Patents

Literature

53results about How to "Soft quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

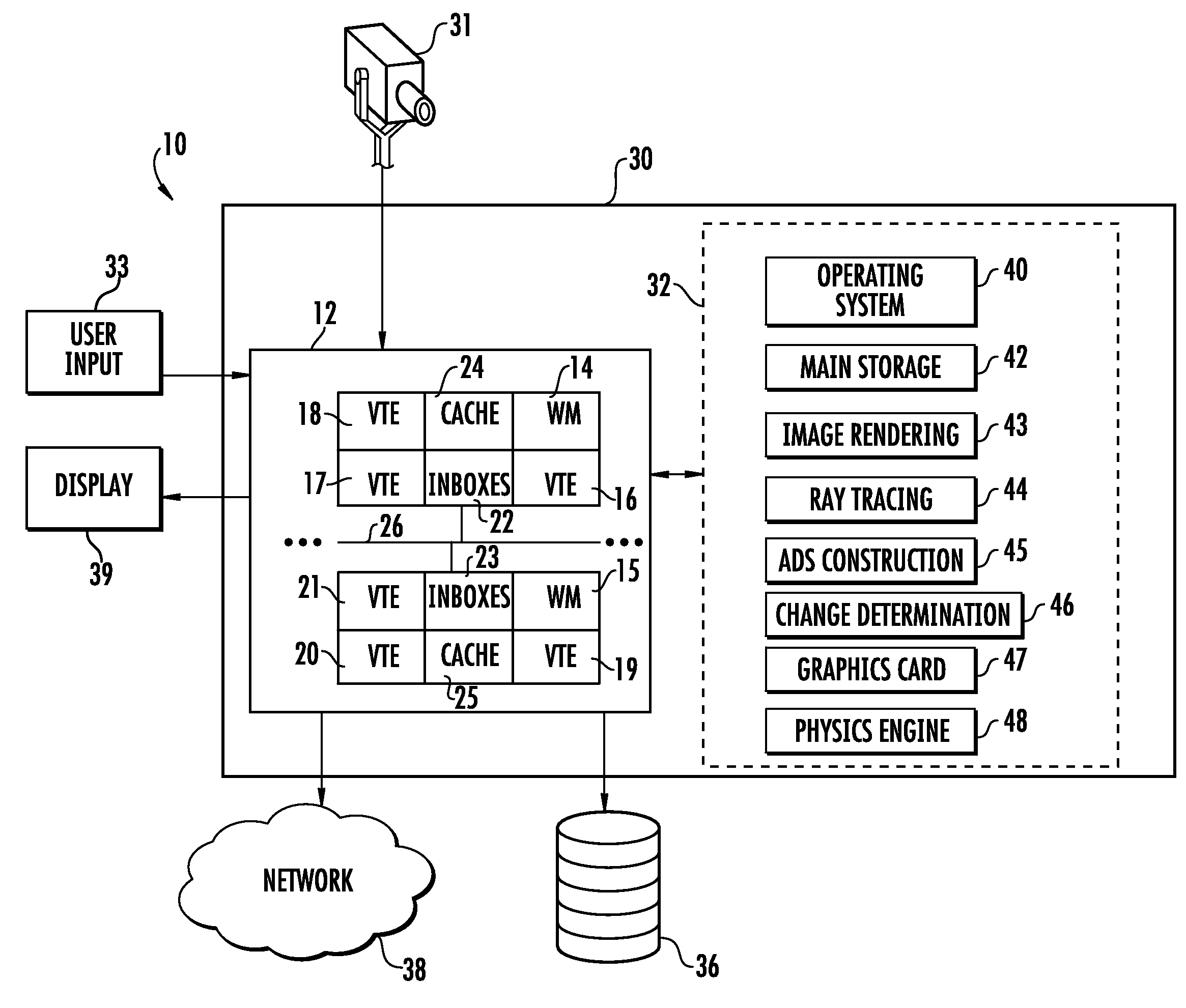

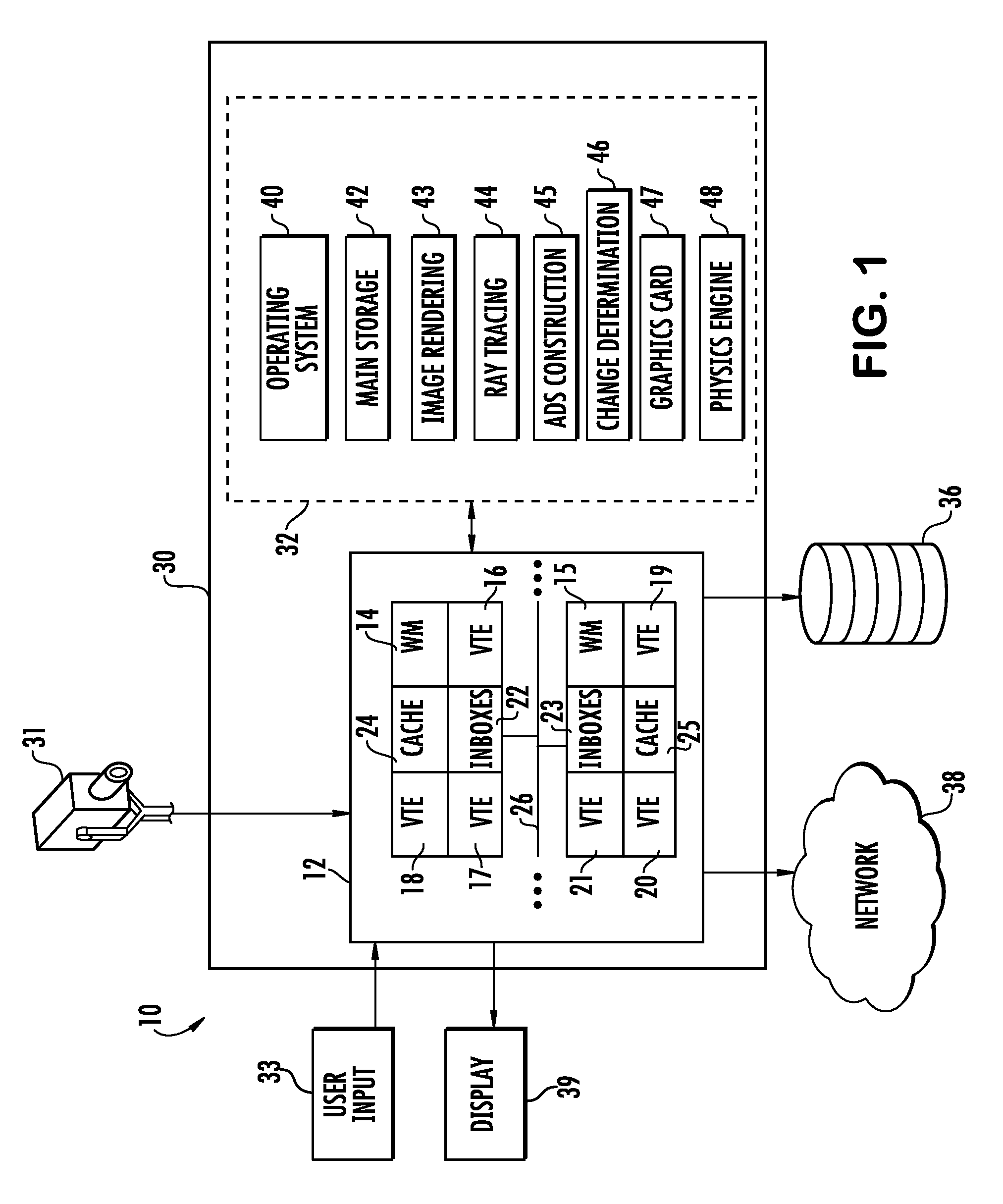

Updating Ray Traced Acceleration Data Structures Between Frames Based on Changing Perspective

InactiveUS20100188396A1Reduce the amount of processingReduced acuityImage data processing detailsSpecial data processing applicationsFrame basedGlobal illumination

