Patents

Literature

187results about How to "Small crystal size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

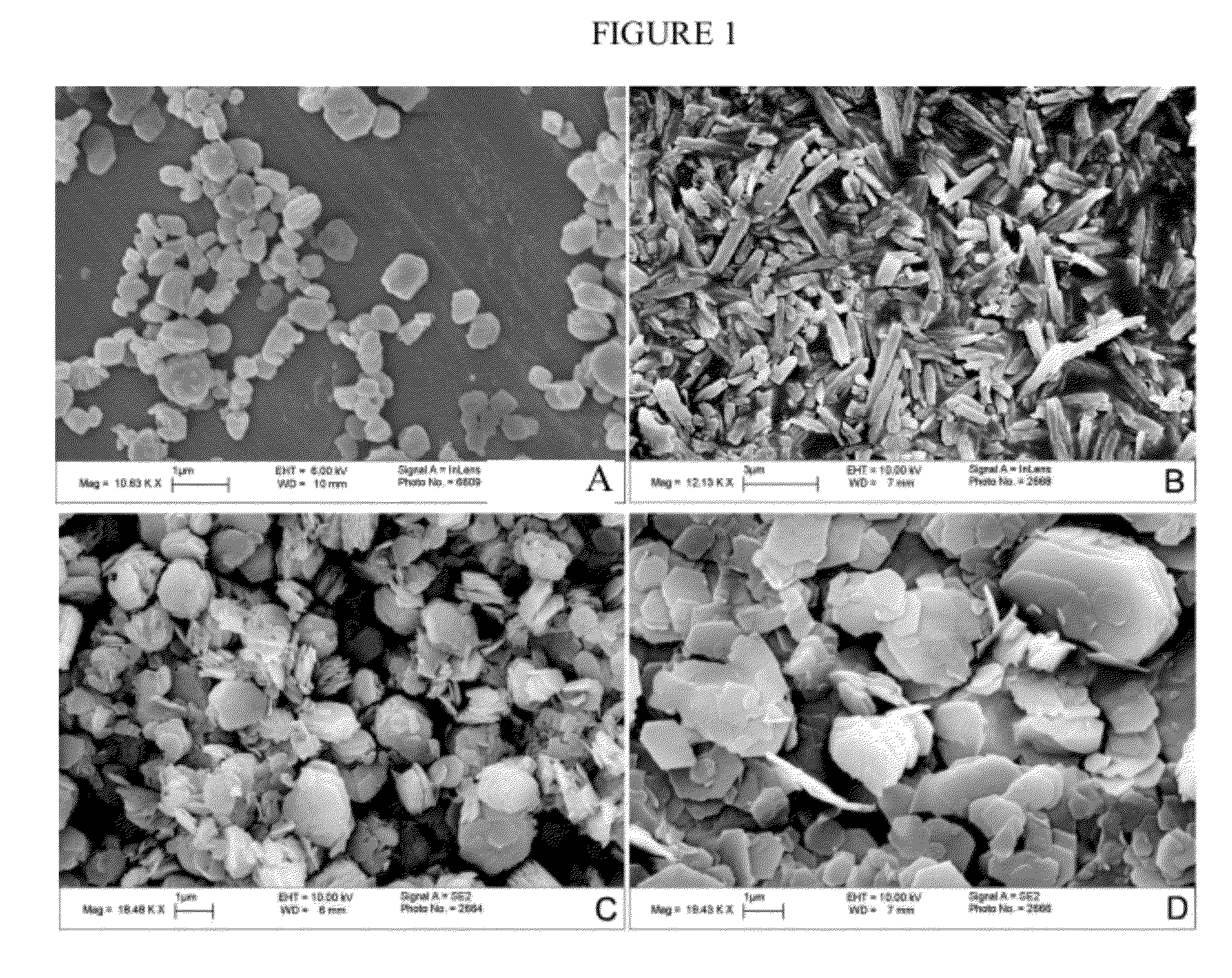

Tricalcium phosphates, their composites, implants incorporating them, and method for their production

InactiveUS20050031704A1Easily controlEnhance packing and densificationBiocideHeavy metal active ingredientsChemistryProsthetic implants

Methods for the synthesis of tricalcium phosphates are presented, as well as a series of specific reaction parameters that can be adjusted to tailor, in specific ways, properties in the tricalcium phosphate precursor precipitate. Particulate tricalcium phosphate compositions having an average crystal size of about 250 nm or less are provided. Compositions of the invention can be used as prosthetic implants and coatings for prosthetic implants.

Owner:PIONEER SURGICAL TECH INC

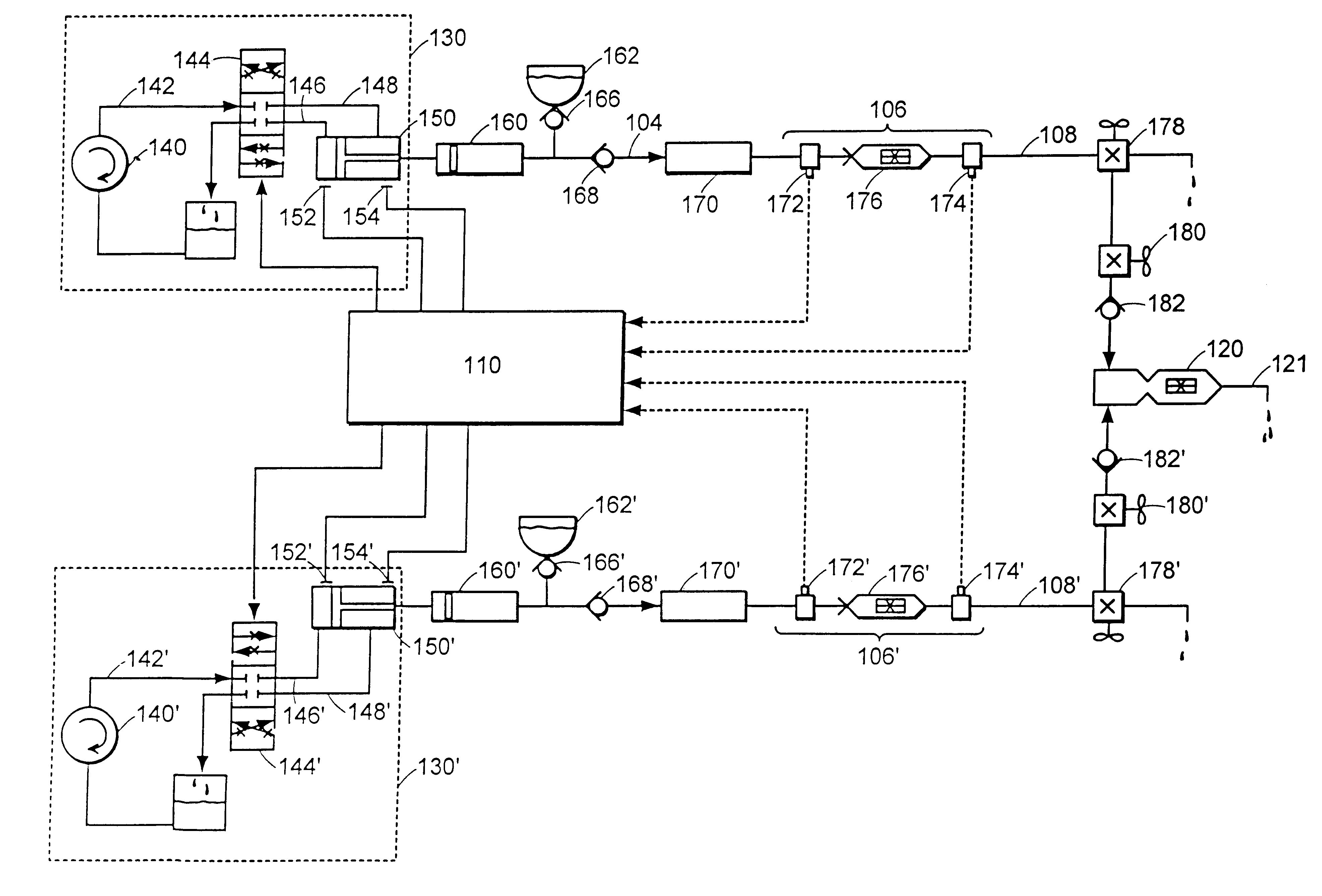

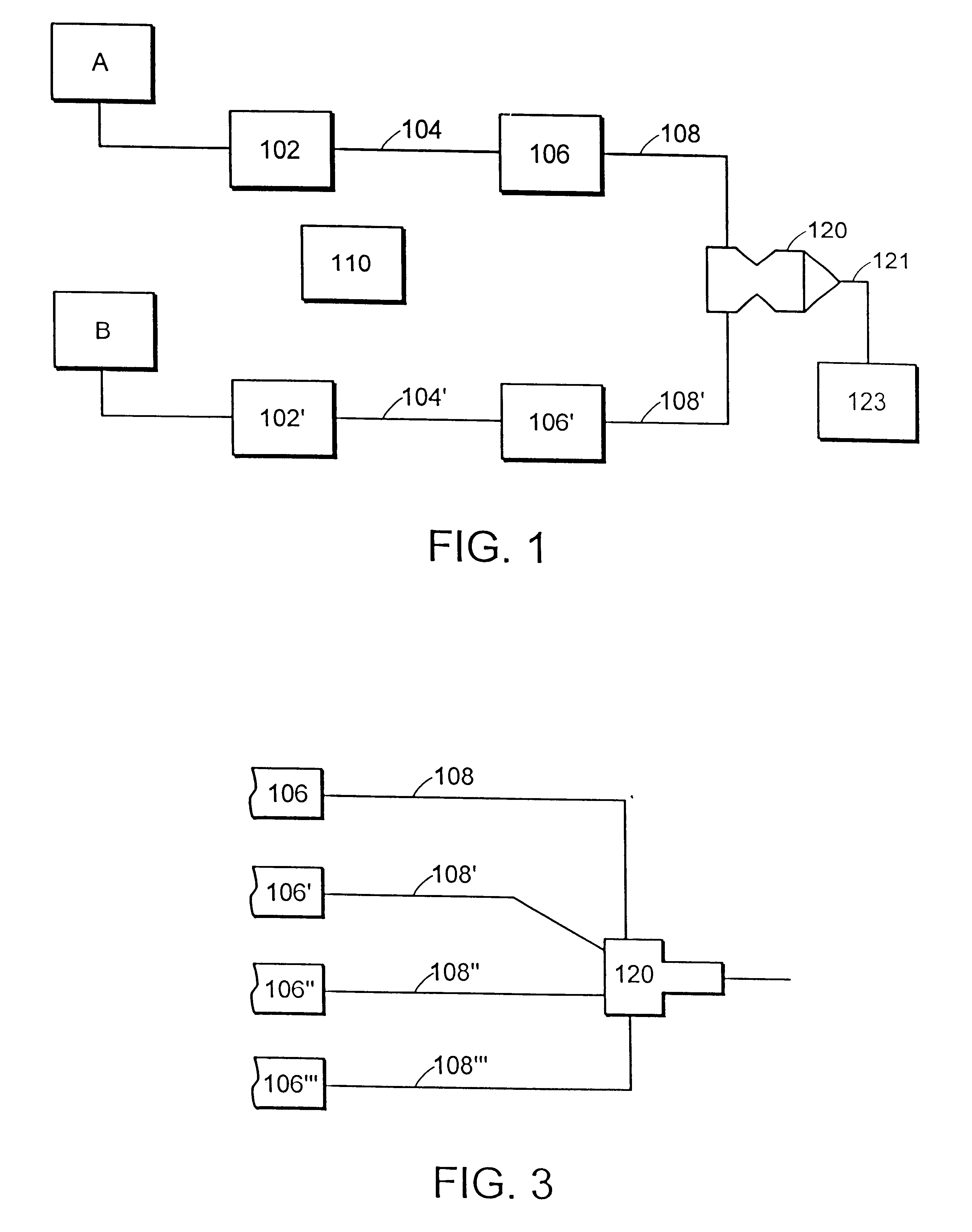

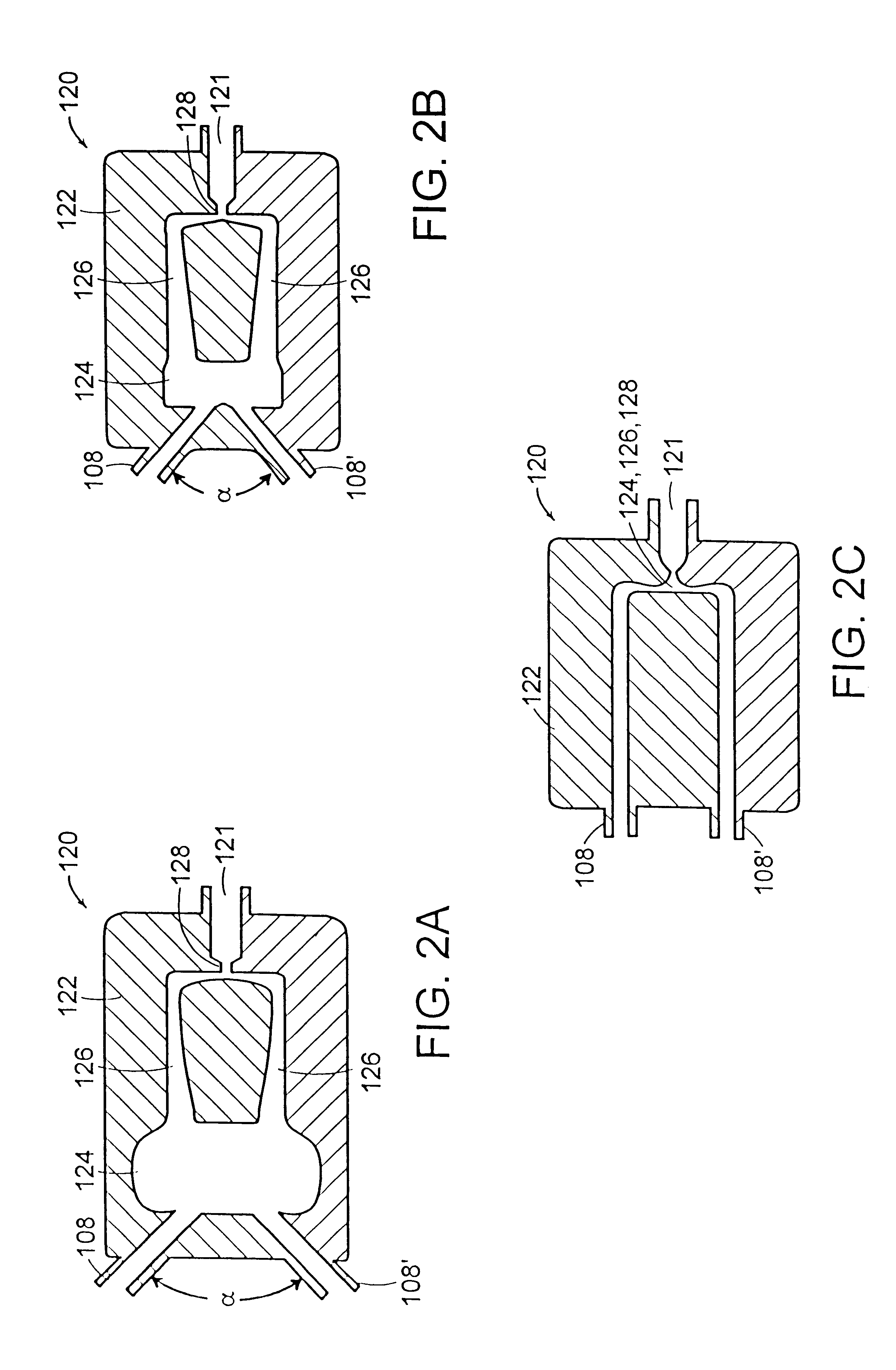

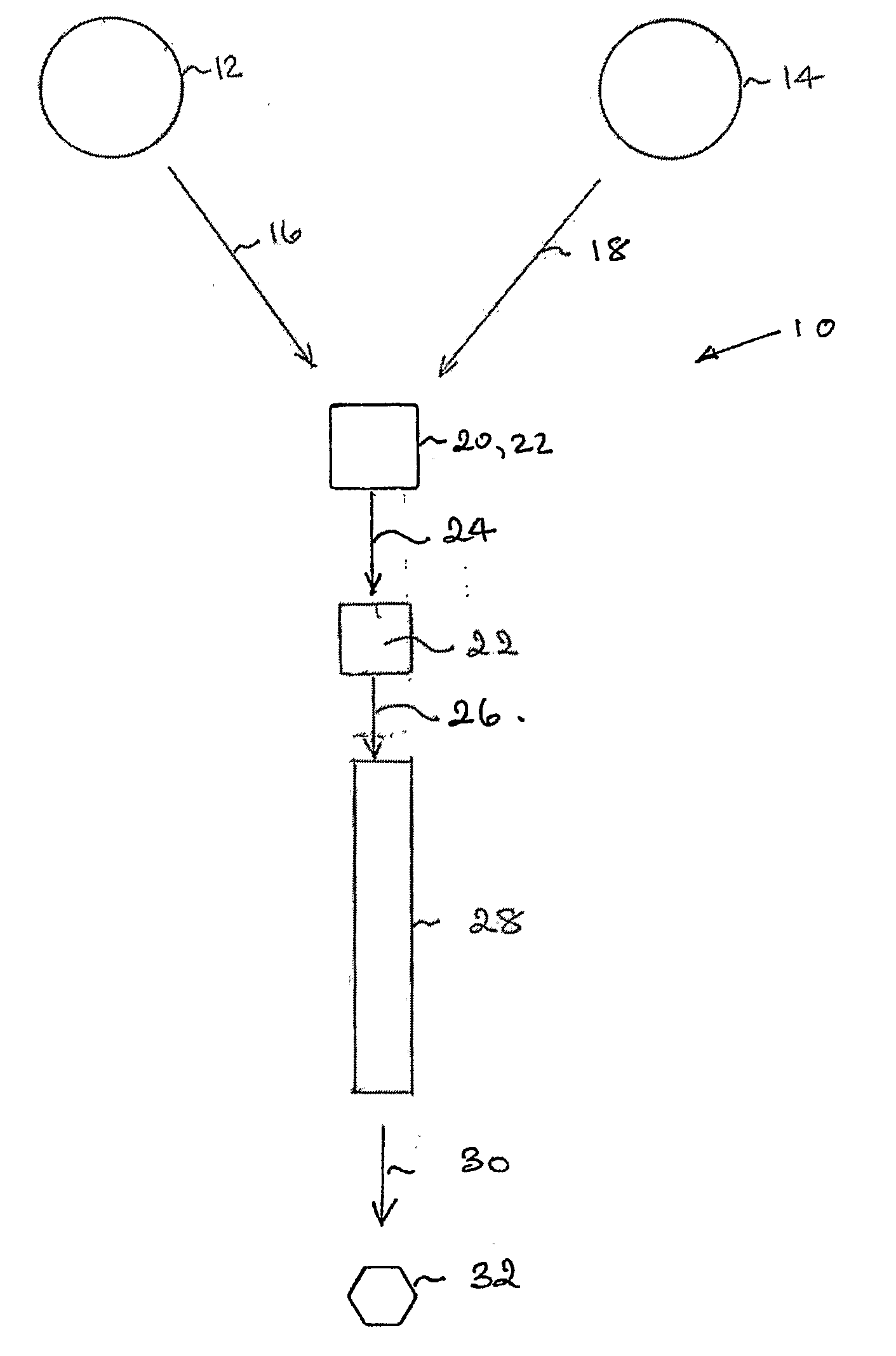

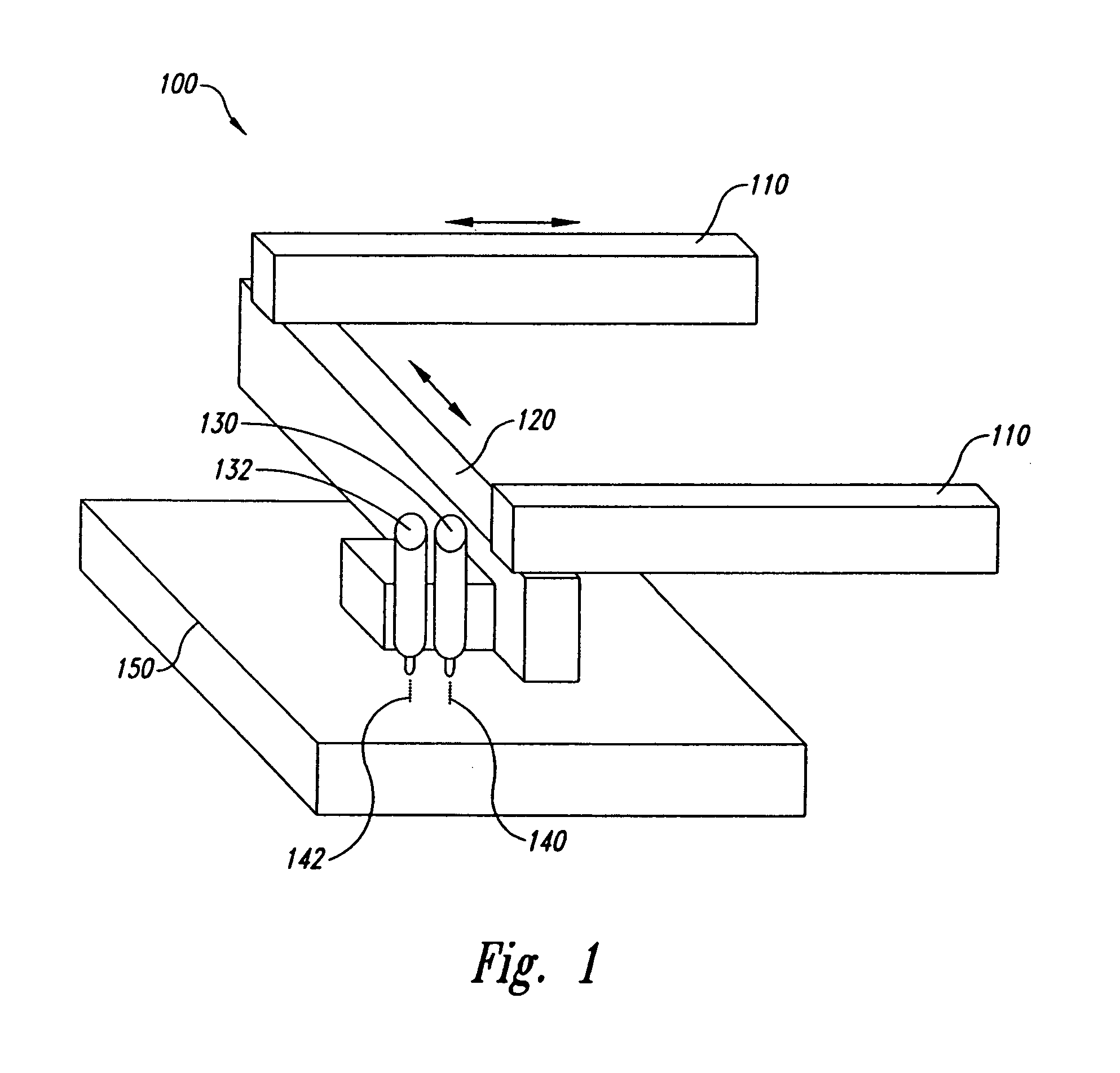

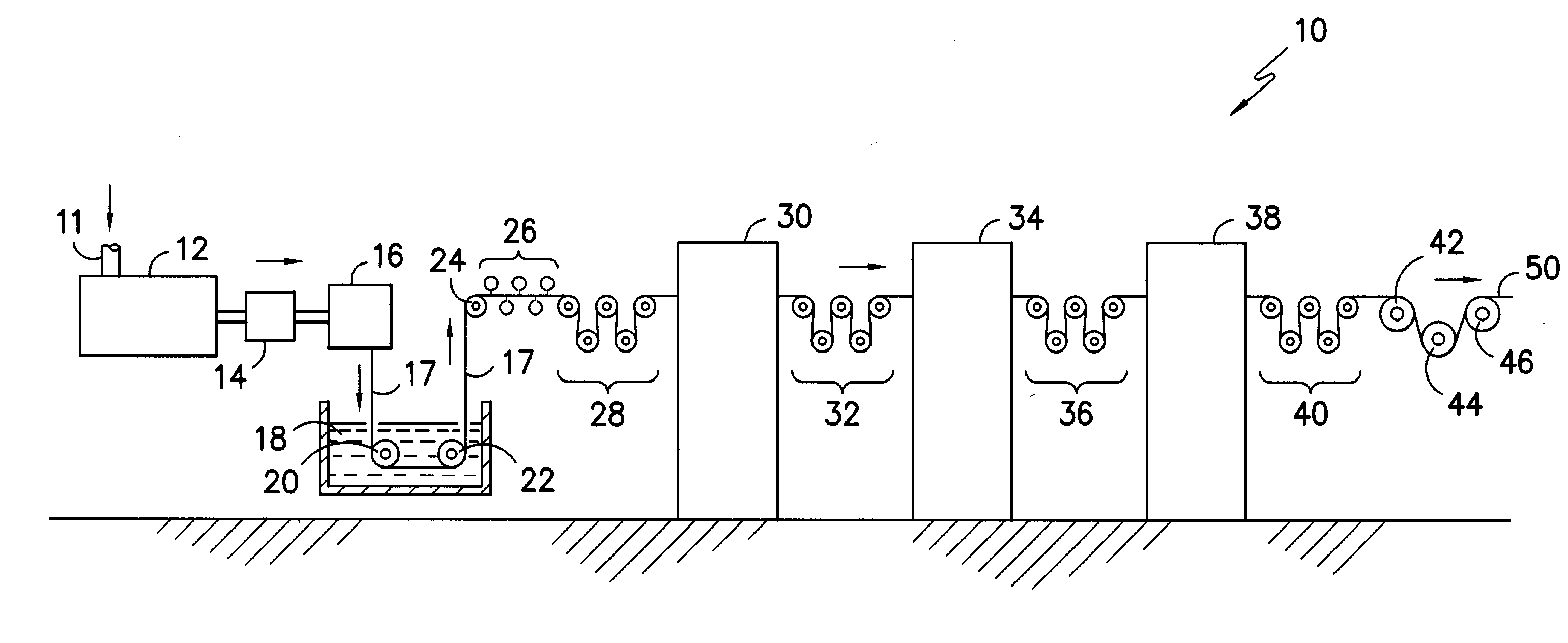

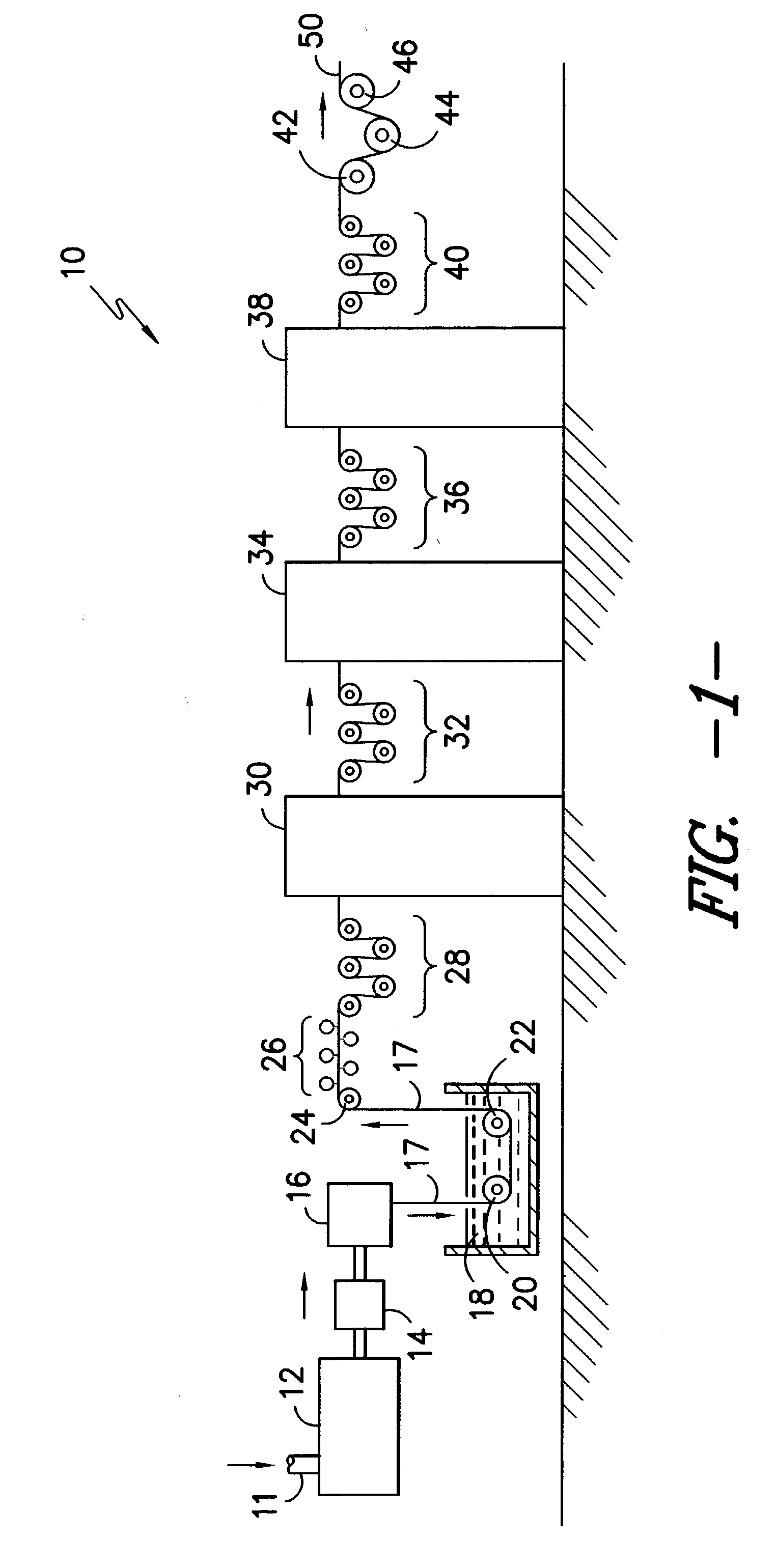

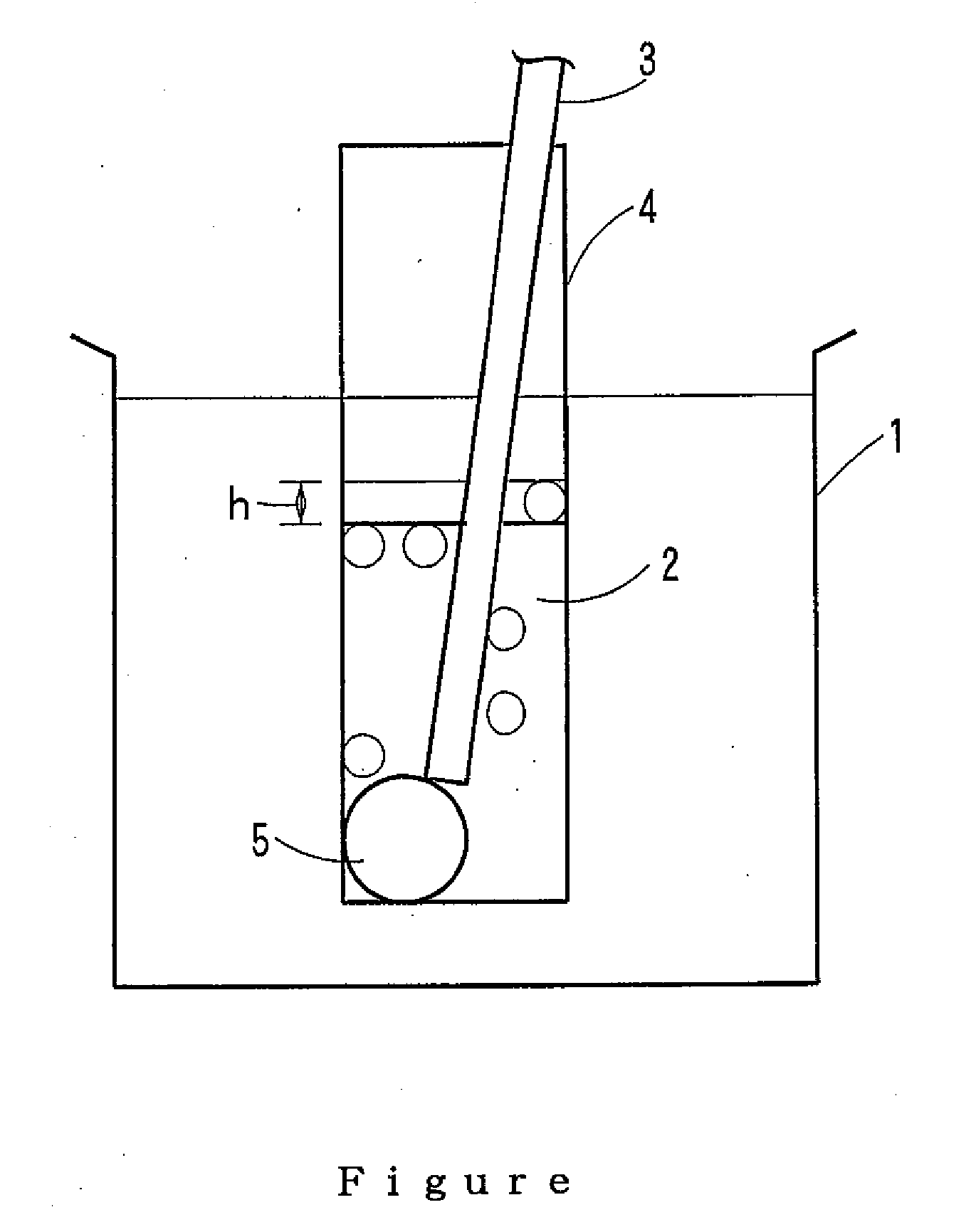

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

Production of meta-block copolymers by polymer segment interchange

Meta-block copolymers and a process for preparing a product mixture comprising meta-block copolymers by contacting a metathesis catalyst under metathesis conditions with a composition comprising two or more ethylenically unsaturated polymers, said unsaturation defining one or more polymer segments in each ethylenically unsaturated polymer, at least one polymer segment in at least one ethylenically unsaturated polymer being chemically distinguishable from at least one polymer segment in at least one other ethylenically unsaturated polymer, characterized in that each meta-block copolymer in the product mixture comprises a random distribution of said chemically distinguishable polymer blocks.

