Patents

Literature

32 results about "Oersted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oersted (symbol Oe) is the unit of the auxiliary magnetic field H in the centimetre–gram–second system of units (CGS). It is equivalent to 1 dyne per maxwell.

Magnetic data recording device

Owner:FITBIT INC

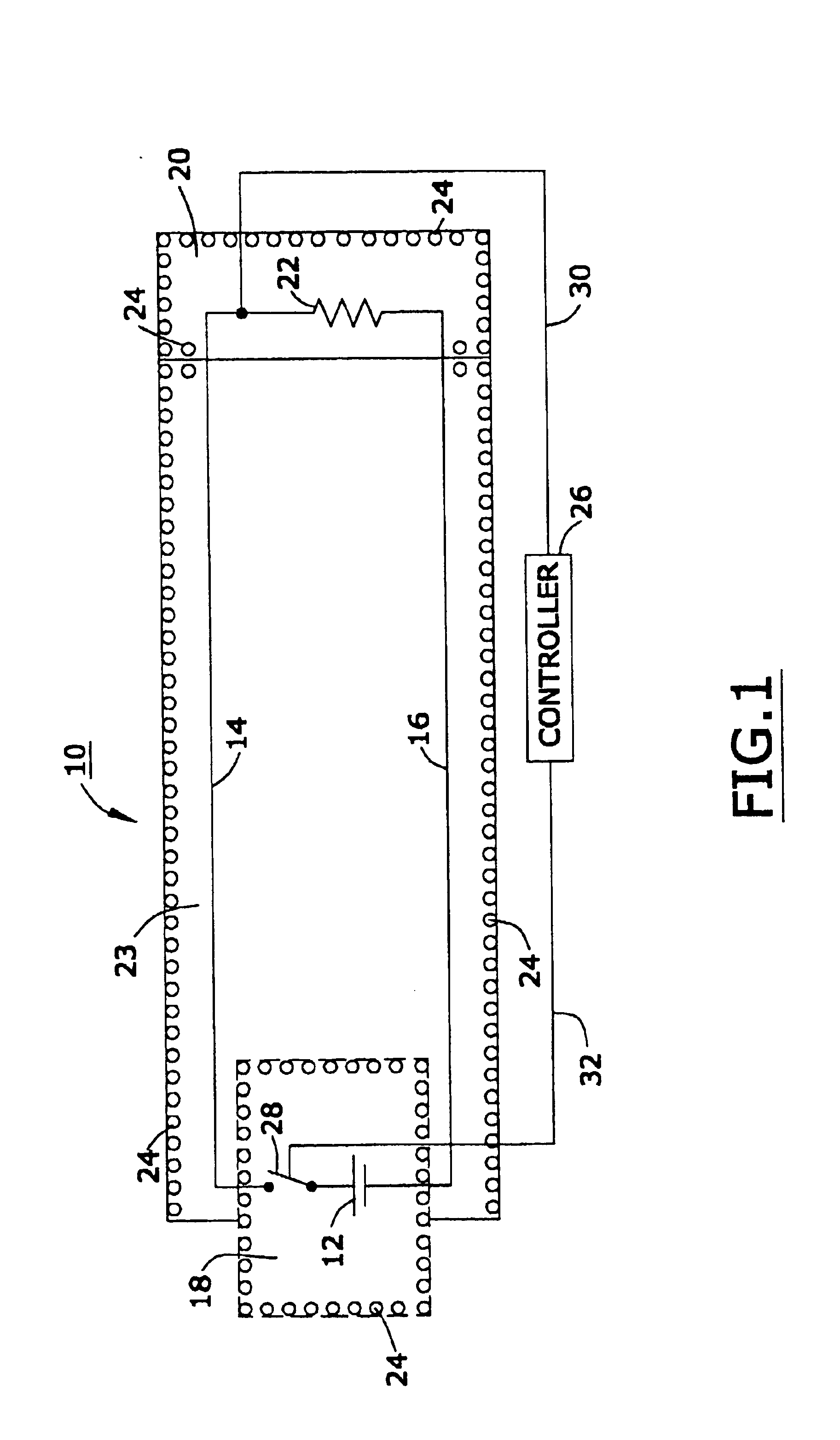

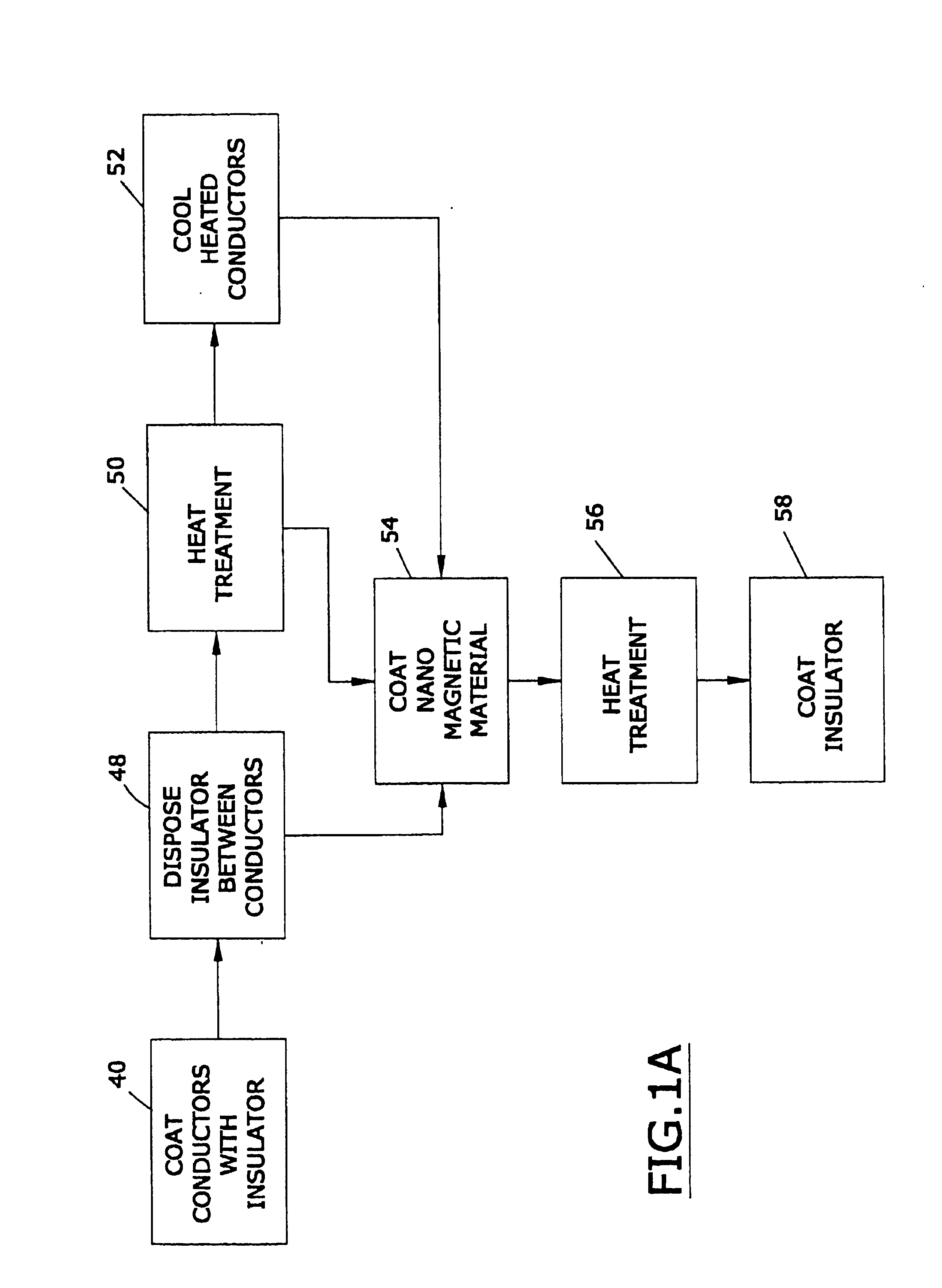

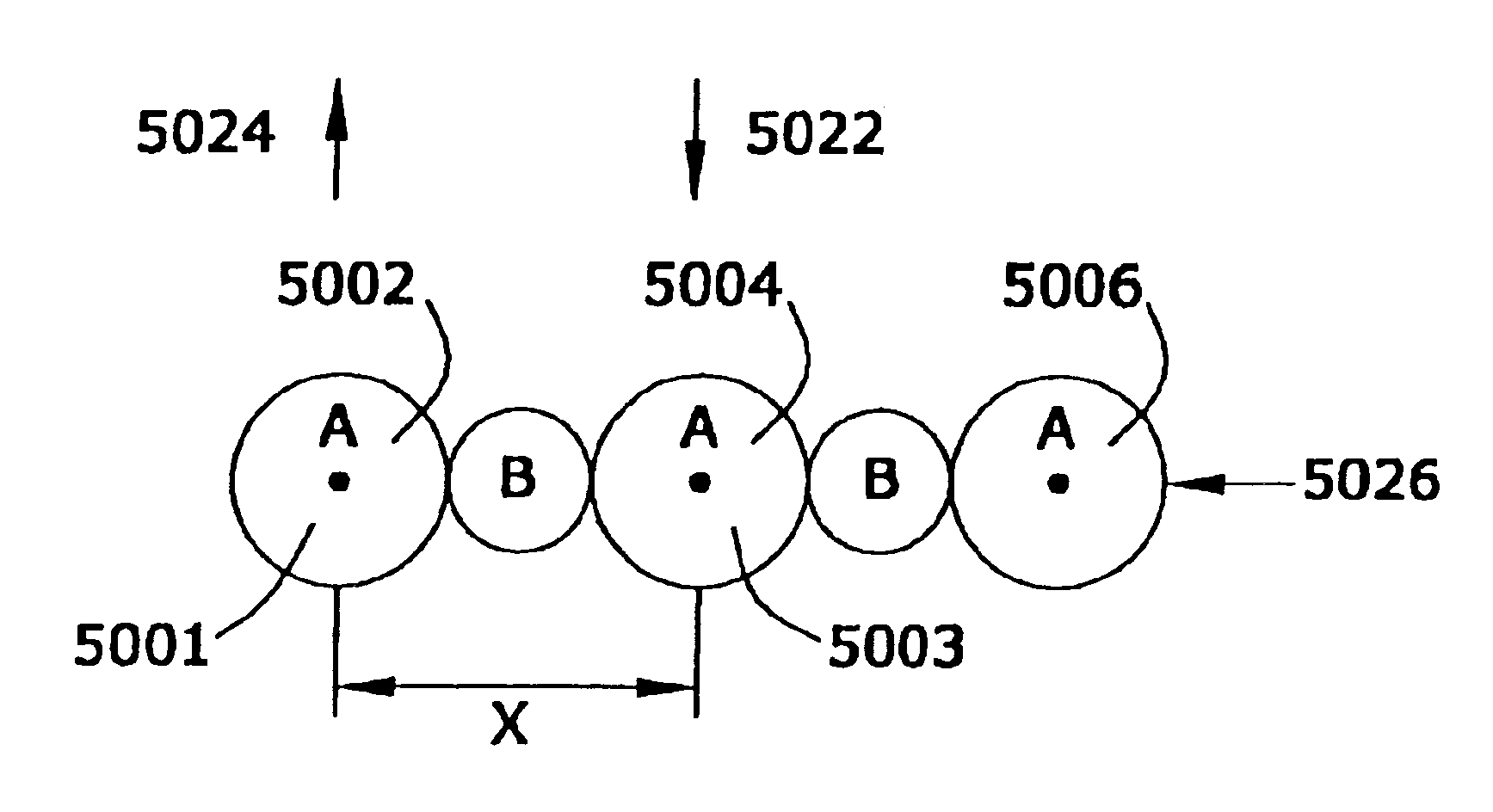

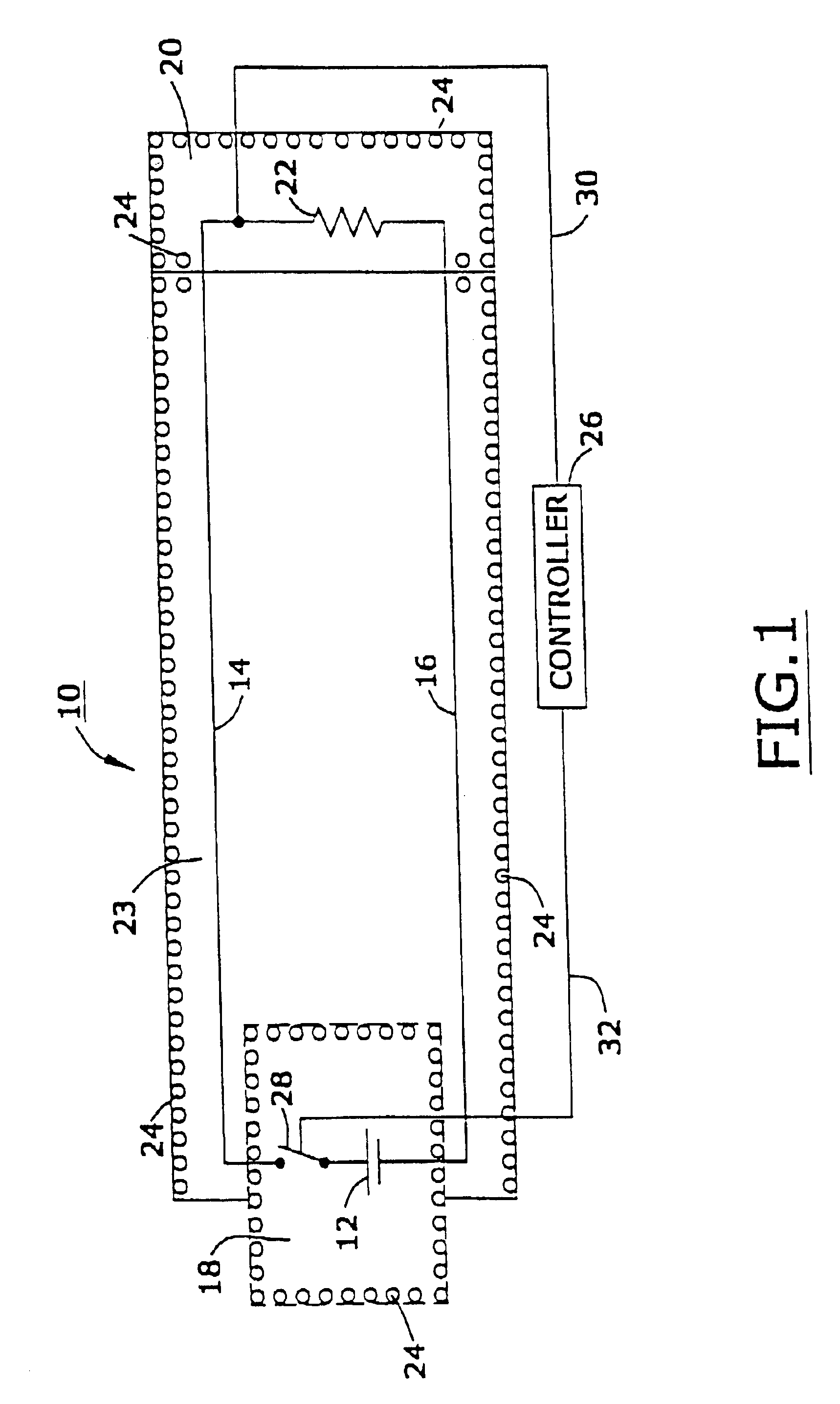

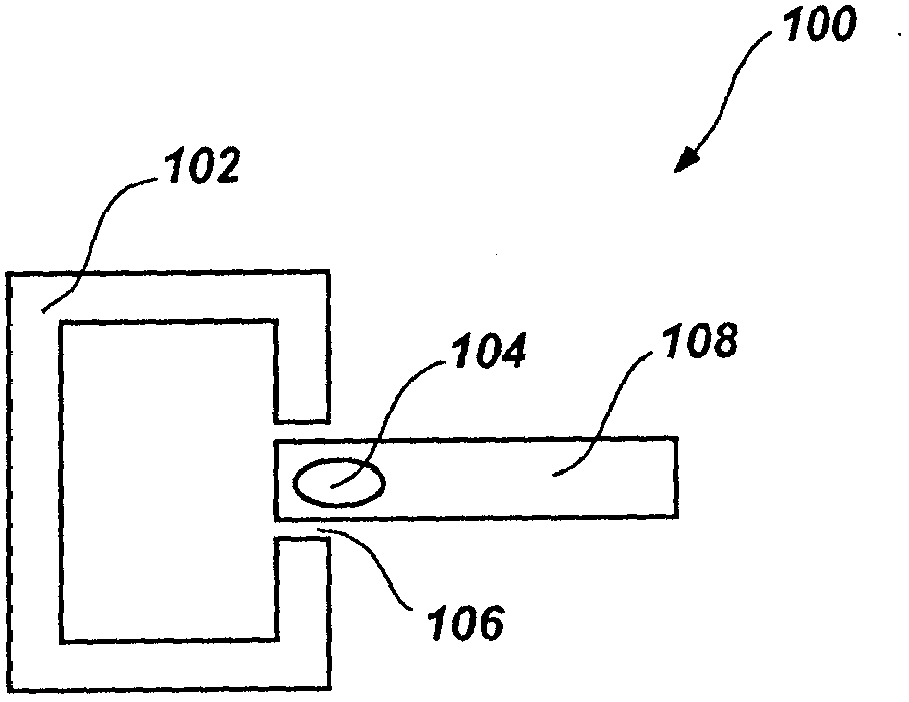

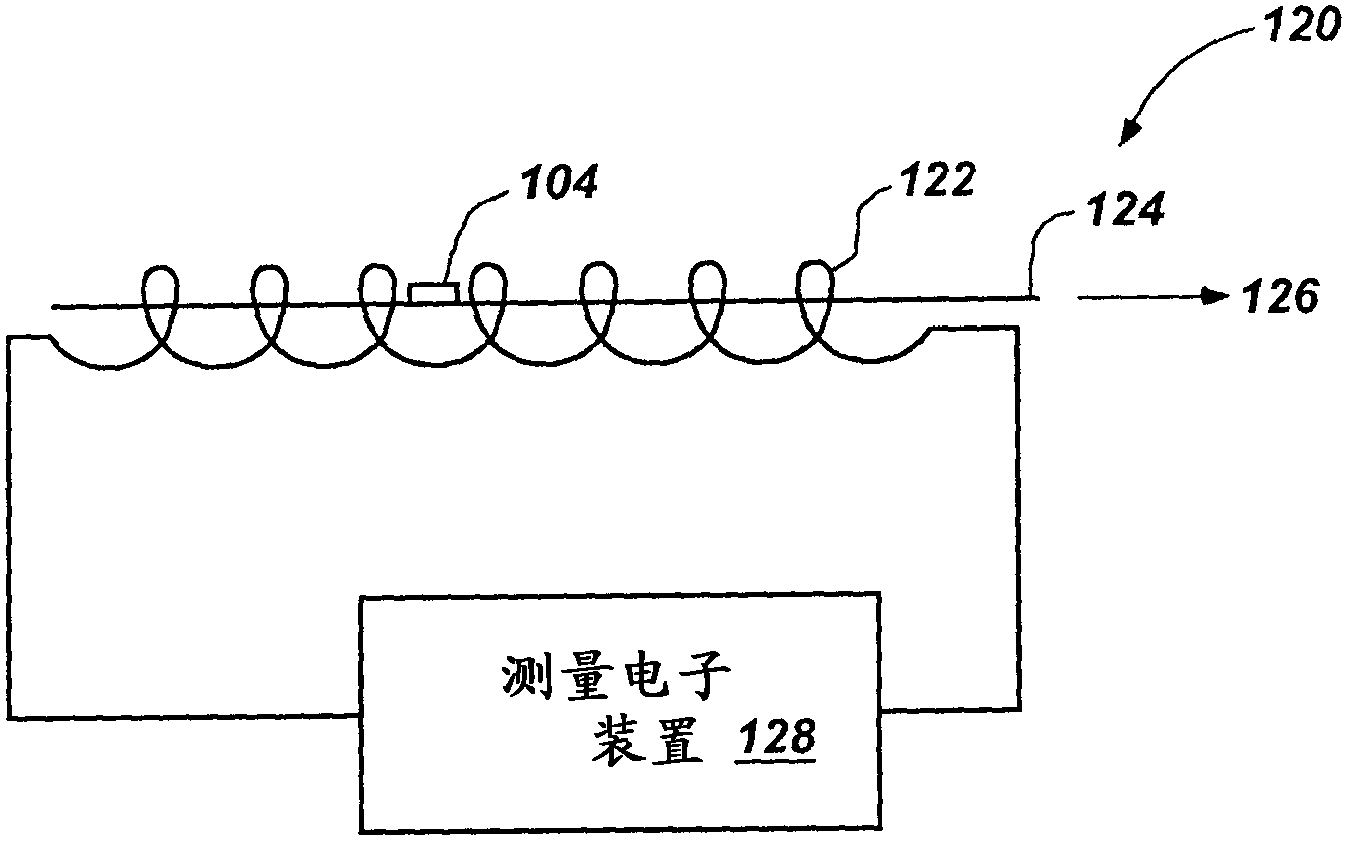

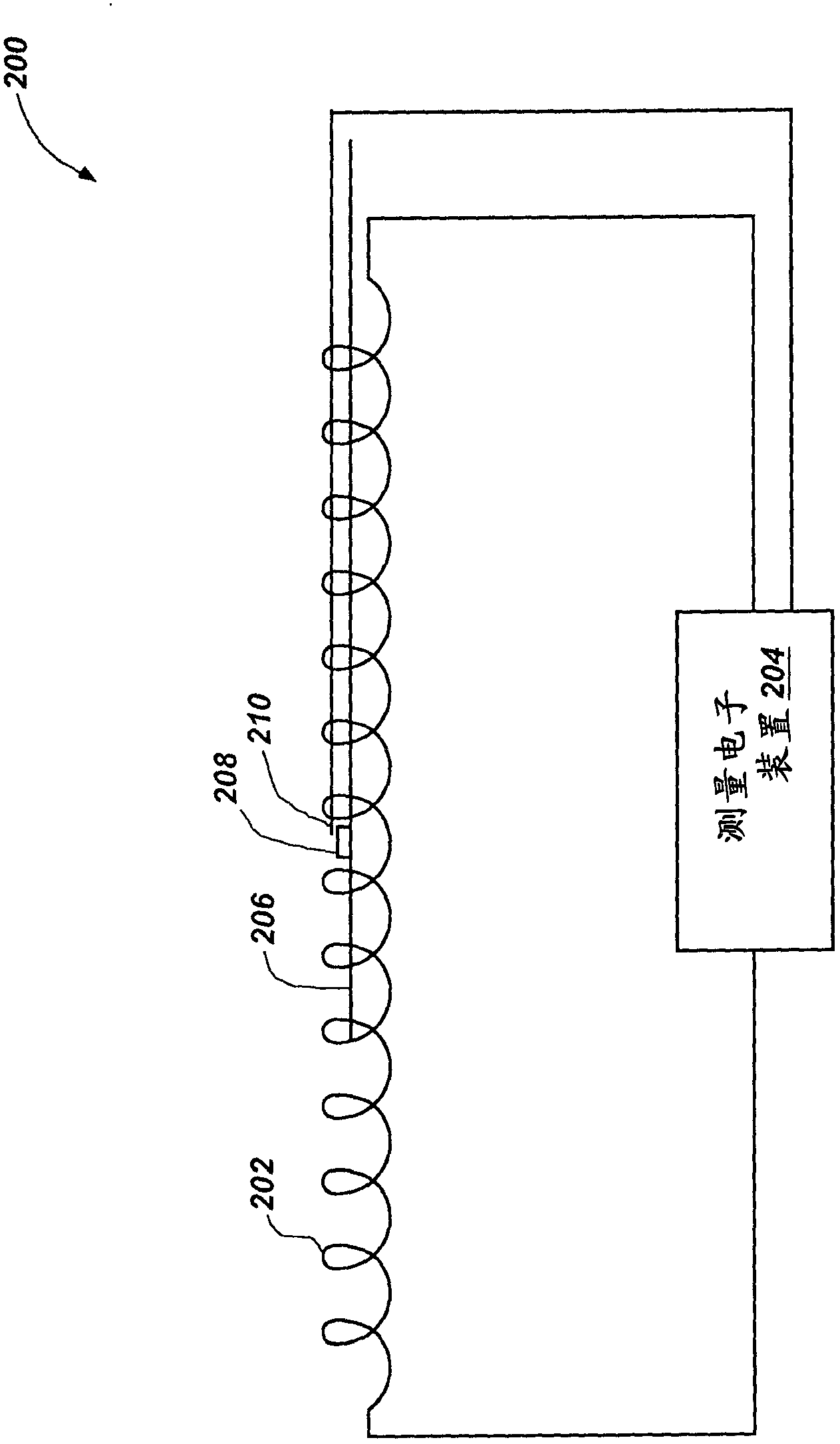

Magnetically shielded conductor

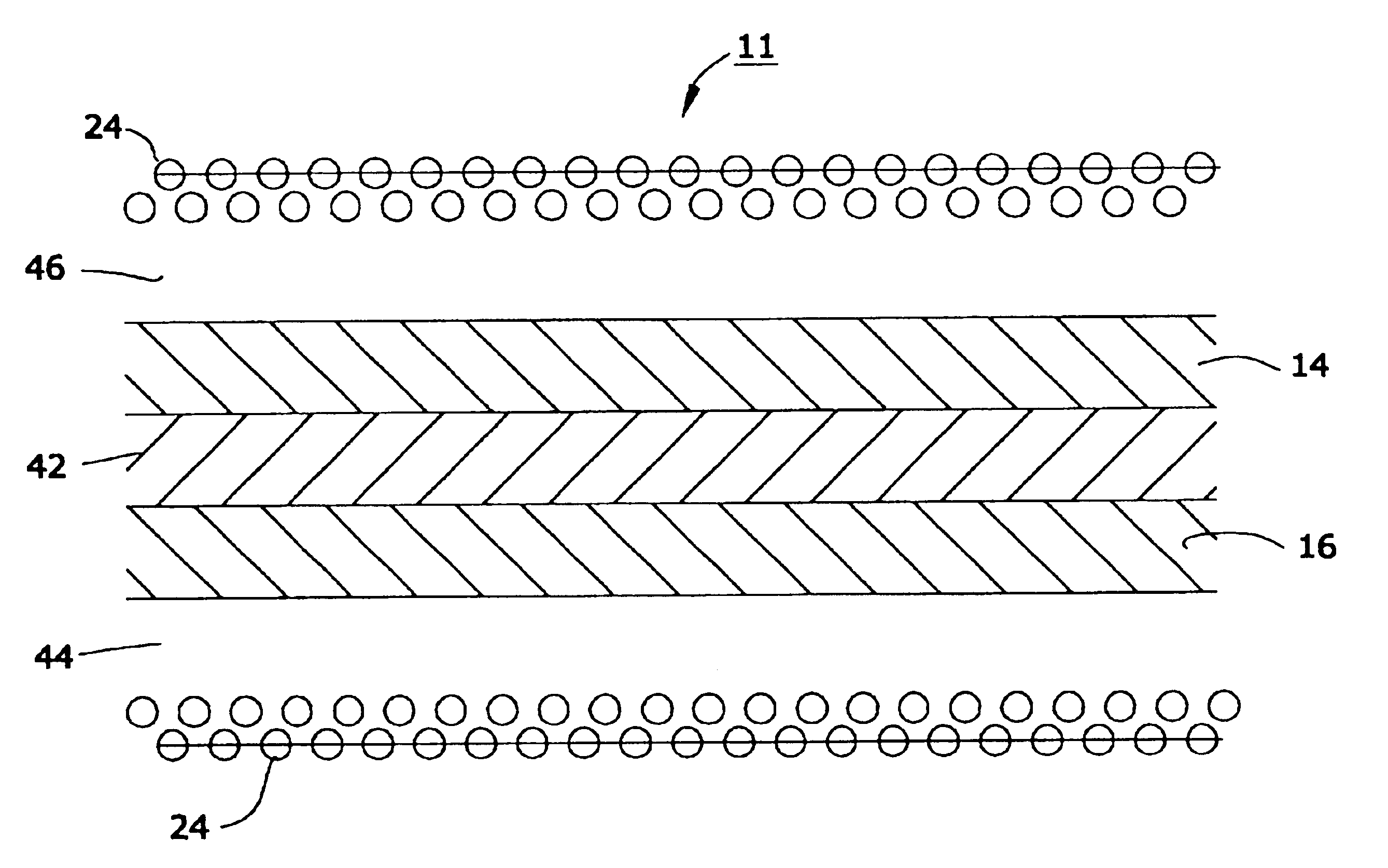

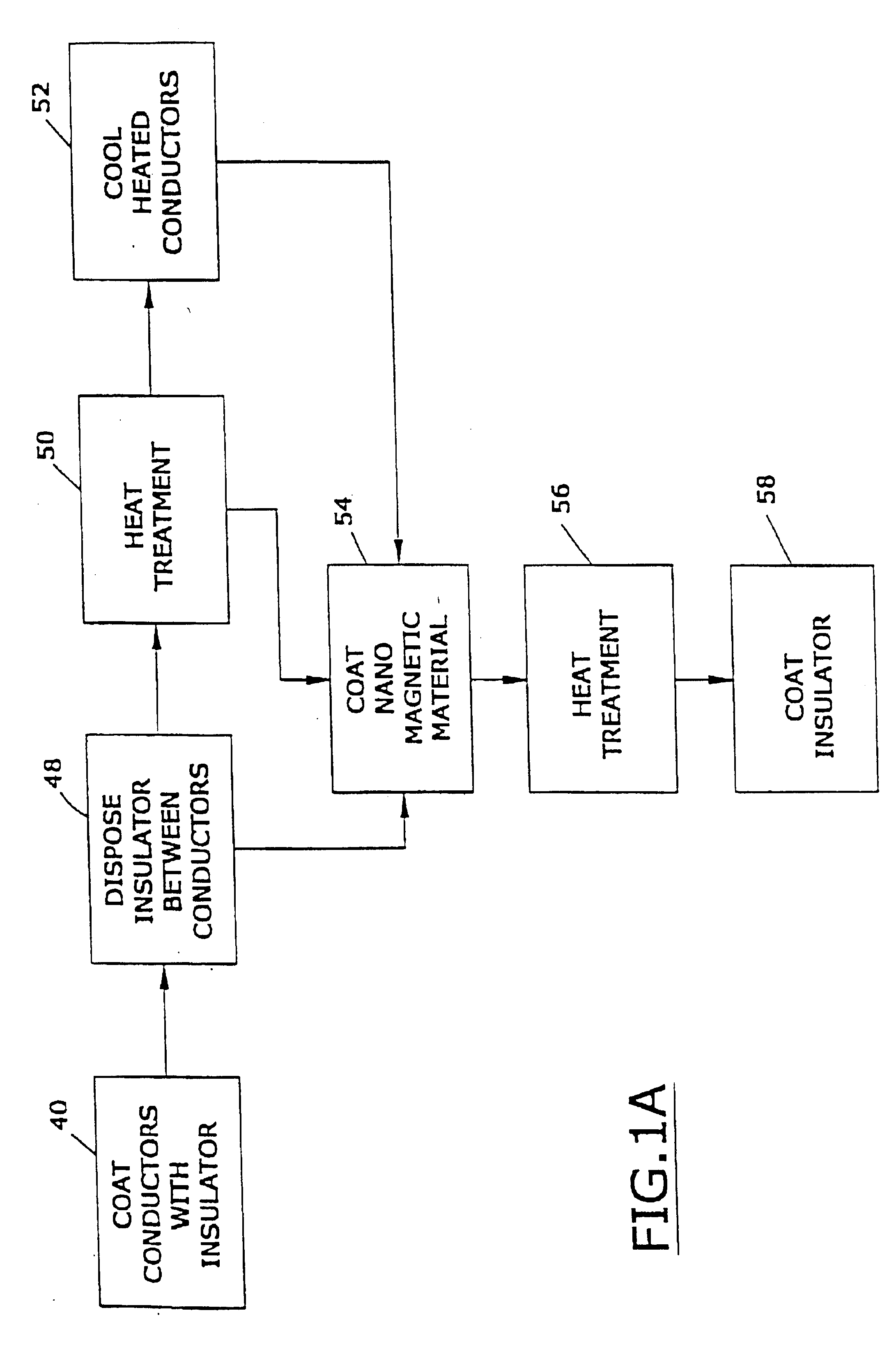

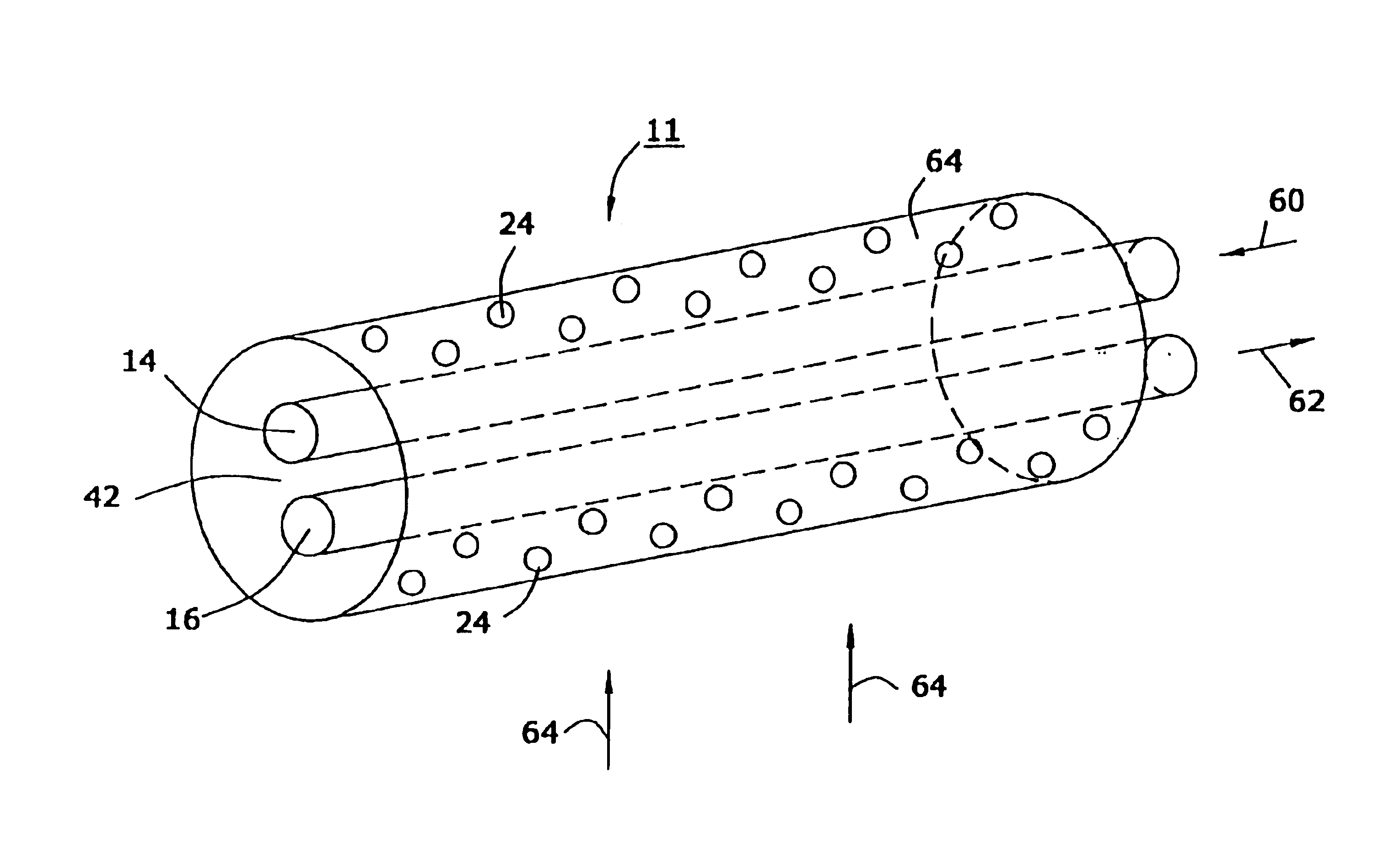

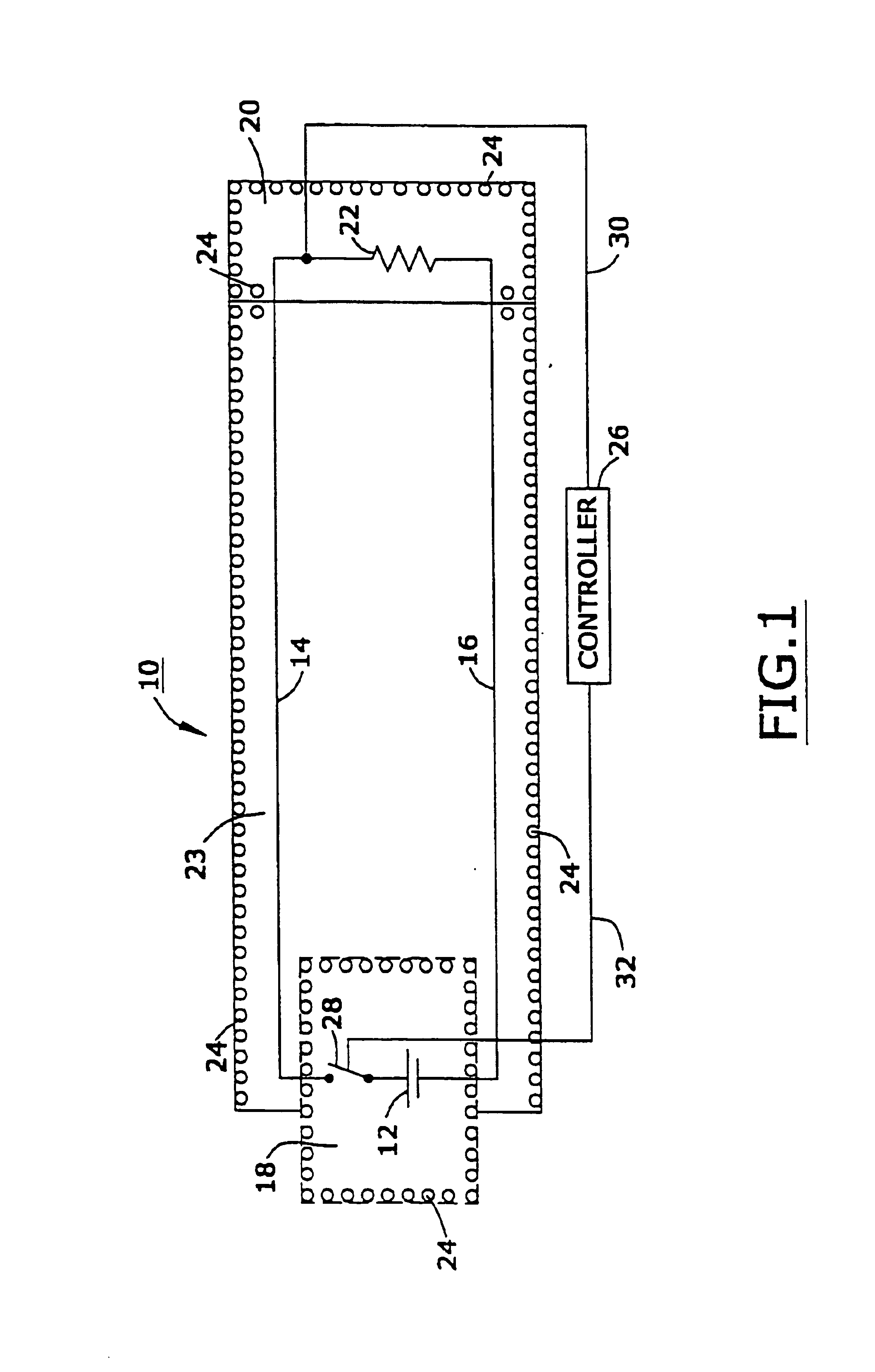

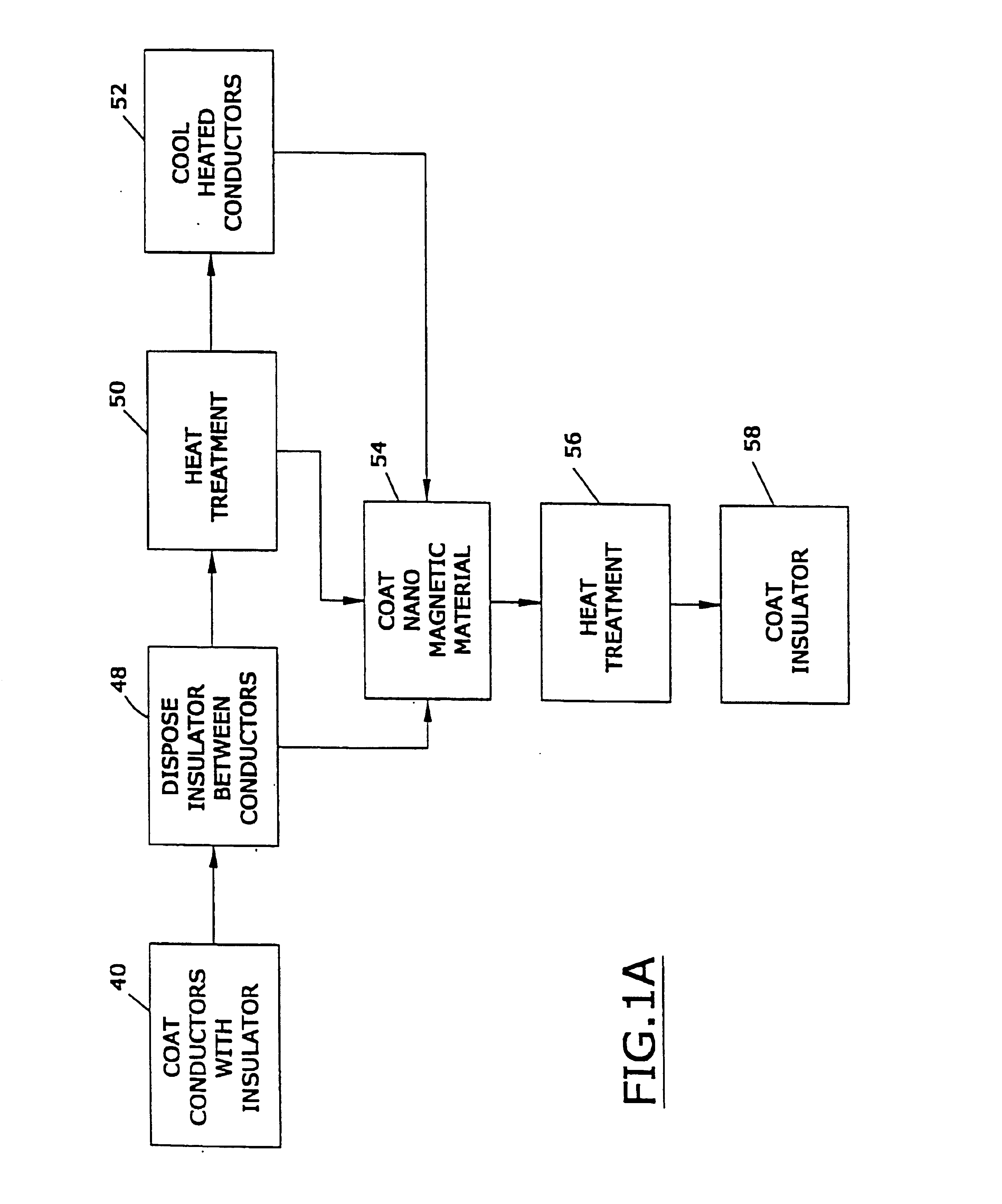

A magnetically shielded conductor assembly with a conductor device and a film of nanomagnetic material located above the conductor device. The conductor device has a resistivity of from about 1 to about 2,000 micro ohm-centimeters. The film of nanomagnetic material has a thickness of from about 100 nanometers to about 10 micrometers and a magnetic shielding factor of at least about 0.5. The nanomagnetic material has a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5,000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers.

Owner:BIOPHAN TECH

Nanomagnetically shielded substrate

A shielded substrate assembly that contains a magnetic shield with a layer of magnetic shielding material; the magnetic shield has a magnetic shielding factor of at least about 0.5. The magnetic shield contains nanomagnetic material nanomagnetic material with a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5,000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers. The nanomagnetic material contains magnetic material with a coherence length of from about 0.1 to about 100 nanometers.

Owner:BIOPHAN TECH

Magnetically shielded assembly

A shielded assembly containing a substrate and a shield. The shield contains both nanomagnetic material and a material with an electrical resistivity of from about 1 microohm-centimeter to about 1×1025 microohm centimeters. The nanomagnetic material has a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers.

