Mother glass, tempered glass and preparation method

A technology for strengthening glass and plain glass, applied in the field of glass production, can solve the problems of uneven distribution of the strength of the compressive stress layer of the strengthened glass, unable to improve the overall strength of the glass, etc., and achieve the effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

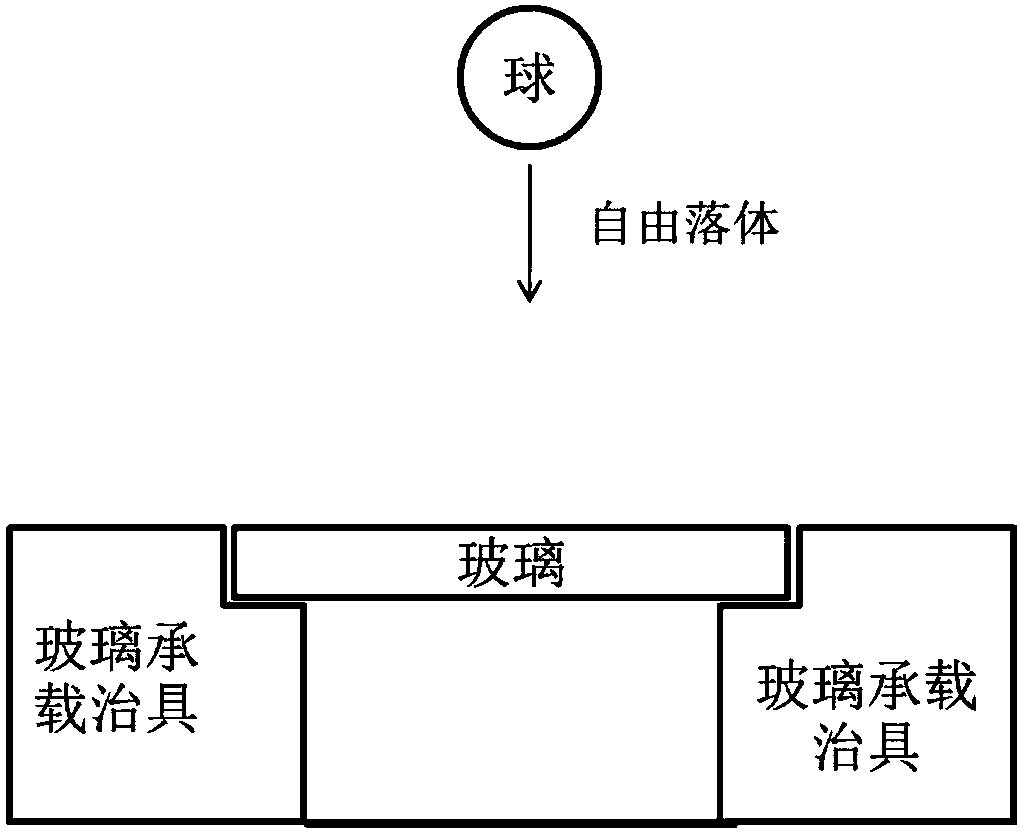

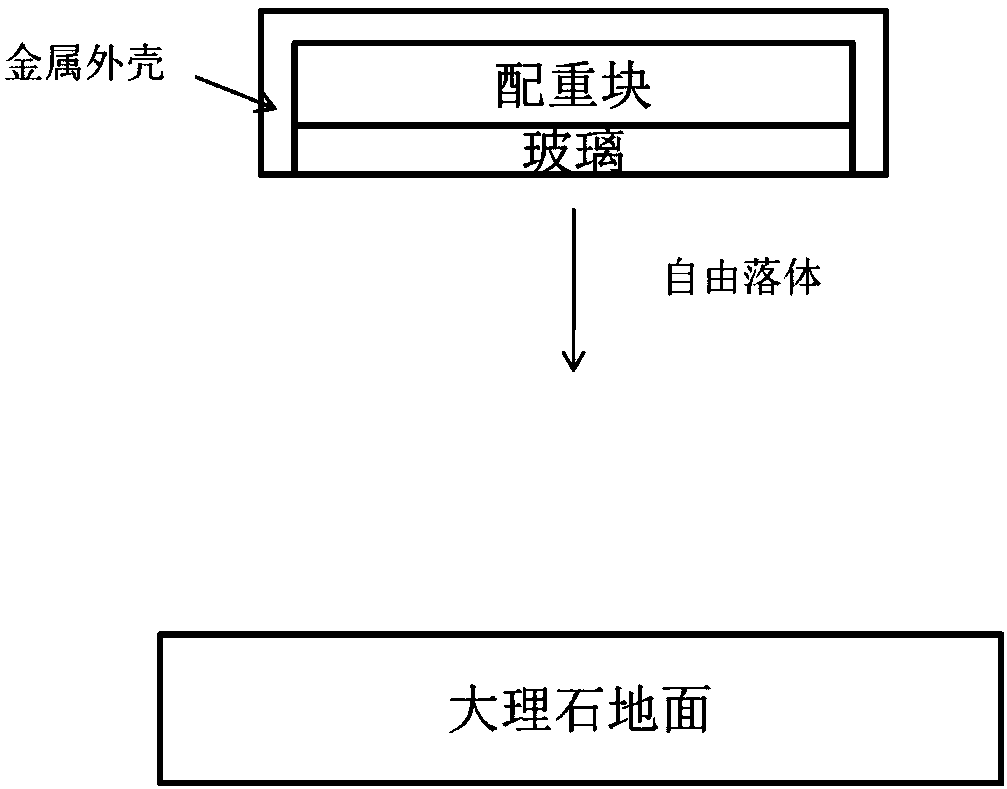

[0061] The present invention provides a kind of preparation method of strengthened layer glass, comprises the following steps:

[0062] Plain glass is provided, the plain glass is preheated in an environment lower than the annealing point temperature of the glass, and then the preheated plain glass is contained in at least two salts of Na ions, K ions, Ru ions and Cs ions The ion exchange treatment is carried out once and only once in the bath liquid, and the plain glass is prepared into strengthened glass with a composite compressive stress layer formed on the surface in one step.

[0063] In the above preparation process, the thickness of the plain glass ranges from 0.4mm to 2.0mm, the transmittance of light with a wavelength of 550nm to the plain glass ranges from 86% to 92.2%, and the refractive index of the plain glass ranges from 1.48 ~1.54, the mol content of alkali metal oxides in the plain glass is 8mol%~22mol%, wherein, the mol content of Na oxides is 2.65mol%~18mol%...