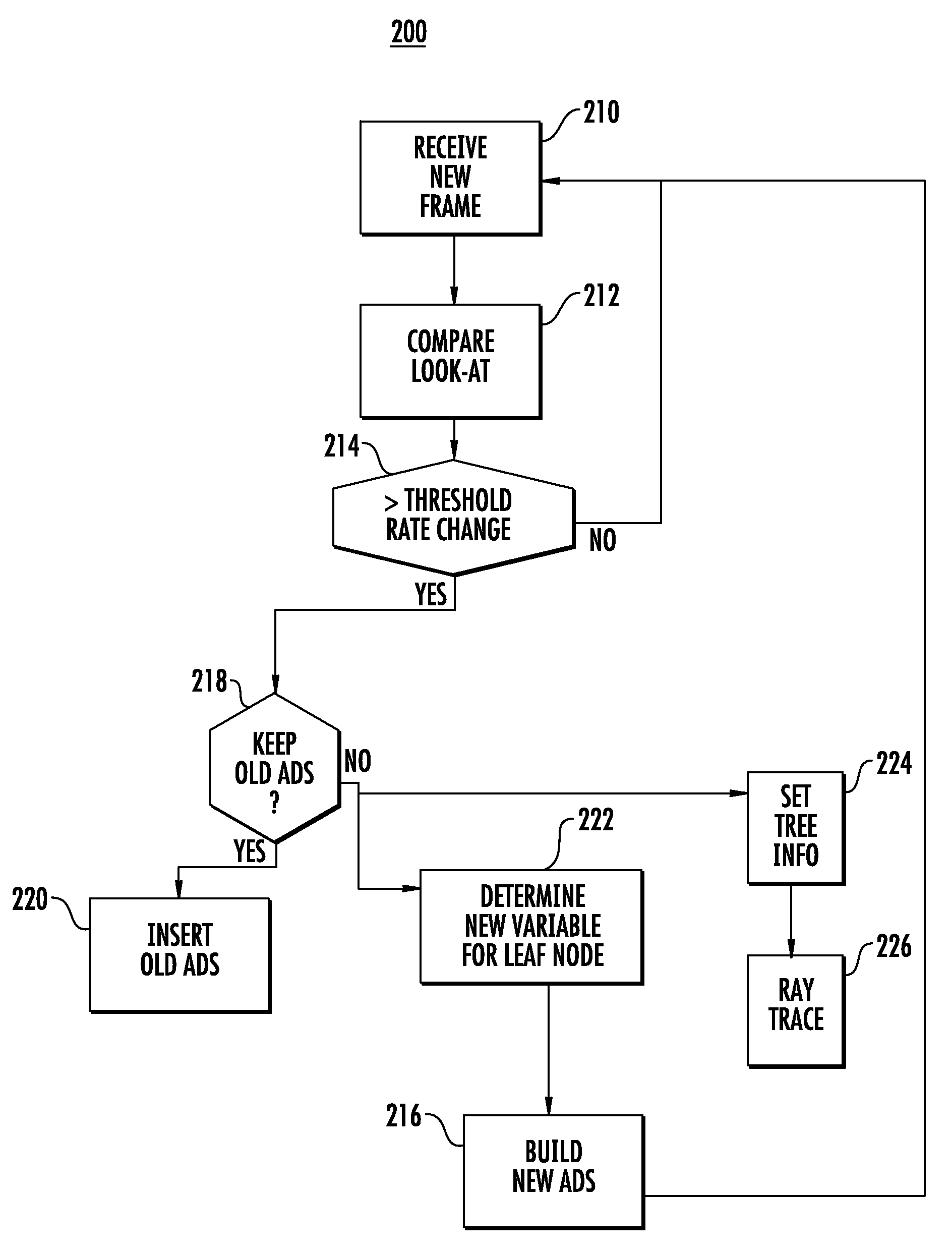

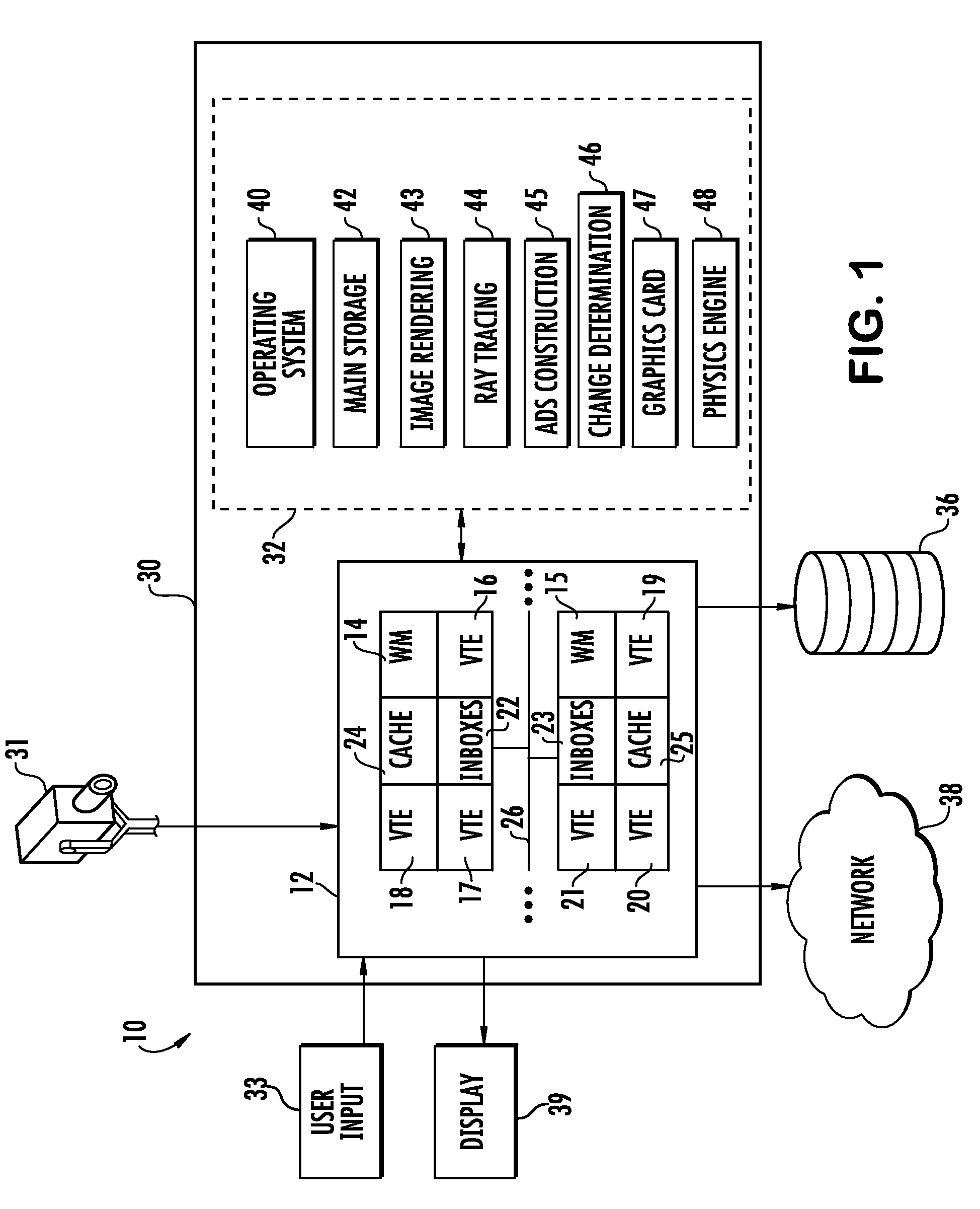

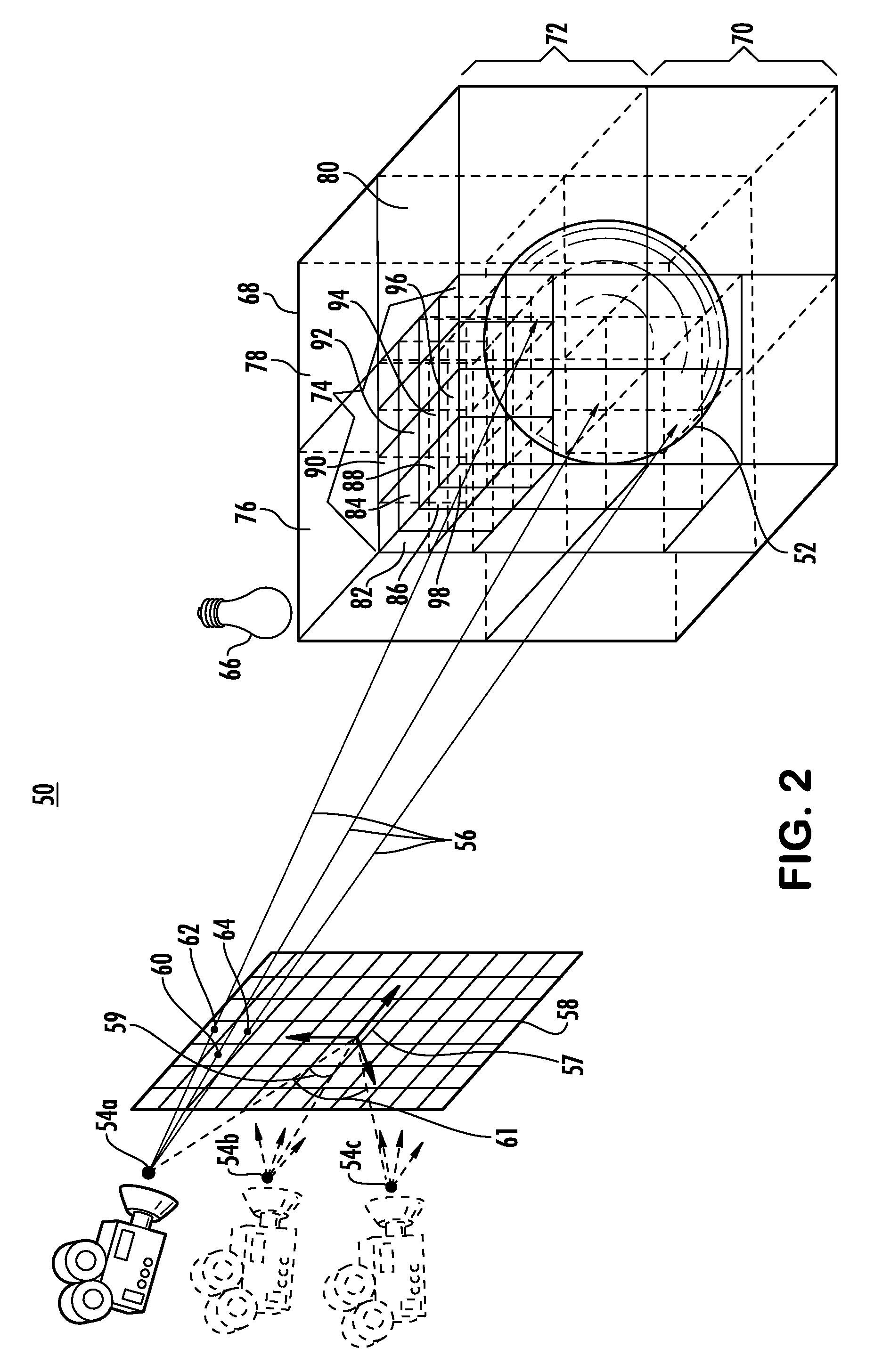

A method, program product and system for conducting a ray tracing operation where the rendering compute requirement is reduced or otherwise adjusted in response to a changing vantage point. Aspects may update or reuse an acceleration data structure between frames in response to the changing vantage point. Tree and image construction quality may be adjusted in response to rapid changes in the camera perspective. Alternatively or additionally, tree building cycles may be skipped. All or some of the tree structure may be built in intervals, e.g., after a preset number of frames. More geometric image data may be added per leaf node in the tree in response to an increase in the rate of change. The quality of the rendering algorithm may additionally be reduced. A ray tracing algorithm may decrease the depth of recursion, and generate fewer cast and secondary rays. The ray tracer may further reduce the quality of soft shadows, resolution and global illumination samples, among other quality parameters. Alternatively, tree rebuilding may be skipped entirely in response to a high camera rate of change. Associated processes may create blur between frames to simulate motion blur.

