Patents

Literature

74results about "Thick magnetic films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

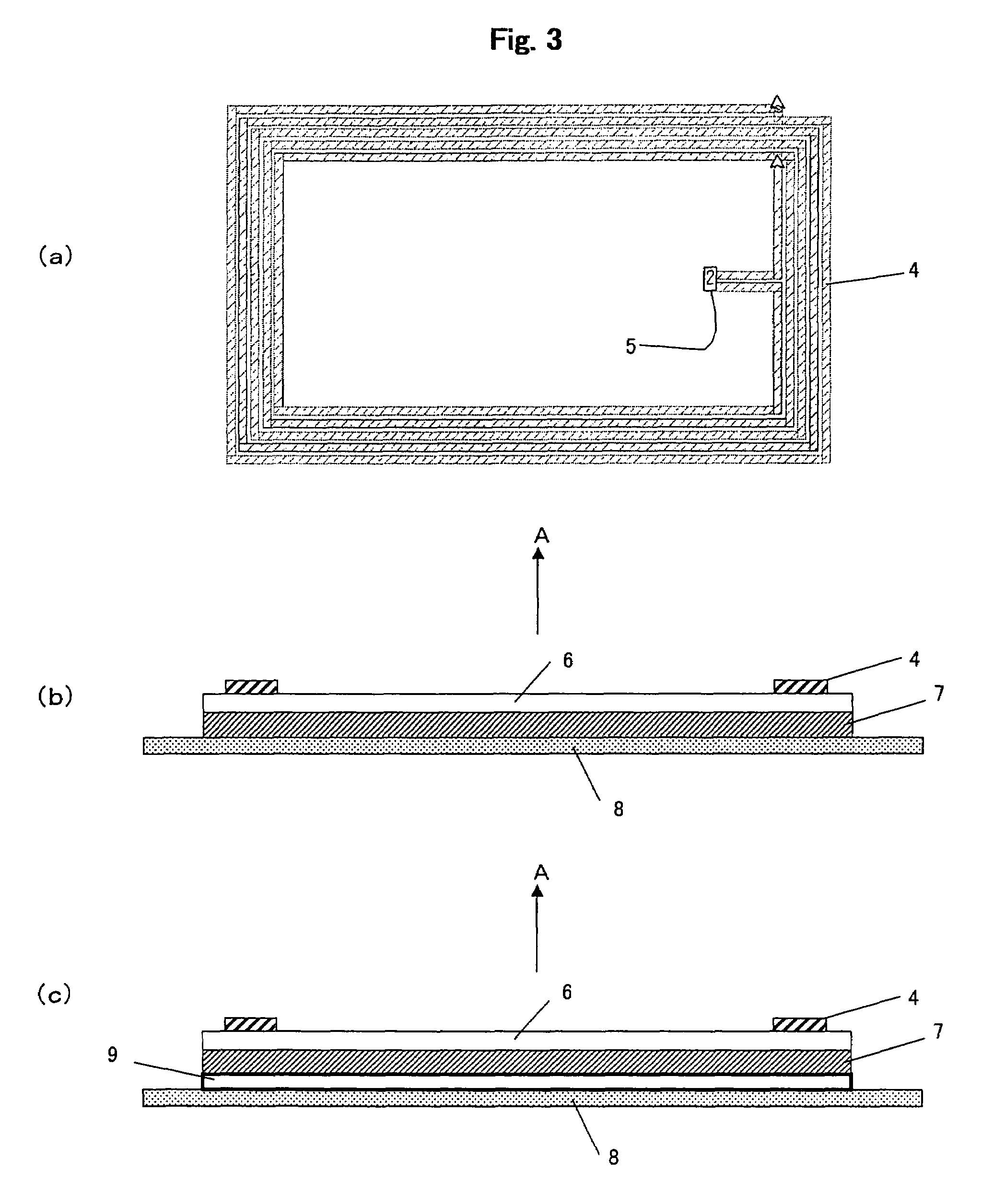

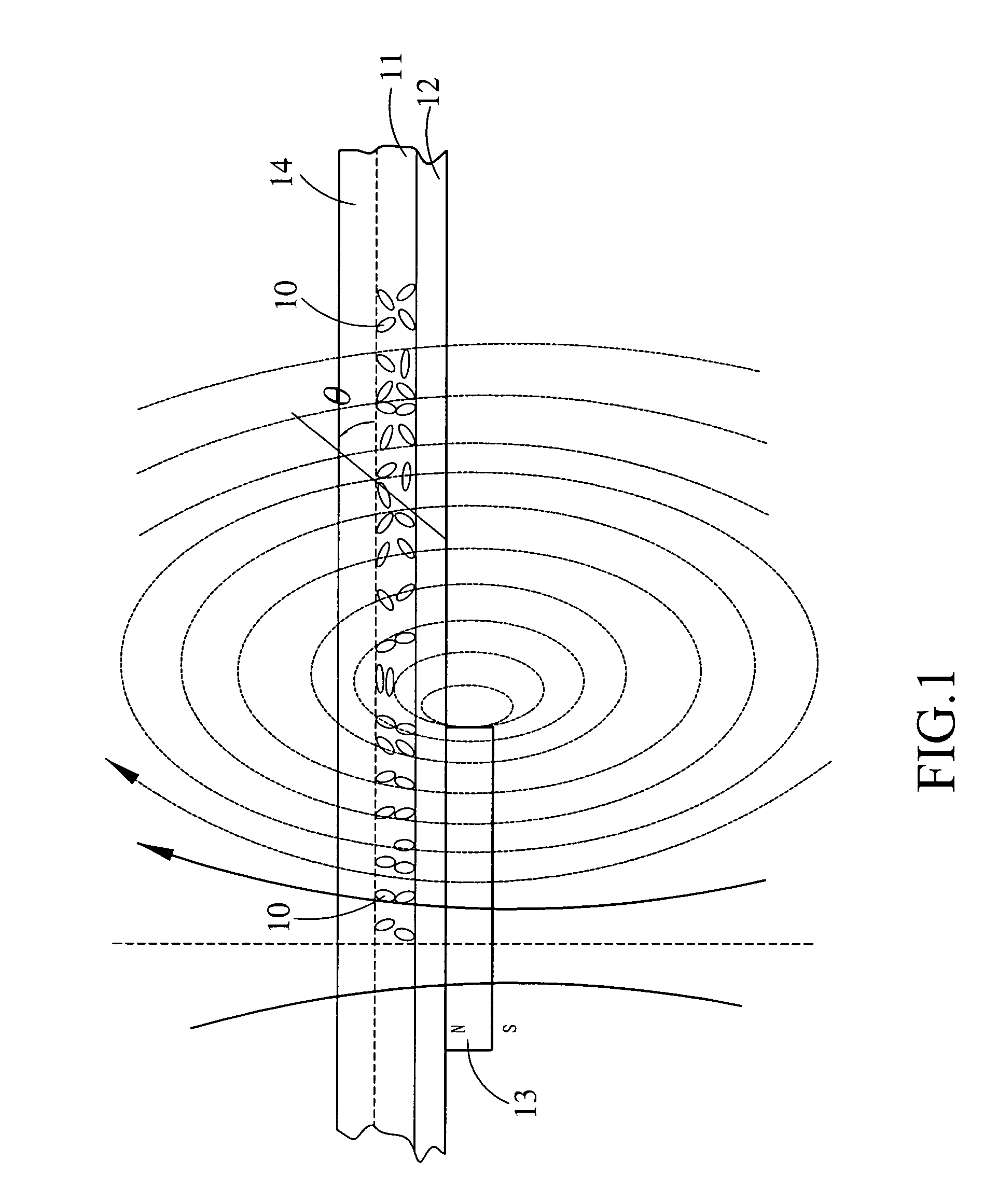

Electromagnetic Interference Suppressor, Antenna Device and Electronic Information Transmitting Apparatus

InactiveUS20070252771A1High densitySuperior electromagnetic interference suppressing effectMagnetic/electric field screeningLayered productsElastomerVitrification

An electromagnetic interference suppressor of substantially unpressurized sheet form is obtained by applying and drying a magnetic paint, and comprises 30 to 80% by volume of soft magnetic powder and 20 to 70% by volume of a binder. The binder is an elastomer or a resin that a glass transition point and / or a softening point is 50° C. or more and a storage modulus (E′) is 107 Pa (JIS K 7244-1) or more in a state containing neither solvent nor filler at room temperature. This electromagnetic interference suppressor exerts a superior electromagnetic interference suppressing effect.

Owner:NITTA CORP

High density magnetic recording compositions and processes thereof

InactiveUS6451220B1NanomagnetismMagnetic materials for record carriersHigh densityCobalt ferrite nanoparticles

A magnetic composition comprised of cobalt ferrite nanoparticles dispersed in an ionic exchange resin.

Owner:XEROX CORP

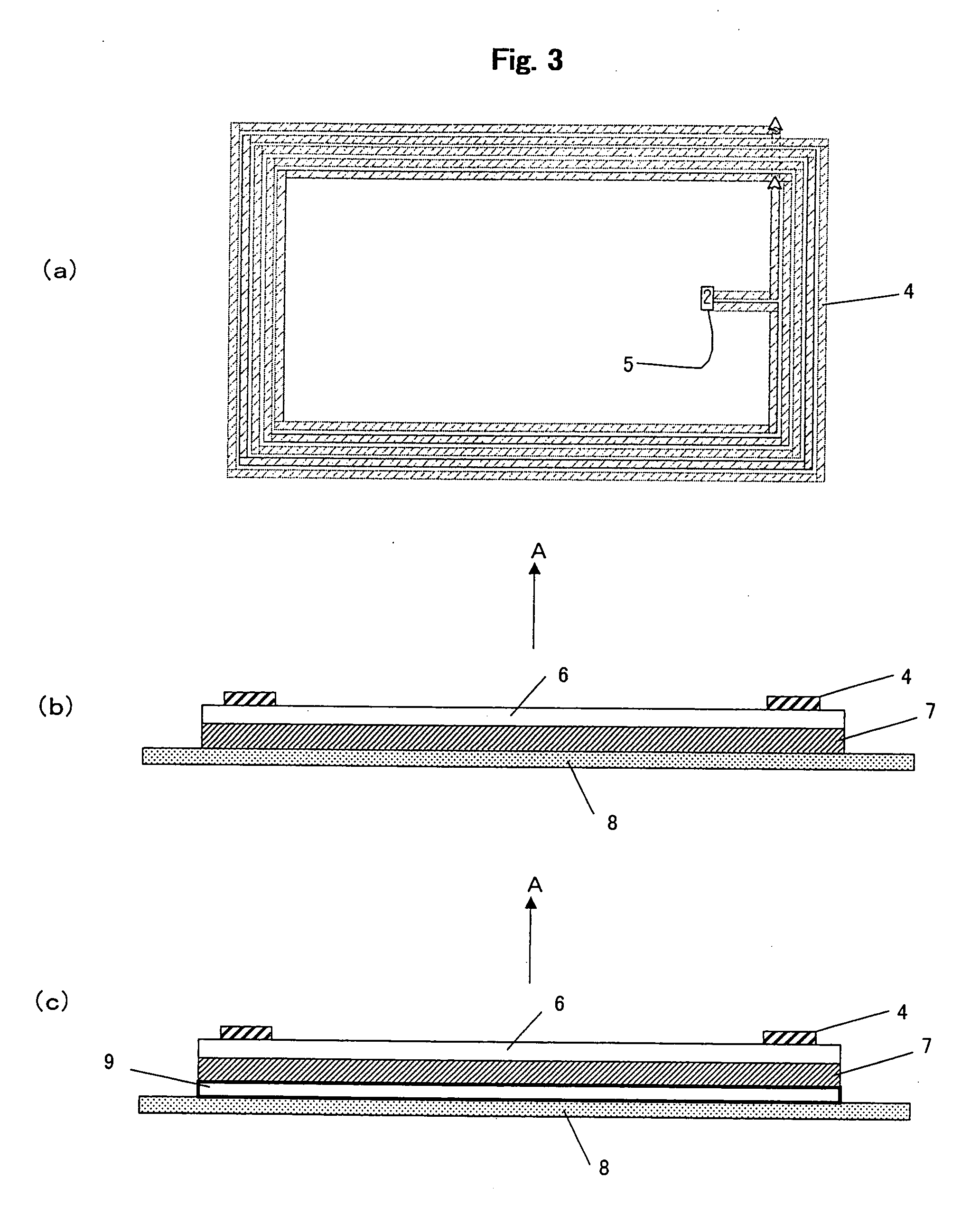

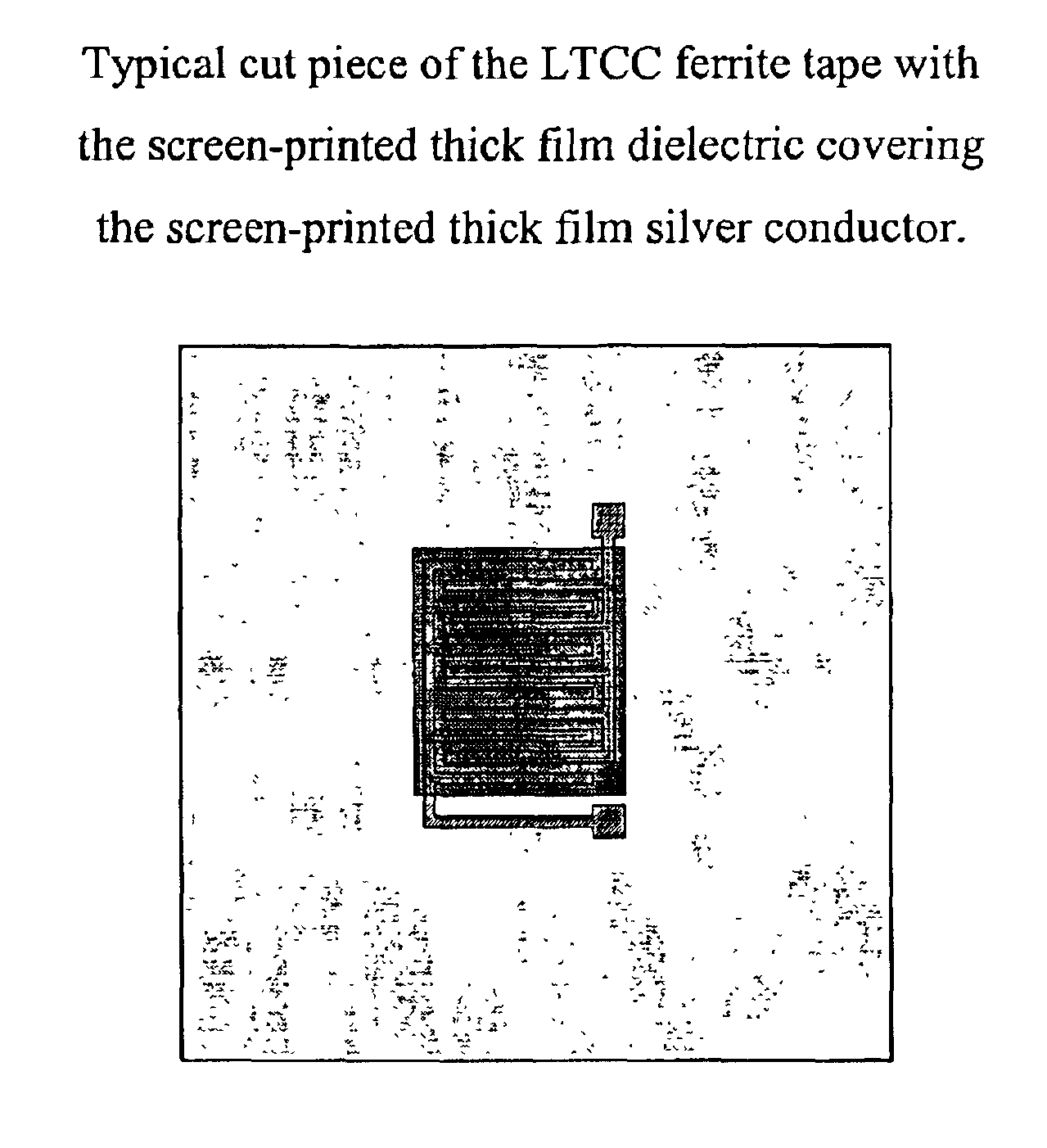

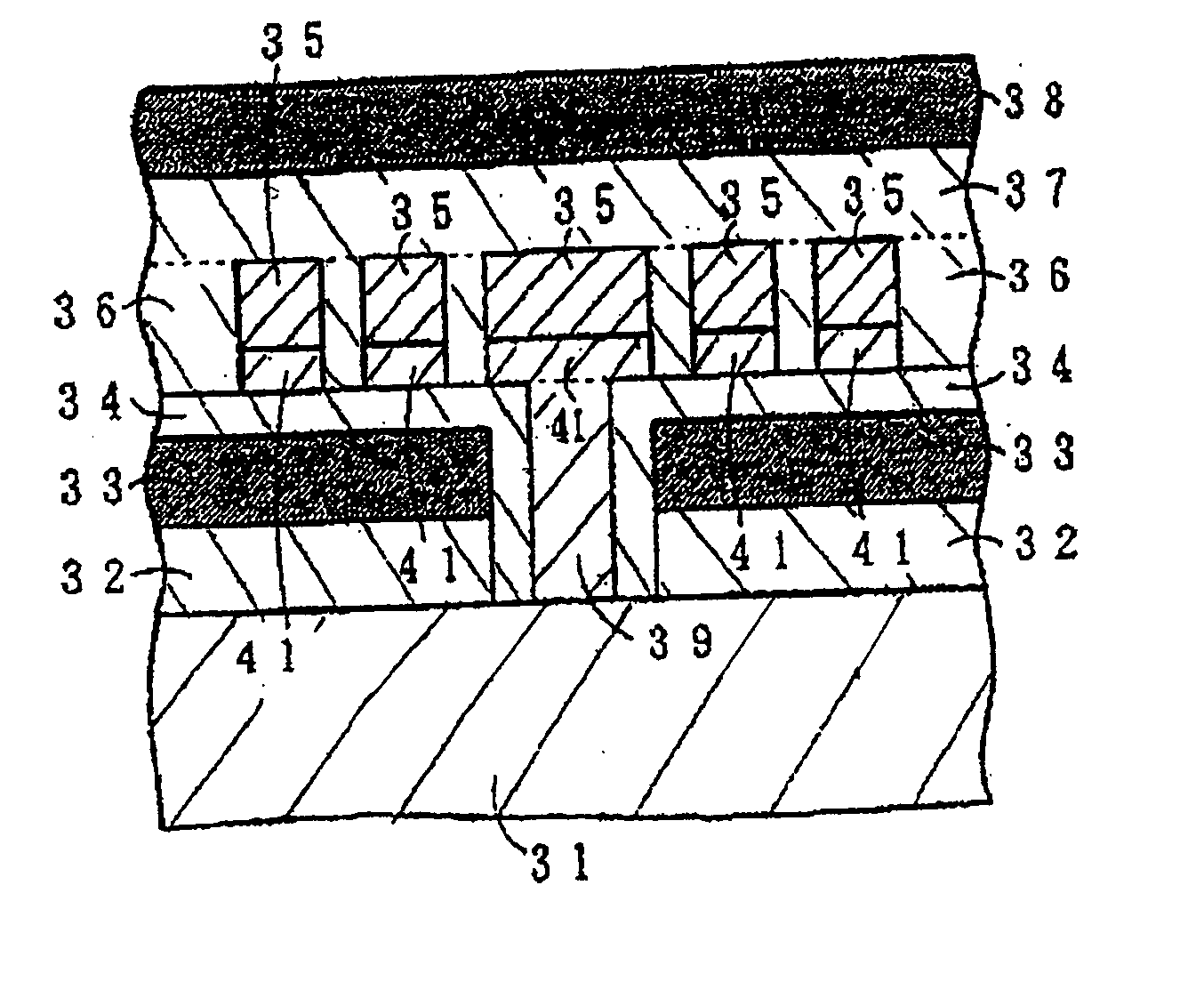

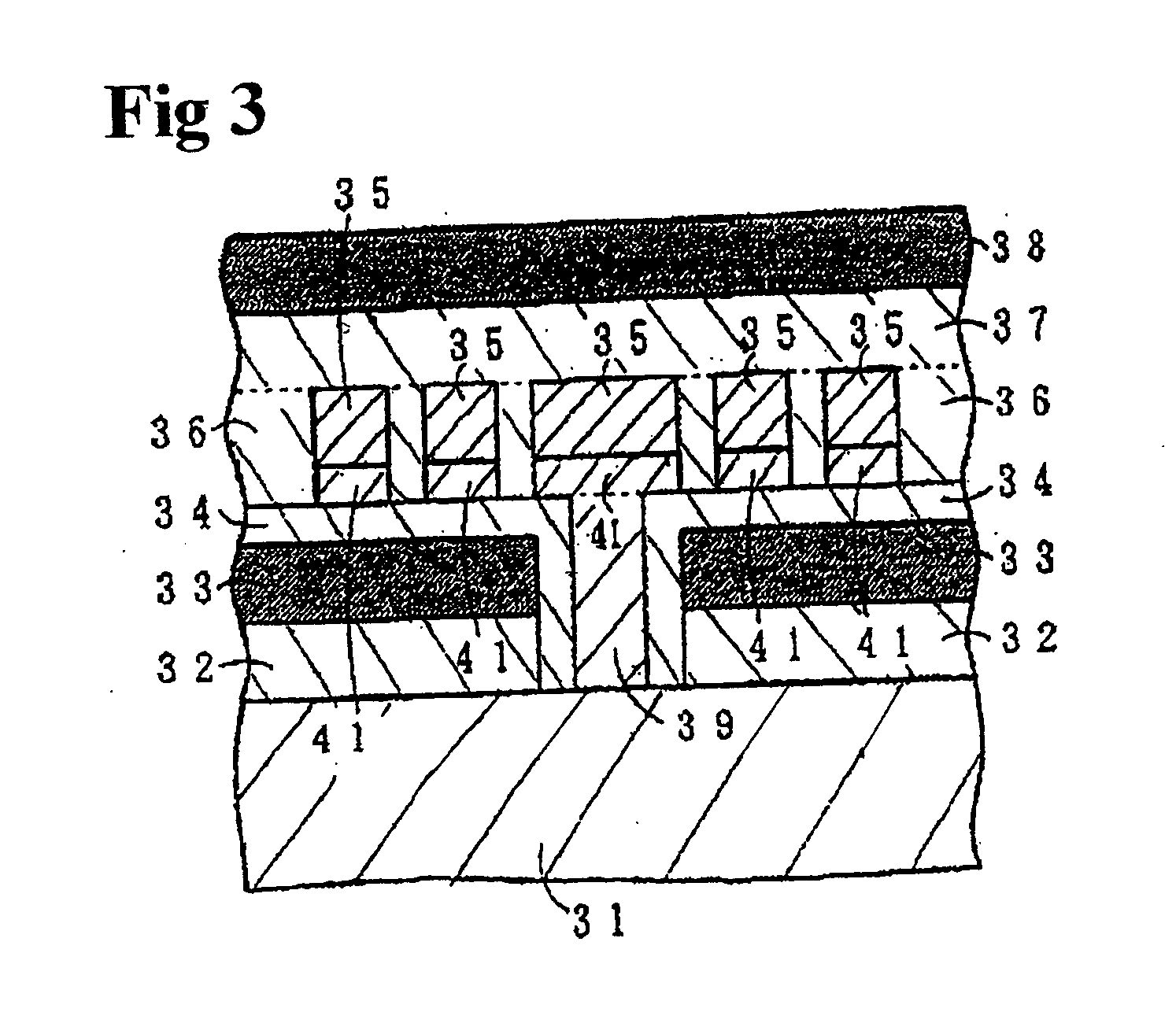

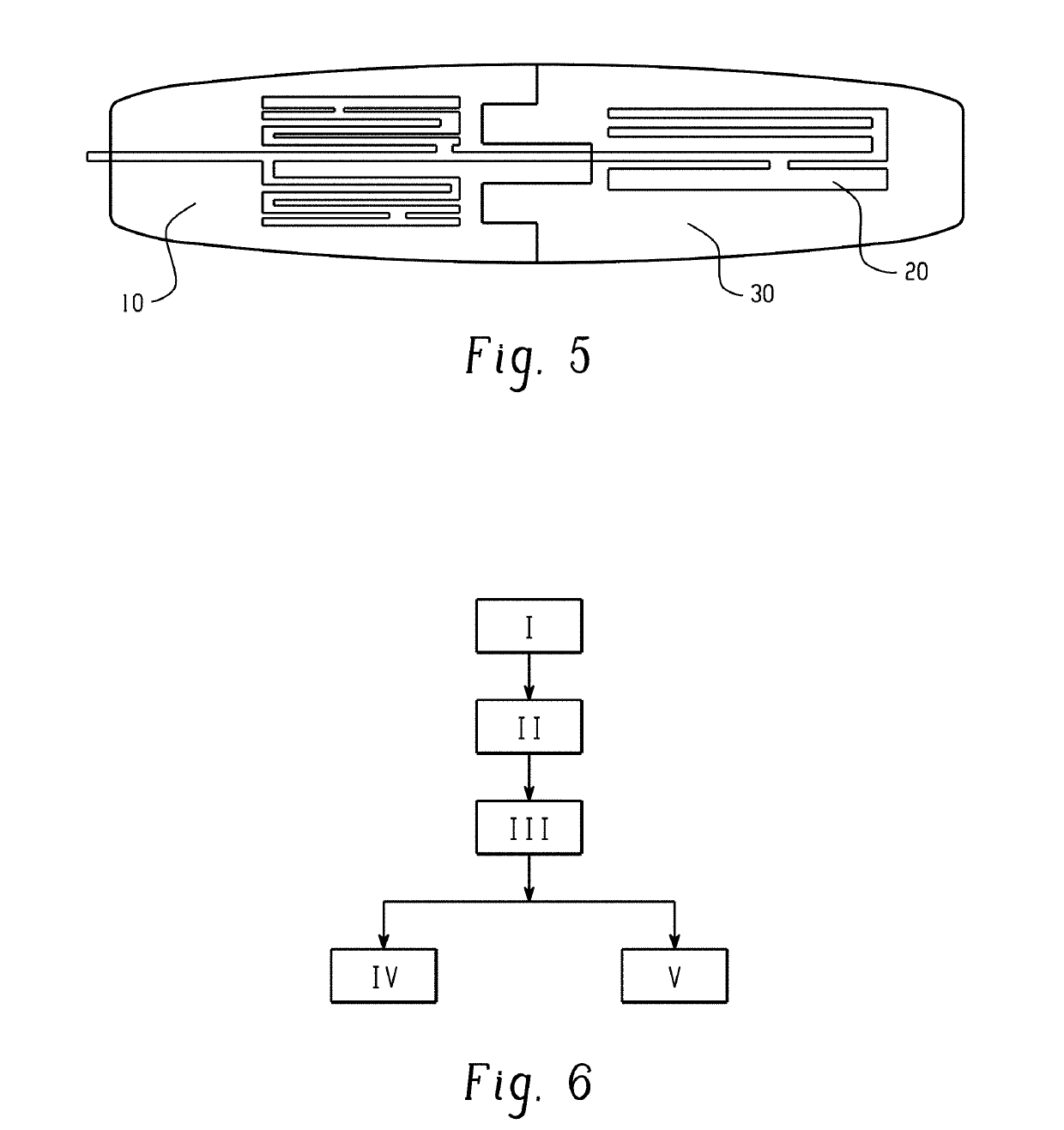

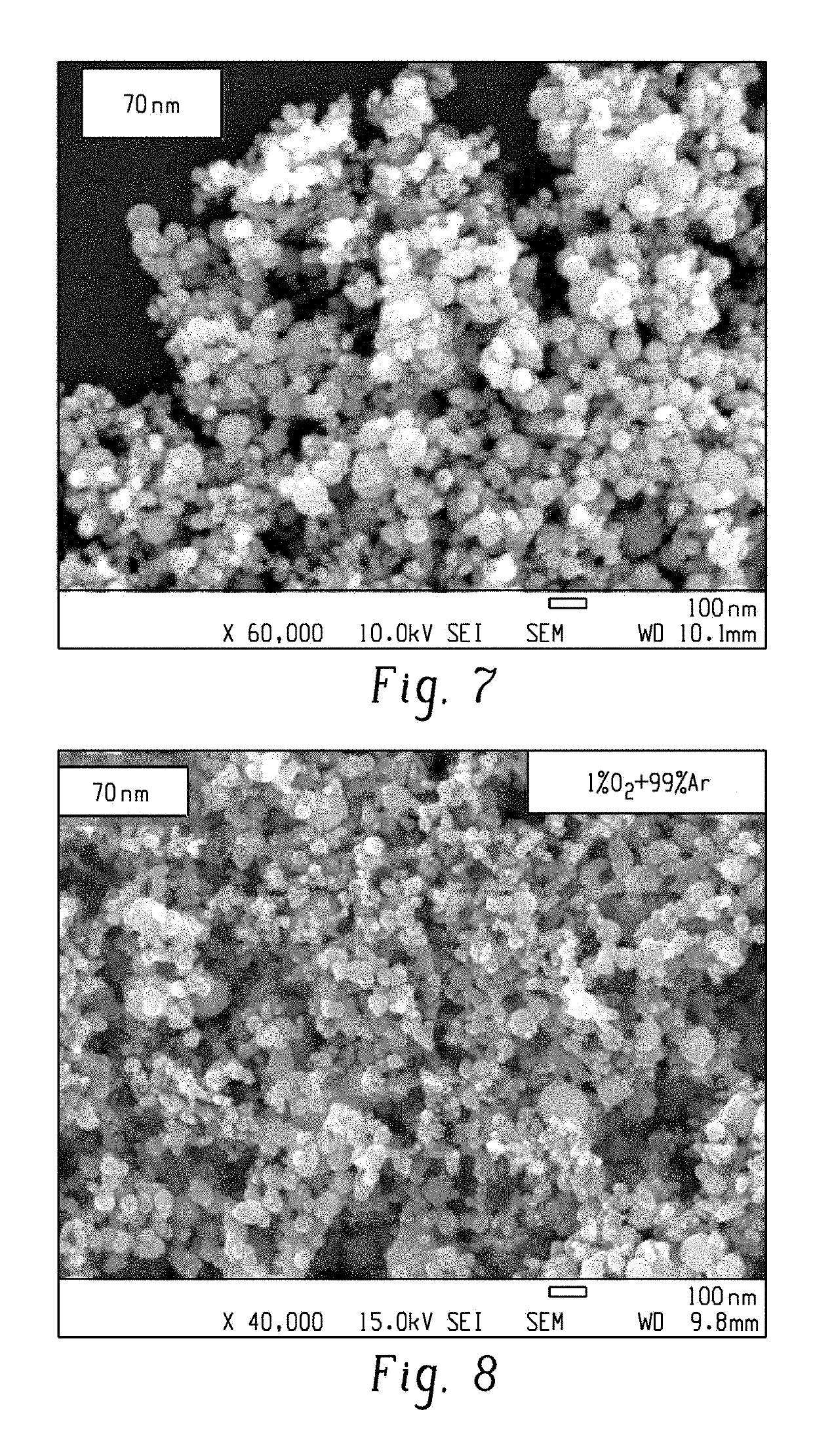

Materials system for low cost, non wire-wound, miniature, multilayer magnetic circuit components

InactiveUS6914513B1Enhancing magnetic coupling coefficientEnhance interestTransformers/inductances coils/windings/connectionsPrinted circuit aspectsDielectricElectrical conductor

This invention describes materials system and processing conditions for manufacturing magnetic circuit components such as induction coils and transformers that are non wire-wound, miniature in size and, have a low manufacturing cost. The materials system of this invention is comprised of: (1) Low Temperature Cofire Ceramic (LTCC) tapes or thick film pastes of ferromagnetic ceramics with a 20 to 750 range of magnetic permeability to form the magnetic core of the components, (2) Thick film buried silver conductor paste to form the planar induction coils on individual magnetic layers, (3) Thick film via-fill silver conductor paste to interconnect two or more of the planar induction coils through the thickness of the magnetic layers, (4) Thick film silver solderable top layer conductor paste compatible with the ferrite and, (5) Thick film dielectric paste with low magnetic permeability to redirect the magnetic flux for enhancing the magnetic coupling coefficient and to insulate the silver conductors for enhancing the dielectric breakdown voltage. The key characteristics of the materials system of this invention that facilitate manufacture of low cost non wire-wound, miniature magnetic circuit components are: (1) Mutual compatibility essential for either of the techniques, the cofire technique or the sequential technique, used for manufacturing multilayer hybrid microelectronic components, (2) Complementary thermo-physical properties such as shrinkage and thermal expansion coefficient essential for manufacturing flat multilayer magnetic components, (3) Magnetic components with magnetic coupling coefficients greater than 0.95 under optimal processing conditions and, (4) Magnetic components with dielectric breakdown voltage greater than 500V / mil under optimal processing conditions.

