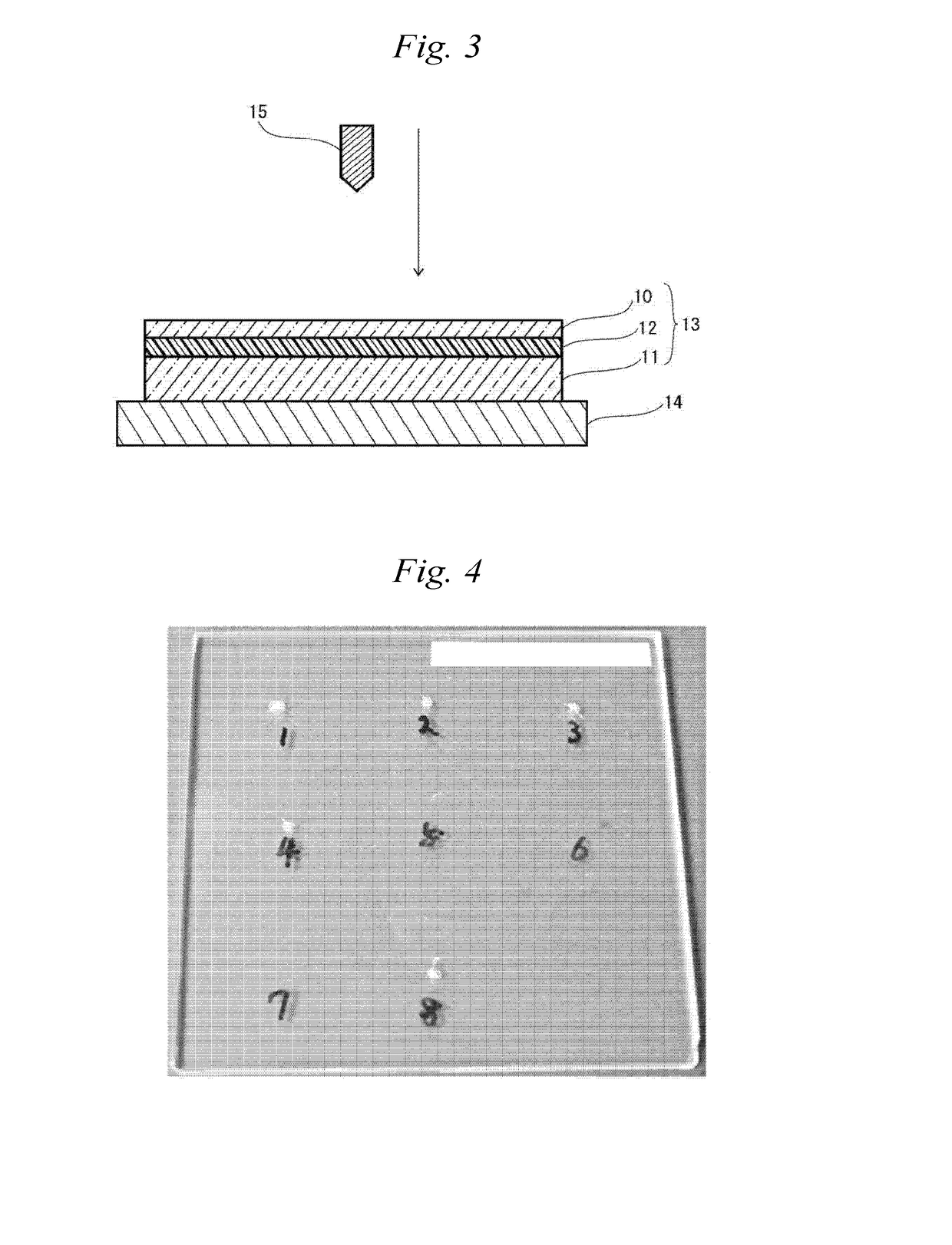

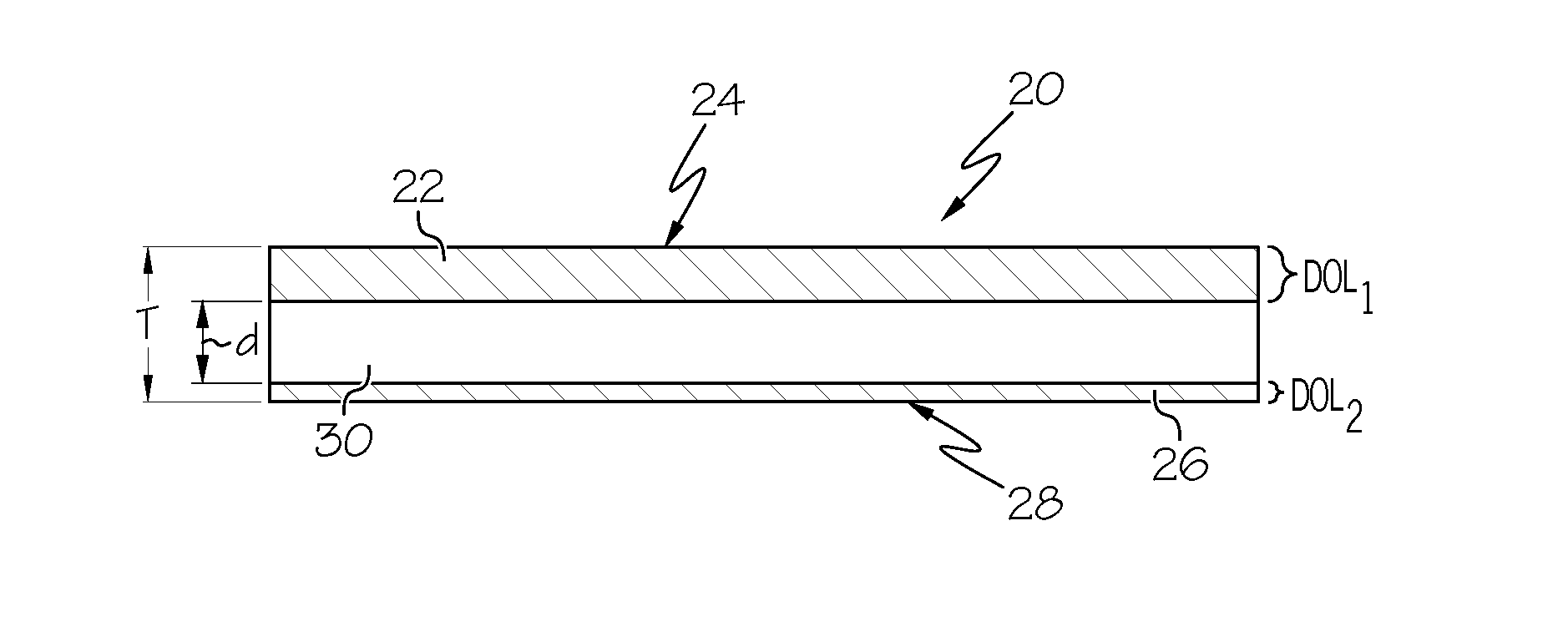

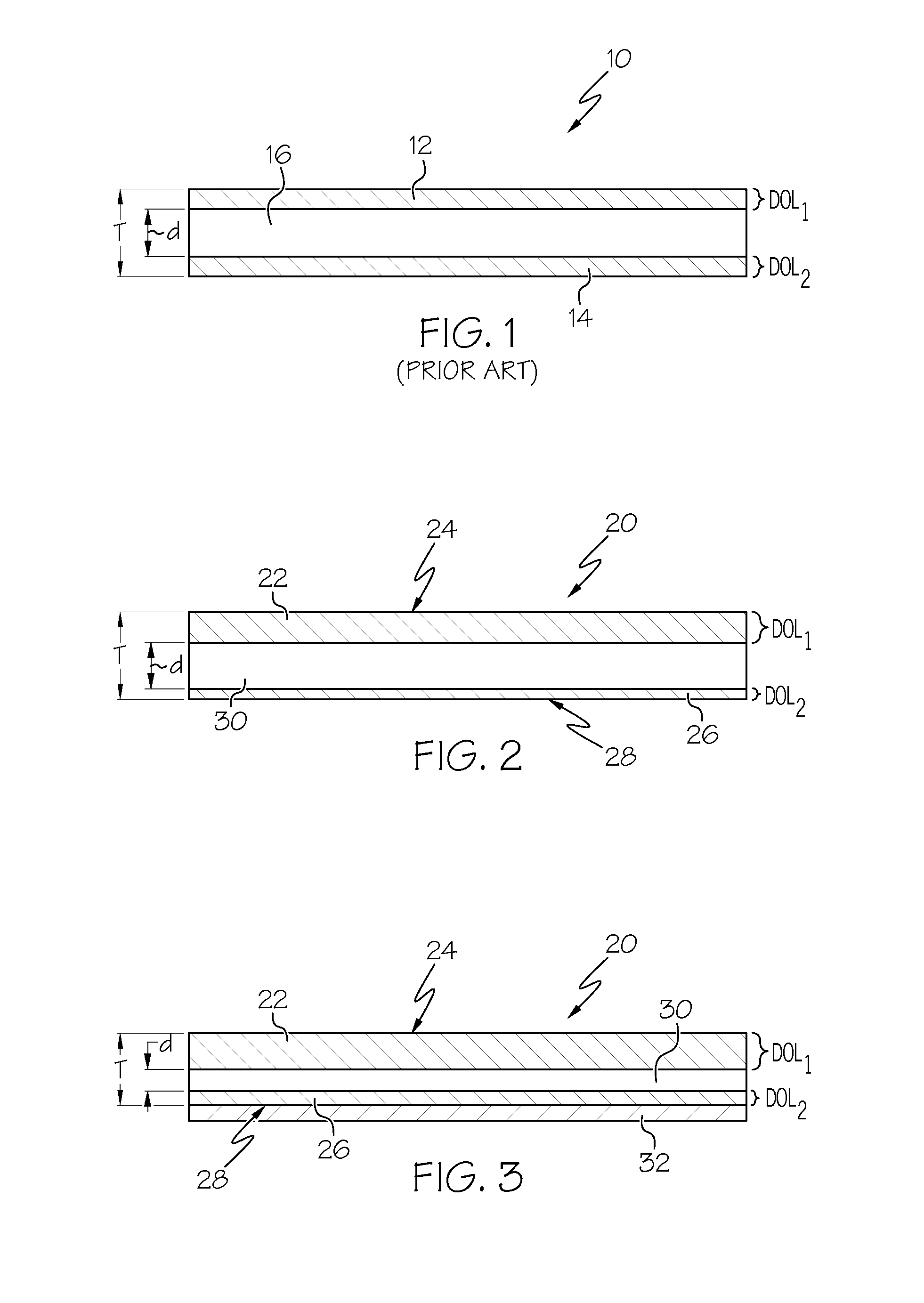

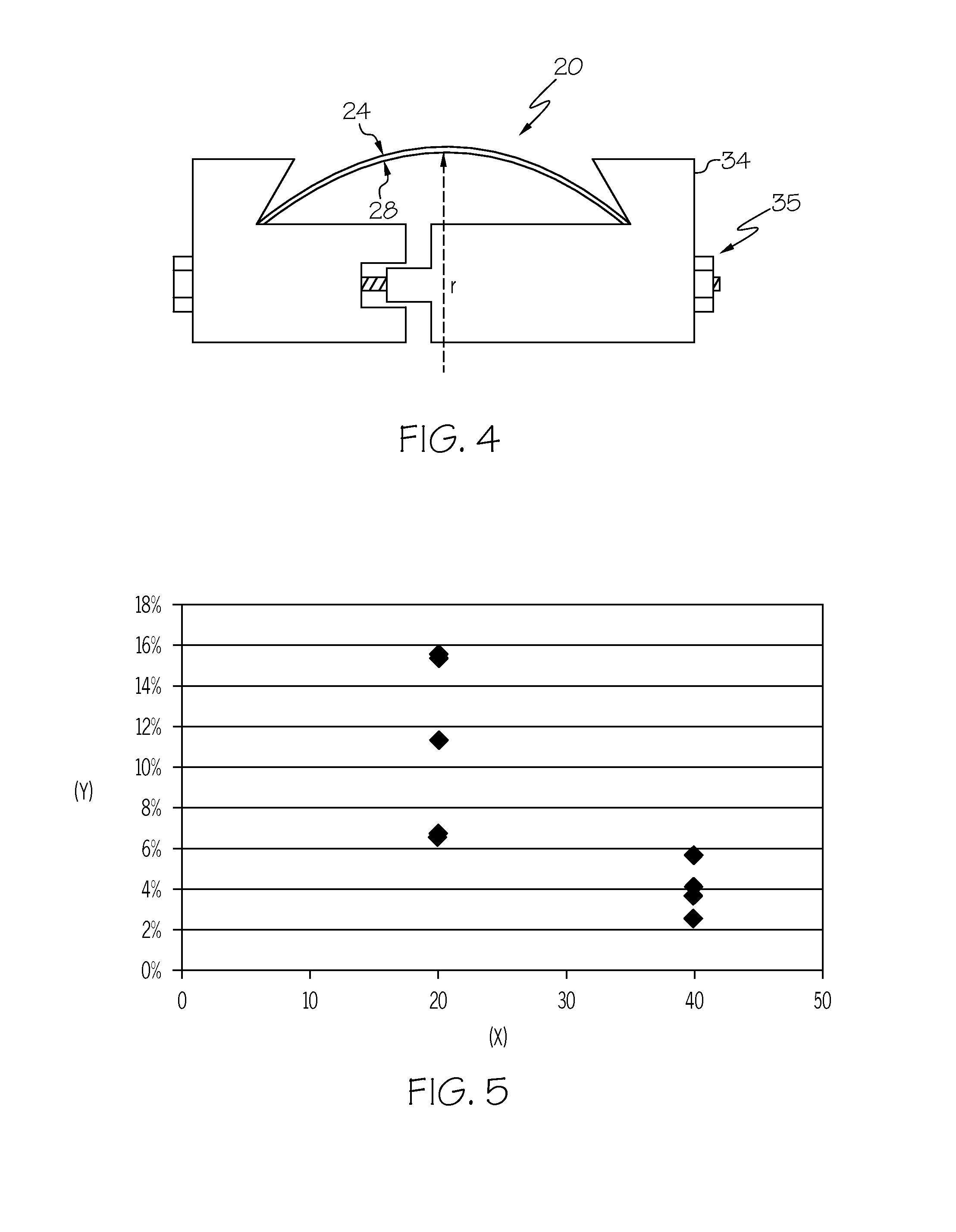

Ion exchange processes and chemically strengthened glass substrates resulting therefrom

ActiveUS20160214889A1High strengthIncreased durabilityGlass/slag layered productsMetallurgyIon exchange

A method of performing ion exchange of a thin, flexible glass substrate having an average thickness equal to or less than about 0.3 mm to chemically strengthen the glass substrate is disclosed. The chemically strengthened glass substrate comprises a first compressive stress layer having a first depth of layer, and a second compressive stress layer having a second depth of layer, the first and second stress layers being separated by a layer of tensile stress. A laminated article comprising the chemically strengthened glass substrate is also described.

