Magnet materials and metallic particles and methods of making same

a technology of magnetic materials and metallic particles, applied in the field of new magnetic materials and new metallic particles, can solve the problems of reducing experimental precision, reducing reproducibility, and expensive commercially available paramagnetic microparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

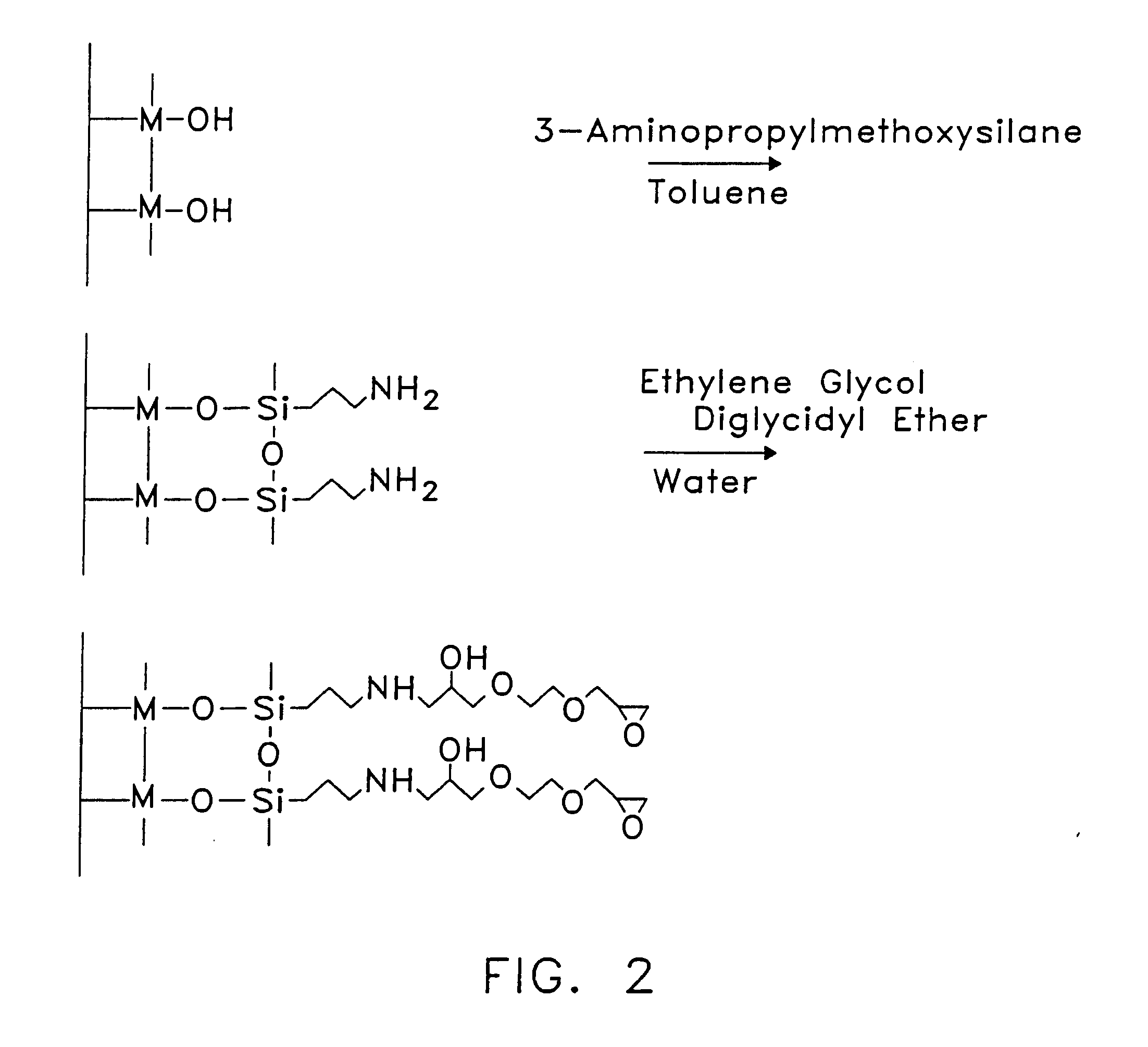

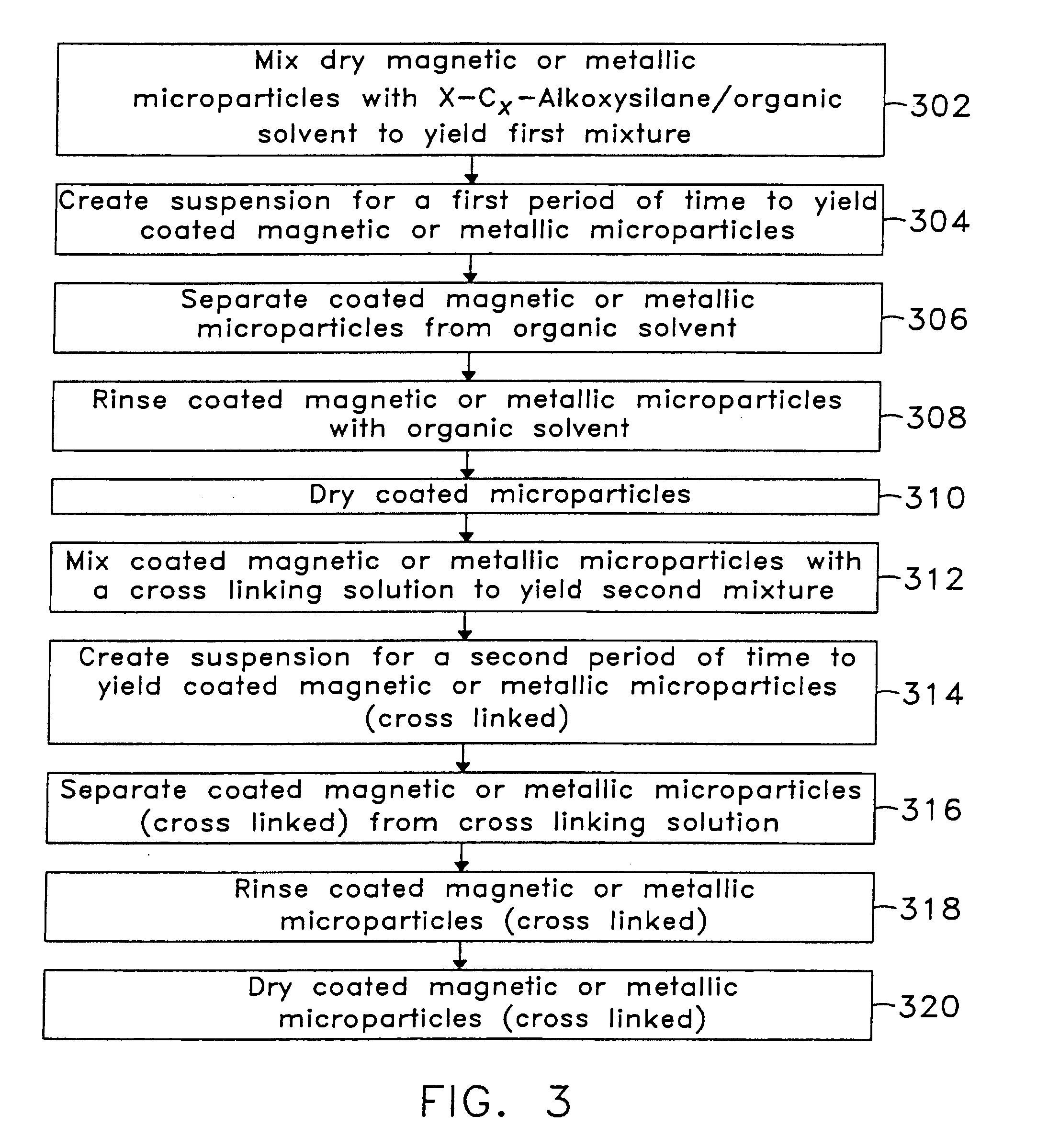

[0053]The new magnetic micromaterials of the present invention were prepared by use of a milling process, followed by a siloxyl coating procedure, as described hereinafter. These processes and procedures have applicability to metallic particles generally. Herein, “metallic” is defined to include any element, compound, or mixture that comprises an element that can be a metal, a semi-metal, or a semiconductor; for example, silver and silver chloride are both metallic according to this definition, as are Si and SiO2.