Owner:DOW GLOBAL TECH LLC +1

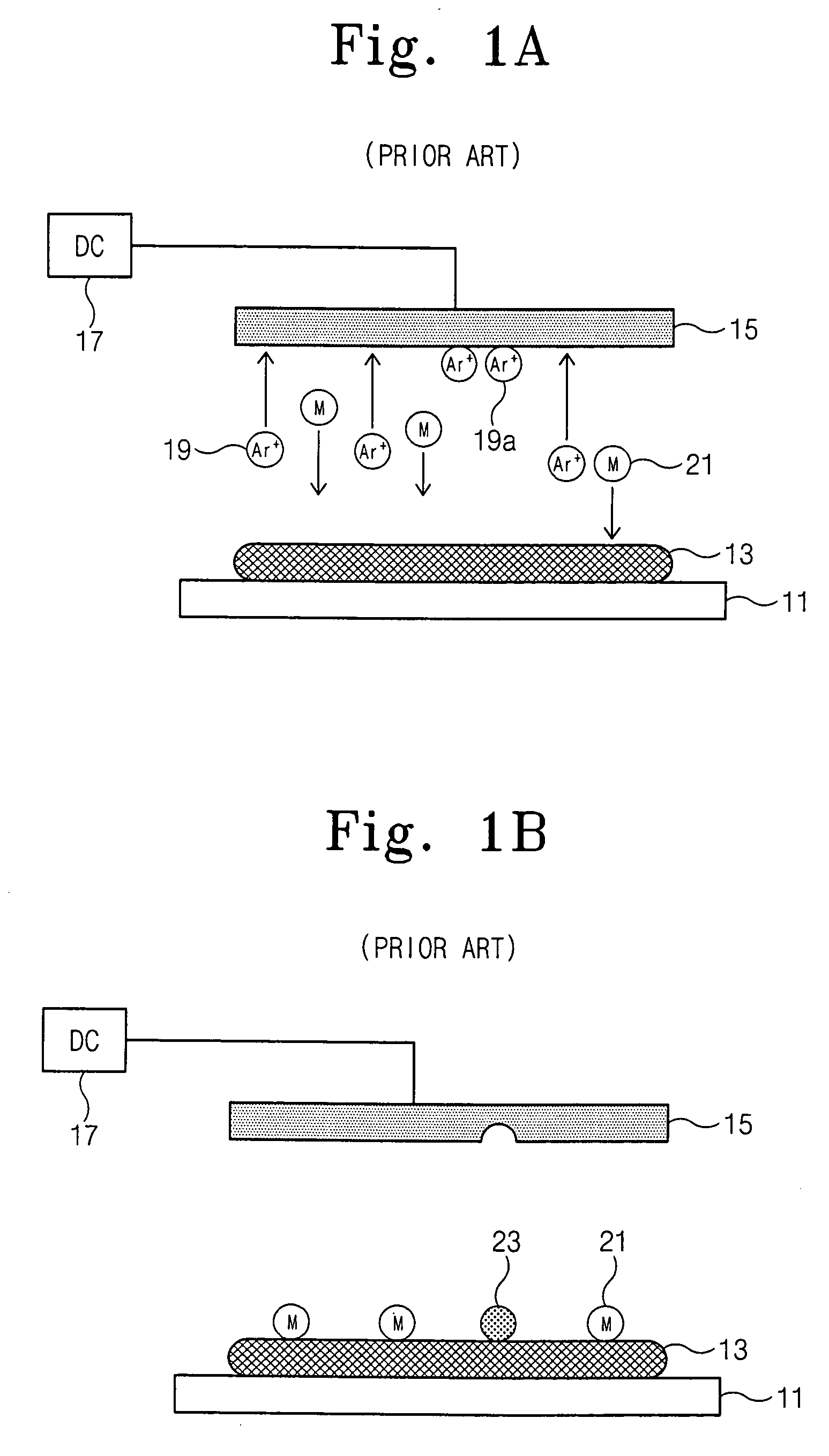

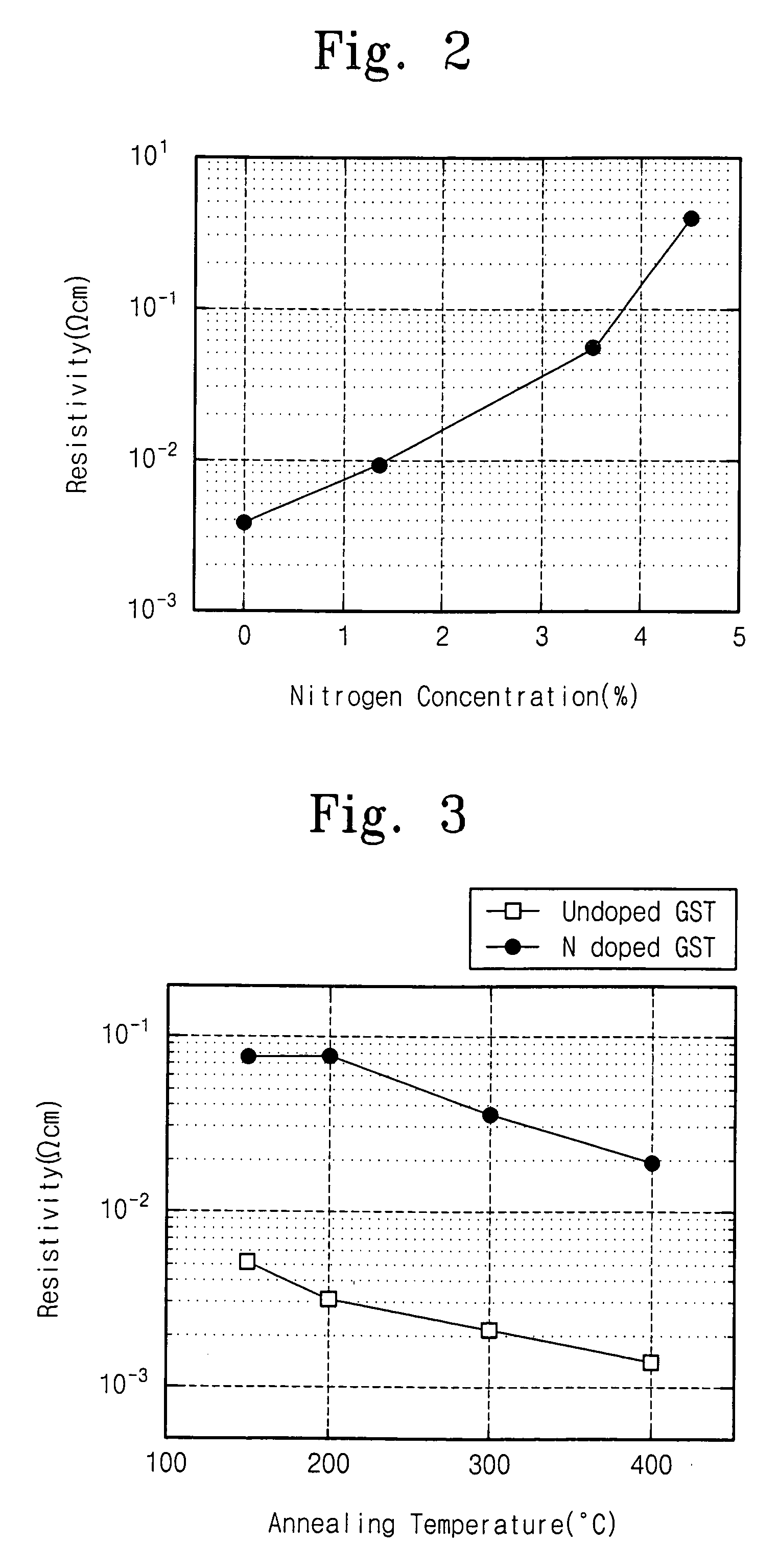

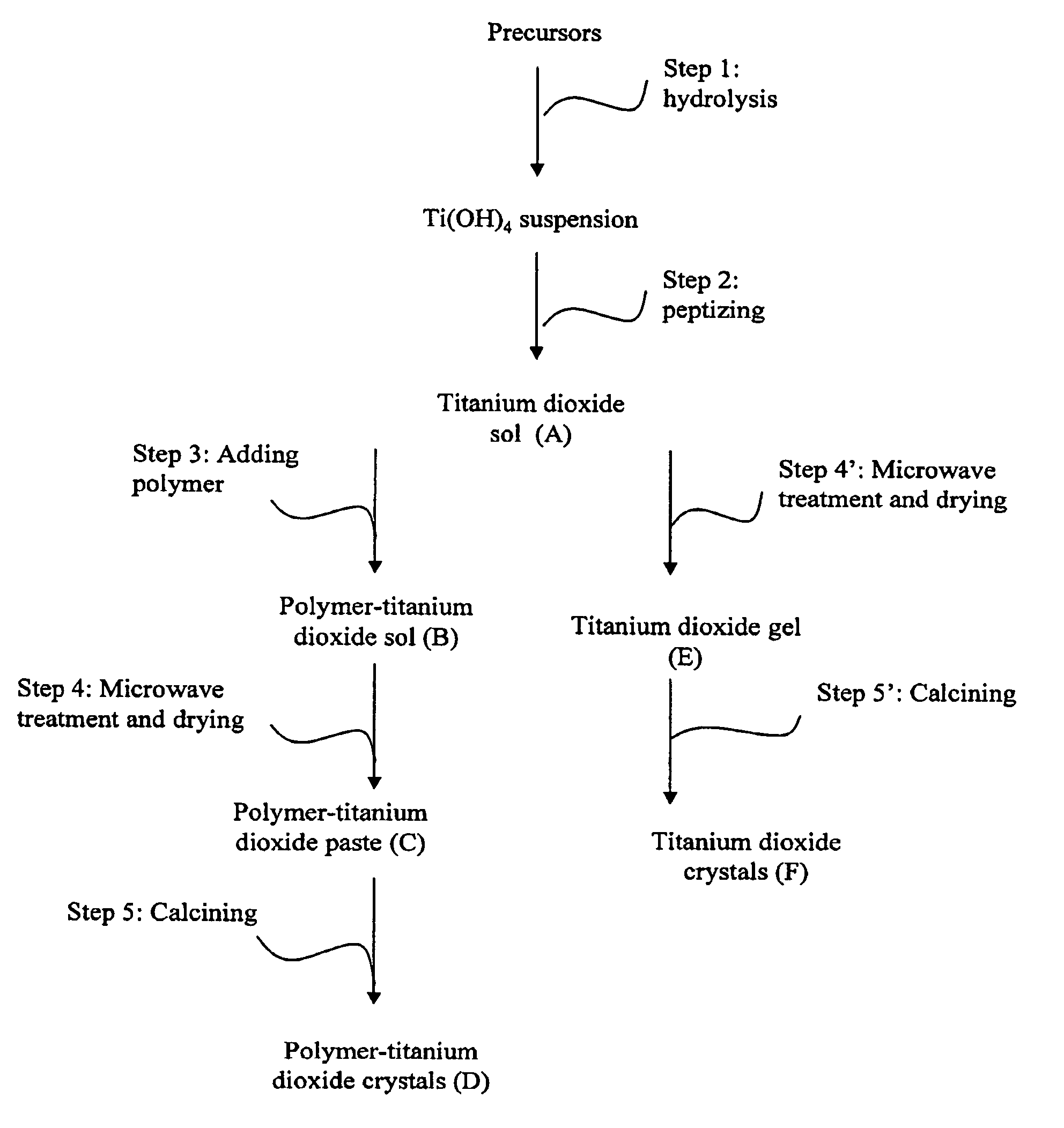

Methods for sputtering a target material by intermittently applying a voltage thereto and related apparatus, and methods of fabricating a phase-changeable memory device employing the same

InactiveUS20060027451A1Reduce the probability of depositionSmall crystal sizeCellsVacuum evaporation coatingSputteringPhase-change memory

A method of sputtering to deposit a target material onto a substrate includes supplying an ionized gas to the substrate and the target material. A first DC bias voltage having a polarity opposite that of the ionized gas is applied to the target material to attract ions theretoward. A second DC bias voltage having a polarity opposite that of the first DC bias voltage is intermittently applied to the target material to reduce ion accumulation thereon. Related apparatus and methods of fabricating phase-changeable memory devices are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

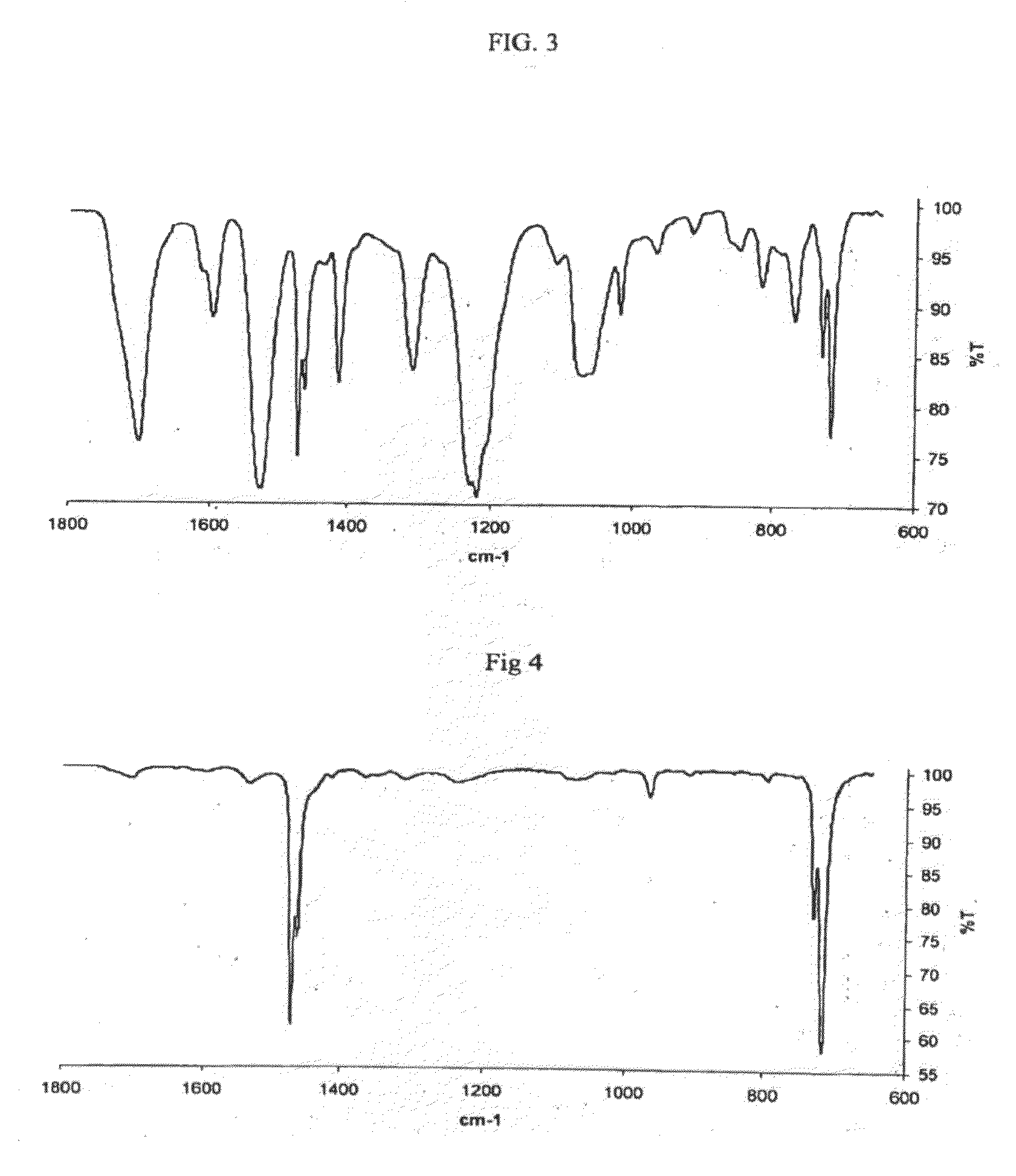

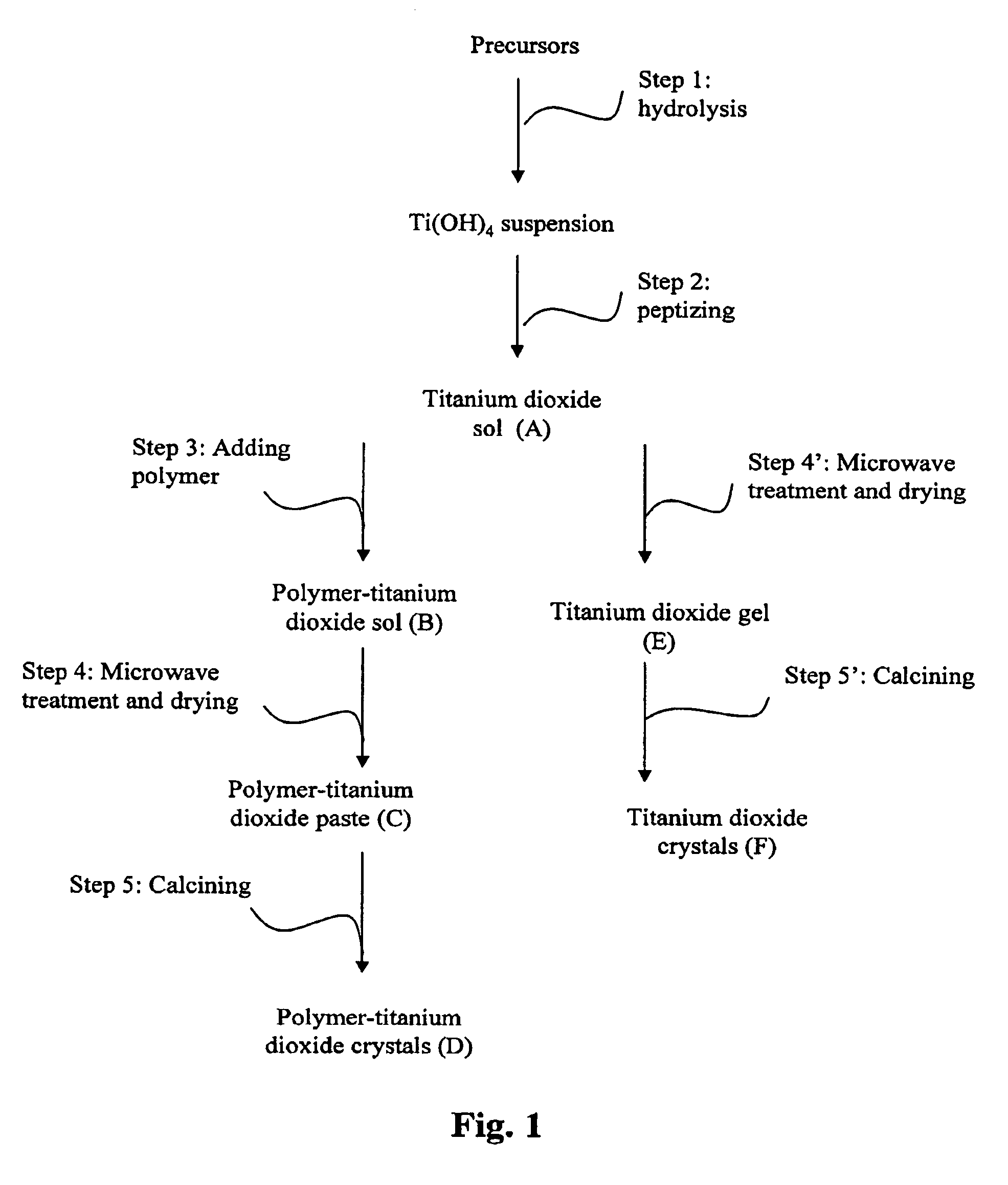

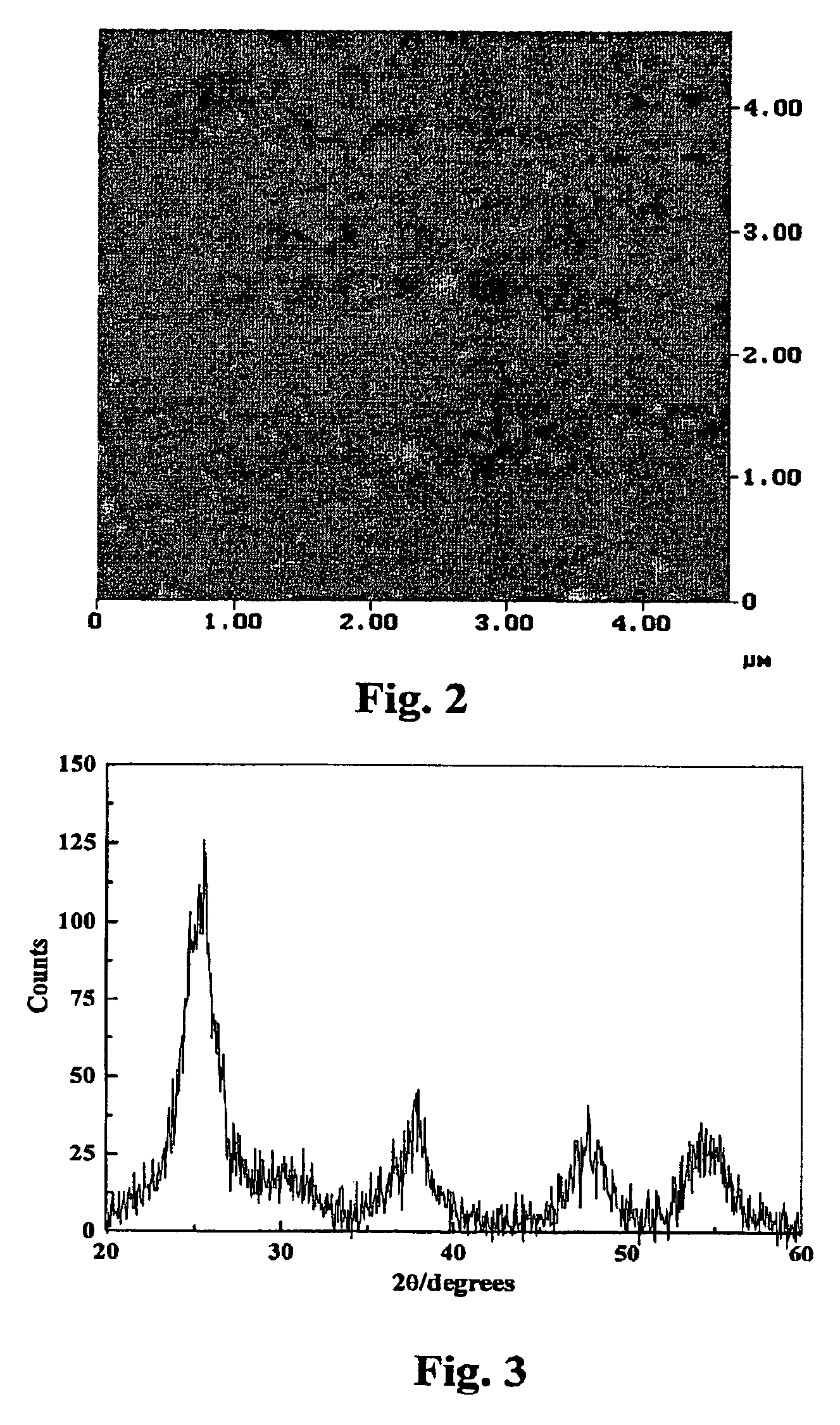

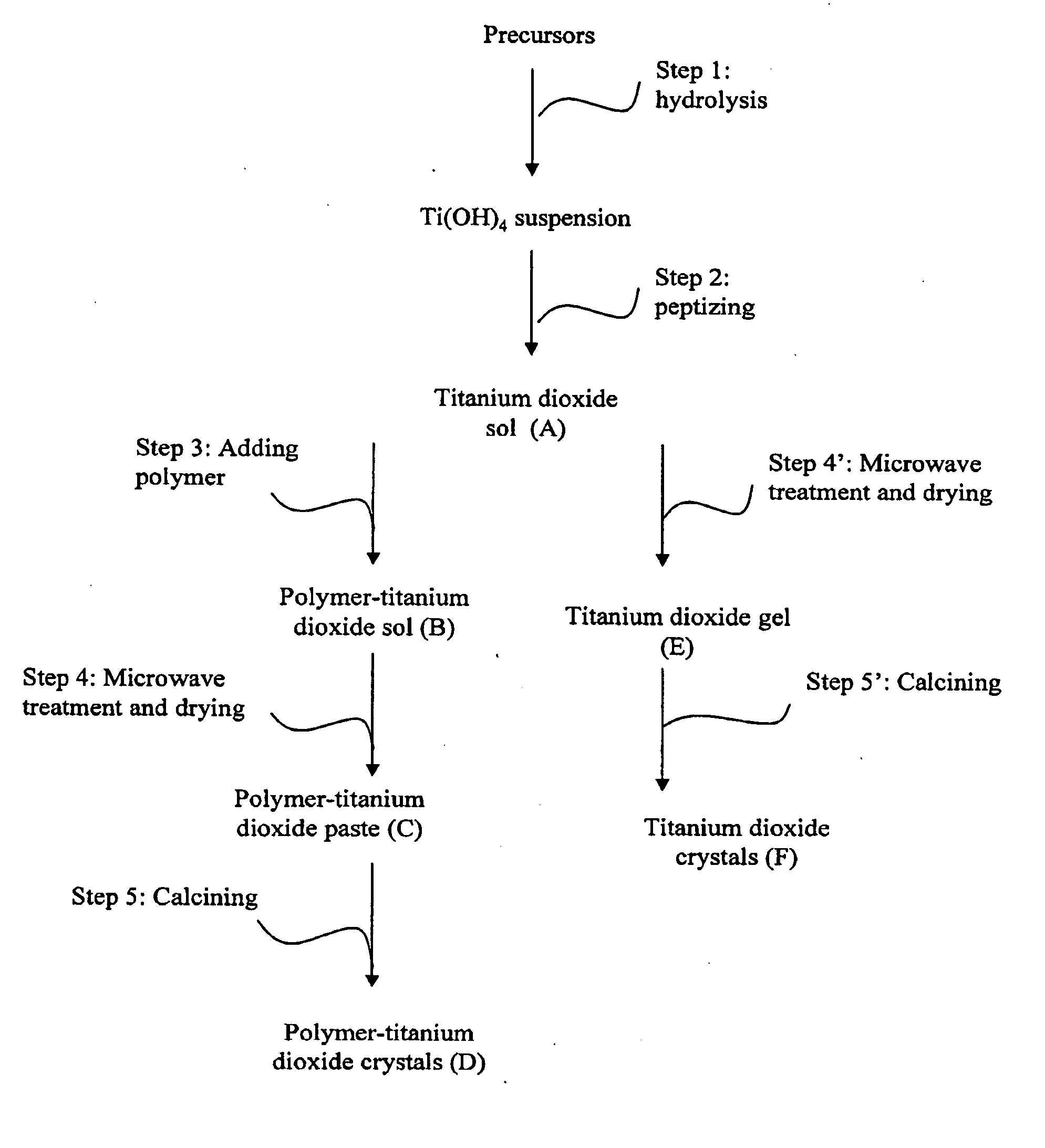

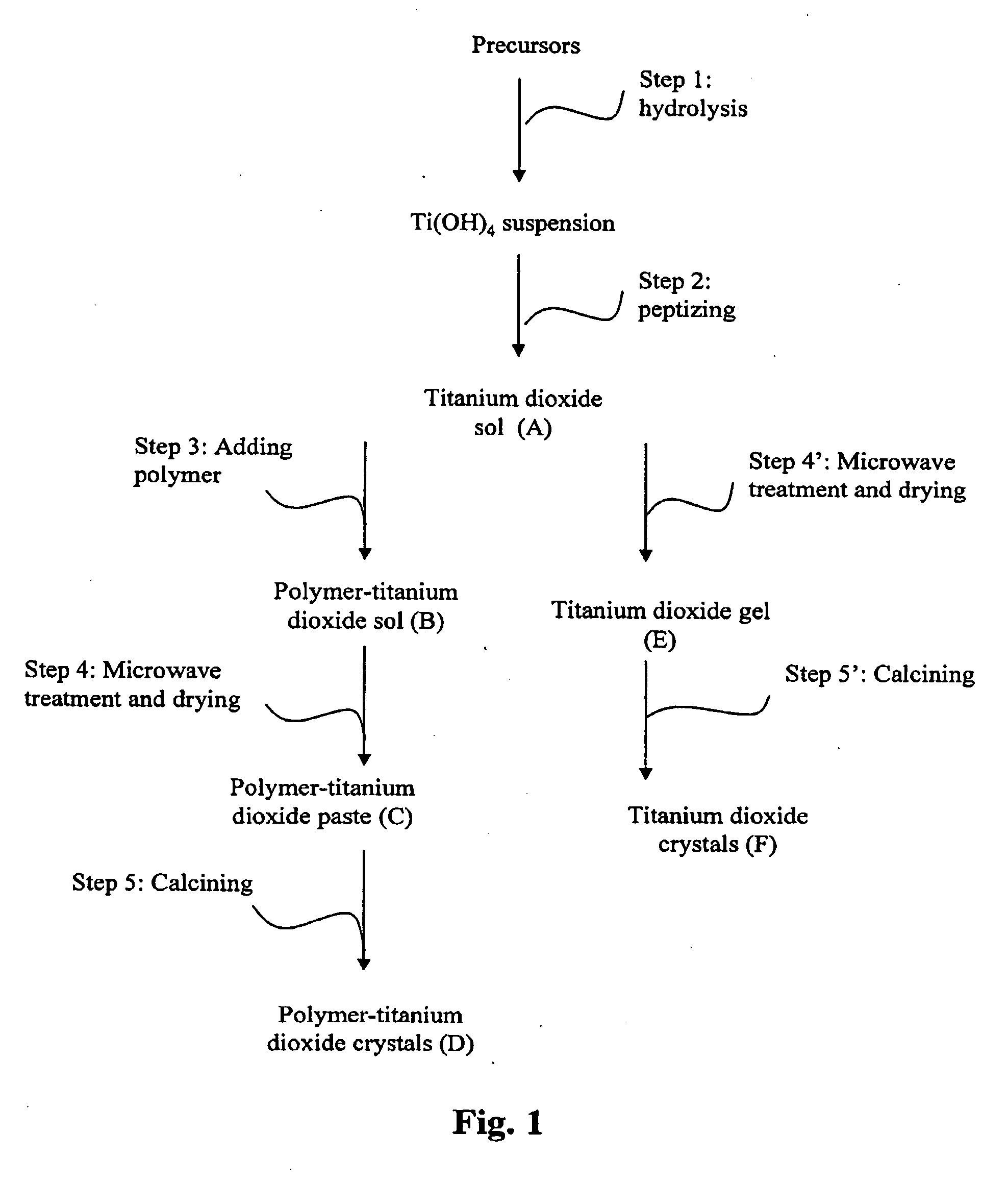

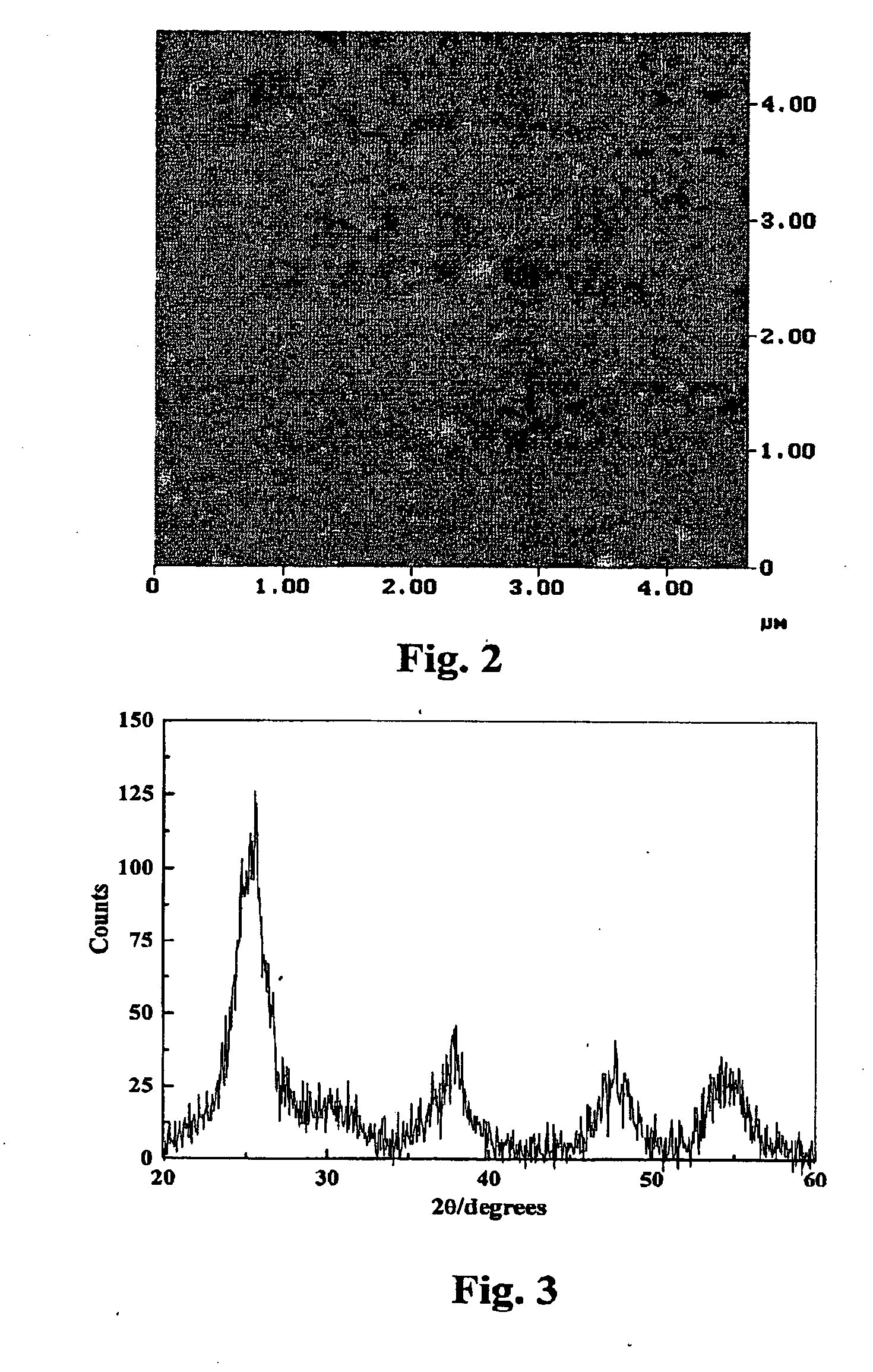

TiO2 material and the coating methods thereof

ActiveUS7144840B2Reduce moistureInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAir purificationTitanium dioxide