Owner:CORNING INC

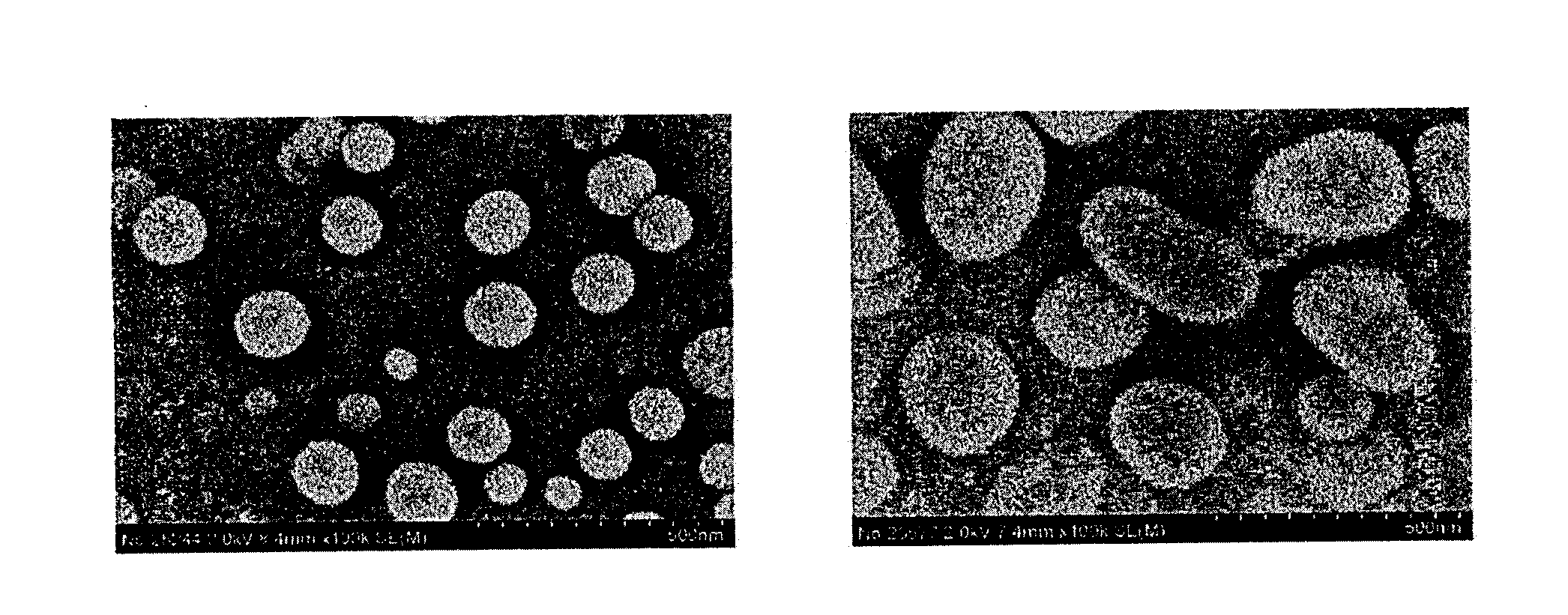

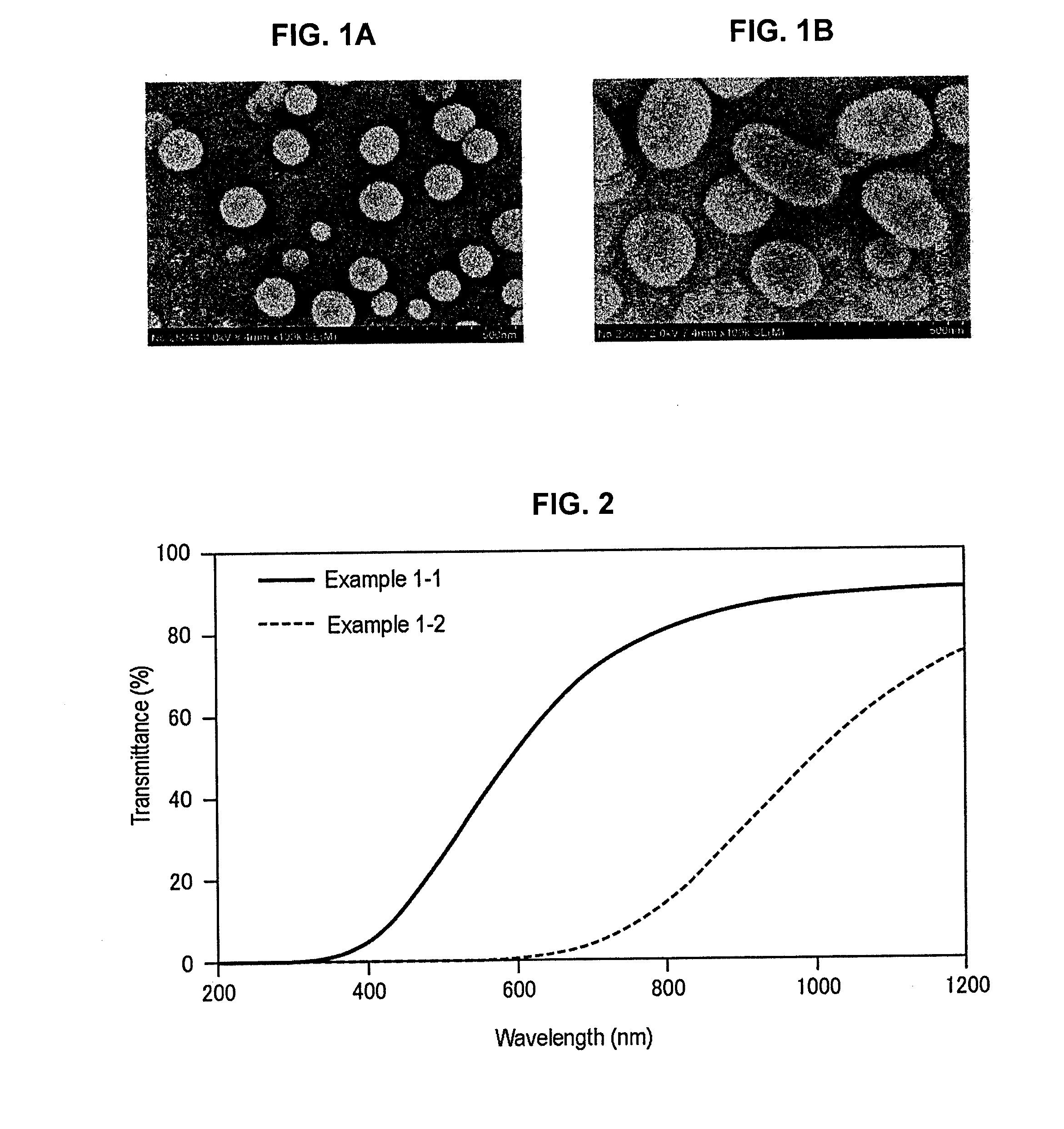

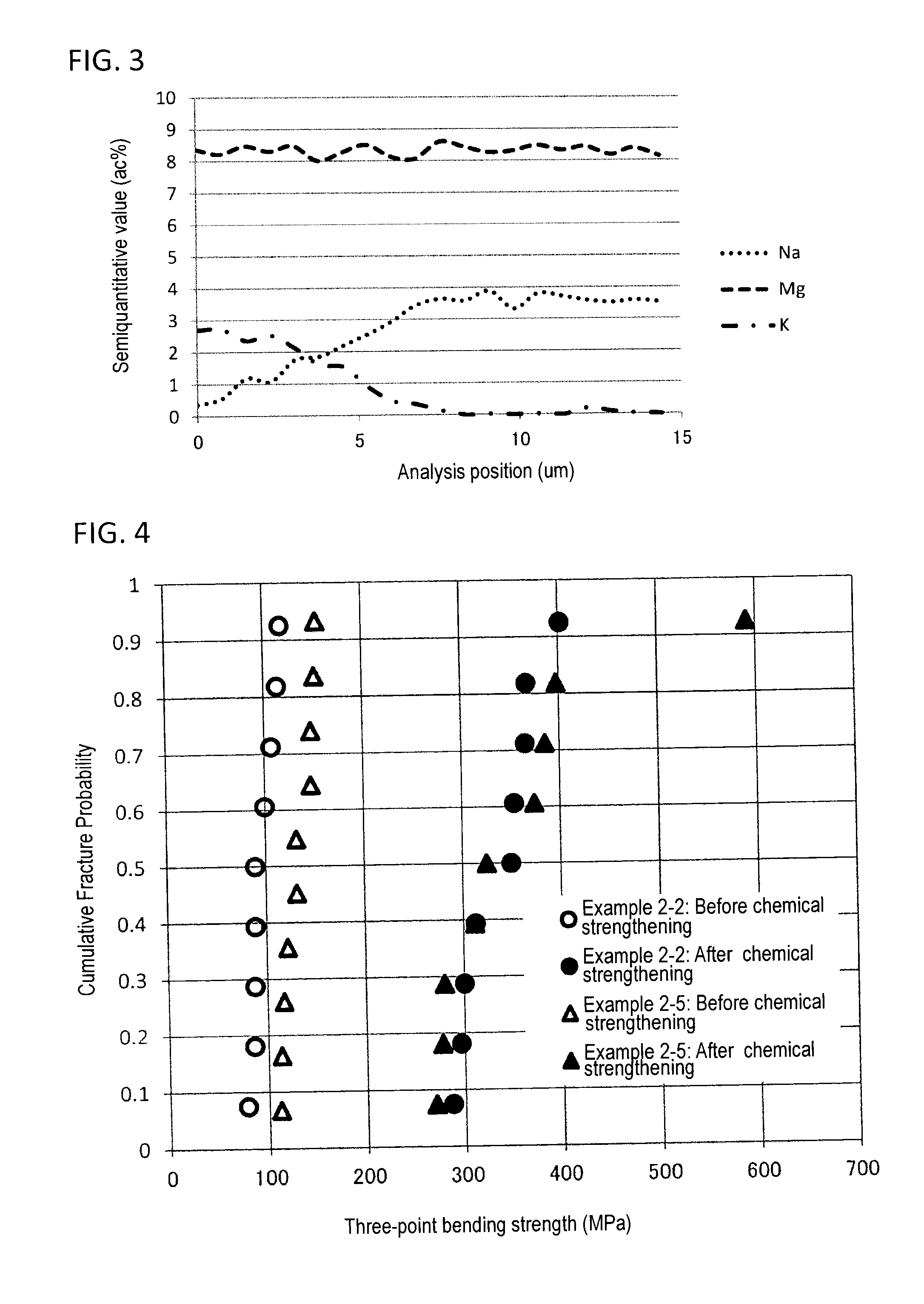

Process for producing chemically strengthened glass

ActiveUS20150111030A1Improve shielding effectHigh strengthCasings/cabinets/drawers detailsRecord information storageIon exchangePhotochemistry

A process for producing a chemically strengthened glass is provided. The method for producing a chemically strengthened glass includes subjecting a phase-separated glass to an ion exchange treatment. A chemically strengthened glass which is obtained by the process and a phase-separated glass which has been subjected to the ion exchange treatment are also provided.