Owner:BIOPHAN TECH

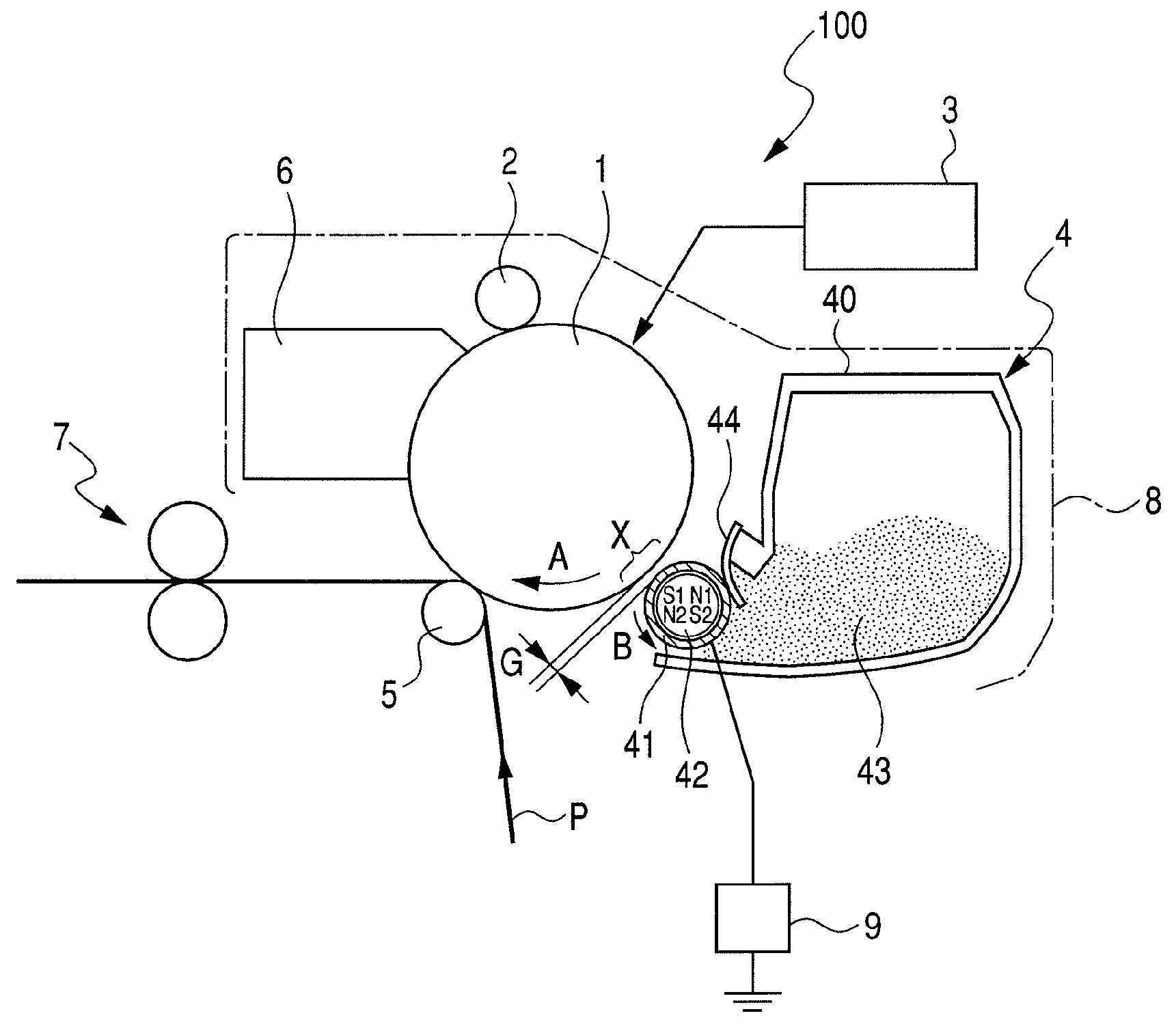

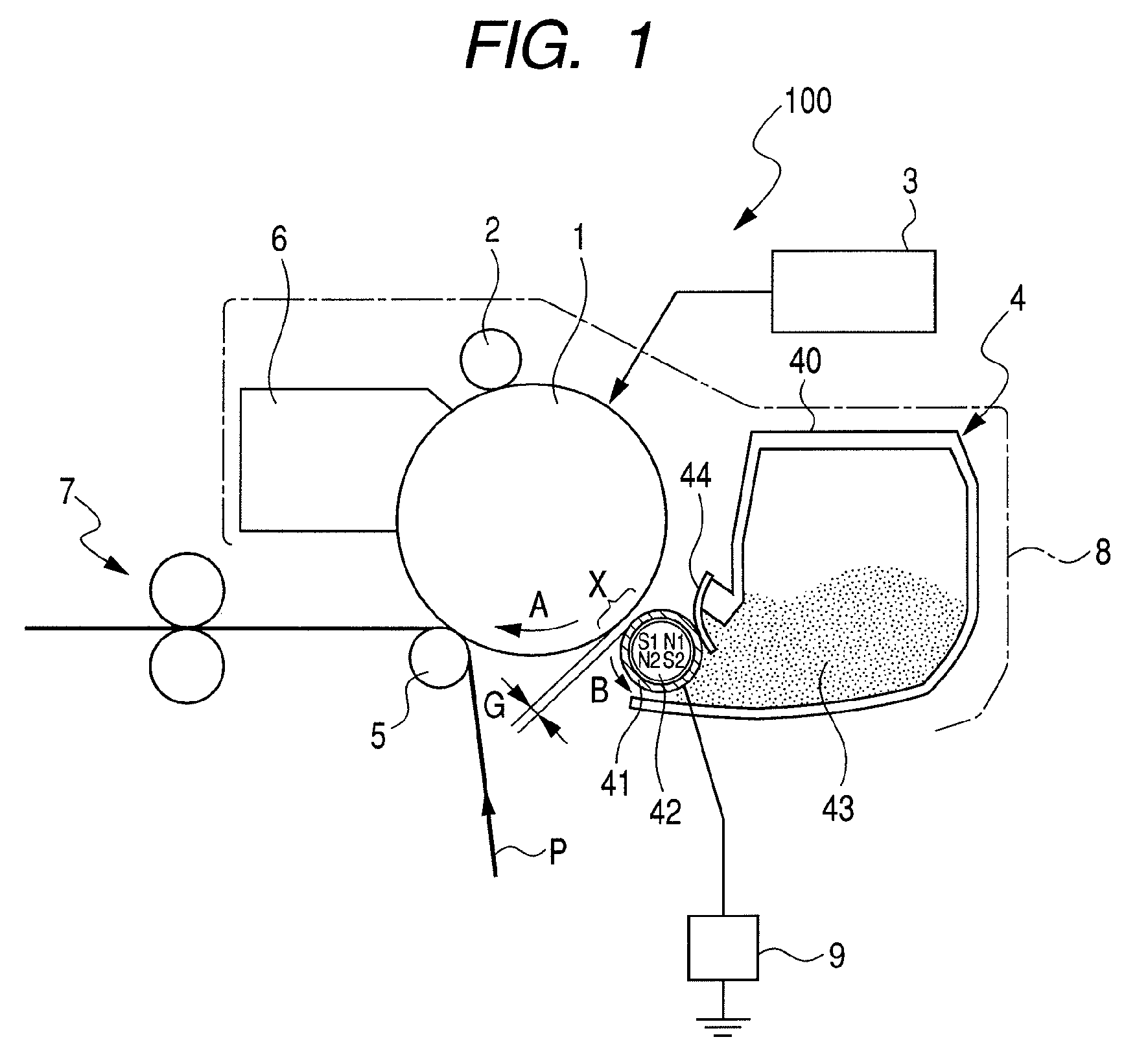

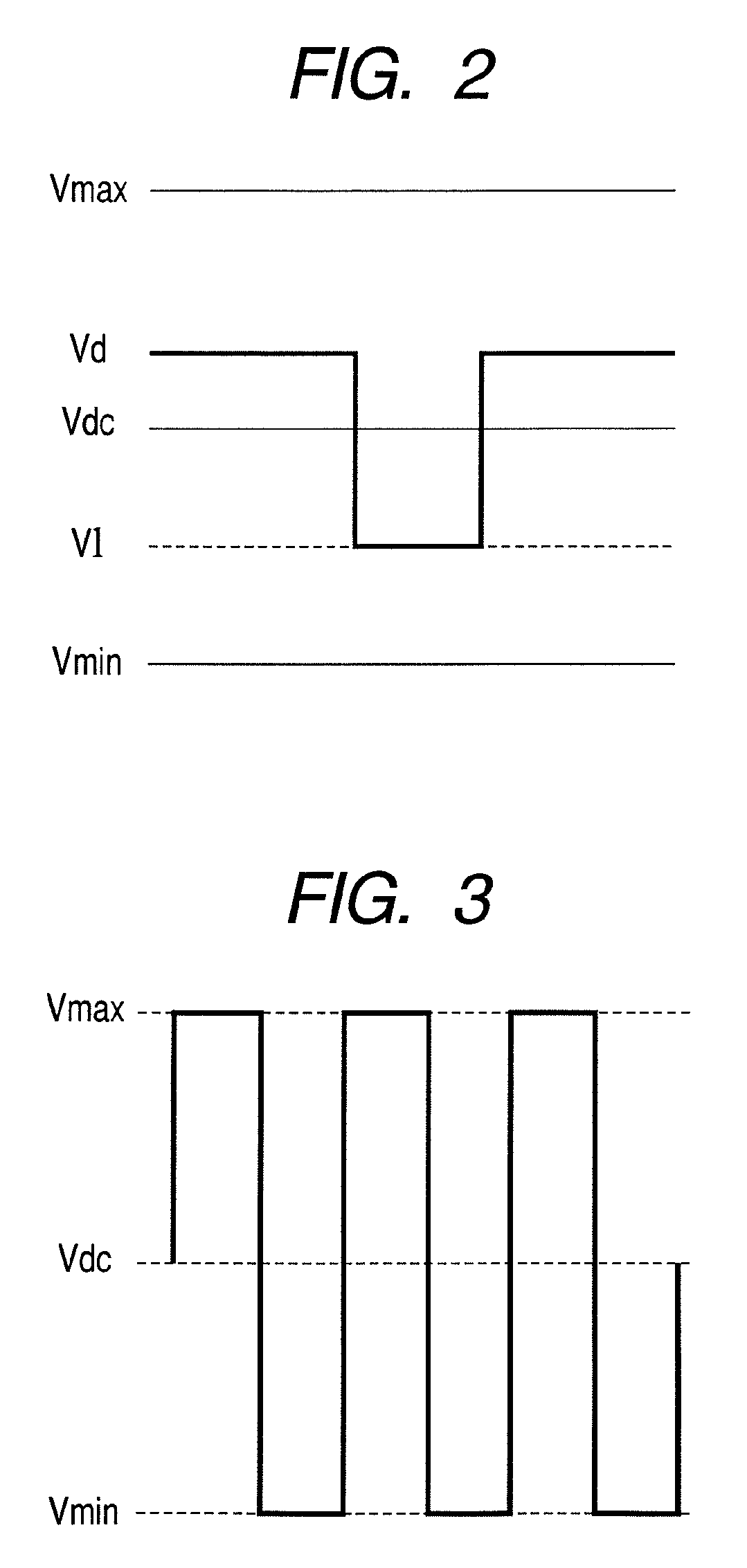

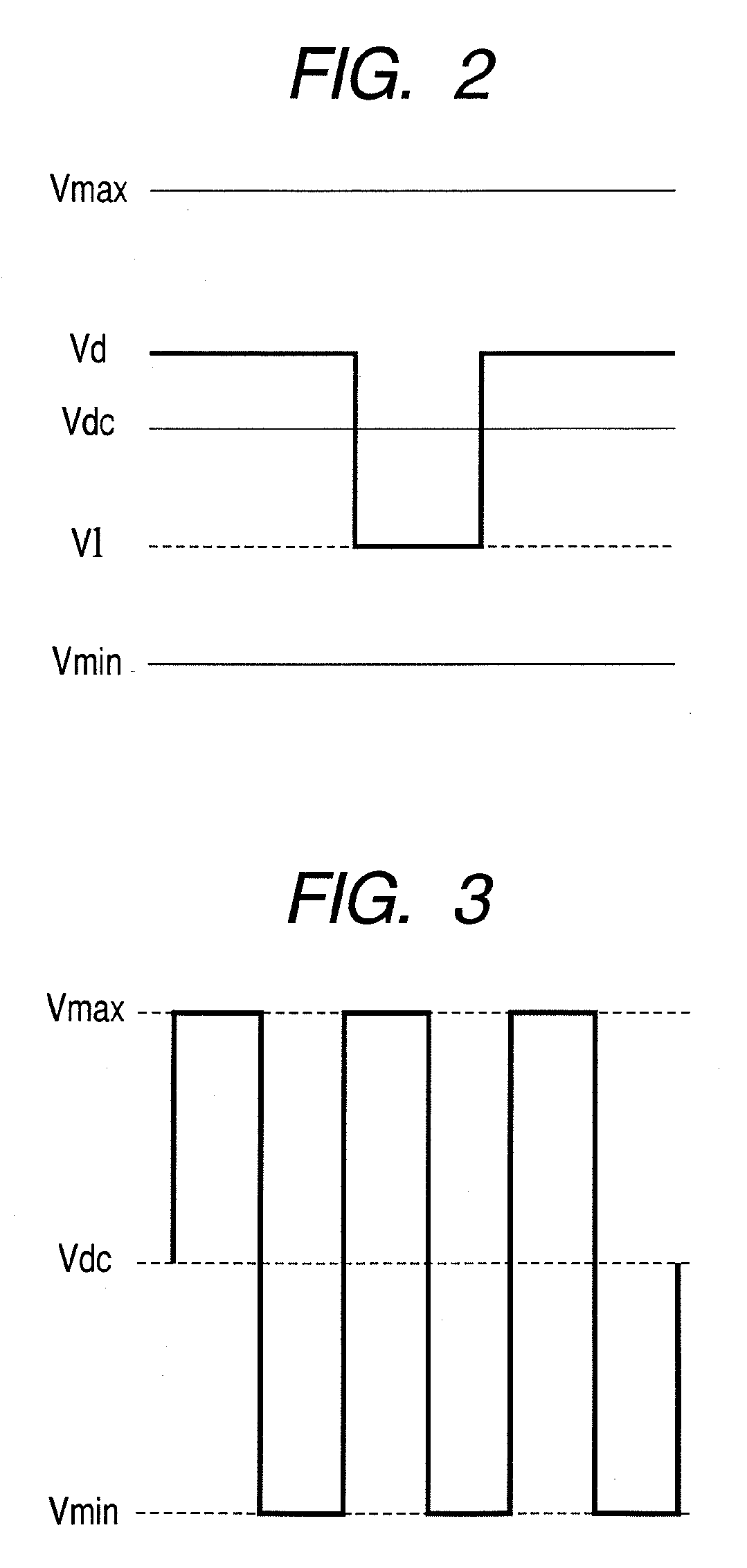

Developing method and developing assembly

A developing method is provided in which a developer is carried on a developer carrying member, a thin layer of the developer is formed thereon and a latent image on a latent image bearing member is developed with a developer. The developer is composed of magnetic toner particles containing a binder resin and a magnetic powder. The magnetic powder has a saturation magnetization of 67.0 Am2 / kg to 75.0 Am2 / kg in a magnetic field of 79.6 kA / m (1,000 oersteds) and has a residual magnetization of 4.5 Am2 / kg or less. In the surface profile of the conductive resin coat layer of the developer carrying member, the relationship 1.00≦S / A≦1.65 is satisfied where S is a surface area of regions zoned by an area A of microscopic unevenness regions from which parts exceeding a reference plane by 0.5×r (r: weight average particle diameter (μm) of a toner used) or more have been excluded.

Owner:CANON KK

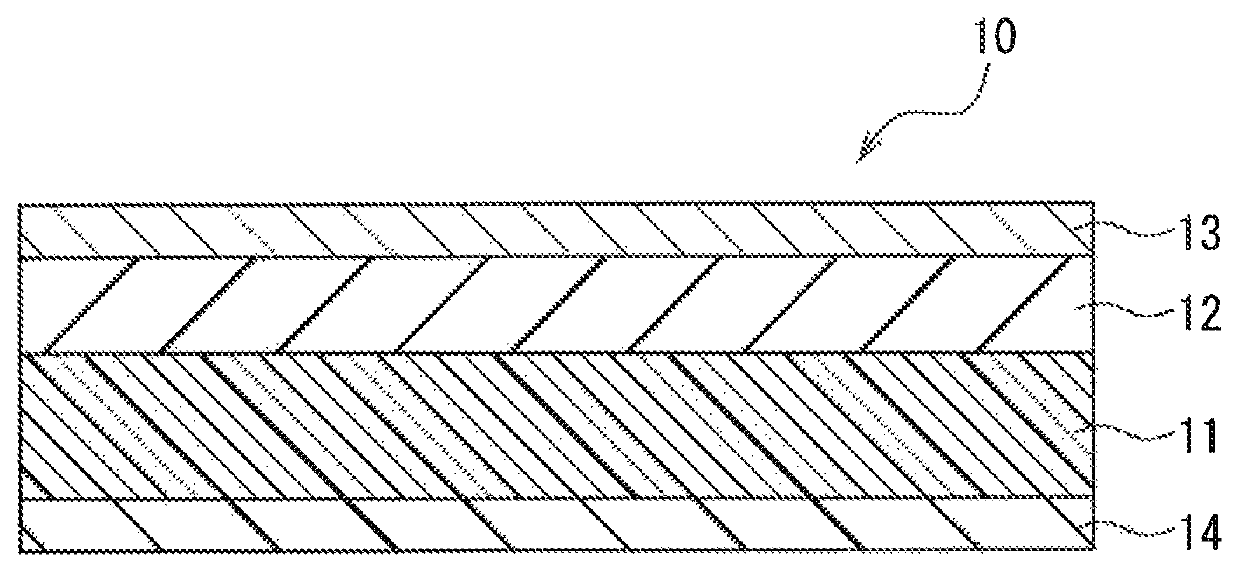

Magnetic cores for inductors and transformers and method of manufacture

InactiveUS20080075975A1Transformers/inductances magnetic coresThick magnetic filmsTransformerEngineering

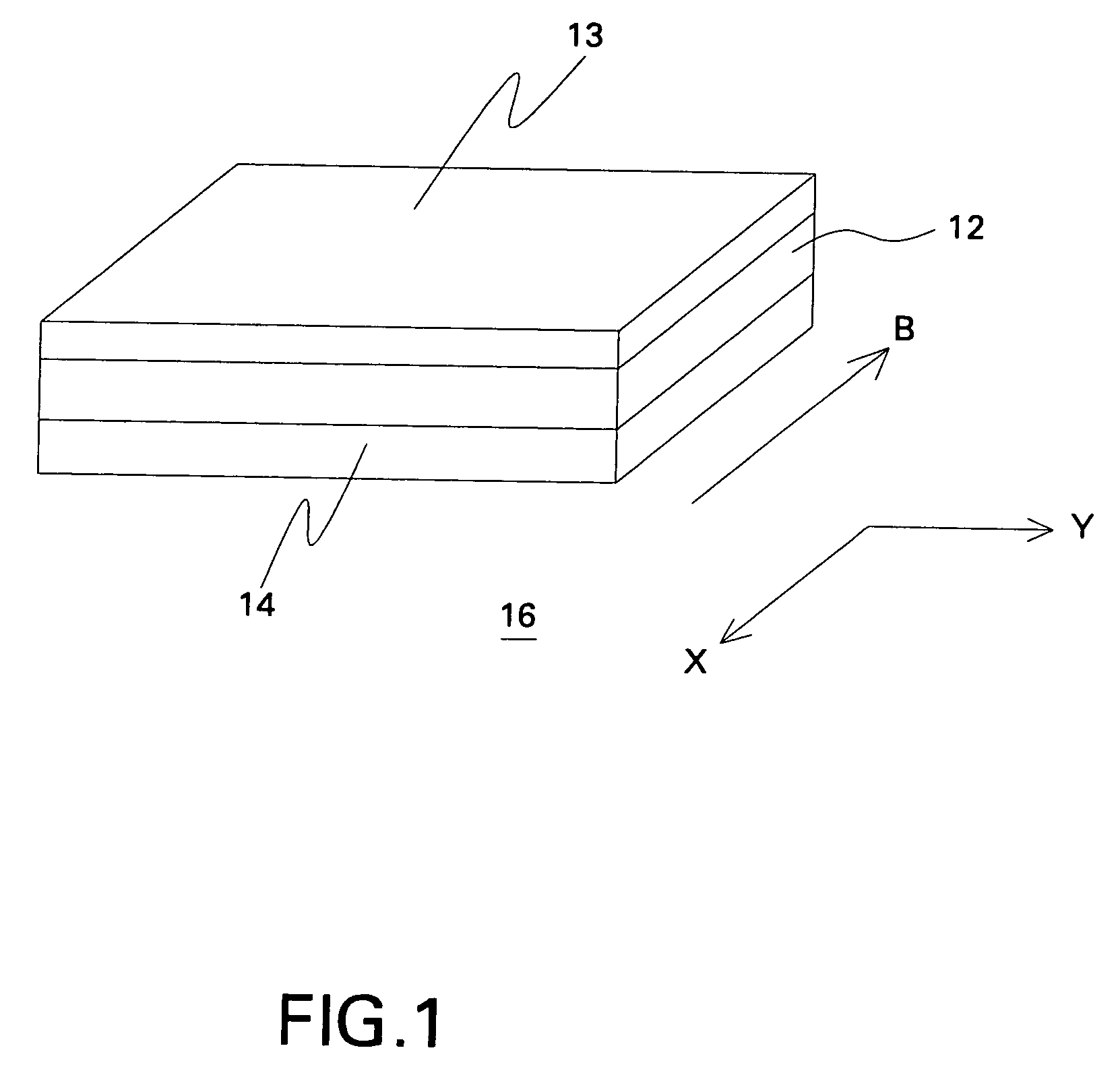

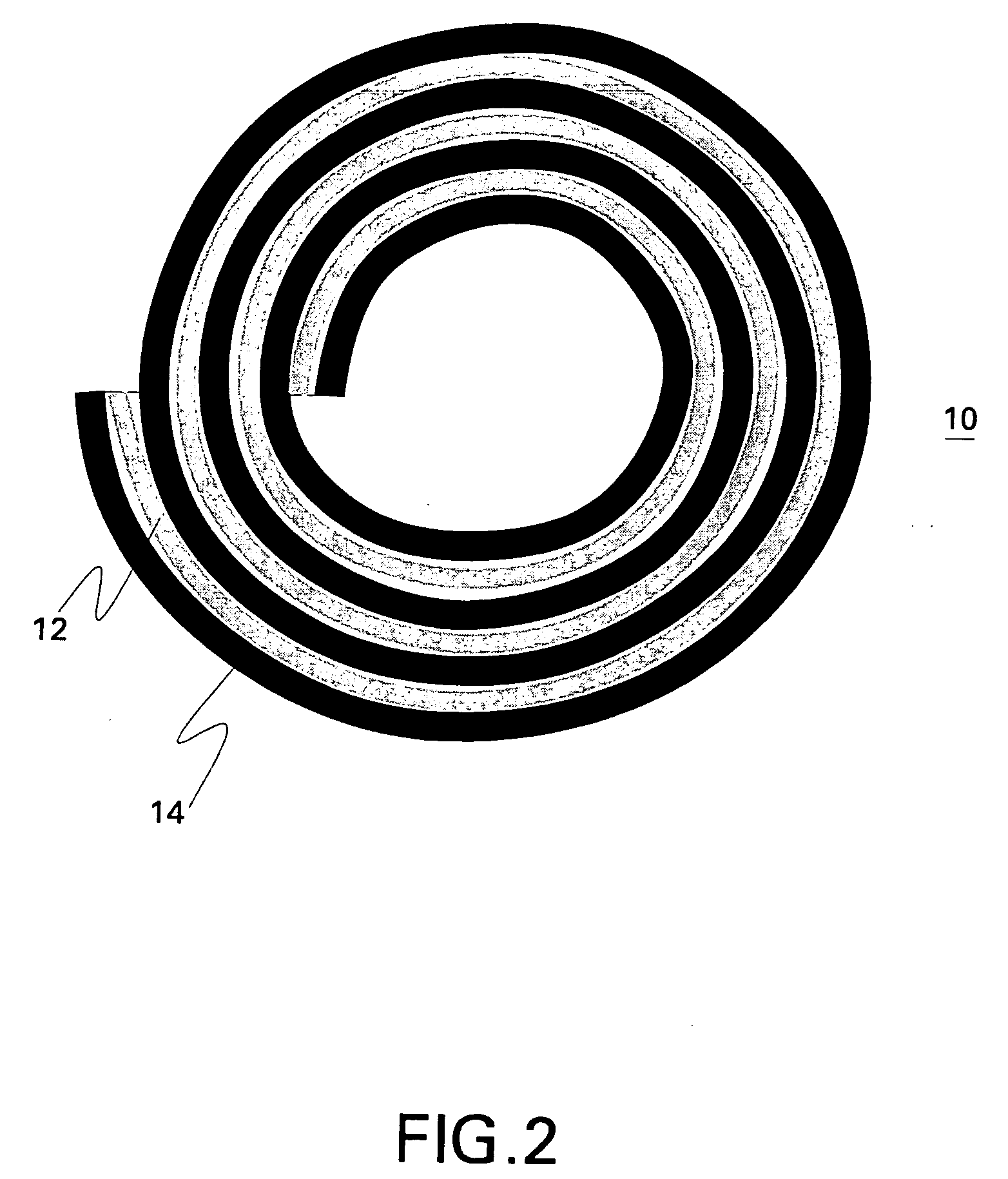

A magnetic core includes a tape comprising a magnetic film disposed on a substrate. The tape is arranged in a winding having a number of turns to form the magnetic core. The magnetic film comprises a magnetic material characterized by a coercivity of less than about ten Oersteds (10 Oe). A transformer includes the magnetic core, and a number of electrically conductive windings, where each of the windings extends around the magnetic core in at least one turn. An inductor includes the magnetic core, and an electrically conductive winding extending around the magnetic core in a number of turns.

Owner:GENERAL ELECTRIC CO

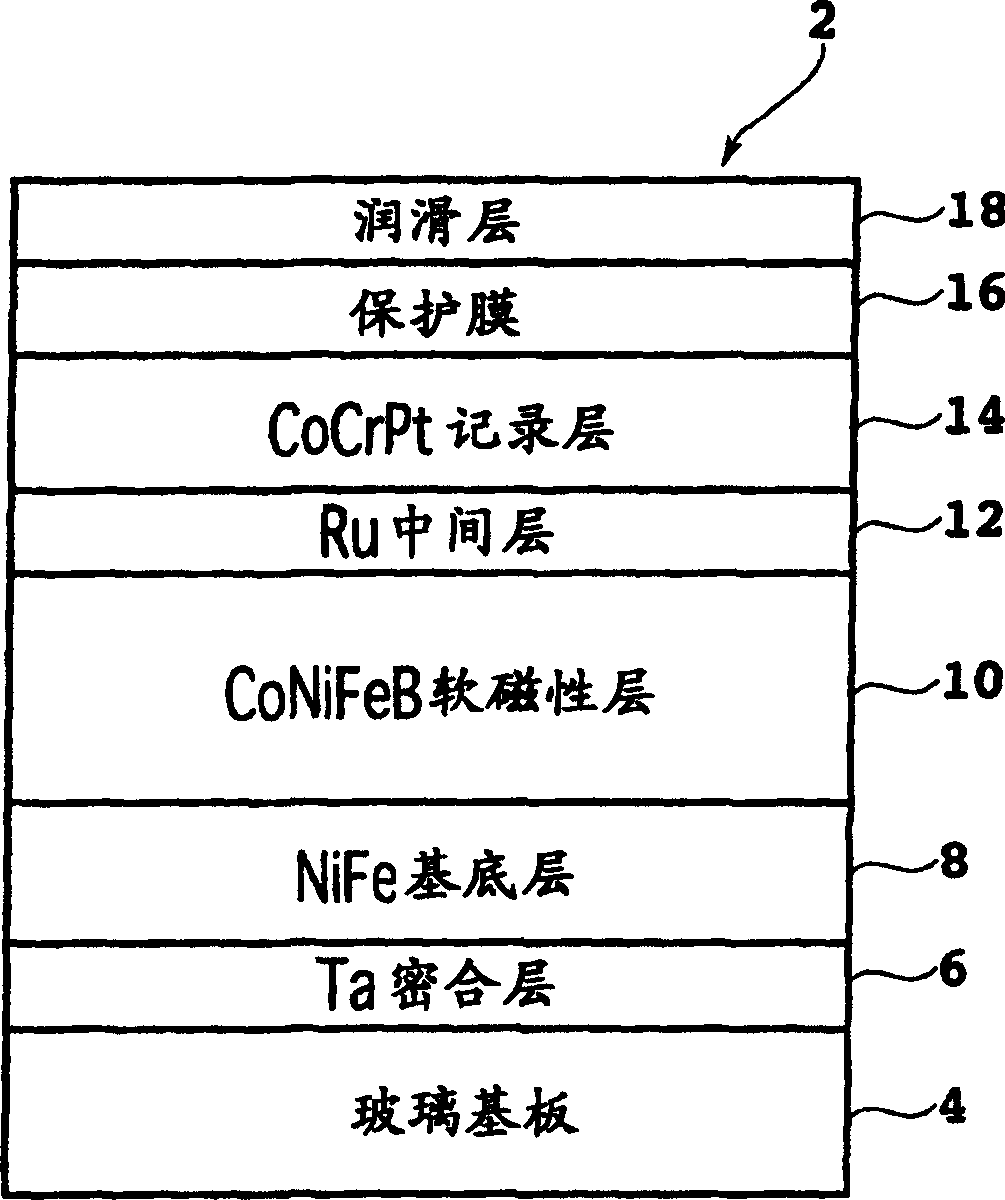

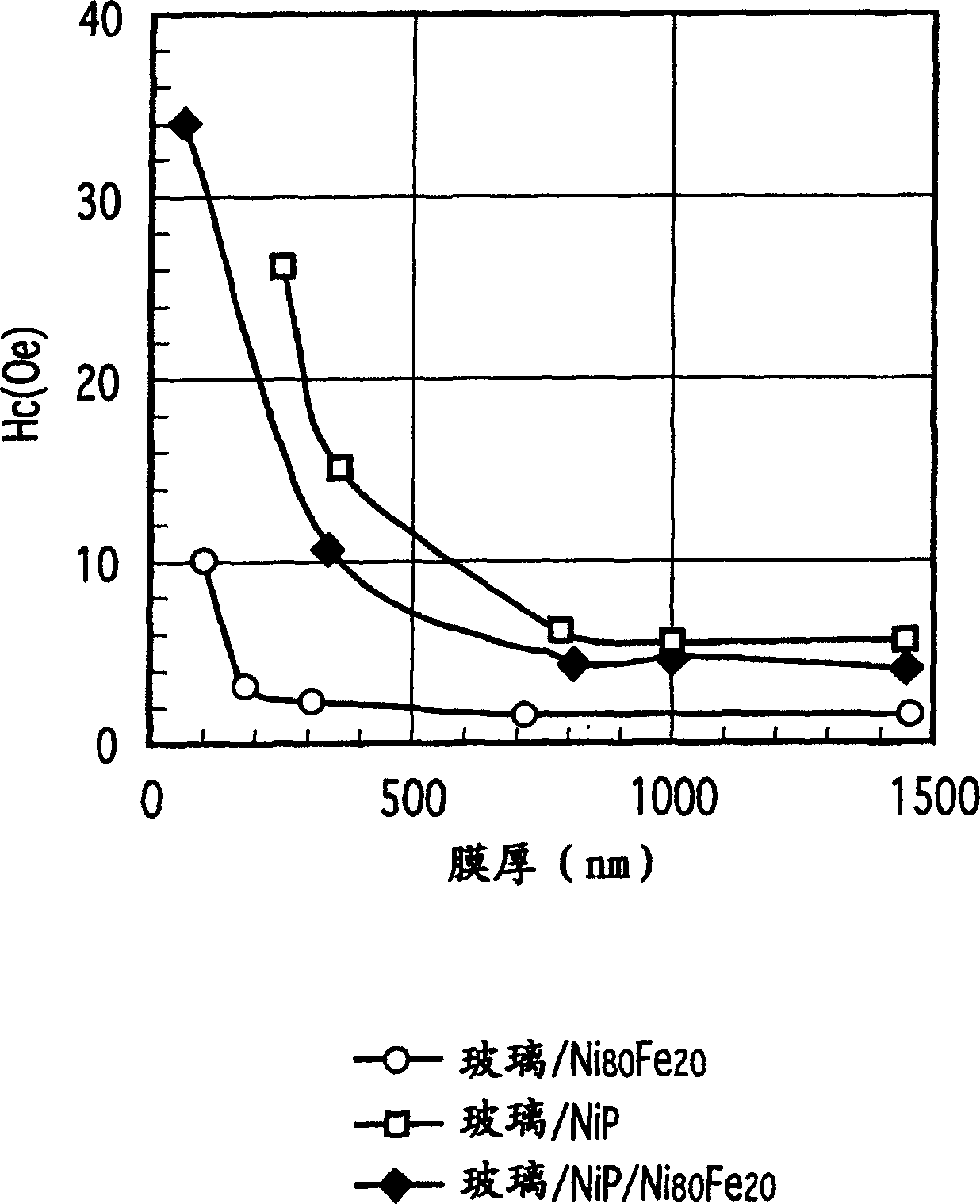

Magnetic recording medium and magnetic recording medium substrate

InactiveUS20050191525A1Occurrence is very lowExcellent spike noise characteristicMagnetic materials for record carriersBase layers for recording layersAlloyUltimate tensile strength

A magnetic recording medium substrate has a diameter of not more than 90 mm and disposed thereon a soft magnetic film plating layer comprising an alloy that comprises at least two metals selected from the group consisting of Co, Ni and Fe. In a concentric circular direction within the substrate plane, a value of the coercive force obtained by a VSM magnetization measurement, is less than 30 oersteds, and a ratio of saturation magnetization to residual magnetization is from 50 / 1 to 5 / 1. Spike noise deterioration of signal reproduction caused by leaking magnetic fields is reduced in the soft magnetic layer.