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

Metal matrix composite material

InactiveUS20100003536A1Reduce size of crystalIncreased strengthLayered productsThin material handlingNanometreMetal matrix composite

According to the present invention there is provided a metal matrix composite material and a method for the manufacture thereof, the material comprising an aluminium-based alloy matrix, the matrix comprising a microstructure composed of at least a first aluminium alloy phase and having a second phase of nanostructured quasicrystalline particles embedded therein and further including in said matrix fibrils of at least one other dissimilar material.

Owner:SMITH GEORGE DAVID WILLIAM +3

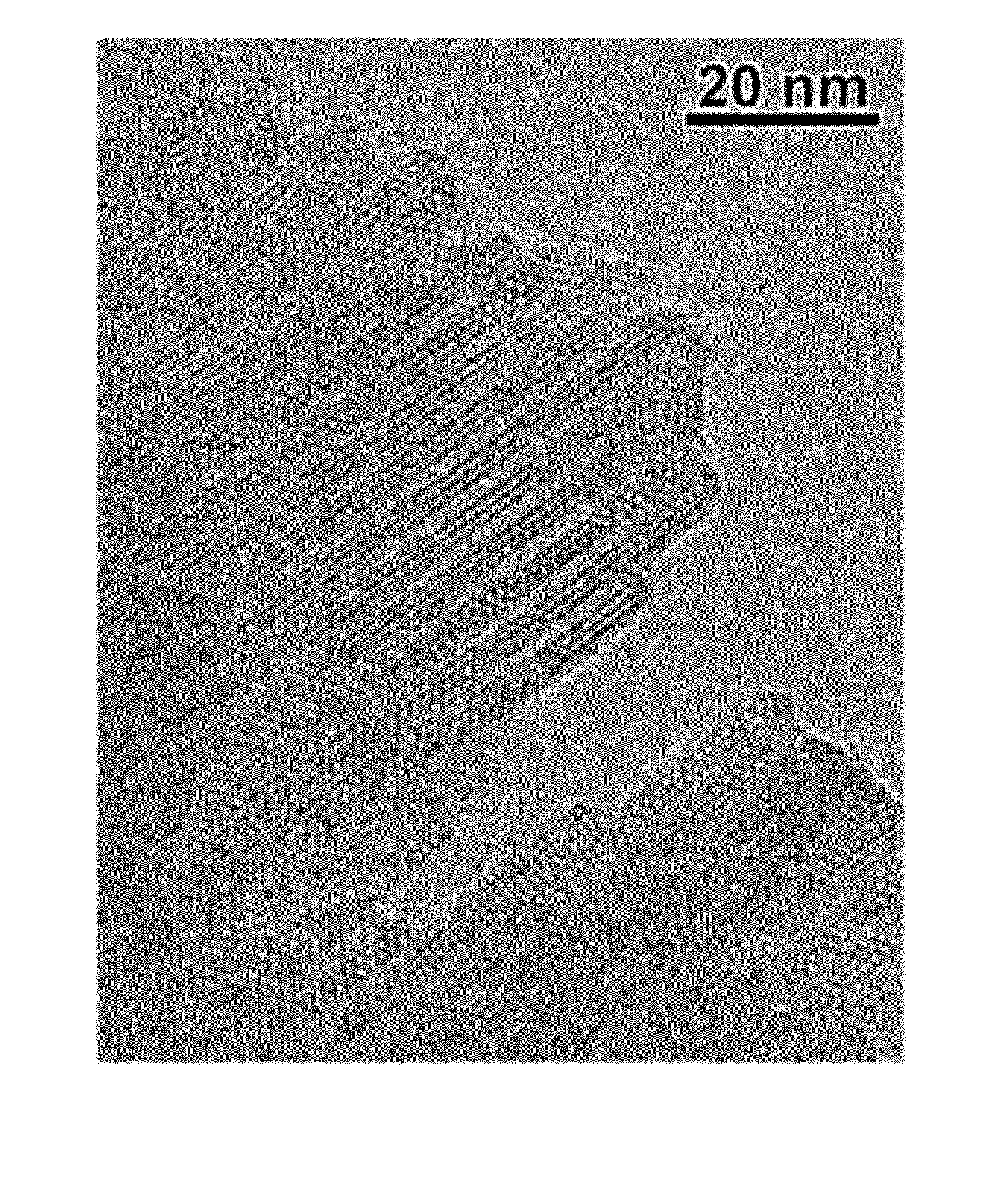

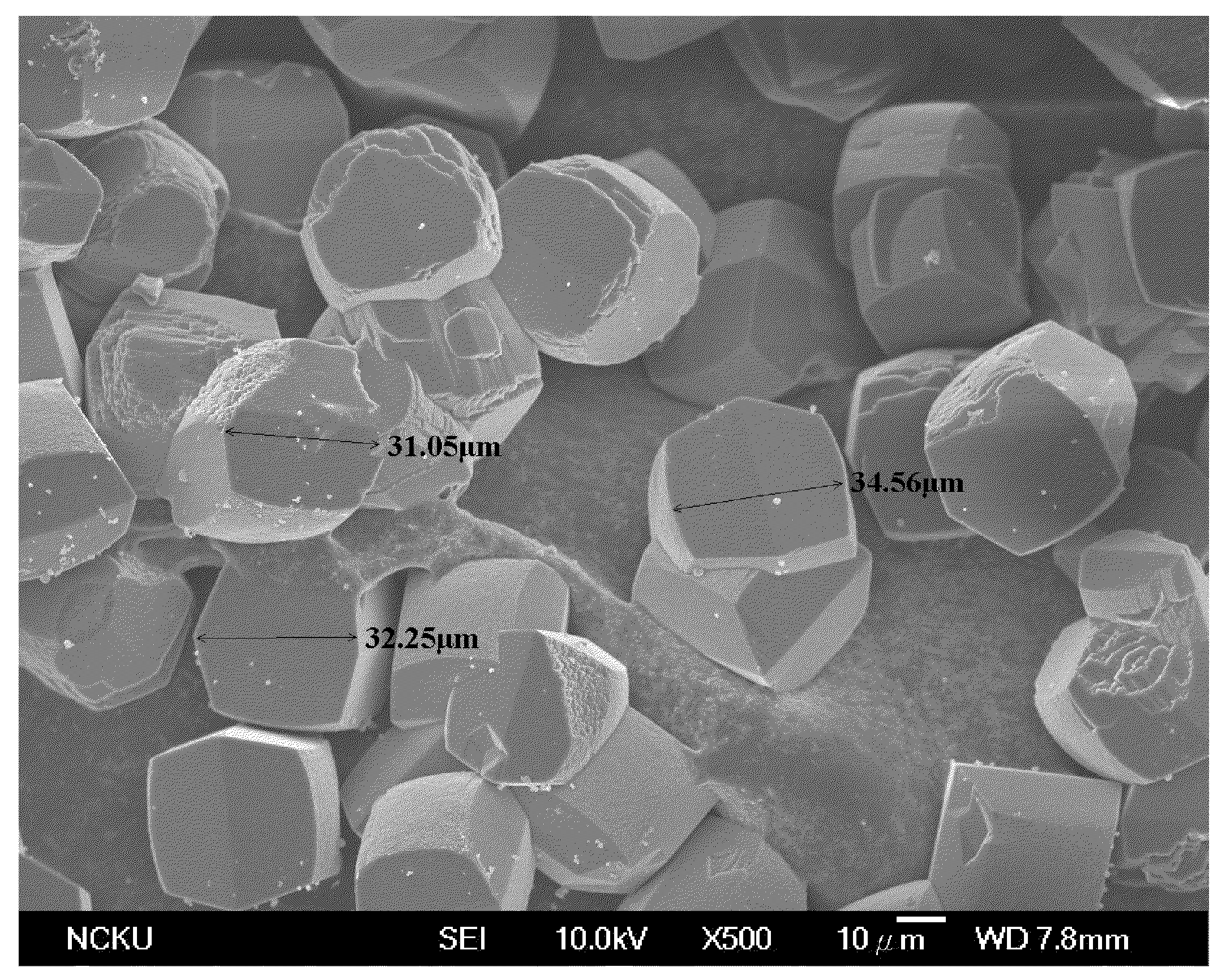

LiFePO4 FLAKES FOR Li-ION BATTERY AND METHOD FOR MANUFACTURING THE SAME

ActiveUS20120328947A1Charge-discharge efficiency can be improvedShort diffusion pathMaterial nanotechnologyPhosphatesCharge dischargeEngineering

LiFePO4 flakes for a Li-ion battery and a method for manufacturing the same are disclosed. The LiFePO4 flakes of the present invention have a thickness of 5 nm-200 nm, and the angle between the flat surface normal of the flake and the Li-ion diffusion channel is 0°-80°. In addition, according to the present invention, the LiFePO4 flakes with short Li ion diffusion path can be prepared through a simple process. Hence, not only the charge-discharge efficiency of the Li-ion battery can be improved by use of the LiFePO4 flakes of the present invention, but also the cost of the Li-ion battery can be further reduced.

Owner:NATIONAL TSING HUA UNIVERSITY

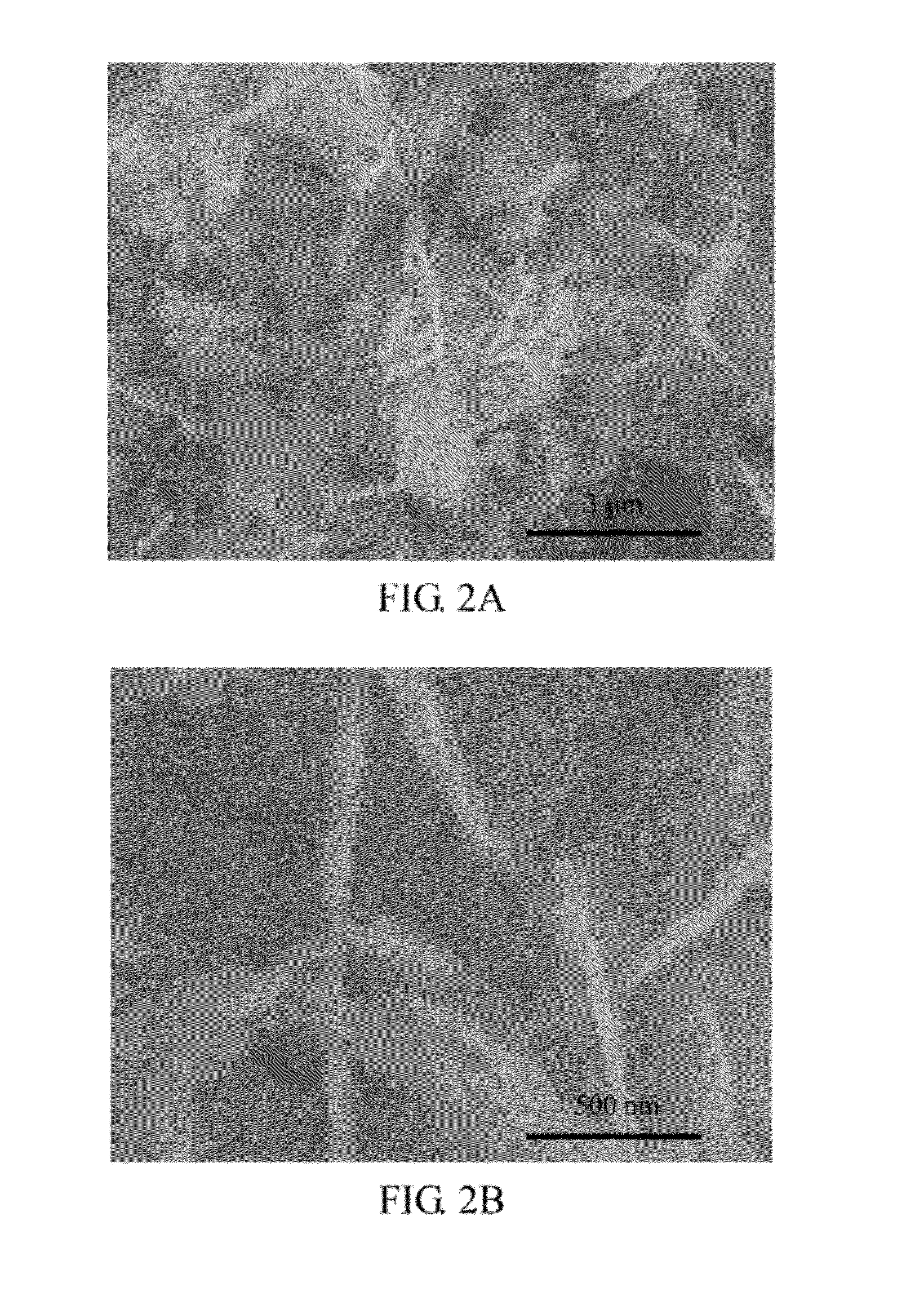

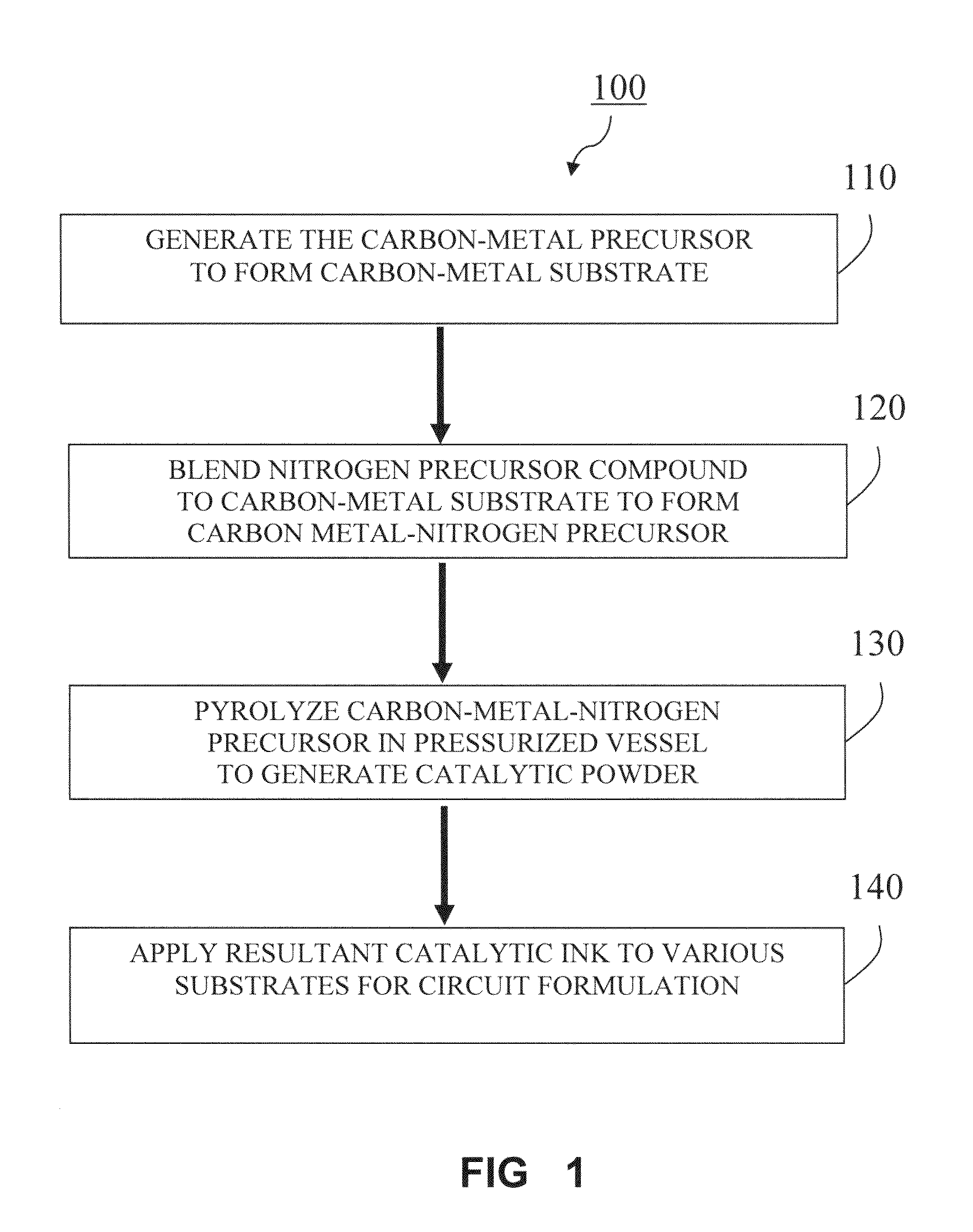

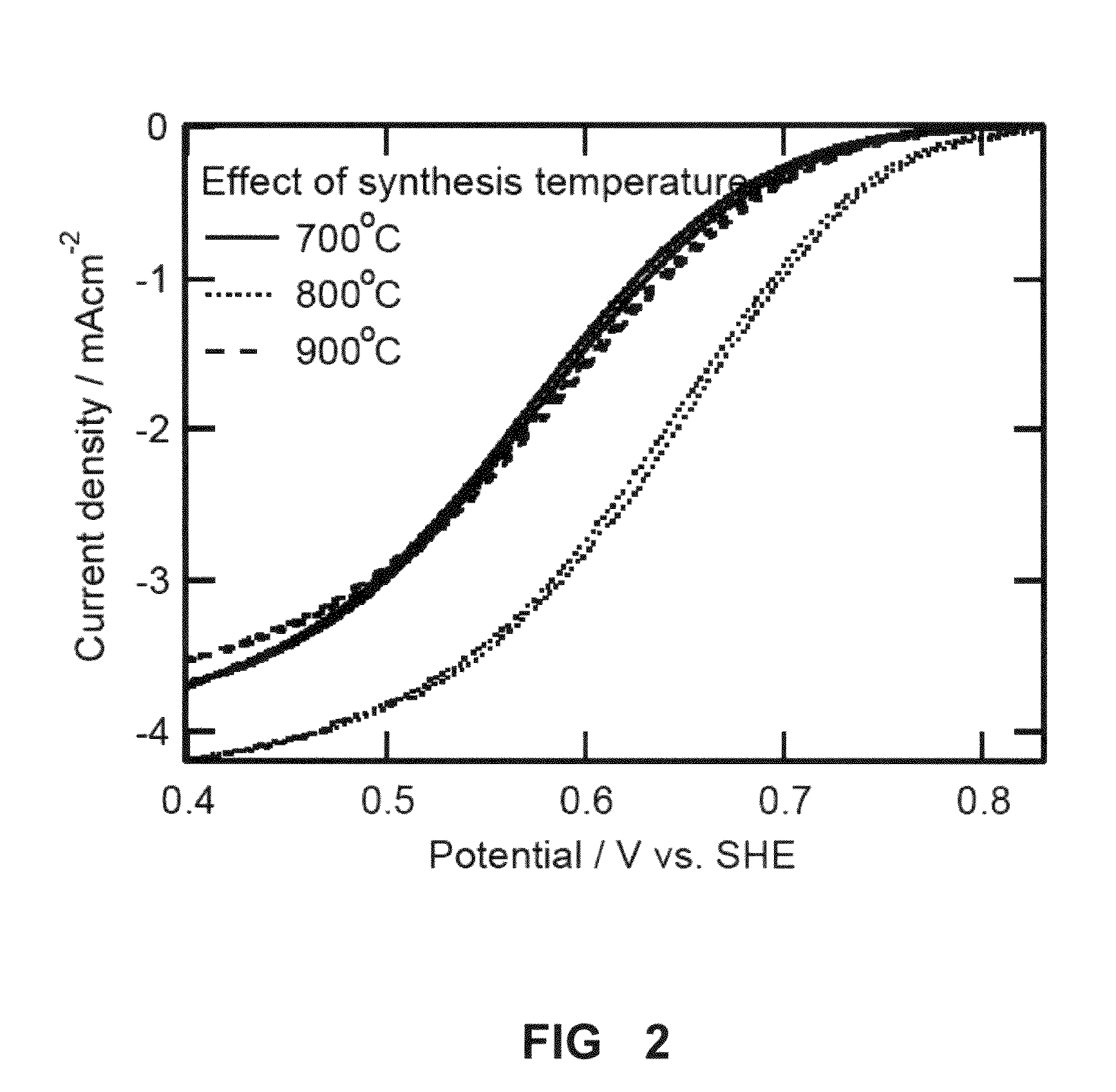

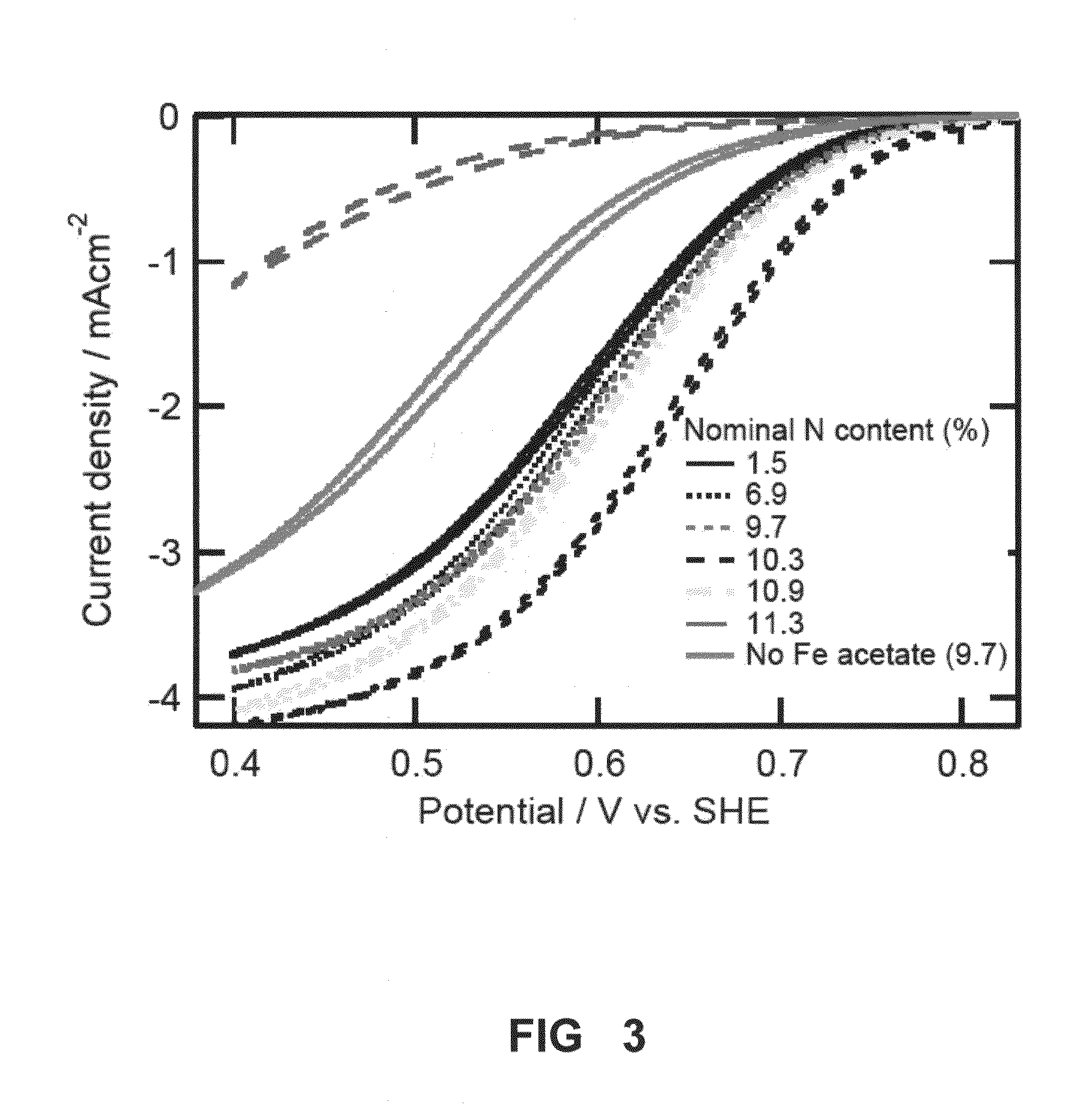

Novel catalyst for oxygen reduction reaction in fuel cells

InactiveUS20110287174A1High catalytic activityImprove usabilityFinal product manufactureCell electrodesFuel cellsNitrogen

A method for making a carbon-metal-nitrogen oxygen reducing cathode catalyst, the method comprising mixing a carbon source with a transition metal precursor to form a metal precursor loaded carbon substrate; adding a nitrogen precursor compound to the metal precursor loaded carbon substrate to form a carbon-metal-nitrogen precursor; and pyrolyzing the carbon-metal-nitrogen precursor in a closed vessel, thereby forming an oxygen reducing cathode catalyst. The carbon-metal-nitrogen catalyst requires no precious metal such as Pt, and also provides benefits such as controlled deposition of catalytically active nitrogenous compounds that can increase the catalytic activity of the catalyst when compared to gaseous deposition of nitrogen to the surface of the carbon support.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method and form of a drug delivery device, such as encapsulating a toxic core within a non-toxic region in an oral dosage form

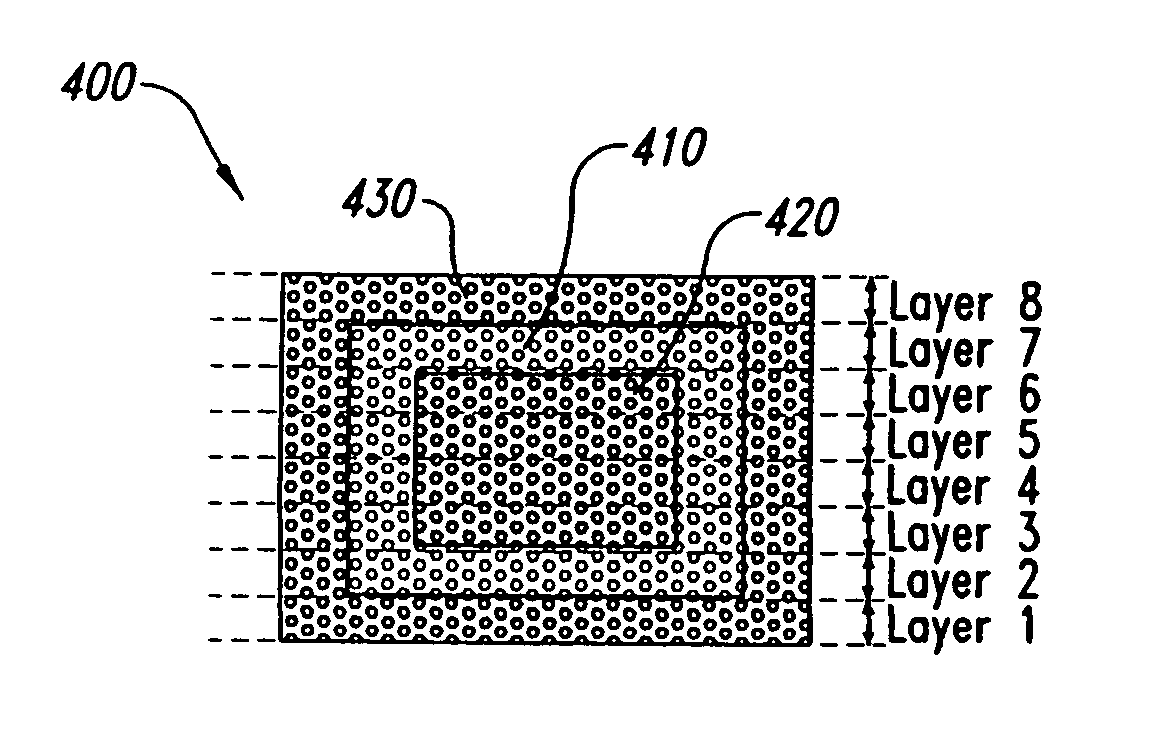

InactiveUS7276252B2Promote absorptionSmall crystal sizeBiocideAdditive manufacturing apparatusHazardous substanceBioavailability

A drug delivery device such as an oral dosage form (ODF) with a toxic or potent core encapsulated by a non-toxic region. The non-toxic region may be a region including multiple layers, coatings, shells, and combinations thereof, which provides protection to and isolation from the toxic or potent core. The drug in the toxic or potent core is incorporated into the dosage form via, for example, three-dimensional printing, as a solution, solubilization or suspension of solid particles in liquid, rather than by the more conventional handling and compressing of dry powder. This minimizes the likelihood of creating airborne particles of the toxic drug during manufacturing, hence controlling and minimizing the exposure of manufacturing personnel to the hazardous substance. Wet dispensing of the toxic or potent drug further provides greater bioavailability of the drug to the patient.