Owner:ASAHI GLASS CO LTD

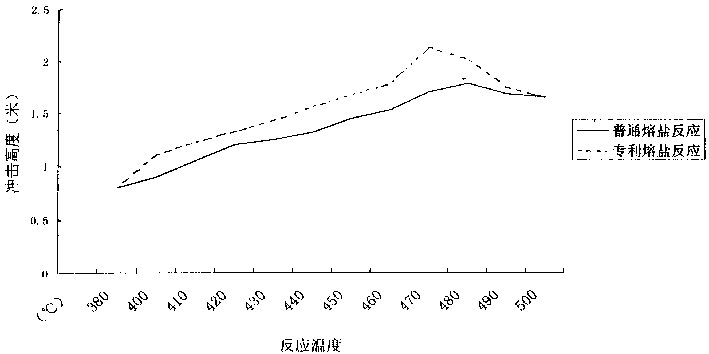

Process for preparing chemically strengthened glass

InactiveCN1381415AImprove flatnessIncrease exchange speedGlass tempering apparatusPotassium nitratePolymer science

A chemically toughened glass is prepared through preparing fused salt from fused salt of potassium nitrate, potassium hydroxide, Al2O3 and diatomite, heating it to 400-500 deg.C, heating cleaned glass to 350 deg.C for 30 min, immersing the glass in the said fused salt at 400 deg.C for 3-8 hr, slowly taking out entering an annealing oven its temp. very close to that of fused salt, and then annealing to room temp. Its advantages are high productivity, high surface stress, thin thickness (less than 3mm), and high smoothness.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP

