Method for separating iron and vanadium and titanium from vanadium titano-magnetite

A technology for separating vanadium titanomagnetite and iron, applied in the field of metallurgy, can solve the problems of iron recovery rate only reaching 69%, no separation index of iron and titanium vanadium, failure to use effectively, etc., so as to reduce energy consumption and crystal size. The effect of reducing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

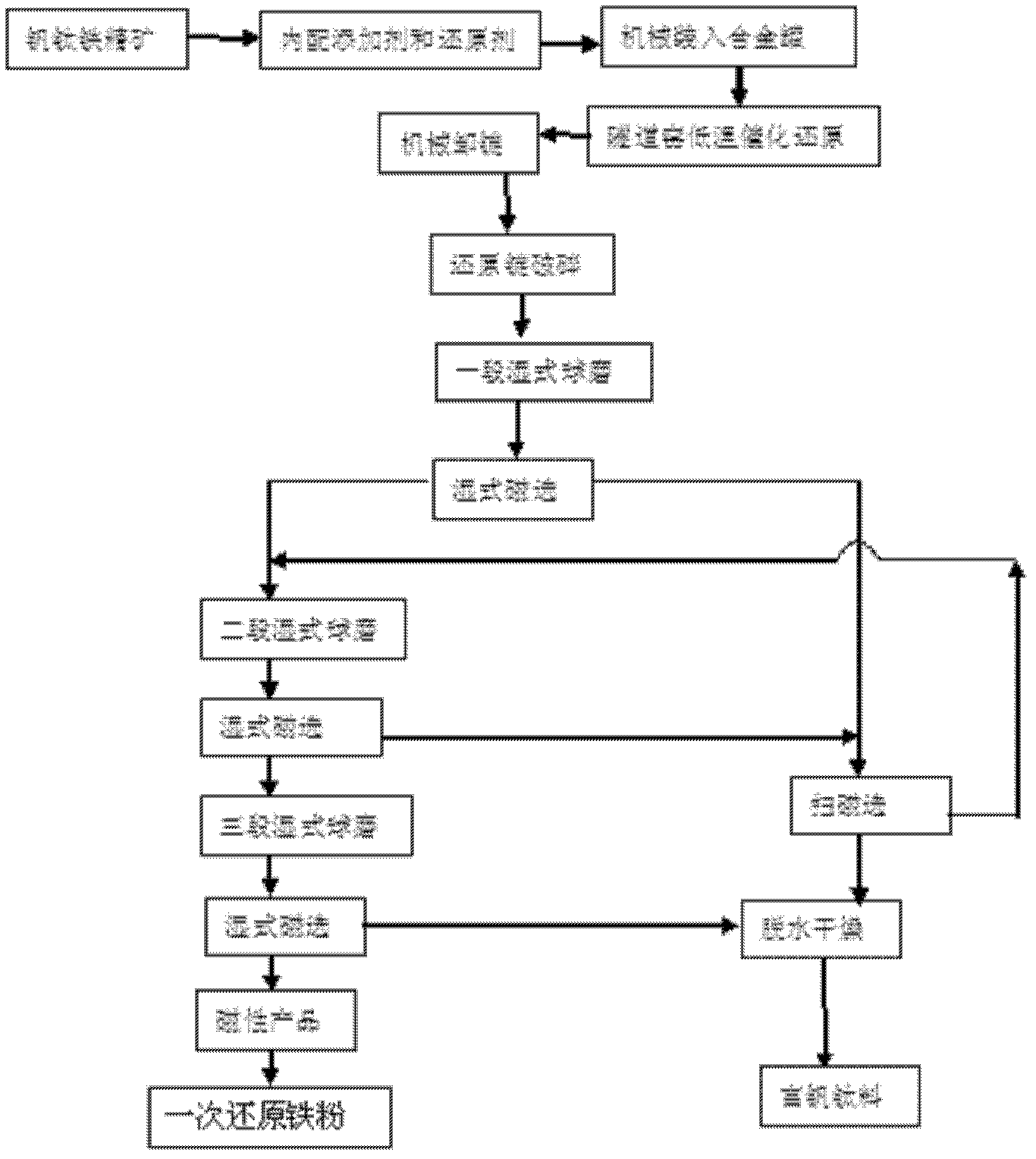

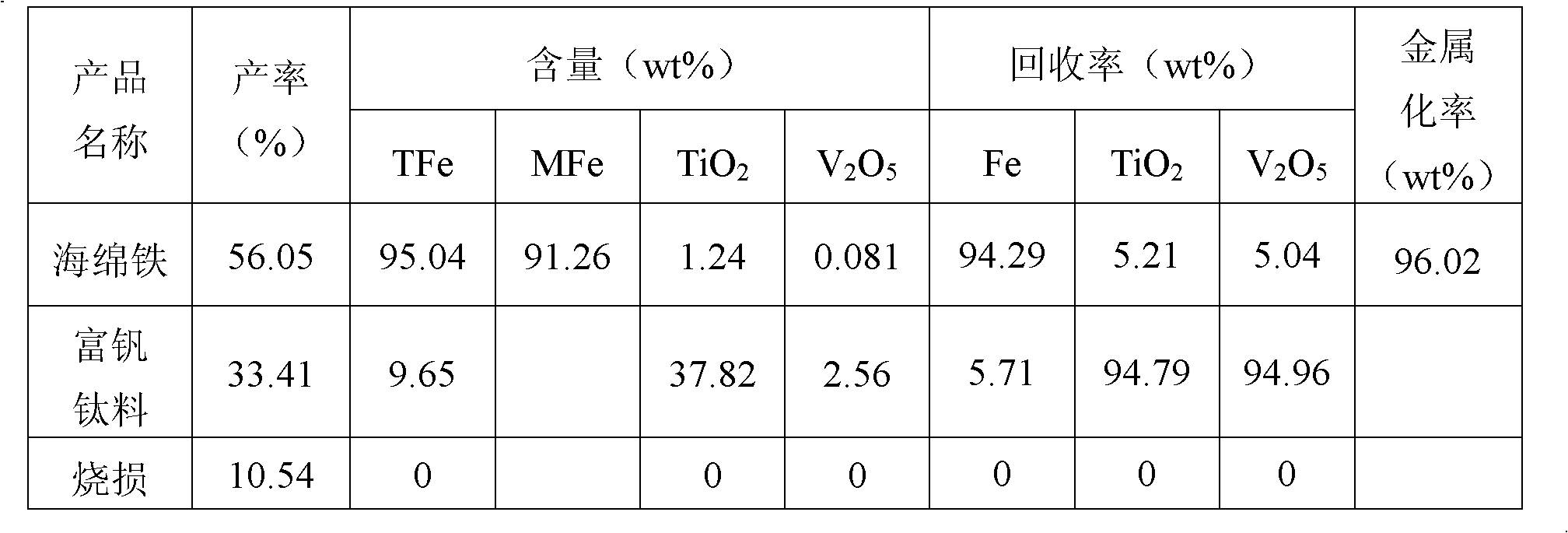

[0038] Embodiment 1 adopts the inventive method to separate iron and vanadium-titanium from vanadium-titanium magnetite

[0039] Mix vanadium-titanium magnetite with additive (sodium chloride) and carbonaceous reducing agent (anthracite) in a weight ratio of 100 / 20 / 20, then put it into an alloy tank, and heat it in a muffle furnace to 950°C and Keep warm for 6 hours to obtain reduced ingots; the reduced ingots are crushed, the first stage grinding fineness is -325 mesh 90%, 1200 Oersted magnetic separation; the magnetic separation concentrate enters the second stage grinding, the second stage grinding fineness is -325 mesh 95%, 1200 Oersted magnetic separation; the magnetic separation concentrate enters three-stage grinding, and the third-stage grinding fineness is -325 mesh 98%, and 500 Oersted magnetic separation, to obtain sponge iron (that is, primary reduced iron powder) and vanadium-rich titanium materials. Among them, the chemical composition and -200 mesh content of t...

