Glass ceramic with ultrahigh bifurcation threshold value

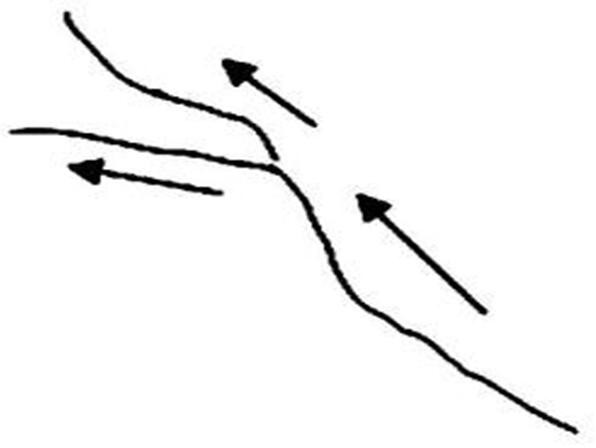

一种微晶玻璃、分叉的技术,应用在玻璃生产制造领域,能够解决整体硬、不能支撑高张应力线密度、自爆等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will now be described in detail. Obviously, the described embodiments are merely the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

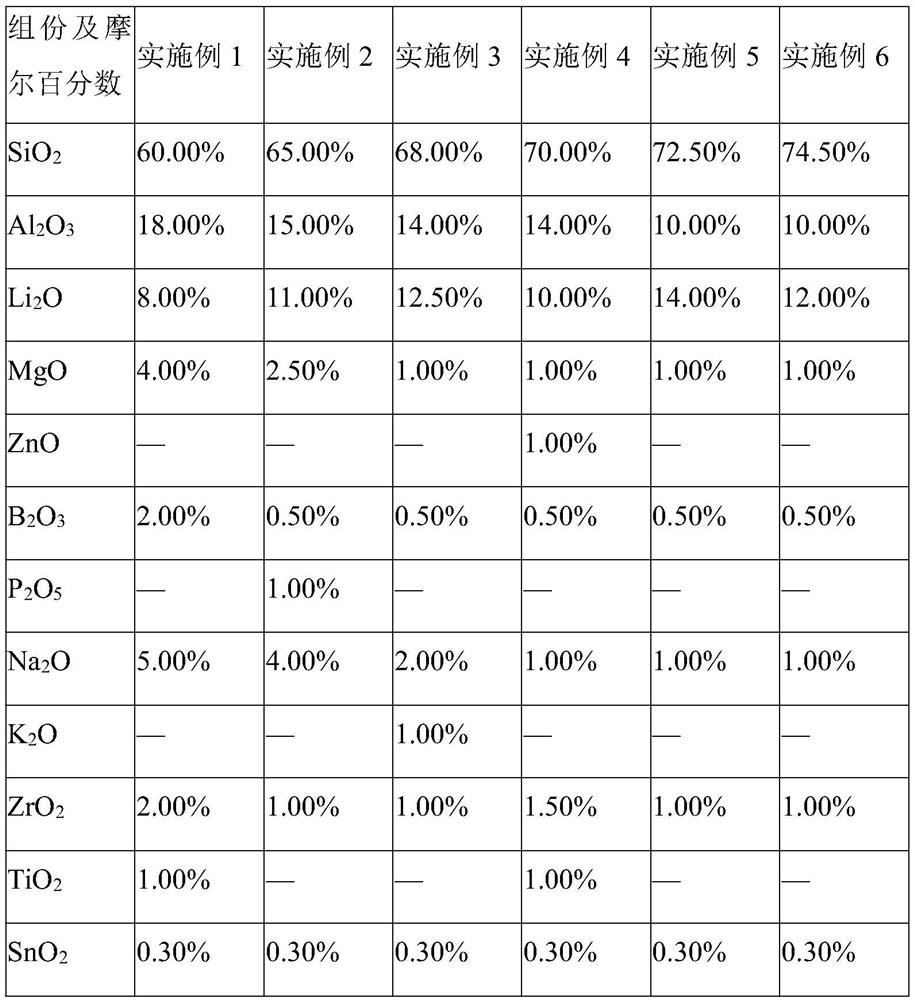

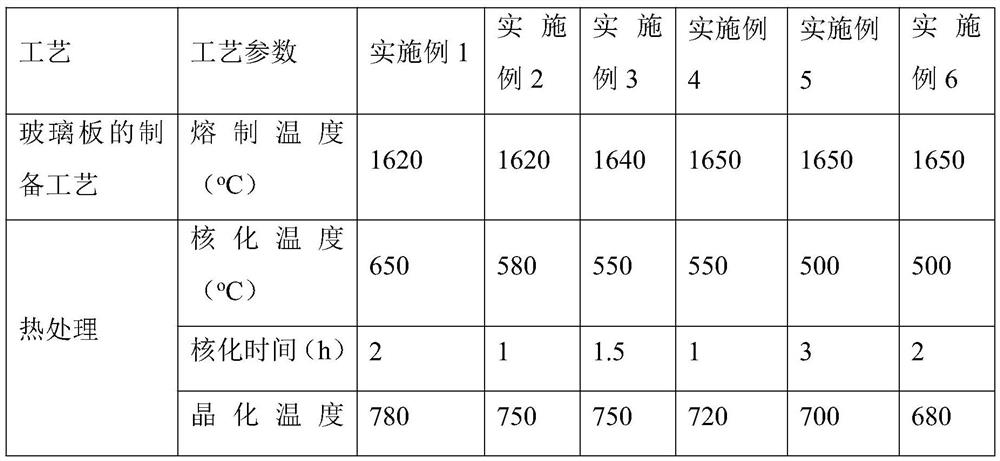

[0034] The present invention provides a crystalline glass having an ultra-high bifurcation threshold, a crystal having an average crystal size of less than or equal to 70 nm in a microcrystalline glass, which is still preferably 10 nm to 30 nm, and the size of the crystal can ensure transparency of the crystalline glass. . The crystal accounts for 50% by weight to 90% by weight, ultra-high crystal ratio of the total weight of the microcrystalline glass, and can effectively improve the structural st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com