[0054]The new metallic and magnetic micromaterials of the present invention have a range of material costs, depending on the specific material. The new metallic and magnetic materials of the present invention include particles made of magnetite and other iron oxides, samarium cobalts of various stoichiometries, nickel, neodymium iron boron, and metallic particles in general.

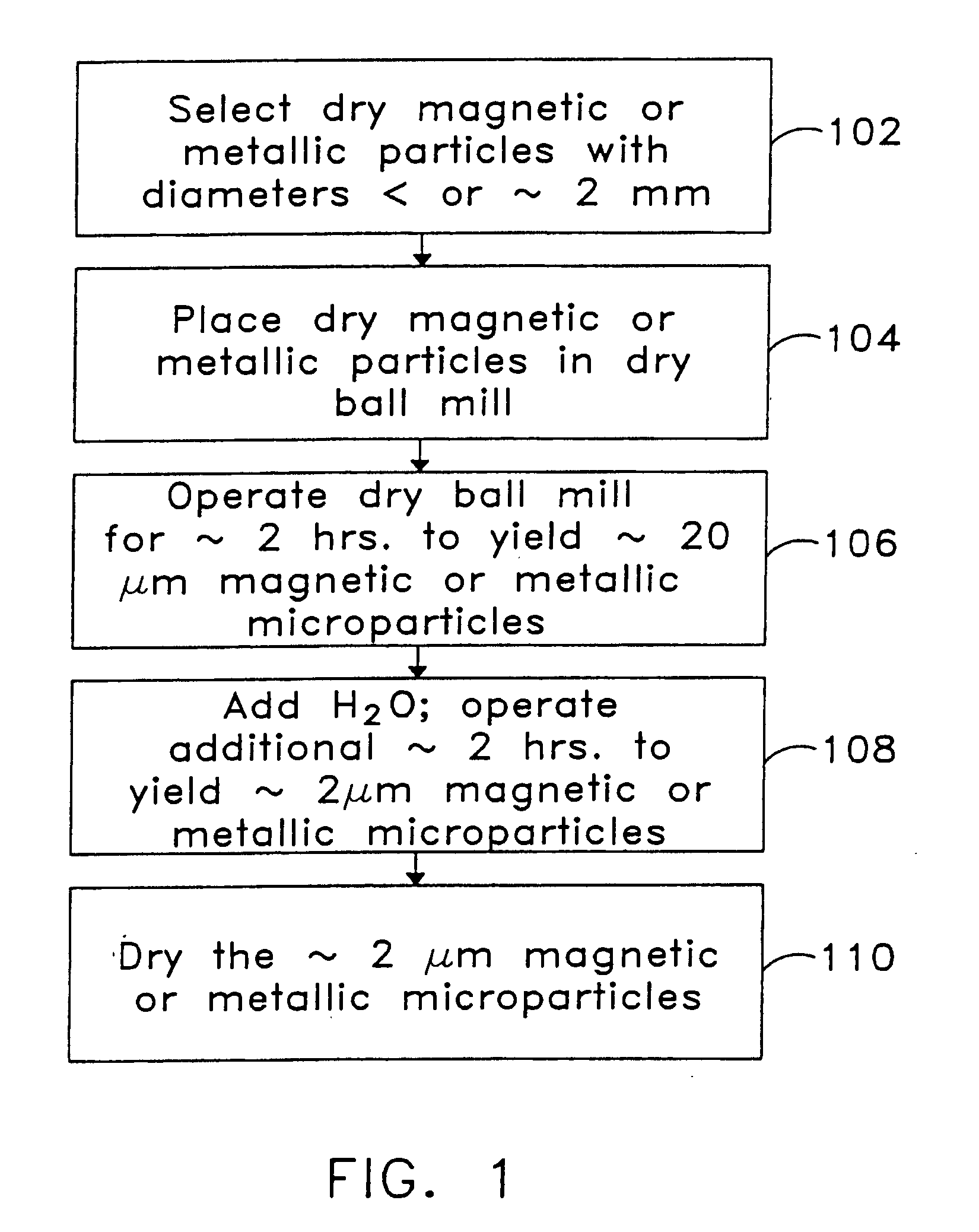

[0055]New magnetic microparticles of the present invention were made by milling metallic or magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com