Owner:APRECIA PHARMA LLC +1

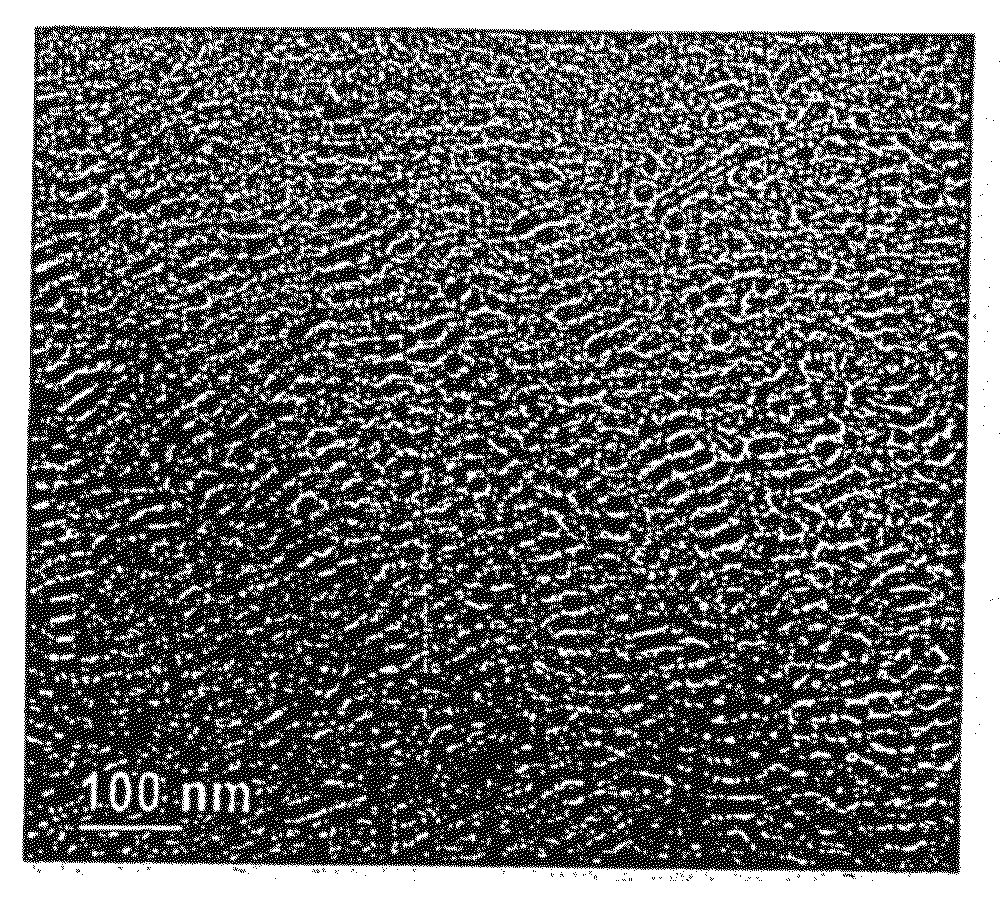

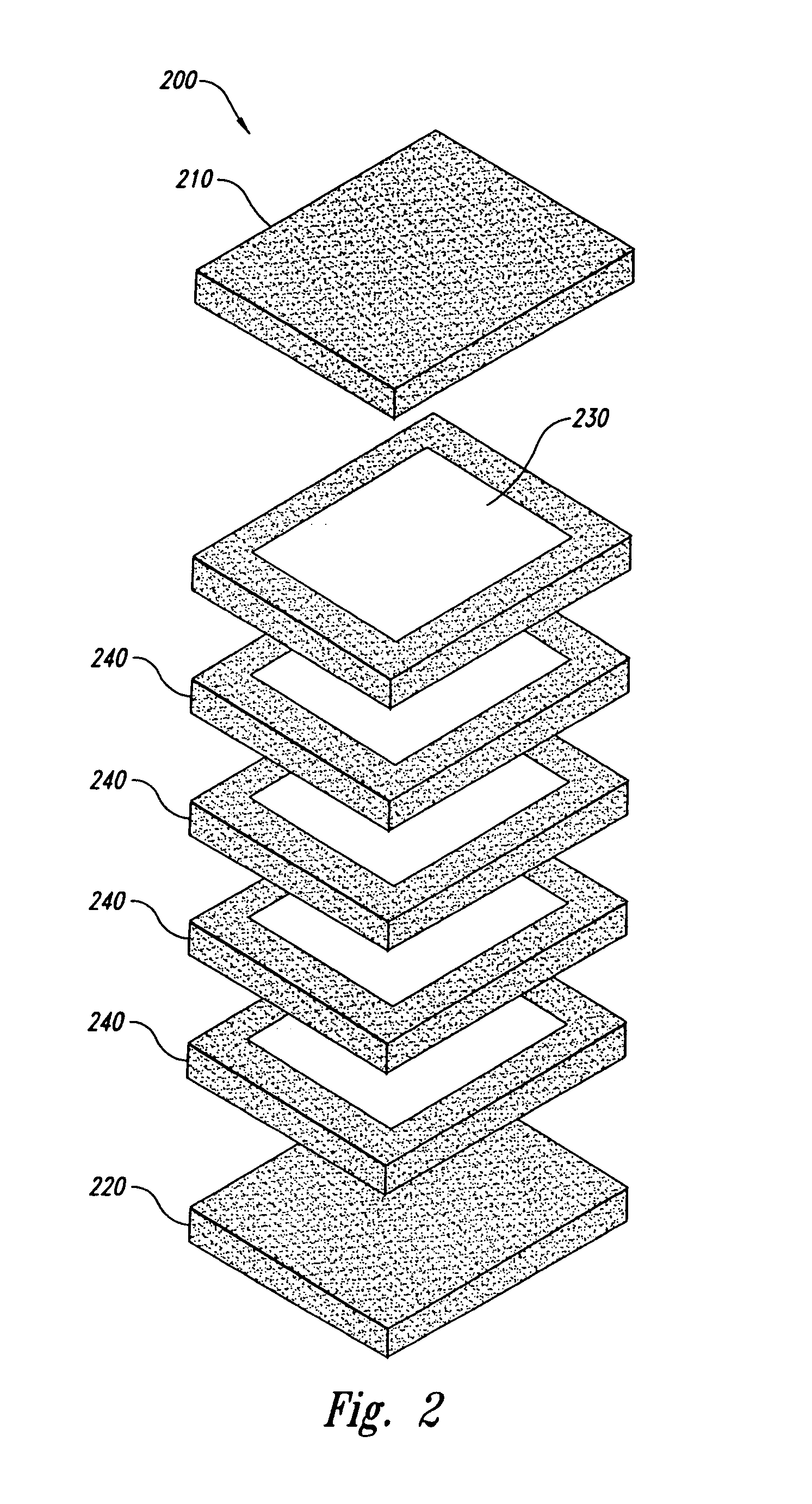

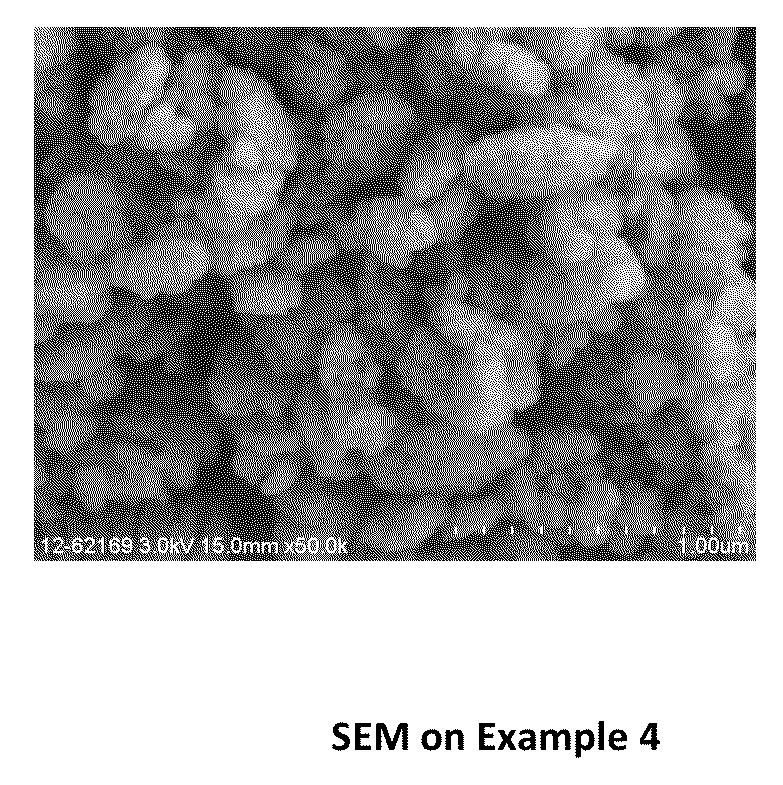

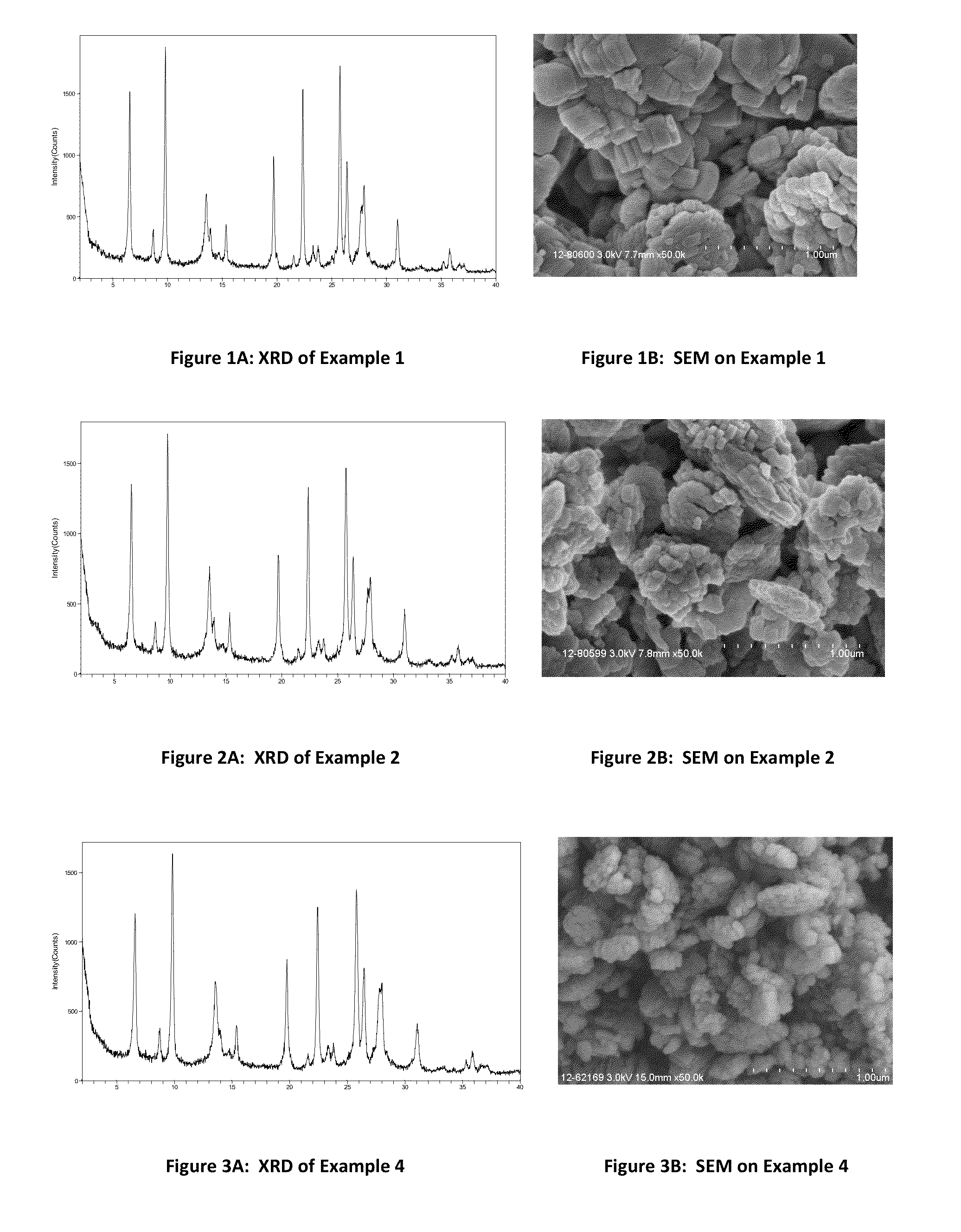

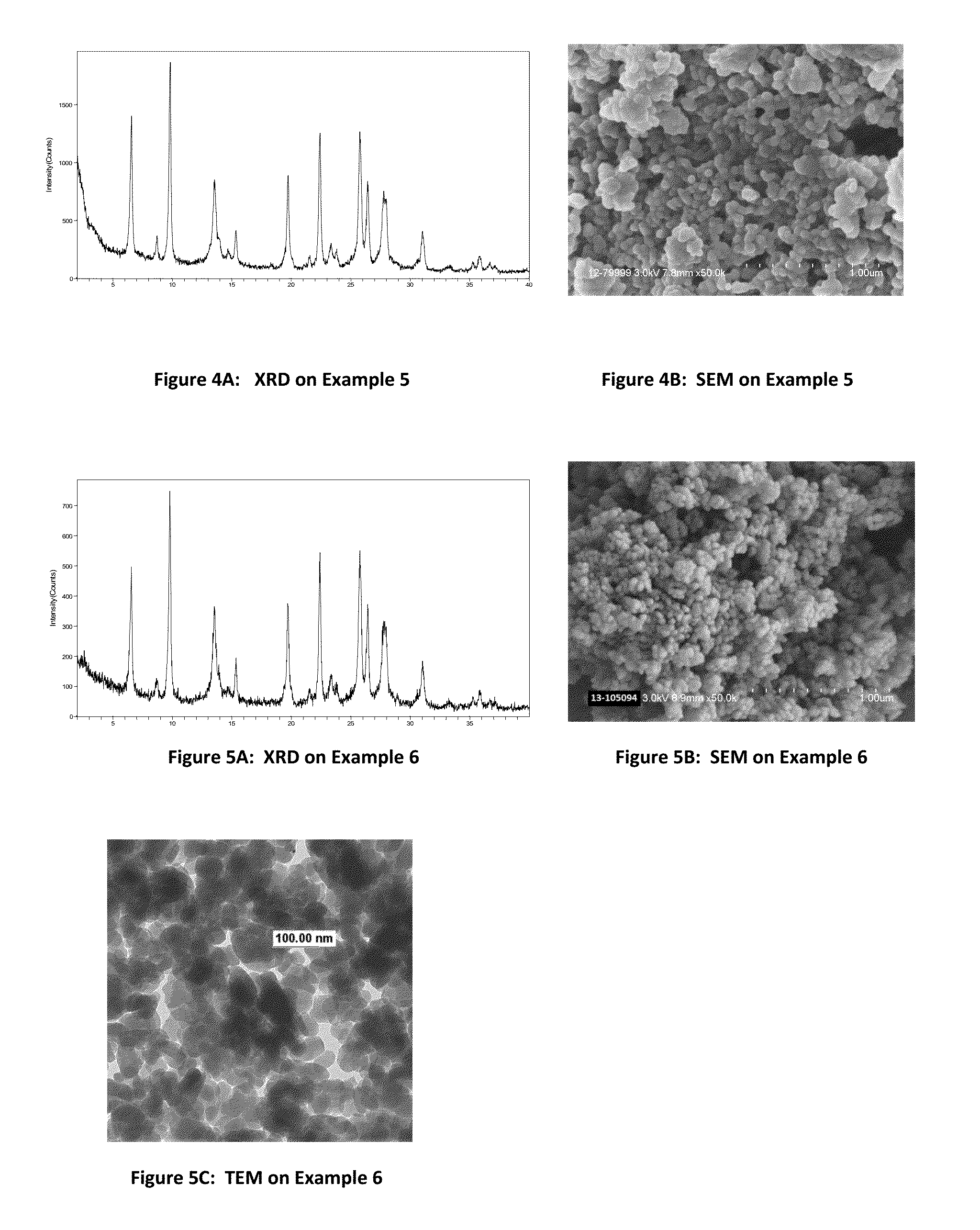

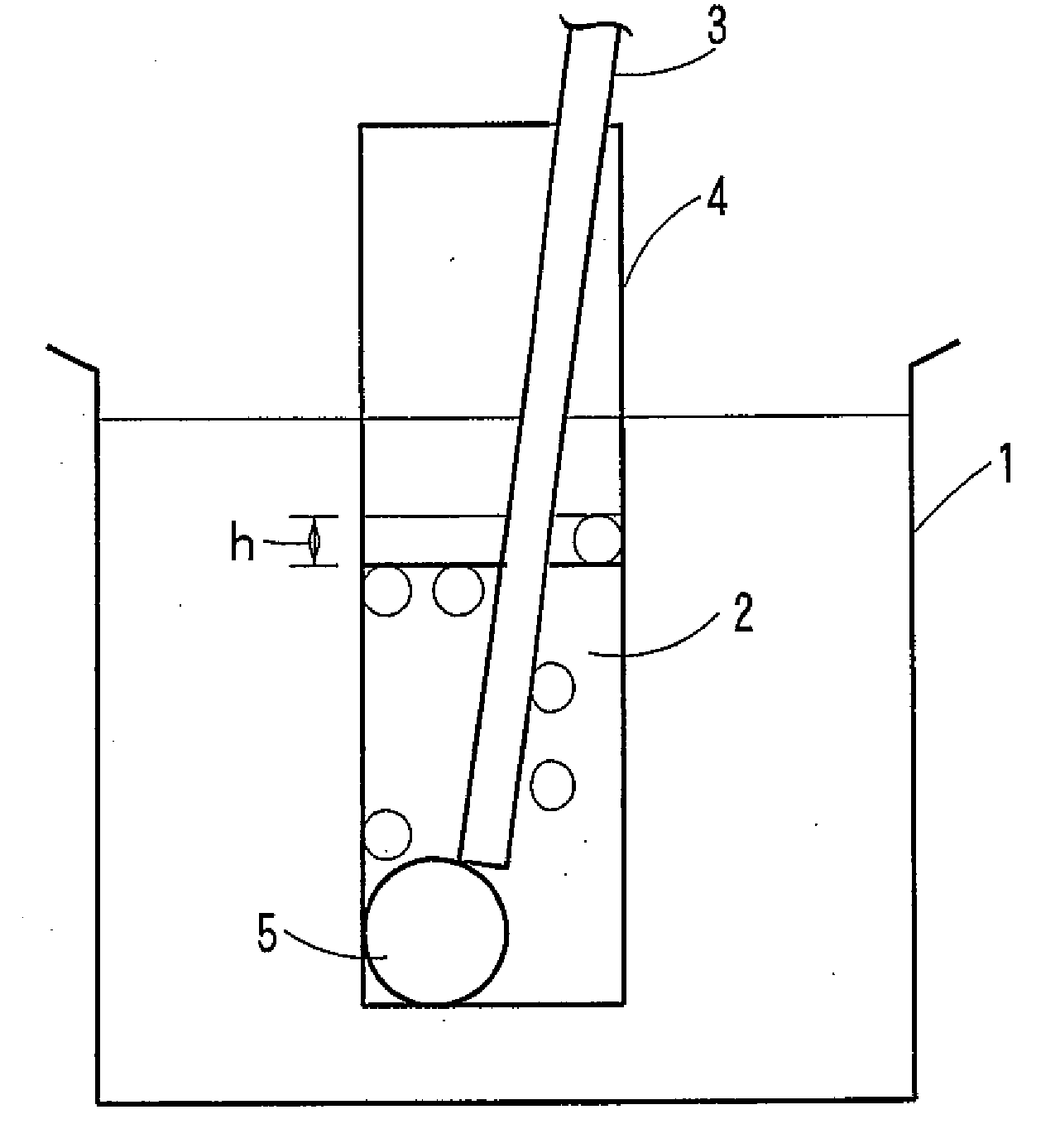

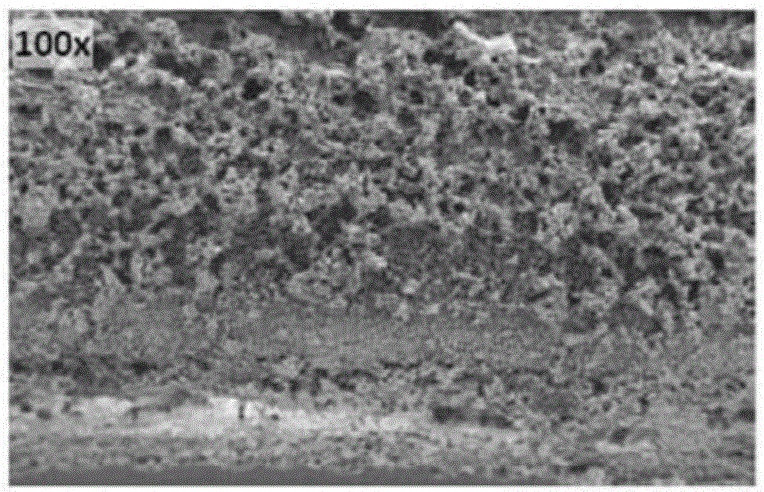

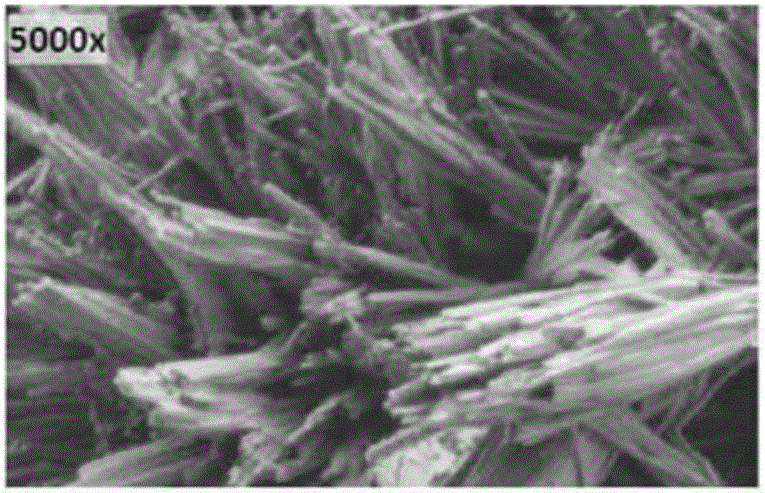

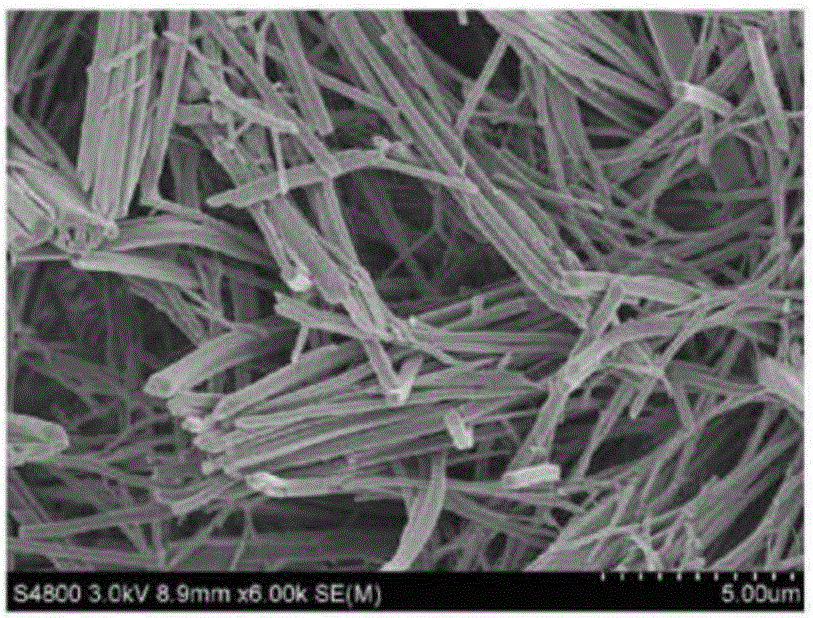

Synthetic Nano-Sized Crystalline Calcium Phosphate and Method of Production

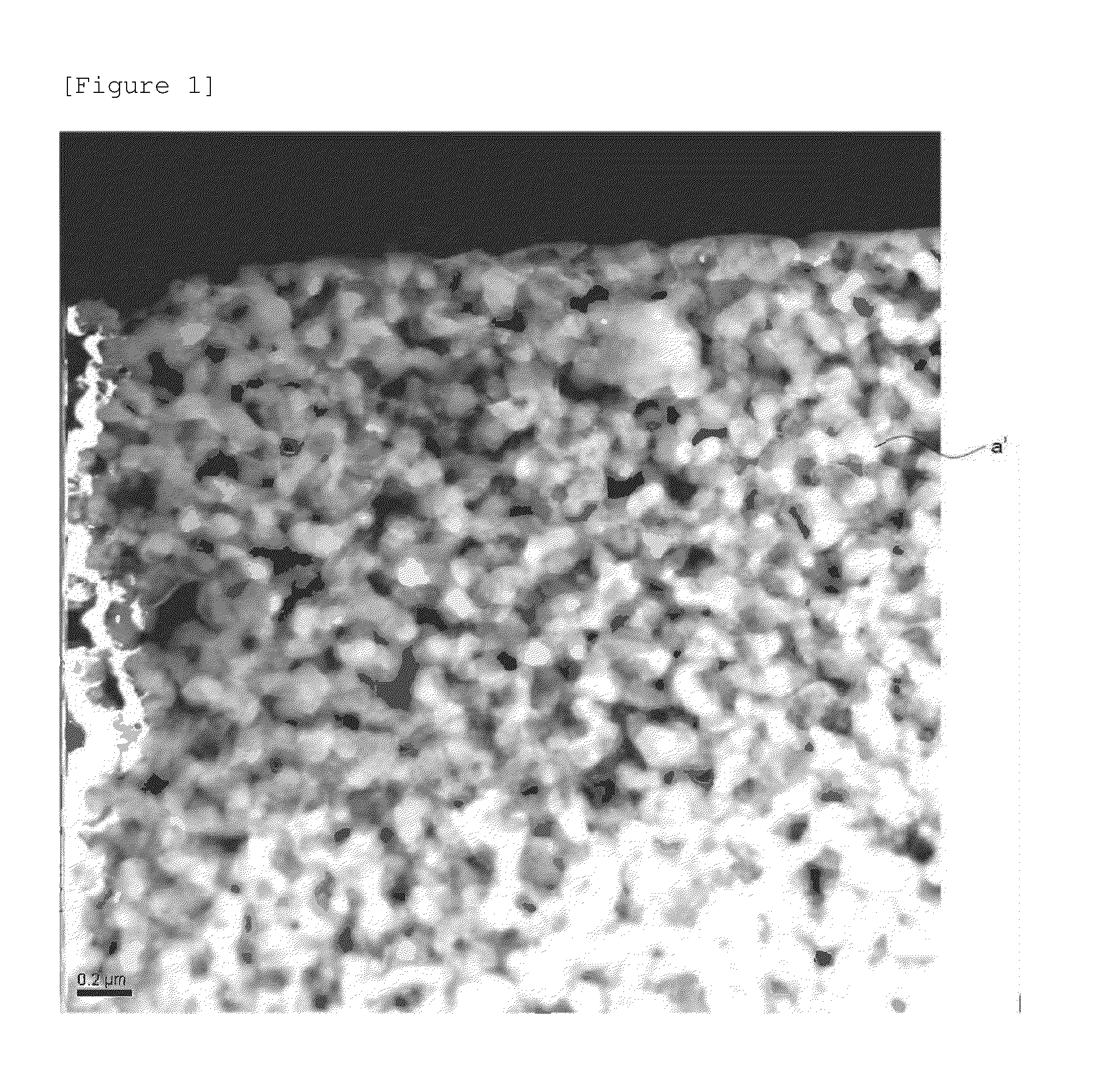

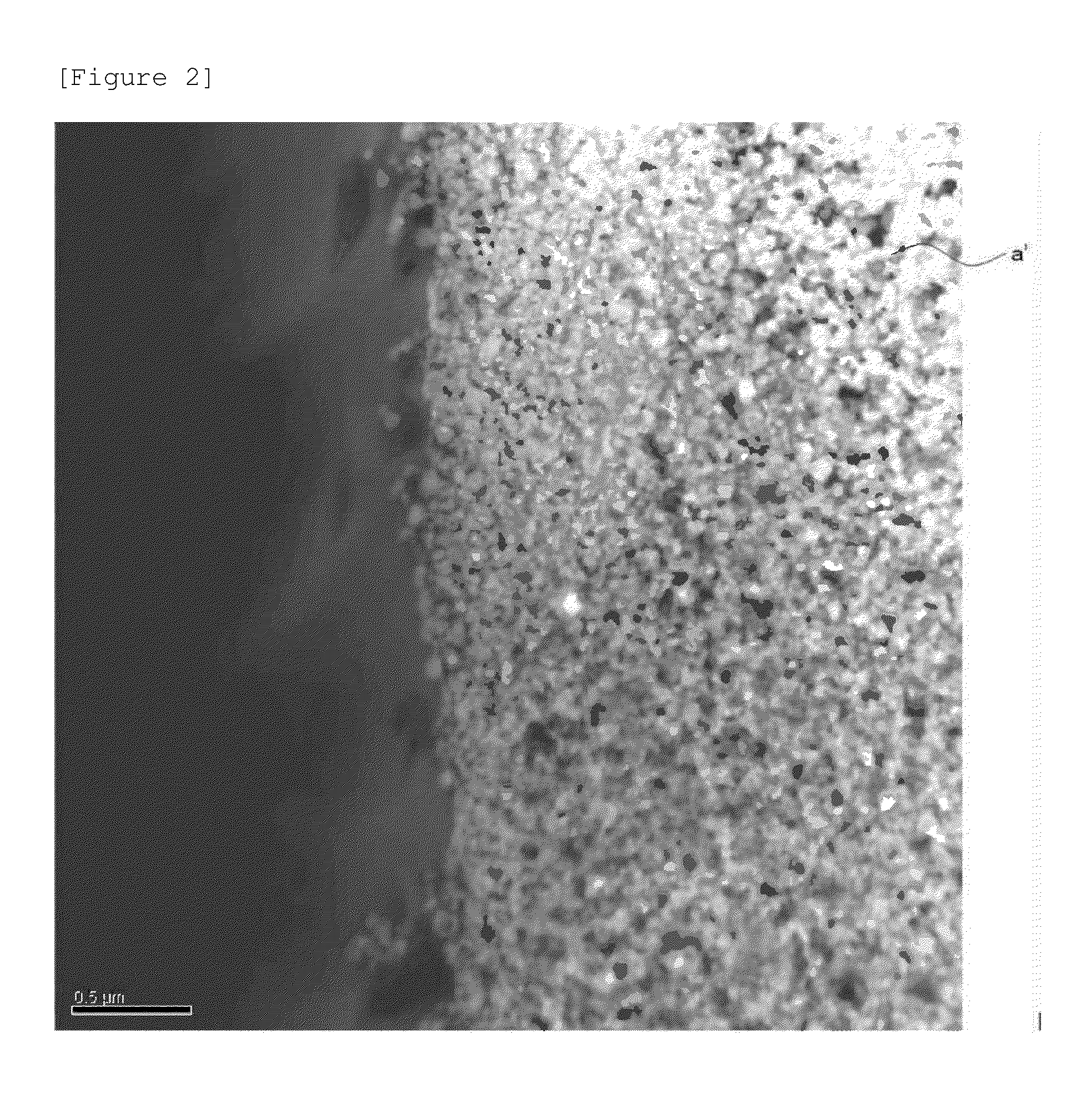

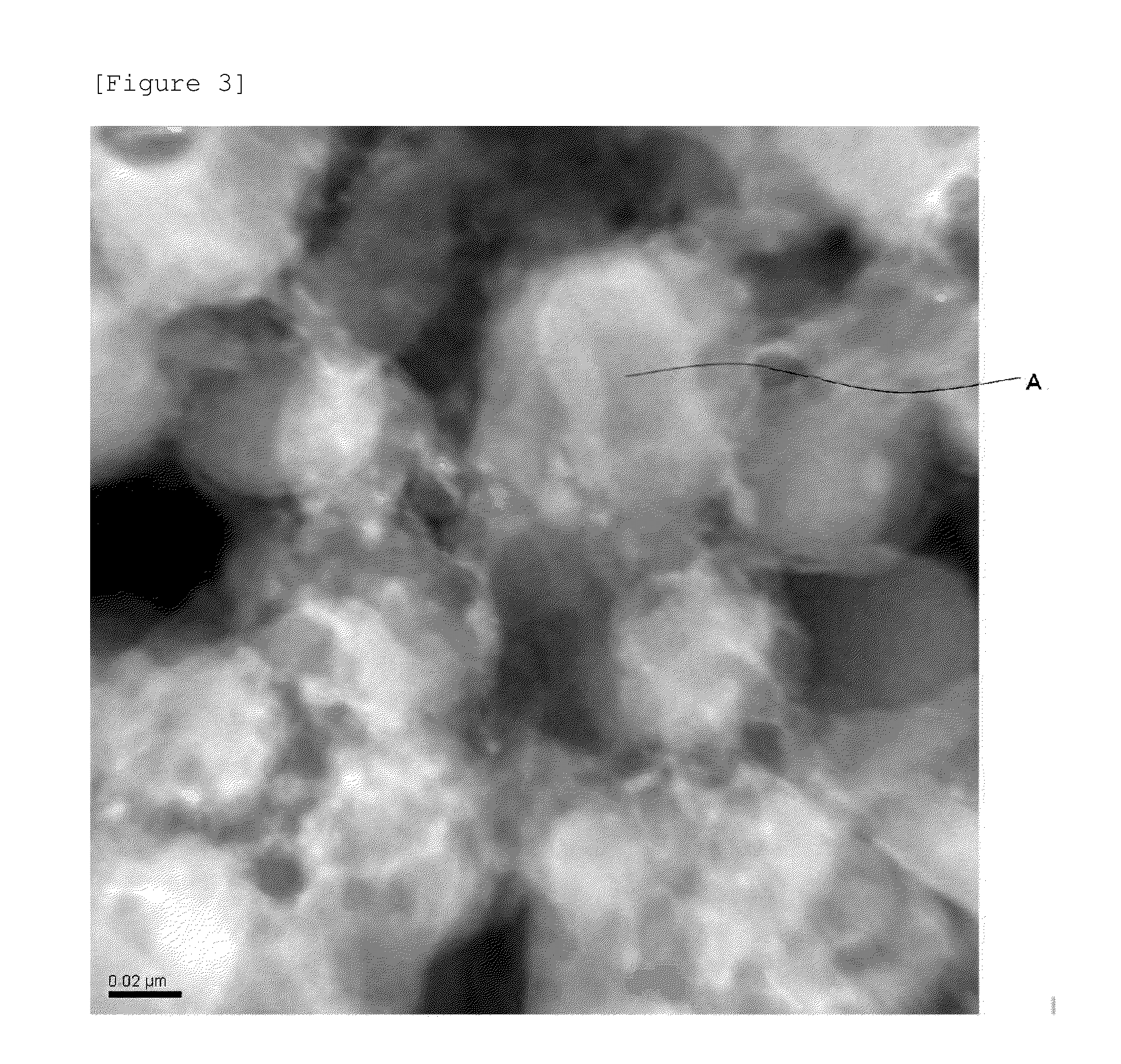

ActiveUS20080220233A1Easy to depositMaximize adherence to surfaceMaterial nanotechnologyNanostructure manufactureLiquid crystallineSolvent

Synthetic nano-sized crystalline calcium phosphate, particularly hydroxyapatite, having a specific surface area in the range of 150 m2 / g to 300 m2 / g, is described. The nano-sized crystalline calcium phosphate may be in the form of a powder or in the form of a coating on a surface. A method of producing a nano-sized crystalline calcium phosphate powder or coating is also described. The method comprises formation of a liquid crystalline phase in a water solution of calcium, phosphor and a surfactant, placing the phase in an ammonia atmosphere so that nano-sized crystals are formed, followed by either removal of the surfactant with a solvent and recovering the nano-sized crystals to obtain the powder, or diluting the ammonia-treated liquid crystalline phase with a hydrophobic organic solvent to create a microemulsion of the nano-sized crystals in water, dipping an oxide layer-coated surface of an object into the microemulsion, or alternatively saving the step of ammonia treatment of the liquid crystalline phase until after the dipping of the surface of an object into the microemulsion, followed by removal of the organic solvent and the surfactant from the surface to obtain the coating.