Owner:FERRO CORP

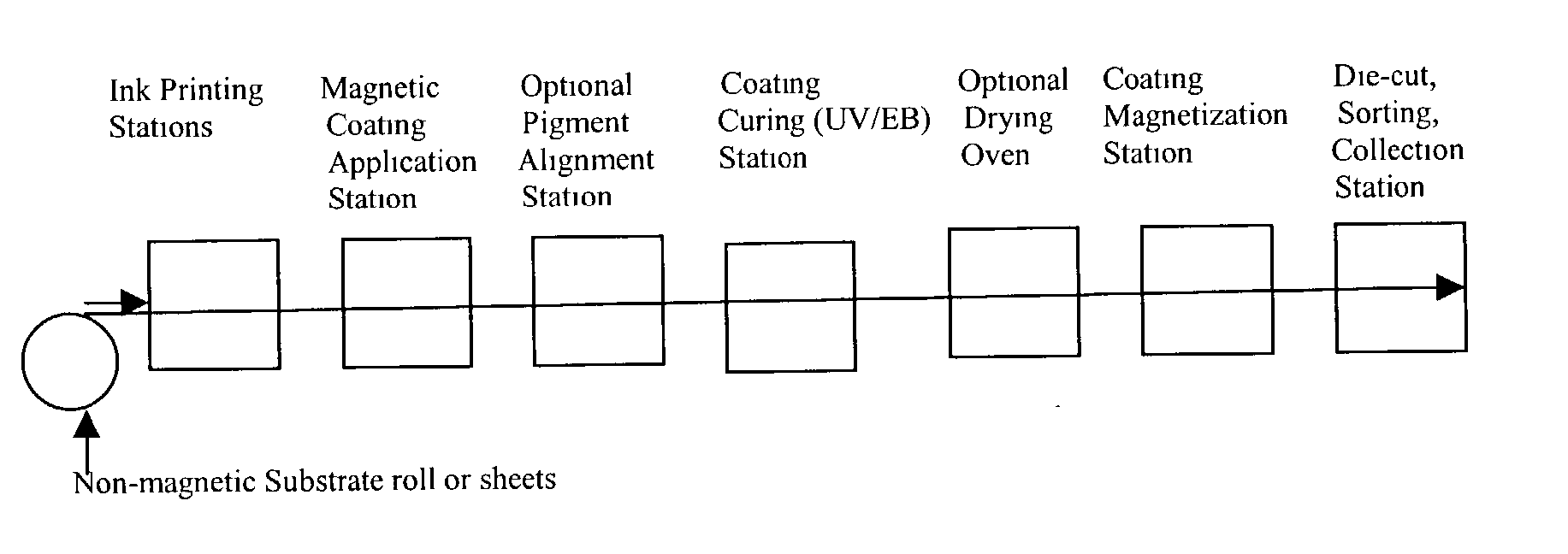

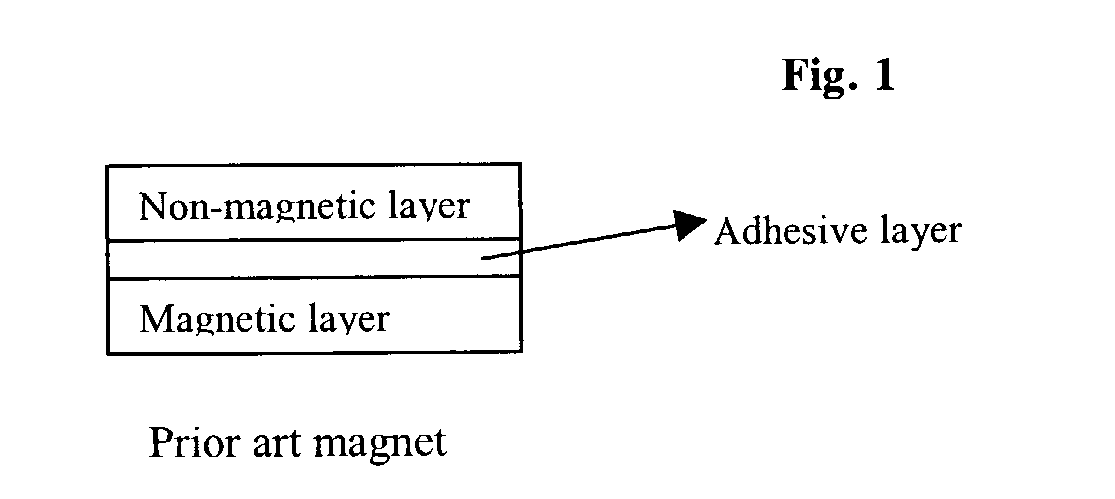

UV/EB cured integrated magnets-composition and method of fabrication

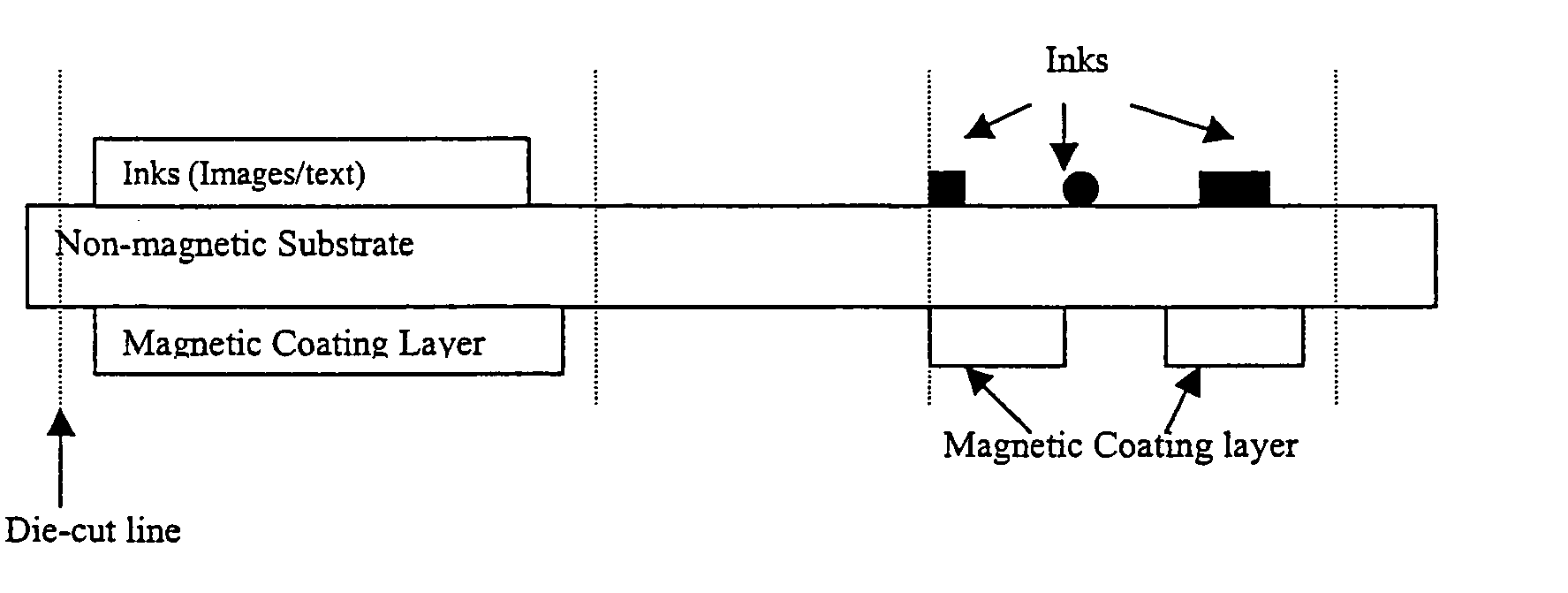

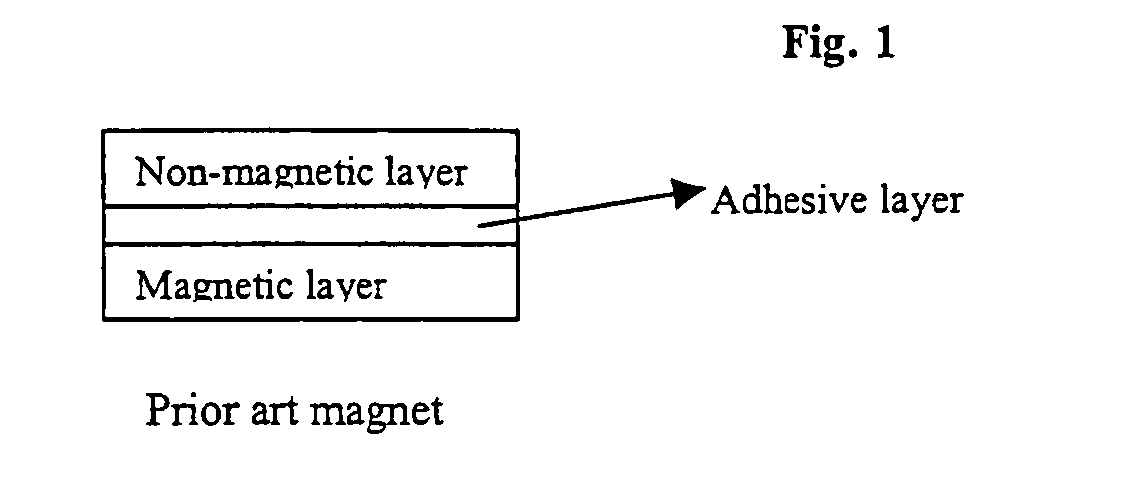

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM +1

Acid stable aqueous dispersion of metal particles and applications

InactiveUS6811885B1Improve colloidal stabilityProtective coatings for layersMagnetic liquidsMetal particleRecording layer

Aqueous coating compositions containing acid stable metal dispersions, prepared by chemical reduction in aqueous medium, are obtained by using a N-quaternized cellulose derivative as binder. They can be used for the preparation of heat mode recording layers, magnetic layers and conductive layers.

Owner:AGFA GEVAERT AG

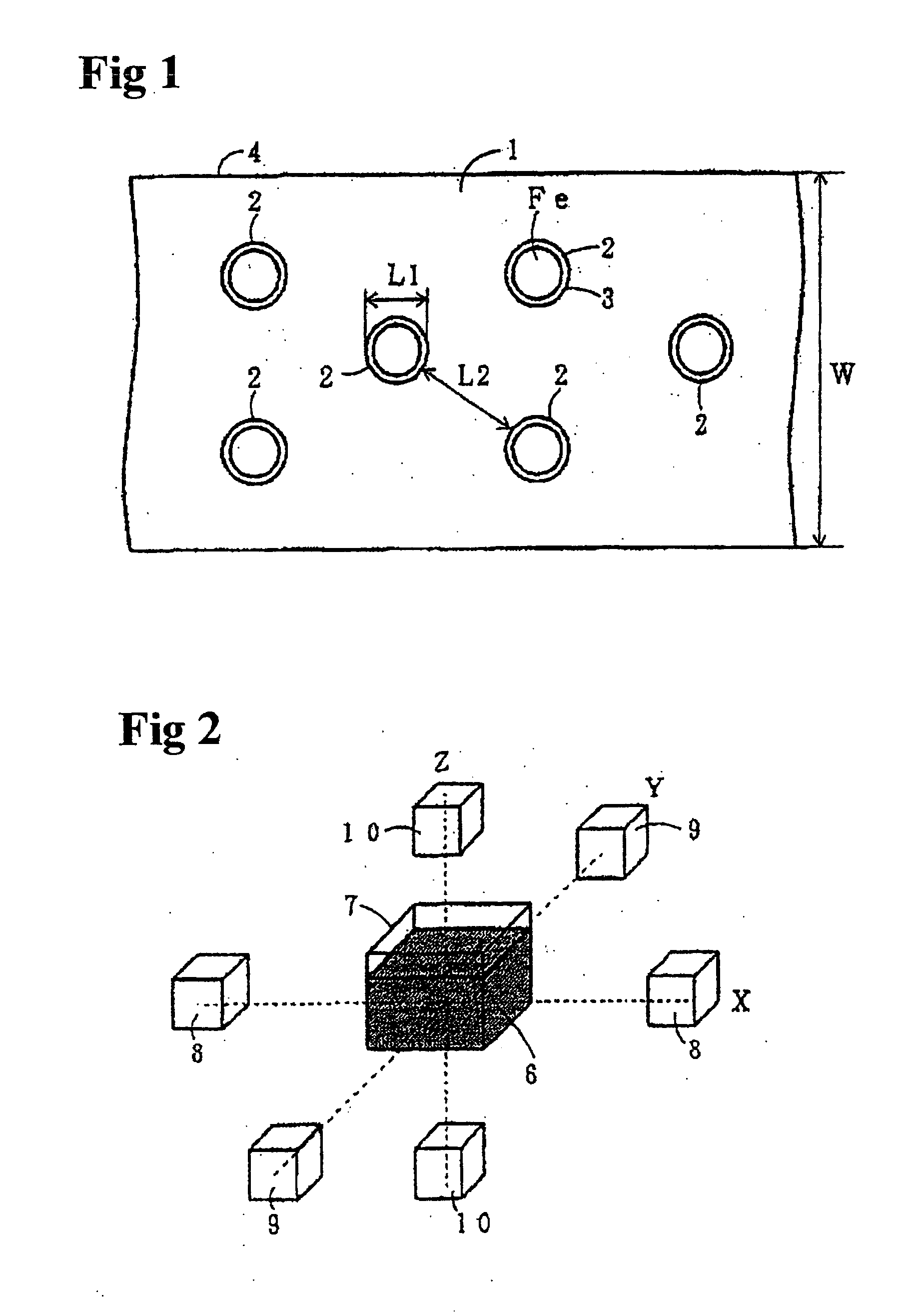

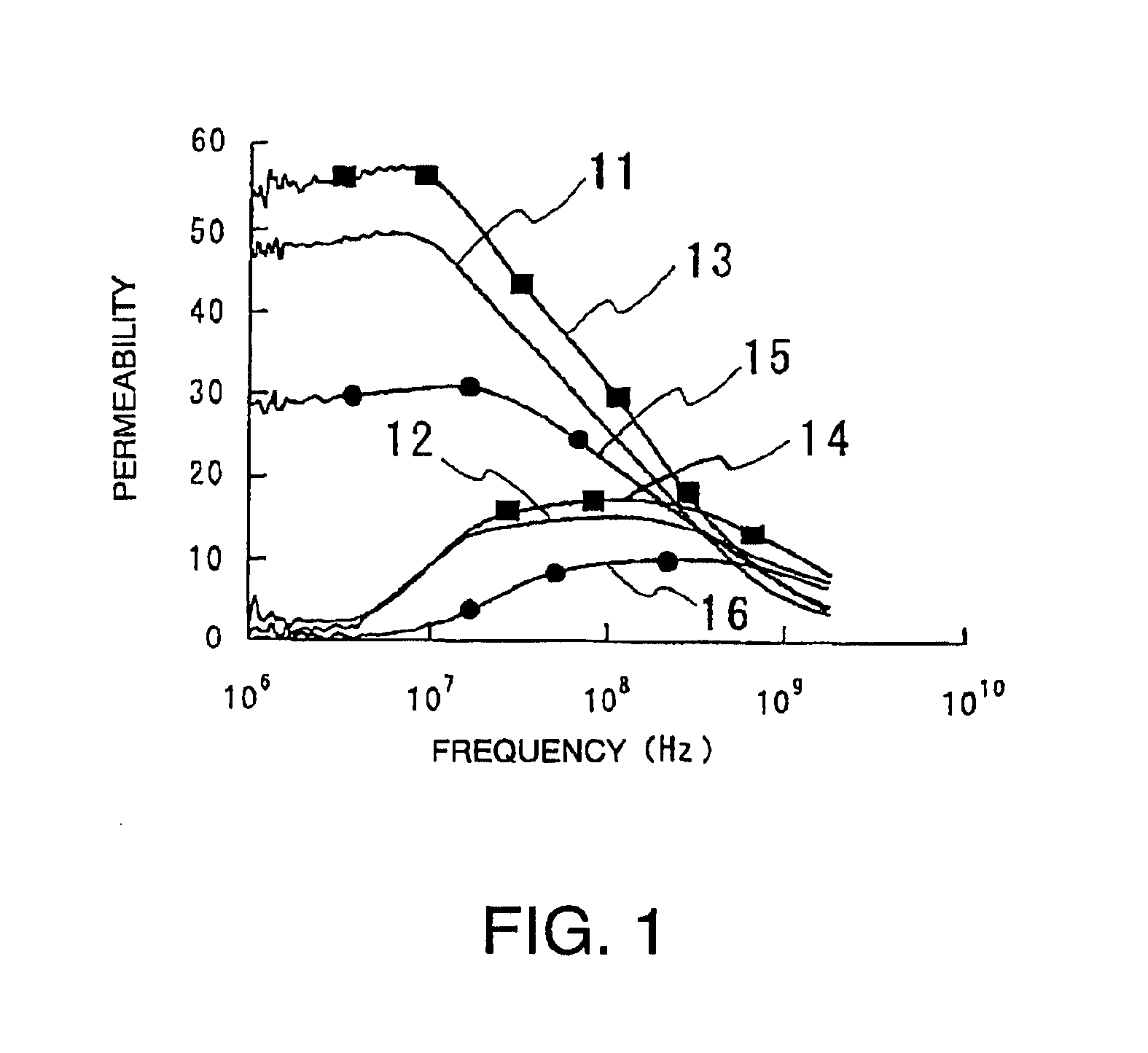

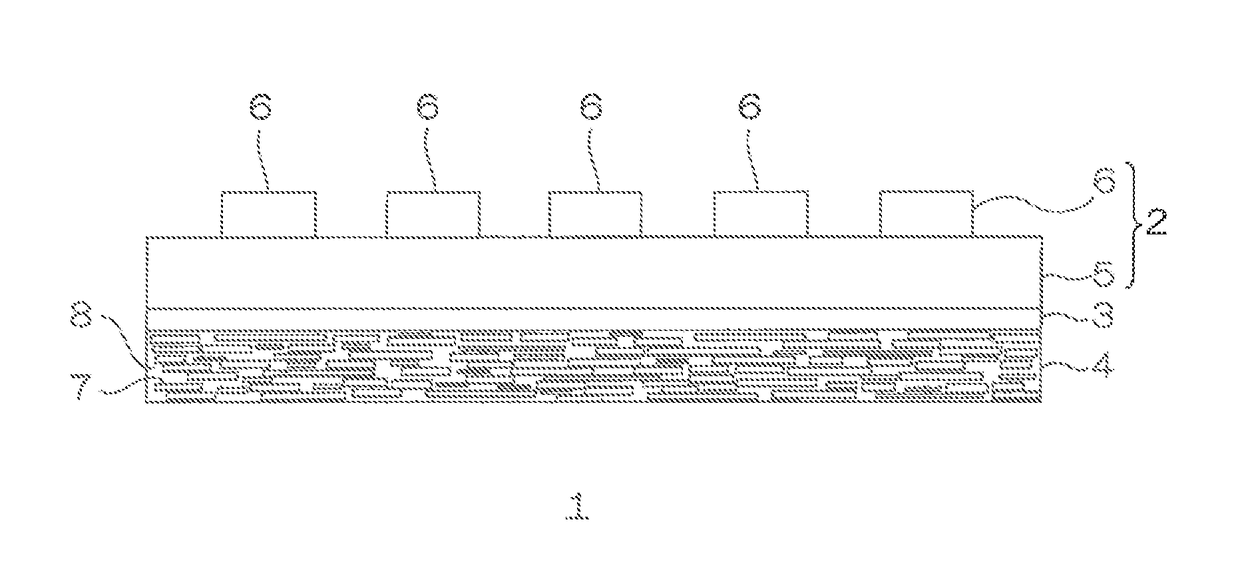

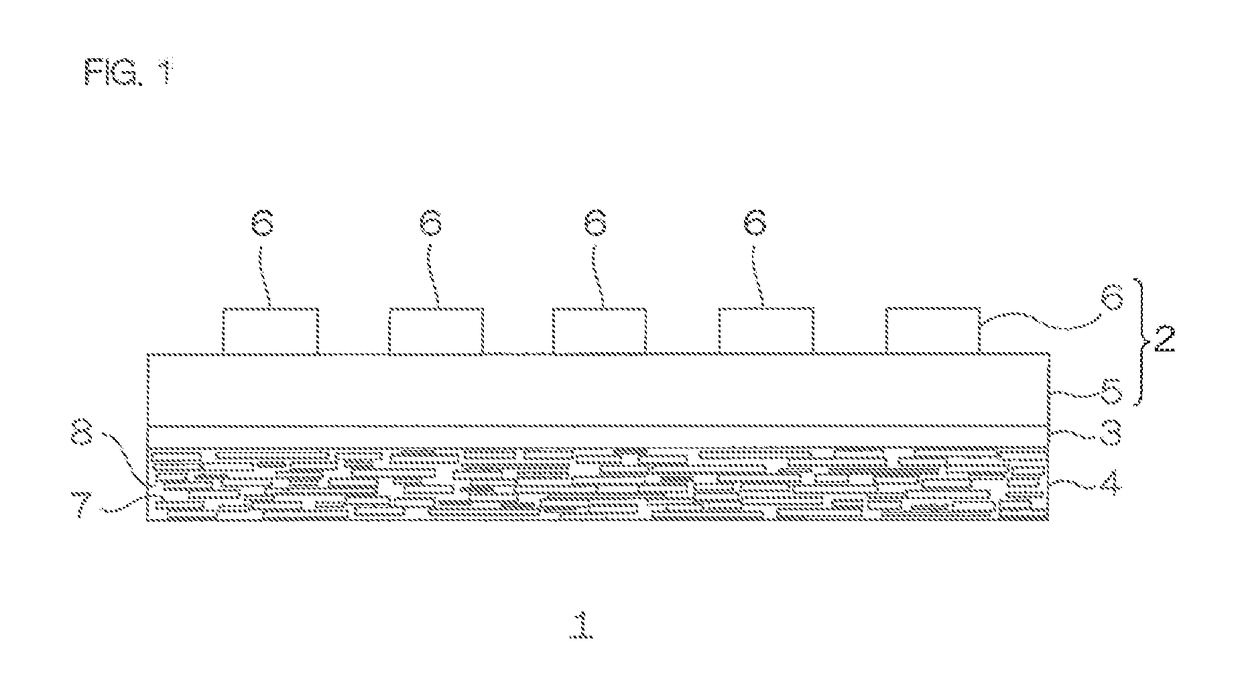

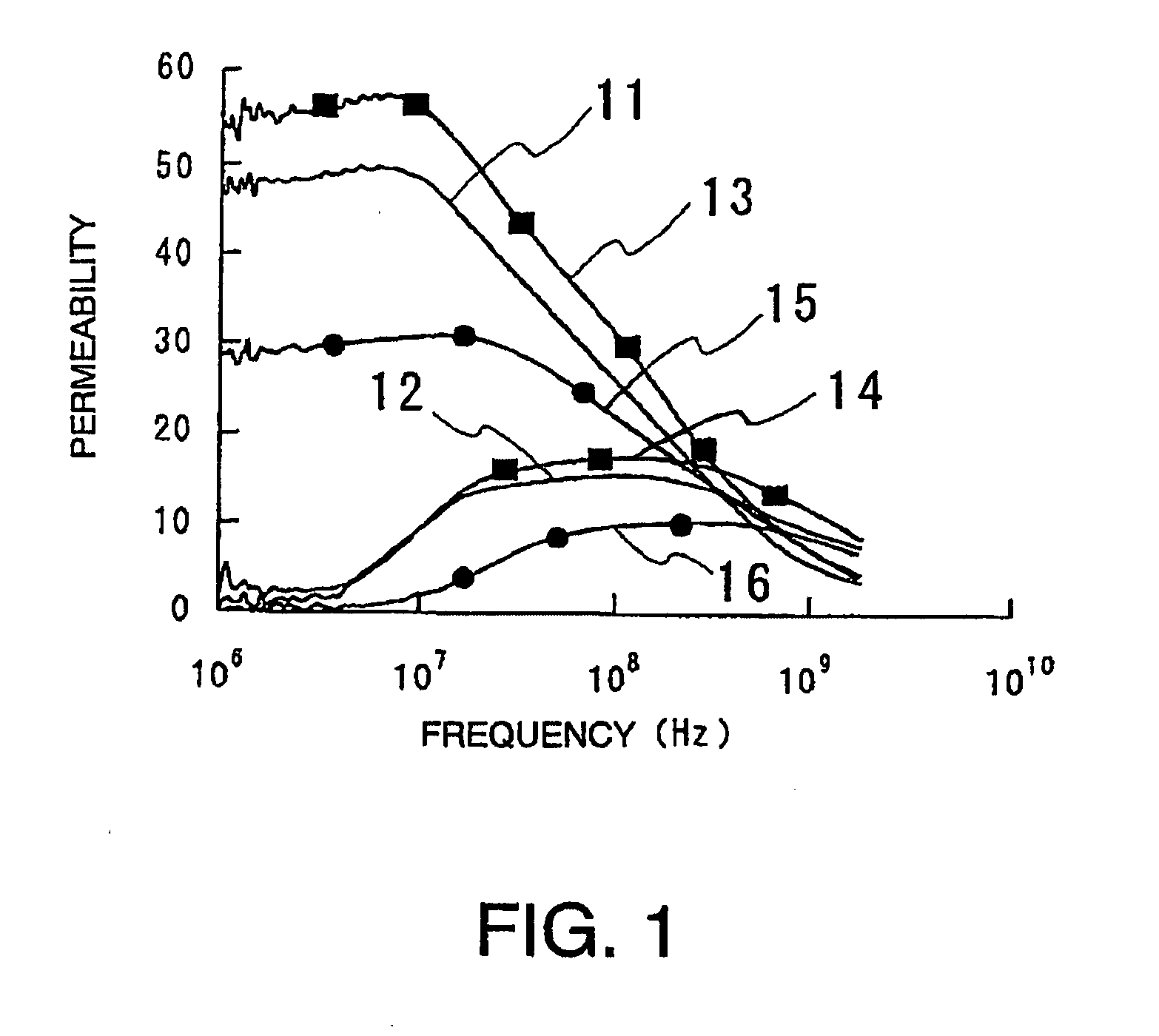

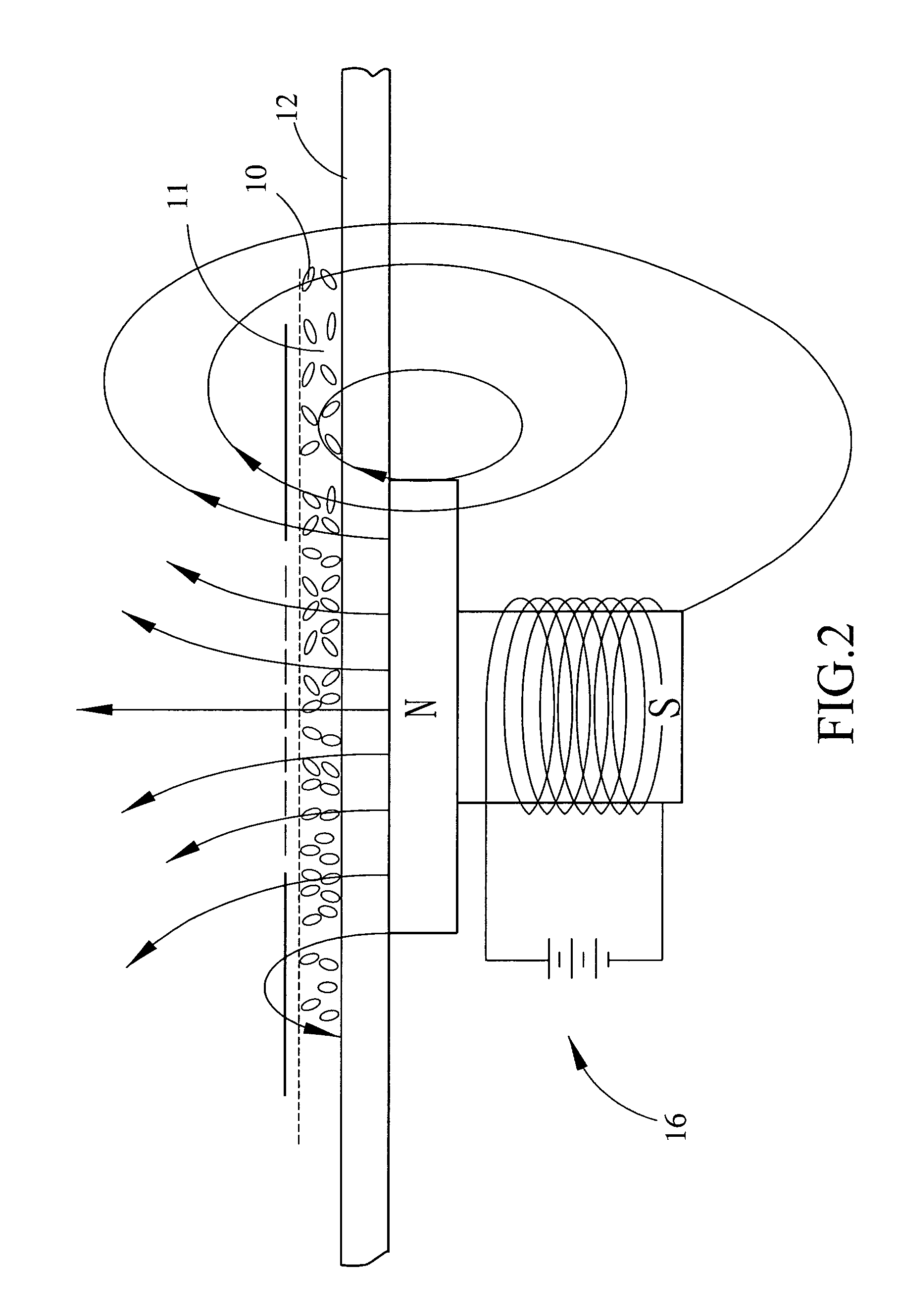

Magnetic thin film, magnetic component that uses this magnetic thin film, manufacturing methods for the same, and a power conversion device

InactiveUS20050094302A1Soft qualityEasy to manufactureNanomagnetismSemiconductor/solid-state device detailsElectric forceElectrical conductor

On top of a silicon substrate, a polyimide film with a thickness of 10 μm is formed. On top of this, a magnetic thin film that is a polyimide film containing Fe fine particles and that has a thickness of 20 μm is formed. On top of this magnetic thin film, a patterned Ti / Au film and a Ti / Au connection conductor are formed. On top of this, a polyimide film with a thickness of 10 μm, and a Cu coil with a height 35 μm, width 90 μm, space 25 μm, and a polyimide layer that fills the spaces in the Cu coil are formed. On top of this, via a polyimide film with a thickness of 10 μm, a magnetic thin film that is a polyimide film containing Fe particles and that has a thickness of 20 μm is formed. This thin film inductor has a small alternating current resistance. The present invention provides a magnetic thin film that is well suited for mass production, can be manufactured easily, can be made into a thick film, has soft magnetic qualities, and is inexpensive. The present invention also provides a magnetic component that uses this magnetic thin film, manufacturing methods for these, and a power conversion device.