Owner:SHIN ETSU CHEM IND CO LTD

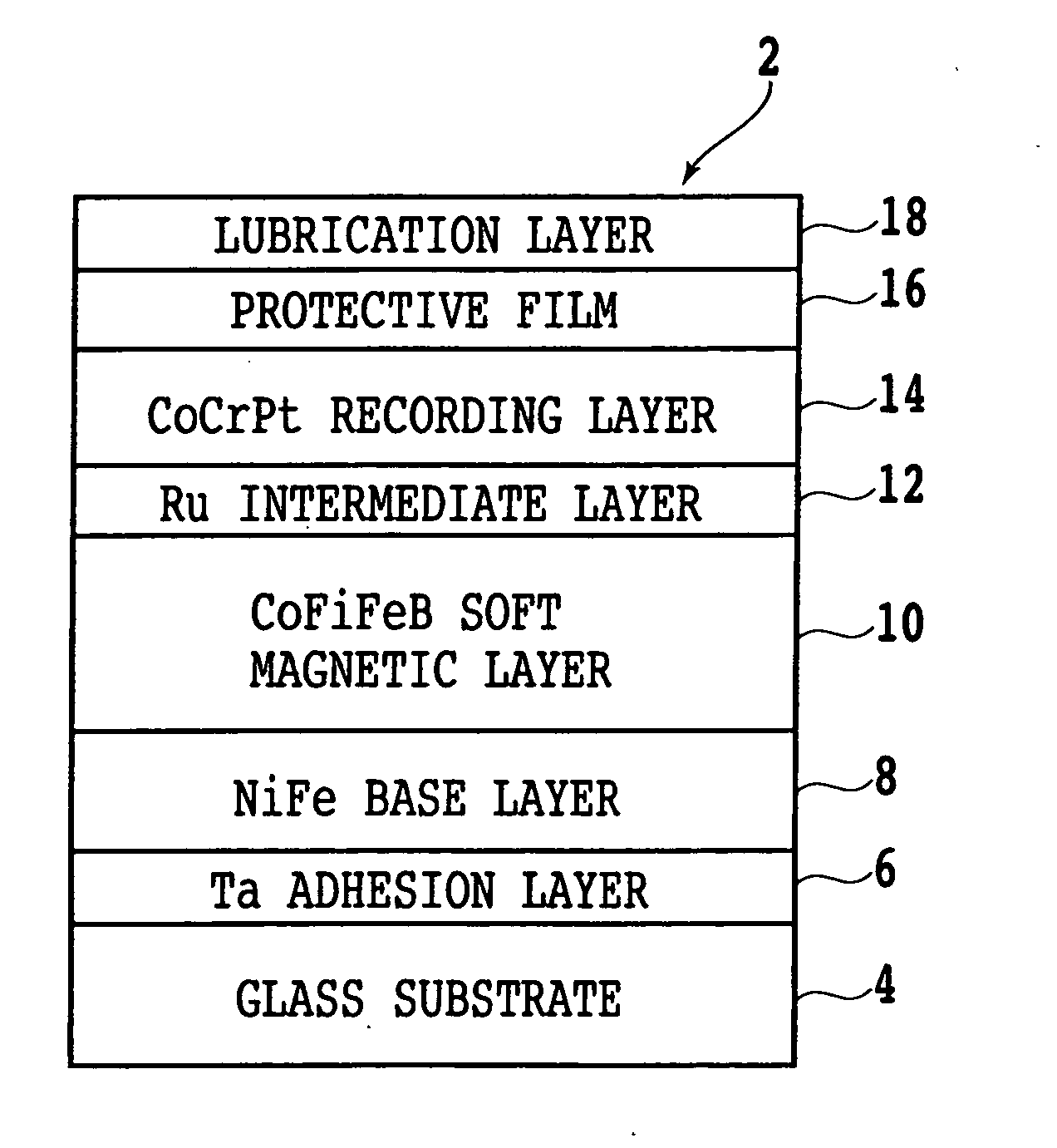

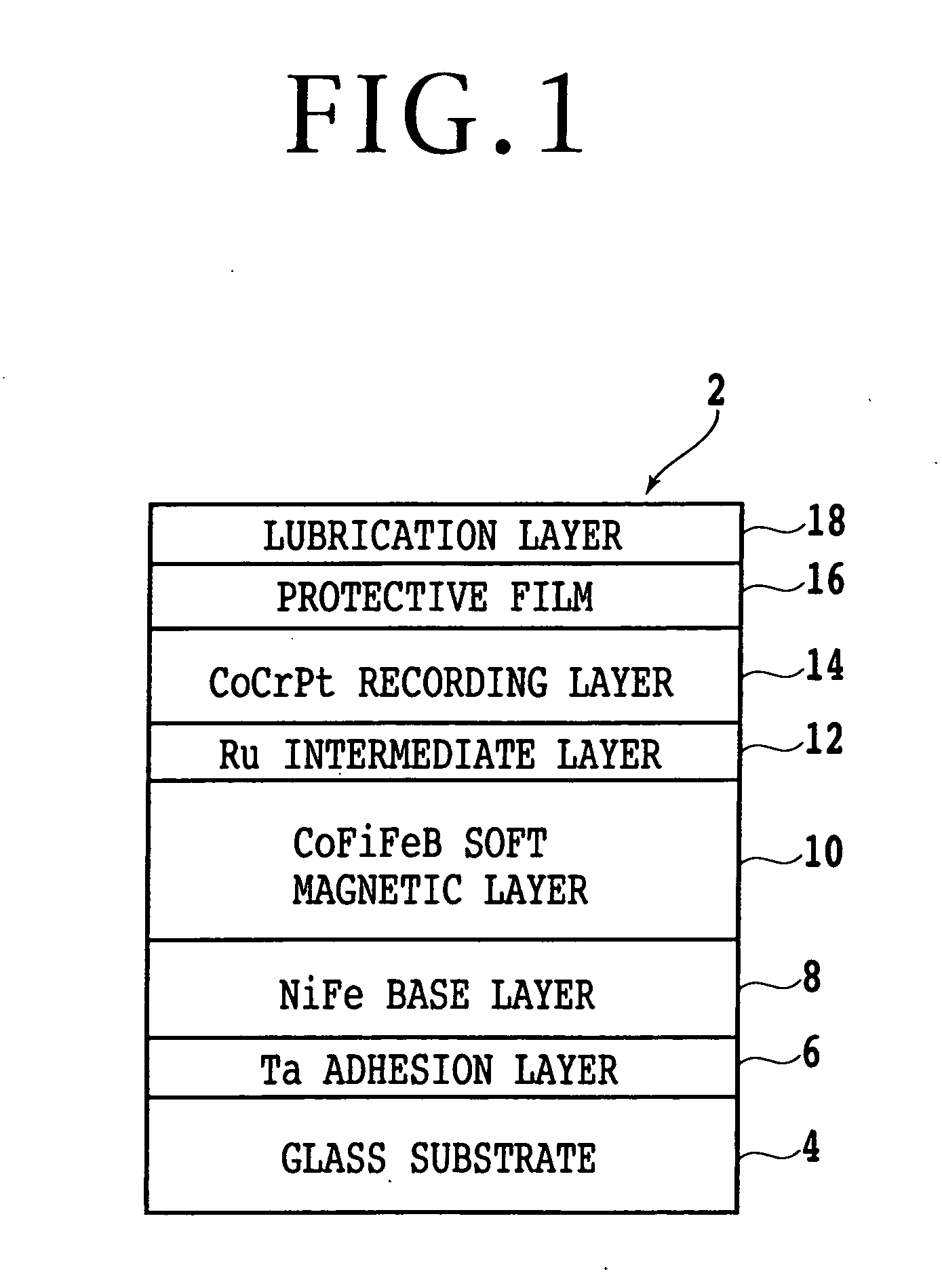

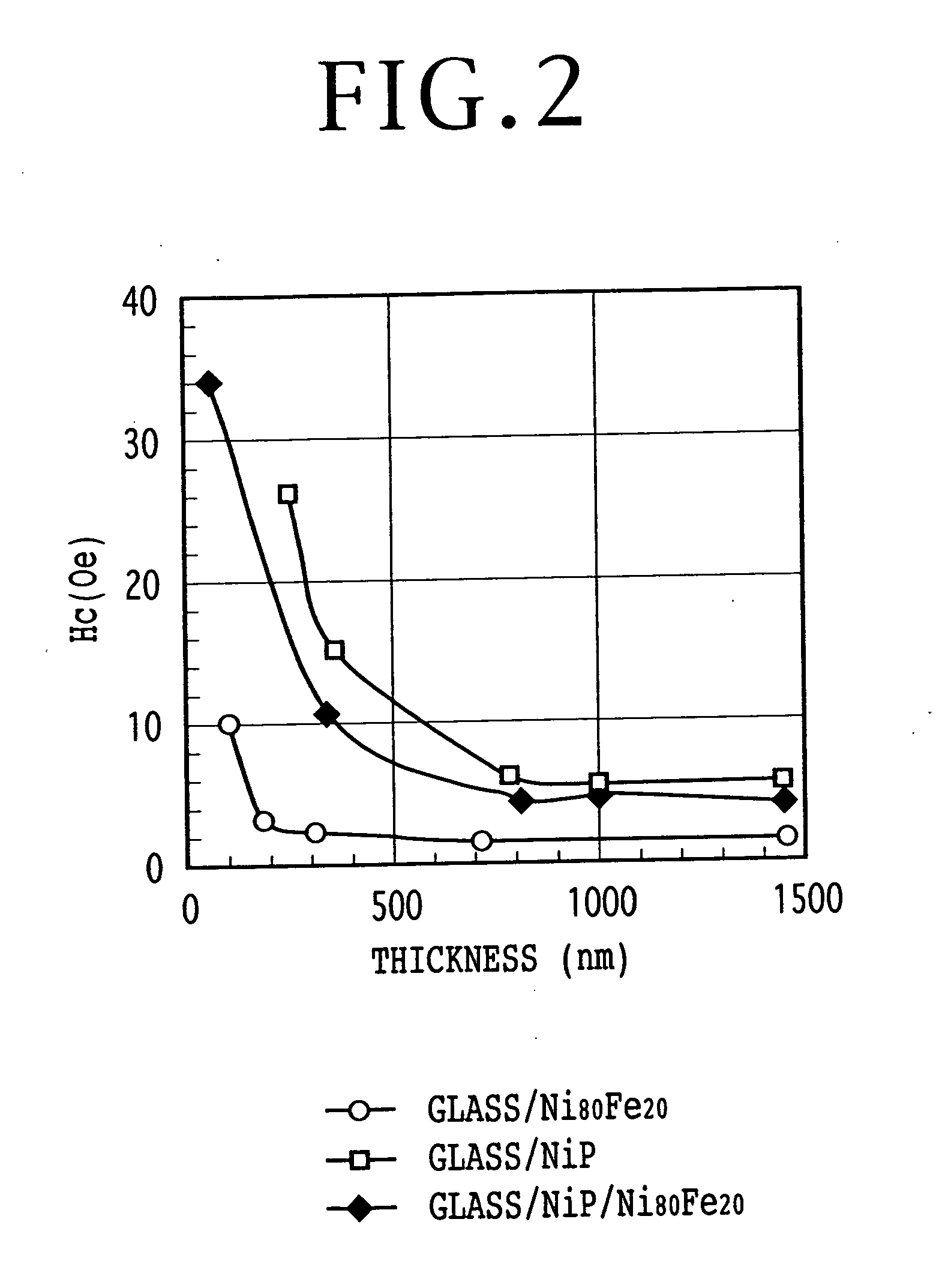

Perpendicular magnetic recording medium

InactiveUS20050123805A1Low costEasy to getBase layers for recording layersRecord information storageMagnetizationAlloy

A perpendicular magnetic recording medium including a substrate, a metal base layer formed on the substrate, a soft magnetic layer formed on the metal base layer by electroless plating and having an axis of easy magnetization in the in-plane direction of the substrate, and a magnetic recording layer formed on the soft magnetic layer and having an axis of easy magnetization in a direction perpendicular to the surface of the substrate. The metal base layer is formed of an alloy containing at least one element selected from the group consisting of Co, Ni, and Fe, and has a coercivity of 3 oersteds (Oe) or less. The soft magnetic layer has a thickness of 100 to 600 nm.