Embodiment 3-7

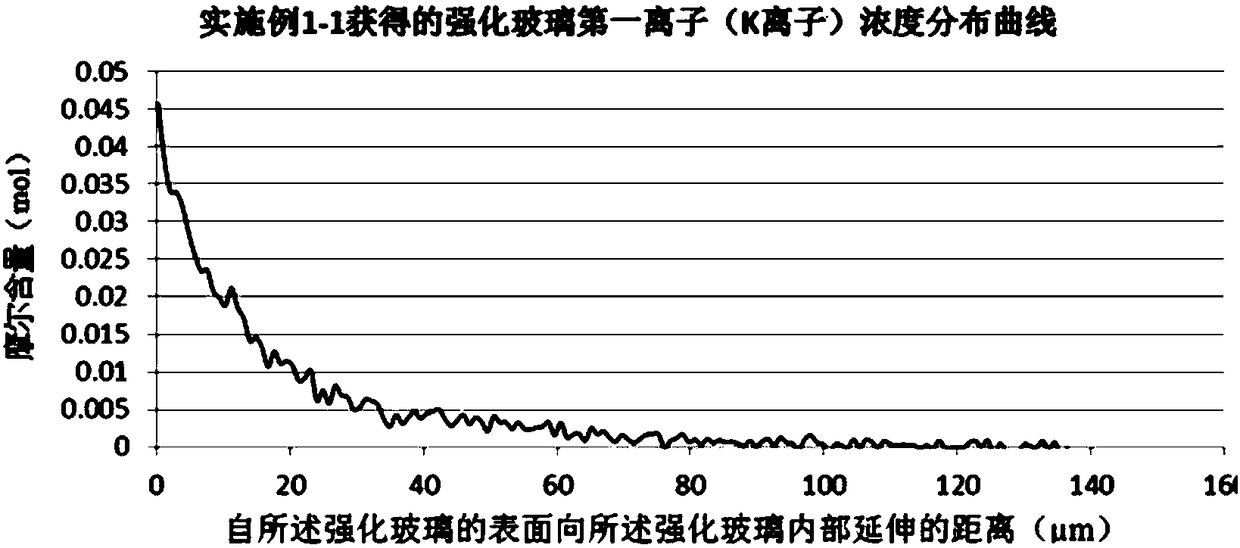

[0189] The applicant has also carried out additional experiment to the plain glass adopted in embodiment 3-5, and its difference with embodiment 3-5 is: change the salt bath of ion exchange for the first time into 100% NaNO 3 , the process conditions are set to 420 degrees Celsius, 270 minutes; change the second ion exchange salt bath to 100% KNO 3 , and the process conditions were set at 390 degrees Celsius for 120 minutes.

[0190] It is detected that the depth of compressive stress of the strengthened glass obtained in Example 3-7 is 300 μm, and the maximum compressive stress value is 800 Mpa. In addition, the strength of each thickness extending from the surface to the inside of the strengthened glass obtained in Example 3-7 is also detected. The compressive stress value can thus draw the compressive stress curve inside the strengthened glass obtained in embodiment 3-7, and the second fitting curve is obtained after the compressive stress curve is adopted by Orihara Pmc so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com