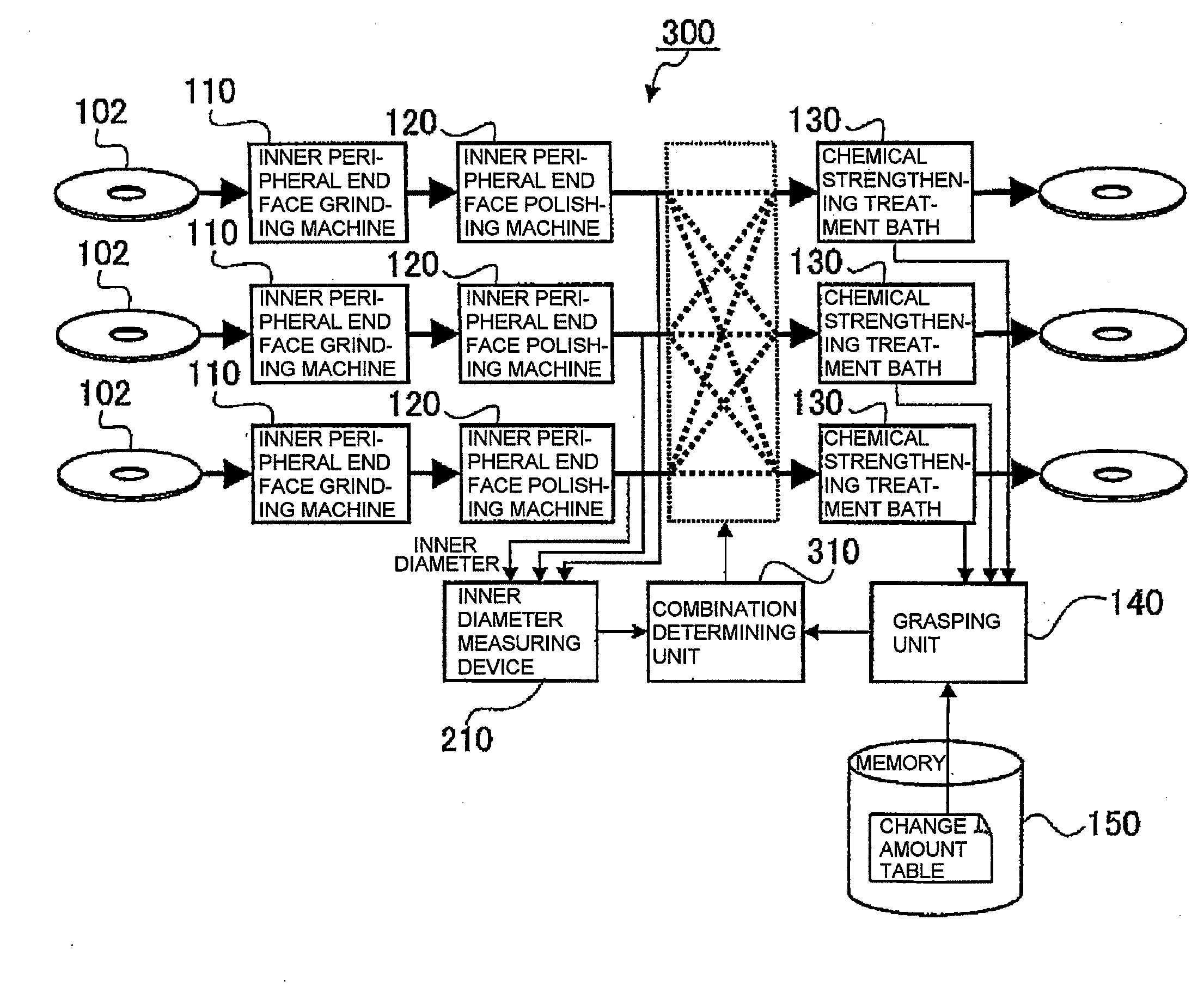

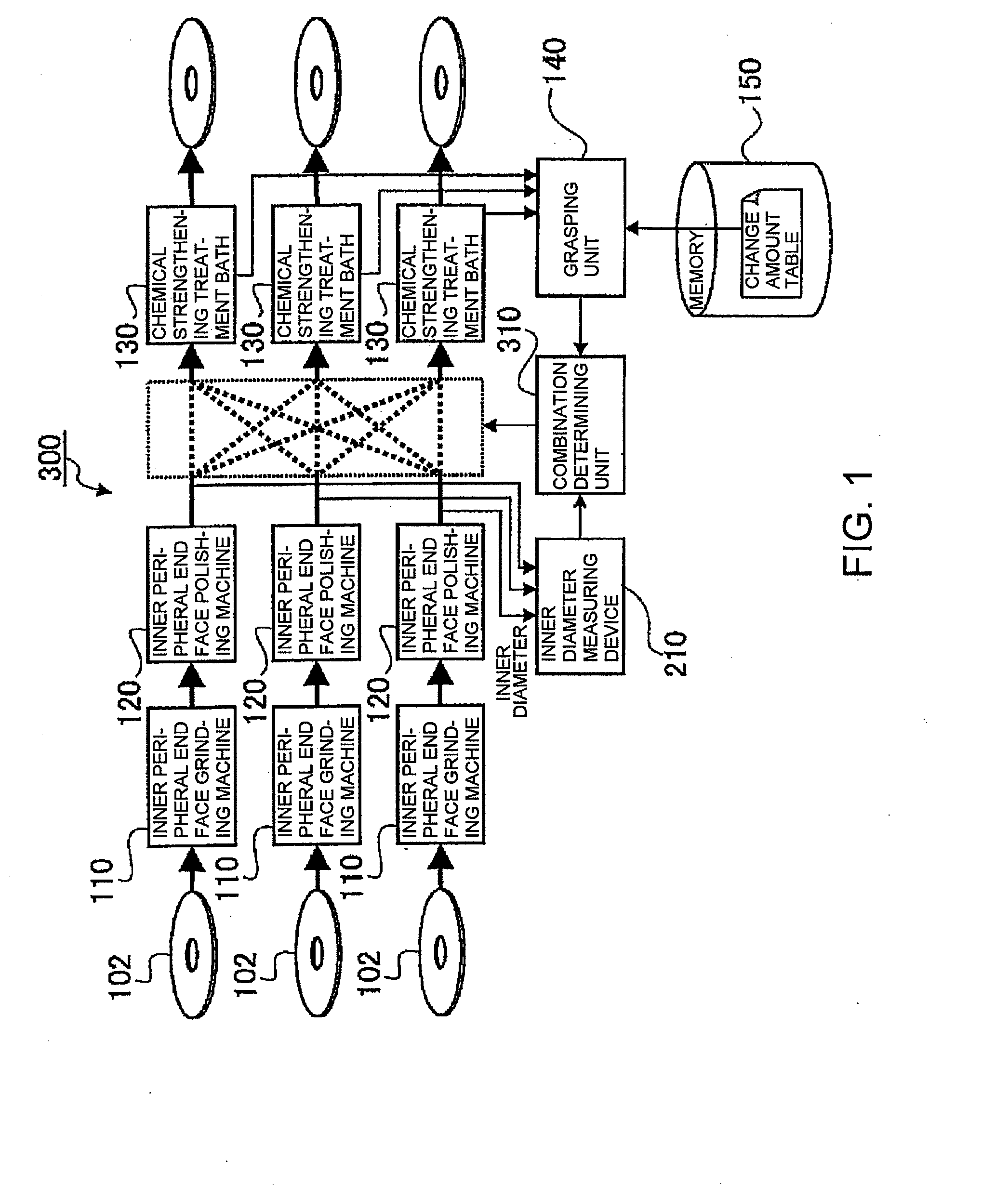

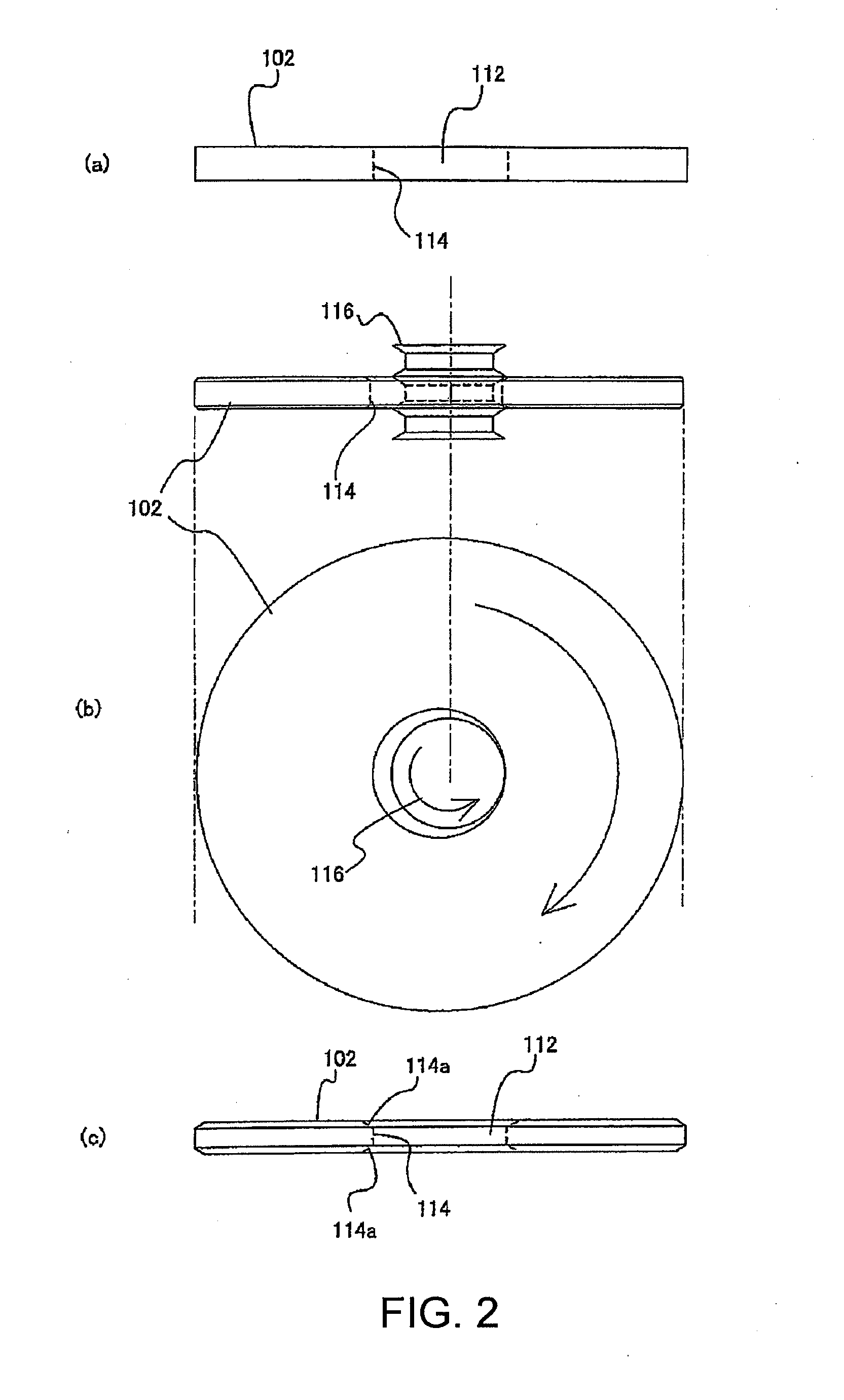

Method of manufacturing glass substrate for magnetic disk and system for manufacturing glass substrate for magnetic disk

ActiveUS20100024484A1Reduce the inner diameter dimensional error of a magnetic-disk glass substrateEdge grinding machinesBlowing machine gearingsMetallurgyMagnetic disks

To provide a magnetic-disk glass substrate manufacturing method that can reduce the inner diameter dimensional error.A magnetic-disk glass substrate manufacturing method of this invention including a chemical strengthening step of bringing a plurality of glass substrates 102 into contact with chemical strengthening treatment solutions of a plurality of chemical strengthening treatment baths 130, respectively, to chemically strengthen the glass substrates further includes an inner diameter measuring step of measuring the inner diameter of each of the glass substrates 102 before the chemical strengthening step, a grasping step of grasping a variation of the inner diameter of the glass substrate 102 to be generated by the chemical strengthening step for each of the chemical strengthening treatment baths 130, and a combination determining step of determining the chemical strengthening treatment baths 130, that perform chemical strengthening, based on the variations so that the inner diameters of the glass substrates, whose inner diameters are measured, after the chemical strengthening step become a desired value. In the chemical strengthening step, the glass substrates 102 are chemically strengthened in the determined chemical strengthening treatment baths 130, respectively.