Owner:PROMIMIC

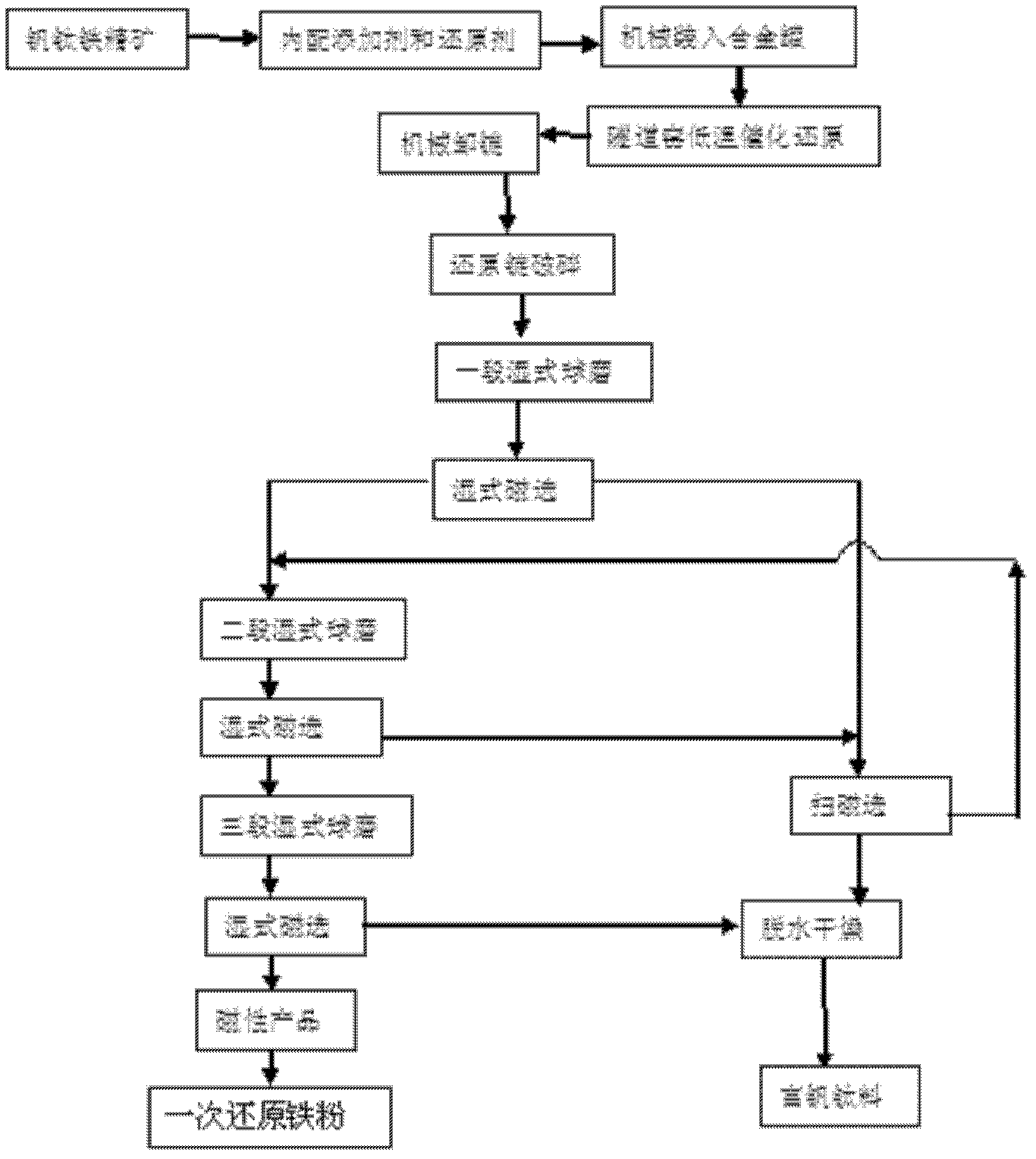

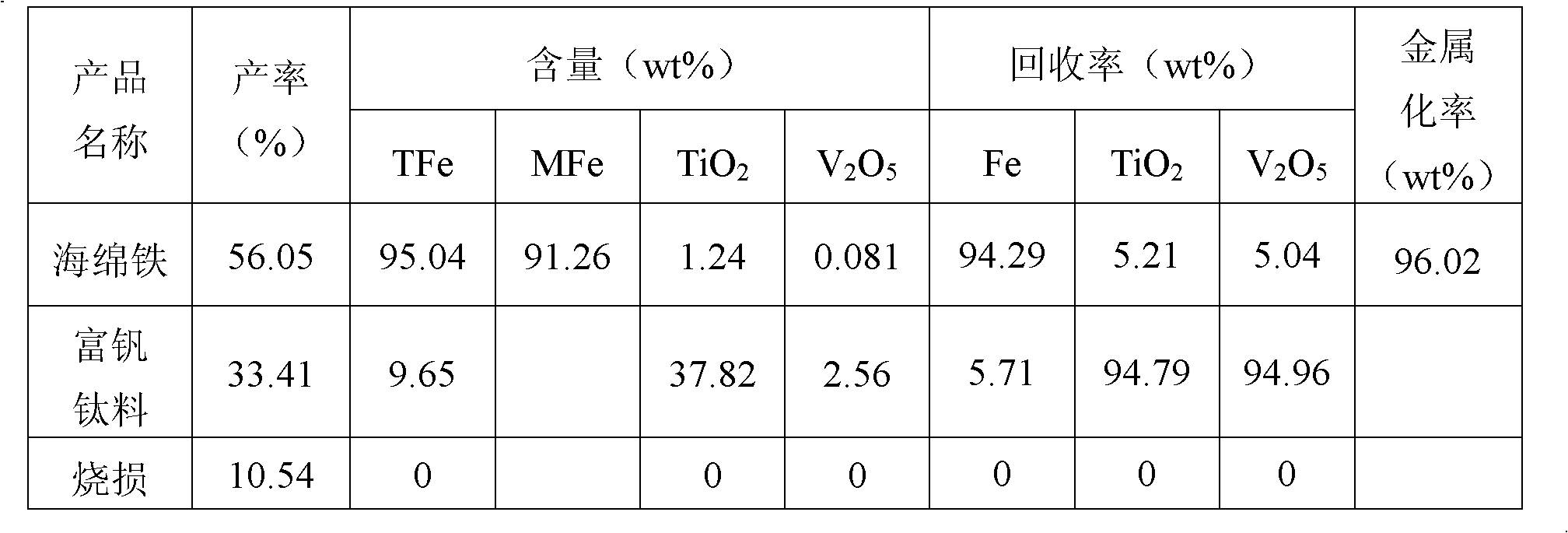

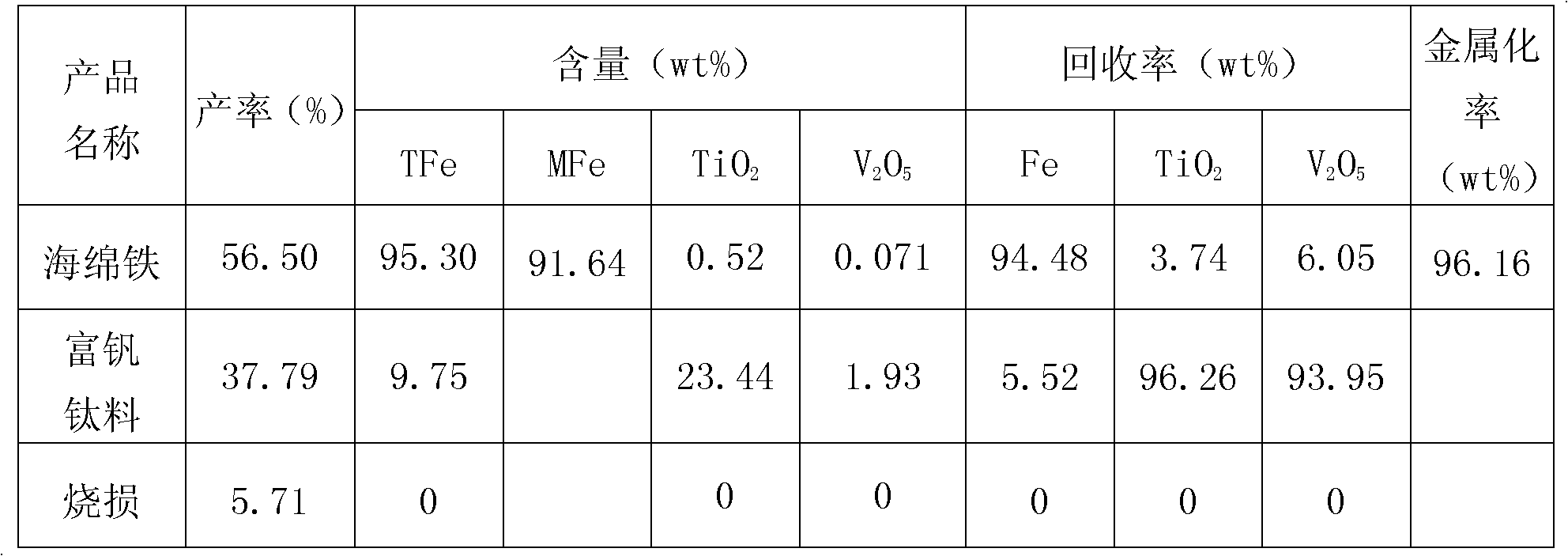

Method for separating iron and vanadium and titanium from vanadium titano-magnetite

InactiveCN102433436ALow reduction temperatureReduce consumptionProcess efficiency improvementGrain treatmentsTunnel kilnIron powder

The invention relates to a method for separating iron and vanadium and titanium from vanadium titano-magnetite, which belongs to the technical field of metallurgy. The technical problem to be solved of the invention is to provide a method for separating iron and vanadium and titanium from vanadium titano-magnetite, which has high iron recovering rate. The method for separating iron and vanadium and titanium from vanadium titano-magnetite comprises the following steps of: a, burdening: uniformly mixing 100 parts by weight of vanadium titano-magnetite, 15-20 parts by weight of additive and 15-25 parts by weight of reducing agent, wherein the additive is at least one of sodium chloride, sodium sulfate and sodium carbonate; b, charging and reducing: charging the mixture which is uniformly mixed in the step a, heating to 920-980 DEG C in a tunnel kiln, and preserving heat for 5-60 hours to obtain reduced ingots; and c, separating: crashing the reduced ingots, and separating magnetically toobtain reduced iron powder and a vanadium and titanium-rich material.

Owner:攀枝花鑫润矿业有限公司 +1

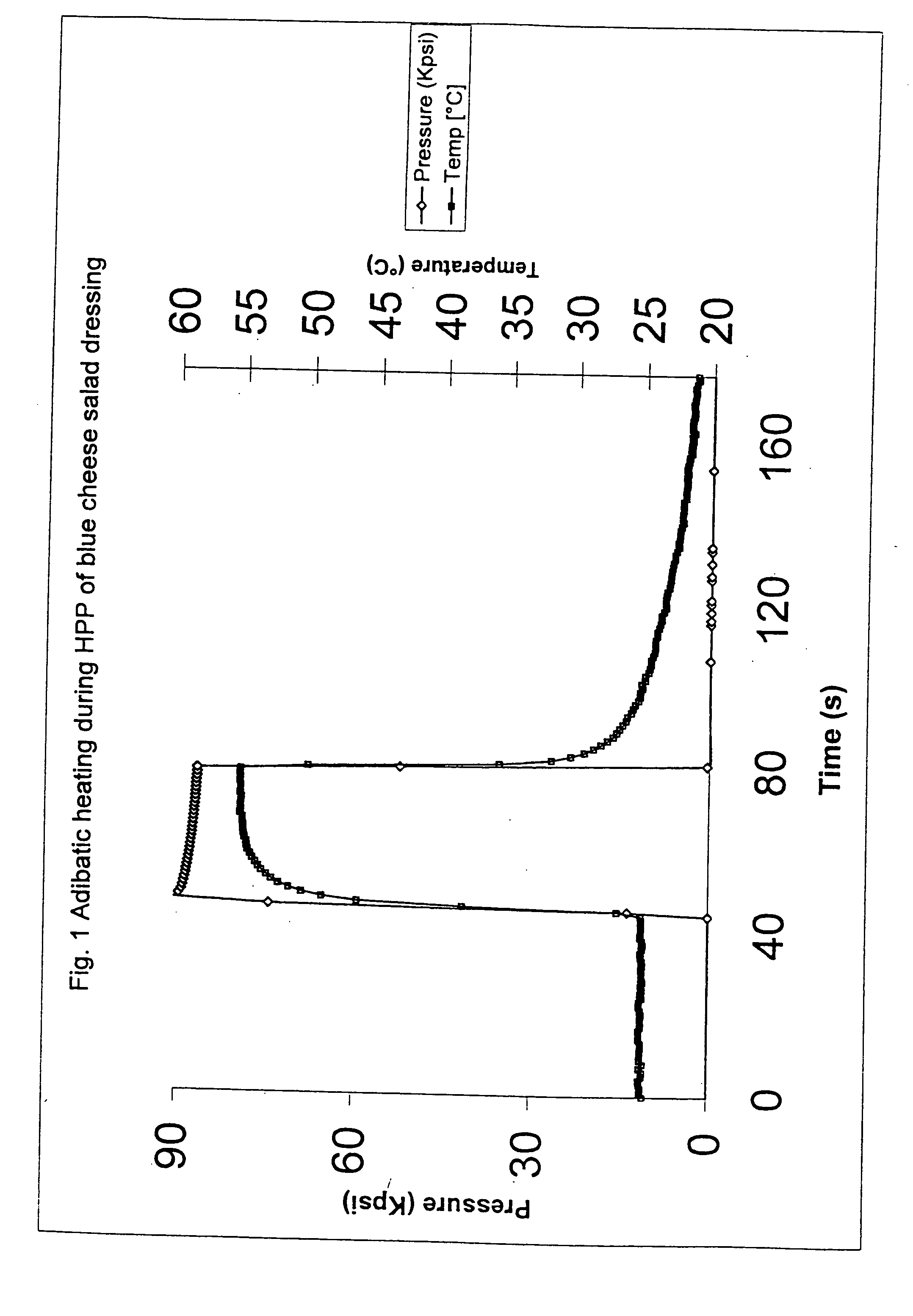

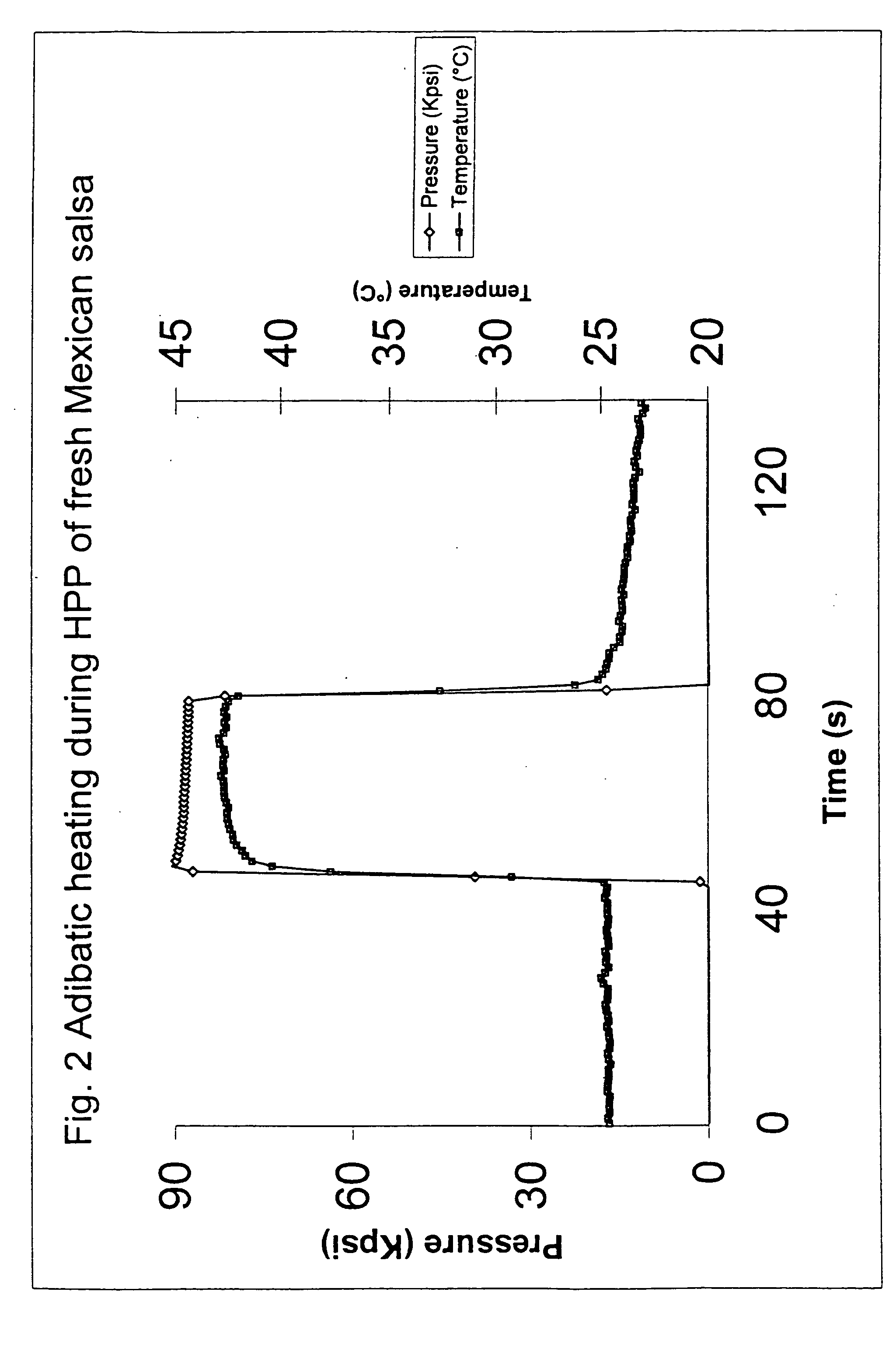

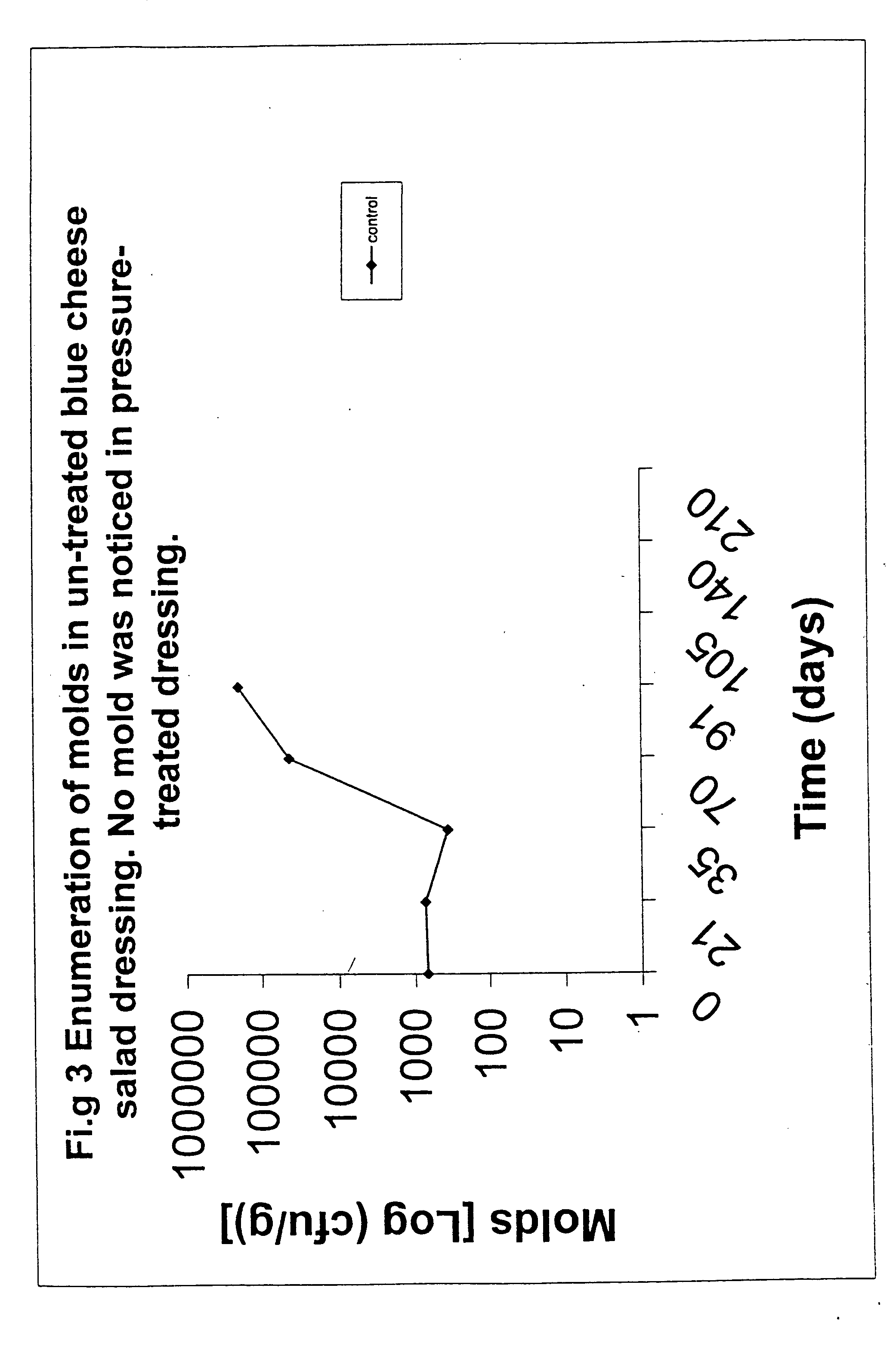

Method to extend the shelf-life of food products using hydrostatic high-pressure processing

InactiveUS20050112252A1Reduce processing timeSacrifice shelf lifeFood preservationPackaging protectionPathogenic microorganismHigh pressure

Owner:TEWARI GUARAV

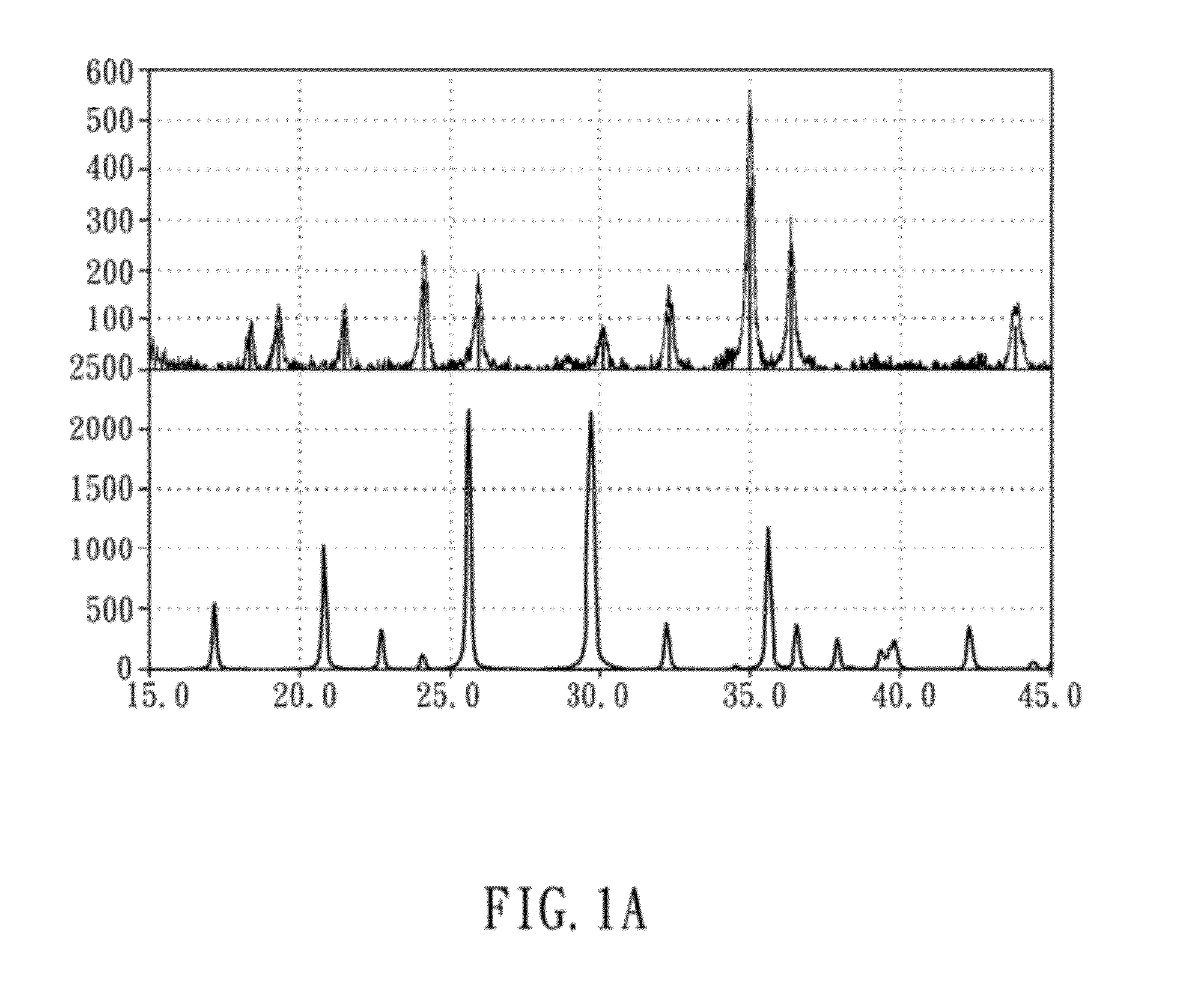

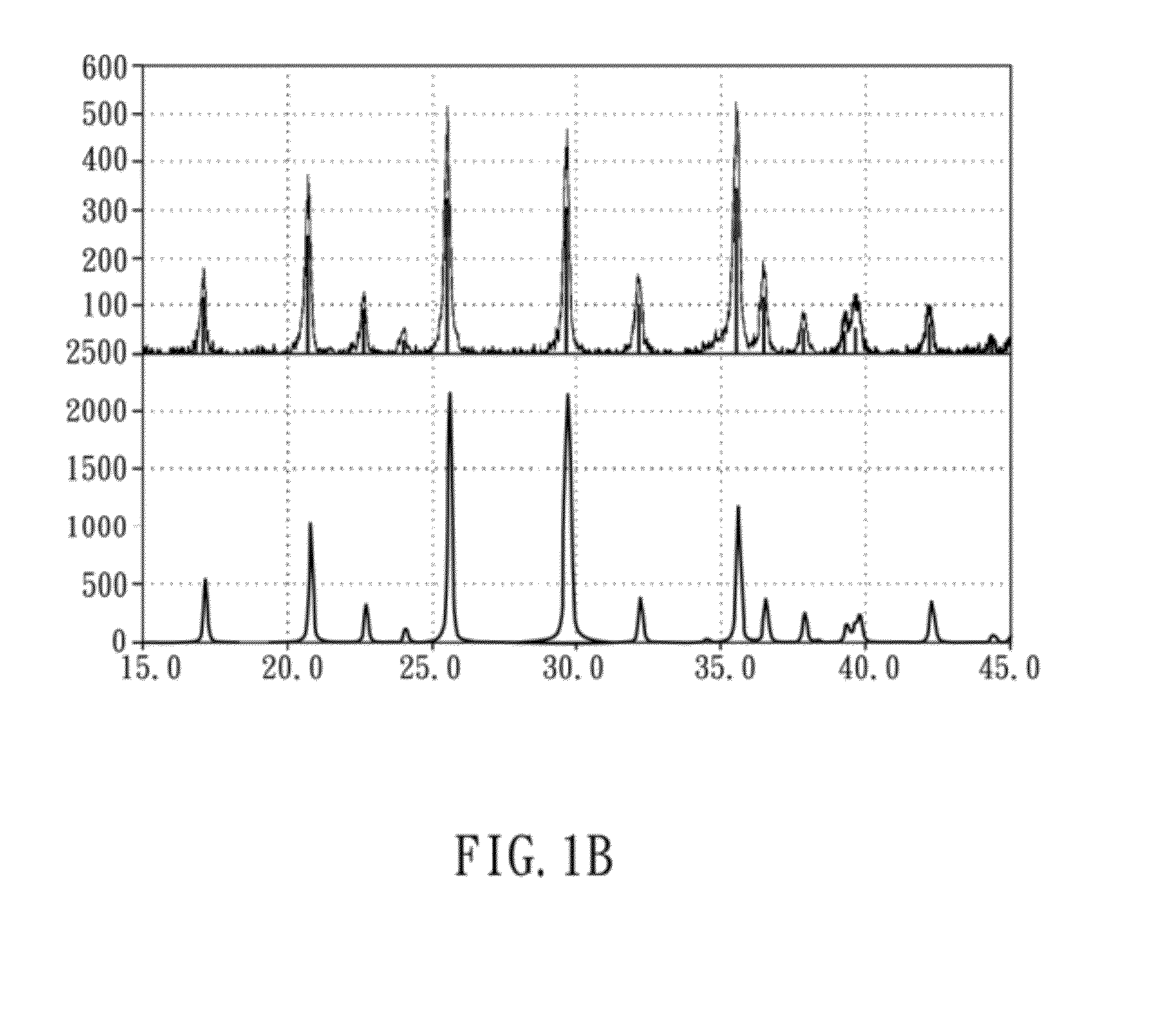

Cathode active material, cathode, secondary battery and manufacturing methods for the same