Owner:IBM CORP

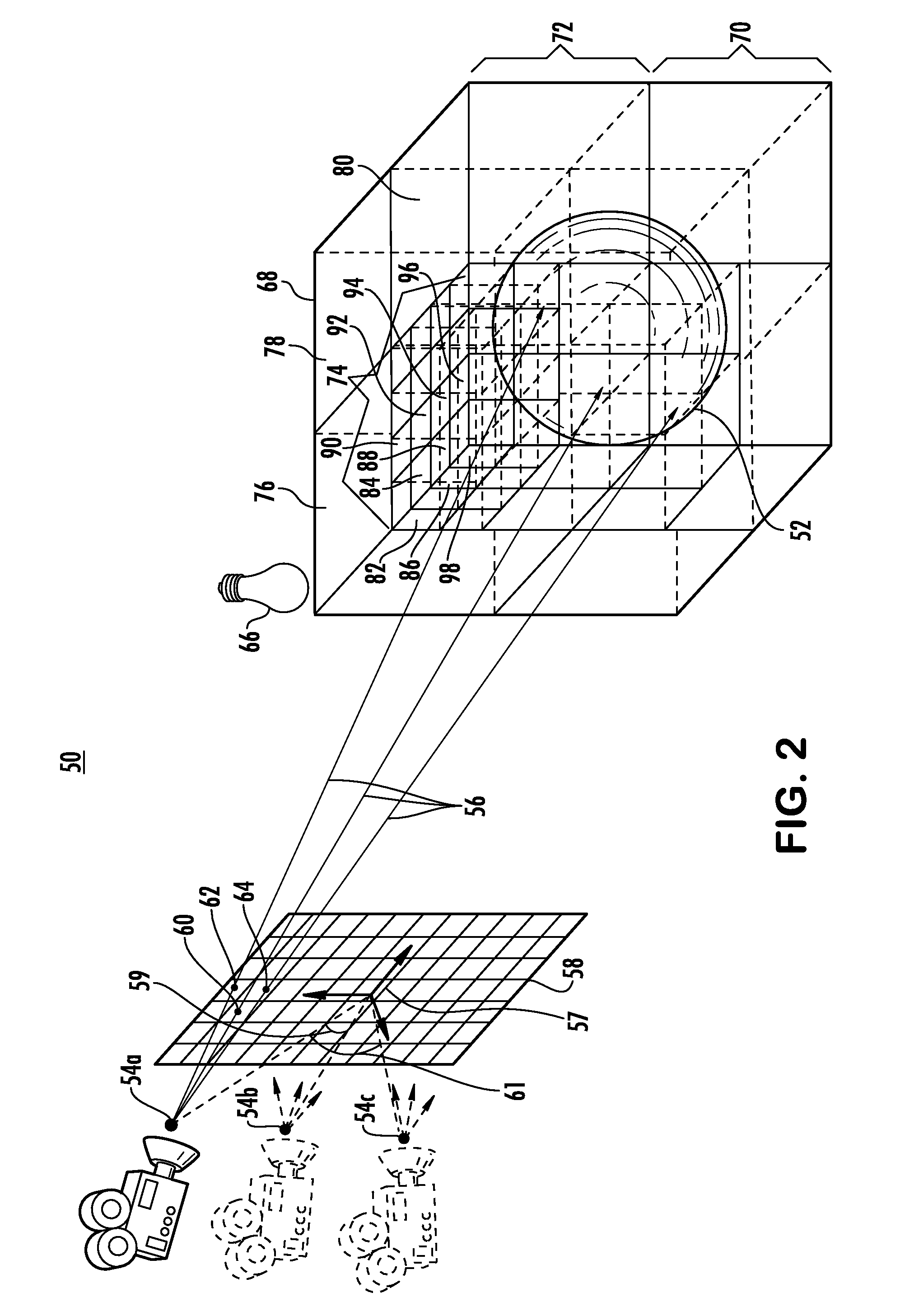