Owner:FUJITSU LTD

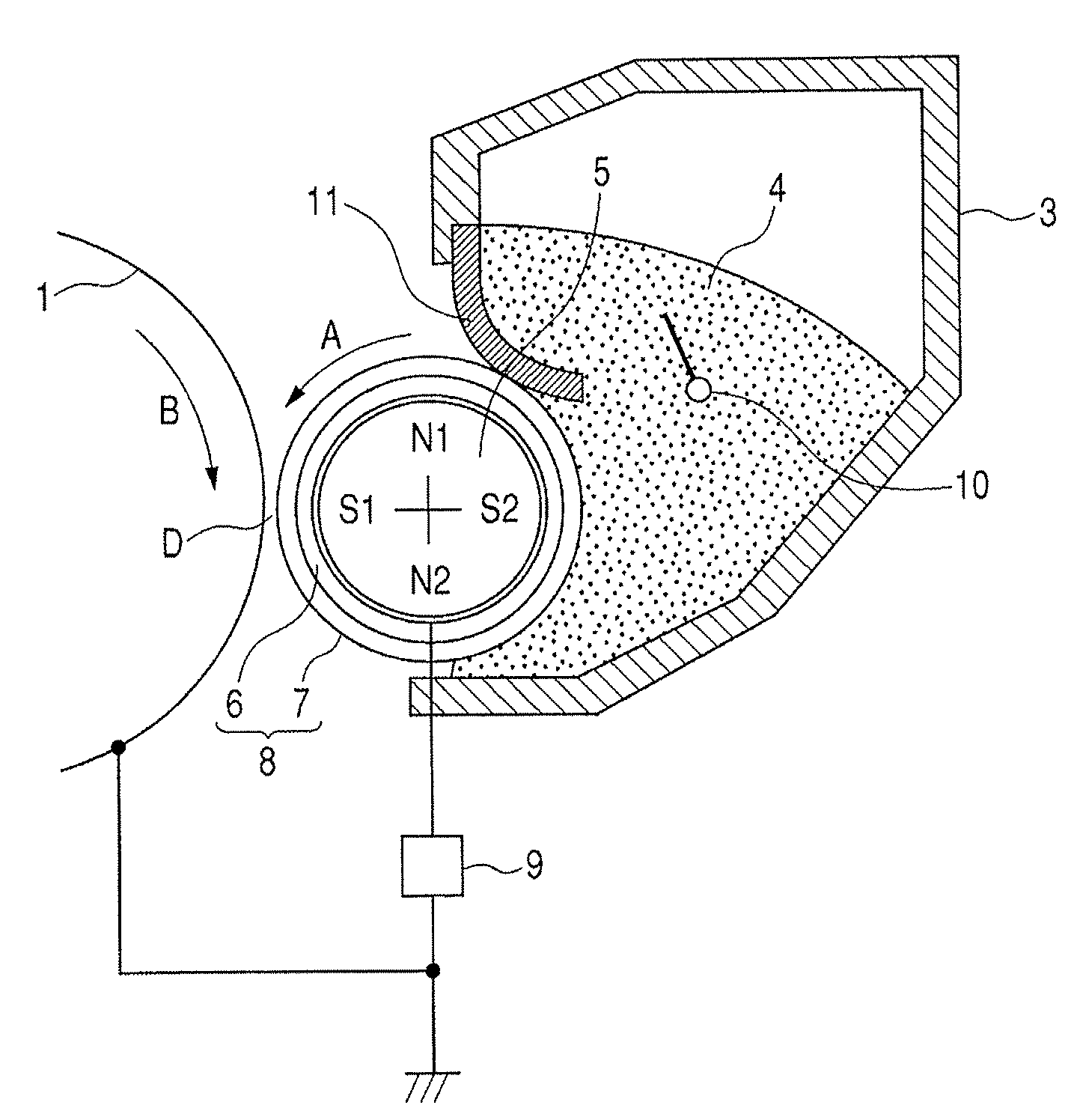

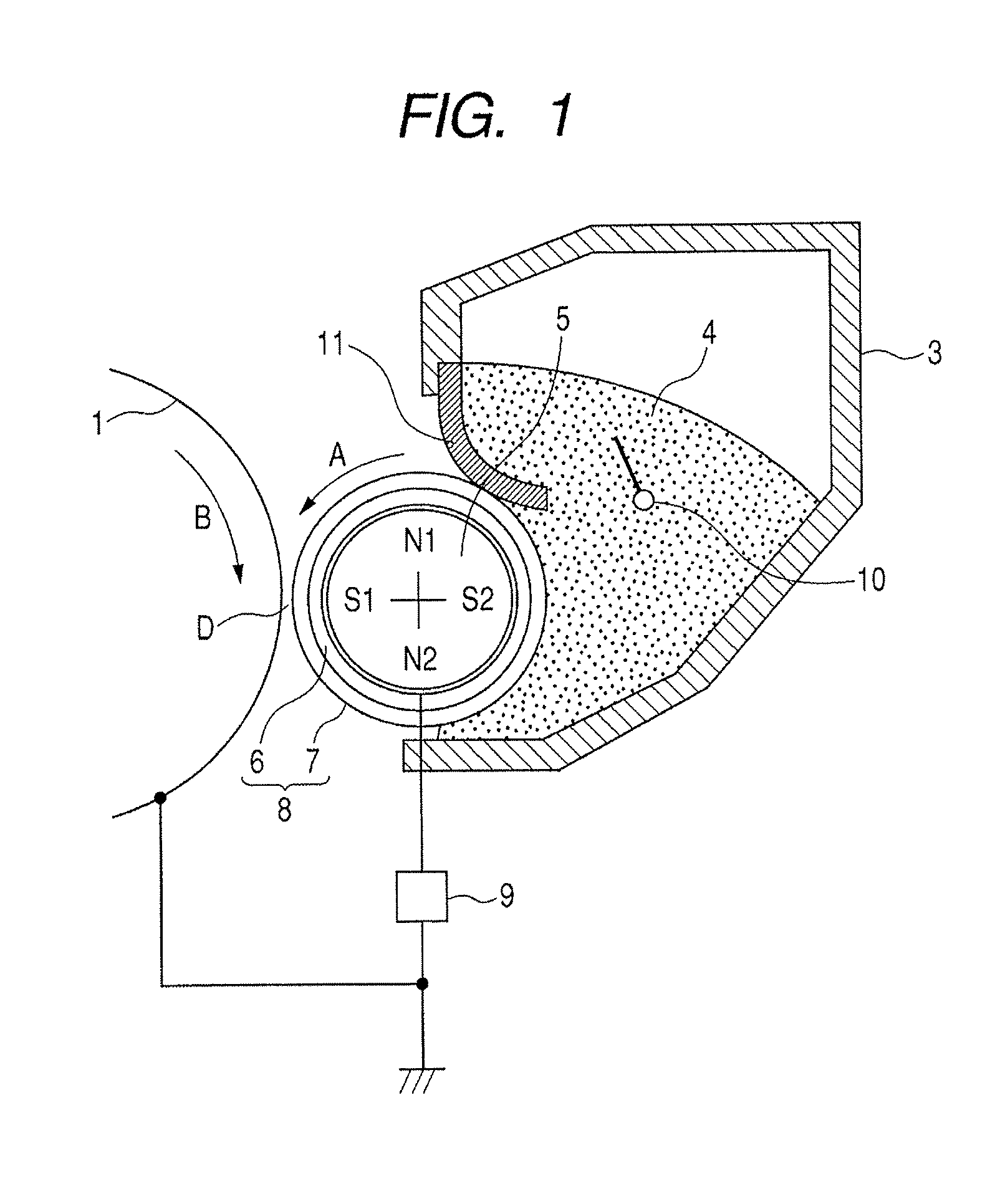

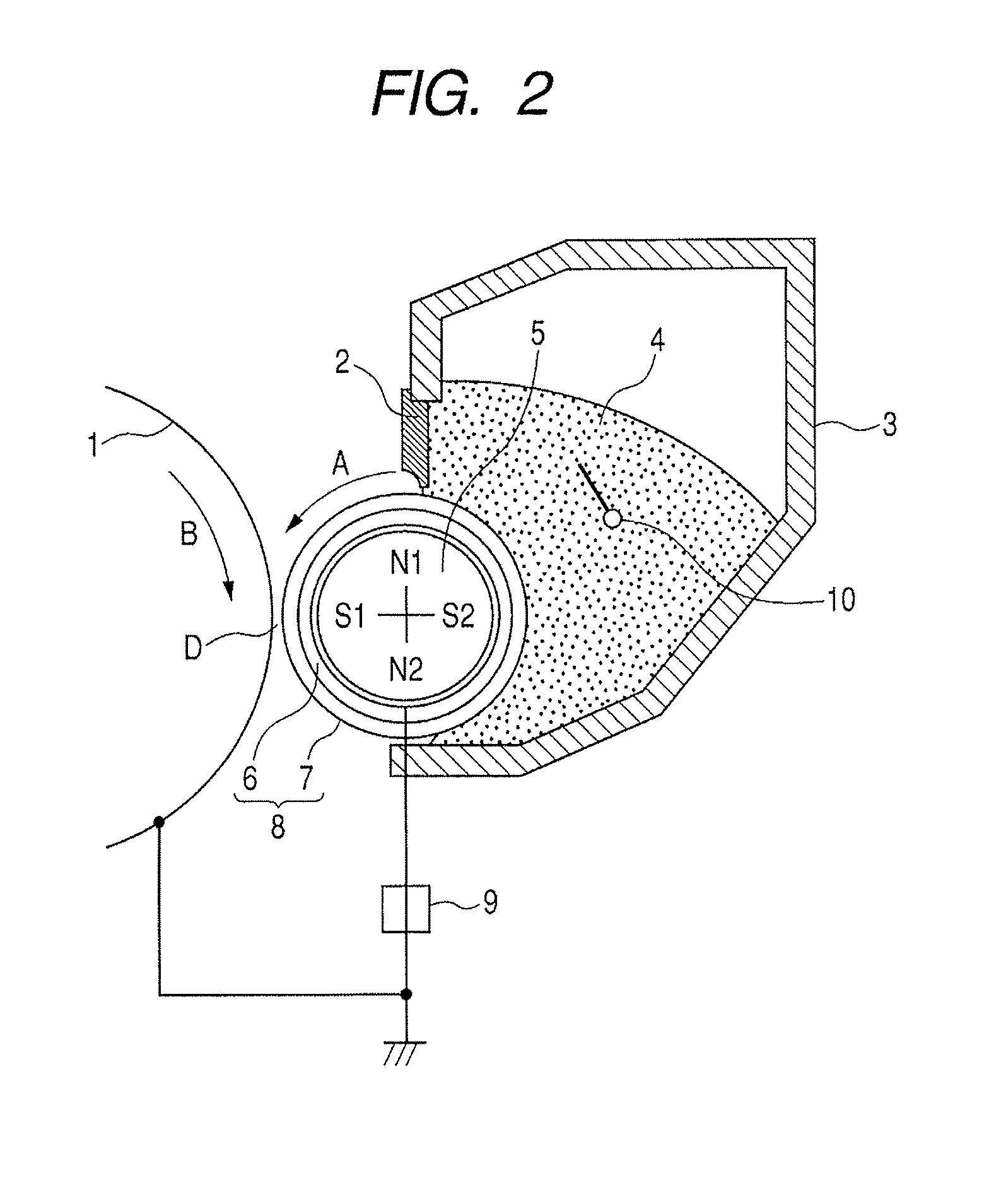

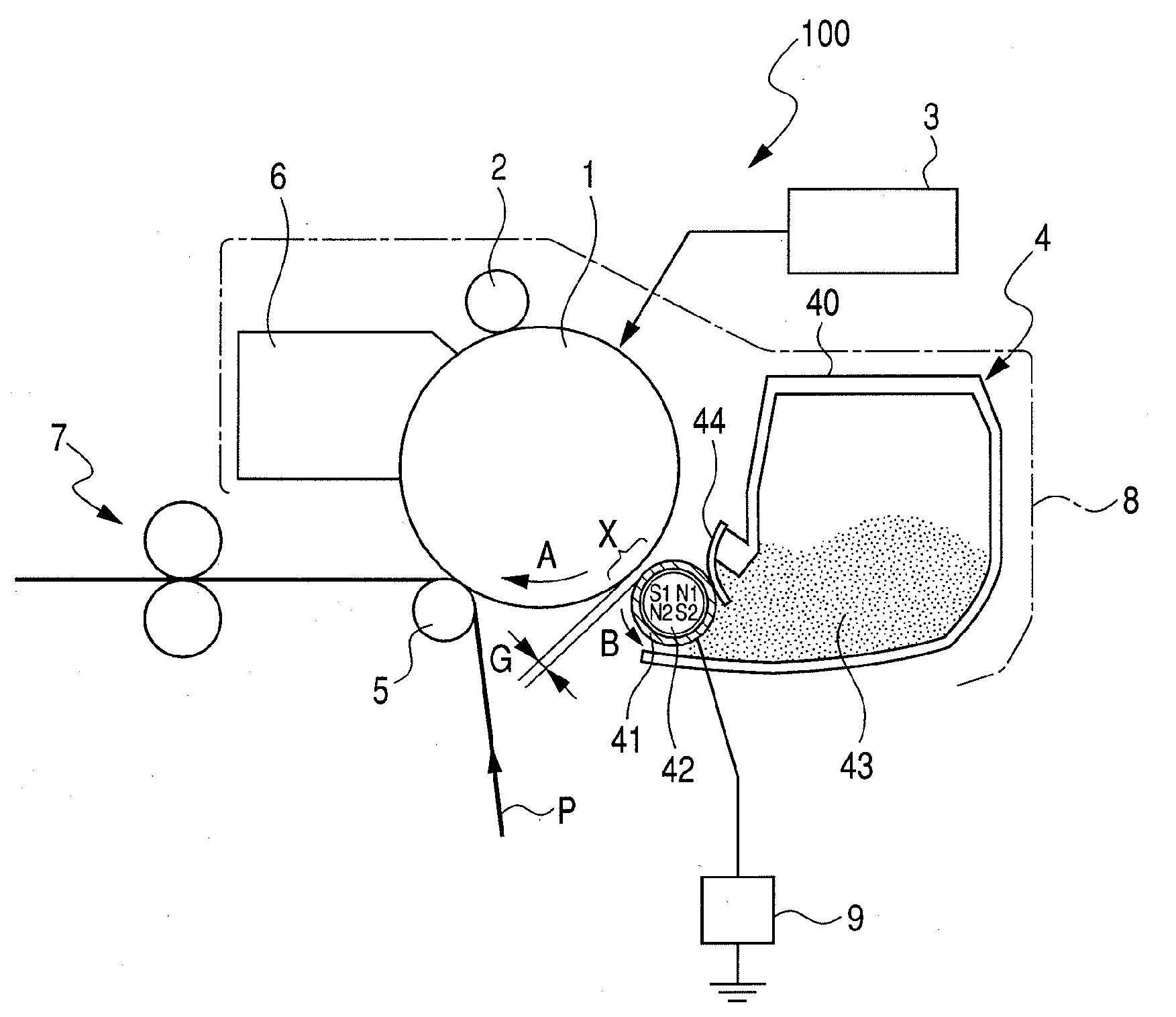

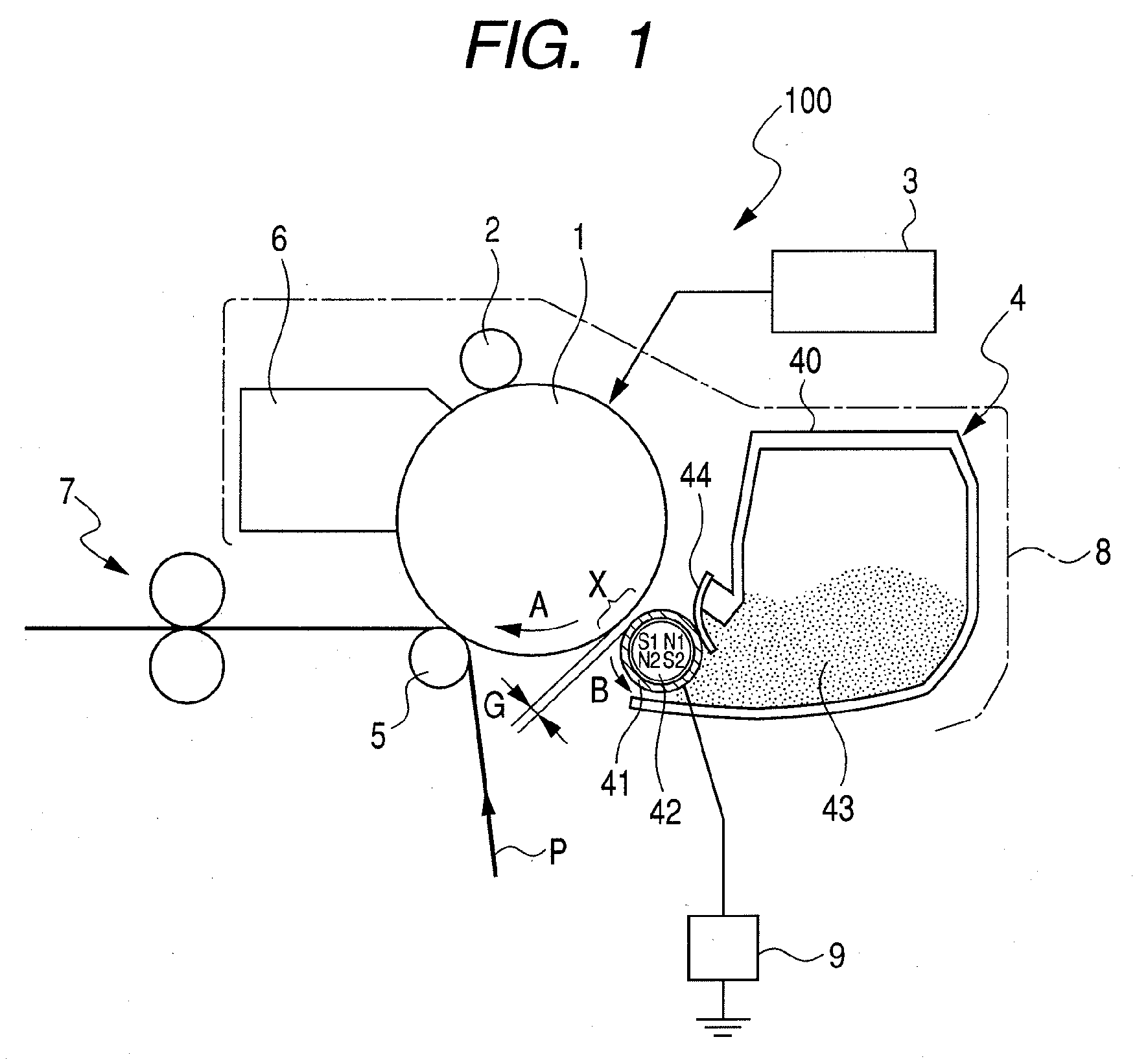

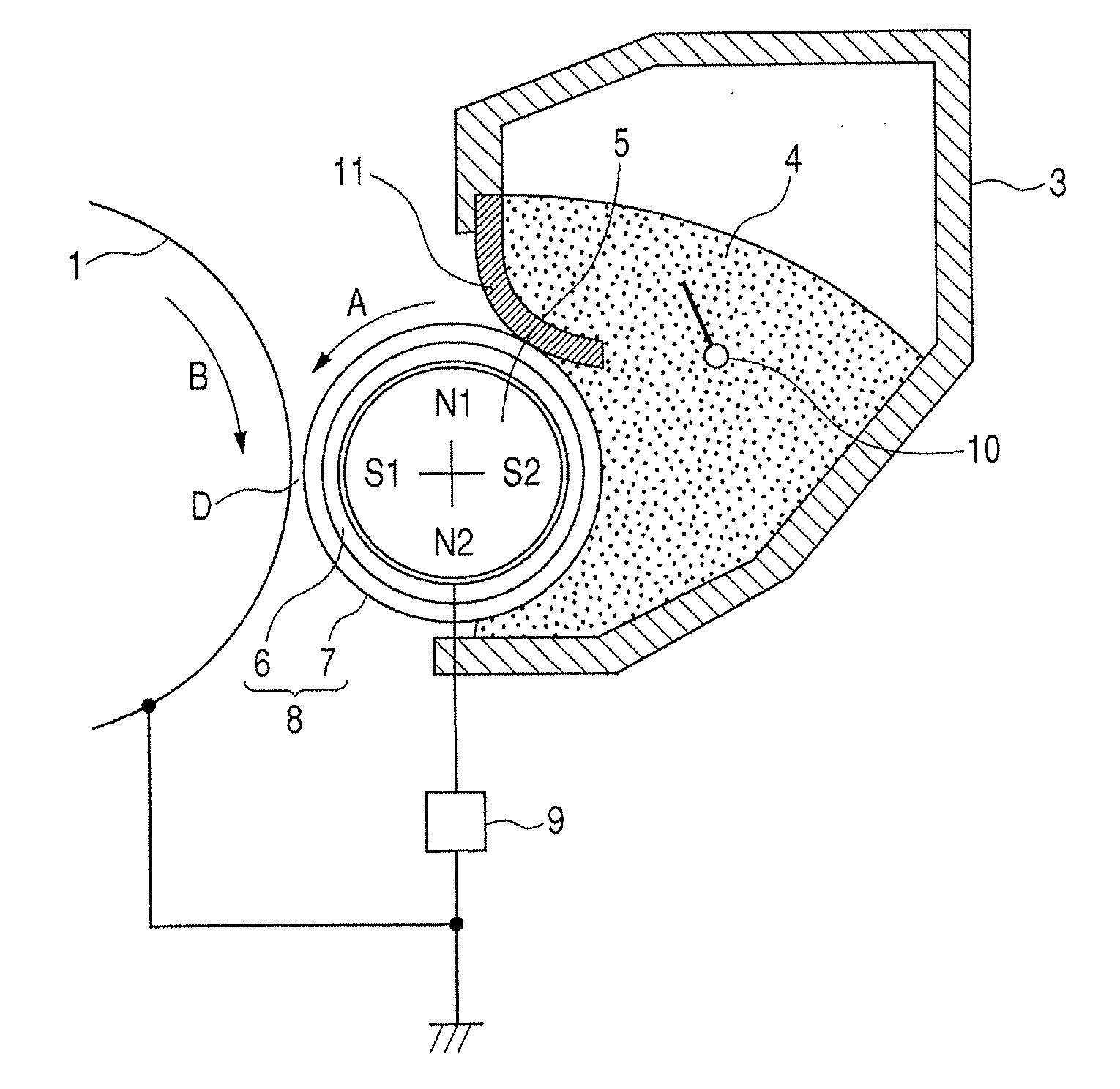

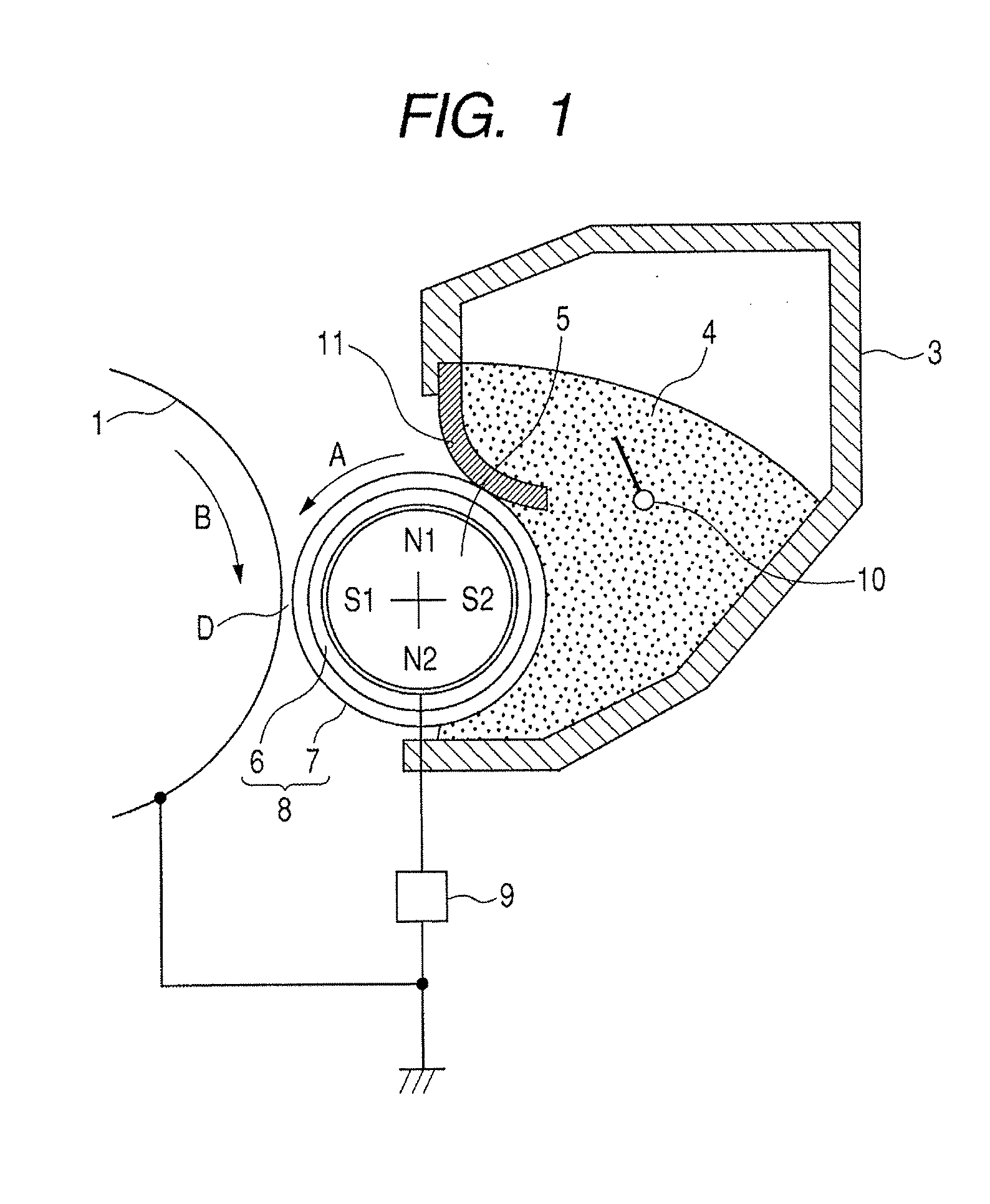

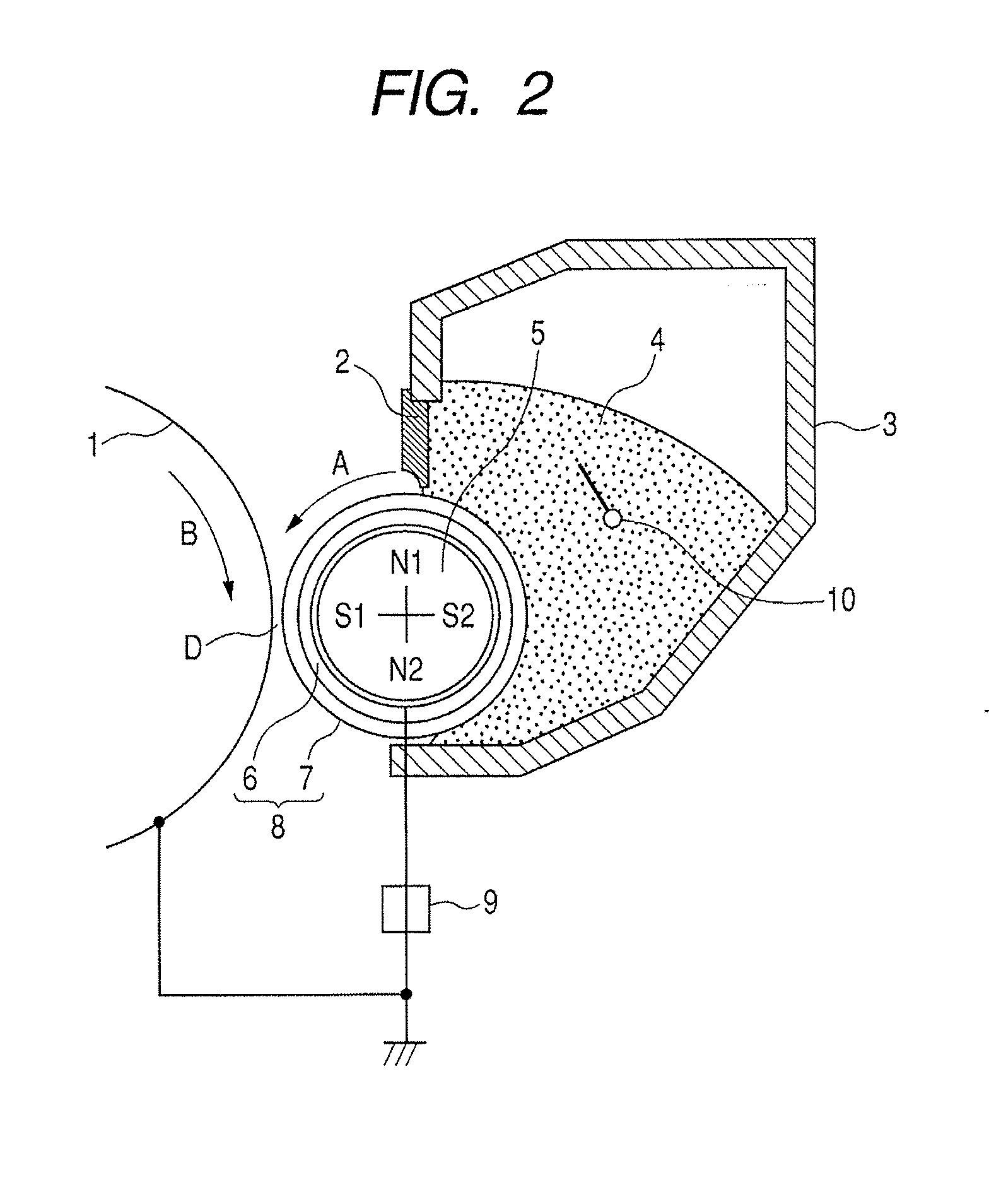

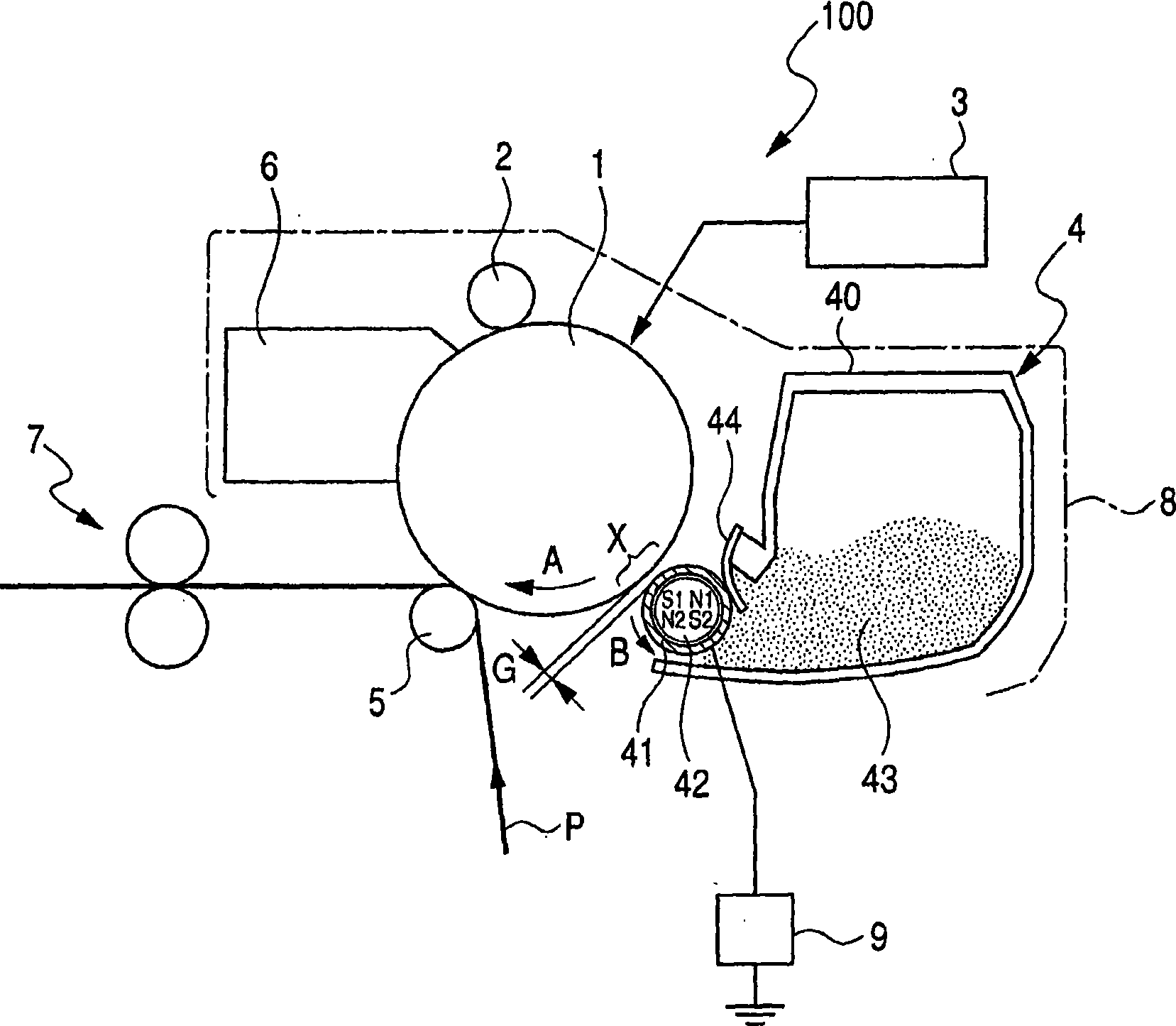

Developing apparatus including a cylindrical developer carrying member conveying a magnetic mono-component developer

A developing apparatus, a process cartridge and an image forming apparatus which form an image whose image density can be maintained, which form a fogged image and which form an image of uneven density within an acceptable range, even when the diameter of a developer carrying member is not more than 12 mm. The apparatus includes a developer carrying member whose outer diameter is in the range of 8 mm to 12 mm, and a magnetic mono-component developer 43 having a saturation magnetization of in a range of 20 Am2 / kg to 37 Am2 / kg when the magnetic field of 79.6 kA / m (1000 oersteds) is applied, the magnetization of not less than 70% and not more than 80% of the saturation magnetization when the magnetic field is lowered to 55.7 kA / m (700 oersteds), and the magnetization of not less than 50% and not more than 62% of the saturation magnetization when the magnetic field is lowered to 39.8 kA / m (500 oersteds).

Owner:CANON KK

Developing apparatus and process cartridge

ActiveUS20080089722A1Maintain image densityImage is limitedElectrographic process apparatusDevelopersMagnetizationEngineering

A developing apparatus, a process cartridge and an image forming apparatus of which the image density can be maintained and the fogged image and the uneven density can be within an acceptable level even when the diameter of a developer carrying member is not more than 12 mm. The outer diameter of the developer carrying member 41 is not less than 8 mm and not more than 12 mm, and a magnetic mono-component developer 43 has a saturation magnetization of not less than 20 Am2 / kg and not more than 37 Am2 / kg when the magnetic field of 79.6 kA / m (1000 oersteds) is applied, the magnetization of not less than 70% and not more than 80% of the saturation magnetization when the magnetic field is lowered to 55.7 kA / m (700 oersteds), and the magnetization of not less than 50% and not more than 62% of the saturation magnetization when the magnetic field is lowered to 39.8 kA / m (500 oersteds).

Owner:CANON KK

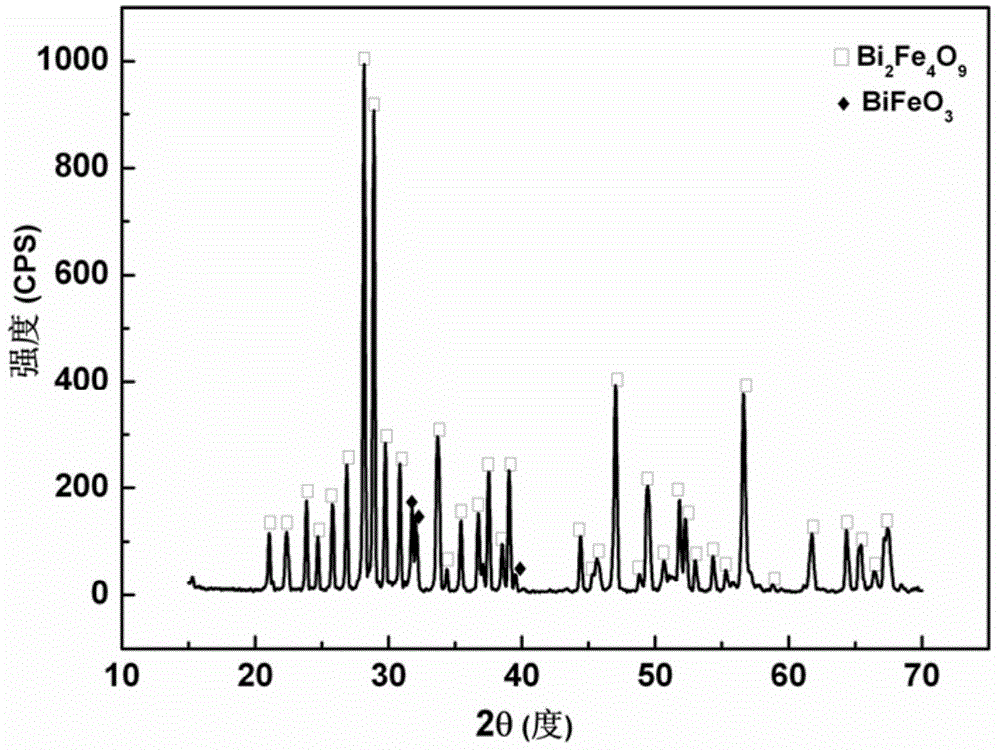

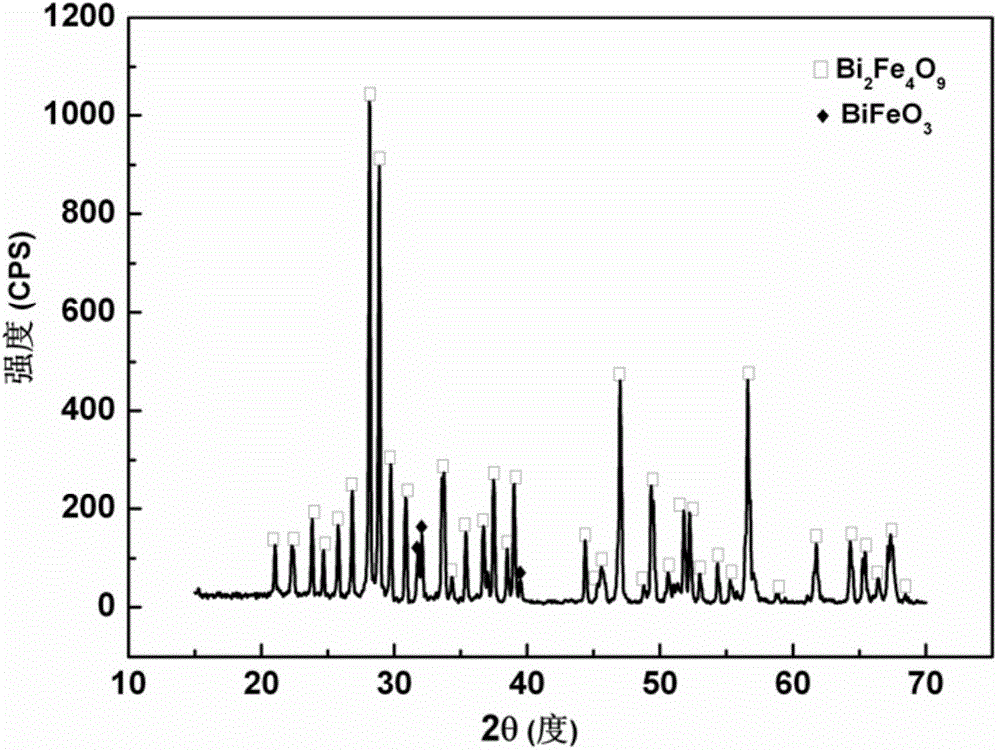

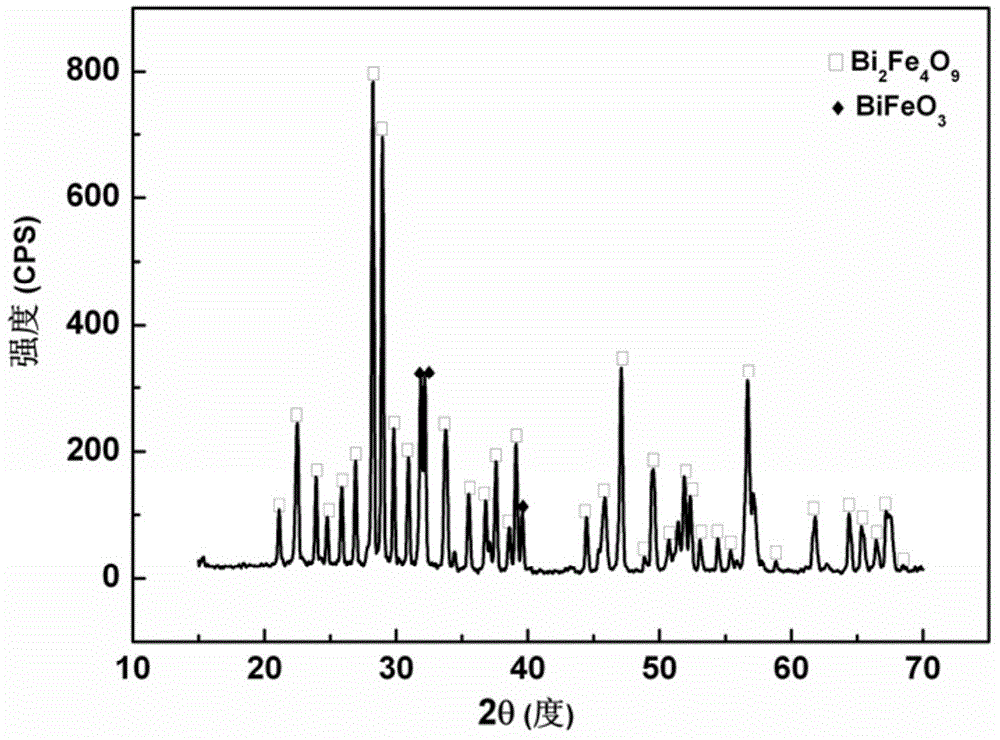

Bismuth ferrite based two-phase magnetic composite powder and preparation method thereof

InactiveCN104591294AEasy to prepareEasy to implementMaterial nanotechnologyIron compoundsMetallurgyAqueous solution

The invention discloses bismuth ferrite based two-phase magnetic composite powder and a preparation method thereof. By mixing Bi(NO3)3, Fe(NO3)3.9H2O and Co(NO3)2.9H2O, adding an aqueous solution of citric acid, adjusting the pH value, stirring, drying, and calcinating at a temperature of 750-800 DEG C, so that the bismuth ferrite based two-phase magnetic composite powder is obtained. The preparation method is simple, easy to implement, and convenient for mass production. The composite powder prepared according to the invention both contains a Bi2Fe4O9 phase and a BiFeO3 phase; with the increasing of the content of cobalt ions, the content of BiFeO3 in the composite powder is increased, the saturation magnetization is increased from 0.097 emu / g to 1.78 emu / g, and the coercive field is increased from 122.27 oersteds to 3327.96 oersteds.

Owner:SHAANXI UNIV OF SCI & TECH

Developing method and developing assembly

ActiveUS20070238043A1Non-uniform densityReduce consumptionDevelopersElectrographic process apparatusLatent imageThin layer