Owner:HOYA LAMPHUN LTD +1

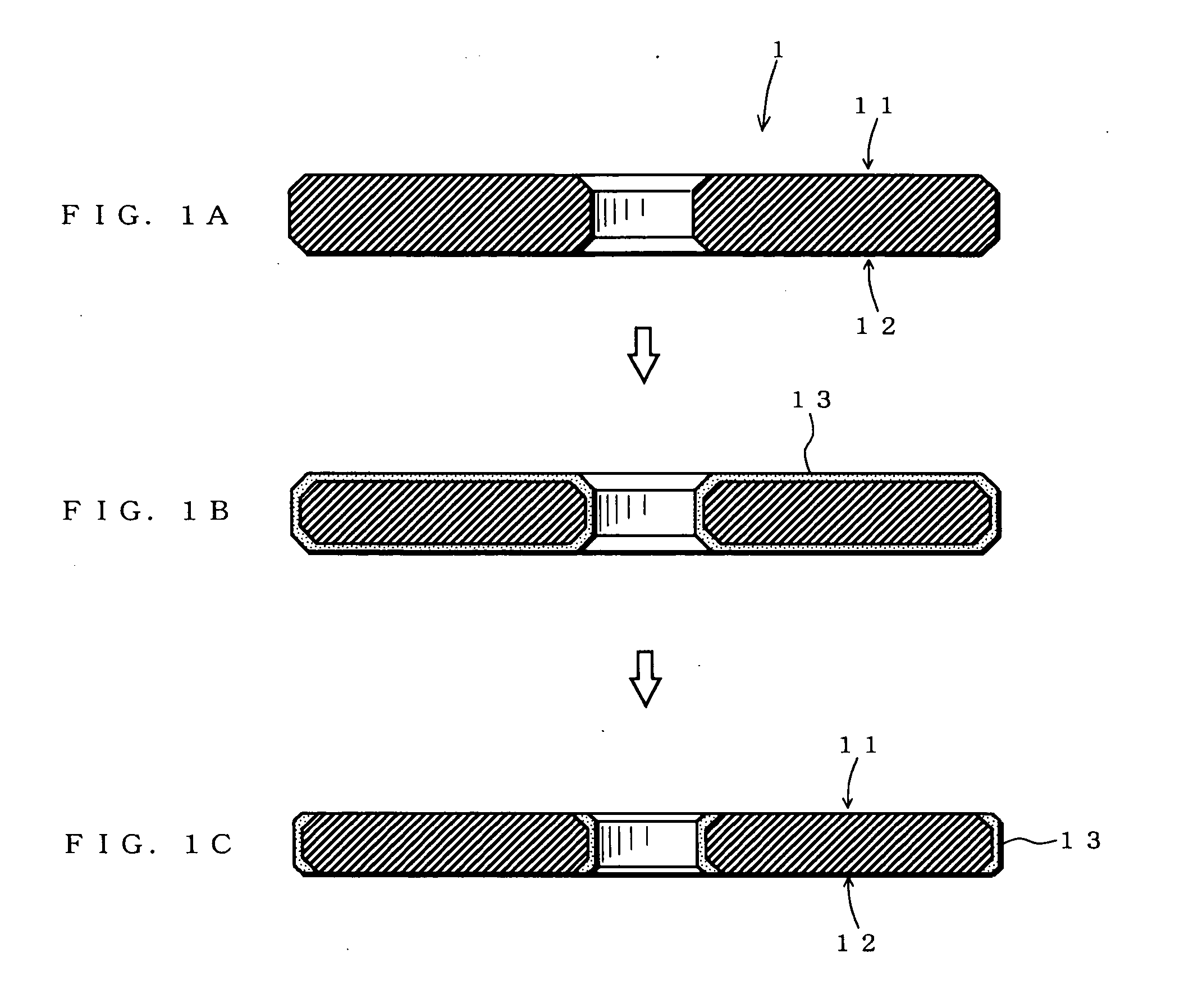

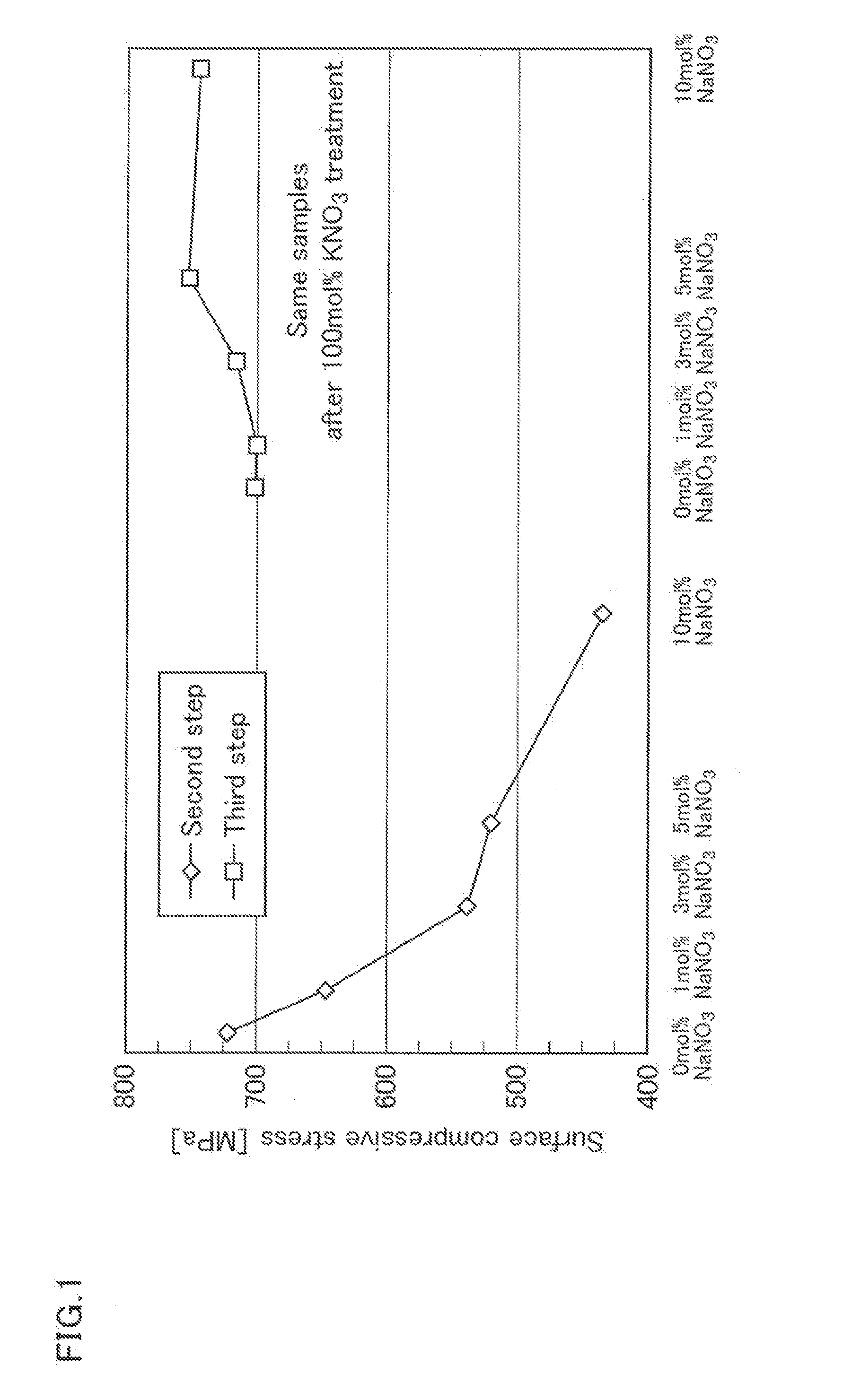

Method of manufacturing chemically strengthened glass plate

InactiveUS20130219966A1Increase the surface compressive stressEfficient productionIon exchangeGlass sheet

[Subject]An object of the present invention is to provide a method for manufacturing a chemically strengthened glass plate having a high surface compressive stress with high efficiency using a soda-lime glass, the composition of which is not particularly suited for chemical strengthening.[Solution]The present invention provides a method of manufacturing a chemically strengthened glass plate by ion-exchanging a glass base plate to replace alkali metal ions A that are the main alkali metal ion component of the glass base plate with alkali metal ions B having a larger ionic radius than the alkali metal ions A at a surface of the glass base plate,the unexchanged glass base plate made of a soda-lime glass,the method including:a first step of contacting the glass base plate with a first salt containing the alkali metal ions A, the first salt containing the alkali metal ions A at a ratio X, as expressed as a molar percentage of total alkali metal ions, of 90 to 100 mol %;a second step of contacting the glass plate with a second salt containing the alkali metal ions B after the first step, the second salt containing the alkali metal ions A at a ratio Y, as expressed as a molar percentage of the total alkali metal ions, of 0 to 10 mol %; anda third step of contacting the glass plate with a third salt containing the alkali metal ions B after the second step, the third salt containing the alkali metal ions B at a ratio Z, as expressed as a molar percentage of the total alkali metal ions, of 98 to 100 mol %.