Owner:FUJI ELECTRIC DEVICE TECH CO

Magnetic paint

Magnetic receptive Paints and coatings have been developed to allow one to paint a wall with this coating and apply magnets to this surface. The further development of magnetic receptive coatings incorporates the use of multiple size particles giving the finished surface a smoother appearance and increasing the particle load in the dry mill surface. This is useful in the coating of substrates where the need to coat the thinnest possible coating on the surface of a substrate such as papers and films as well as painting on walls, gives you the highest magnetic receptive surface possible at the thinnest mill thickness of applied coating.

Owner:DEETZ DAYTON JOSEPH

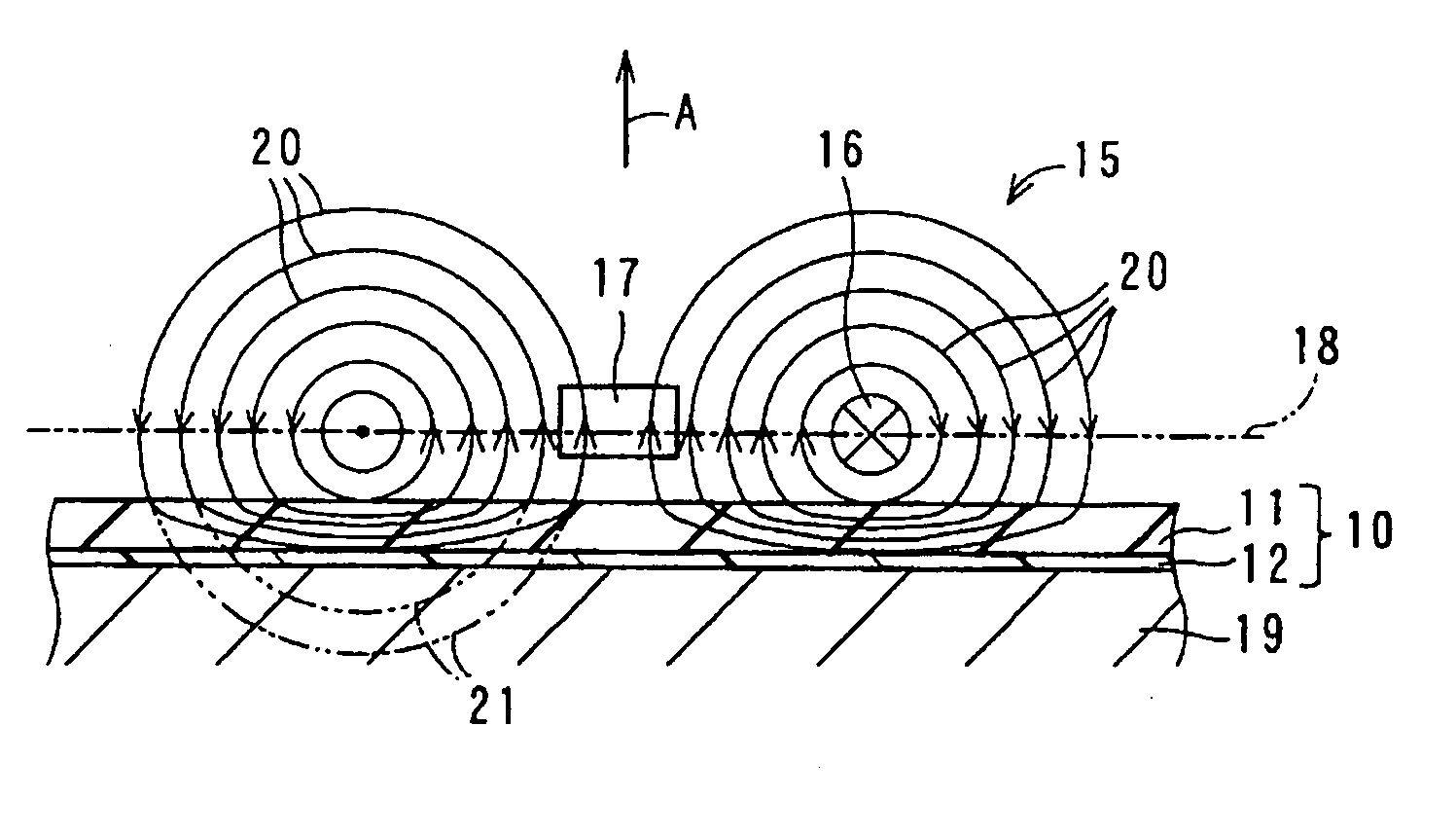

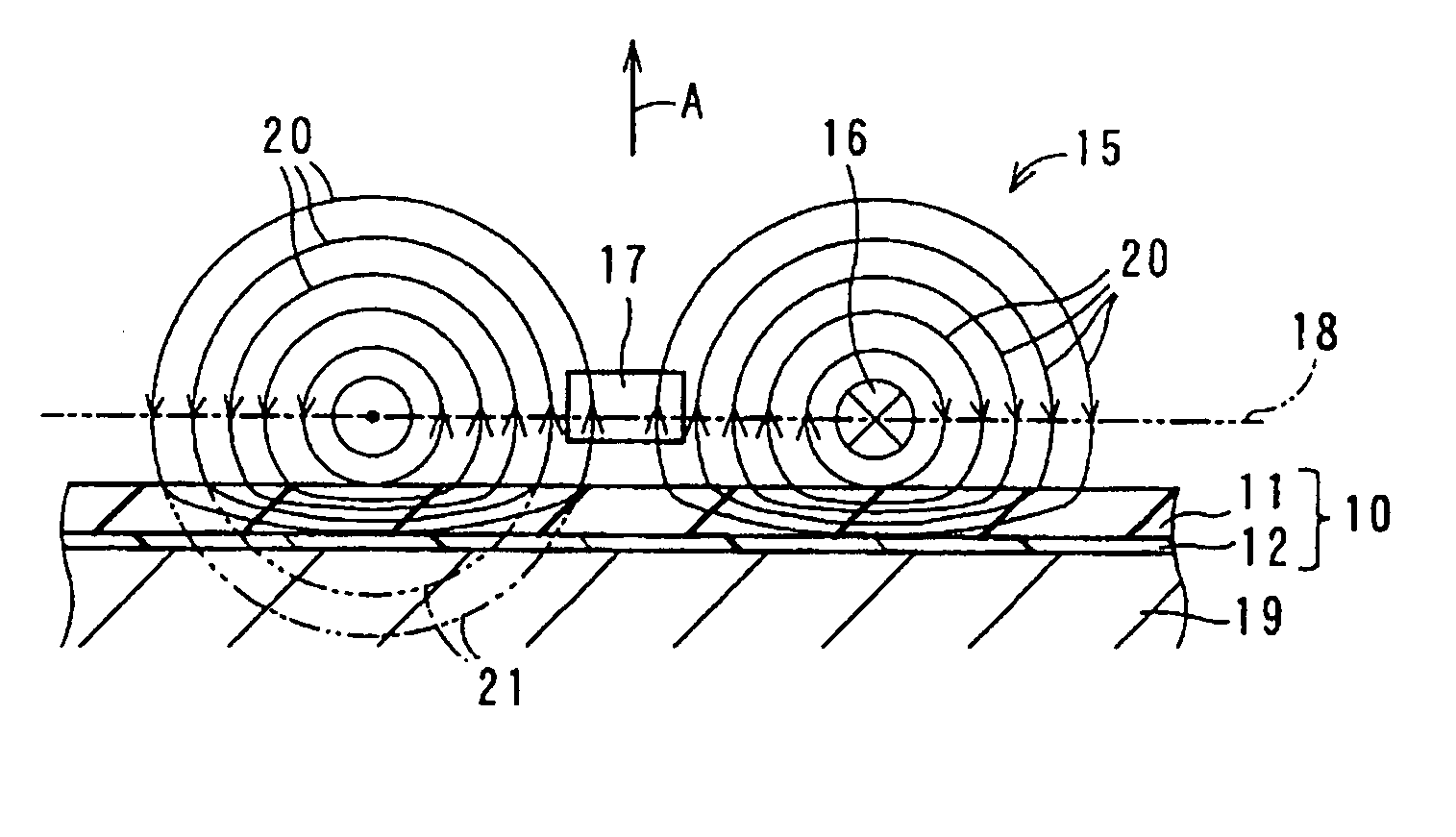

Electromagnetic interference suppressor, antenna device and electronic information transmitting apparatus

InactiveUS7561114B2Reduce interferenceHigh densityMagnetic/electric field screeningLayered productsVitrificationElastomer

Owner:NITTA CORP

Core-shell particles, magneto-dielectric materials, methods of making, and uses thereof

In an aspect, a magnetic particle, comprises a core comprising iron, and a second metal comprising cobalt, nickel, or a combination thereof; wherein a core atomic ratio of the iron to the second metal is 50:50 to 75:25; and a shell at least partially surrounding the core, and comprising an iron oxide, an iron nitride, or a combination thereof, and the second metal. In another aspect, a magneto-dielectric material comprises a polymer matrix and a plurality of the magnetic particles; wherein the magneto-dielectric material has a magnetic loss tangent of less than or equal to 0.07 at 1 GHz.

Owner:ROGERS CORP

Recording paper

ActiveCN101054782ASuppress wrinklesCoatings with pigmentsMaterials with cobaltFiber orientationWave velocity