A developing method is provided in which a developer is carried on a developer carrying member, a thin layer of the developer is formed thereon and a latent image on a latent image bearing member is developed with a developer. The developer is composed of magnetic toner particles containing a binder resin and a magnetic powder. The magnetic powder has a saturation magnetization of 67.0 Am2 / kg to 75.0 Am2 / kg in a magnetic field of 79.6 kA / m (1,000 oersteds) and has a residual magnetization of 4.5 Am2 / kg or less. In the surface profile of the conductive resin coat layer of the developer carrying member, the relationship 1.00≦S / A≦1.65 is satisfied where S is a surface area of regions zoned by an area A of microscopic unevenness regions from which parts exceeding a reference plane by 0.5×r (r: weight average particle diameter (μm) of a toner used) or more have been excluded.

Owner:CANON KK

Polycrystalline diamond compacts, method of fabricating same, and various applications

Embodiments of the invention relate to polycrystalline diamond ("PCD") exhibiting enhanced diamond- to-diamond bonding. In an embodiment, polycrystalline diamond compact ("PDC") includes a PCD table having a maximum thickness. At least a portion of the PCD table includes a plurality of diamond grains defining a plurality of interstitial regions. A metal-solvent catalyst occupies at least a portion of the plurality of interstitial regions. The plurality of diamond grains and the metal-solvent catalyst collectively exhibit a coercivity of about 115 Oersteds ("Oe") or more and a specific magnetic saturation of about 15 Gauss -cm3 / grams ("G-cm3 / g") or less. The PDC includes a substrate having an interfacial surface that is bonded to the PCD table. The interfacial surface exhibits a substantially planar topography. Other embodiments are directed to methods of forming PCD and PDCs, and various applications for such PCD and PDCs in rotary drill bits, bearing apparatuses, and wire-drawing dies.

Owner:US SYNTHETIC CORP

Magnetic recording medium having narrow pulse width characteristics

InactiveUS20050181241A1Construction of head windingsMagnetic materials for record carriersRemanenceParticulates

A dual-layer magnetic recording medium including a non-magnetic substrate having a front side and a back side, a lower support layer formed over the front side and a magnetic upper recording layer formed over the lower layer, wherein the magnetic layer contains a volume concentration of at least about 35% of a magnetic metallic particulate pigment having a coercivity of at least about 2000 Oersteds (Oe), and a binder system for the pigment. The magnetic recording medium exhibits an orientation ratio greater than 2.0, a pulsewidth (PW50) value of less than about 500 nm, and a remanence-thickness product, Mr*t, of less than about 5.0 memu / cm2.

Owner:IMATION

Developing device and process cartridge

A developing apparatus, a process cartridge and an image forming apparatus of which the image density can be maintained and the fogged image and the uneven density can be within an acceptable level even when the diameter of a developer carrying member is not more than 12 mm. The outer diameter of the developer carrying member 41 is not less than 8 mm and not more than 12 mm, and a magnetic mono-component developer 43 has a saturation magnetization of not less than 20 Am / kg and not more than 37 Am / kg when the magnetic field of 79.6 kA / m (1000 oersteds) is applied, the magnetization of not less than 70% and not more than 80% of the saturation magnetization when the magnetic field is lowered to 55.7 kA / m (700 oersteds), and the magnetization of not less than 50% and not more than 62% of the saturation magnetization when the magnetic field is lowered to 39.8 kA / m (500 oersteds).