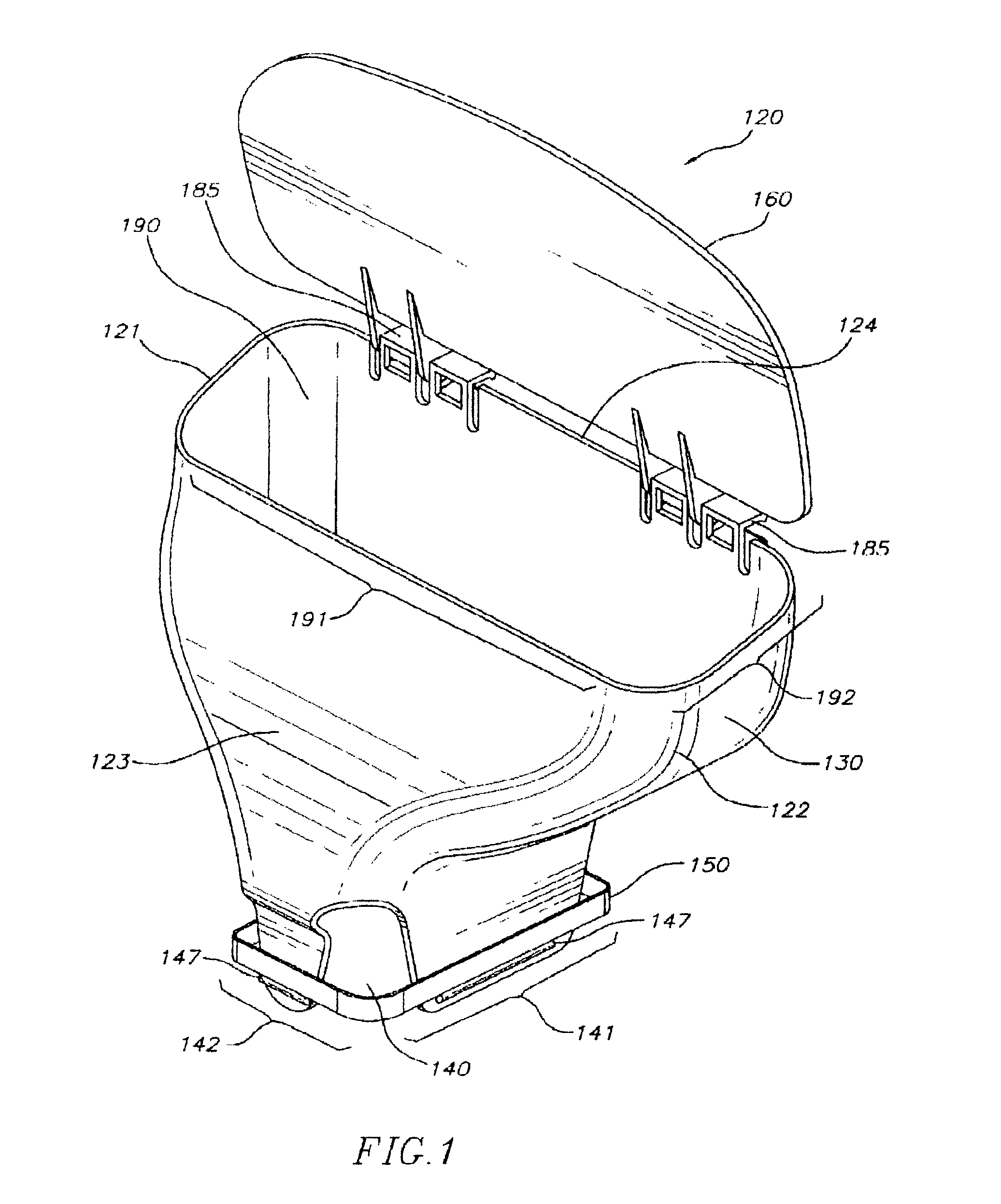

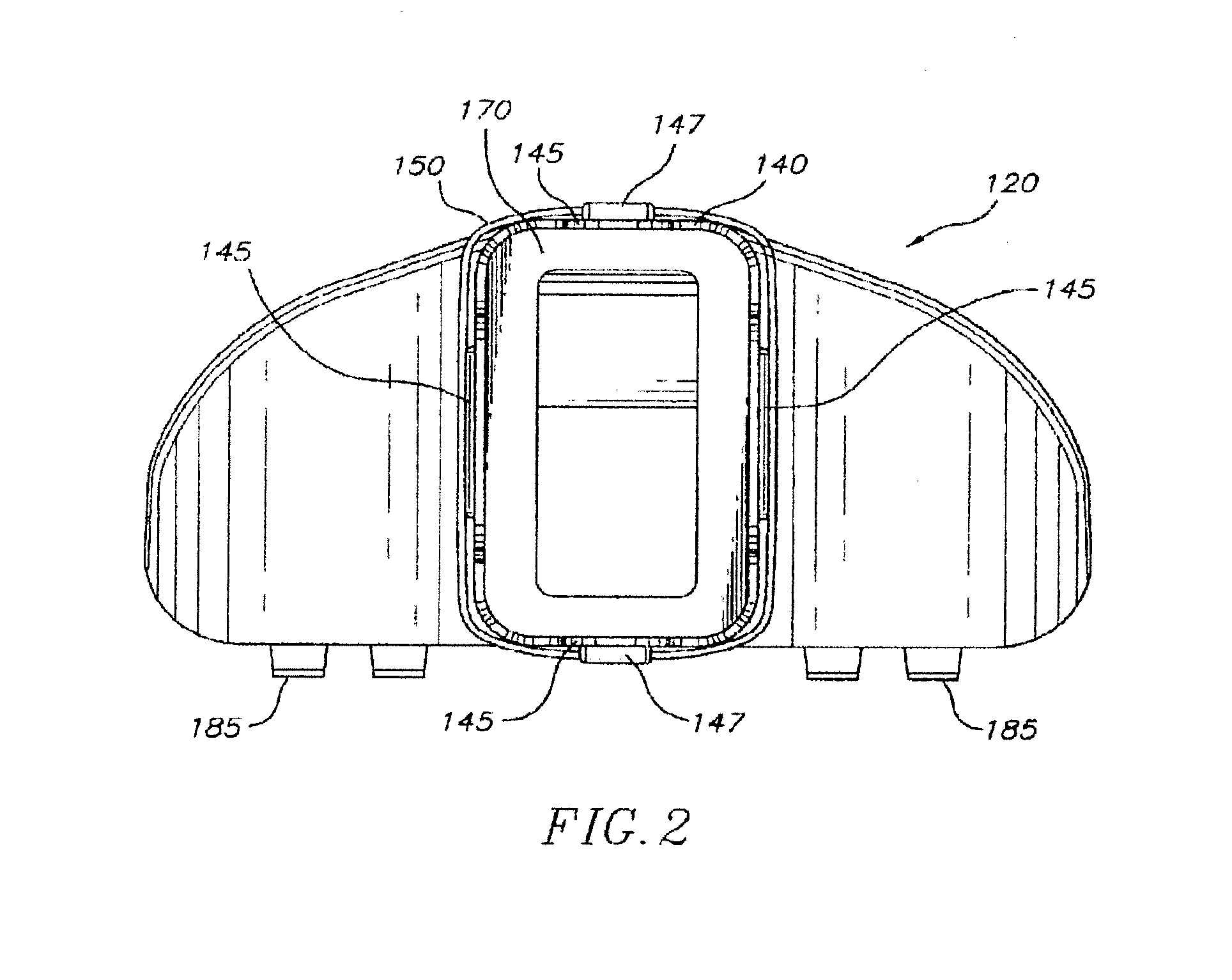