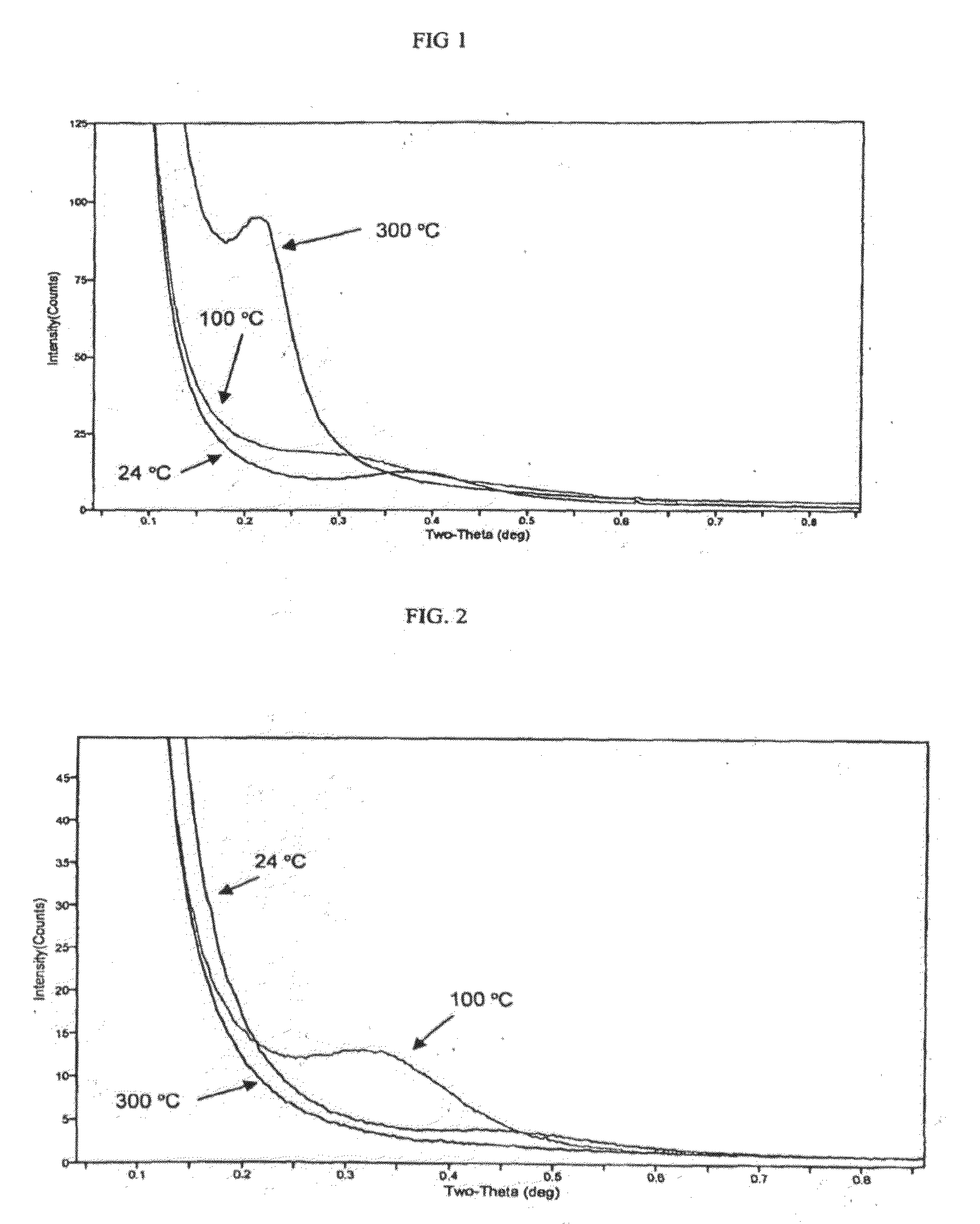

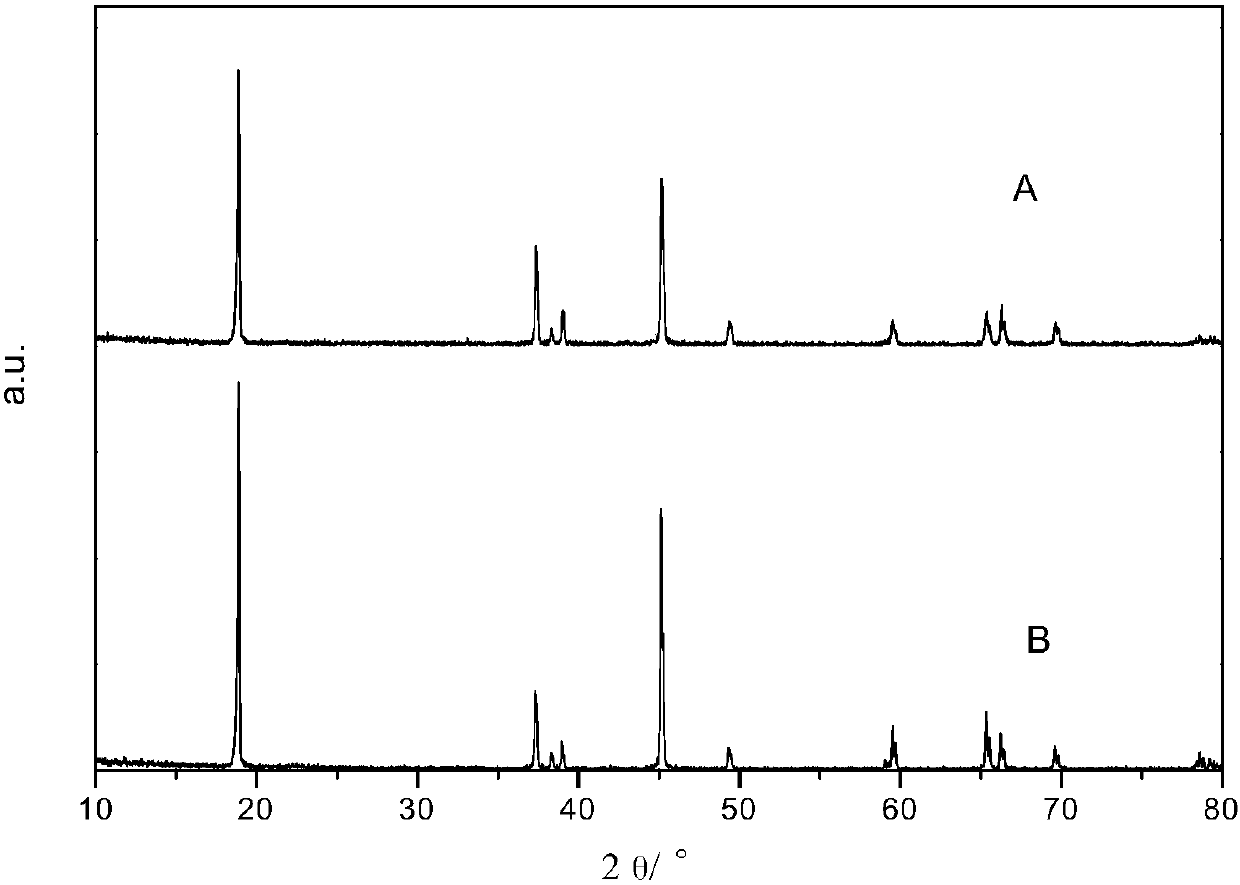

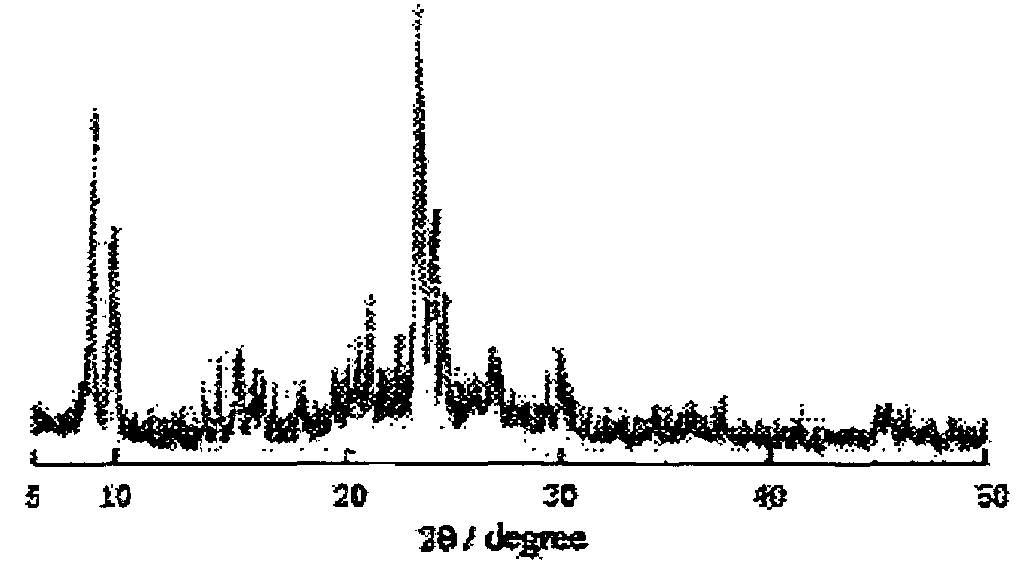

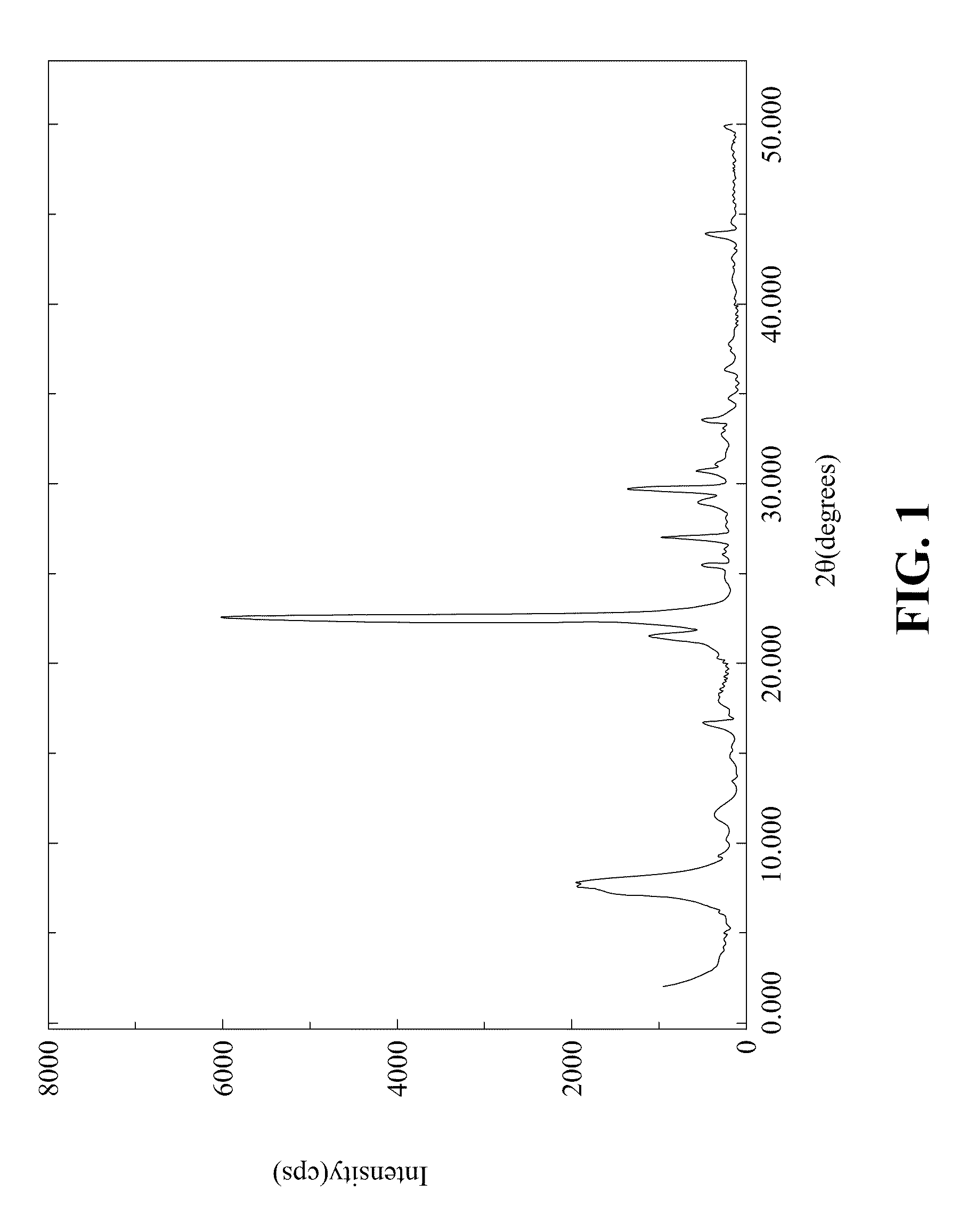

ActiveUS20130052544A1Improve discharge capacityIntercalation is facilitatedMaterial nanotechnologyPhosphatesX-rayRoom temperature

An object of the present invention is to provide a cathode active material which contains small-particle sized and low-crystalline lithium transition metal silicate and which undergoes charge-discharge reaction at room temperature.The cathode active material for a non-aqueous electrolyte secondary battery is characterized by containing a lithium transition metal silicate and exhibits diffraction peaks having half widths of 0.175 to 0.6°, the peaks observed through powder X-ray diffractometry within a 2θ range of 5 to 50°.

Owner:FURUKAWA ELECTRIC CO LTD +1

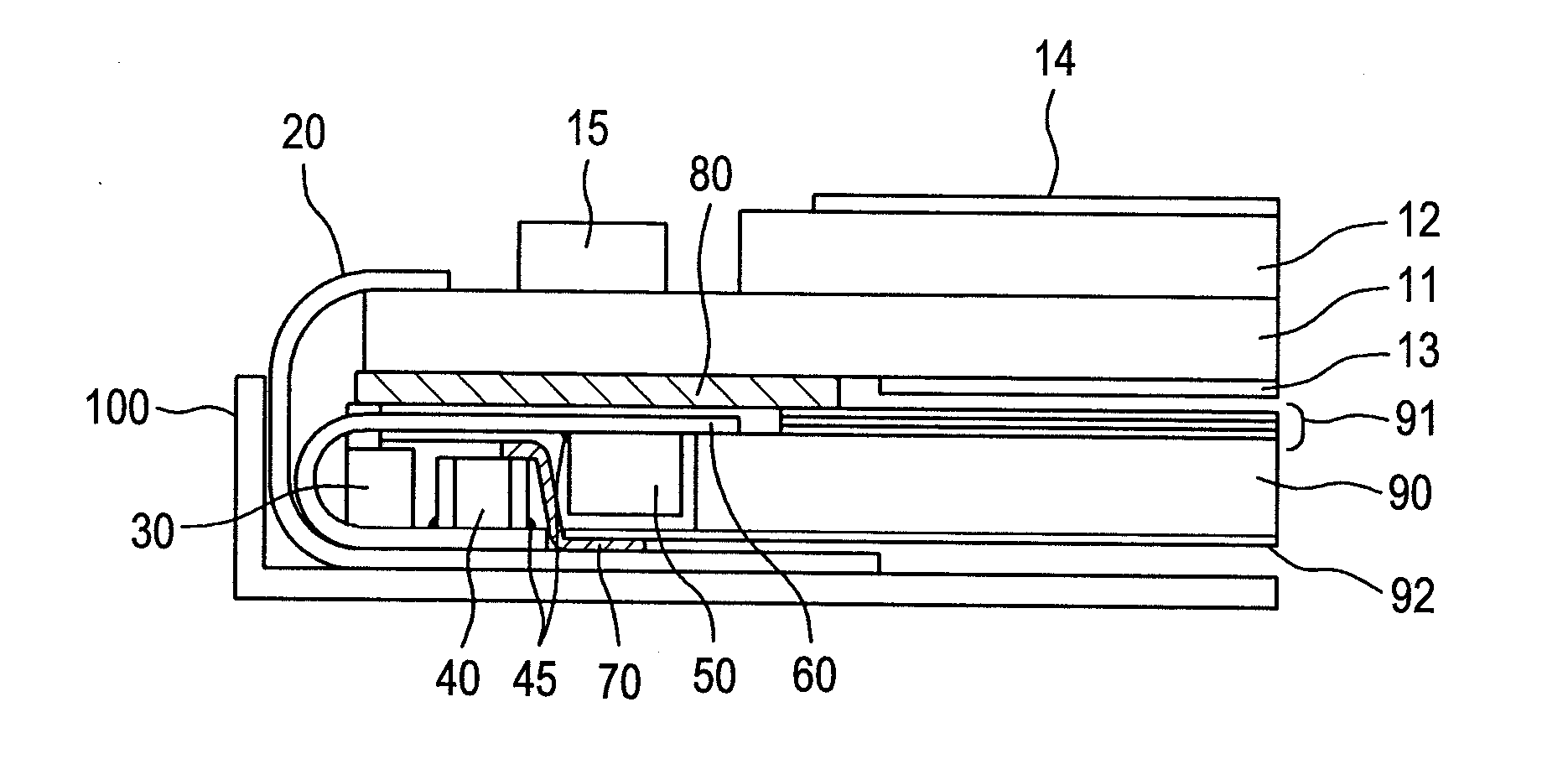

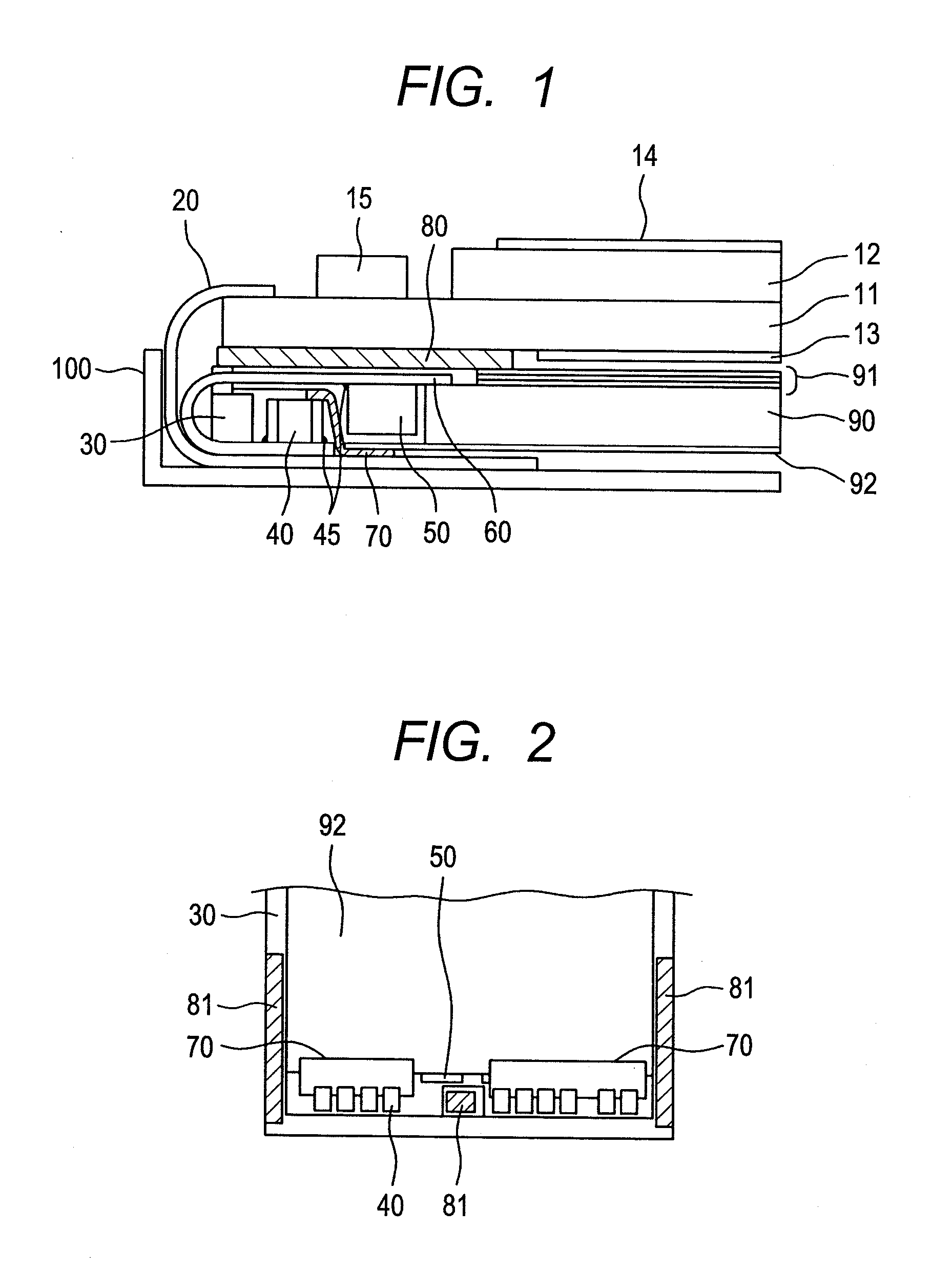

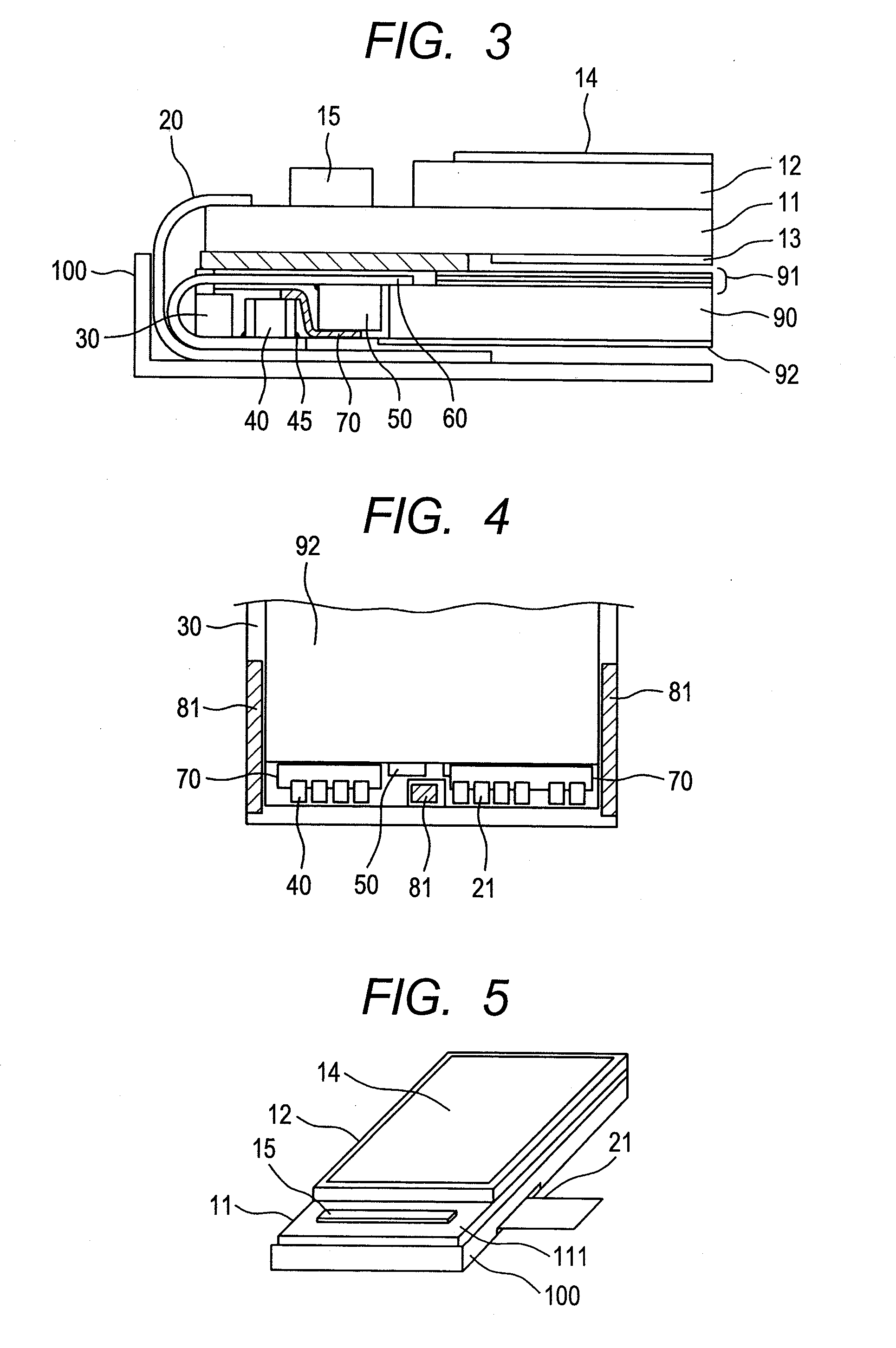

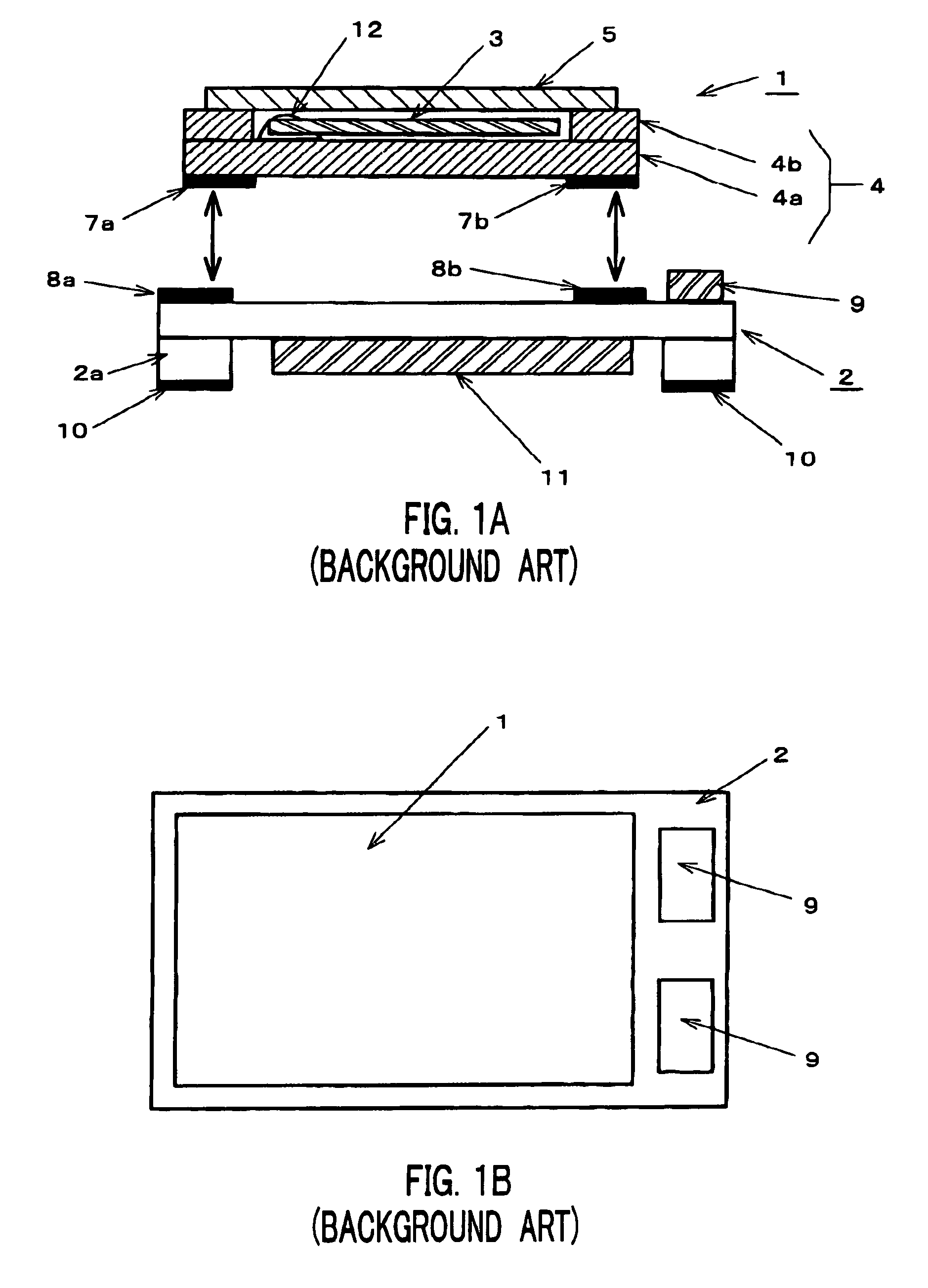

Liquid crystal display device

ActiveUS20110157512A1Reduce in sizeEliminate spaceOptical light guidesNon-linear opticsLiquid-crystal displayEngineering

It is desirable to reduce an overall size of a small liquid crystal display device, while keeping a screen size to a certain value. Thus, there is provided a liquid crystal display device including a liquid crystal display panel on a mold, and a backlight placed in the mold. The backlight includes a light guide panel, an LED provided on a side surface of the liquid guide panel, and other components. A main flexible wiring substrate is attached to the liquid crystal display panel, and extends to a back surface of the mold. The LED is mounted on an LED flexible wiring substrate. An electronic component mounted on the main flexible wiring substrate is placed on the back side of the mold. Then, an insulating sheet is provided between the electronic component and the LED to prevent short circuit between them, instead of using a partition wall for electrical insulation.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