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

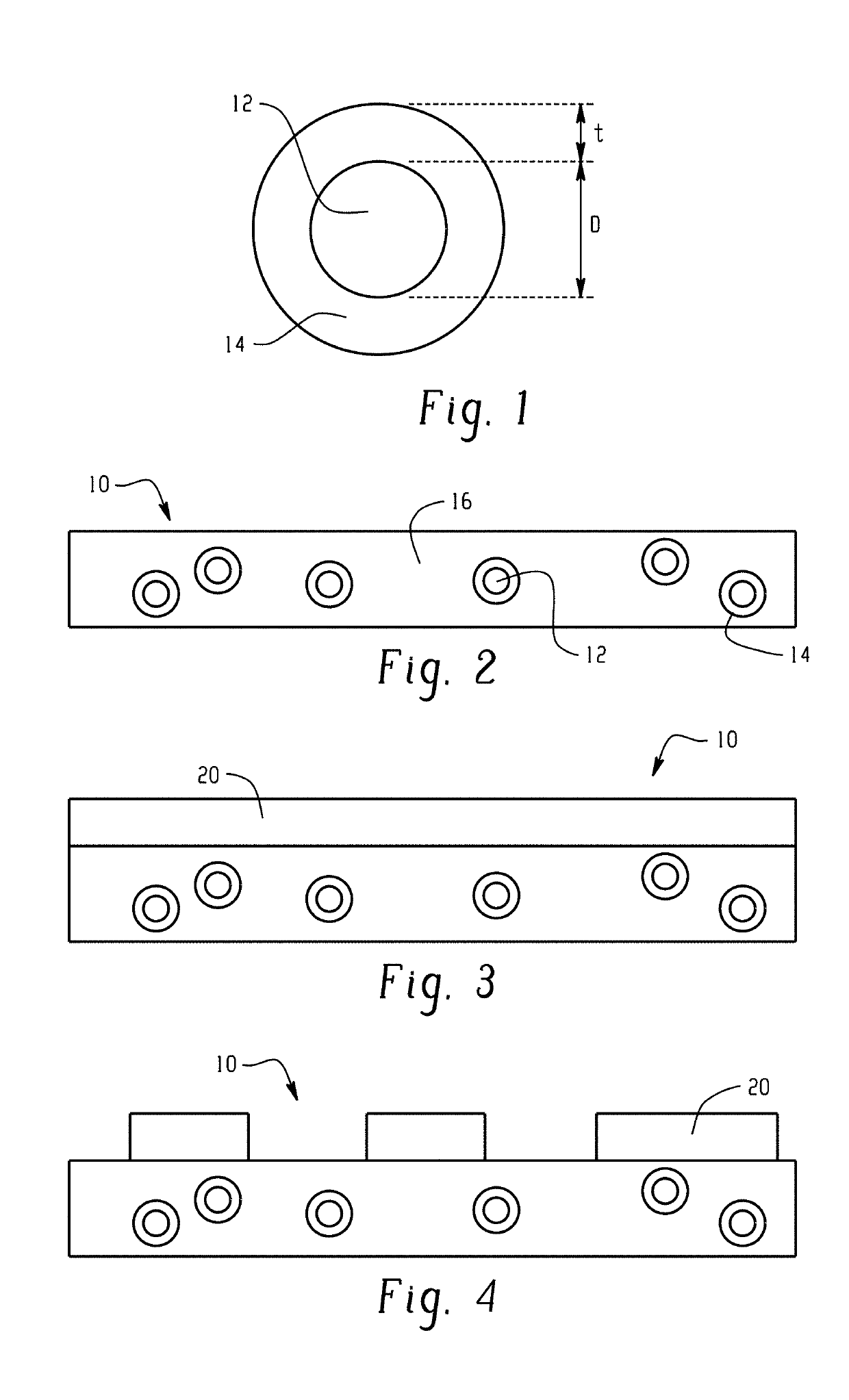

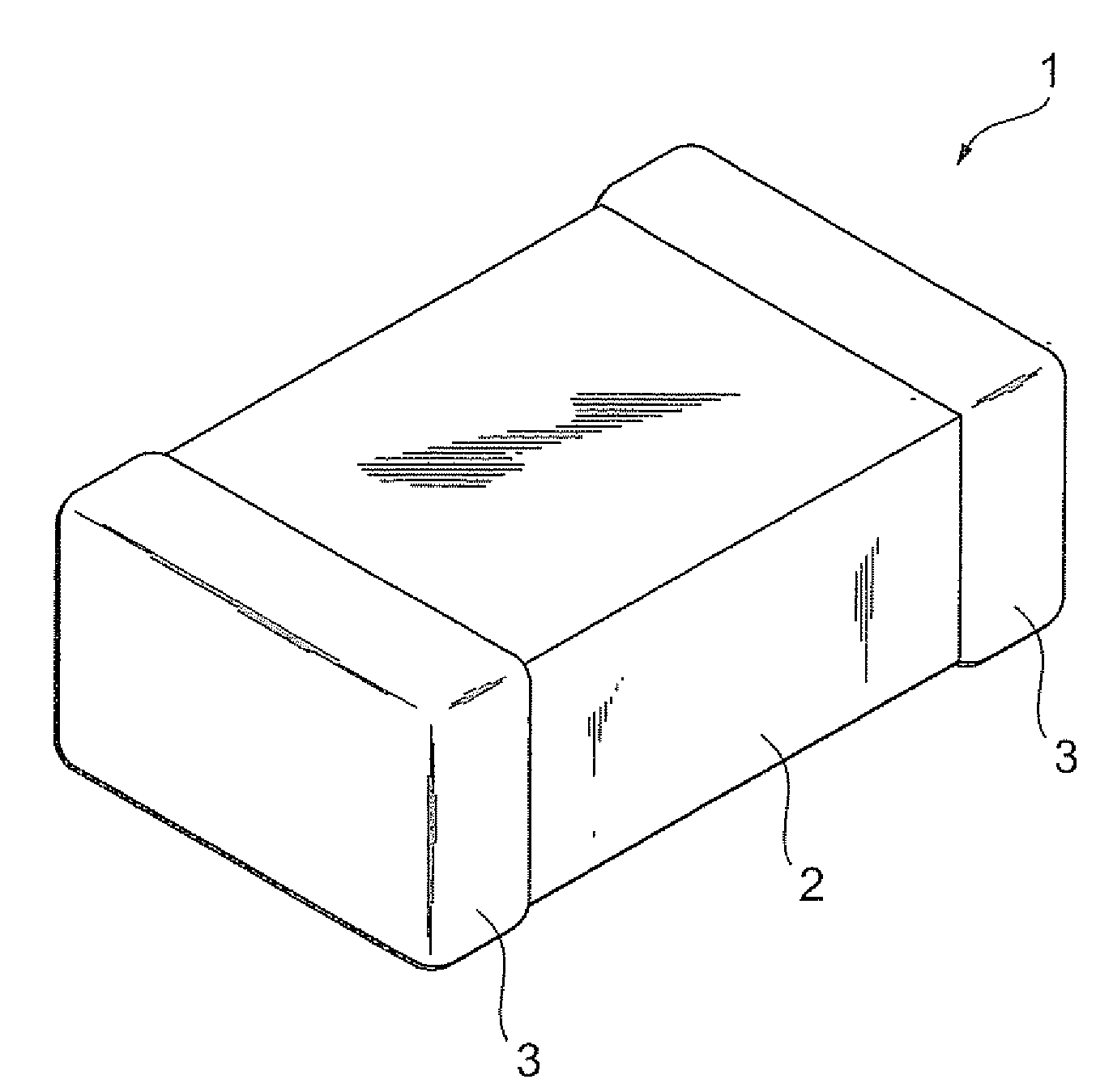

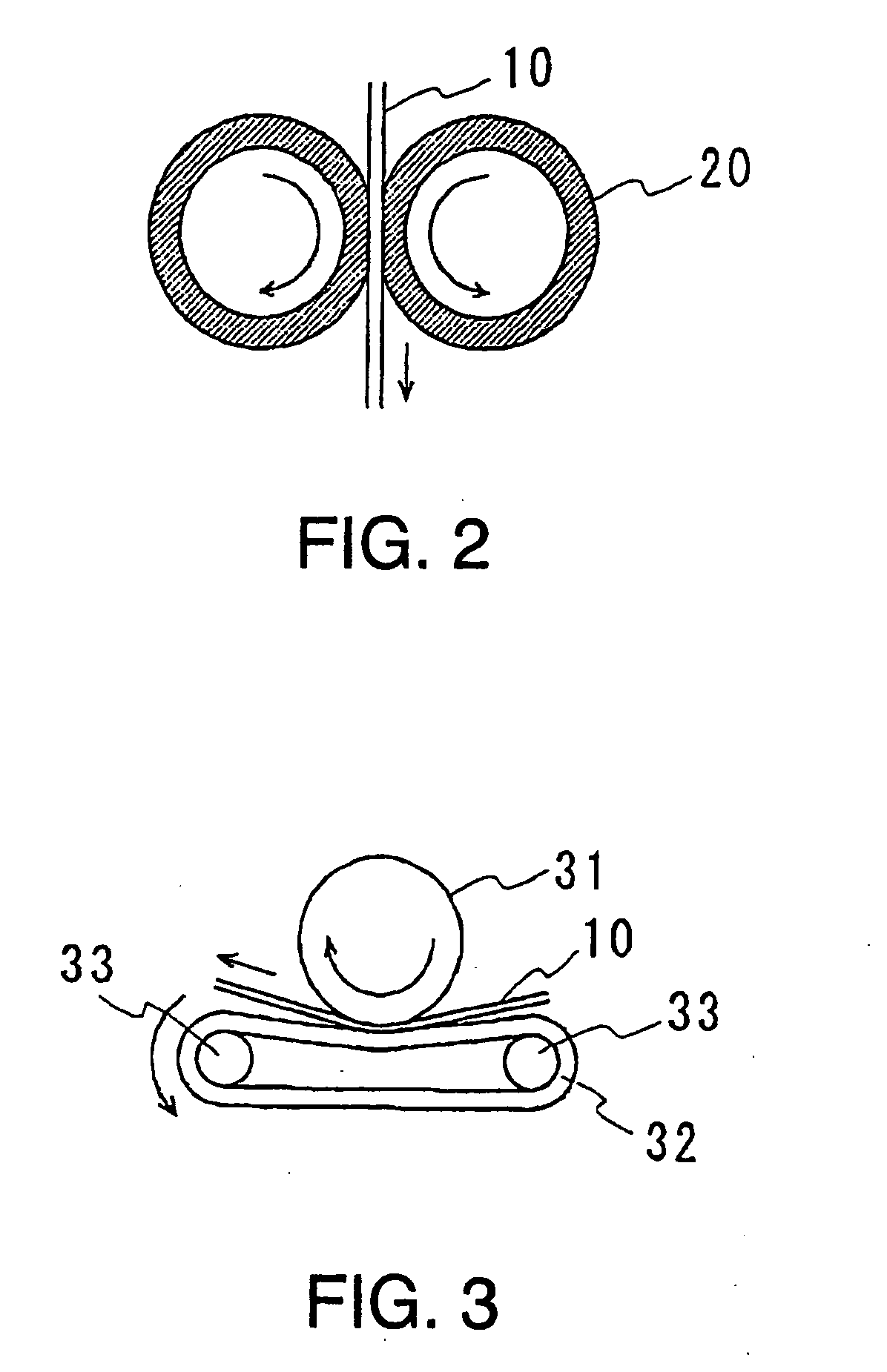

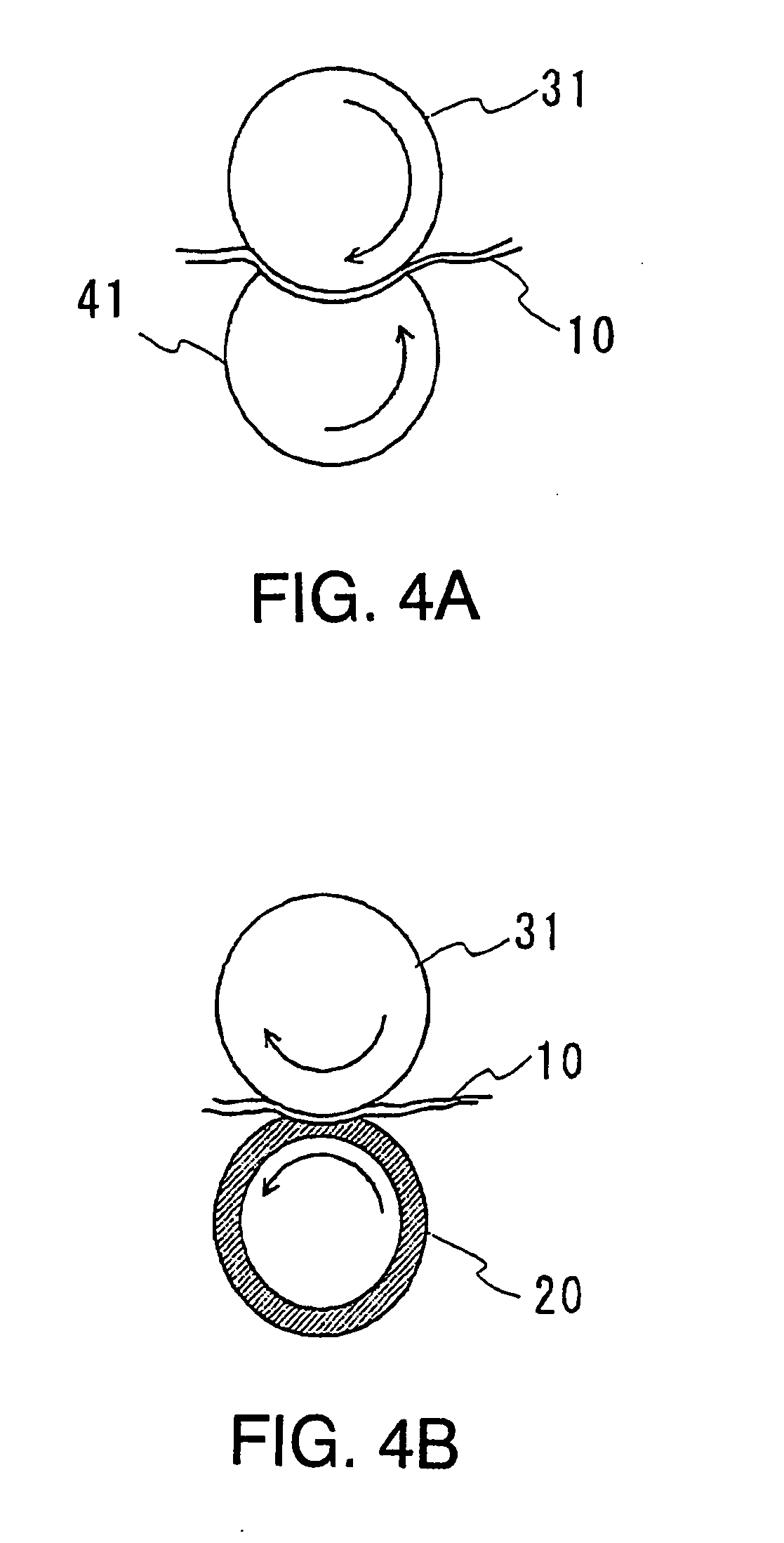

Magnetic cores for inductors and transformers and method of manufacture

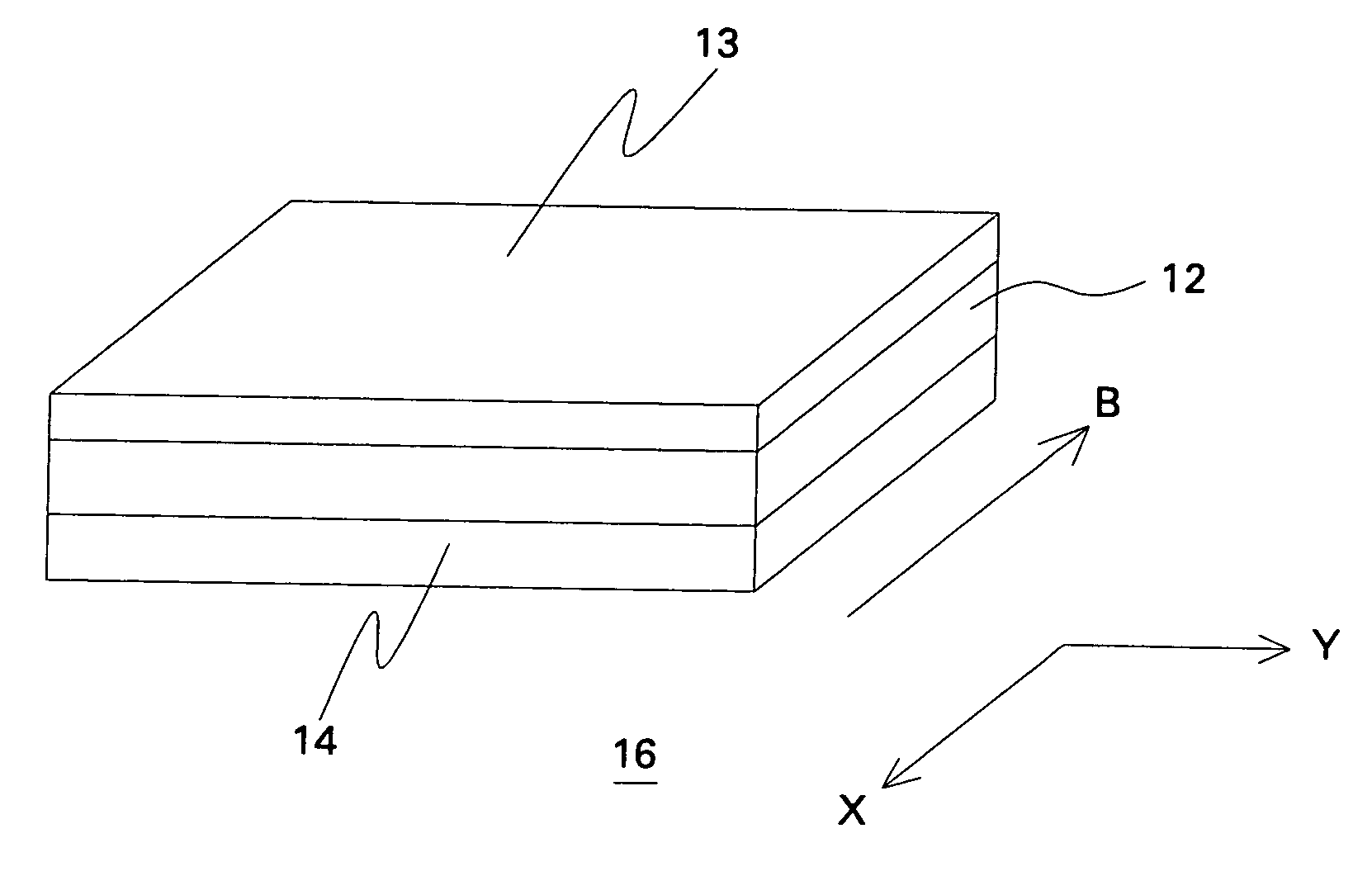

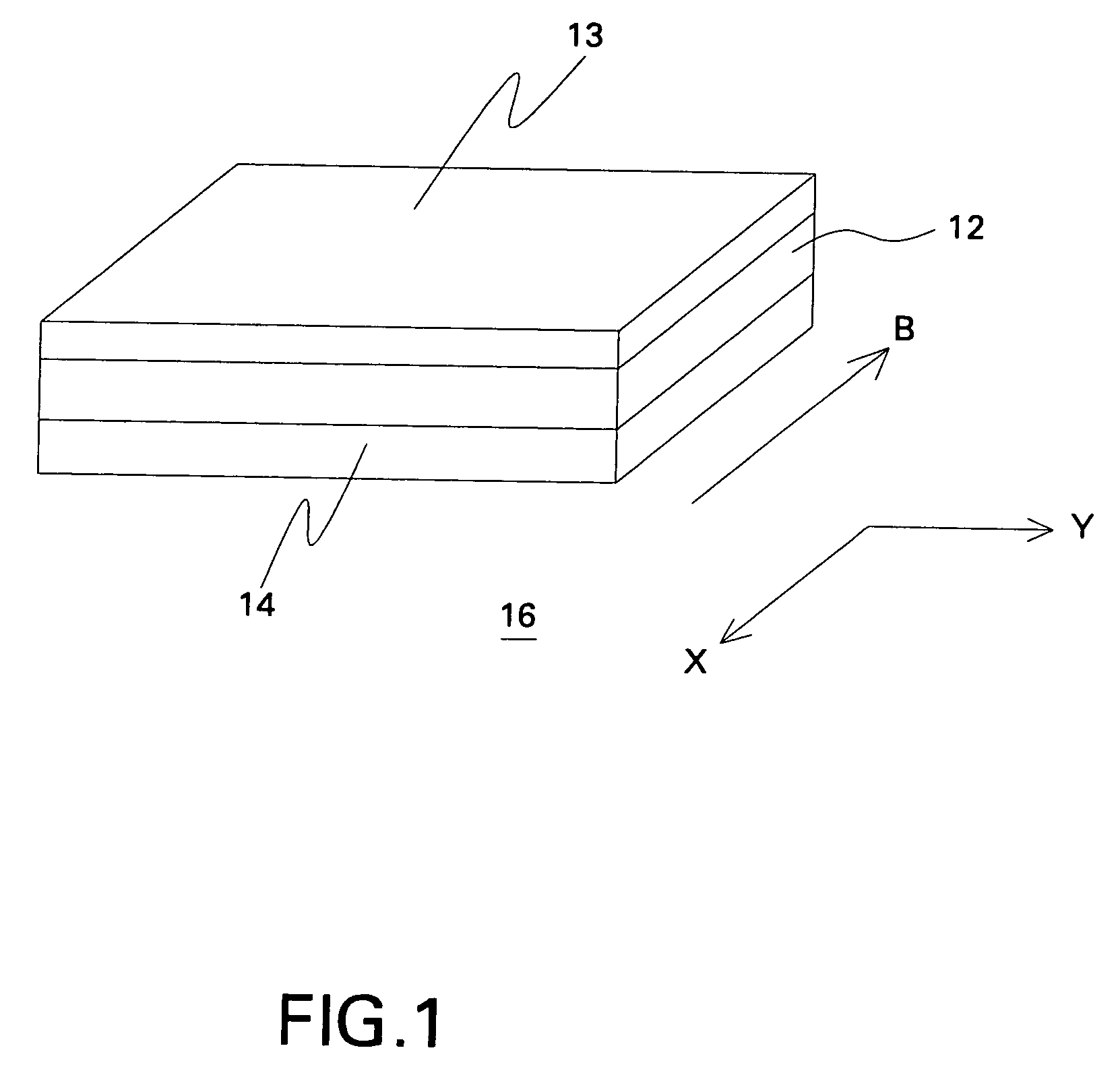

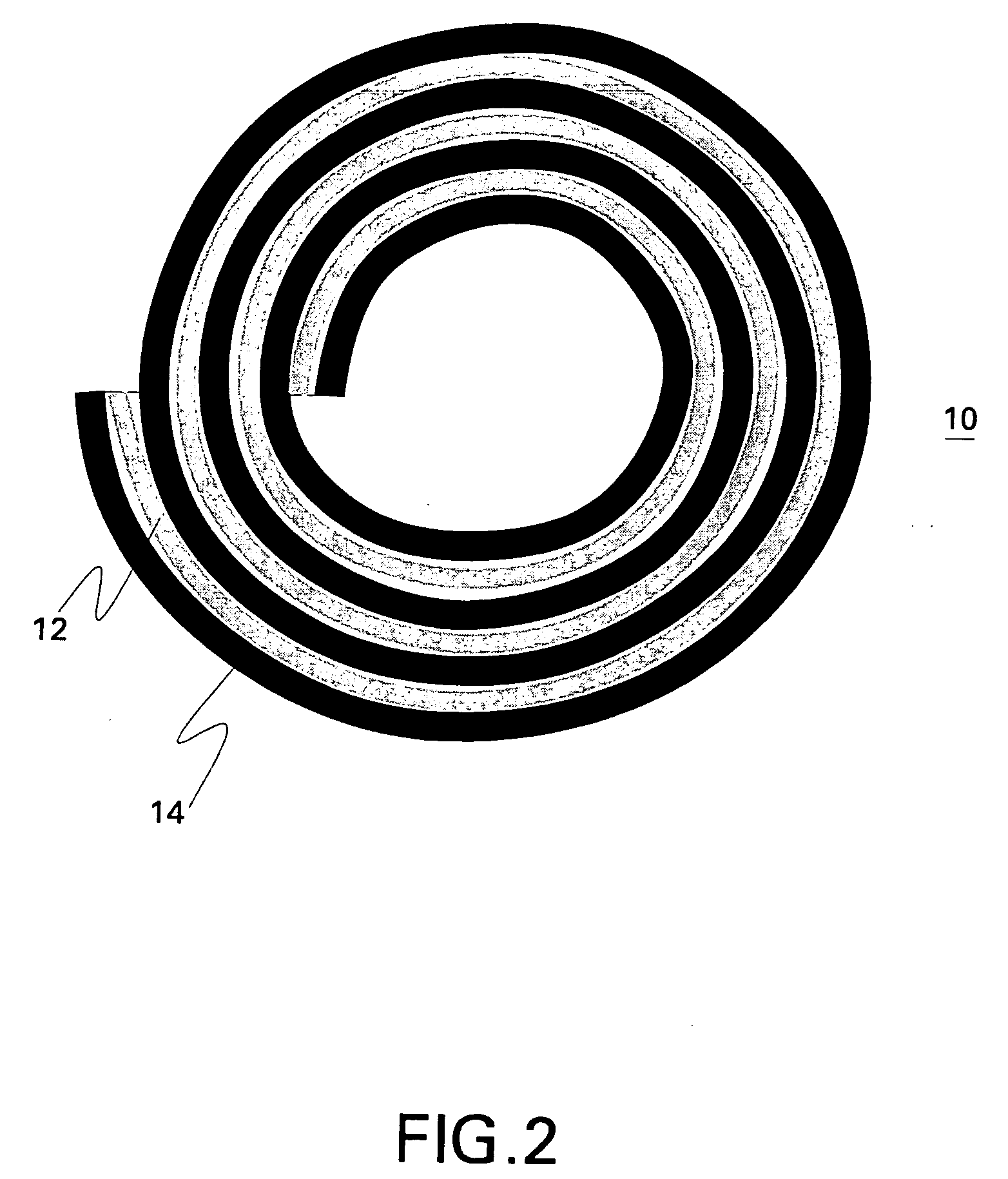

InactiveUS20080075975A1Transformers/inductances magnetic coresThick magnetic filmsTransformerEngineering

A magnetic core includes a tape comprising a magnetic film disposed on a substrate. The tape is arranged in a winding having a number of turns to form the magnetic core. The magnetic film comprises a magnetic material characterized by a coercivity of less than about ten Oersteds (10 Oe). A transformer includes the magnetic core, and a number of electrically conductive windings, where each of the windings extends around the magnetic core in at least one turn. An inductor includes the magnetic core, and an electrically conductive winding extending around the magnetic core in a number of turns.

Owner:GENERAL ELECTRIC CO

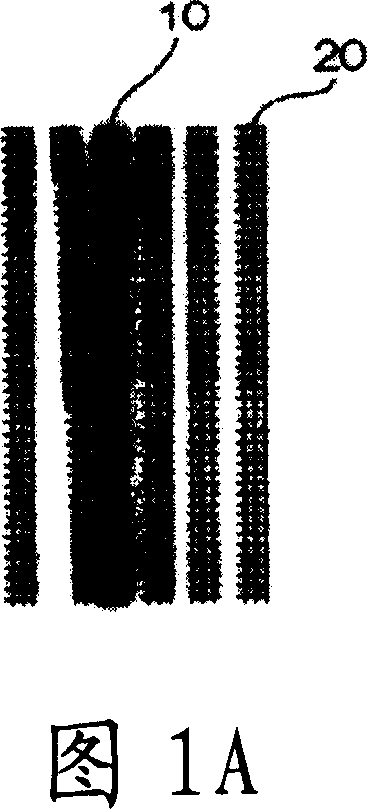

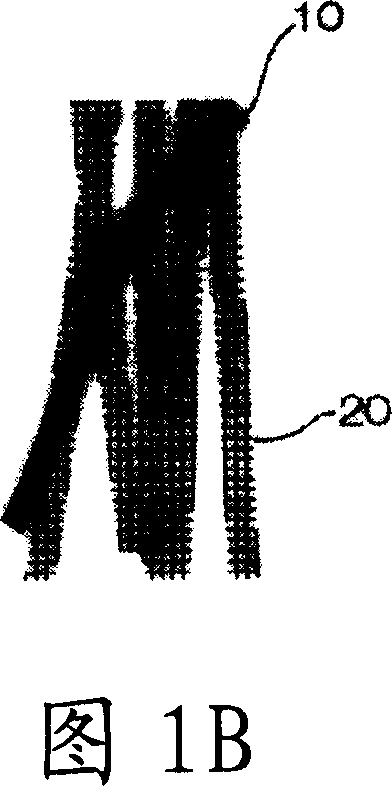

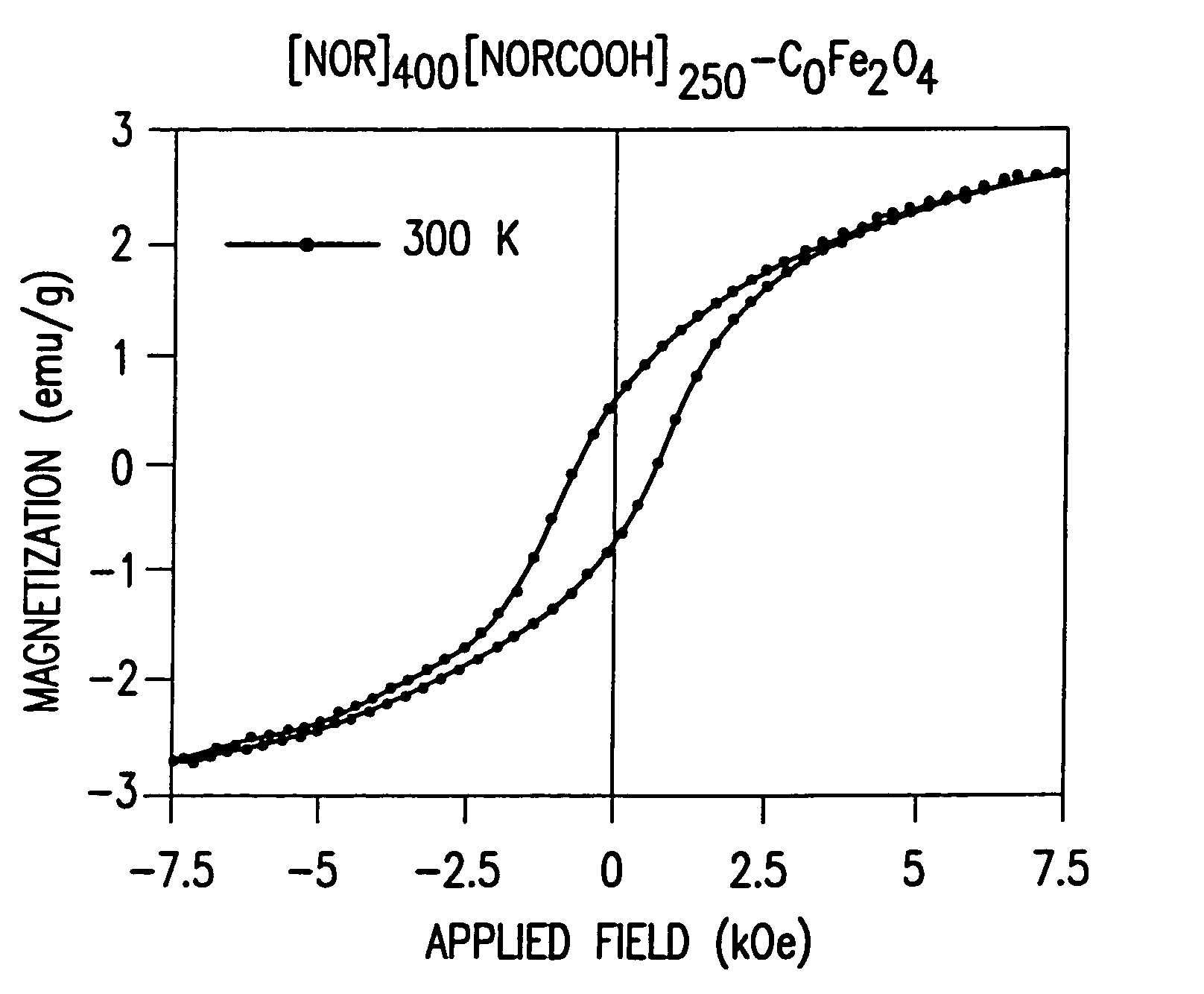

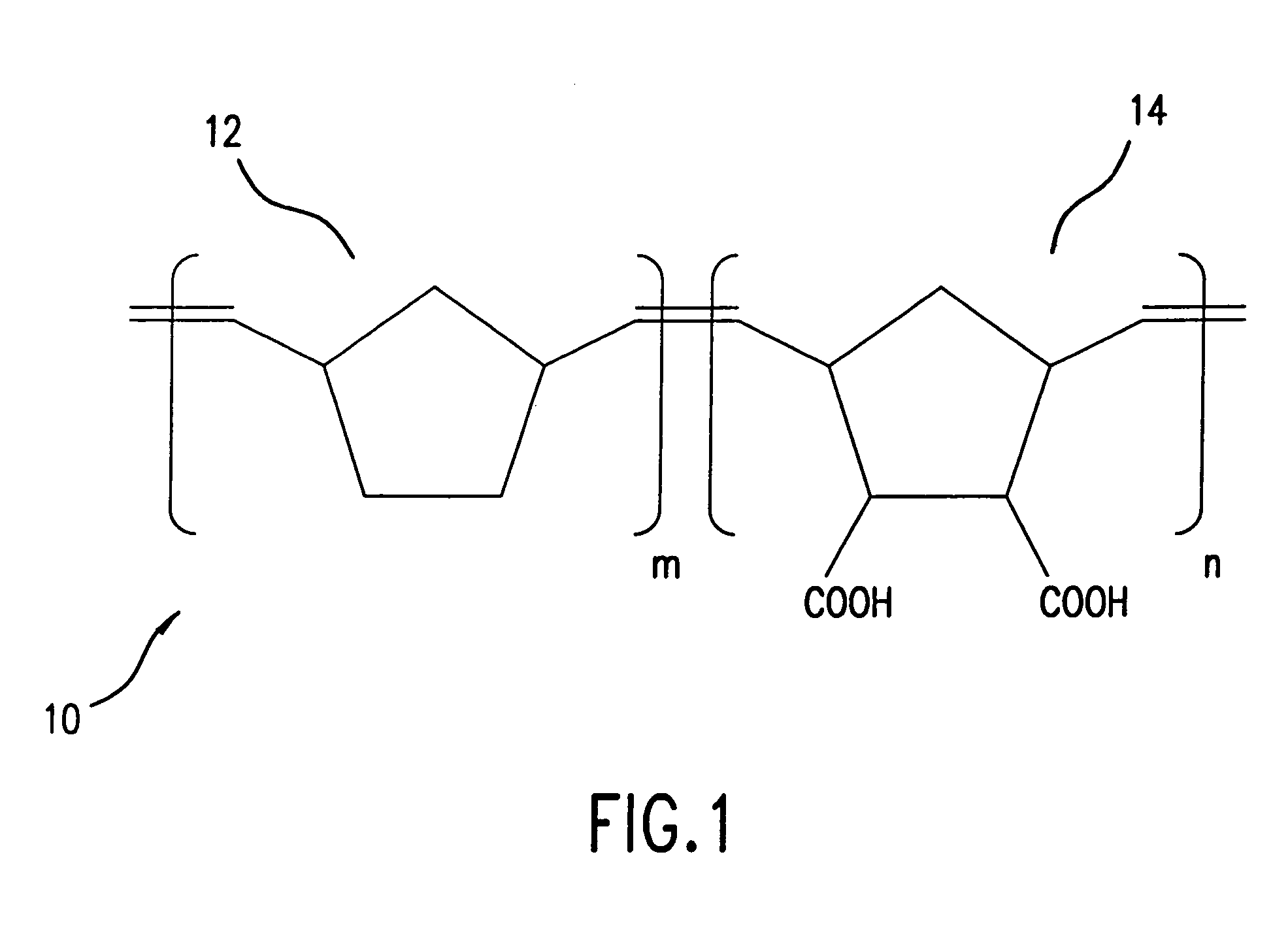

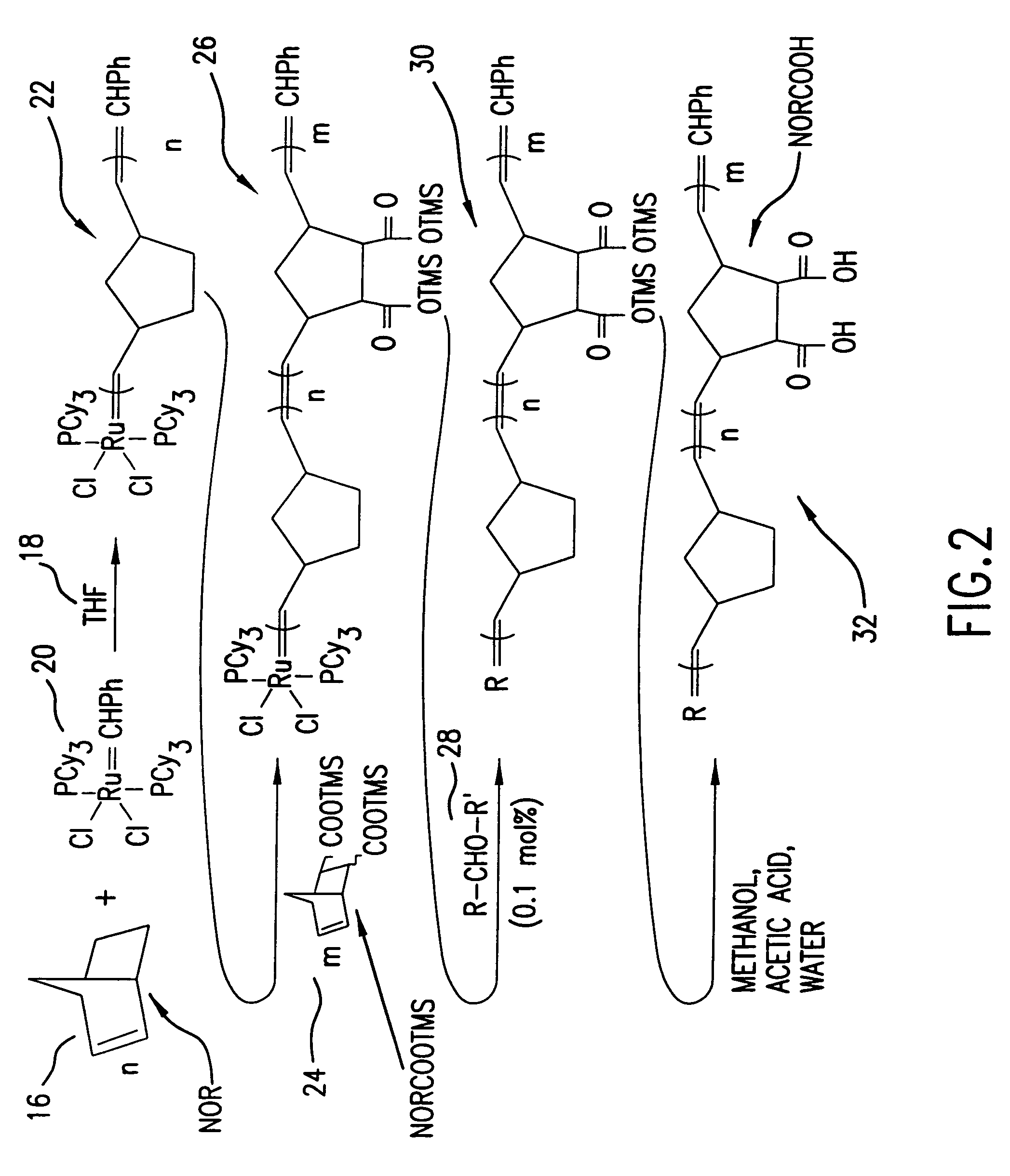

Controlled room temperature synthesis of magnetic metal oxide nanoclusters within a diblock copolymer matrix

InactiveUS6991741B2Improve uniformityPromotes even distributionNanomagnetismFilm/foil adhesivesRoom temperatureControl room

A method of room temperature synthesis of magnetic metal oxide nanoclusters within a diblock copolymer matrix includes the step of synthesizing, by ring opening metathesis polymerization technique, a diblock copolymer having a repeat unit ratio m / n, introducing, at room temperature, one or several metal containing precursors into the one block of the diblock copolymer, and processing the metal containing diblock copolymer by wet chemical technique to form nanoclusters of the metal(s) oxide within the diblock copolymer matrix. Specific reaction for synthesis of CoFe3O4 and Co3O4 nanoclusters within diblock copolymers, such as [NOR]m / [NORCOOH]n and [NOR]m / [CO(bTAN)]n, respectively is used in the method of the present invention.