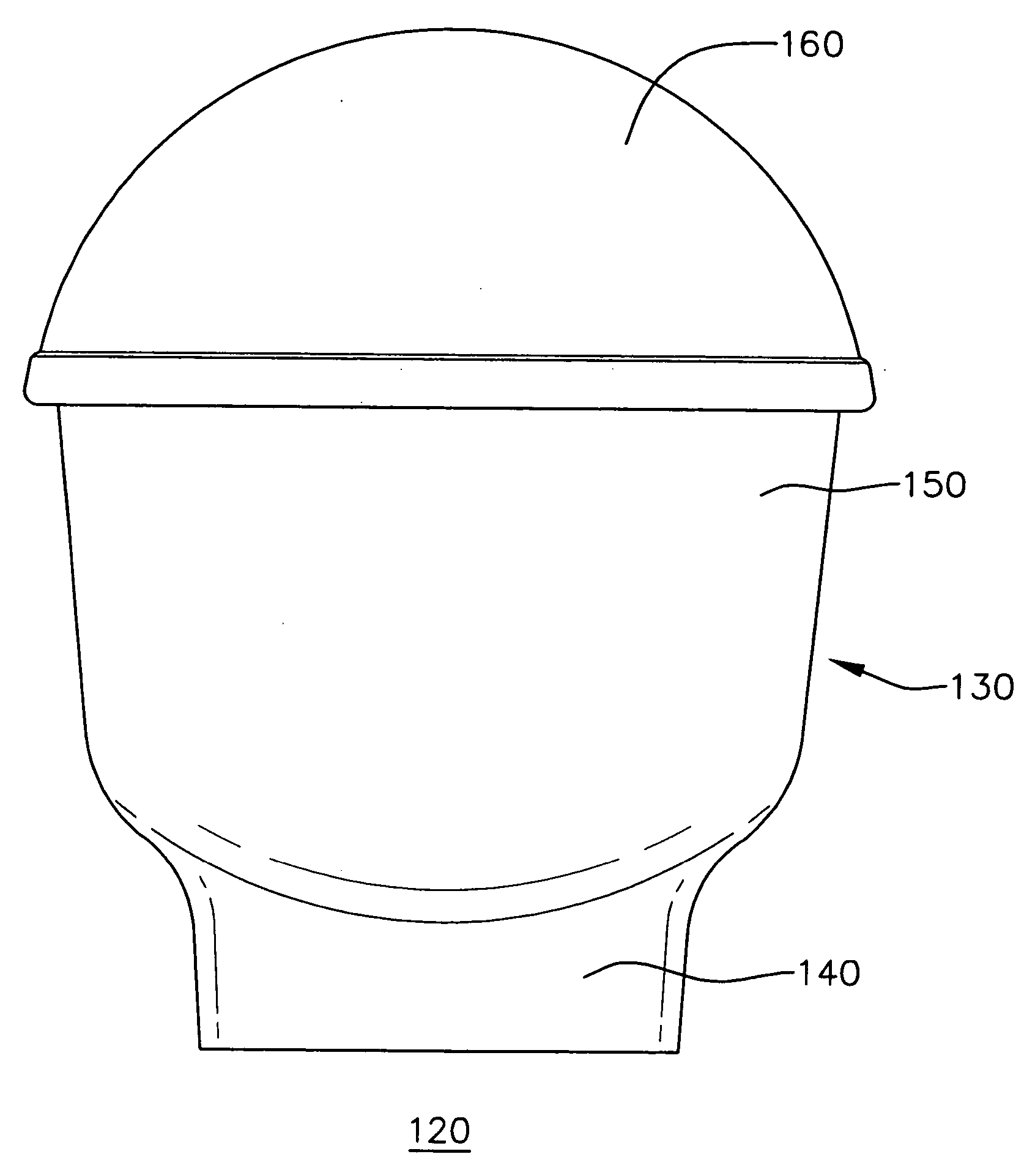