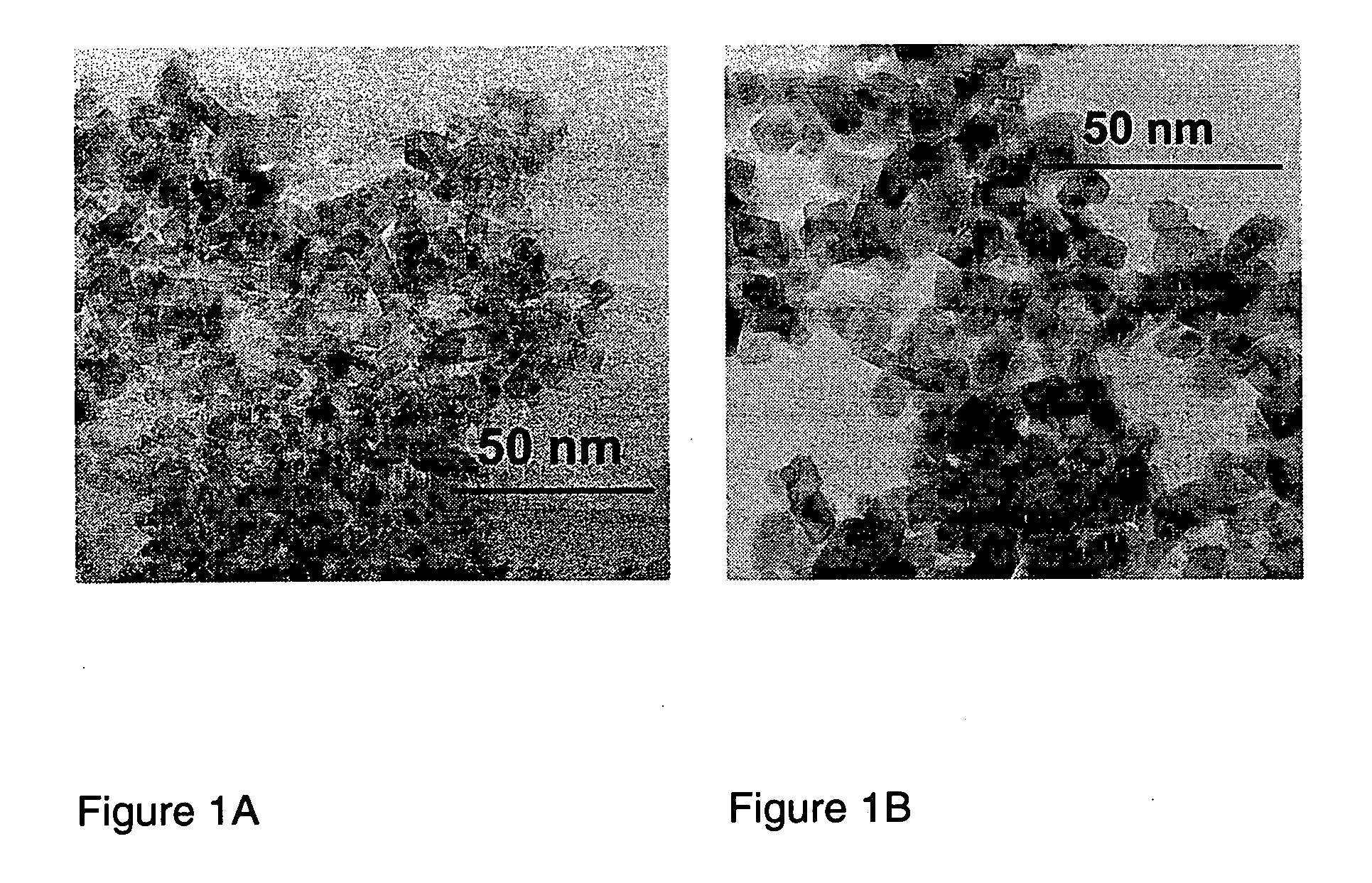

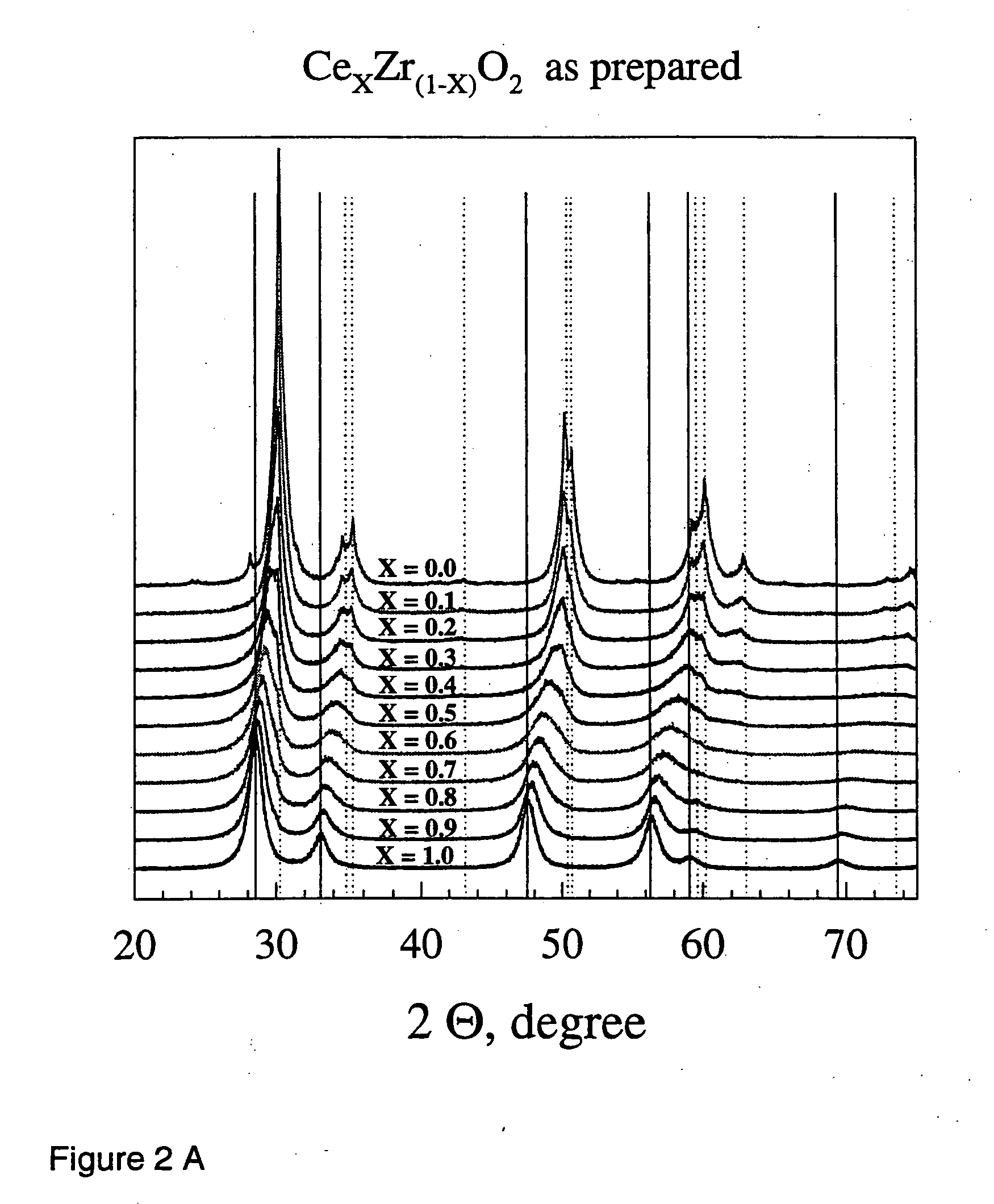

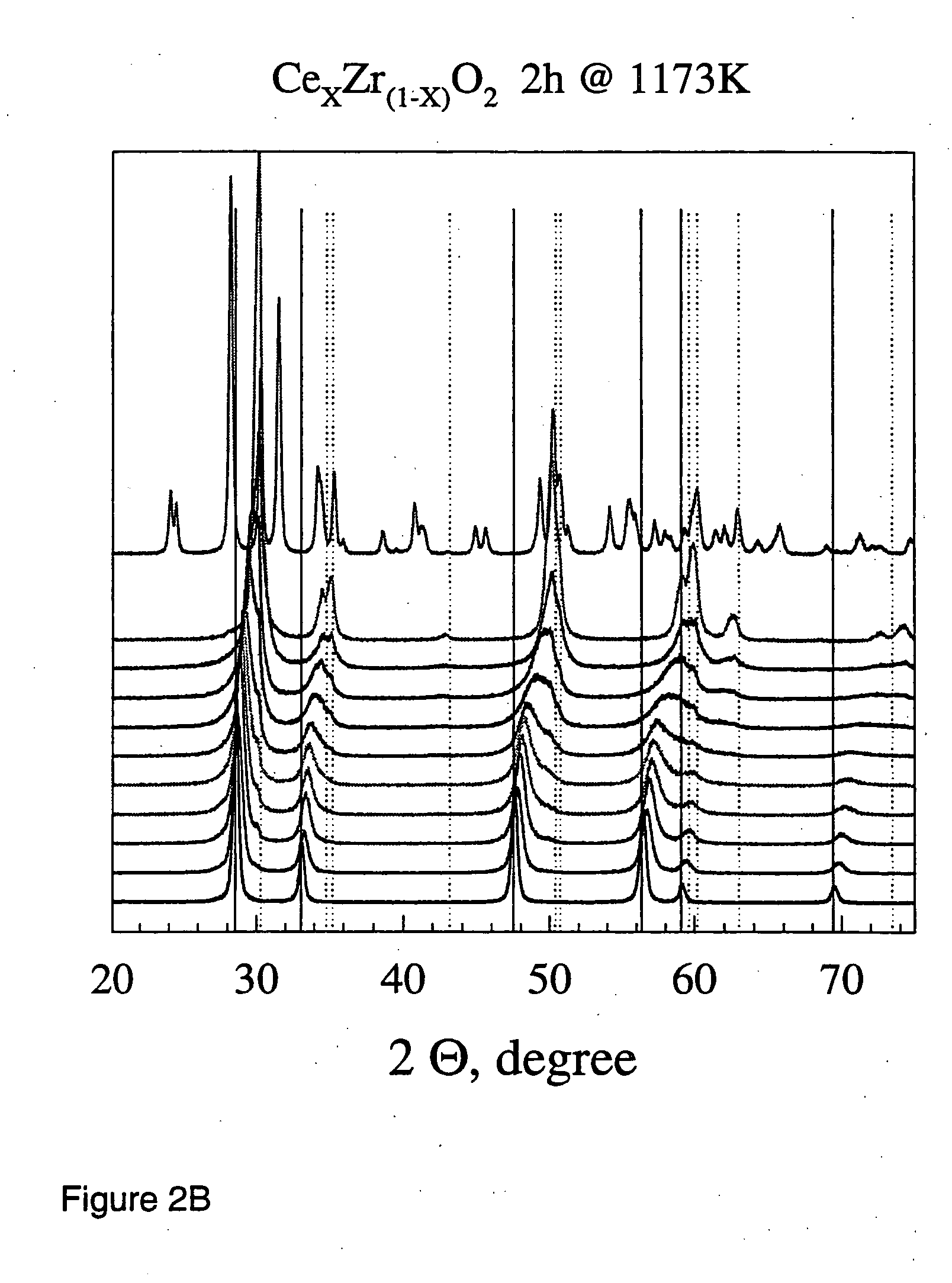

Flame made metal oxides

ActiveUS20040126298A1Improve stabilitySmall crystal sizeMaterial nanotechnologyZirconium oxidesCarboxylic acidSolvent

Described is a method for the production of metal oxides, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

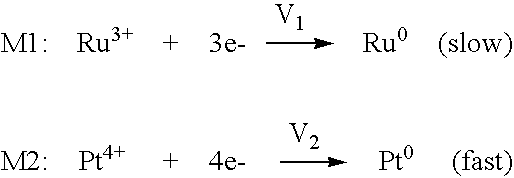

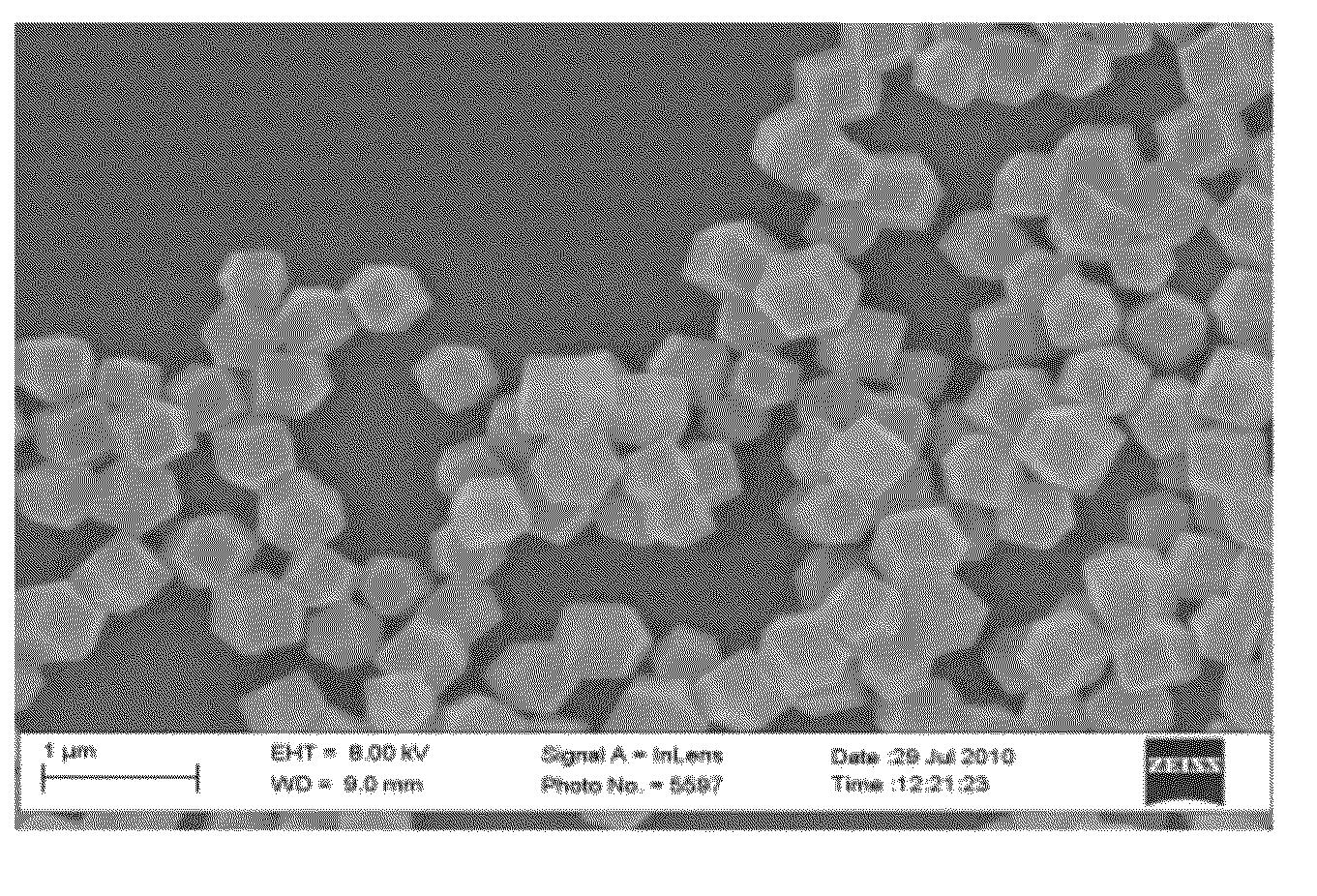

Method for manufacture of noble metal alloy catalysts and catalysts prepared therewith

ActiveUS20060094597A1High degreeEasy to manufactureMaterial nanotechnologyGas treatmentGas phaseReaction temperature

The present invention provides a method for manufacture of supported noble metal based alloy catalysts with a high degree of alloying and a small crystallite size. The method is based on the use of polyol solvents as reaction medium and comprises of a two-step reduction process in the presence of a support material. In the first step, the first metal (M1=transition metal; e.g. Co, Cr, Ru) is activated by increasing the reaction temperature to 80 to 160° C. In the second step, the second metal (M2=noble metal; e.g. Pt, Pd, Au and mixtures thereof) is added and the slurry is heated to the boiling point of the polyol solvent in a range of 160 to 300° C. Due to this two-step method, an uniform reduction occurs, resulting in noble metal based catalysts with a high degree of alloying and a small crystallite size of less than 3 nm. Due to the high degree of alloying, the lattice constants are lowered. The catalysts manufactured according to the method are used as electrocatalysts for polymer electrolyte membrane fuel cells (PEMFC), direct-methanol fuel cells (DMFC) or as gas phase catalysts for CO oxidation or exhaust gas purification.

Owner:UMICORE AG & CO KG

Mof nanocrystals

ActiveUS20120247328A1Small crystal sizeSmaller more isotropic crystalsMaterial nanotechnologySemi-permeable membranesParticle-size distributionEnvironmental geology

Owner:GEORGIA TECH RES CORP

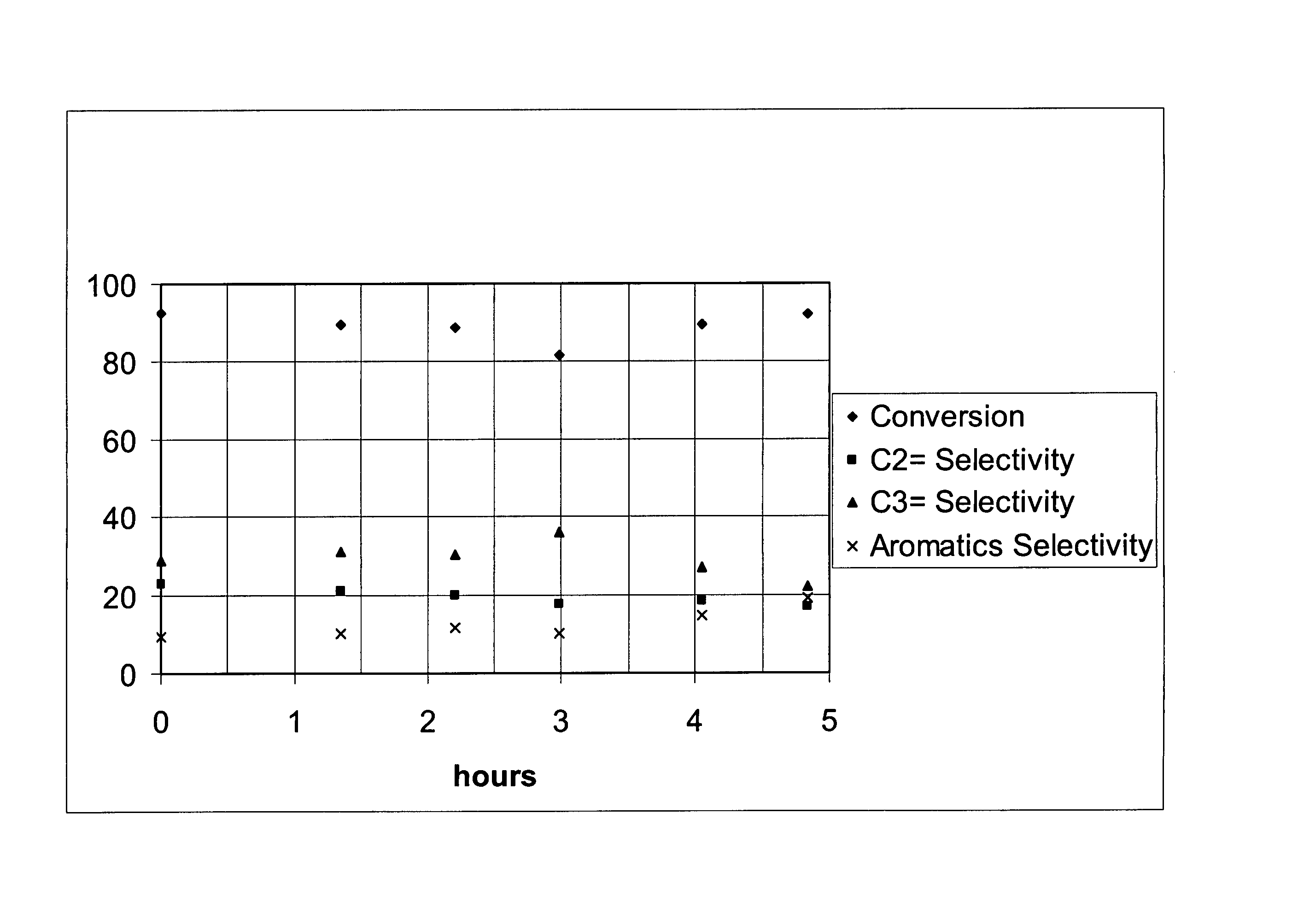

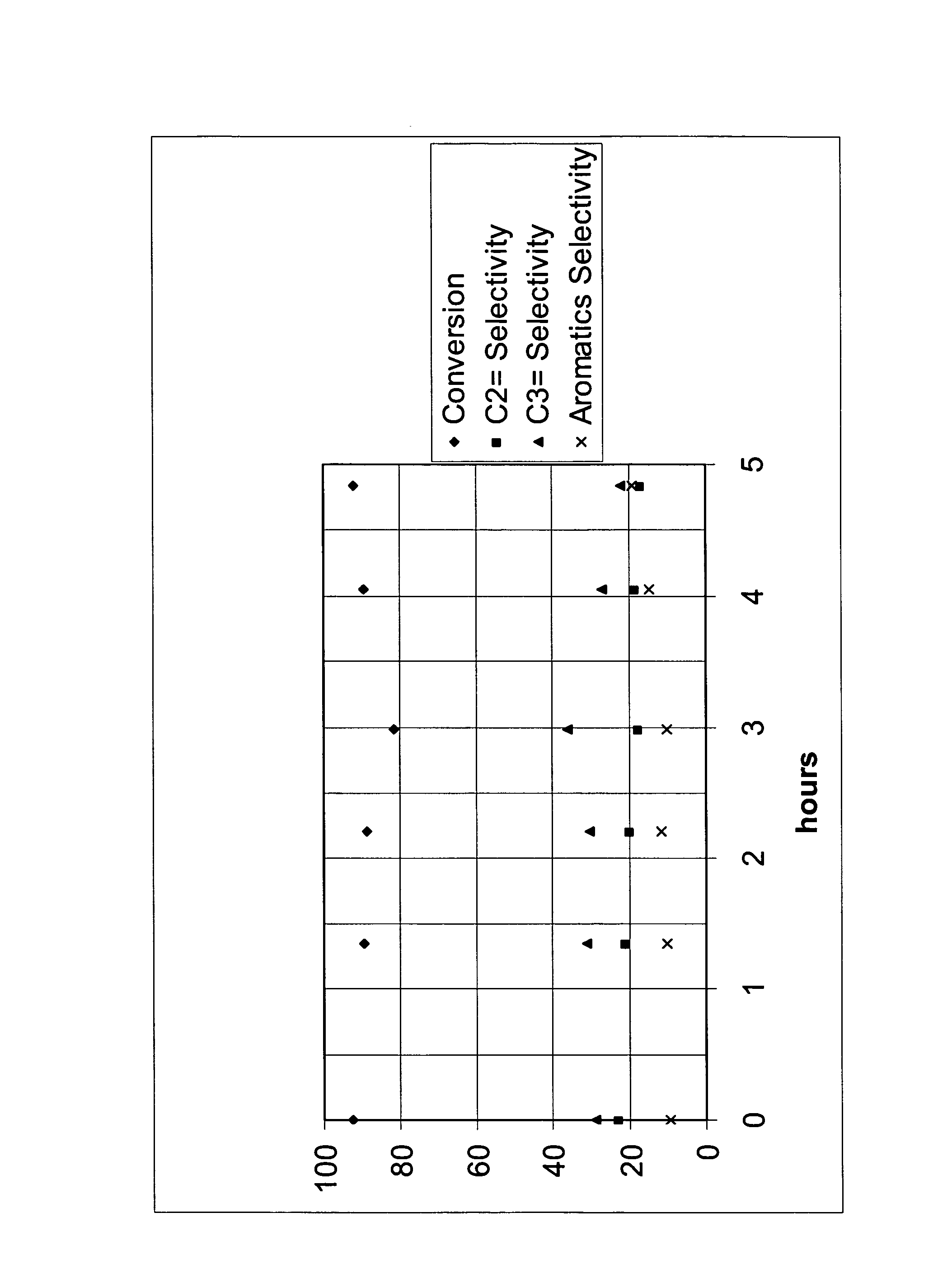

Nanocrystalline silicalite for catalytic naphtha cracking

InactiveUS7459596B1High silica to alumina ratioSmall crystal sizeCatalytic crackingHydrocarbonsNaphthaSilicon dioxide

A method is provided for converting a hydrocarbon feedstock in the naphtha boiling range to light olefins. The method includes contacting the hydrocarbon feedstock with a zeolitic material having a crystal size from 50 to 300 nanometers, having a silica to alumina ratio greater than 200 and where the zeolitic material has a silicalite structure.

Owner:UOP LLC

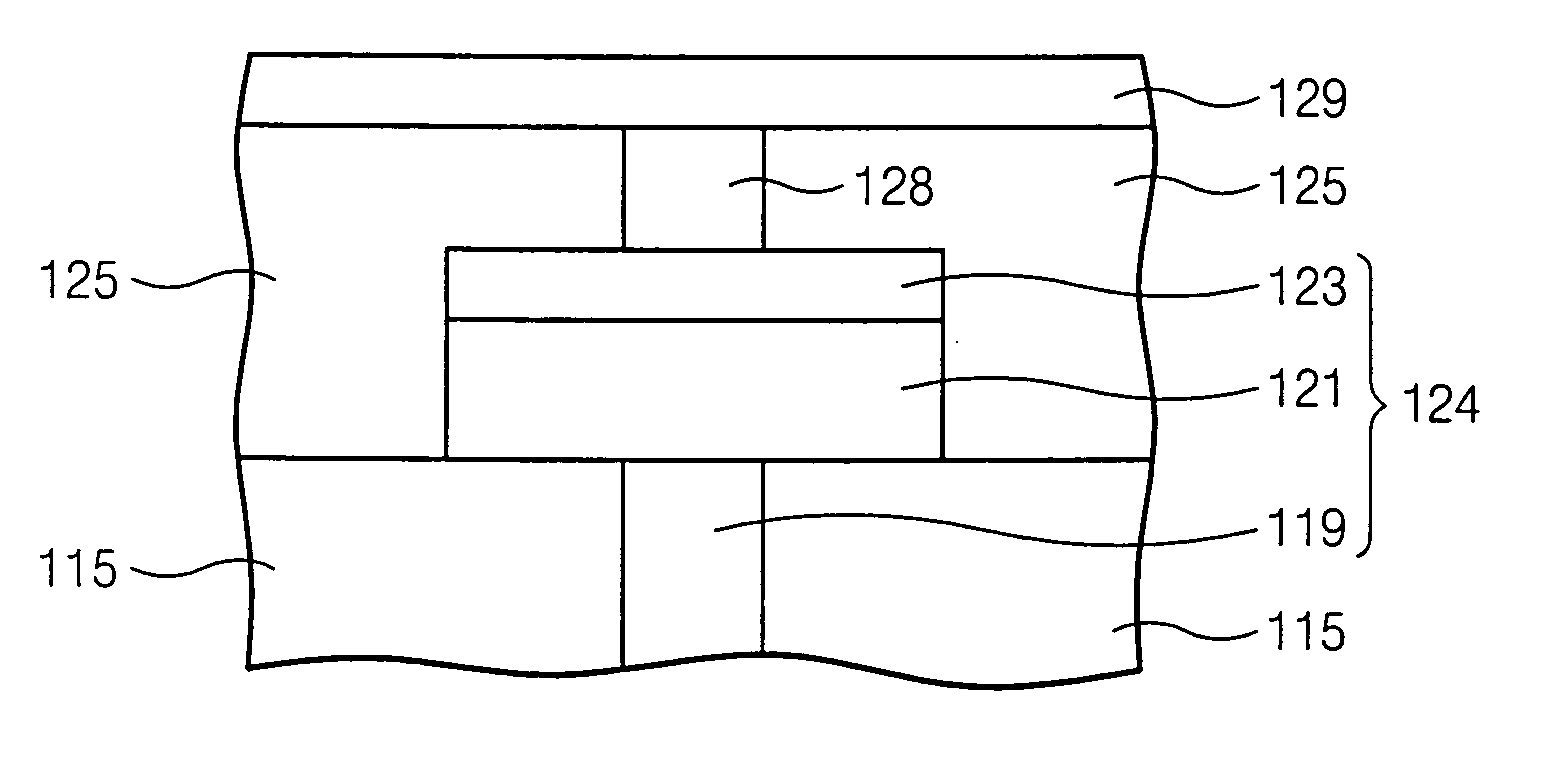

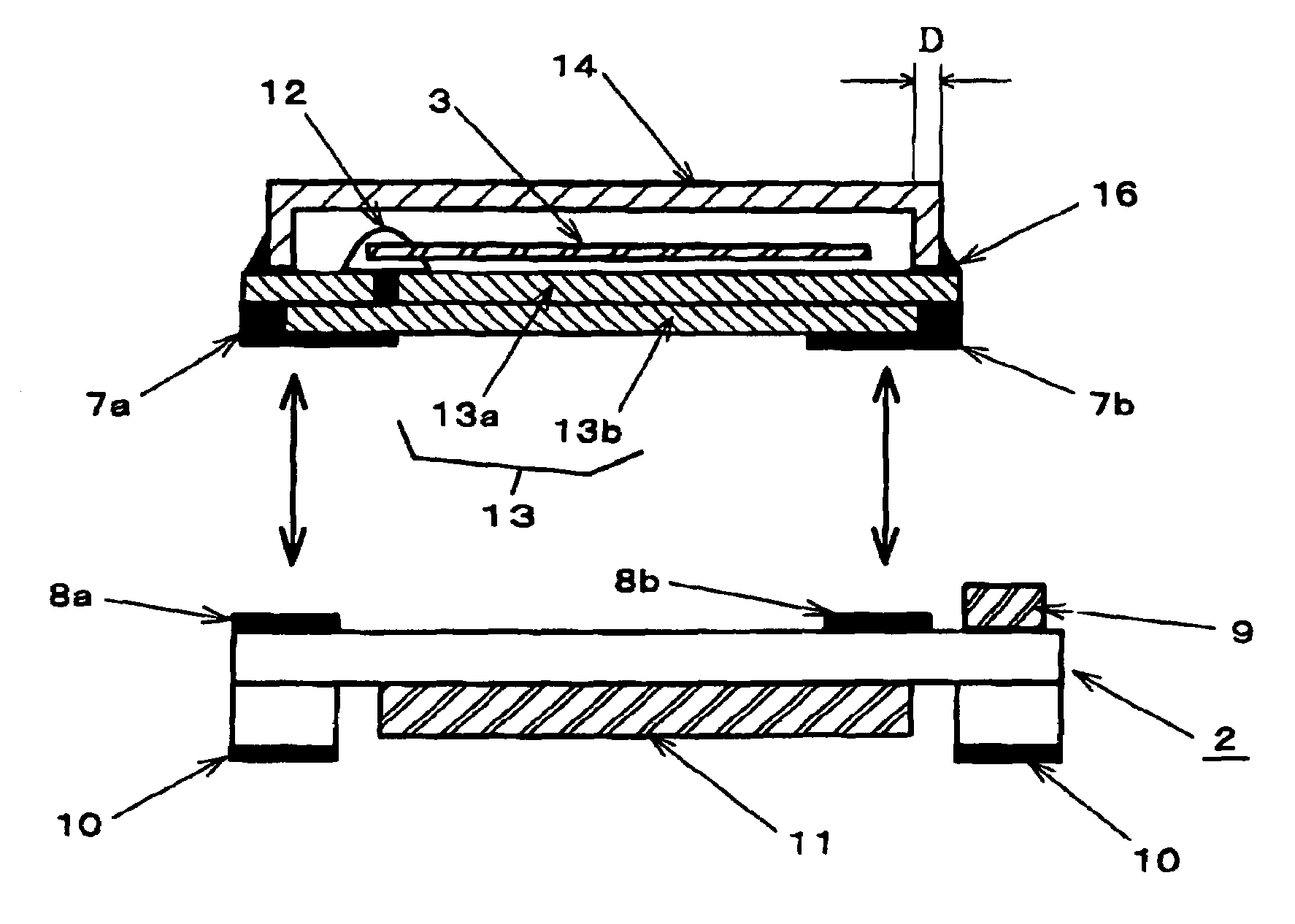

Surface-mount crystal oscillator

InactiveUS6998925B2Small crystal sizeSmall sizePiezoelectric/electrostriction/magnetostriction machinesSolid-state devicesPlanar substrateSurface mounting

A surface-mount crystal oscillator includes a quartz crystal unit, a mounting substrate on which an IC (Integrated Circuit) chip is mounted and which is bonded to the rear surface of the crystal unit, and an electronic components which is mounted on one end of the surface of the mounting substrate on which the crystal unit is bonded. The crystal unit includes a planar substrate, a quartz crystal blank held on one principal surface of the planar substrate, a metal film formed along the outer periphery of the principal surface, and a concave metal cover having an open-ended face. In the crystal unit, the open-ended face of the metal cover is brazed to the metal film, whereby the crystal blank is hermetically sealed between the metal cover and the planar substrate.

