Process for preparing chemically strengthened glass

A technology of chemically tempered glass and production process, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easy deformation of glass, optical distortion, and a large amount of volatile matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It can be seen that the ion exchange time has been shortened by three to four times, the ion exchange depth has been increased by nearly ten times, and the surface ion concentration has been increased by more than eight times, which greatly improves the production efficiency.

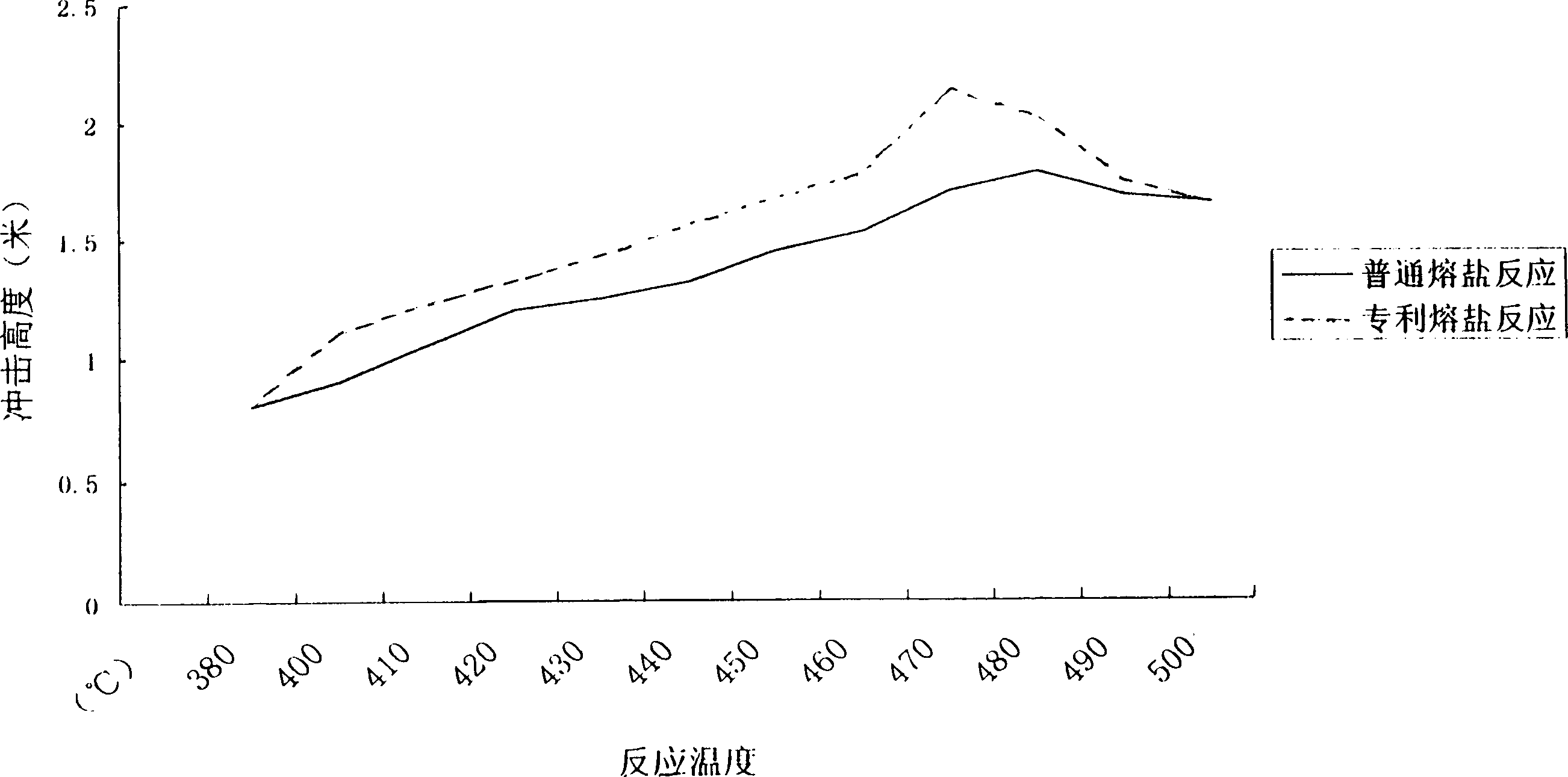

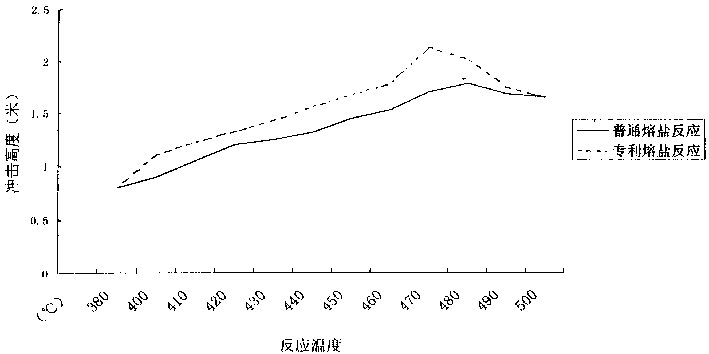

[0017] Accompanying drawing is with common molten salt and with mixed molten salt of the present invention, has carried out the comparative test curve of reaction temperature, can find out from figure, adopts the required temperature of molten salt reaction of formula of the present invention to reduce slightly, and efficiency obviously increases, Energy saving.

[0018] The mixed molten salt prepared by the present invention has the aforementioned important effects, and is based on the following main principles: 1. To speed up the ion exchange rate, the network structure of the glass surface must first be made open, and the mixed molten salt of the present invention has a disconnected part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com