Embodiment 2

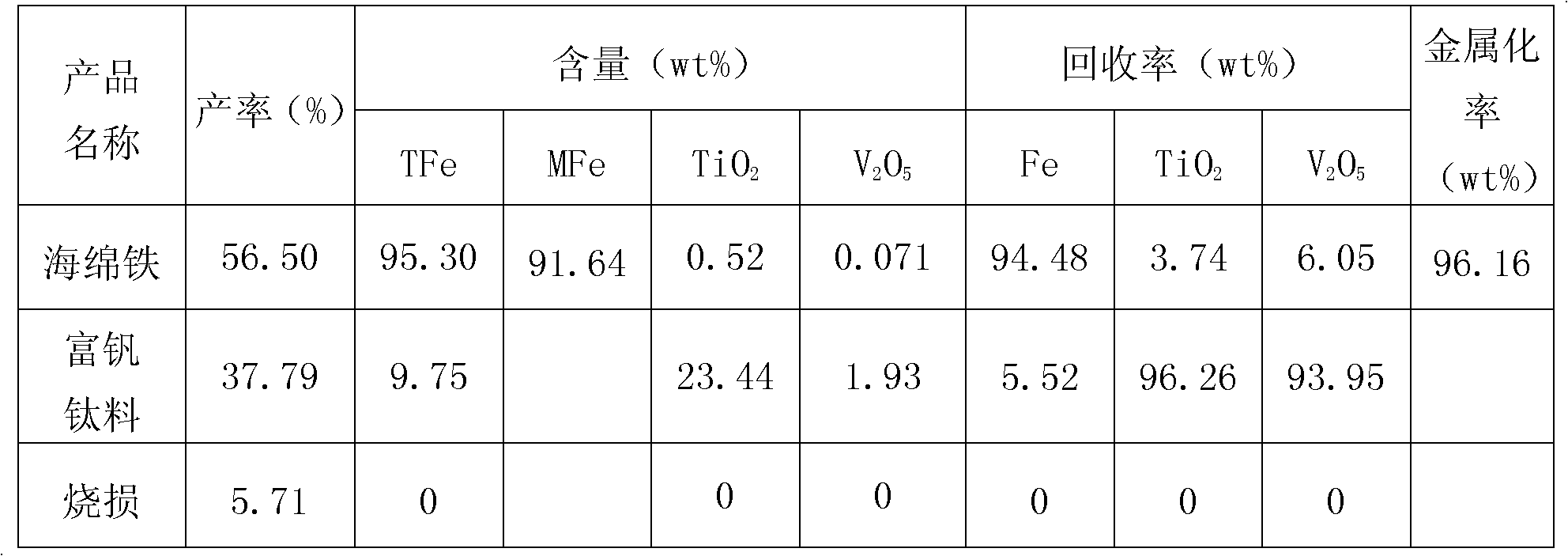

[0040] Embodiment 2 adopts the inventive method to separate iron and vanadium-titanium from vanadium-titanium magnetite

[0041]Mix vanadium-titanium magnetite with additive (sodium chloride) and carbonaceous reducing agent (anthracite) in a weight ratio of 100 / 20 / 22, then put it into an alloy tank, and heat it in a tunnel kiln to 920°C and keep it warm After 60 hours, the reduced ingot was obtained; the reduced ingot was crushed, the first-stage grinding fineness was -200 mesh 60%, and 1200 Oersted magnetic separation; the magnetic separation concentrate entered the second-stage grinding, and the second-stage grinding fineness was -200 mesh 65 %, 1200 Oersted magnetic separation; the magnetic separation concentrate enters three-stage grinding, and the three-stage grinding fineness is -200 mesh 70%, and 500 Oersted magnetic separation obtains sponge iron (i.e. primary reduced iron powder) and Vanadium-rich titanium material. Among them, the chemical composition and -200 mesh ...

Embodiment 3

[0042] Embodiment 3 adopts the inventive method to separate iron and vanadium-titanium from vanadium-titanium magnetite

[0043] Mix vanadium-titanium magnetite with additive (sodium chloride) and carbonaceous reducing agent (anthracite) in a weight ratio of 100 / 15 / 18, then put it into an alloy tank, and heat it in a tunnel kiln to 980°C and keep it warm After 60 hours, the reduced ingot was obtained; the reduced ingot was crushed, the first-stage grinding fineness was -200 mesh 60%, and 1200 Oersted magnetic separation; the magnetic separation concentrate entered the second-stage grinding, and the second-stage grinding fineness was -200 mesh 65 %, 1200 Oersted magnetic separation; the magnetic separation concentrate enters three-stage grinding, and the three-stage grinding fineness is -200 mesh 70%, and 500 Oersted magnetic separation obtains sponge iron (i.e. primary reduced iron powder) and Vanadium-rich titanium material. Among them, the chemical composition and -200 mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com