Owner:NIHON DEMPA KOGYO CO LTD

Novel TiO2 material and the coating methods thereof

ActiveUS20060019028A1Similar effectReduce moistureMaterial nanotechnologyLiquid surface applicatorsAir cleaningMaterials science

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

Process for Preparing a Molecular Sieve

ActiveUS20160221832A1Increase mesopore surface areaGood removal effectMolecular sieve catalystsMolecular sieve catalystMolecular sieveZeolite

Owner:EXXONMOBIL CHEM PAT INC

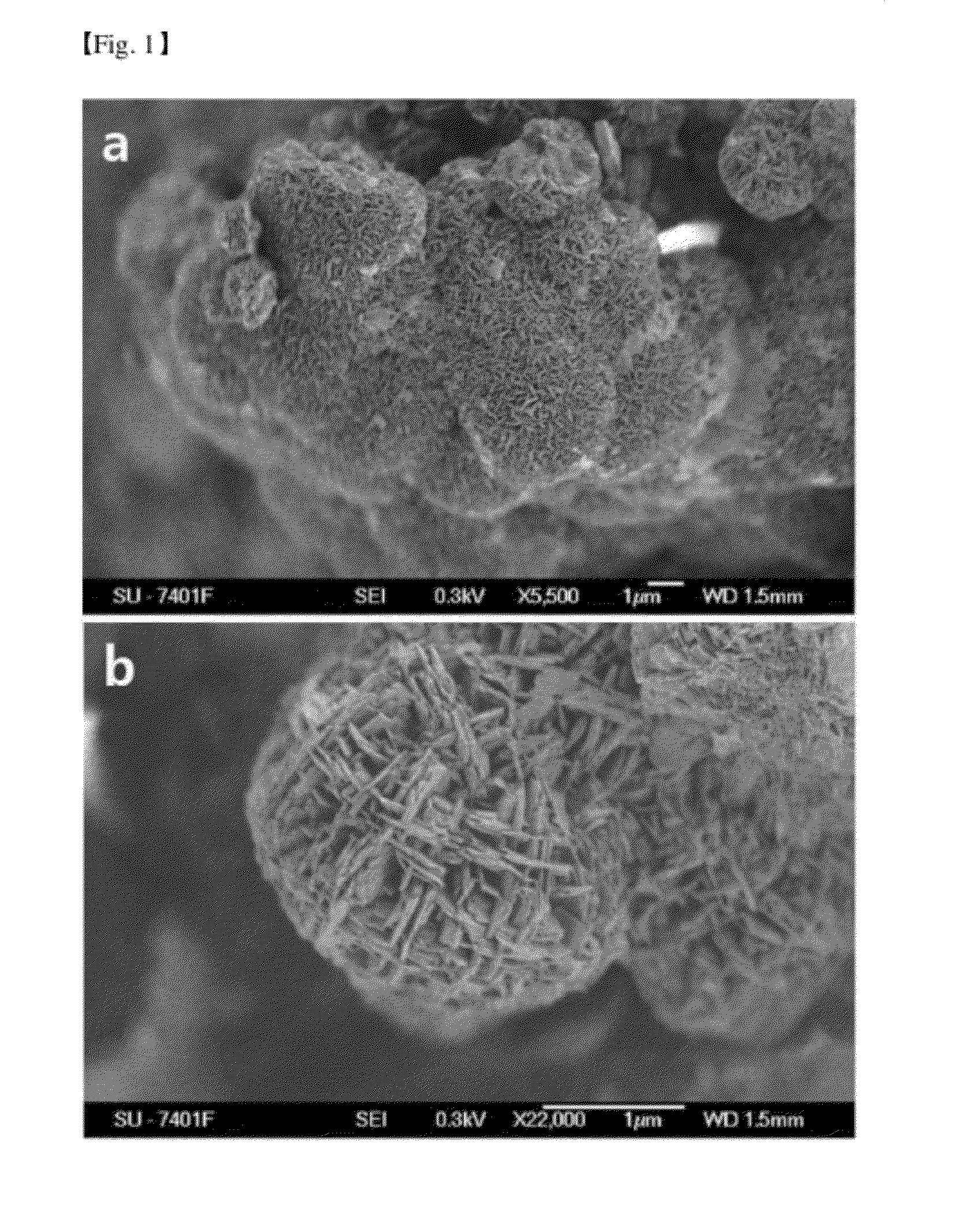

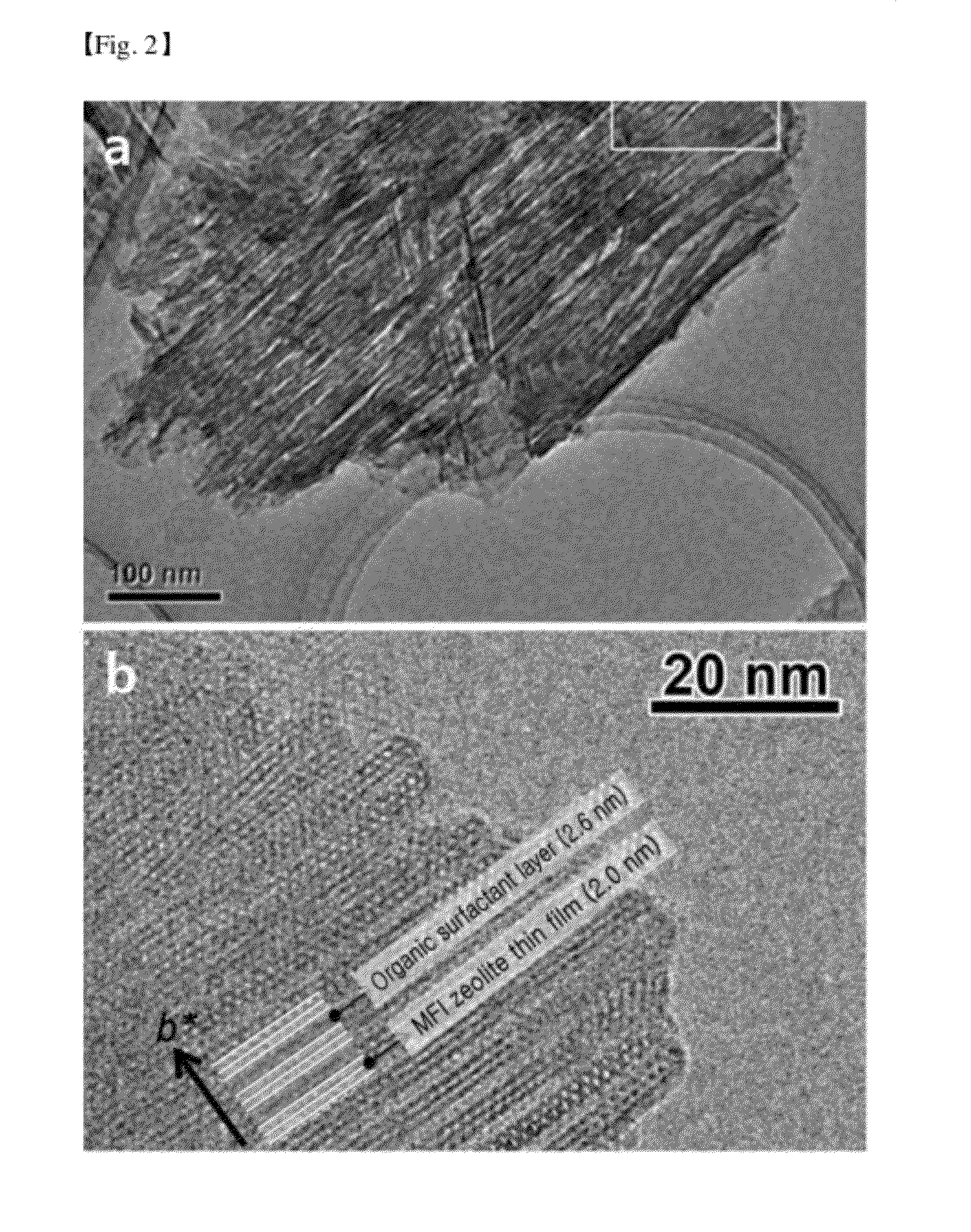

Regularly stacked multilamellar and randomly aligned unilamellar zeolite nanosheets, and their analogue materials whose framework thickness were corresponding to one unit cell size or less than 10 unit cell size

InactiveUS20120165558A1Increase surface areaHigh catalytic activityHydrogenAluminium compoundsIon exchangeOrganic reaction

The present invention relates to microporous molecular sieve materials and their analogue molecular sieve materials having a crystalline unilamellar or multilamellar framework with a single unit cell thickness in which layers are aligned regularly or randomly, the molecular sieve materials being synthesized by adding an organic surfactant to the synthesis composition of zeolite. In addition, the present invention relates to micro-mesoporous molecular sieve materials activated or functionalized by dealumination, ion exchange or other post treatments, and the use thereof as catalyst. These novel materials have dramatically increased external surface area by virtue of their framework with nano-scale thickness, and thus exhibit improved molecular diffusion, and thus have much higher activities as catalyst and ion exchange resin than conventional zeolites. In particular, the materials of the present invention exhibit high reactivity and dramatically increased catalyst life in various organic reactions such as carbon-carbon coupling, alkylation, acylation, etc. of organic molecules.

Owner:KOREA ADVANCED INST OF SCI & TECH

Quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material and preparation method

InactiveCN105958038AImprove structural stabilityImprove securityCell electrodesSecondary cellsLithiumHigh voltage

The invention relates to a preparation method of a quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material. The preparation method comprises the following steps: preparing Li<2>CO<3> and Co<3>O<4> as raw materials, adding a doping element M, adding a grain refiner and a cosolvent, and performing first sintering; and adding a grain refiner and a coating compound into a firstly-sintered material serving as a raw material, and performing surface coating and second sintering, wherein the doping element M is one or more of Ti<4+>, Zr<4+>, Mn<4+>, Sn<4+>, Ce<4+>, Ir<3+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and Co<2+>, a molecular formula of doped lithium cobaltate is LiCo<1-x>M<y>O<2-y>; and the grain refiner is one or more of oxides of Ti, Nb, V, Al and Zr. The prepared lithium cobaltate positive electrode material has the characteristics of rapid charging, high capacity, high voltage, high cycle and low cost, can be applied under a rapid-charging high-voltage condition, and has superior electrochemical performance.

Owner:湖南美特新材料科技有限公司 +1

Polypropylene monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS20040096661A1Reduced shrinkage performanceLow shrinkageSynthetic resin layered productsMonocomponent polypropylene artificial filamentThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:ROYER JOSEPH R +2

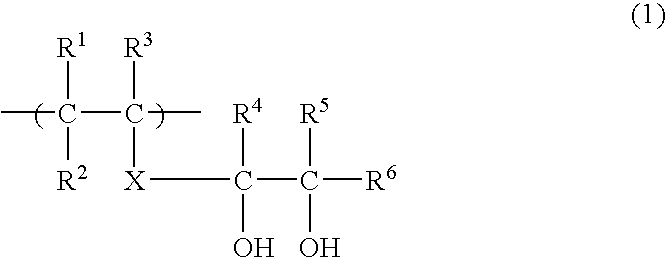

Water-soluble polyvinyl alcohol resin filament and nonwoven fabric made by using the same

InactiveUS20090061719A1Good water solubilityRadiation suppressionLayered productsMonocomponent synthetic polymer artificial filamentSolubilityDissolution

A water-soluble polyvinyl alcohol resin filament is provided, which is formed by melt-spinning a material consisting essentially of a water-soluble polyvinyl alcohol resin having a 1,2-diol structural unit represented by the following general formula (1). A nonwoven fabric is also provided, which is produced by using the water-soluble polyvinyl alcohol resin filament. Therefore, the nonwoven fabric is excellent in water solubility at a lower temperature, and substantially free from bubbling during dissolution thereof in water. In addition, a fully saponified PVA can be used for melt-forming. This suppresses emanation of acetic acid odor, thereby improving the working environment.wherein R1, R2, R3, R4, R5 and R6, which may be the same or different, are each a hydrogen atom or a monovalent organic group, and X is a single bond or a connecting chain.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

Production method for drug balloon

The invention discloses a production method for a drug balloon. The production method comprises the following steps: 1) preparing a medicinal solution; 2) spraying the medicinal solution on the surface of a balloon with layer by layer through a multi-time spraying technology. The production method has the beneficial effects that an oversaturated paclitaxel medicinal solution is prepared, and is directly applied to ultrasonic spraying to obtain a completely-crystallized medicinal coating. The multi-time spraying technology is used, and the medicinal coating is subjected to solvent steam treatment to obtain a medicinal coating with a small crystal size and a good binding effect between the crystal and a substrate. The drug balloon produced by the production method has the advantages that medicinal loss can be lowered greatly in passing and expanding processes, and the drug utilization rate is increased.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

High protein frozen food product

InactiveUS6558731B1Excellent smooth, creamy mouth-feelSmall crystal sizeFrozen sweetsBiotechnologyWater soluble

A frozen food with a high protein to fat ratio with a smooth creamy mouth-feel is provided. The frozen food can be prepared with a low sugar (available carbohydrate) content and a high protein to sugar and a high protein to fat ratio. A major portion of the protein is derived from water soluble protein.

Owner:PARADISE POPS

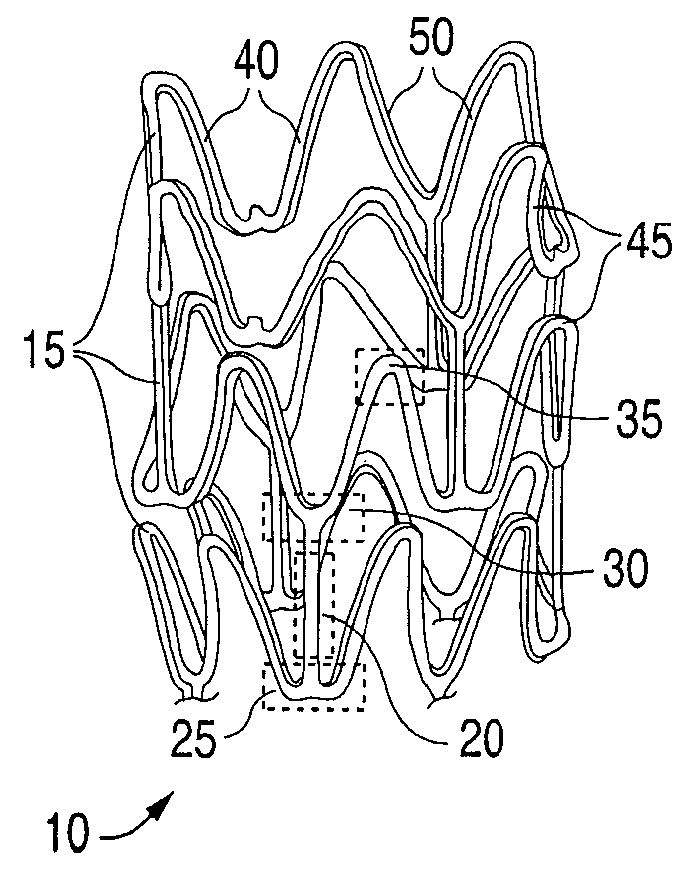

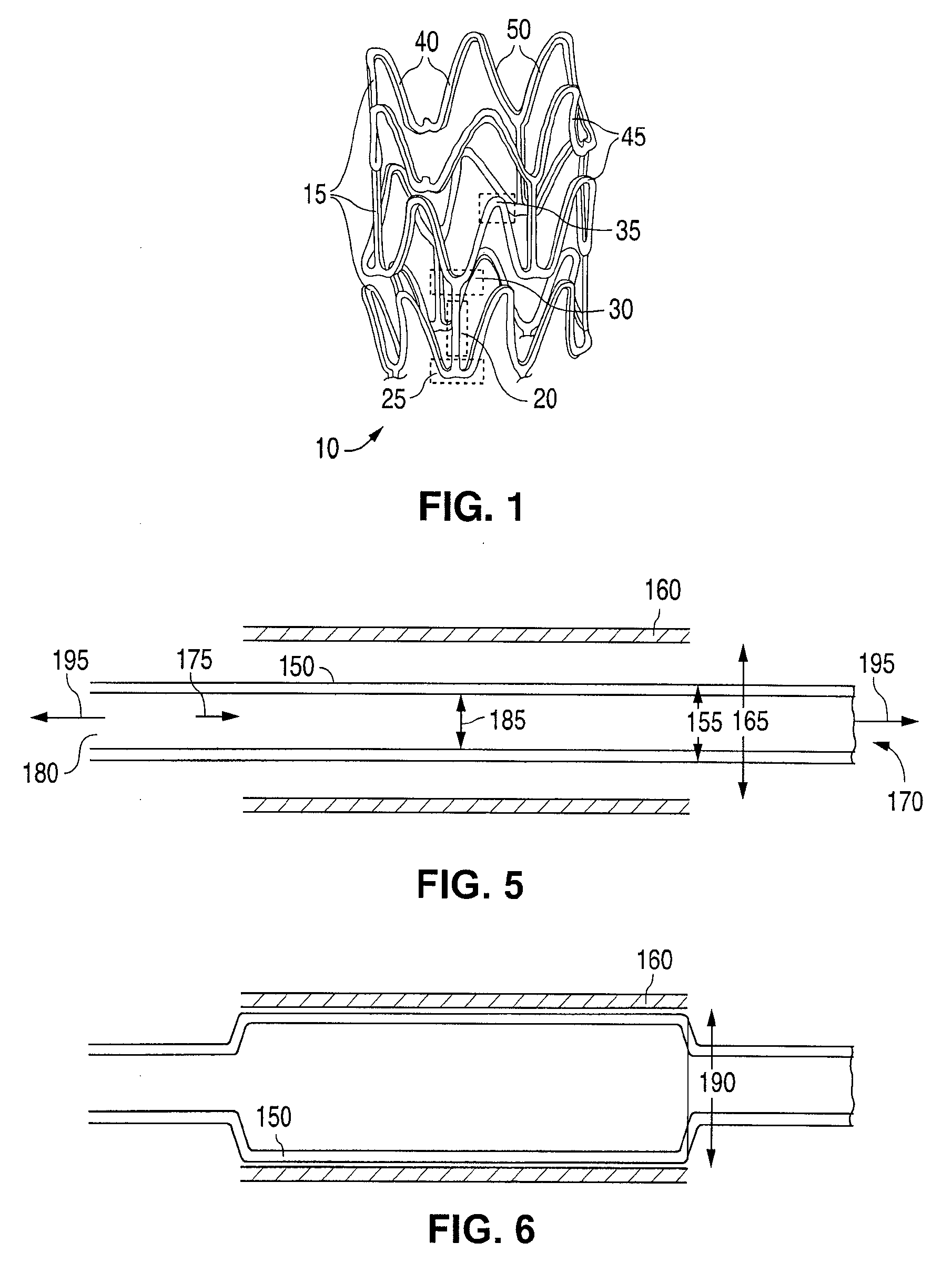

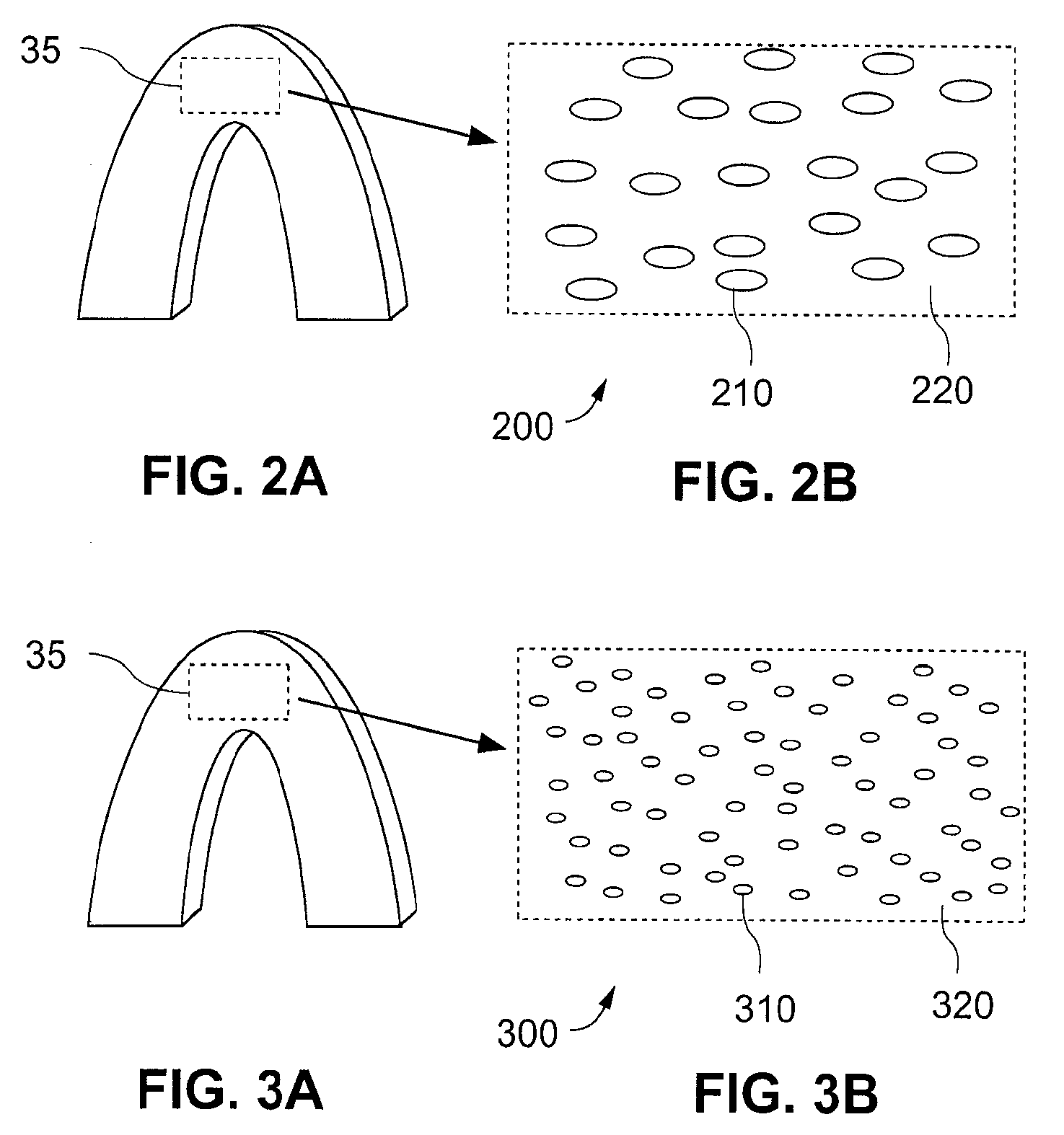

Stent With Nucleating Agent

InactiveUS20090248147A1High crystallinitySmall crystal sizeStentsButtonsCrystallinityMechanical property

The use of nucleating agents to manufacture polymeric stents is disclosed. The resulting stents may have increased crystallinity, decreased crystal size, increased mechanical properties, and faster degradation times.

Owner:ABBOTT CARDIOVASCULAR

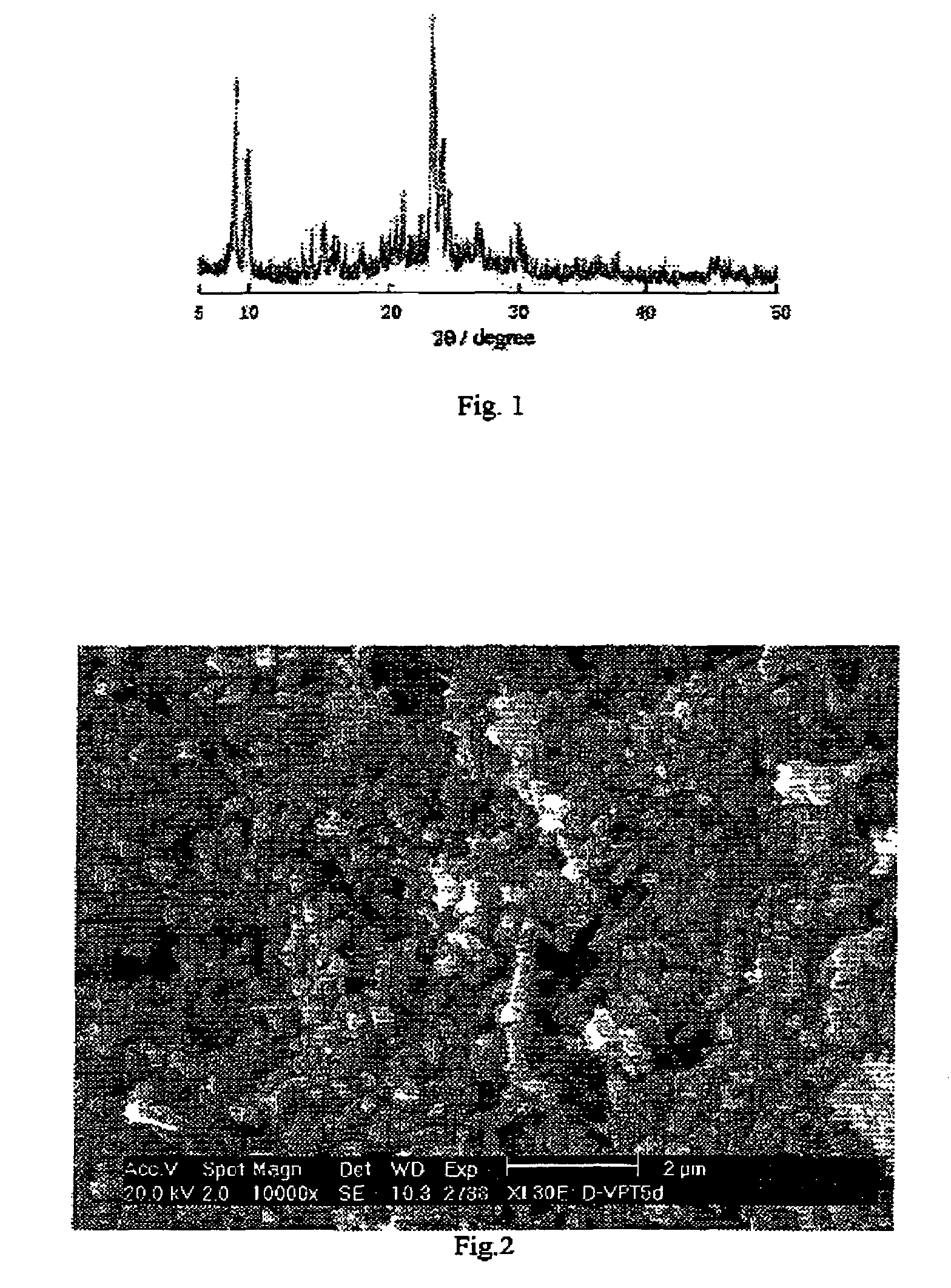

Process for producing binder-free ZSM-5 zeolite in small crystal size

ActiveUS7601330B2Readily availableLarge crystal sizeAluminium compoundsMolecular sieve catalystsEffective surfaceWater vapor

The present invention relates to a process for producing a binder-free ZSM-5 zeolite in small crystal size. The invention is primarily used for solving the problems in the practical application, e.g., the zeolite powder is difficult to be recovered and easily inactivates and aggregates, and the addition of the binder in the shaping process will result in the reduction of effective surface areas and introduce the diffusional limitation. Said problems are better solved in the present invention by using diatomite or silica aerogel as the main starting material, adding a seed crystal orienting agent, a silica sol and sodium silicate for kneading and shaping, and then converting to integrative ZSM-5 in small crystal size by vapor-solid phase crystallization with organic amine and water vapor. Said process can be used in the industrial preparation of ZSM-5 molecular sieve catalyst in small crystal size.

Owner:CHINA PETROCHEMICAL CORP +1

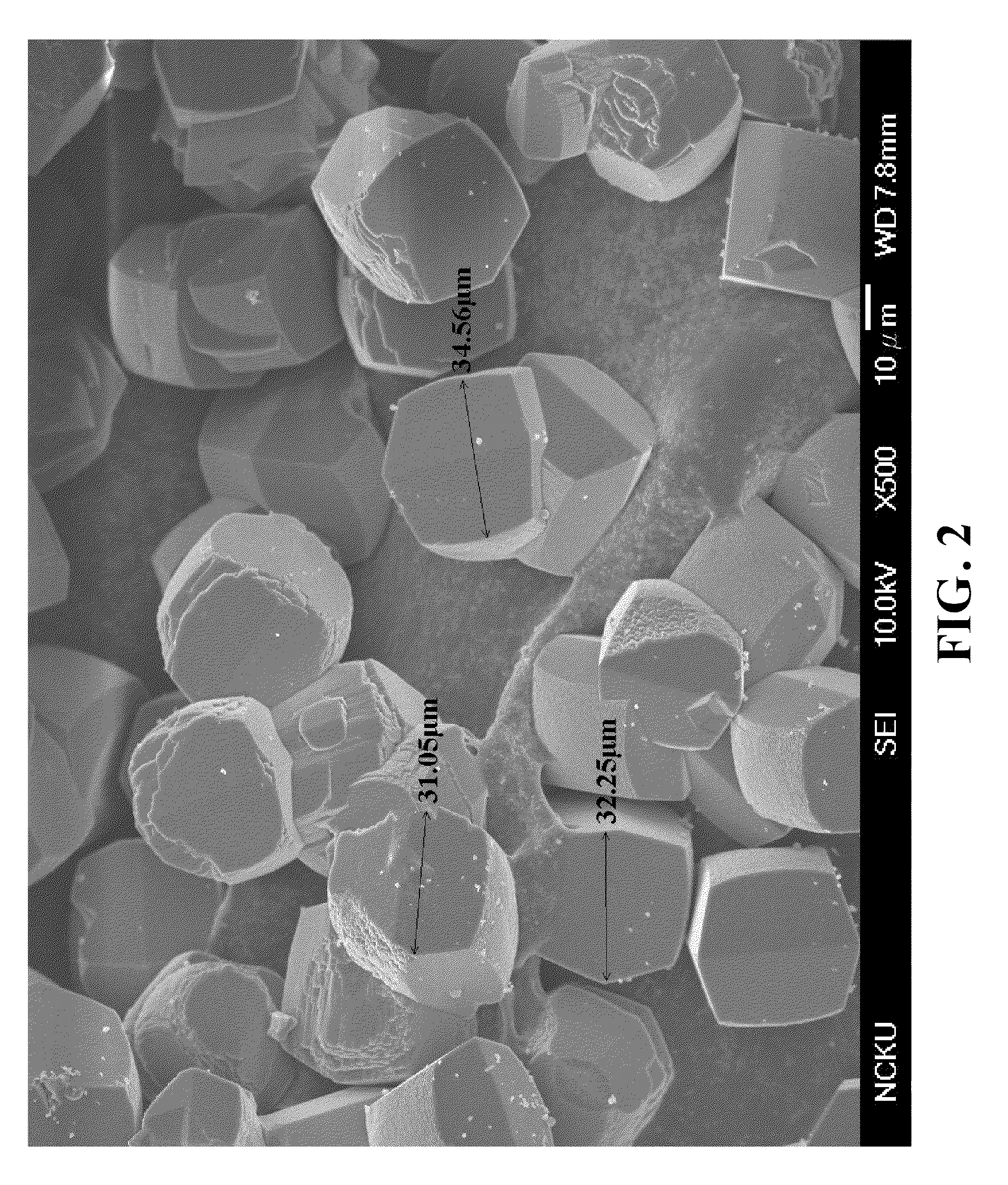

Method for synthesizing all-silica zeolite beta with small crystal size

ActiveUS20100254894A1Rapid and efficientSmall crystal sizeAluminium compoundsMolecular-sieve silica-polymorphsCrystalline materialsFluoride

A method for synthesizing the all-silica zeolite beta with small crystal size is disclosed. This method comprises the steps of: (a) forming a reaction mixture comprising (1) a source of silicon dioxide (SiO2), (2) a source of fluoride ions (F−), (3) a source of tetraethylammonium cations (TEA+), and (4) water (H2O), at predetermined mole ratios of the source of silicon dioxide, the source of fluoride ions, the source of tetraethylammonium cations, and water; (b) crystallizing the reaction mixture; and (c) recovering the crystalline material formed, wherein the pH of the mixture before crystallization has a value of 6 to 9, and the pH of the mixture after crystallization has a value of 6 to 8. This improved method gives a fast and efficient way of synthesis of all-silica zeolite beta with an average crystal size of less than 5 μm.

Owner:FORMOSAN UNION CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com