Owner:CANON KK

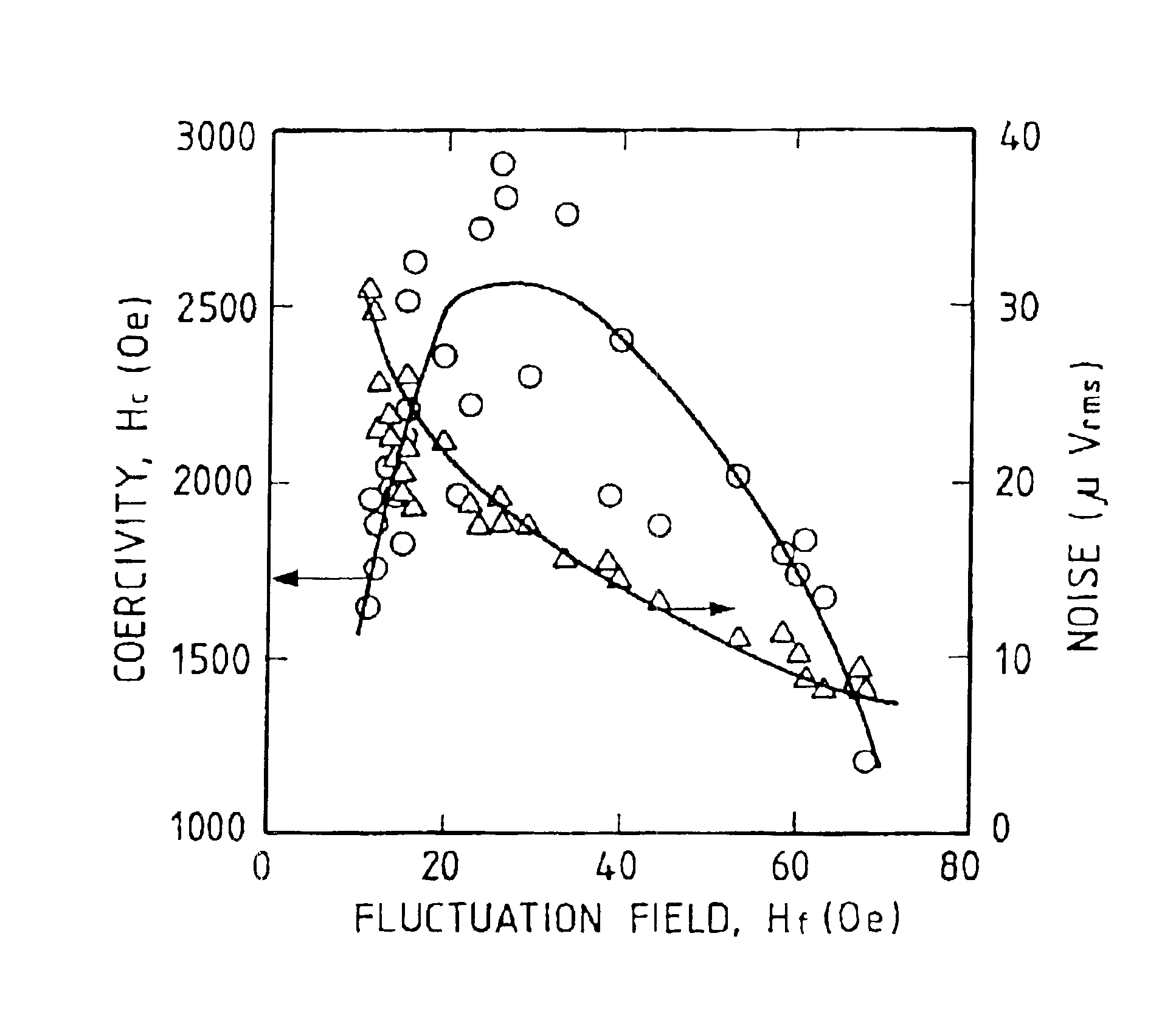

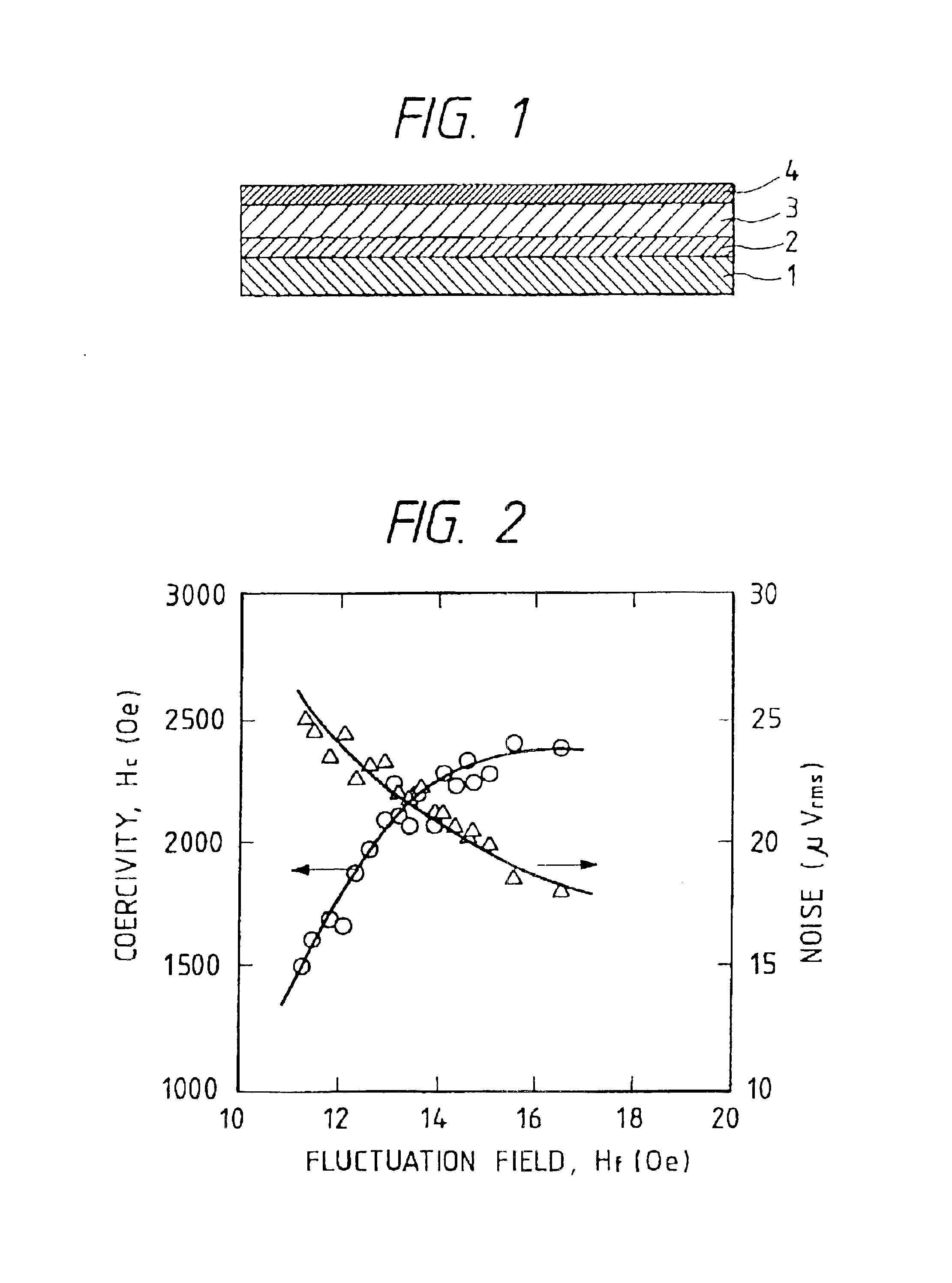

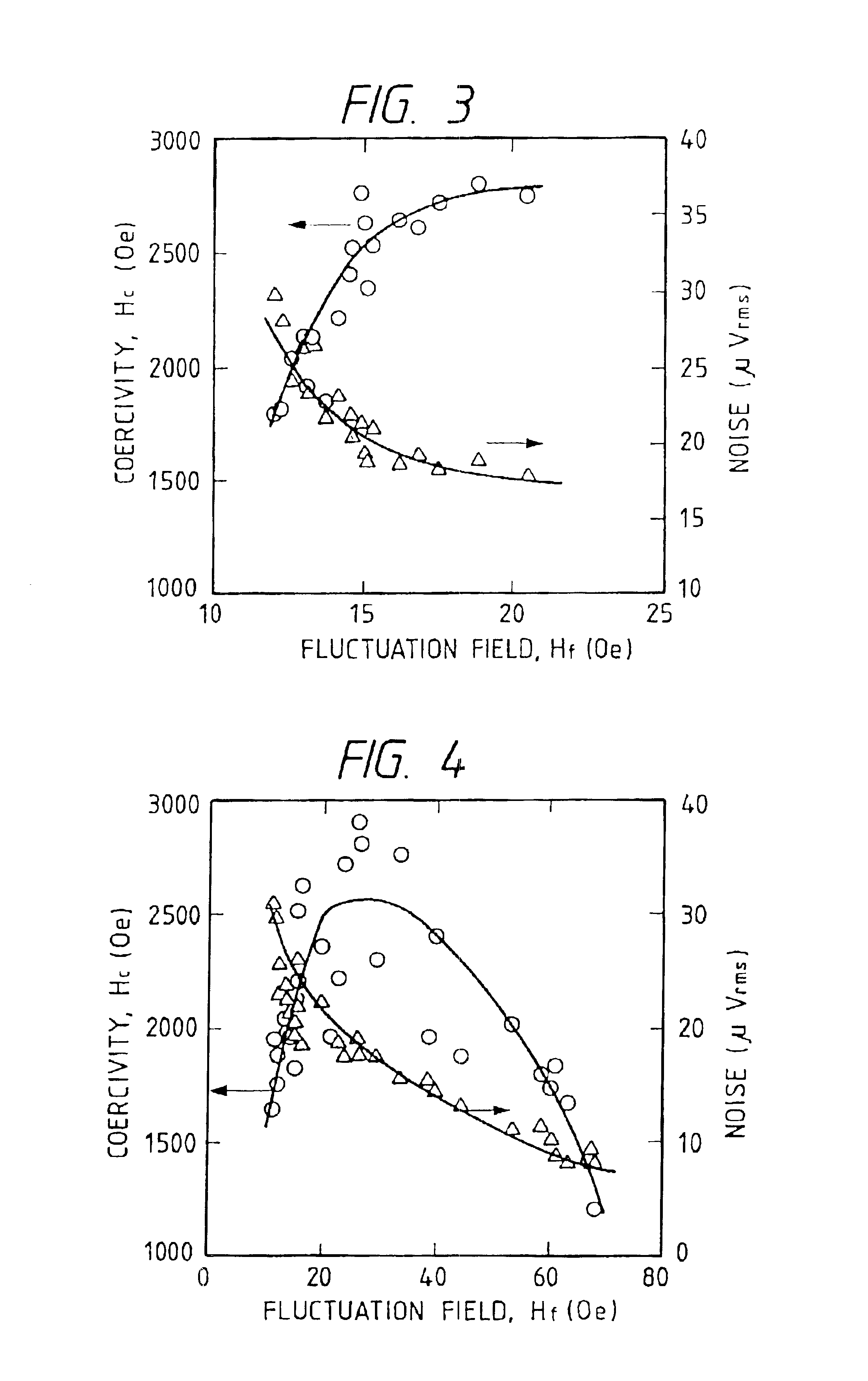

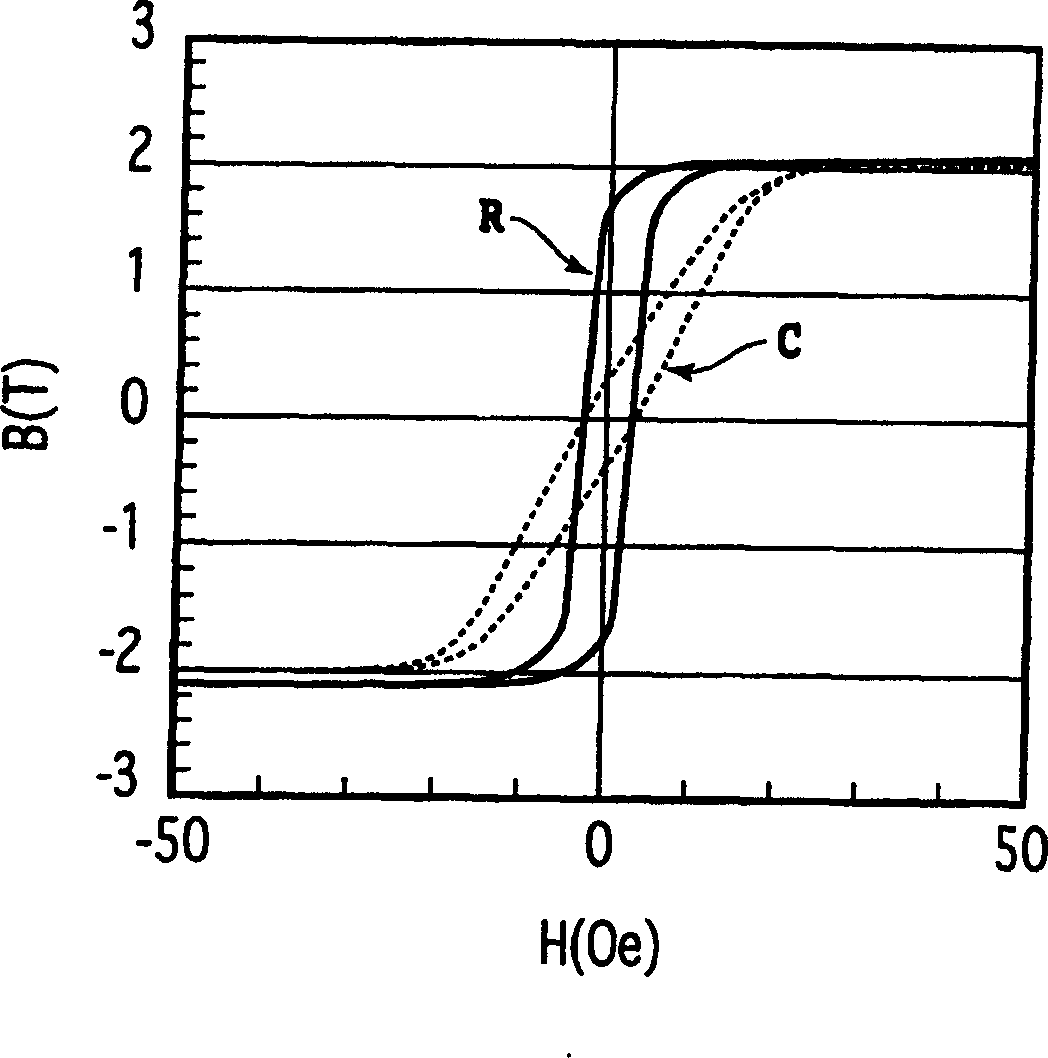

Magnetic recording medium possessing a fluctuation field of not less than 30 Oe

InactiveUS6846577B2Reduce noise levelRaise S/N valueBase layers for recording layersSoldering apparatusUltimate tensile strengthField strength

An ferromagnetic thin film is used to provide a magnetic recording medium whose noise is low and whose S / N value is high. The ferromagnetic thin film as the magnetic film of the magnetic recording medium is such that the fluctuation field of magnetic viscosity at 25° C. at the field strength equal to remanence coercivity or coercivity is not less than 15 oersteds and the coercivity is not less than 2000 oersteds.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

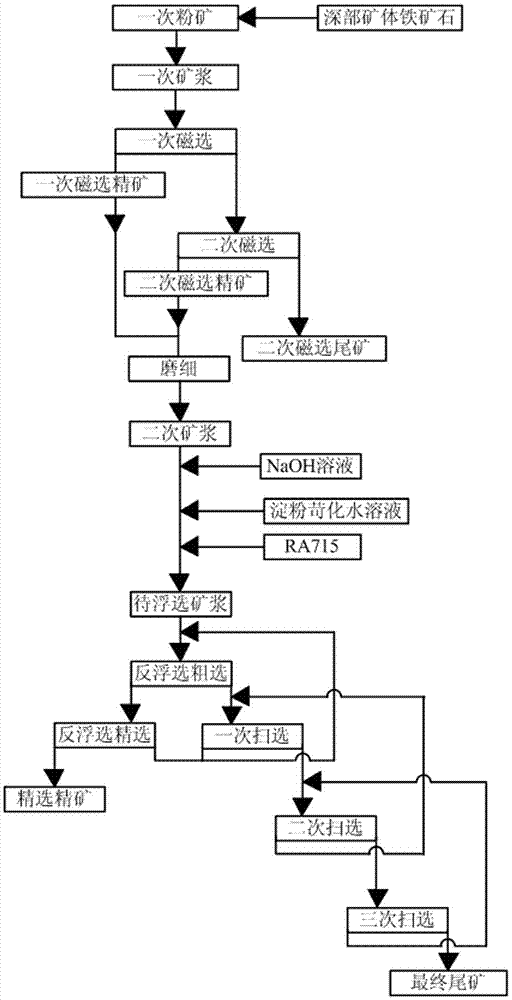

Method for purification of iron ores in deep ore body

The invention provides a method for purification of iron ores in a deep ore body and belongs to the technical field of mining. The method includes the first step of crushing and grinding the iron ores in the deep ore body to obtain primary fine ores, the second step of adding water into the primary fine ores to make primary ore pulp, and carrying out primary magnetic separation at the magnetic field intensity ranging from 1000 oersteds to 2000 oersteds to obtain primary magnetic concentrate and primary magnetic tailings, the third step of carrying out secondary magnetic separation after the primary magnetic tailings are concentrated to obtain secondary magnetic concentrate and the secondary magnetic tailings, the fourth step of mixing the primary magnetic concentrate and secondary magnetic concentrate evenly to form mixed magnetic concentrate and then carrying out ore grinding to obtain secondary fine ores, the fifth step of adding water into the secondary fine ores to form secondary ore pulp, regulating the PH value, adding causticized starch water solution and then adding lime and RA715 to form reverse flotation feed, and the sixth step of carrying out reverse floatation roughing separation on the reverse flotation feed and carrying out reverse flotation concentration on roughing concentrate to obtain cleaner concentrate and cleaner tailings. Through the method, the recovery rate of iron is substantially increased; the method has the advantages of being low in comprehensive cost, small in environmental pollution, good in comprehensive utilization effect and the like.

Owner:NORTHEASTERN UNIV

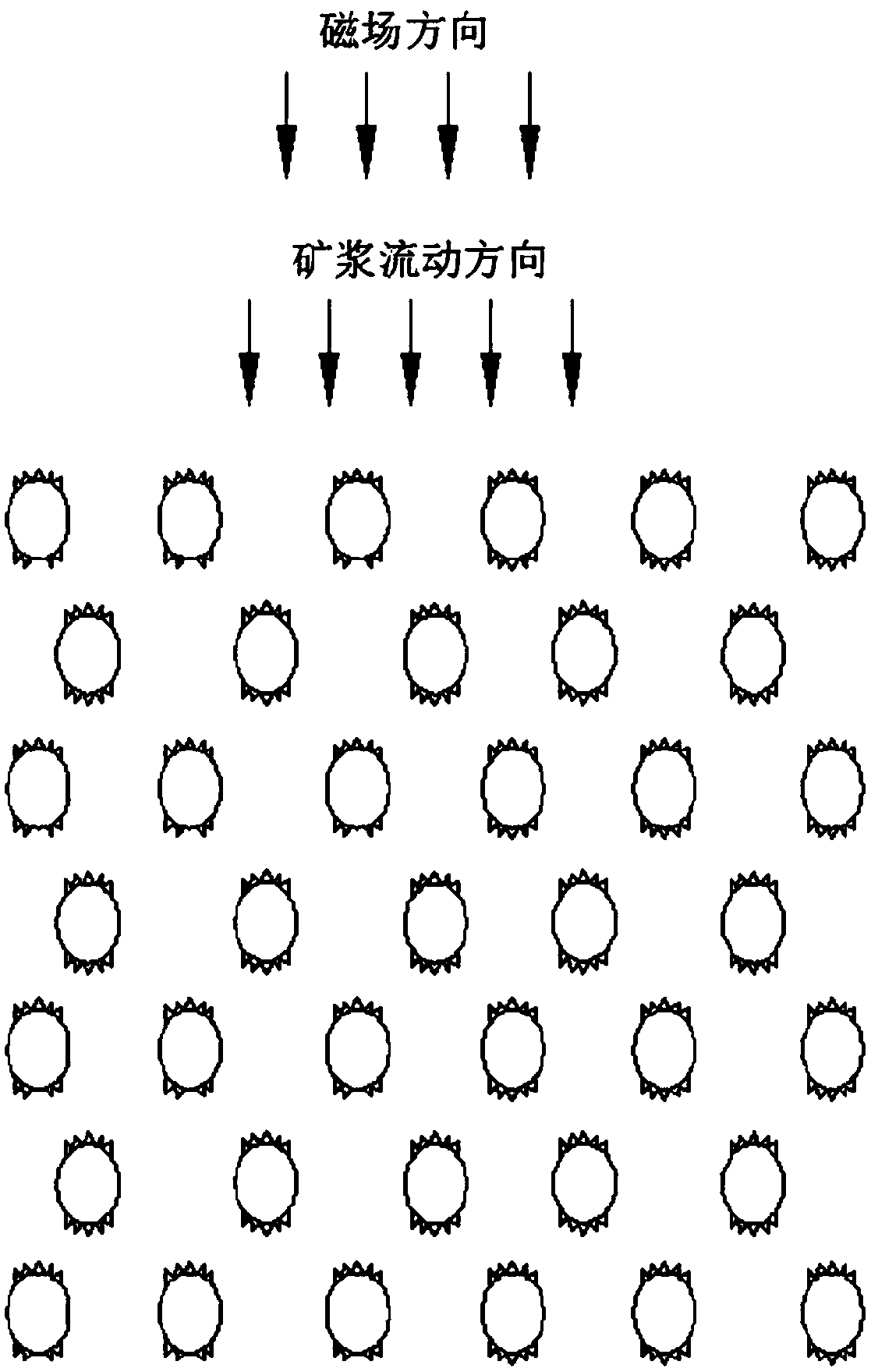

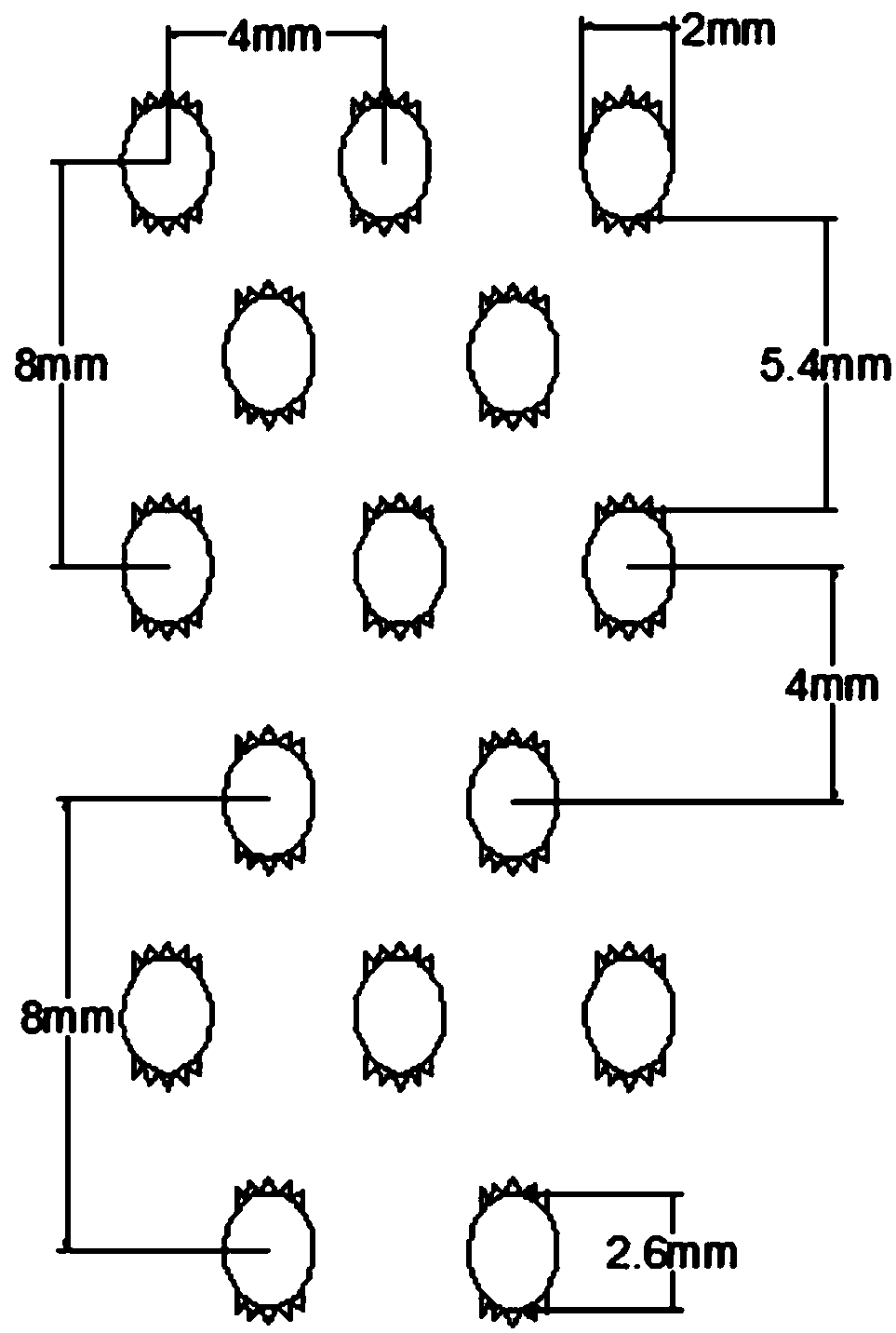

Corn starch pretreatment-unusual medium magnetic separation process

InactiveCN108654834AIncrease catch rateEasy to recycleHigh gradient magnetic separatorsFlocculationMagnetic media

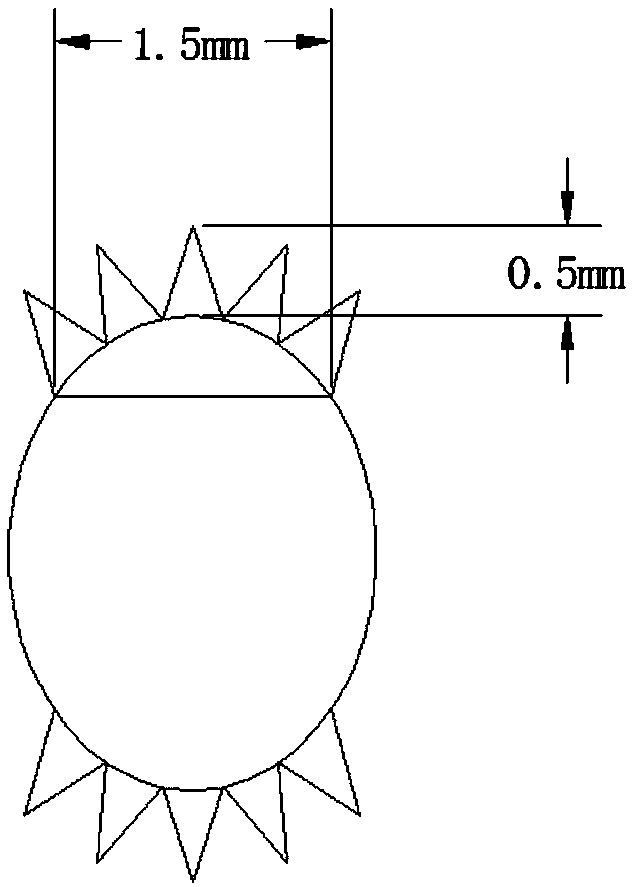

The invention relates to a corn starch pretreatment-unusual medium magnetic separation process and belongs to the technical field of mineral processing. The corn starch pretreatment-unusual medium magnetic separation process comprises the steps of pulp mixing, weak magnetic iron mineral flocculation pretreatment, magnetic separation and scavenging, wherein the magnetic separation step is that strong magnetic separation work is carried out on obtained pretreated ore pulp through a vertical ring pulsating high gradient magnetic separator with an elliptic unusual magnetic medium box under the condition that the background field intensity is 5,000 oersted-10,000 oersted, the pulsation stroke is 0 mm-20 mm and the pulsation frequency of stroke is 0-250 per minute, a strong magnetic separation magnetic product is obtained, and the cross section of the unusual magnetic medium box is provided with saw teeth. Compared with an existing intensifying micro-fine particle weak magnetic iron mineralrecovering process, the method has the advantages of being high in iron recovering rate, low in composite cost, simple in flowage structure and the like.