Owner:CENT GLASS CO LTD

Mother glass, tempered glass and preparation method

The invention discloses mother glass. Thickness of the mother glass is 0.4-2.0mm, transmittance range of light of 550nm in wavelength to the mother glass is 86-92.2%, refraction coefficient range of the mother glass is 1.48-1.54, alkaline metal oxide content in the mother glass is 11-22mol%, oxide content of Na is 5-18mol%, and oxide content of Al is 7-16mol%. Aiming at the technical problem thatmechanical performance of existing tempered glass needs to be improved, content proportion of components in the mother glass is designed reasonably to enable the components to give play to synergism and cooperate with each other, so that the mother glass has the advantages of high refraction coefficient, high 550nm-wavelength transmittance and good chemical strengthening effect, and study and application of chemically strengthened glass are well pushed. The invention further discloses tempered glass prepared from the mother glass and a preparation method of the tempered glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

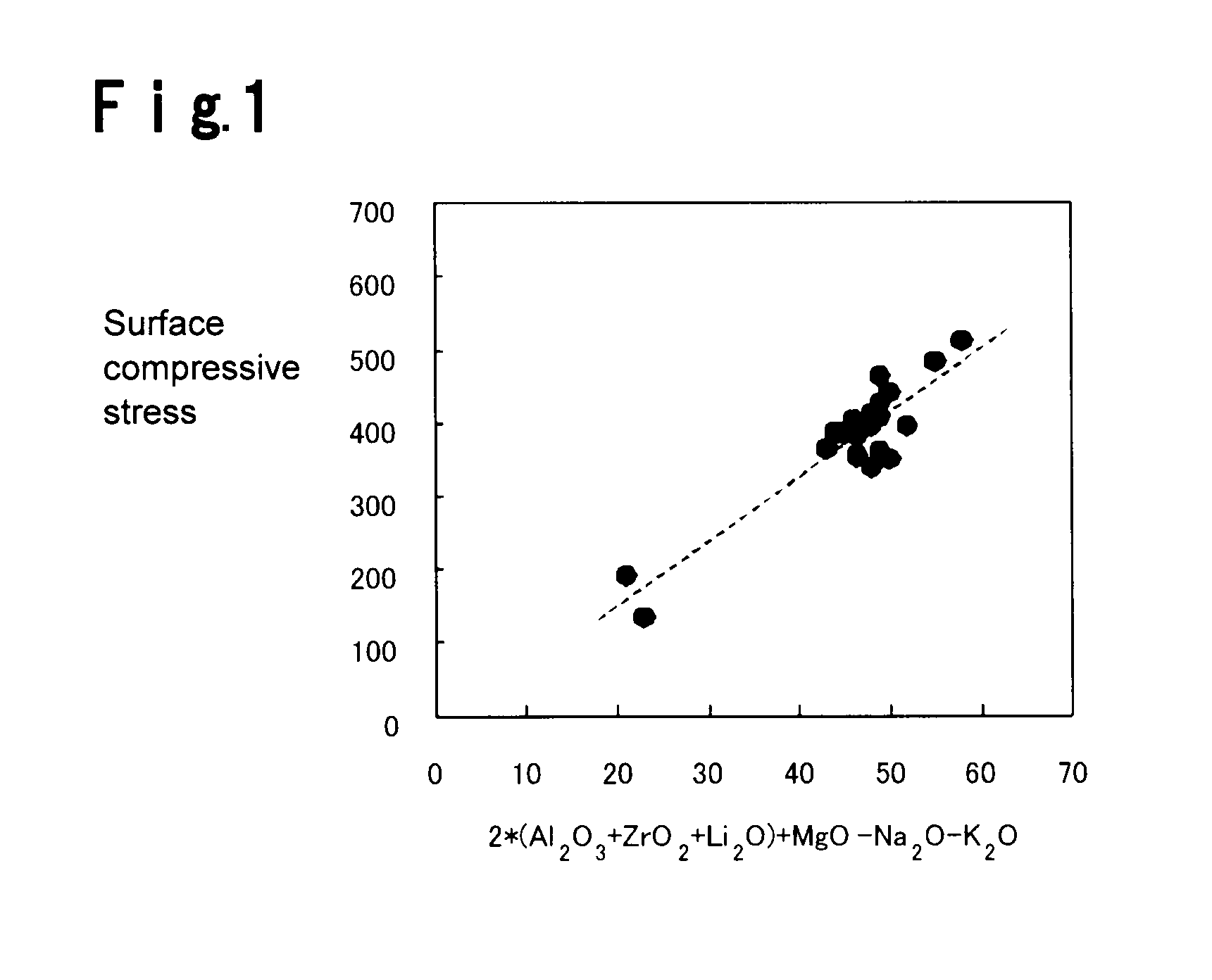

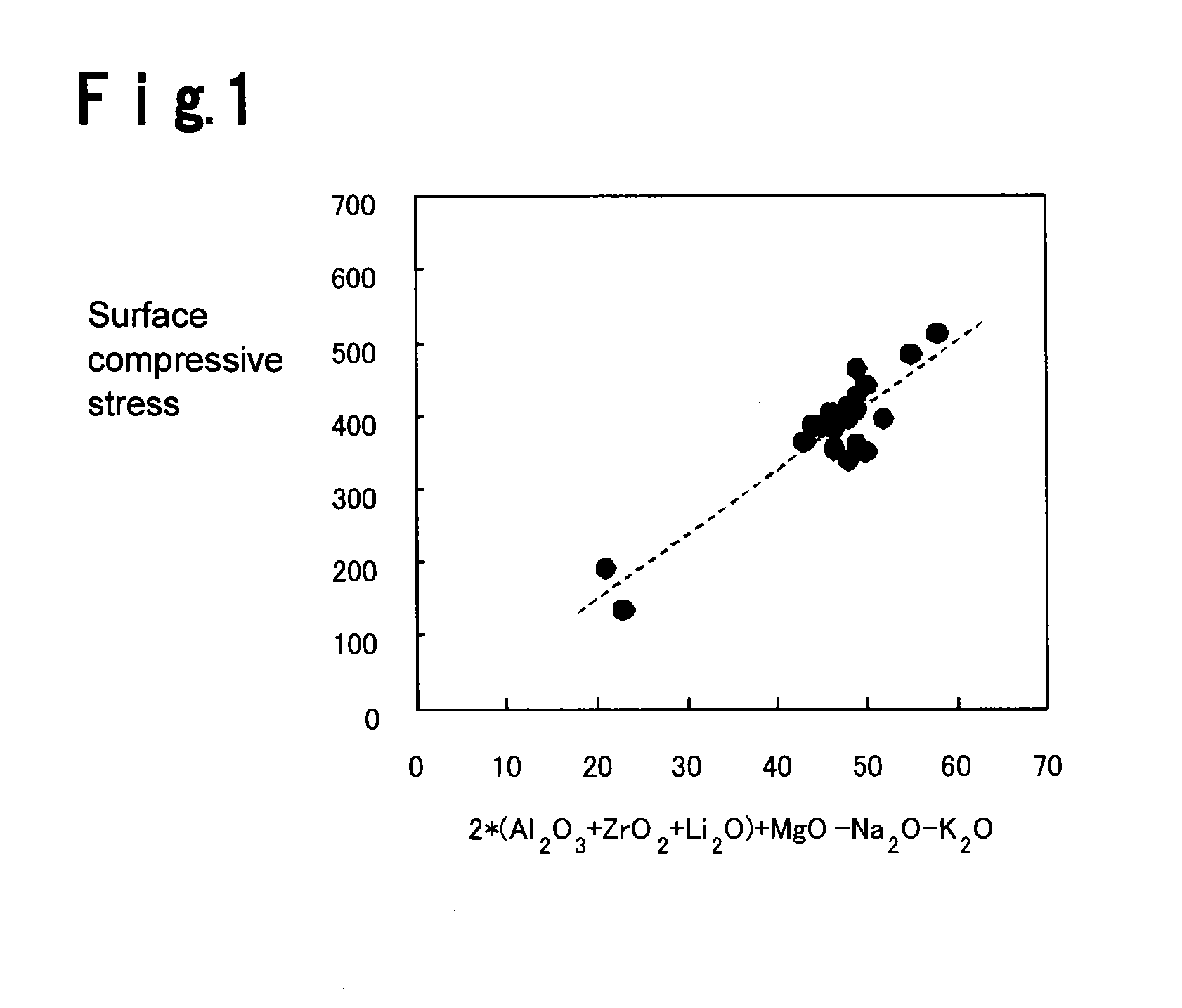

Chemically reinforced glass and method for production thereof

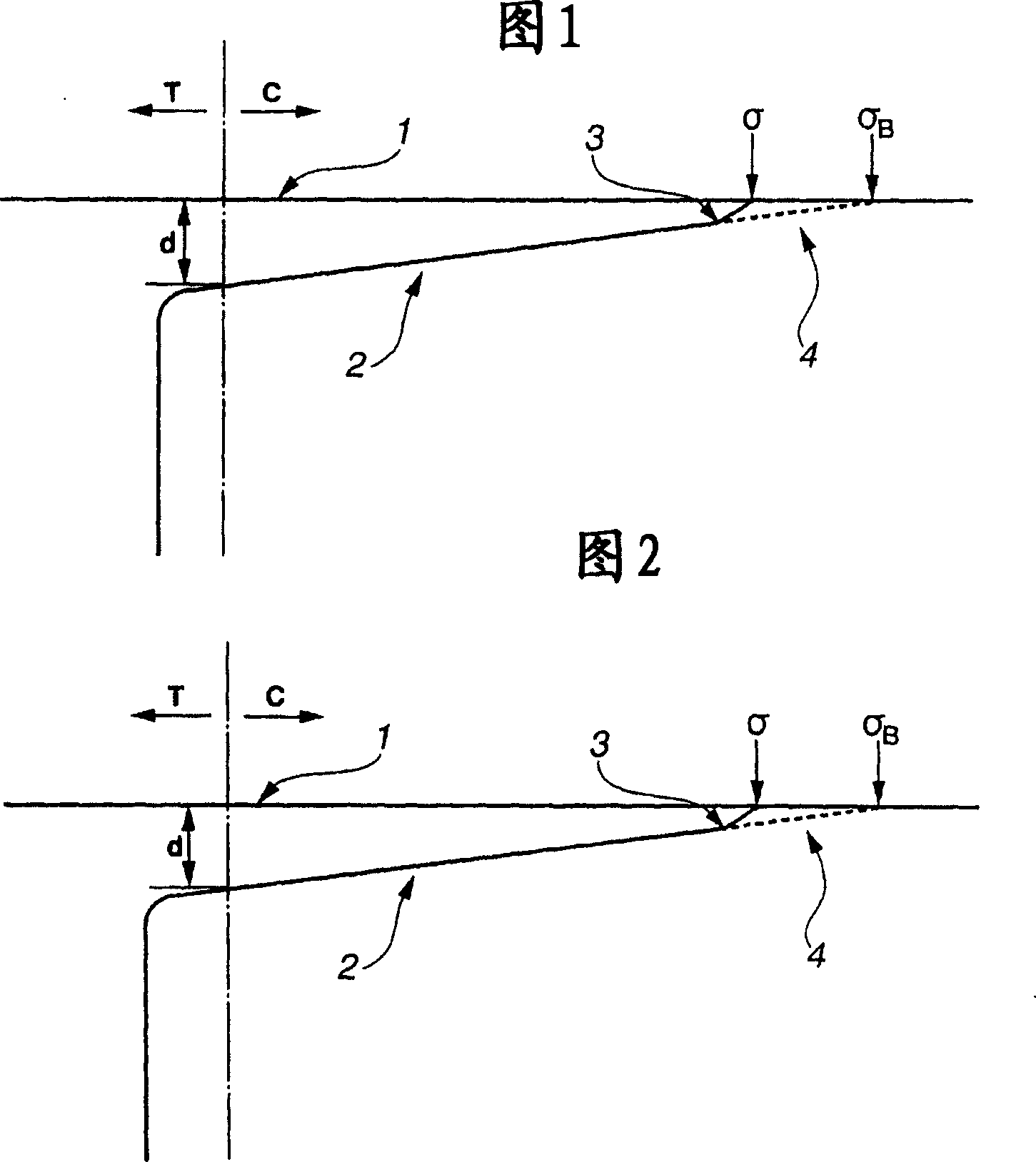

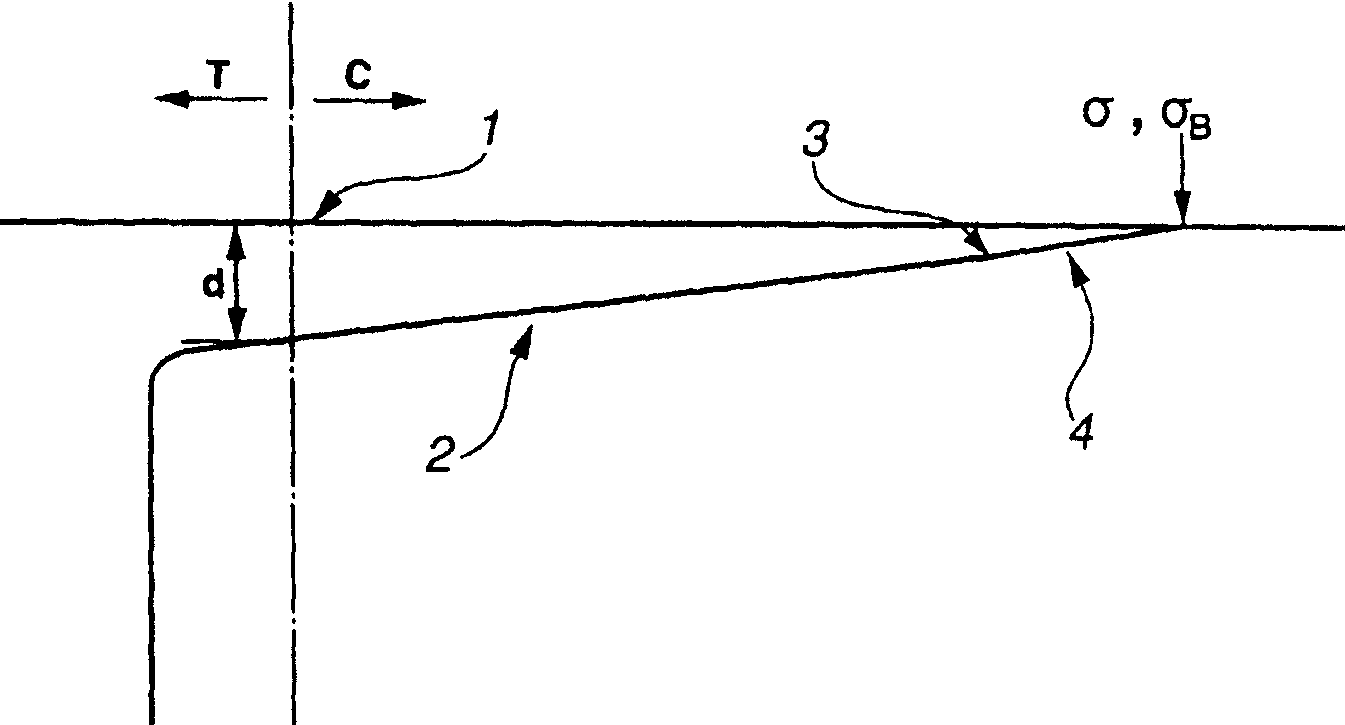

The invention relates to a chemically reinforced glass having a compressive stress layer formed in the surface layer thereof by ion exchange, characterized in that it has two types of compressive stress curves in the compressive stress layer: an A curve present nearer to the surface of the glass, and a B curve present in the side of an inner layer of the glass; a first method and a second method for producing the chemically reinforced glass: a fist method, wherein, after the immersion treatment for ion exchange, a second immersion treatment is carried out at