Owner:UNIV OF MARYLAND

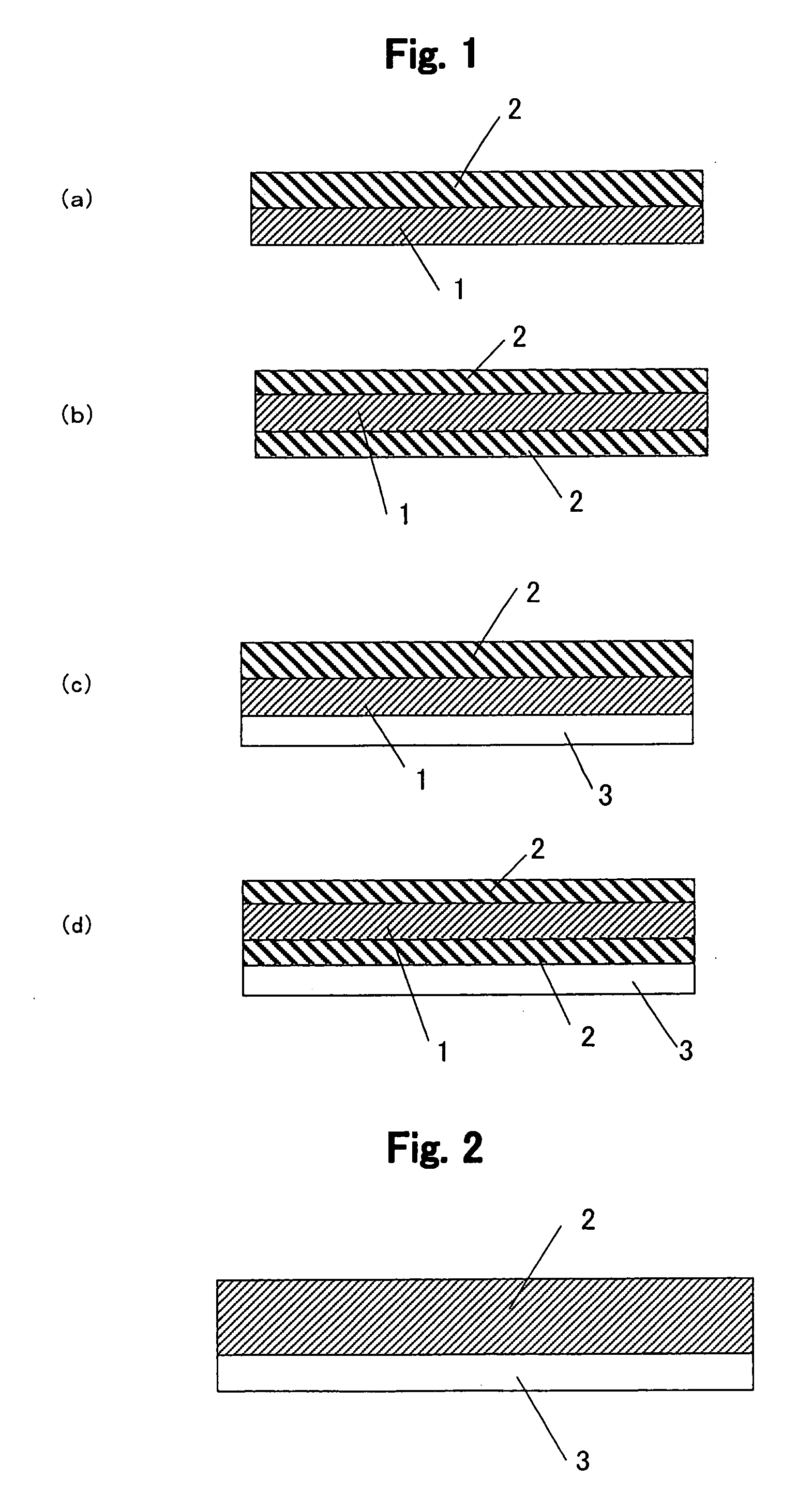

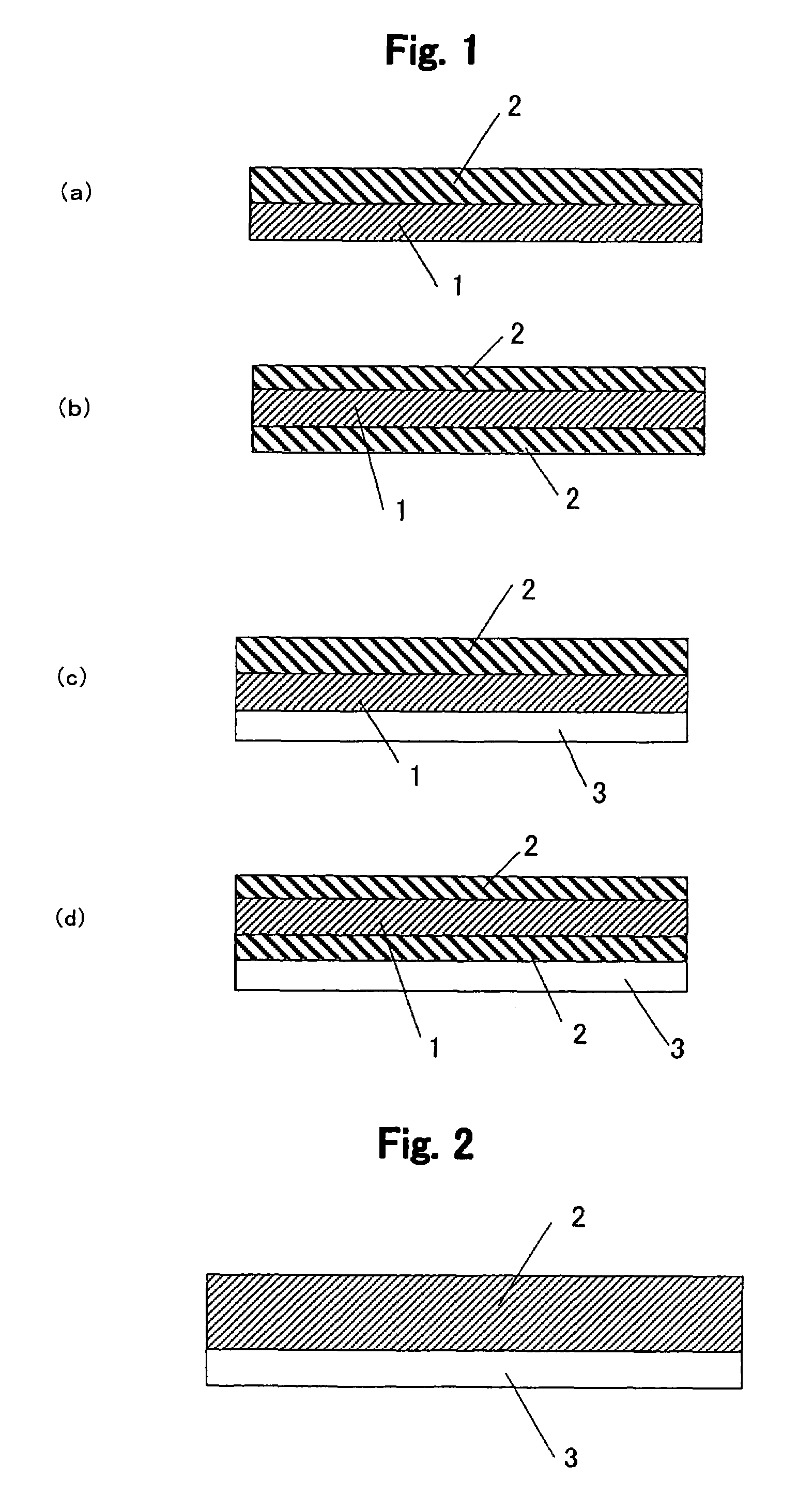

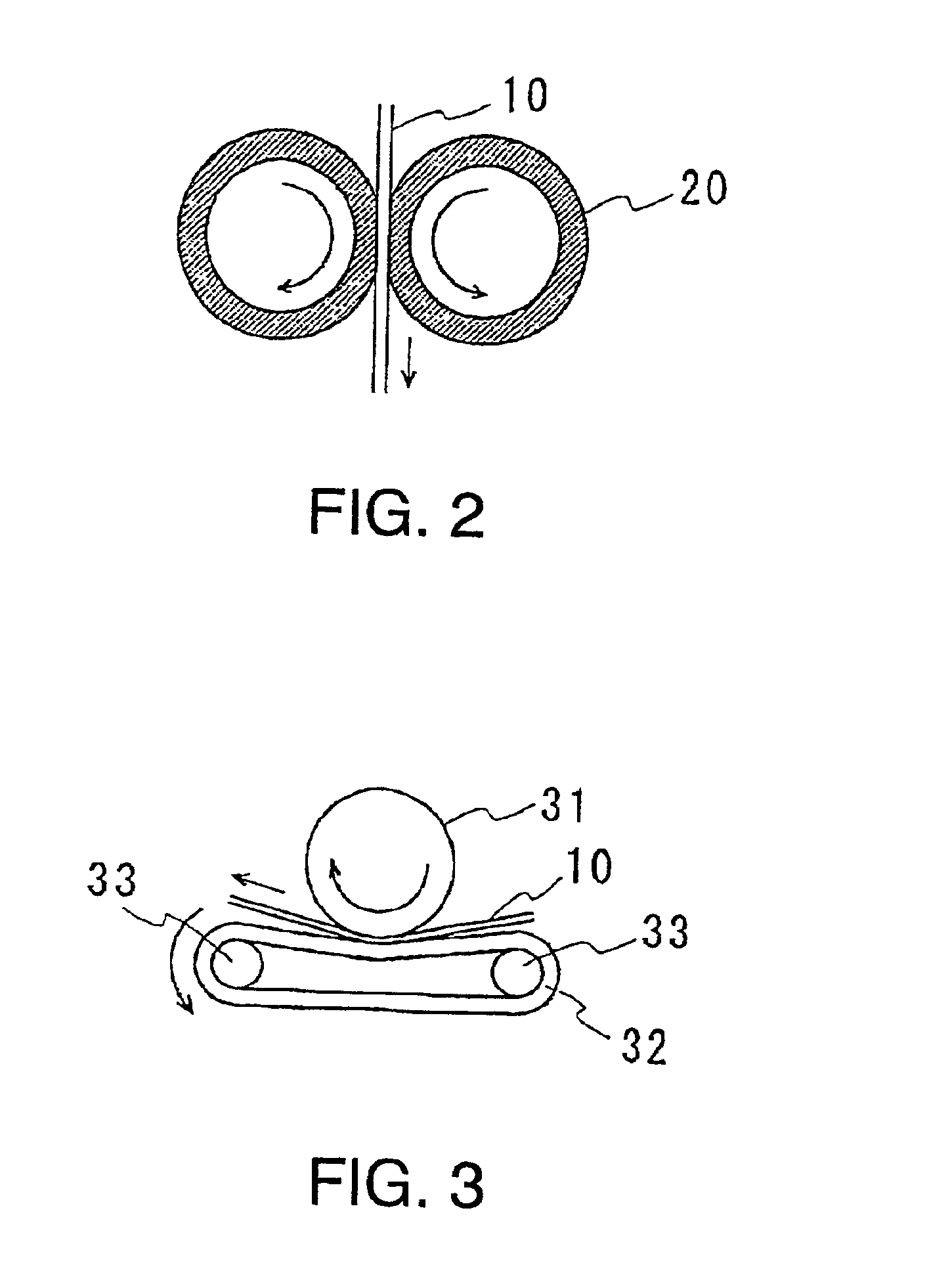

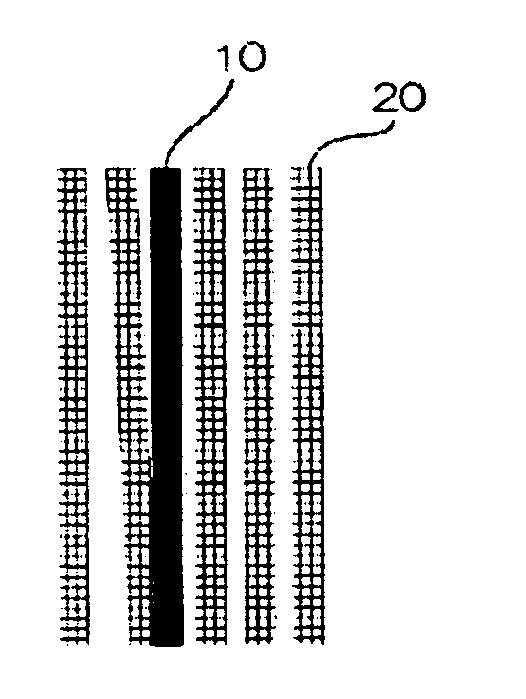

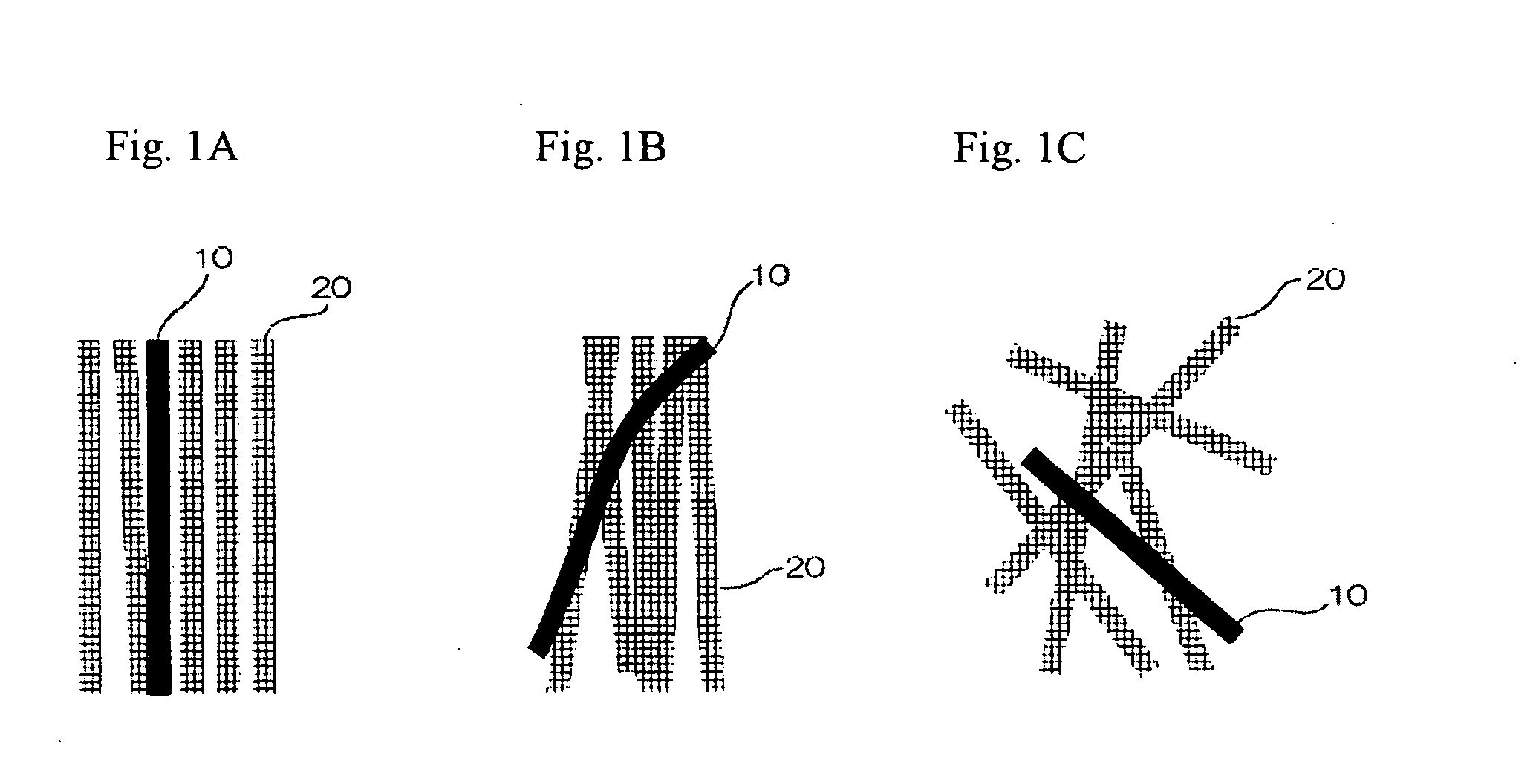

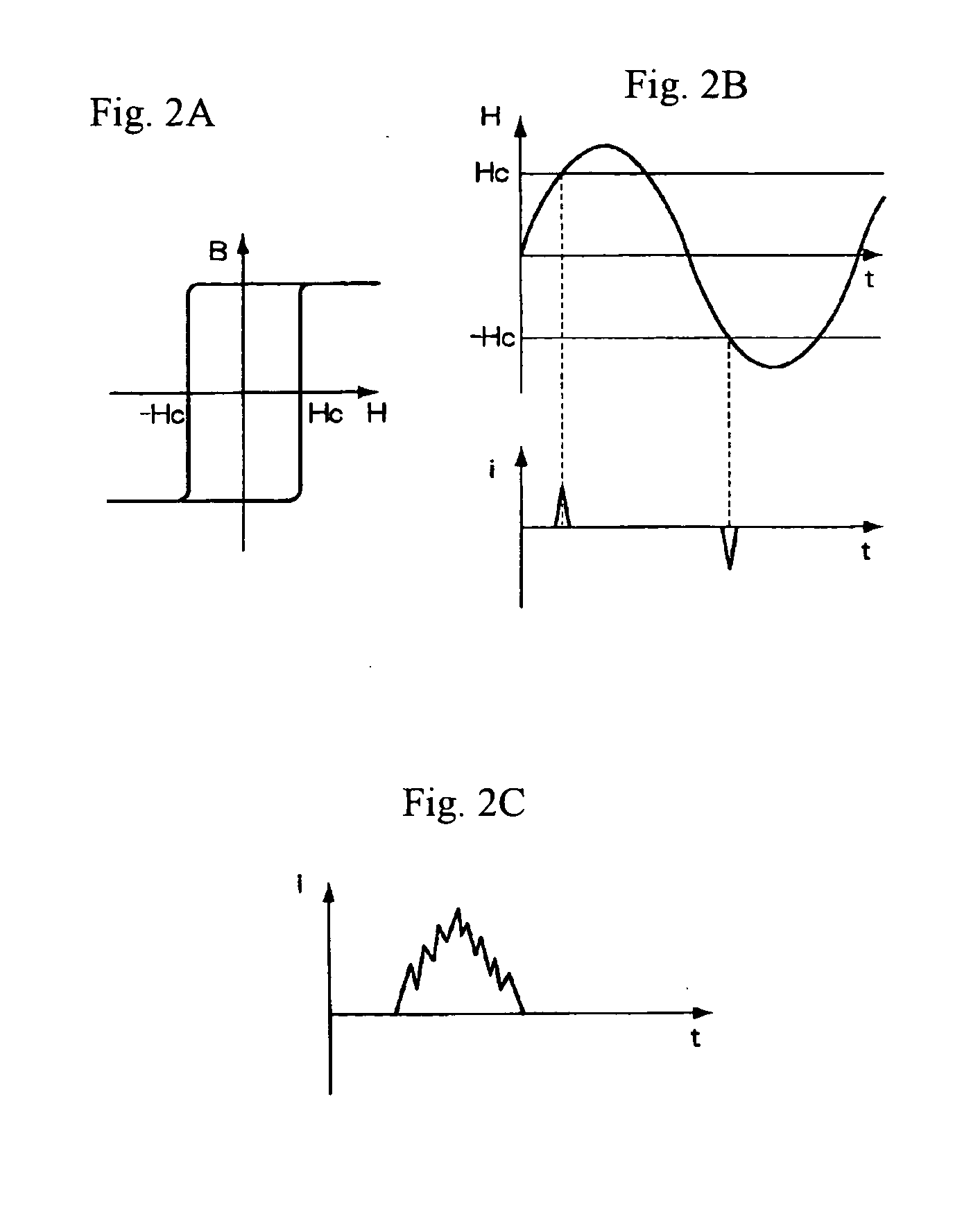

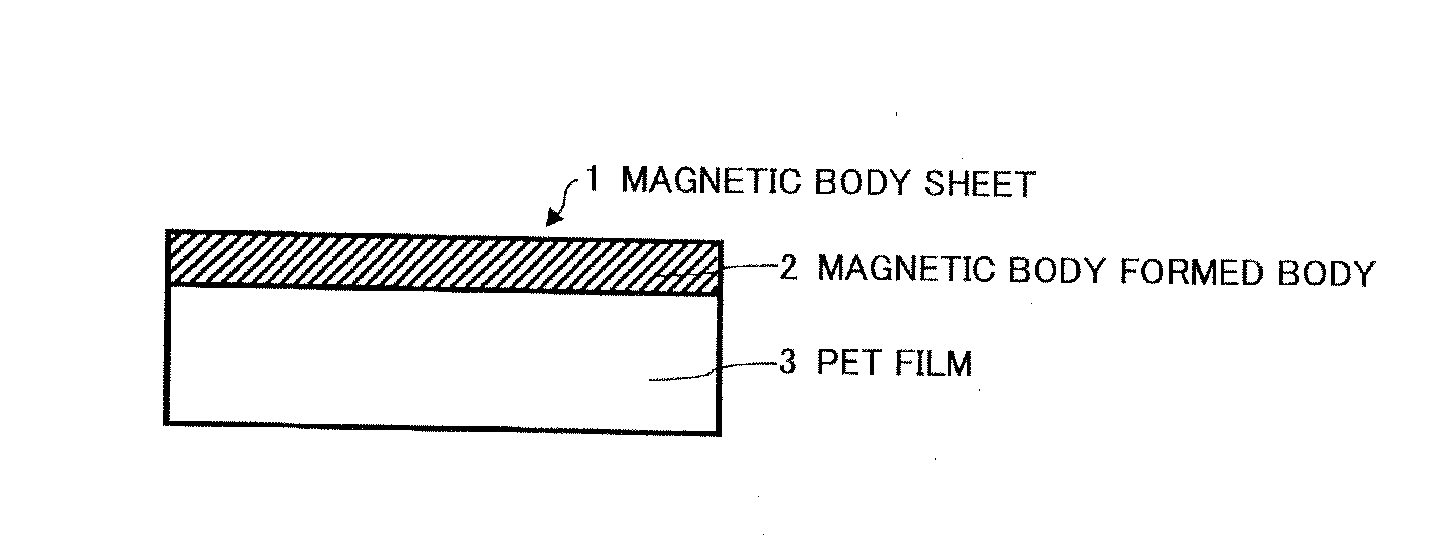

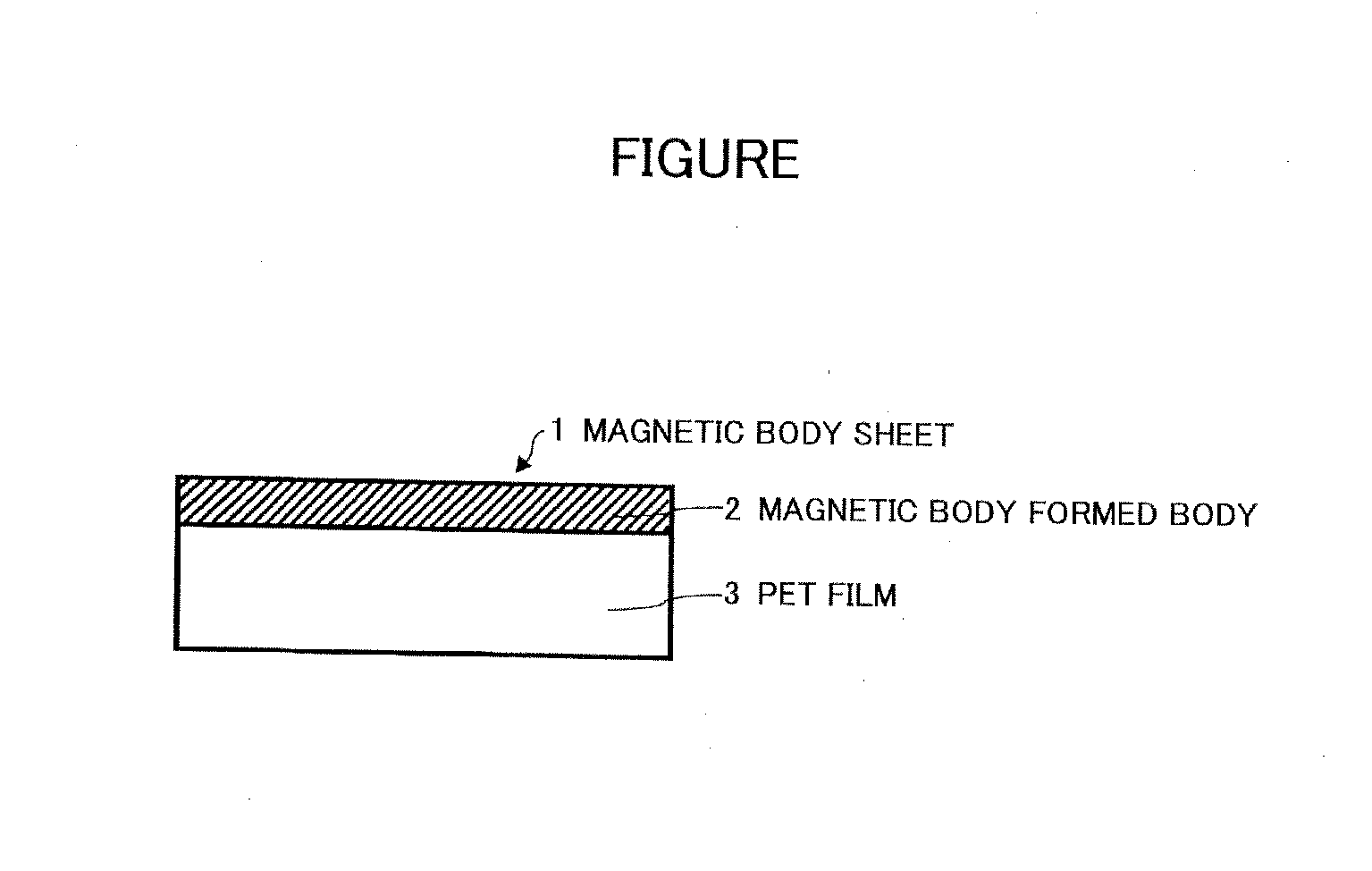

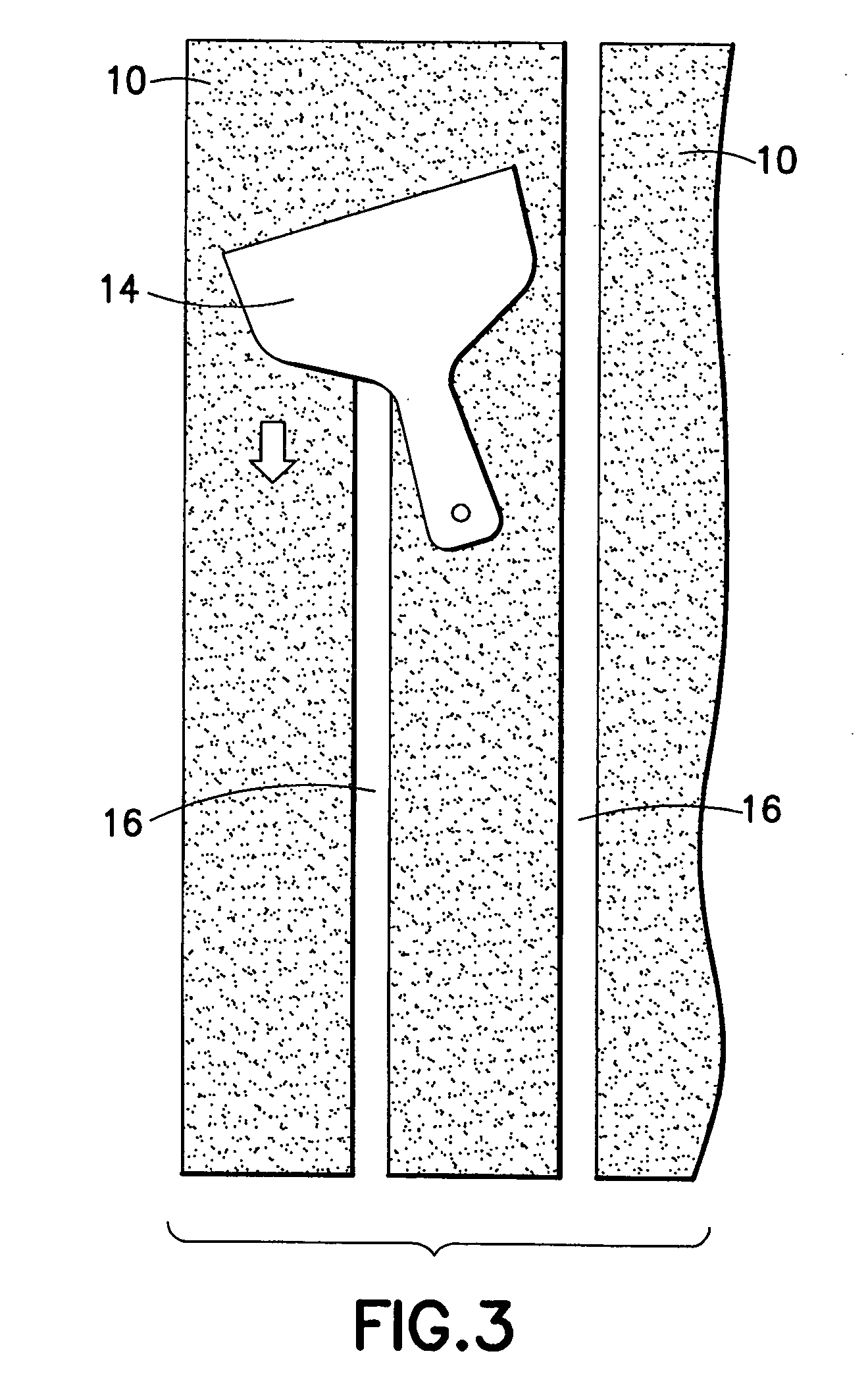

Composite magnetic sheet and method of producing the same

InactiveUS6887412B1Easy to getImproved in electromagnetic interference suppressing effectOther chemical processesMagnetic/electric field screeningSlurrySolvent

In a method of producing a composite magnetic body, flat soft magnetic powder subjected to annealing to be free from stress strain is prepared and mixed with a binder and a solvent for dissolving the binder to form a slurry-like mixture. The mixture is formed into a film. Then, the solvent is removed. Thus, a sheet of the composite magnetic body is produced.

Owner:TOKIN CORP

Ferrite paste, and method for manufacturing laminated ceramic component

InactiveUS20080283188A1Reduced strengthLow shape requirementLamination ancillary operationsLaminationOrganic solventPolyvinyl alcohol

The ferrite paste according to the present invention contains a ferrite powder and an organic vehicle, and the organic vehicle contains an organic solvent and a binder made of a polyvinyl acetal resin and ethyl cellulose. The binder content in the ferrite paste is at least 3.0 weight parts and no more than 5.0 weight parts per 100 weight parts of the ferrite powder, and the polyvinyl acetal resin content is at least 0.5 weight part and no more than 2.0 weight parts per 100 of the weight parts ferrite powder. The ethyl cellulose content is the remainder of subtracting the polyvinyl acetal resin content from the binder content.

Owner:TDK CORPARATION

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM

Recording paper

InactiveUS20070243403A1Control conditionReduce opacityDuplicating/marking methodsMaterials with cobaltUltrasonic velocityFiber orientation

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Magnetic body composition and a magnetic body product

InactiveUS20130306903A1Magnetic/electric field screeningInorganic material magnetismMagnetite NanoparticlesCondensed matter physics

Disclosed is a magnetic body composition, including a resin and a magnetic nanoparticle, the magnetic nanoparticle including an oxide of at least one kind of metal selected from the group composed of Ga, Zn, and Sn and an FeCo oxide.

Owner:RICOH KK

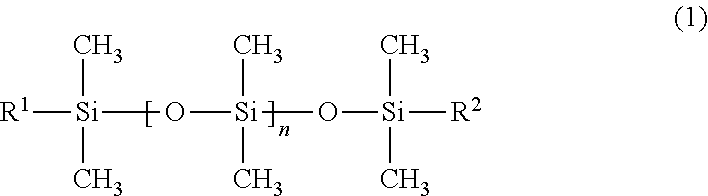

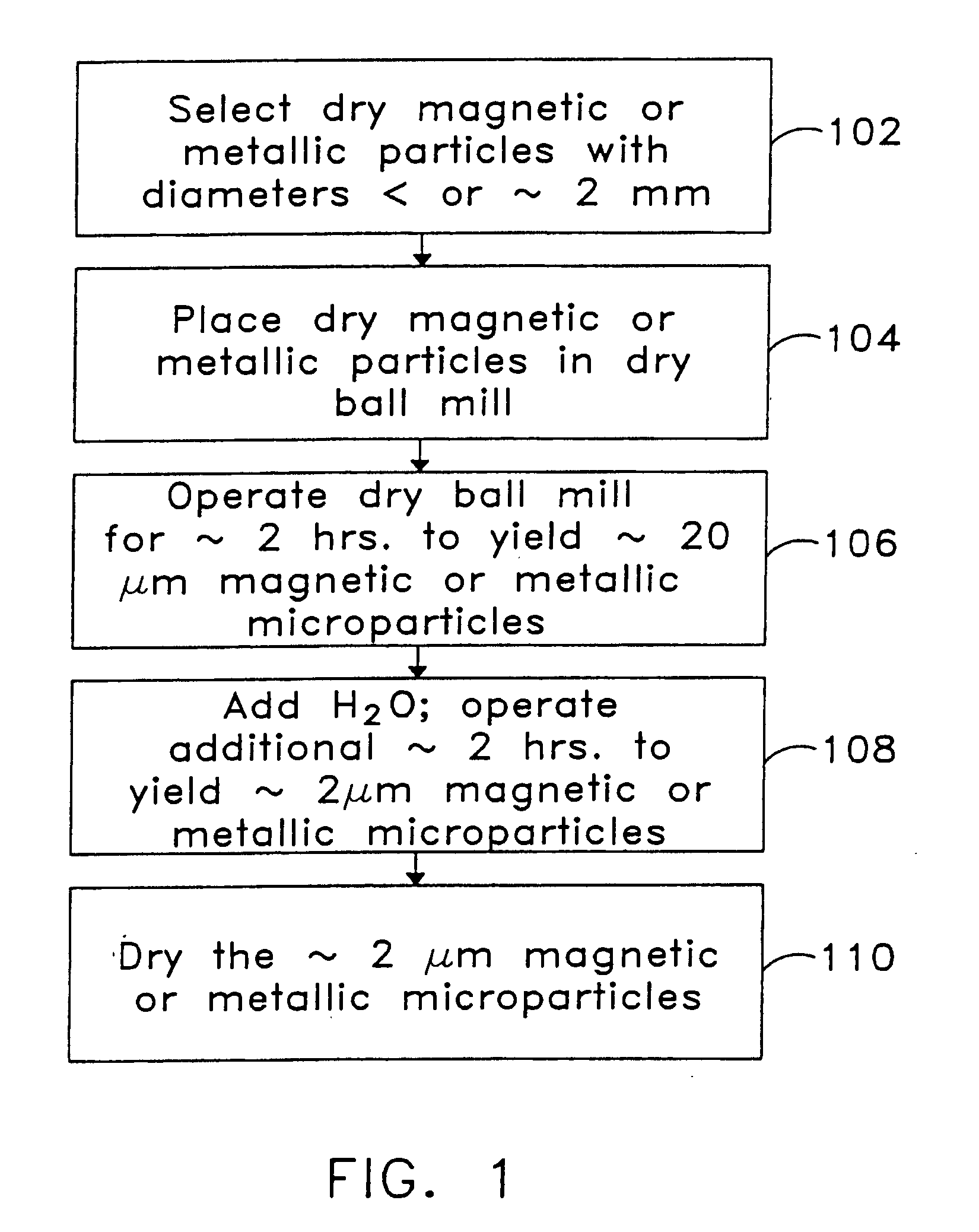

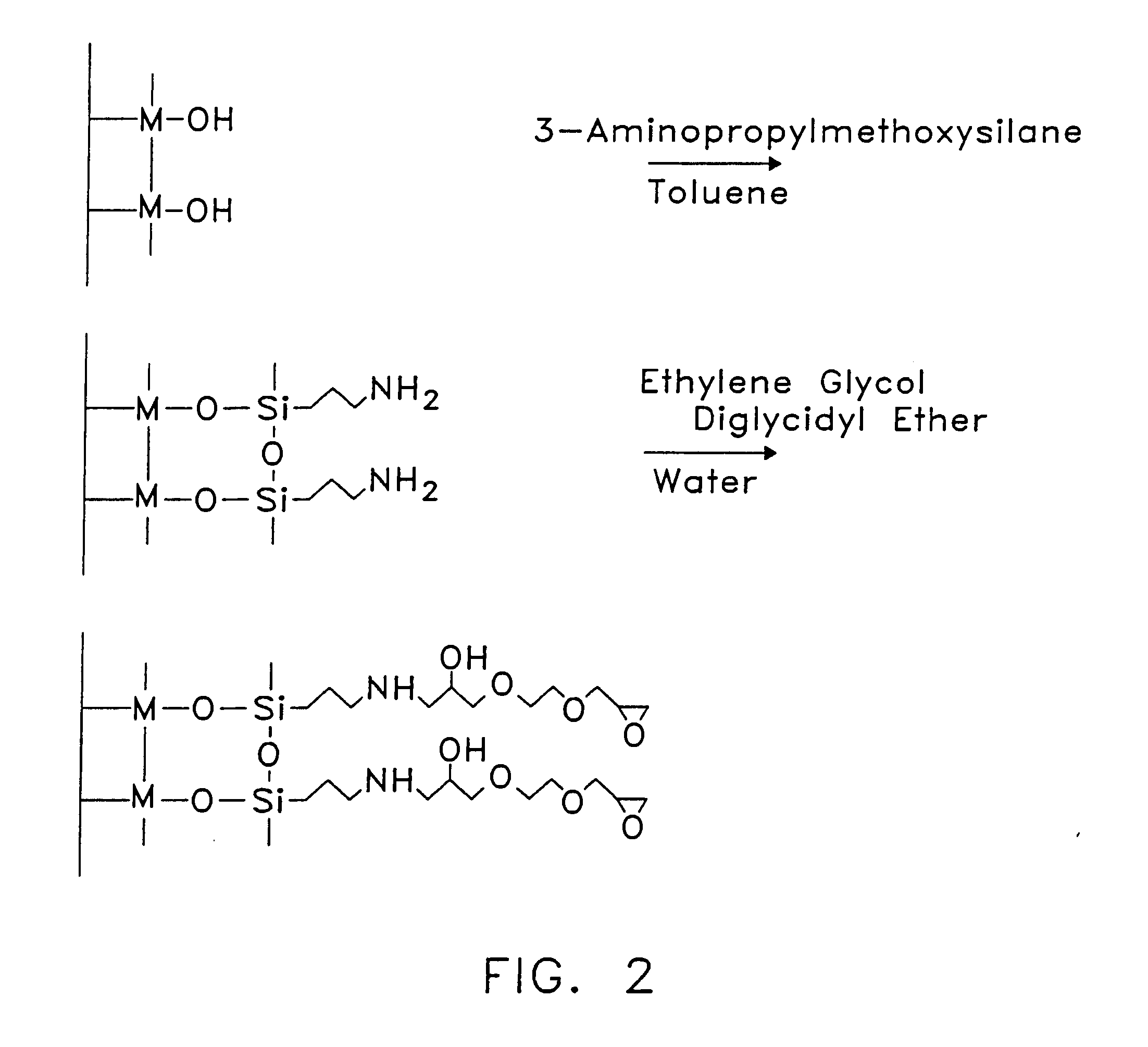

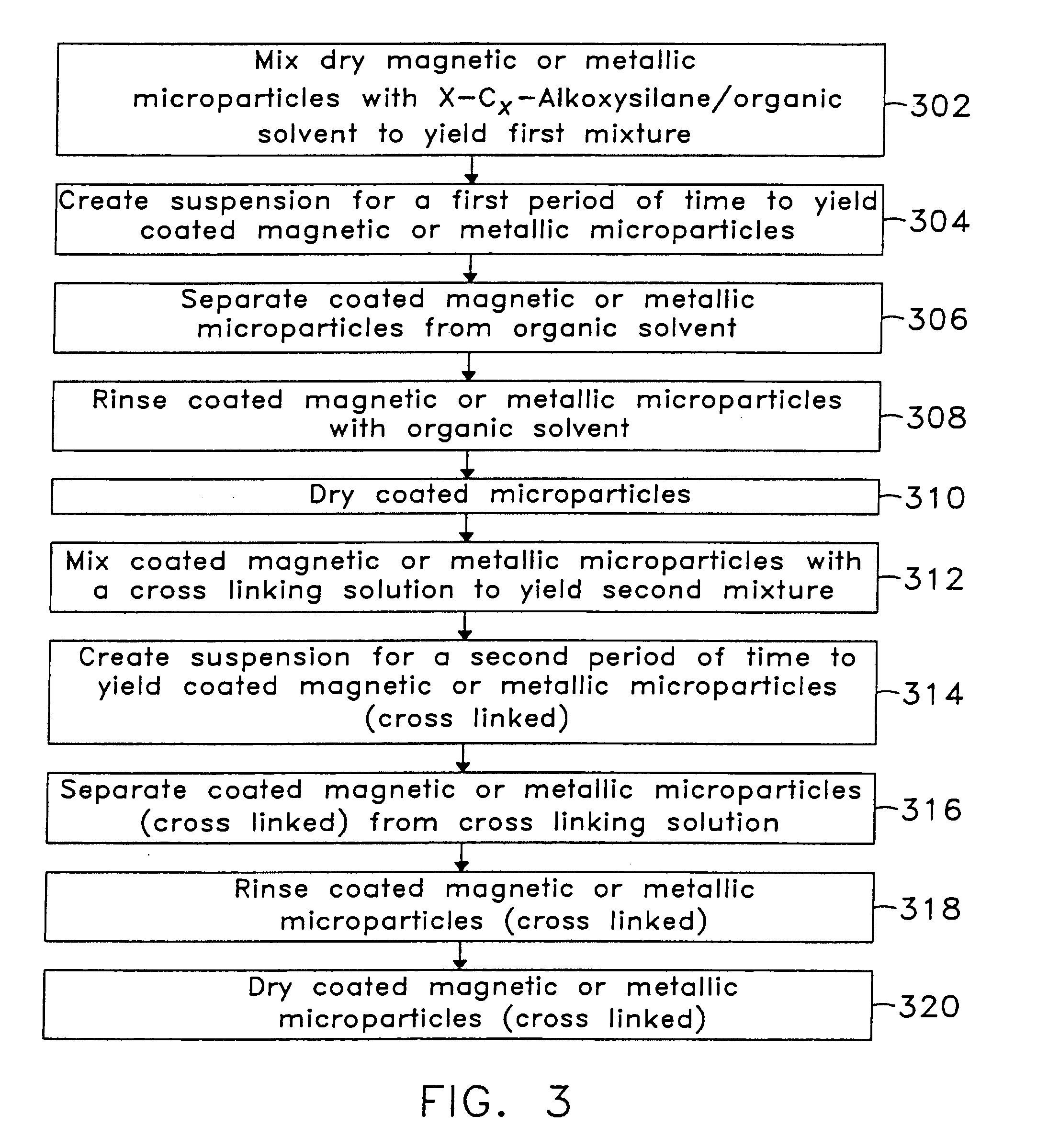

Magnet materials and metallic particles and methods of making same

InactiveUS20100092779A1Low variabilityEnhanced and altered functionCell electrodesMetal-working apparatusReactions on surfacesCross-link

New magnetic materials and new metallic particles, new methods of making and using same, for example, to prepare magnetically modified electrodes and fuel cells, and coated metallic particles in general. The present invention discloses methods of preparation of cheaper and more uniformly sized magnetic and metallic microparticles formed from the exemplary materials magnetite, nickel, samarium cobalt and neodymium iron boron. In addition, the present invention discloses methodology for preparation and use of coated magnetic and metallic microparticles, in particular, exemplary siloxyl coating of magnetic particles, metallic particles, and magnetic and metallic microparticles with an exemplary silane, 3-aminopropyltrimethoxysilane, that is cross linked thereon. In addition, methods and results are described for preparing and using larger siloxyl coated samarium cobalt milliparticles. Coated magnetic milliparticles and magnetic microparticles are useful as component of composites that are applied to electrodes to alter electrochemical fluxes across those electrodes, as well as to alter chemical reactions on surfaces of those electrodes, when magnetically susceptible reactions occur there.