Owner:NORTHEASTERN UNIV

Coating-type magnetic recording medium for heat-assisted recording, and heat-assisted magnetic recording apparatus and heat-assisted magnetic recording method using the same

ActiveUS11100948B2Excellent electromagnetic conversion characteristic and durabilityLarge capacityMagnetic materials for record carriersRecord information storageHeat-assisted magnetic recordingNon magnetic

The magnetic recording medium disclosed in the present application includes a non-magnetic support, an undercoat layer, a magnetic layer containing magnetic particles, and a back coat layer. The coercive force Hc of the magnetic layer in the thickness direction at 25° C. is not 4100 oersteds (Oe) or more, and the coercive force Hc of the magnetic layer in the thickness direction at a temperature between 55° C. and 80° C. inclusive is not less than 1200 oersteds (Oe) and not more than 3700 oersteds (Oe).

Owner:MAXELL HLDG LTD

Polymerization method for light olefins

ActiveCN101440013BEnhanced mass transferImprove heat transfer performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPolymer sciencePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

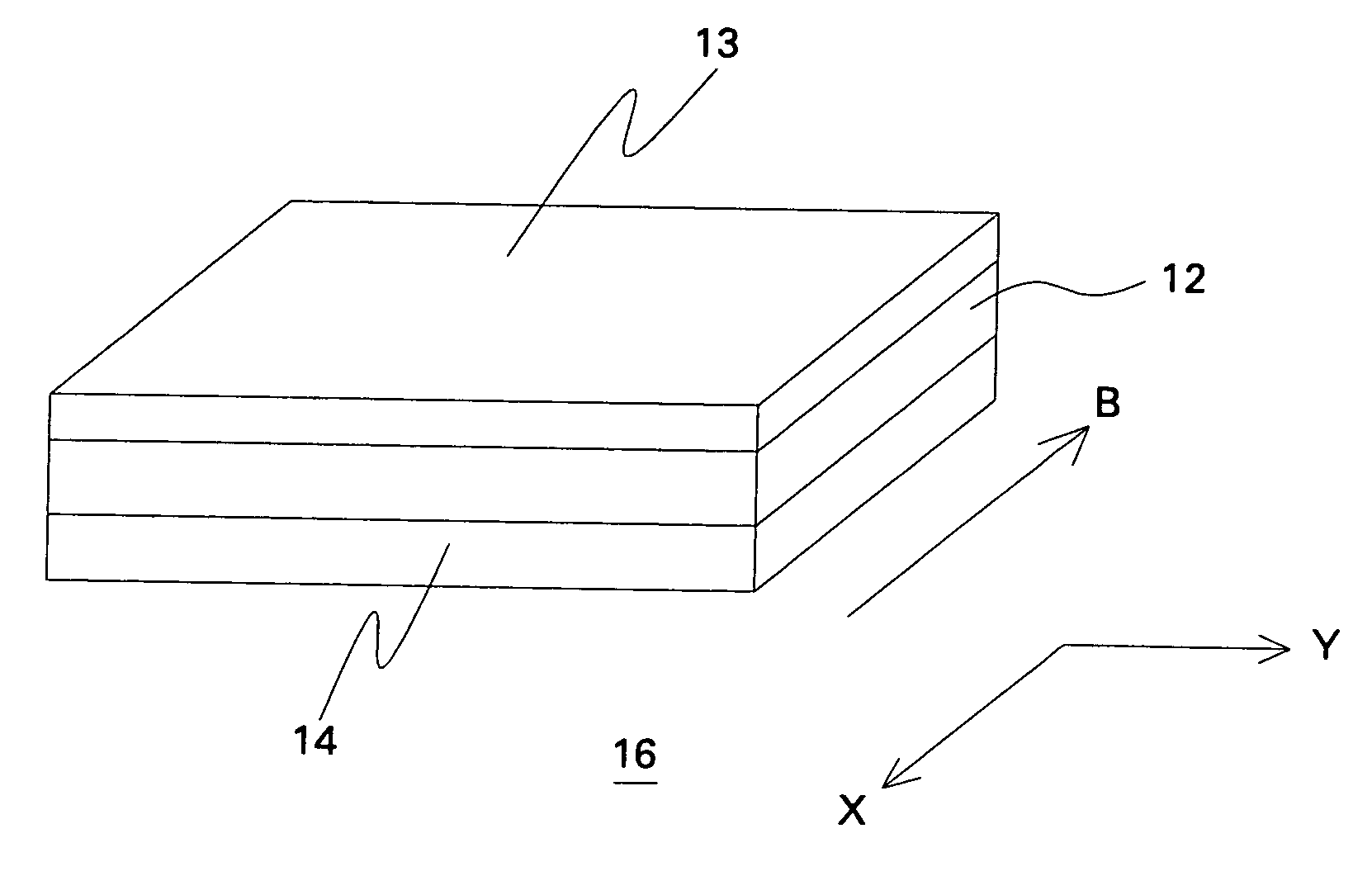

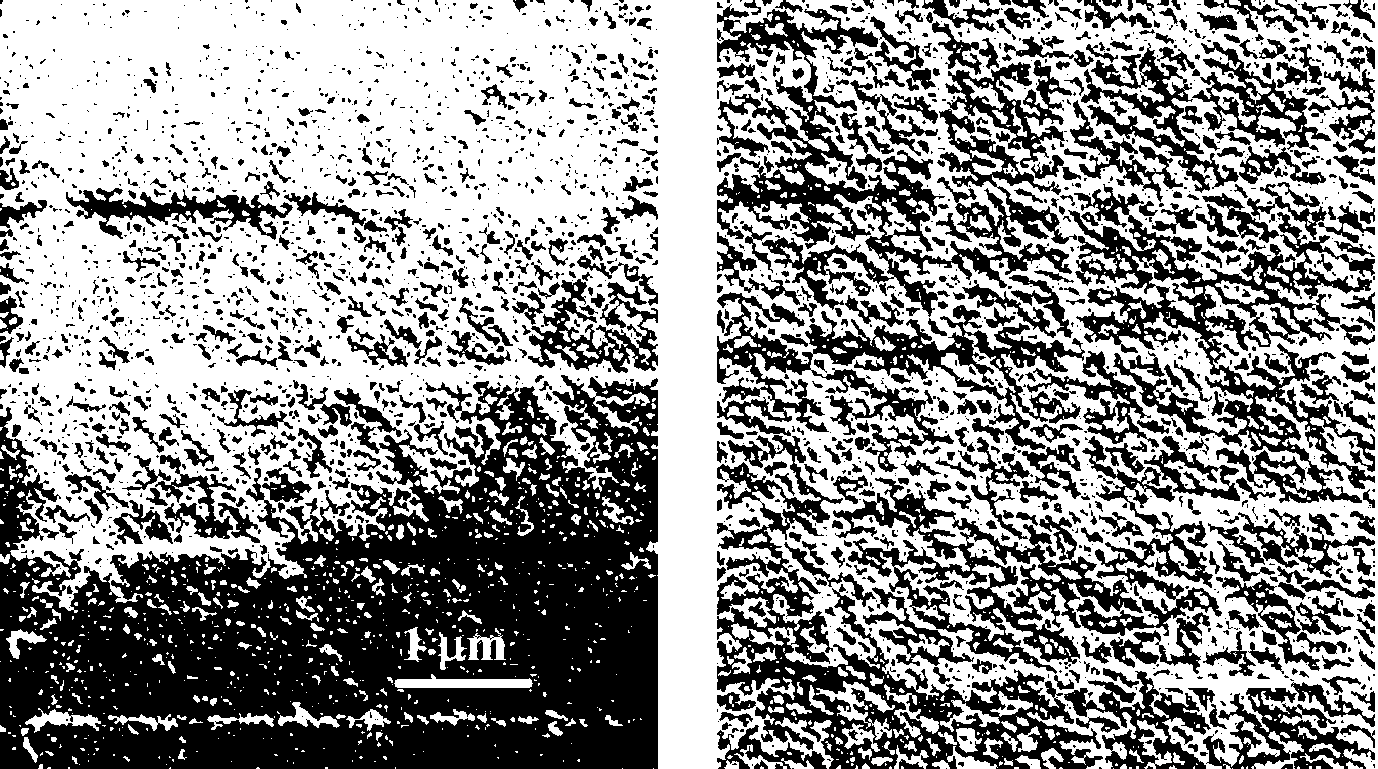

Method utilizing femtosecond laser non-mask method to prepare magnetic sensitive microstructure unit

ActiveCN102838081AShort pulse durationHigh peak powerDecorative surface effectsChemical vapor deposition coatingFemto second laserMaterials science

The present invention discloses a method utilizing a femtosecond laser non-mask method to prepare a magnetic sensitive microstructure unit. The method comprises the following steps: (1) manufacturing a magnetic membrane in precipitation mode according to the sequence of a substrate, a buffer layer, a magnetic layer and a protective layer; and (2) using femtosecond laser as a light source, accurately controlling the position of a sample platform through a computer, conducting non-mask irradiation of the magnetic membrane to obtain the magnetic sensitive microstructure unit. Parameters of the femtosecond laser includes that single pulse energy is 5-50 mu joules, the pulse width is 90-150 femtoseconds, the wavelength is 800 nanometers, the pulse frequency is 10-100 hertzes, the movement speed of the sample table is 60-500 micrometers per minute, and an induced magnetic field of 0-500 oersteds is applied along the direction which is paralleled to or perpendicular to the membrane surface of the magnetic membrane during irradiation according to requirements. The method is simple, efficient and controllable, and is without prefabrication of masks.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

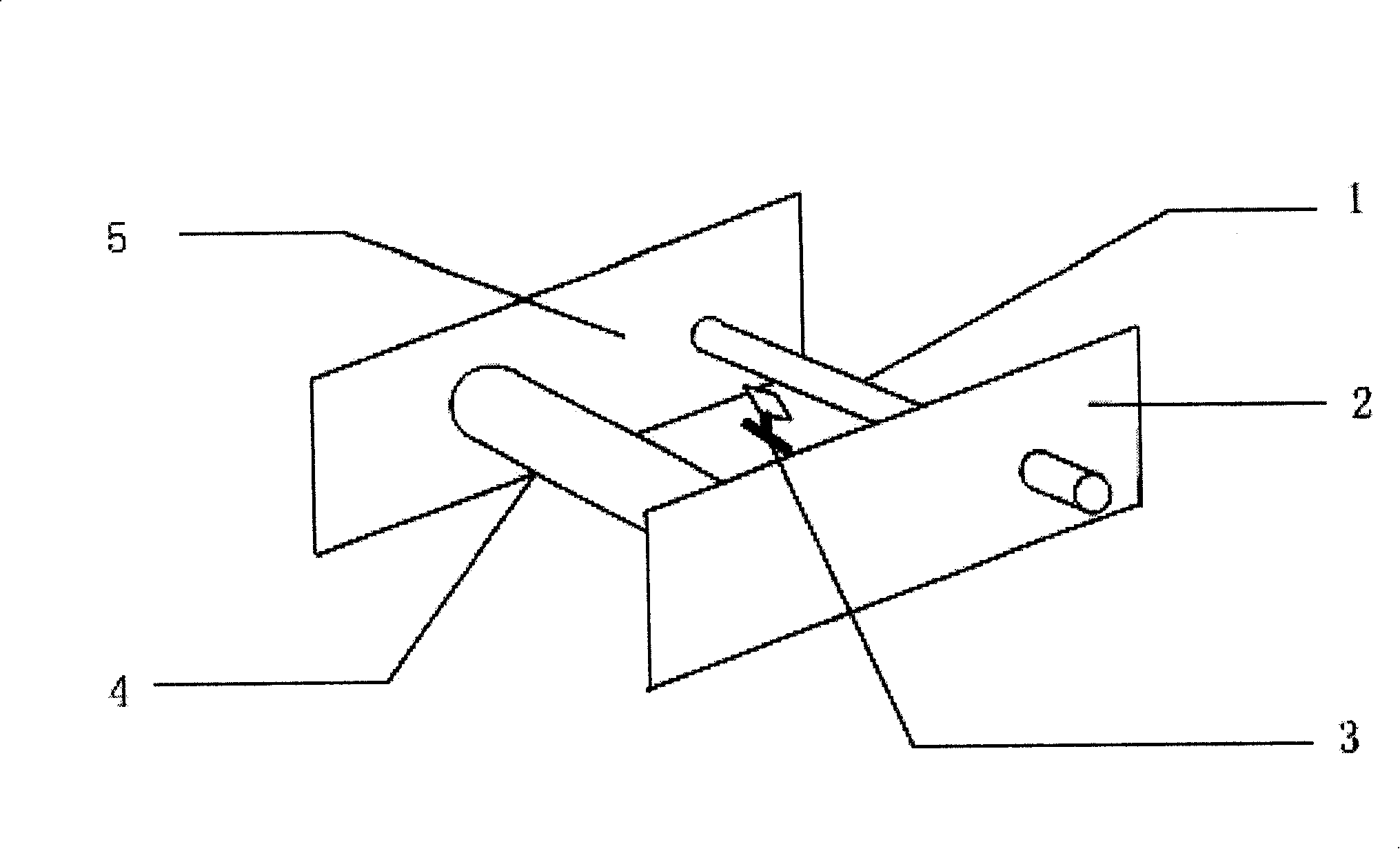

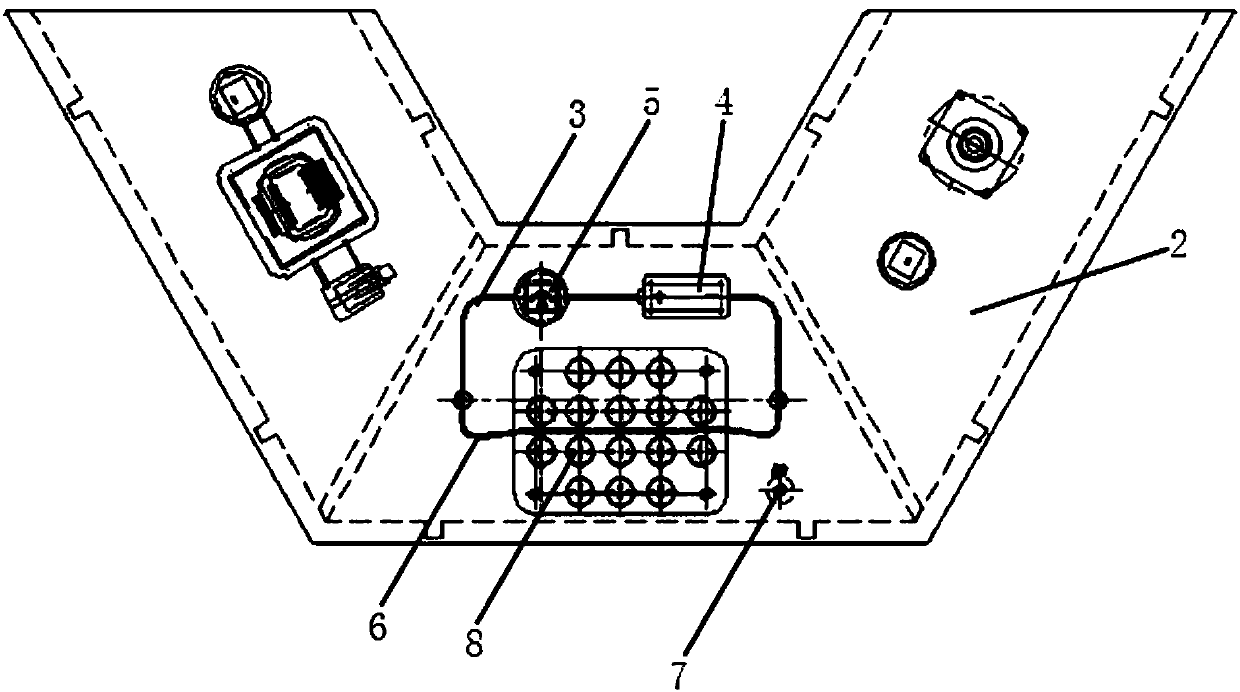

Oersted experimental device for student

The invention discloses an Oersted's experiment device for students, which comprises batteries, a small magnetic needle, a cell bracket and straight wire. The straight wire passes through circular holes on two metal plates of the cell bracket and is fixed by screws. The small magnetic needle is positioned right under of the straight wire to be parallel with the straight wire. If pinching the metal plates with hand, the students can observe magnetic phenomenon discovered by Oersted. The invention has the advantages of simple structure, convenient operation and no need of regulation, which is not easy to damage electric power and is suitable for being used in student group experiments.

Owner:上海市嘉定区第二中学

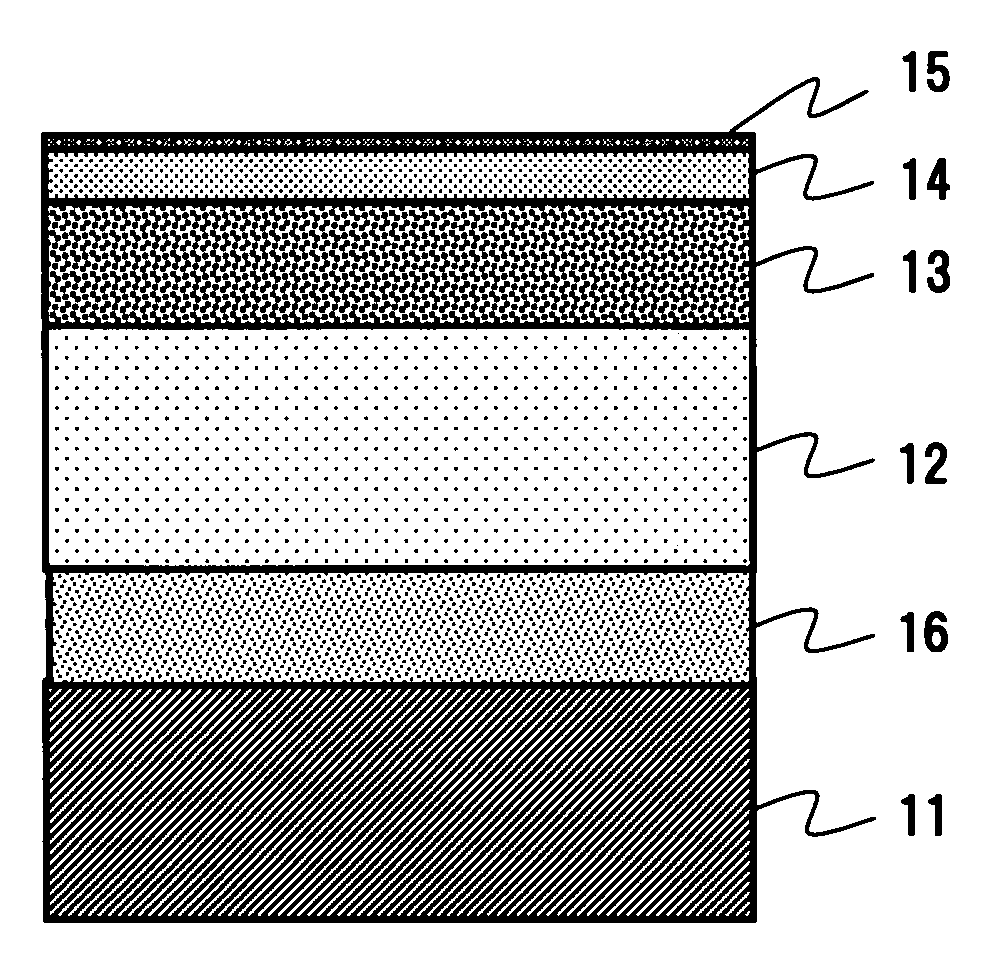

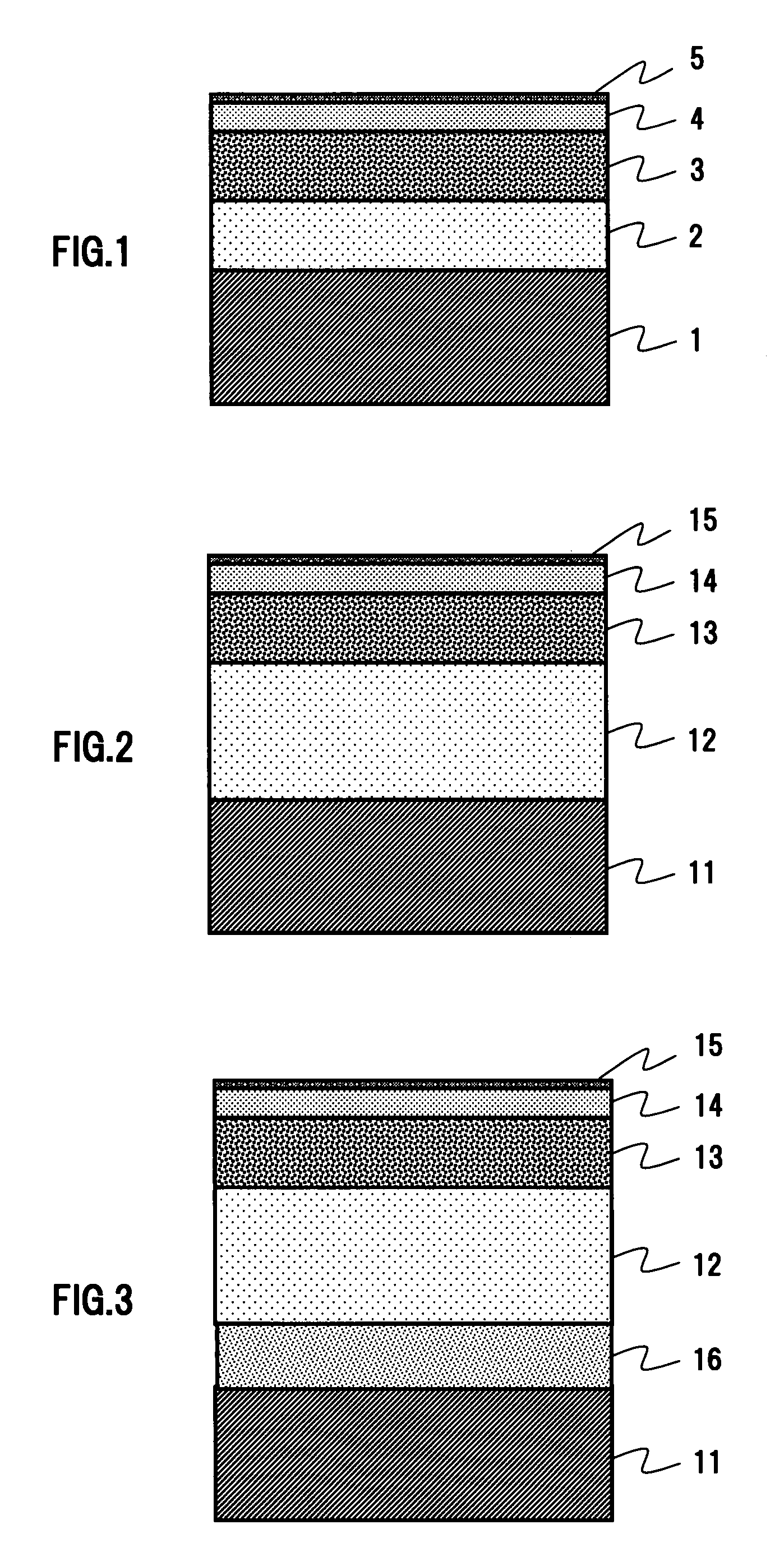

Ultra-resolution thin-film structure of photomagnetic mixing stored record

InactiveCN101393275ASmall spot sizeIncrease the optical pathRecord information storageOptical record carriersAlloyRecording layer

The invention relates to a super-resolution membrane structure for photomagnetic hybrid recording, which is characterized in that the super-resolution membrane structure for photomagnetic hybrid recording comprises a substrate, a dielectric layer, a super-resolution mask layer, a thermal-protective layer, a magnetic recording layer and a protective layer in turn, wherein the substrate is glass; the dielectric layer, the thermal-protective layer and the protective layer are formed by SiN or SiO2; the super-resolution mask layer consists of Si(x)Ag(1-x) alloy, wherein X is more than 0 and less than 1; and magnetic recording layer is TbFeCo. The recording magnetic domain of 100 nanometers is obtained through auxiliary heating by blue light the laser wavelength of which is 406.7 nanometers and recording by an objective with a numerical aperture of 0.80 and an external magnetic field of 300 oersteds.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method for preparing magnetic sensitive microstructure unit by femtosecond laser non-mask method

ActiveCN102838081BShort pulse durationHigh peak powerDecorative surface effectsChemical vapor deposition coatingFemto second laserWavelength

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Super resolution film structure of light-magnet mixing memory record

InactiveCN100575986CSmall spot sizeIncrease the optical pathRecord information storageOptical record carriersAlloyRecording layer

The invention relates to a super-resolution membrane structure for photomagnetic hybrid recording, which is characterized in that the super-resolution membrane structure for photomagnetic hybrid recording comprises a substrate, a dielectric layer, a super-resolution mask layer, a thermal-protective layer, a magnetic recording layer and a protective layer in turn, wherein the substrate is glass; the dielectric layer, the thermal-protective layer and the protective layer are formed by SiN or SiO2; the super-resolution mask layer consists of Si(x)Ag(1-x) alloy, wherein X is more than 0 and less than 1; and magnetic recording layer is TbFeCo. The recording magnetic domain of 100 nanometers is obtained through auxiliary heating by blue light the laser wavelength of which is 406.7 nanometers and recording by an objective with a numerical aperture of 0.80 and an external magnetic field of 300 oersteds.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