a temperature higher than that for the previous immersion treatment by 20 to 50 DEG C for 10 to 60 minutes, and a second method, wherein, after a first immersion treatment for ion exchange, a second immersion treatment is carried out at a temperature higher than that for the first immersion treatment by 20 to 50 DEG C for 10 to 60 minutes.

Owner:CENT GLASS CO LTD

Glass composition including zirconium, chemically strengthened glass article, glass substrate for magnetic recording media, and method of producing glass sheet

ActiveUS7273668B2High mechanical strengthReduce probabilityMagnetic materials for record carriersLayered productsTO-18Heat resistance

The present invention provides a glass composition that has excellent heat resistance and ion exchange ability and can be provided with high strength by a chemical strengthening treatment through an ion exchange. This glass composition includes, in terms of mass %: 59 to 68% of SiO2; 9.5 to 15% of Al2O3; 0 to 1% of Li2O; 3 to 18% of Na2O; 0 to 3.5% of K2O; 0 to 15% of MgO; 1 to 15% of CaO; 0 to 4.5% of SrO; 0 to 1% of BaO; 0 to 2% of TiO2; and 1 to 10% of ZrO2. The glass composition of the present invention is suitable for a glass substrate for magnetic recording media and also can be formed as a chemically strengthened glass article through an ion-exchange treatment.

Owner:HOYA CORP

Chemically strengthened glass plate, cover glass, chemically strengthened glass with touch sensor, and display device

A chemically strengthened glass plate which has front and back main surfaces and edge surfaces between the front and back main surfaces, has undergone a chemical strengthening treatment, and is approximately rectangular and which has a surface compression stress of 800 MPa or greater and in which the internal tensile stress layer has a tensile stress of 42 MPa or less.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com