Owner:UNIV OF IOWA RES FOUND

Sizing agent for NFC magnetic sheet, preparing method of sizing agent and NFC magnetic sheet

InactiveCN103632795AReduce bridgingHigh resistivityLayered productsMagnetic liquidsMagnetic effectNano al2o3

The invention provides a sizing agent for an NFC magnetic sheet and a preparing method of the sizing agent. The sizing agent comprises magnetic powder and an organic carrier, and further comprises nanometer alumina powder, wherein the mass ratio of the nanometer alumina powder to the magnetic powder is 0.0005: 0.005. The invention further provides the NFC magnetic sheet prepared through the sizing agent. By means of the added nanometer alumina, the number of bridge connection among the magnetic powder is effectively reduced, the specific resistance rate of the magnetic sheet is increased, the imaginary part, namely the magnetic loss, of the complex permeability is obviously reduced within the range allowed by the reducing of the real part of the complex permeability, accordingly the quality factor of the whole magnetic sheet is improved, and the magnetic effect of the magnetic sheet is improved.

Owner:BYD CO LTD

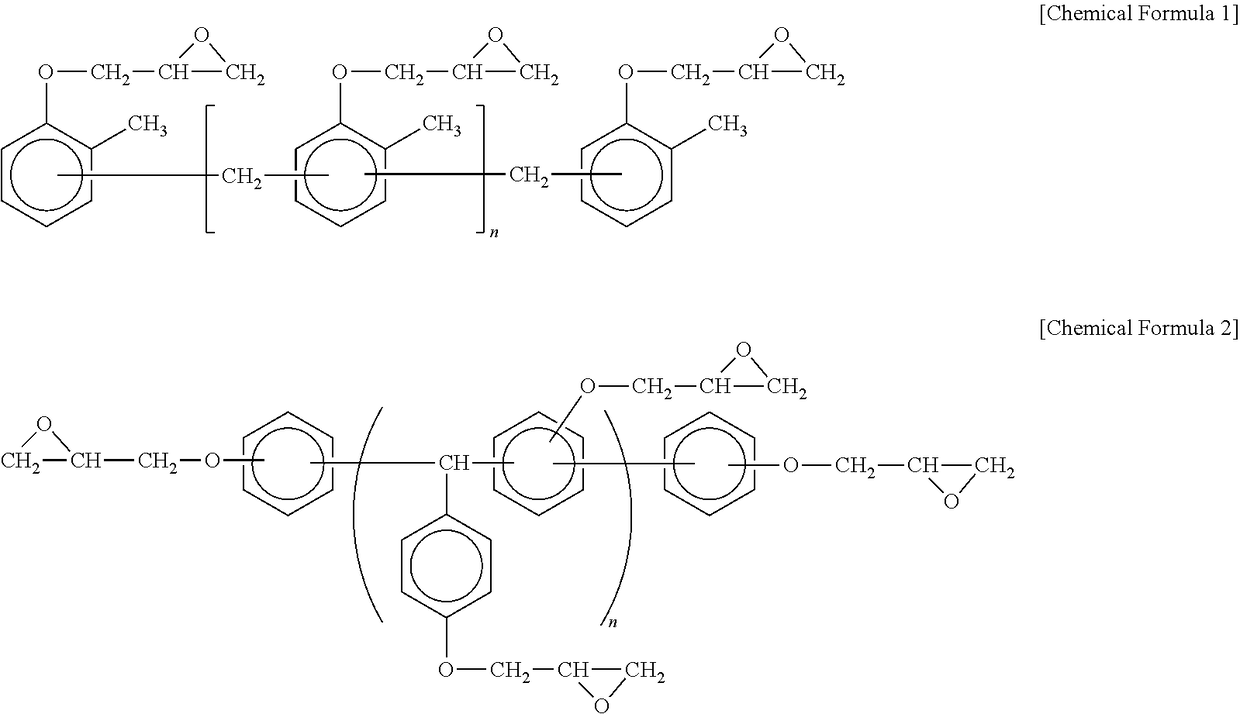

Soft magnetic resin composition and soft magnetic film

ActiveUS20170271062A1Improve magnetic propertiesSuppression gapShielding materialsTransformersEpoxyAcrylic resin

A soft magnetic resin composition contains flat soft magnetic particles, and a resin component containing an epoxy resin, a phenol resin, and an acrylic resin. The epoxy resin consists of only an epoxy resin having three or more functional groups, the phenol resin consists of only a phenol resin having three or more functional groups, and the content ratio of the acrylic resin in the resin component is 25 mass % or more.

Owner:NITTO DENKO CORP

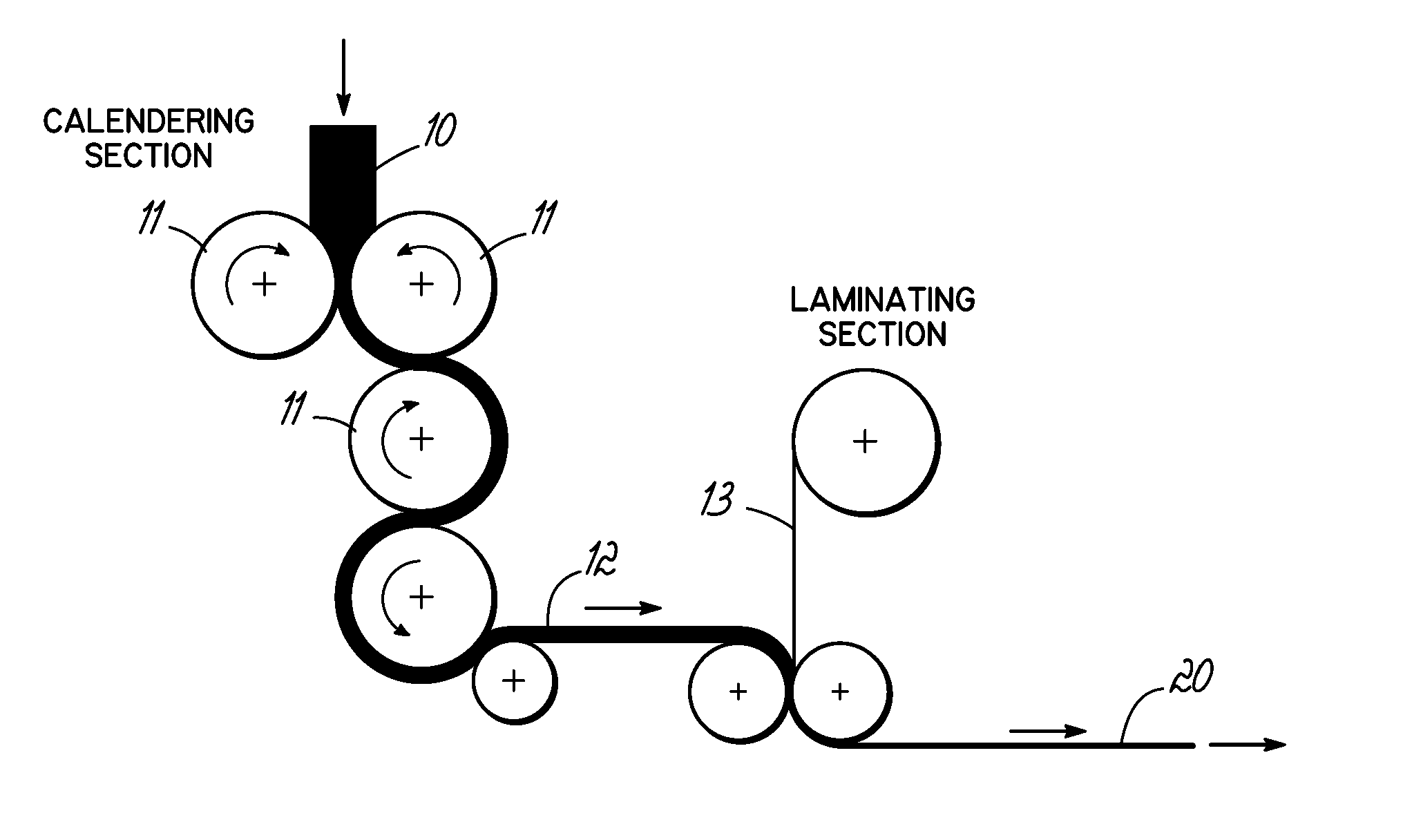

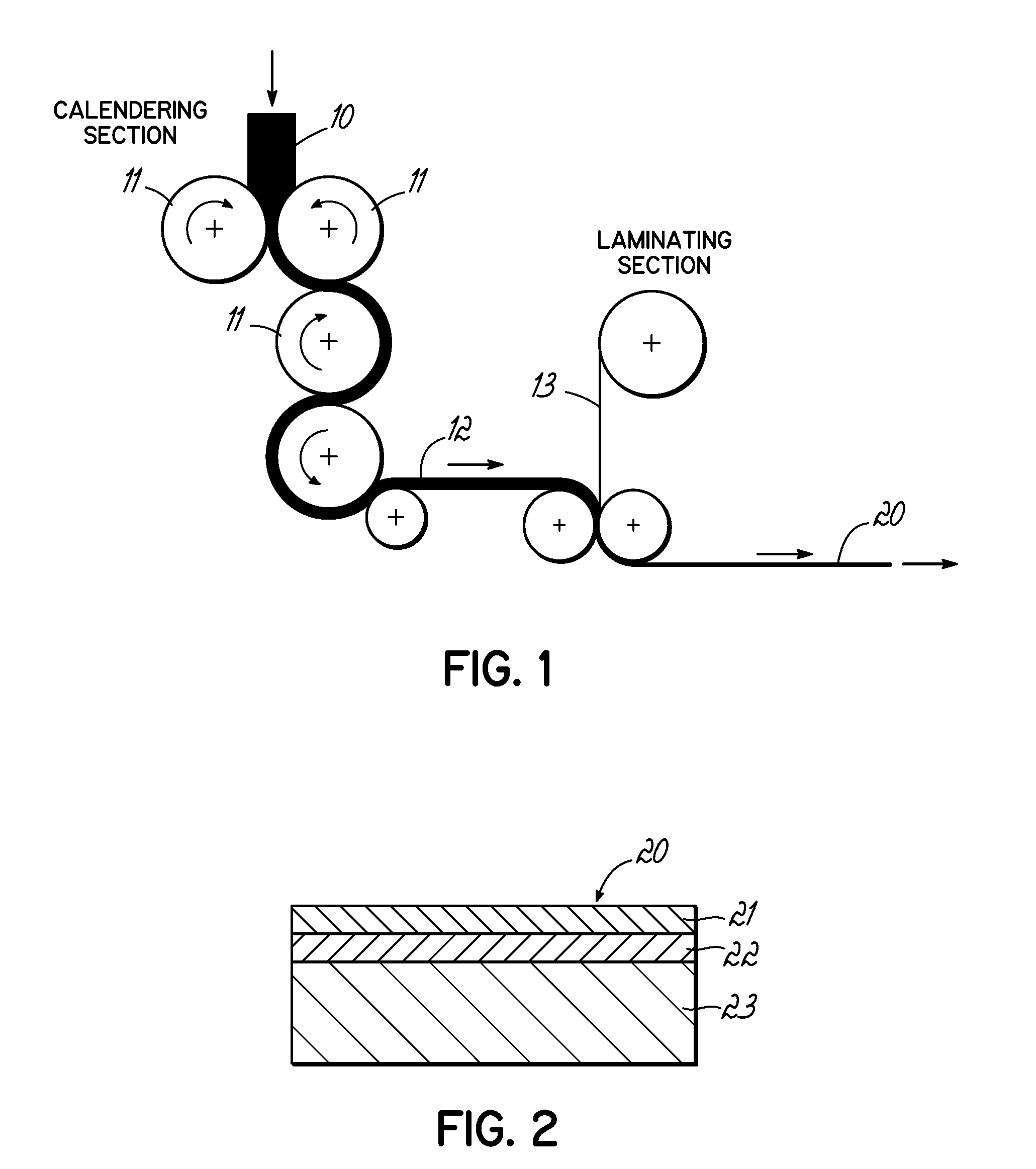

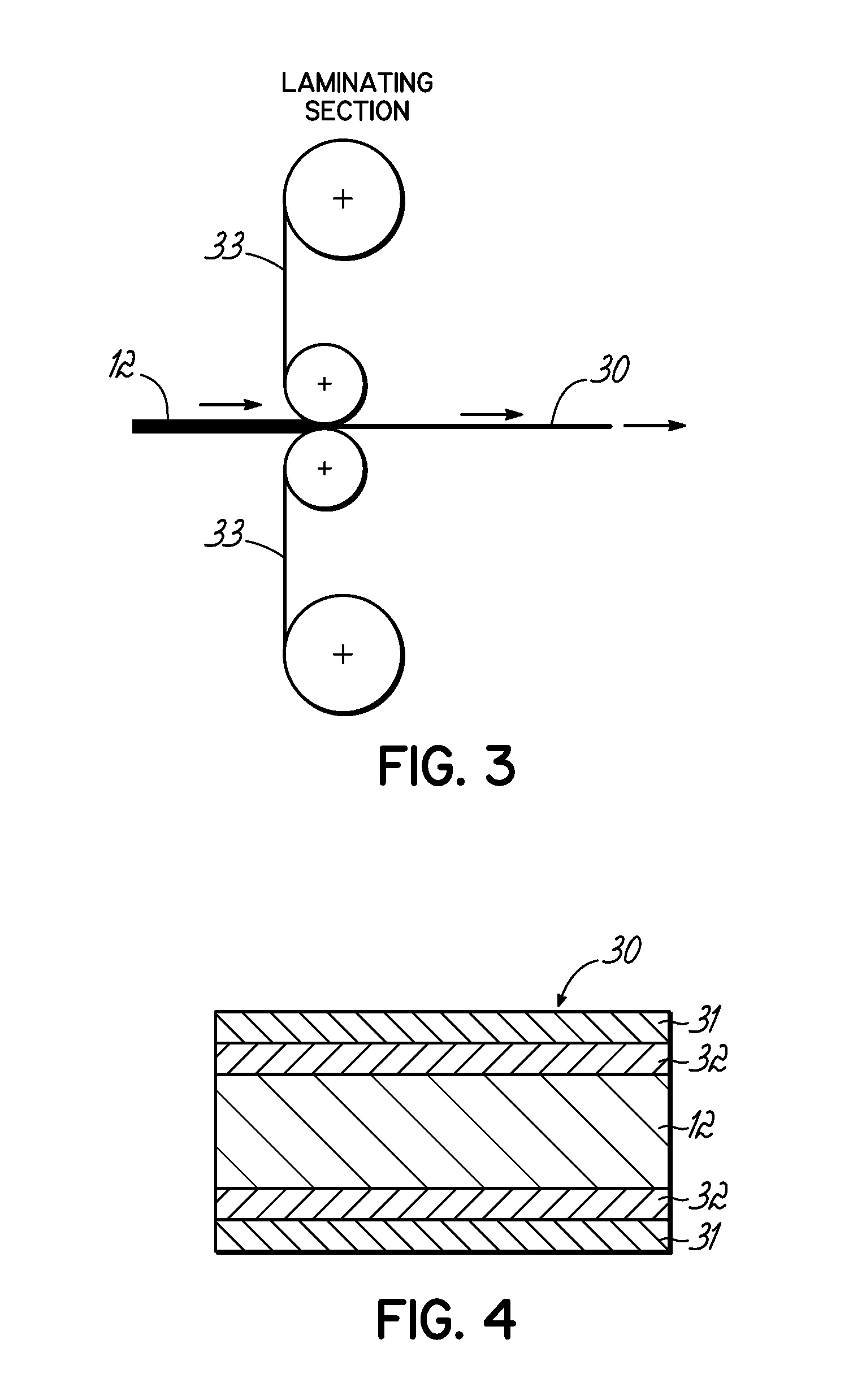

Printable magnetic receptive composite sheet and method of making

ActiveUS20160250783A1Easily conveying informationEasy to printDuplicating/marking methodsLaminationThin layerMaterials science

Owner:SCHLEICHER ENTERPRISES LLC

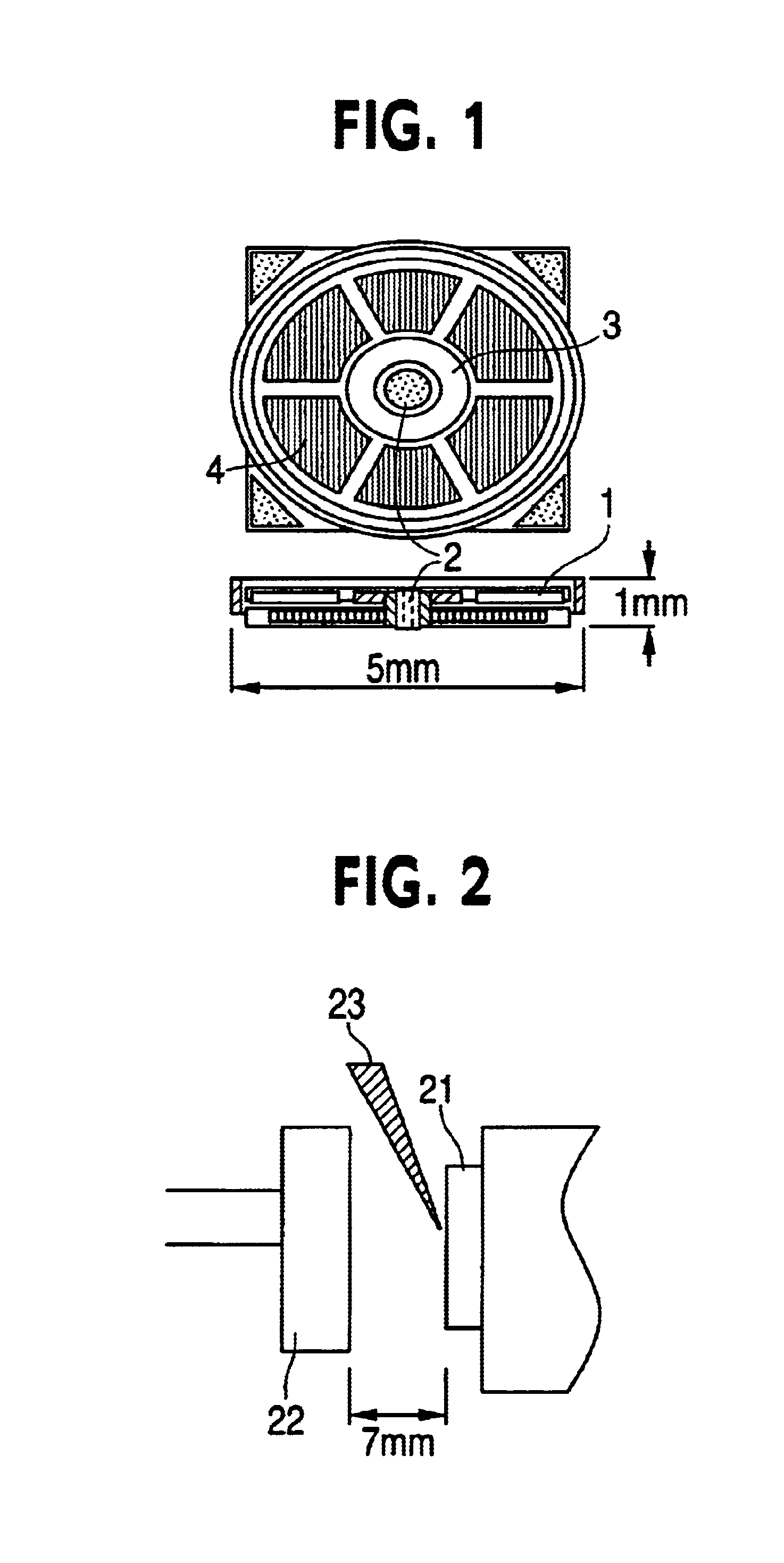

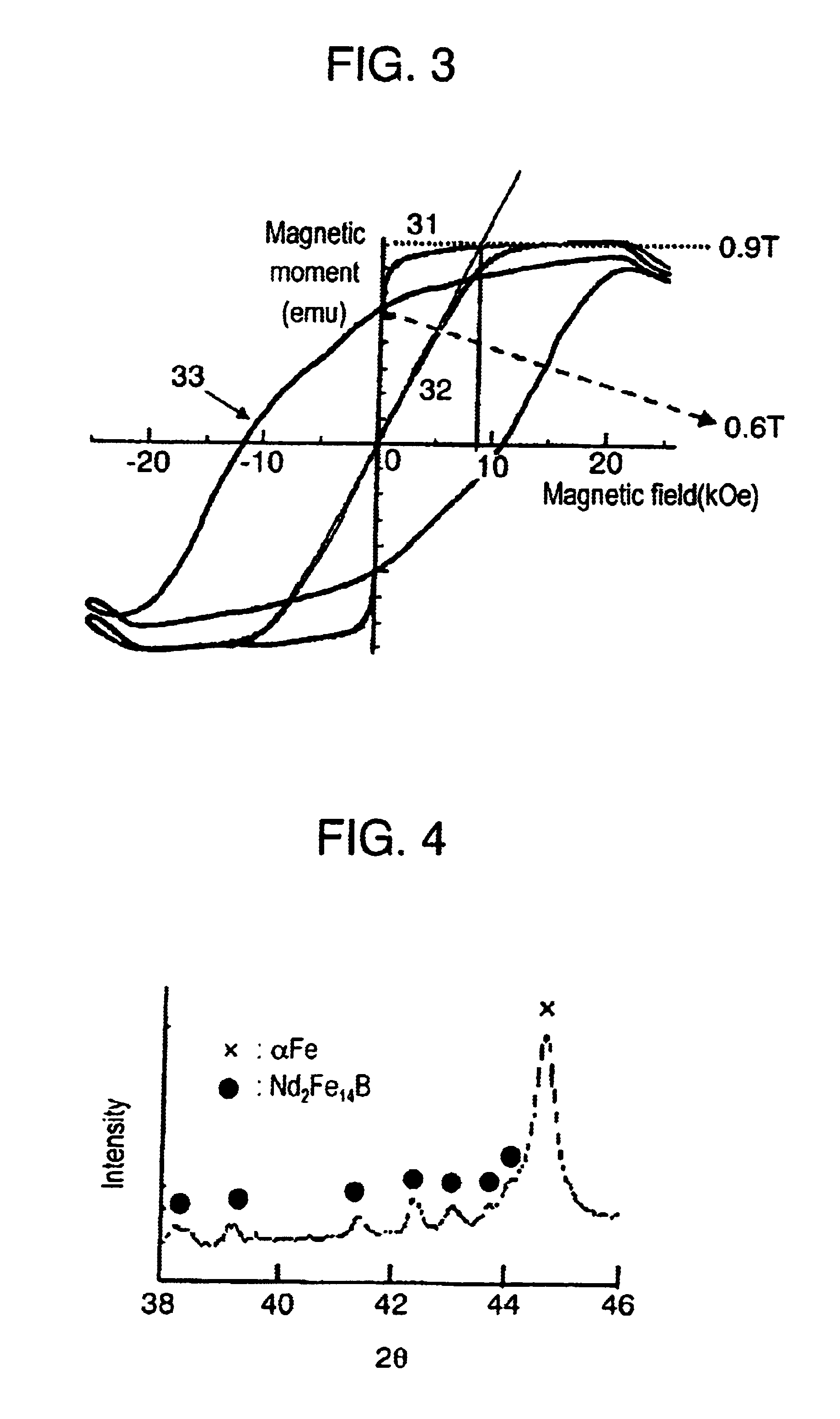

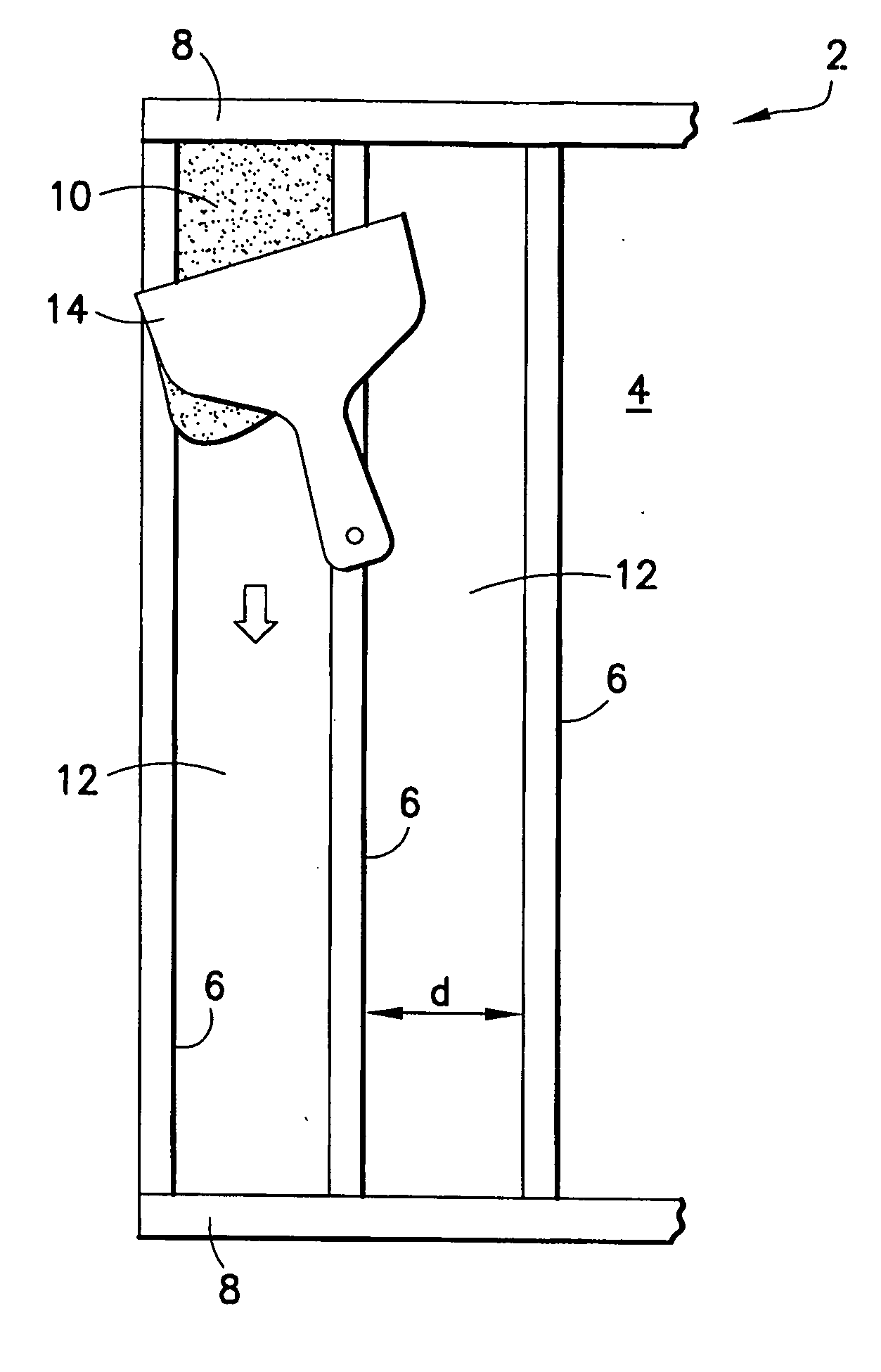

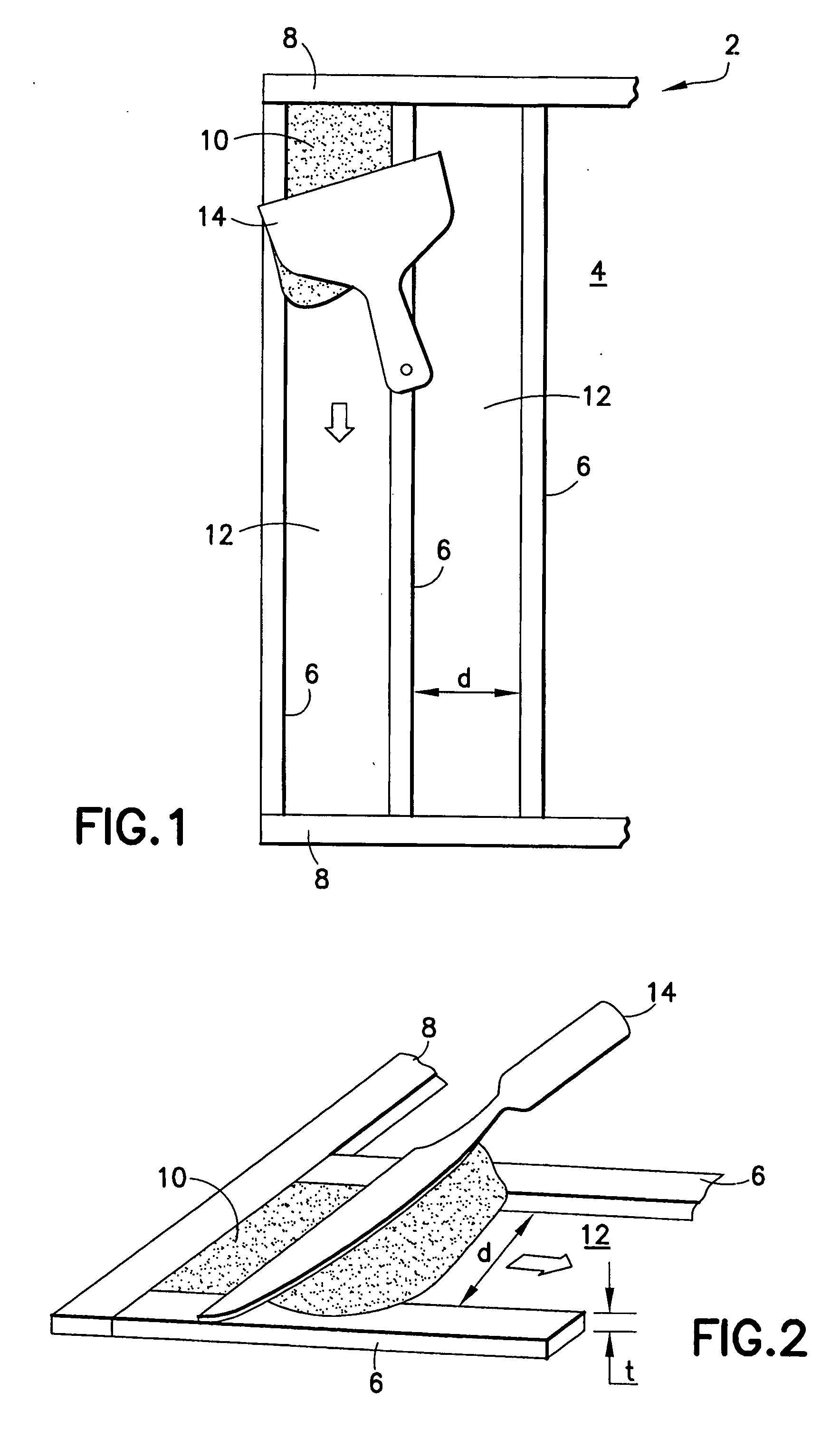

Method of manufacturing a motor comprising a rare earth thick film magnet

InactiveUS6941637B2Easy to assembleSmall sizeElectromagnets without armaturesEvaporation applicationRare-earth elementAlloy

