Completely biodegradable film and preparation method thereof

A biodegradable and film technology, applied in the field of completely biodegradable film and its preparation, can solve the problem of improving the tear strength of polyglycolic acid film, affecting the wide application of polyglycolic acid film, and the film's non-tear resistance and flexibility, etc. problems, to achieve the effect of improving biodegradability, great economic and social significance, and improving tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

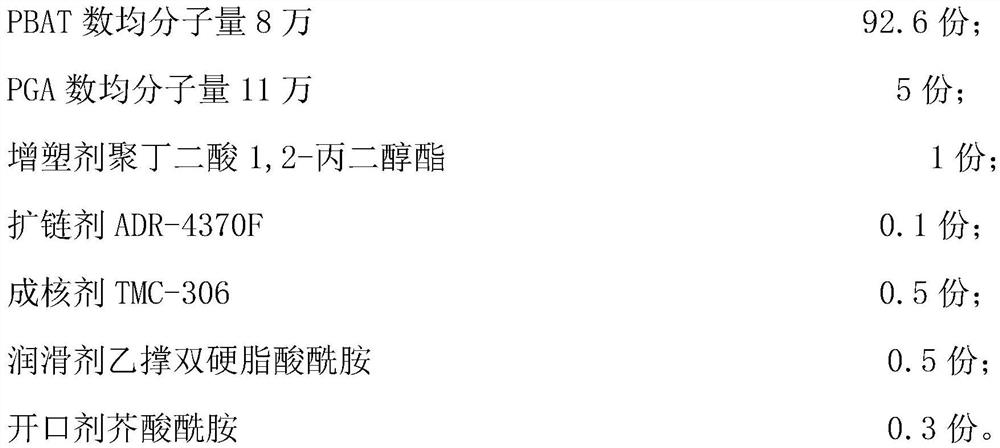

Embodiment 1

[0022] Embodiment 1: The present invention provides a kind of fully biodegradable film, and the composition of its formula and the ratio of mass parts are:

[0023]

[0024]Weigh polylactic acid, polybutyl carbonate, ethylene bis stearic acid amide, erucic acid amide according to the above formula, carry out mechanical blending of each component for 5 minutes, put the mixed raw materials into the twin-screw extruder, extrude During the extruder side line, use a peristaltic pump to quantitatively add the above-mentioned 1,2-trimethylene adipate. The conditions for extrusion and granulation are: the set temperature of the twin-screw extruder is: Zone 1: 130-150°C , Zone 2: 160-180℃, Zone 3: 160-190℃, Zone 4: 160-190℃, Zone 5: 160-190℃, Zone 6: 160-190℃, Zone 7: 160-190℃, Zone 8 Zone: 160-190°C, machine head: 160-190°C, screw speed: 100-300rpm, extrude, granulate and dry to obtain polylactic acid blown film resin. The resin is blown into a film by a blown film machine. The se...

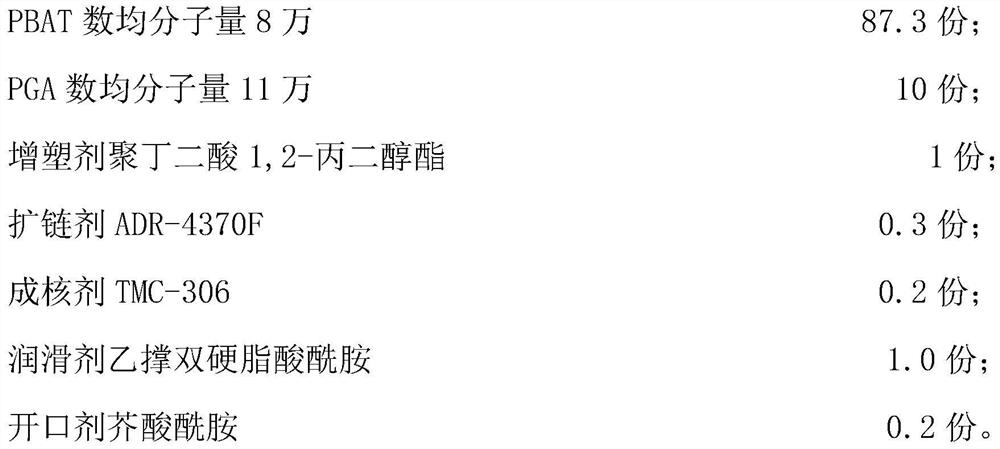

Embodiment 2

[0025] Embodiment 2: The present invention provides a kind of fully biodegradable film, and the composition of its formula and the ratio of mass parts are:

[0026]

[0027] This step of extrusion granulation and film blowing process is the same as in Example 1, the film thickness is controlled at 0.025 mm, and the mechanical properties of the film are tested. The test results are listed in Table 1.

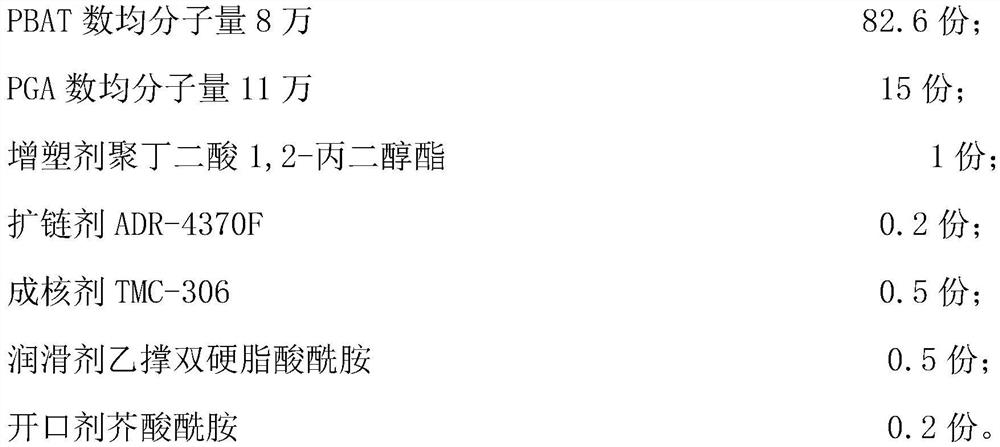

Embodiment 3

[0028] Embodiment 3: The present invention provides a kind of fully biodegradable film, and the composition of its formula and the ratio of mass parts are:

[0029]

[0030] This step of extrusion granulation and film blowing process is the same as in Example 1, the film thickness is controlled at 0.025 mm, and the mechanical properties of the film are tested. The test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com