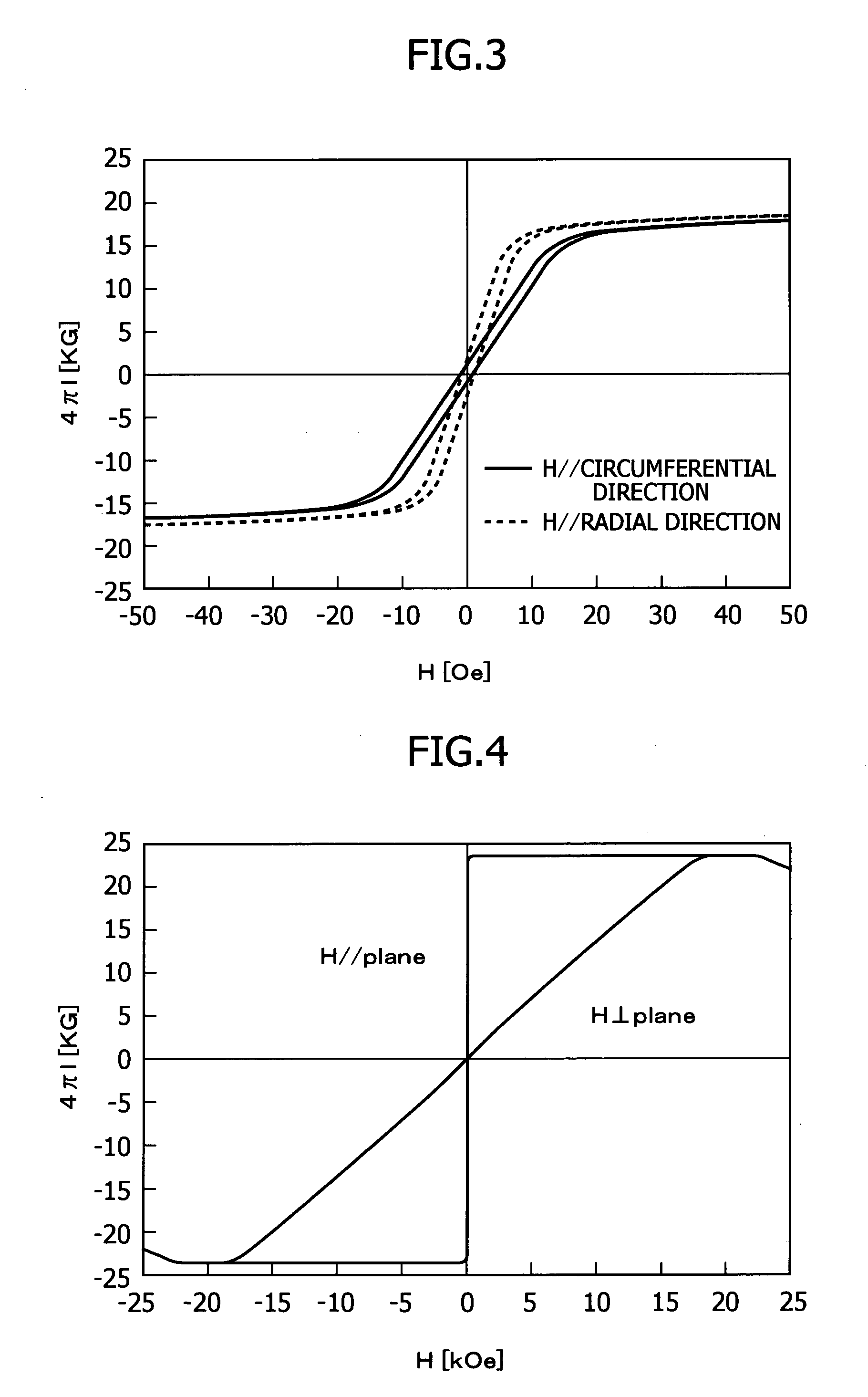

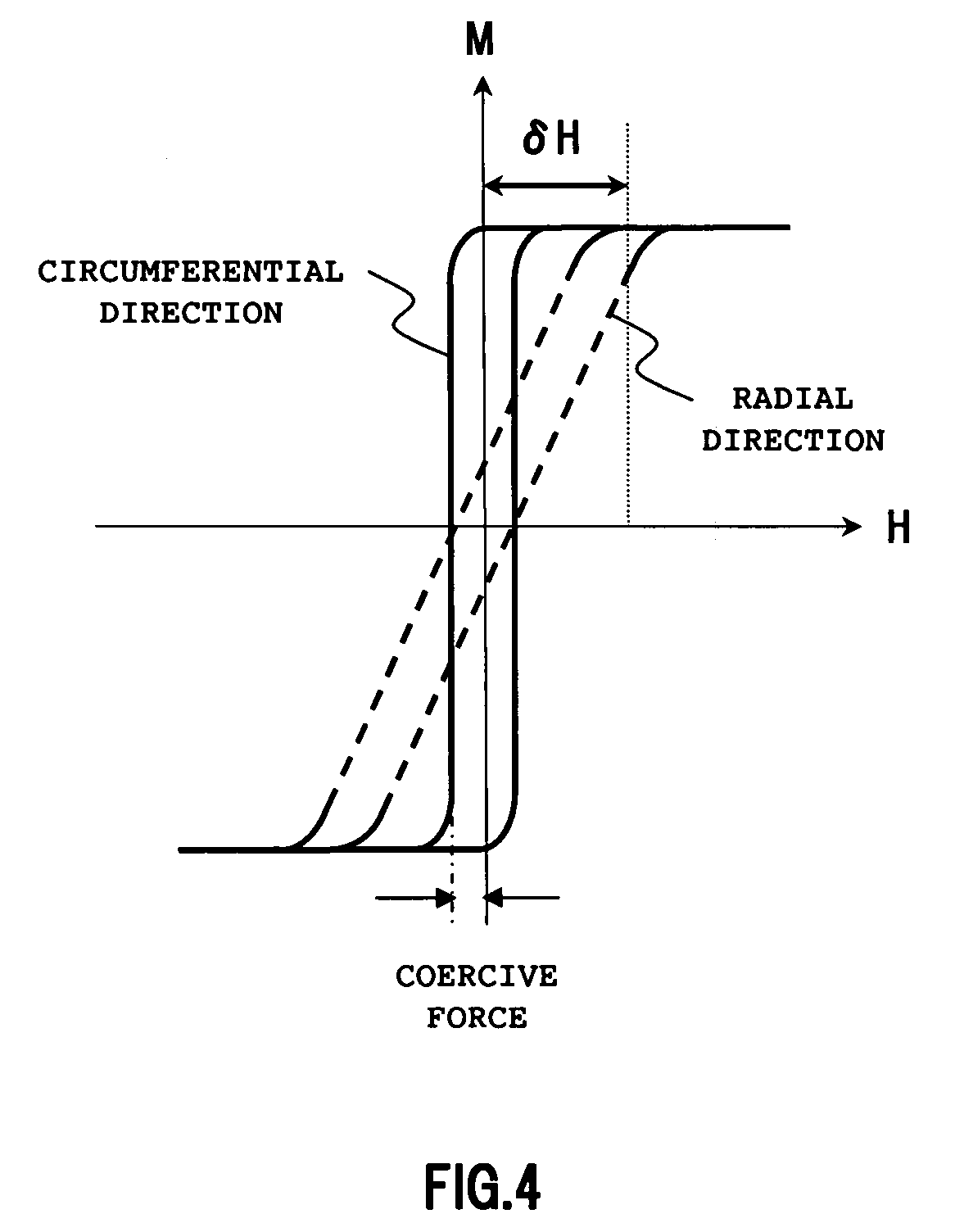

Substrate for magnetic recording medium, fabrication method thereof, and magnetic recording medium

InactiveUS20070231607A1Excellent signal generation characteristicReduce noiseLiquid surface applicatorsMagnetic materials for record carriersIn planeNon magnetic

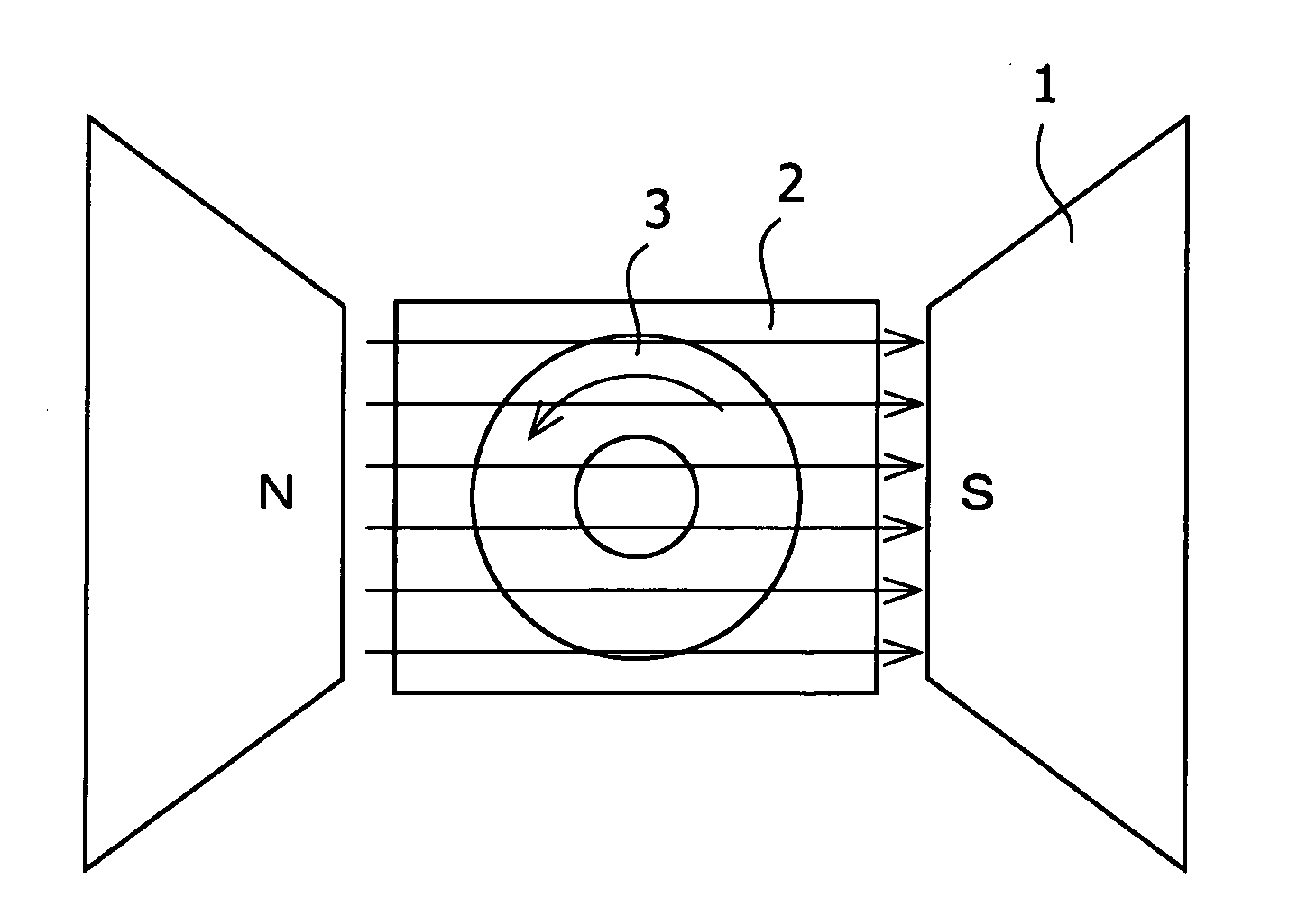

A soft magnetic under layer (SUL) is formed on a non-magnetic substrate by an electroless plating method. The SUL formed by plating is subjected to magnetic field heat treatment on conditions that the heat treatment temperature is 150° C. to 350° C., a magnetic field applied to the substrate has a strength of 50 oersteds (Oe) or more, and the treatment time is selected within a range of five minutes to ten hours. Through the magnetic field heat treatment, magnetic anisotropy is obtained with a difference (δH=Hd−Hc) of 5 oersteds (Oe) or more in terms of absolute value between a magnetization saturation magnetic field strength (Hd) in the in-plane radial direction of a soft magnetic film and a magnetization saturation magnetic field strength (Hc) in the in-plane circumferential direction of the soft magnetic film, and the magnetic anisotropy is symmetric with respect to the axis of the substrate.

Owner:SHIN ETSU CHEM IND CO LTD

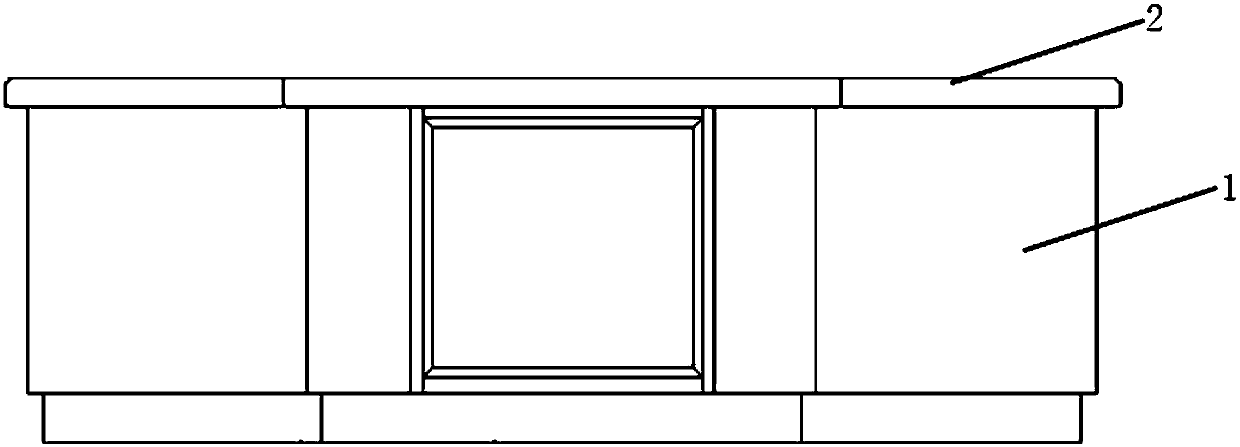

Oersted's experiment demonstration device suitable for science popularization venue

The present invention relates to the science popularization education technology field, in particular to an Oersted's experiment demonstration device suitable for a science popularization venue. The Oersted's experiment demonstration device comprises a table body and a table-board arranged on the table body, a battery, an ammeter, a movable conducting wire and a switch which are in series connection orderly via the conducting wires are arranged on the table-board, and a plurality of compasses are arranged around the movable conducting wire. According to the Oersted's experiment demonstration device suitable for the science popularization venue, the switch is used to connect a circuit, the ammeter displays whether a current flows through a loop, the battery supplies power, and the pluralityof compasses arranged around the movable conducting wire deviate, by observing the pointer change situations of the compasses around the movable conducting wire when the current flows through and thecurrent does not flow through, a magnetic effect of the current is learned.

Owner:HEFEI TANAO AUTOMATION

Production method of extremely fine lean magnetite

InactiveCN113426567AOvercoming the Difficulties in Development and UtilizationTroubleshooting Grading DifficultiesMagnetic separationWet separationMagnetitePhysical chemistry

The invention relates to a production method of extremely fine lean magnetite. The production method is characterized by comprising the following steps that mineral aggregate with the particle size being not larger than 30mm is crushed to be 8-0mm through a high-pressure roller mill; water is added into the mineral aggregate with the particle size being 8-0 mm for size mixing till the solid mass concentration is 55%-60%, the mineral aggregate enters a wet screening machine with the screen mesh not exceeding 6 mm, the moisture of oversize return materials with the particle size larger than 6 mm is controlled to be within 8%, coarse-particle-size pre-selection tailing discarding is conducted on the mineral aggregate with the particle size smaller than 6 mm, and the magnetic field intensity is 4500 oersteds; the mineral aggregate with the particle size being smaller than or equal to 38 microns is mixed with water to form slurry; the 38-micron graded feeding mass concentration is controlled within 24.50%, and the graded product fineness P95 is equal to 38 microns; and the 25-micron graded feeding mass concentration is controlled within 20.00%, and the graded product fineness P95 is equal to 25 microns. According to the method, the ore grinding power index of the ore is greatly reduced, the ore grinding load and energy consumption are reduced, effective grading of superfine grinding narrow particle fractions is achieved, and metal loss is reduced.

Owner:TAIYUAN IRON & STEEL GROUP

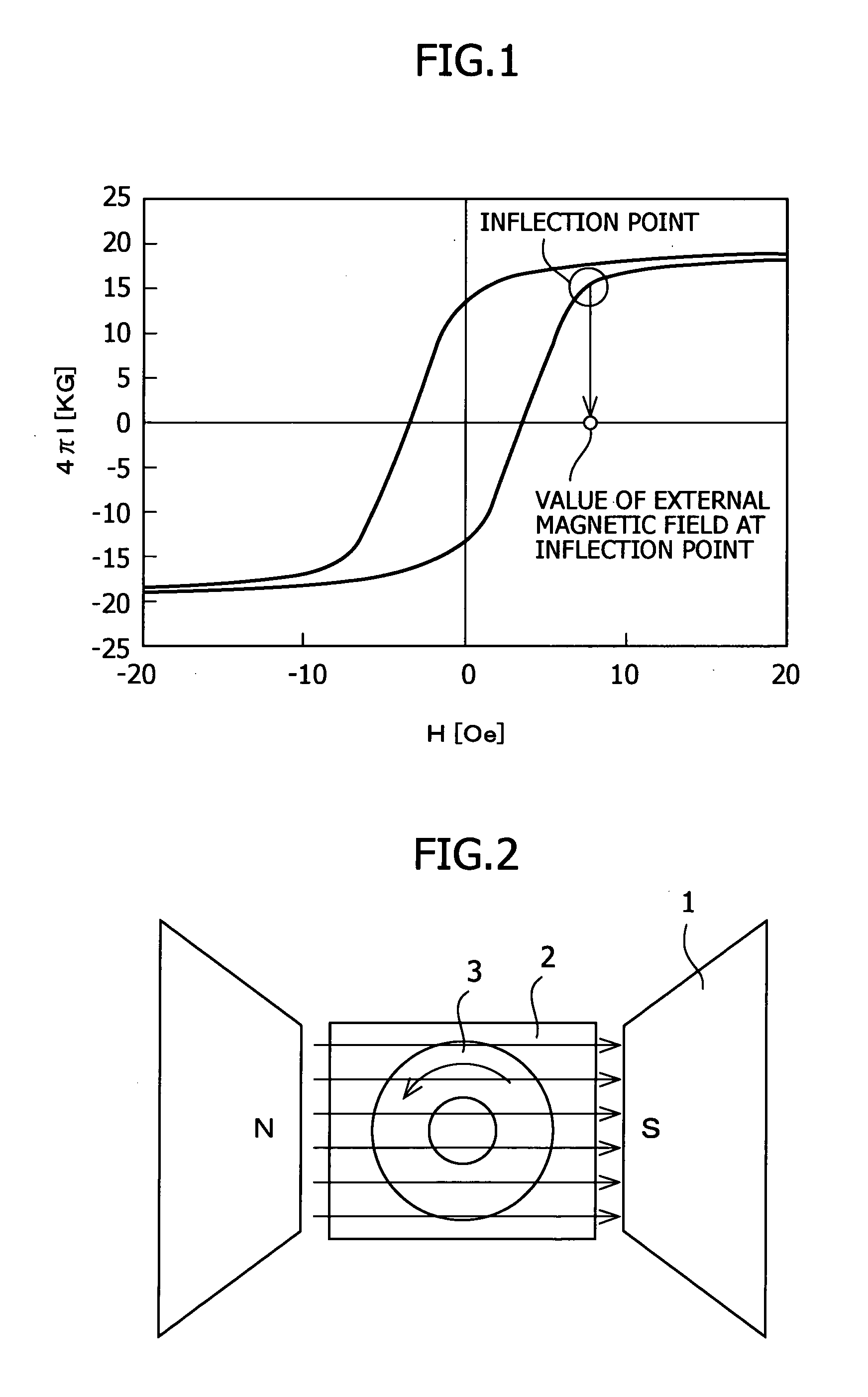

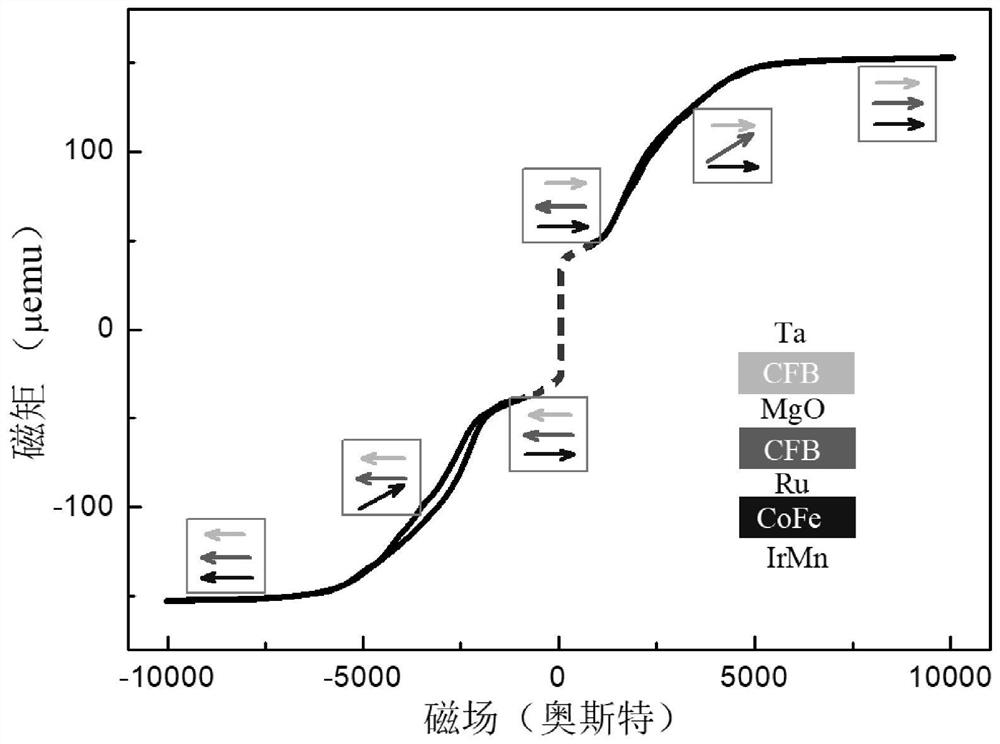

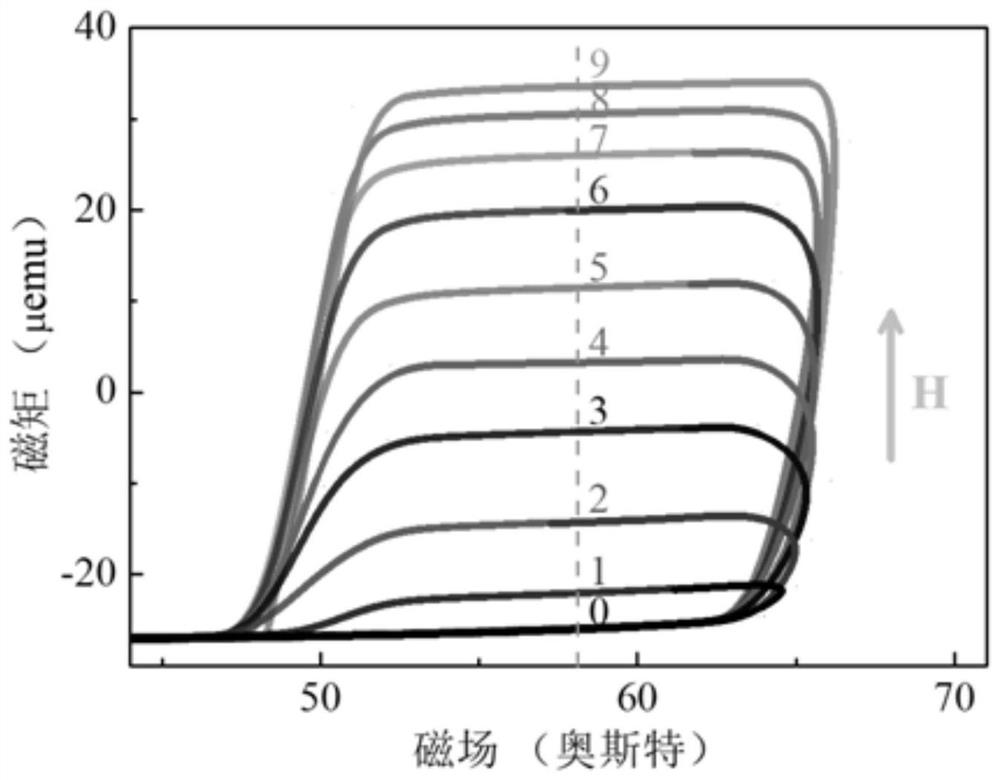

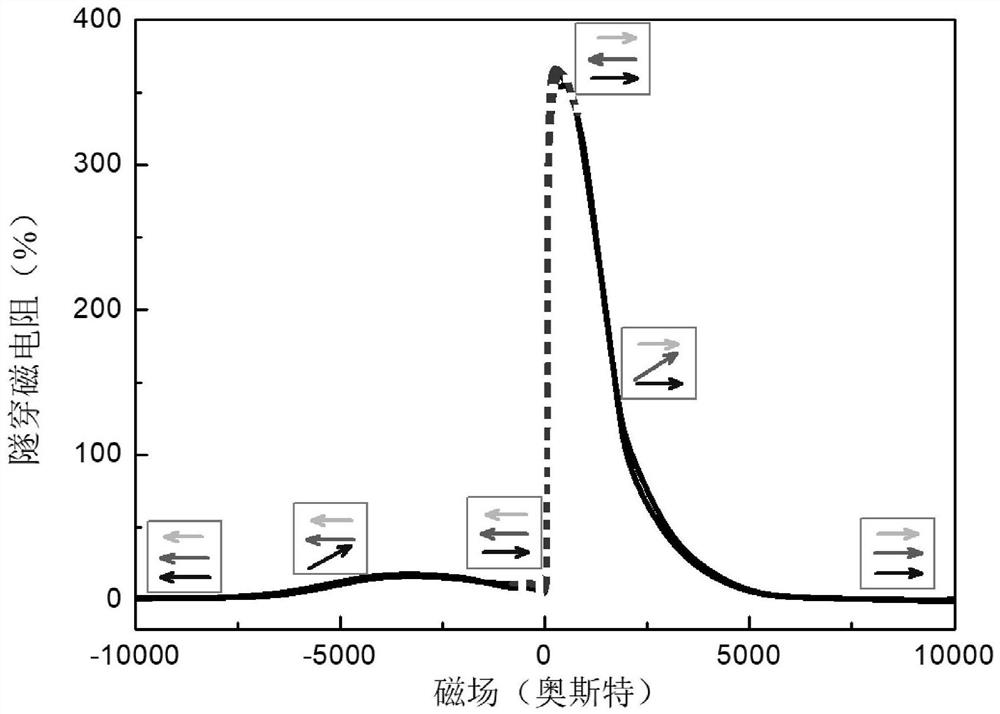

A Method of Controlling Free Layer Domain Structure to Realize Ten-state Data Storage in Magnetic Tunnel Junction

ActiveCN109243511BImprove performanceEasy to operateMagnetic-field-controlled resistorsDigital storageHigh densityData store

The invention relates to a method for controlling the domain structure of a free layer to realize ten-state data storage in a magnetic tunnel junction, comprising: (1) measuring the hysteresis loop of the magnetic tunnel junction to find out the initial magnetic field; (2) in the direction of the negative magnetic field Apply an initial magnetic field to the magnetic tunnel junction; (3) apply a positive direction magnetic field to the magnetic tunnel junction, and increase the positive direction magnetic field to the writing magnetic field at an increase rate of 0-200 Oersted / s through the No overshot mode, and obtain A certain multi-magnetic domain state; (4) changing the size of the write magnetic field, and performing steps (2) to (3) to obtain another multi-magnetic domain state; repeating this step until ten kinds of multi-magnetic domain states are obtained; (5) Ten kinds of multi-magnetic domain states are read out. The invention can be directly applied to the existing magnetic tunnel structure, and greatly expands the performance of the current magnetic tunnel junction. The invention has a good application prospect in high-density, low-power consumption novel spintronic memory.

Owner:SHANDONG UNIV

Perpendicular magnetic recording medium

A perpendicular magnetic recording medium comprises a substrate, a metal underlying layer formed on the substrate, a soft magnetic layer formed on the metal underlying layer by electroless plating and having an easy axis of magnetization parallel to the substrate, and a magnetic recording layer formed on the soft magnetic layer and having an easy axis of magnetization perpendicular to the substrate. The metal underlying layer is made of an alloy of elements selected from the group consisting of Co, Ni, and Fe an dhas a coercive force of 3 oersteds or less. The soft magnetic backing layer has a thickness of 100 to 600 nm.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com