The method of manufacturing rare earth thick film magnet comprising a step of forming an alloy layer of 30-100 μm thick having a general formula RXBYTMZ on a substrate by a physical deposition process, and a step of heat-treating the alloy layer to form a thick film magnetic layer having R2TM14B phase as a main phase. In the general formula, R is at least one of rare earth elements, B is boron, TM is iron or its alloy partly substituted by cobalt. X is 0.1-0.2, Y is 0.05-0.2 and Z=1-X-Y. Further, the method of the present invention includes a step of laminating a plurality of alloy layers formed on a substrate together with the substrate. A motor comprising rare earth thick film magnet of the present invention is extremely small while obtaining high output.

Owner:PANASONIC CORP

Method for the production of a magnetic layer on a substrate and printable magnetizable varnish

InactiveUS20100129540A1Improve magnetic propertiesHigh strengthInorganic material magnetismThick magnetic filmsScreen printingStrontium

The current invention relates to a method for the production of a magnetic layer on a substrate, comprising the production of a printable varnish, containing 60 weight-% of neodym iron boron powder, 10 weight-% of ferrite powder, preferably strontium hexaferrite powder, 1.4 weight-% of a catalyst, 1.1 weight-% of a dispersing additive, and as the remainder a matrix, preferably an epoxy polyol matrix. These agents are mixed by means of stirring or kneading, and rolled in a three-roll mill. Preferably, they are applied to a substrate by screen printing, and subsequently pre-cured at 80 to 120° C. for six to twelve hours, and then cured at 200° C. to 220° C. for three hours.

Owner:BOURNS INC

Method and device for applying wall coatings

InactiveUS20060283989A1Strength of magnetic attractionMaintain sufficiencyBurnersCovering/liningsBiomedical engineeringMagnetic coating

A method of applying a magnetic coating to a surface including steps of releasably attaching a framing member to a surface, the framing member defining at least one opening; applying a magnetic coating to the surface within said opening; allowing the magnetic coating to dry; and removing the framing member from the surface, such that the magnetic coating remains fixed to the surface. The framing member is removed from the surface, and additional magnetic coating is applied to the surface to fill in gaps left from removing the framing member.

Owner:DAVID B LYTLE PRODS

Composite magnetic sheet and method of producing the same

InactiveUS20050205831A1Improved in electromagnetic interference suppressing effectImprove permeabilityOther chemical processesMagnetic/electric field screeningSlurrySolvent

A composite magnetic body is produced from flat soft magnetic powder subjected to annealing to be free from stress strain is prepared and mixed with a binder and a solvent for dissolving the binder to form a slurry-like mixture. The mixture is formed into a film. Then, the solvent is removed. Thus, a sheet of the composite magnetic body is produced.

Owner:ONO NORIHIKO

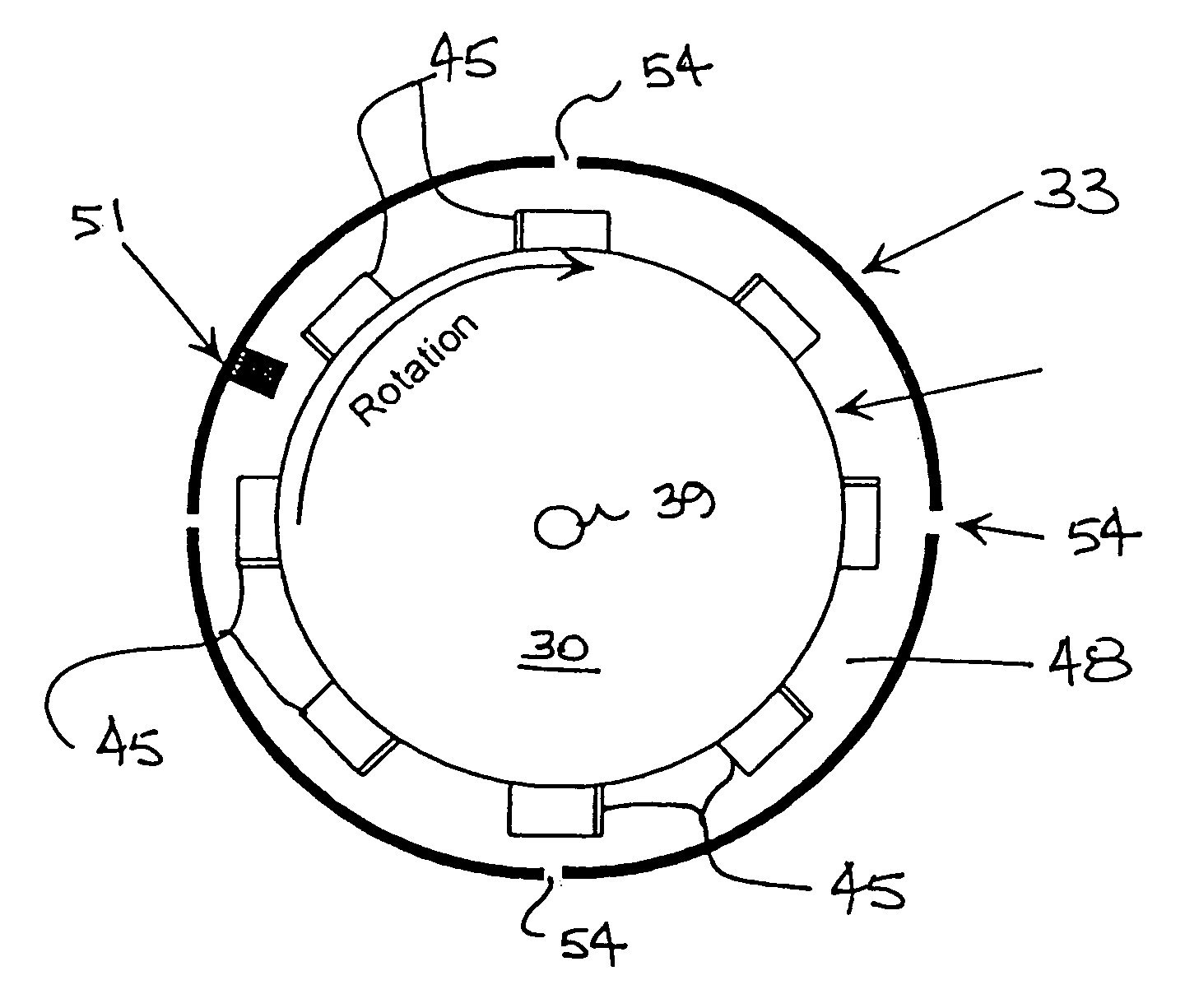

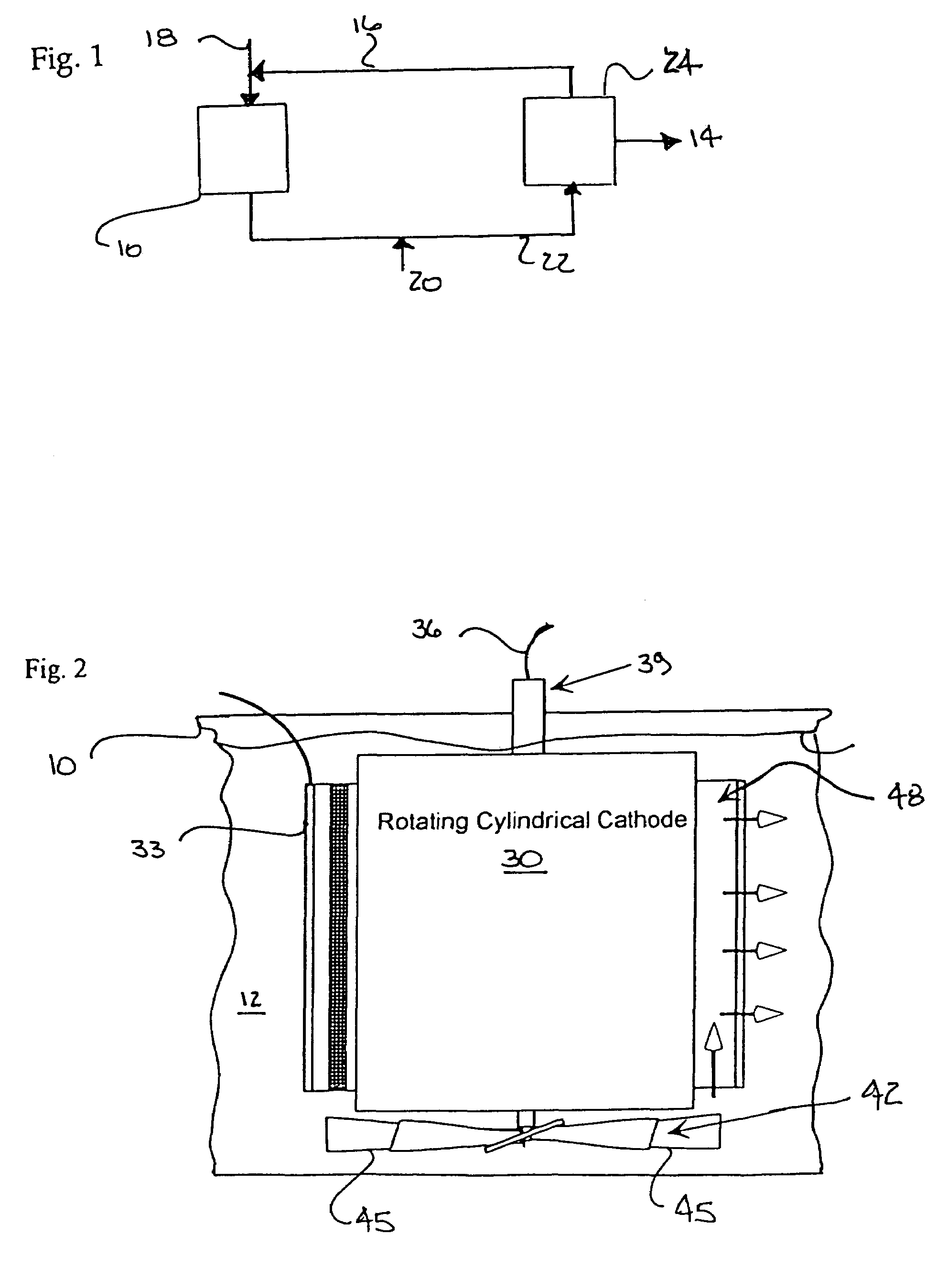

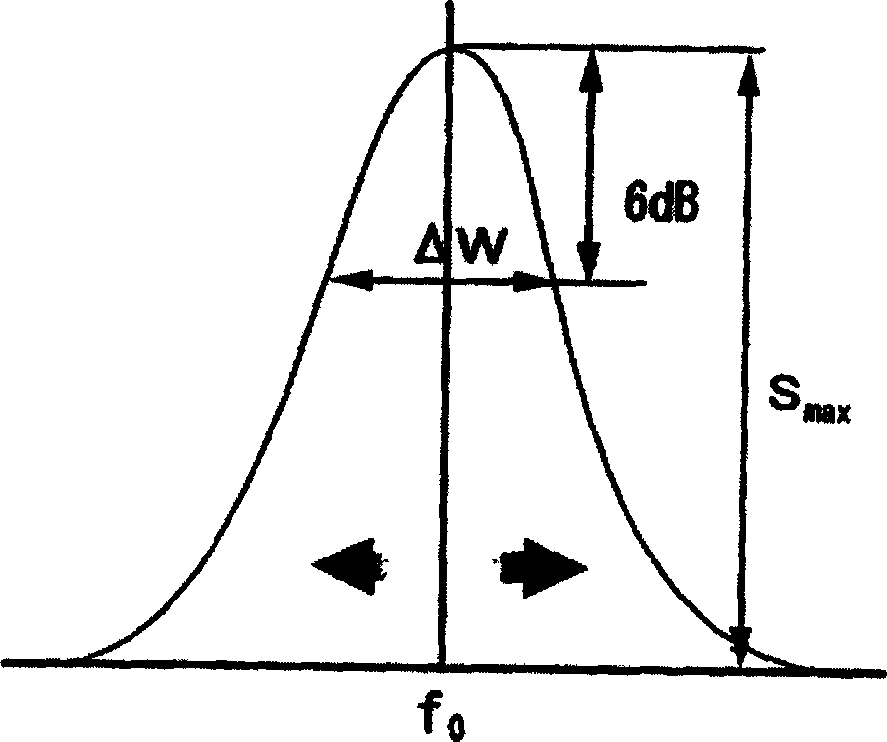

Apparatus for making particulates of controlled dimension

We make particulates, especially magnetic Fe—Co alloys having high magnetic permeability, of controlled dimensions, especially those having a narrow thickness size distribution centered around a median or target thickness in the range of about 0.1–1.0 μm, using electrodeposition typically on a smooth (polished) titanium cathode. Our preferred continuous process uses a rotating drum cathode inside a fixed anode to grow flakes and to produce them automatically by inherent instability in the deposited film. The drum preferably rotates about a substantially vertical axis. The particulates shed (slough off) into the electrolyte (because of mismatch between the cathode surface and the plated metal or alloy at the molecular level) where they are separated in a magnetic separator or other suitable device. If the flakes are soft iron or iron-cobalt alloys, the drum generally is titanium or titanium alloy.

Owner:THE BOEING CO

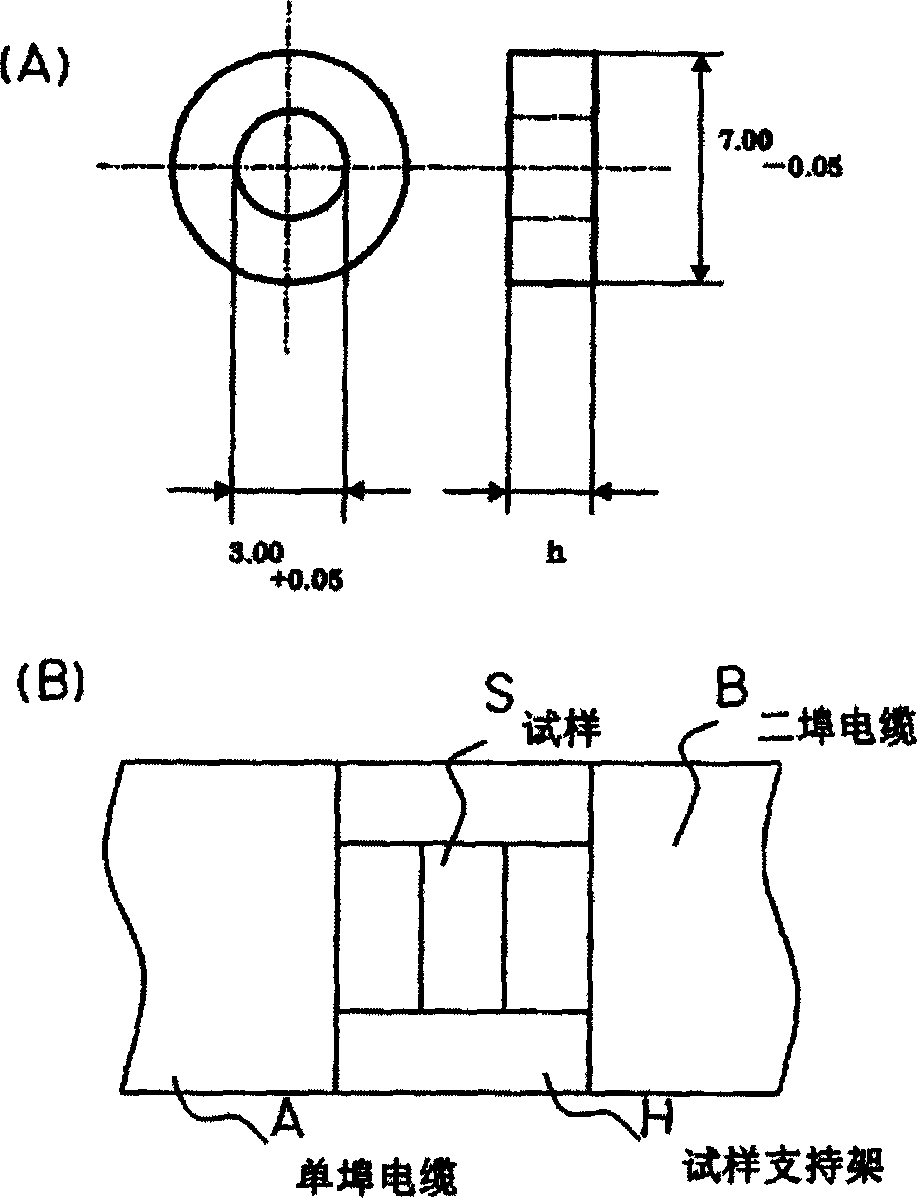

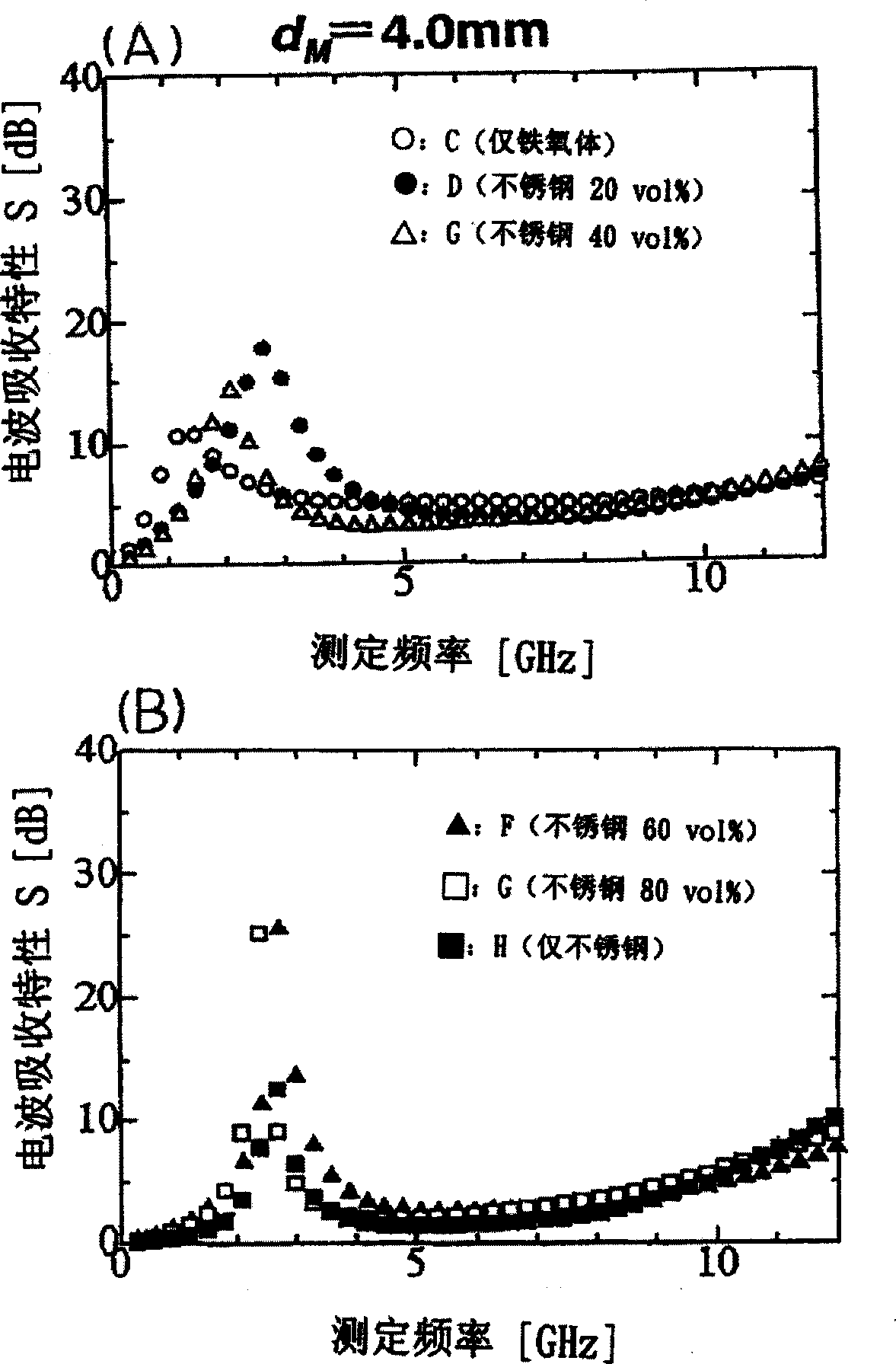

Woody electric wave absorber

InactiveCN1906989ASuperior radio wave absorption characteristicsEasy to manufactureMagnetic/electric field screeningInorganic material magnetismFerrite powderConductive materials

Various electric wave absorbers for the GHz band have been developed. However, parameters for obtaining the optimal electric wave absorption characteristic are only the shape and the content of a dielectric material or a conductive material, and the degree of freedom of the parameters is small. Furthermore, in a recent wireless LAN, electric wave absorbers that can be used for absorbing potentially electric waves in a plurality of bands, for example, in two frequency bands of 2.45 GHz band and 5.2 GHz band, have also been desired. A woody electric wave absorber is also disclosed, characterized in that it is a laminate type magnetic wood prepared by pressure-pasting an opposed plate material pair comprising natural wood or a processed woody material via a magnetic layer containing a ferrite powder, it contains a non-magnetic stainless steel powder in an amount of 20 to 80 vol % relative to the ferrite powder, and the magnetic layer has a total volume content for the ferrite powder and the non-magnetic stainless steel powder of 10 to 40 % and has a thickness of 0.5 to 5.0 mm, it has a central frequency within 1 to 8 GHz, and has an electric wave absorption characteristic of 10 dB or more in a 2.45 GHz band or a 5.2 GHz band of frequency.

Owner:JAPAN SCI & TECH CORP

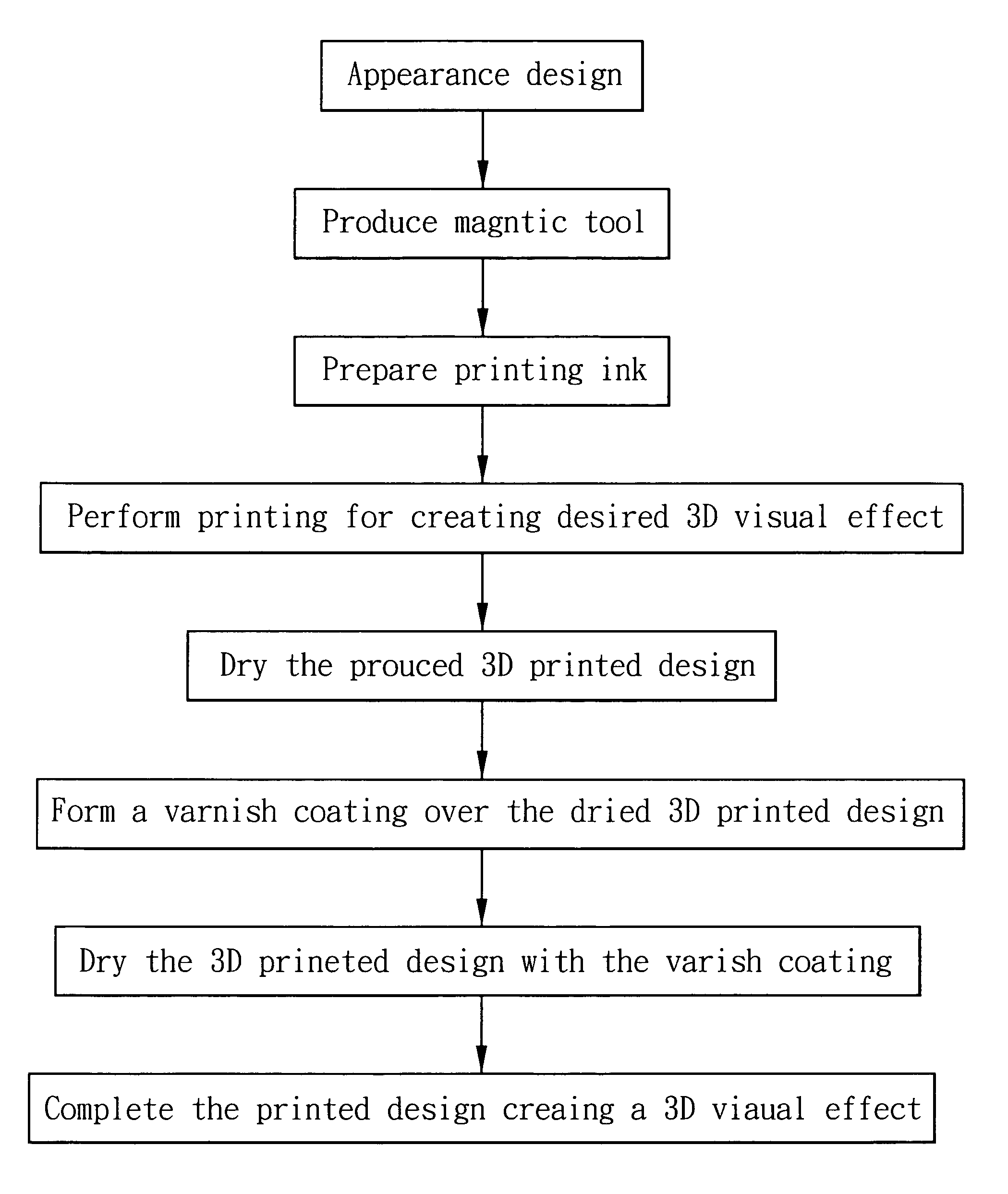

Process and compound for producing printed design creating three-dimensional visual effect

In a process for producing a printed design creating 3D visual effect, a compound consisting of a printing ink blended with magnetic particles is used. The printing ink containing the magnetic particles is applied onto a printing plate on a printing apparatus, and a tool capable of producing a required magnetic force is positioned at a predetermined area of the applied printing ink, so that the magnetic particles in the printing ink are attracted and gathered to form ups and downs in the area and create a 3D visual effect.

Owner:SANRITZ CORP

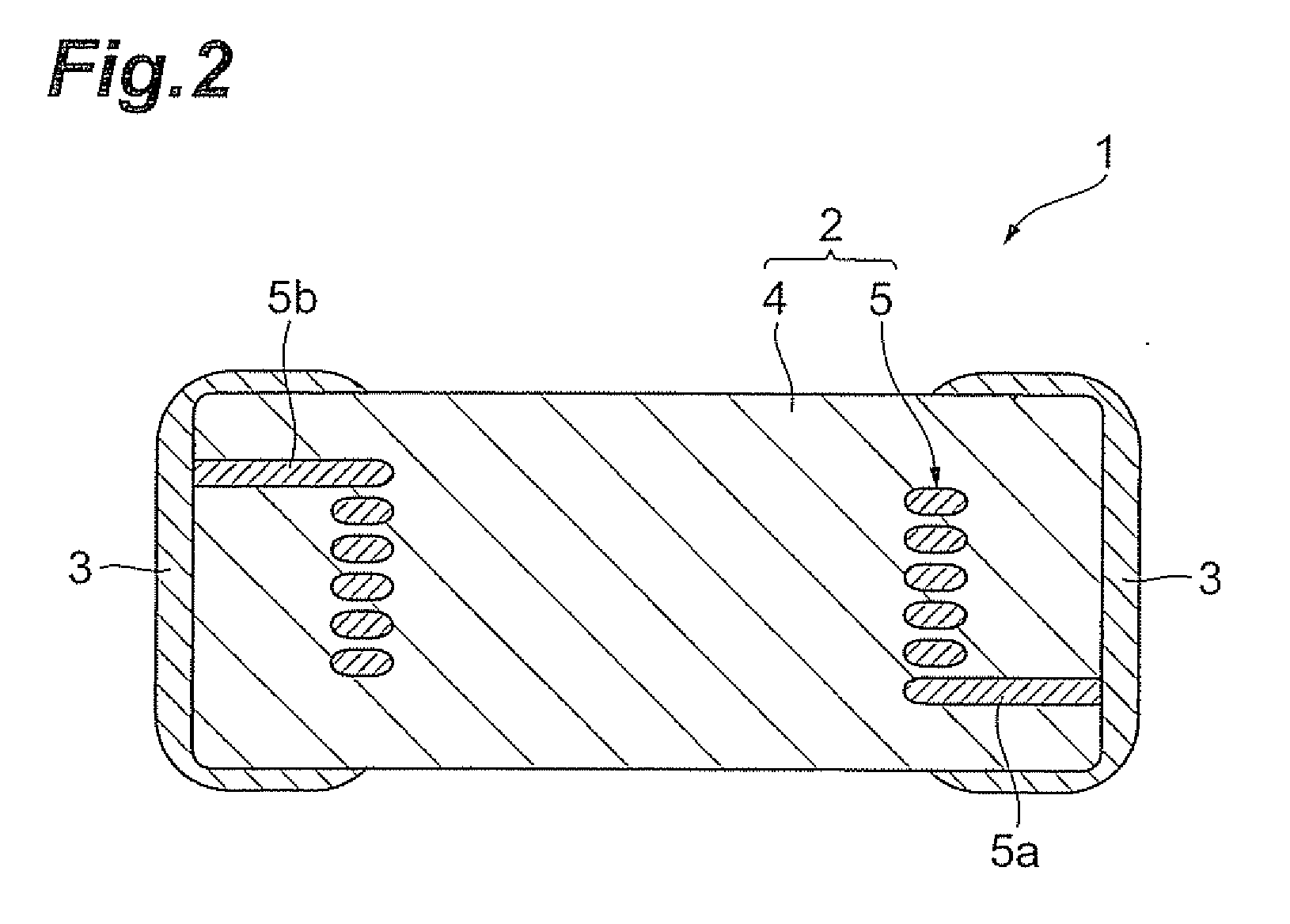

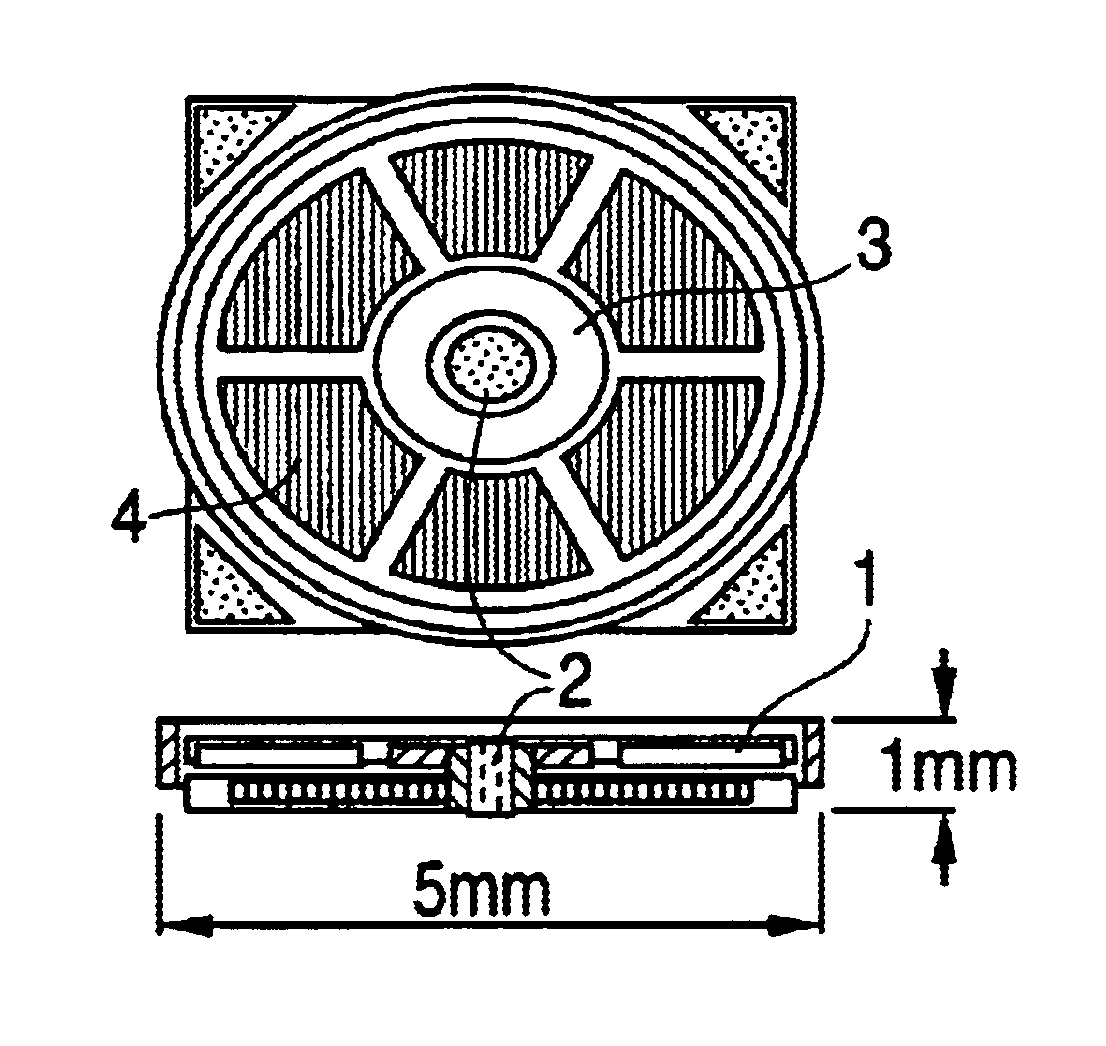

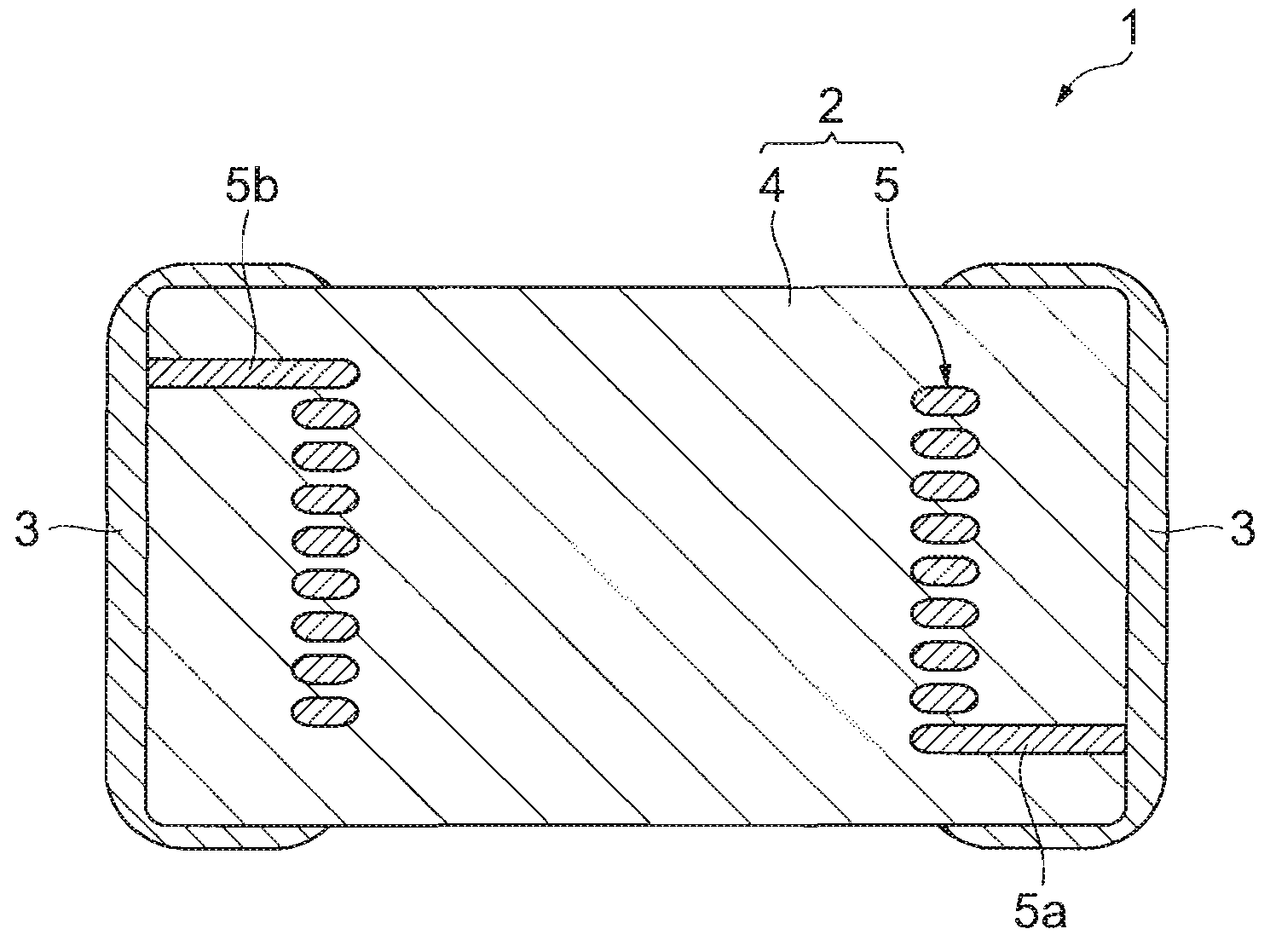

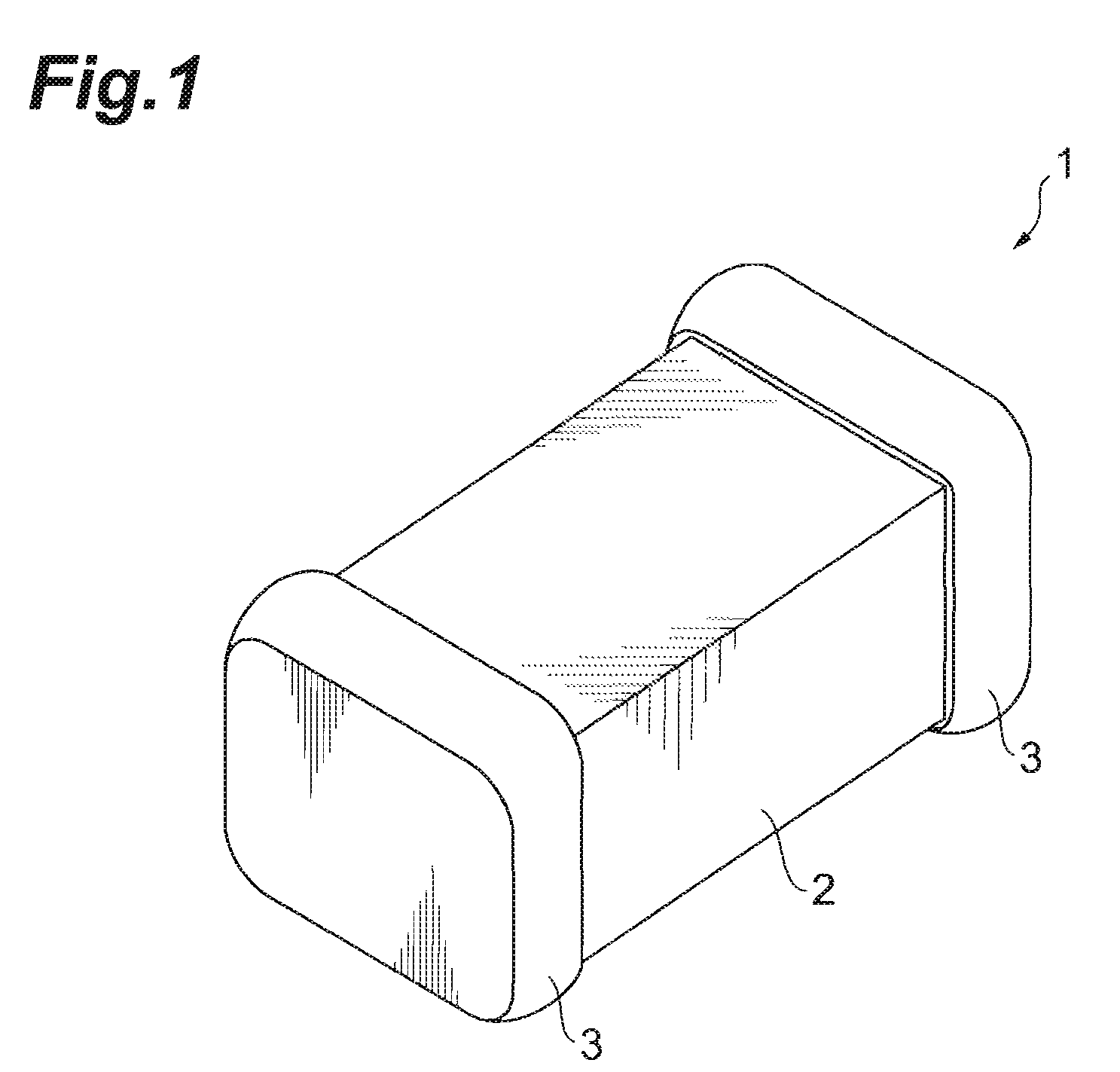

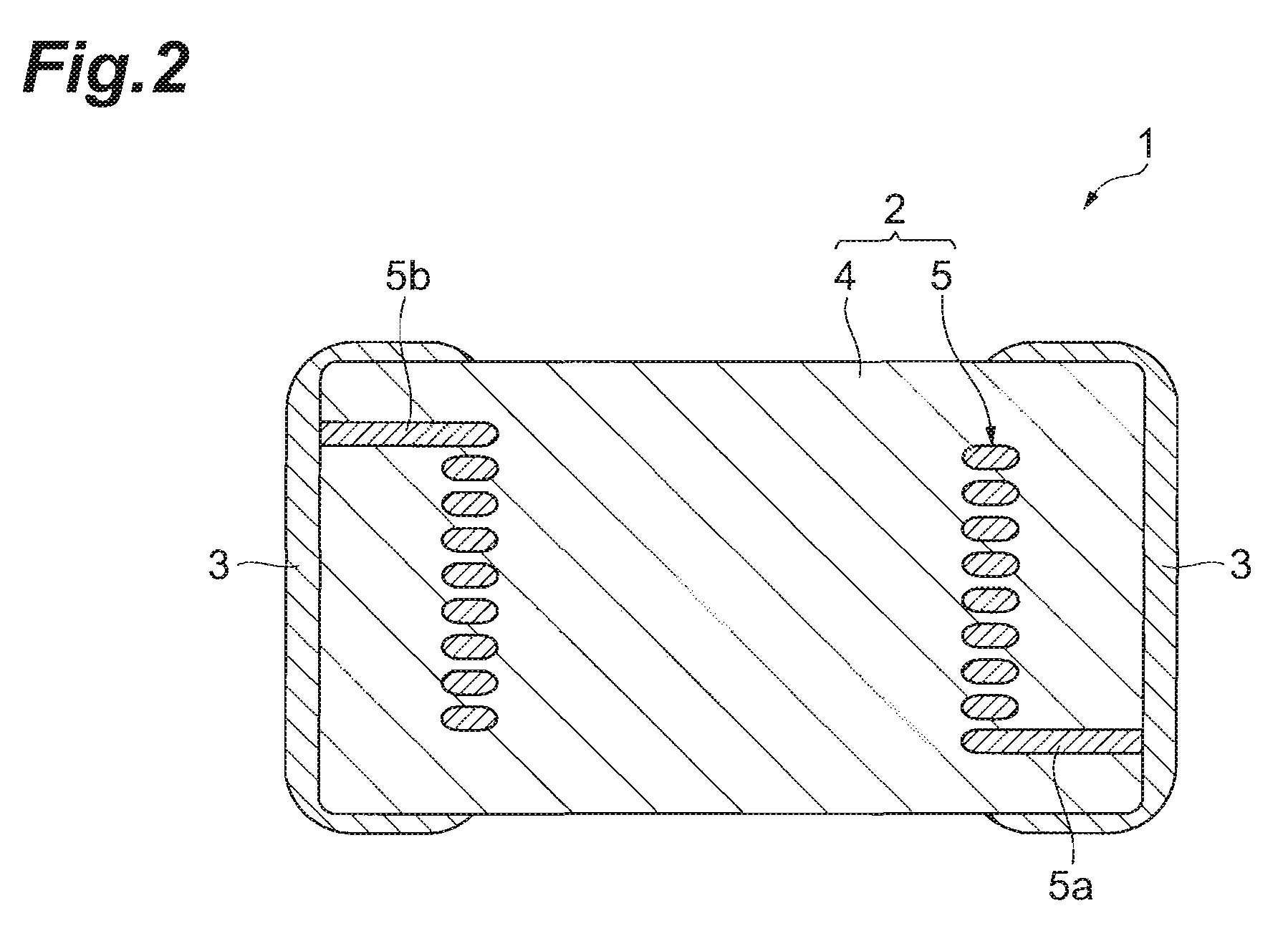

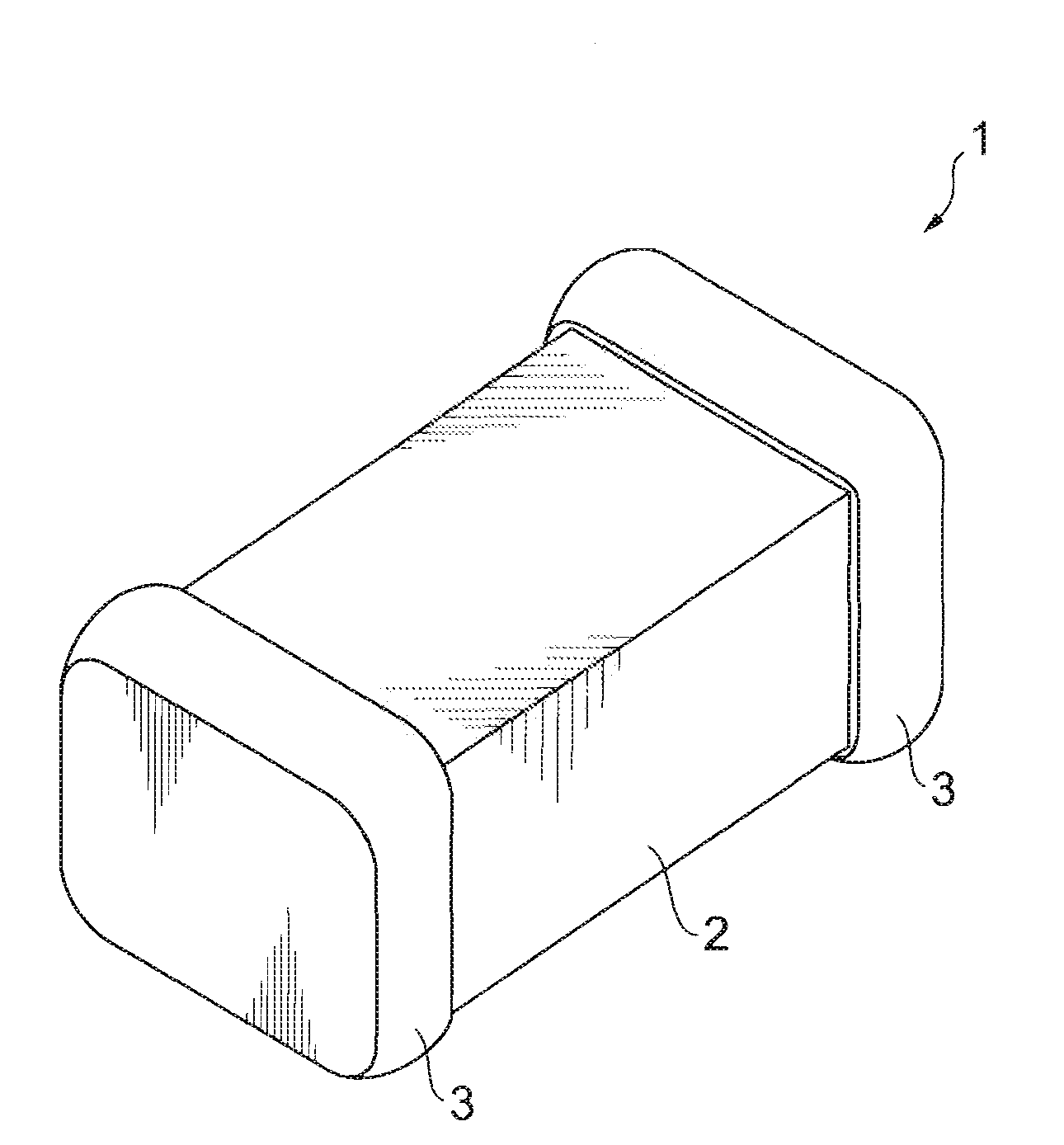

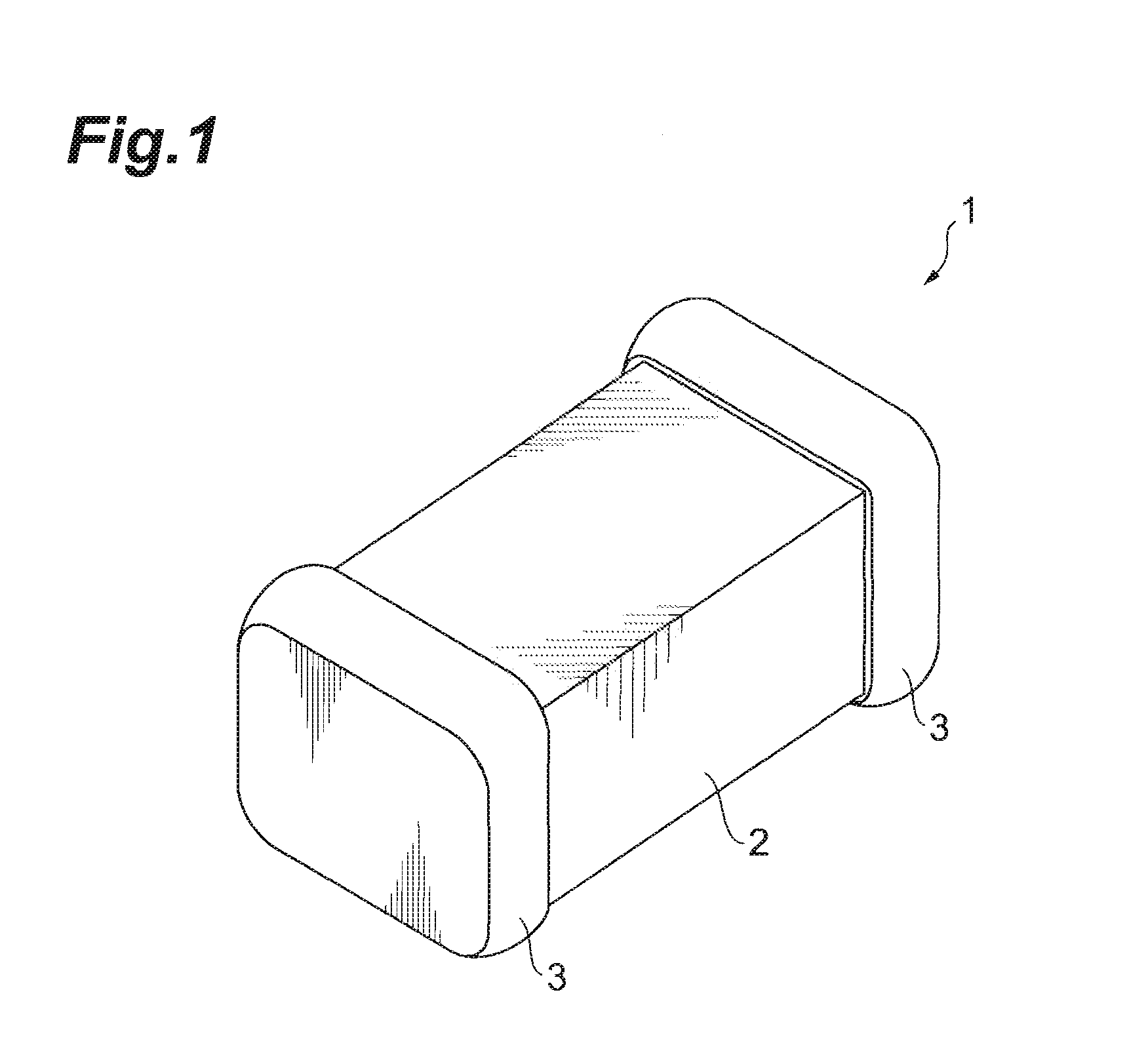

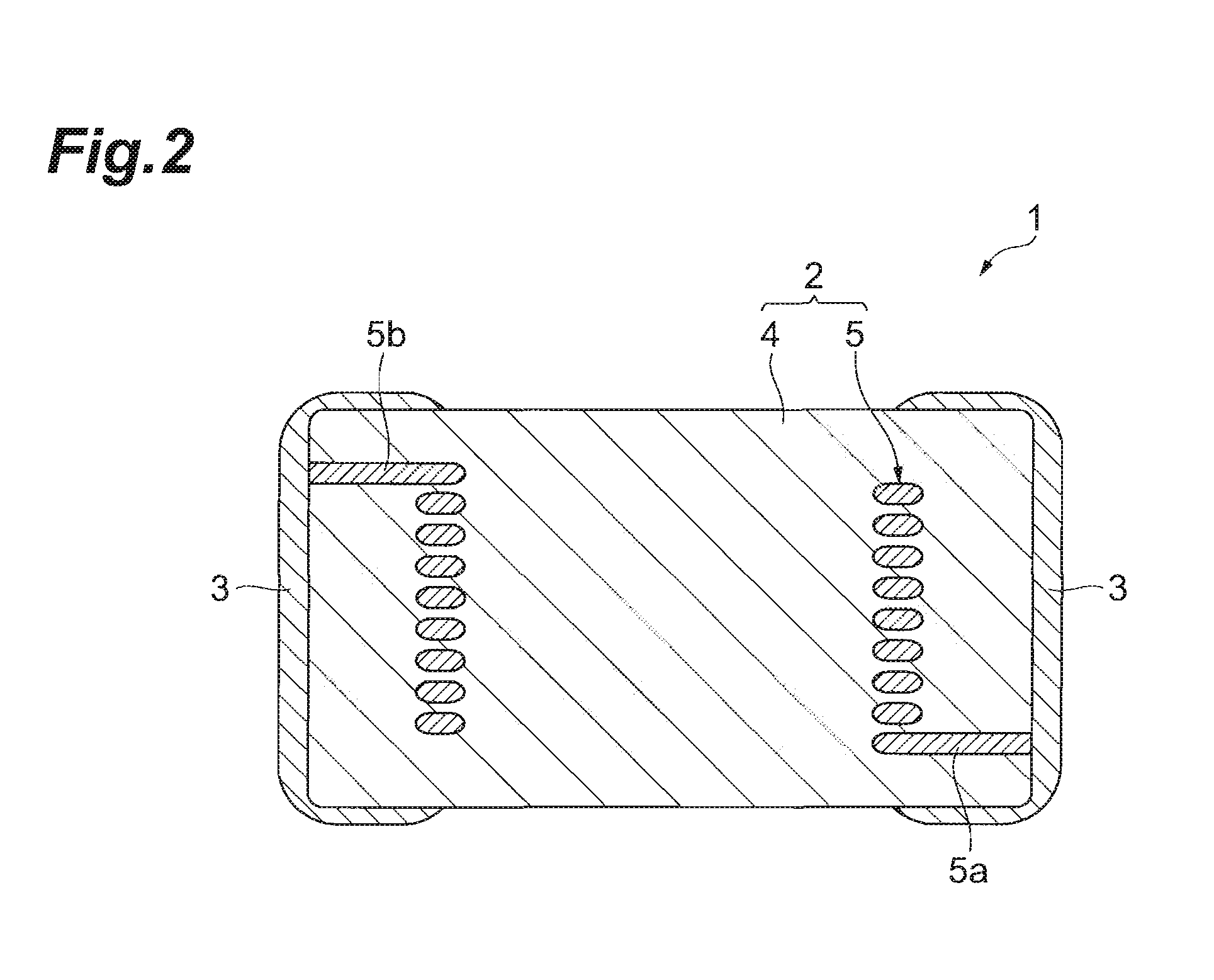

Multilayer inductor component

ActiveUS7589609B2High frequencyImproving impedanceTransformers/inductances magnetic coresThick magnetic filmsElectrical conductorInductor

A multilayer inductor component has a multilayer part having a plurality of magnetic layers laminated therein and a conductor part arranged within the multilayer part. The magnetic layers are formed from a ferrite material and an additive. The ferrite material contains Fe2O3, NiO, CuO, and ZnO. Fe2O3 is 30 to 45 mol %. NiO is 45 to 58 mol %. CuO is 6 to 10 mol %. ZnO is 0 to 3 mol %. The additive contains CoO. The content of CoO is 0.1 to 2.5 mass % with respect to the ferrite material as a whole. The multilayer inductor component has an impedance peak of 500 Ω or greater at an operating frequency of 1 GHz or higher.

Owner:TDK CORPARATION

Multilayer inductor component

ActiveUS20080296528A1Cancel noiseImpedance unnecessaryTransformers/inductances magnetic coresThick magnetic filmsElectrical conductorInductor

A multilayer inductor component has a multilayer part having a plurality of magnetic layers laminated therein and a conductor part arranged within the multilayer part. The magnetic layers are formed from a ferrite material and an additive. The ferrite material contains Fe2O3, NiO, CuO, and ZnO. Fe2O3 is 30 to 45 mol %. NiO is 45 to 58 mol %. CuO is 6 to 10 mol %. ZnO is 0 to 3 mol %. The additive contains CoO. The content of CoO is 0.1 to 2.5 mass % with respect to the ferrite material as a whole. The multilayer inductor component has an impedance peak of 500Ω or greater at an operating frequency of 1 GHz or higher.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com