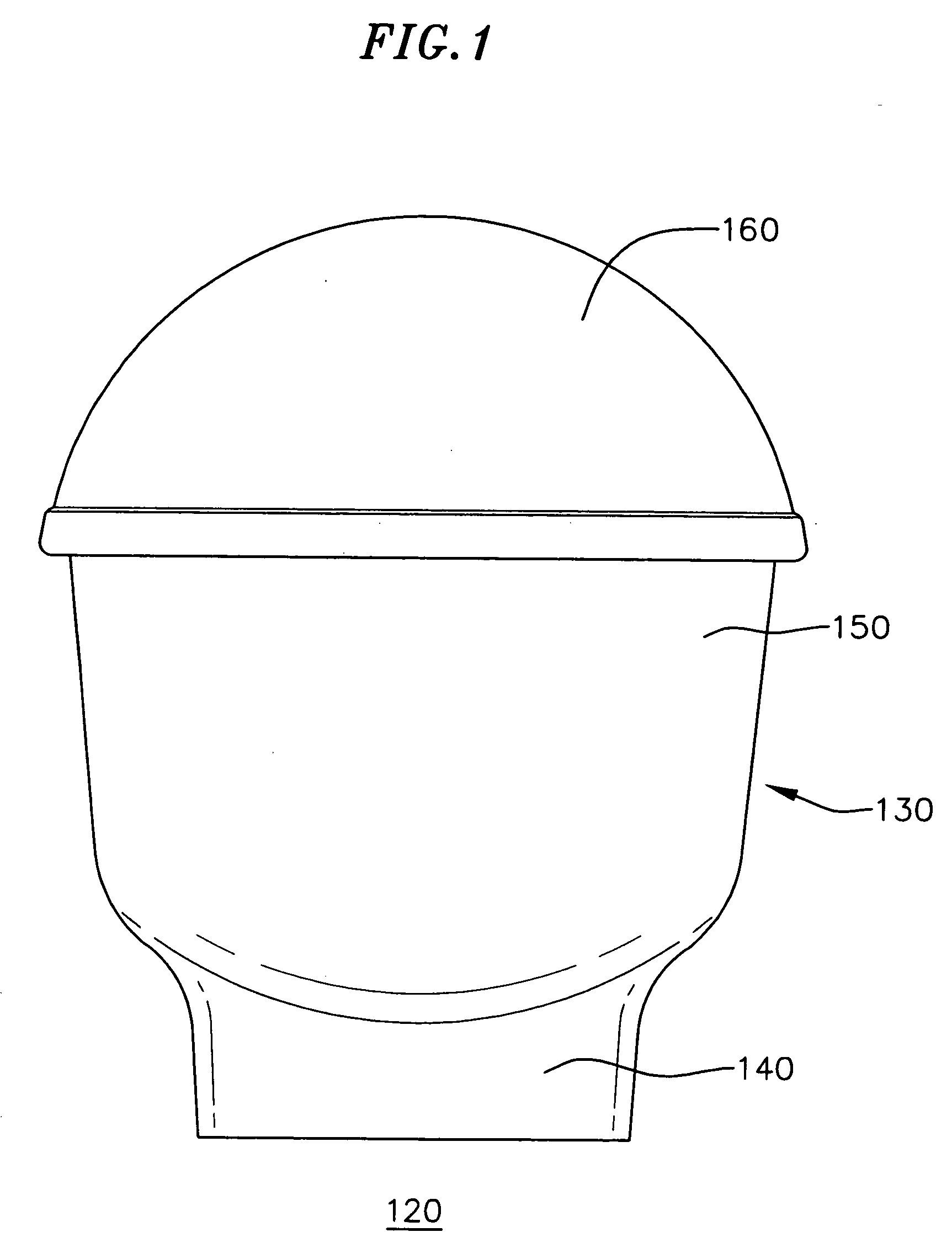

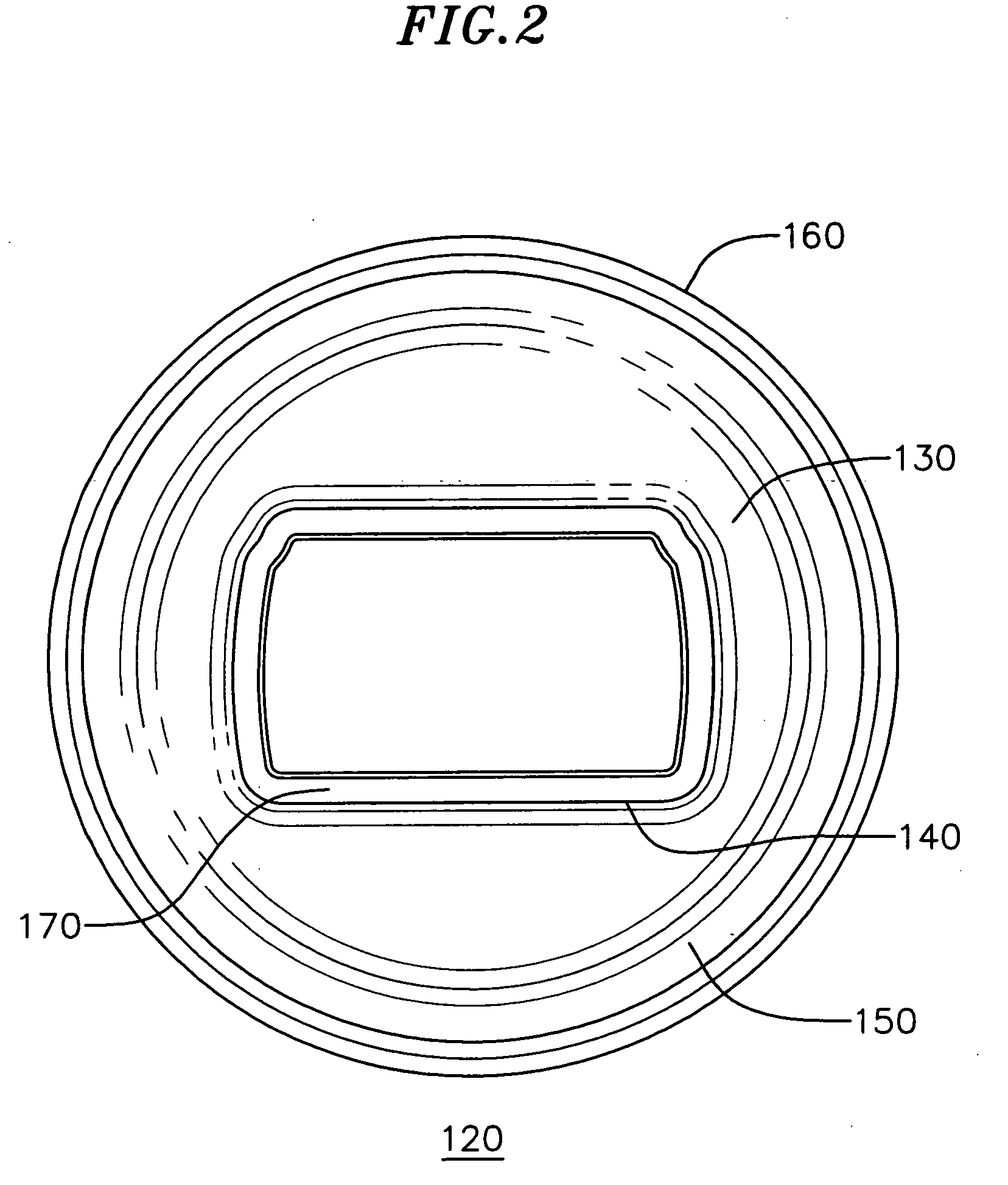

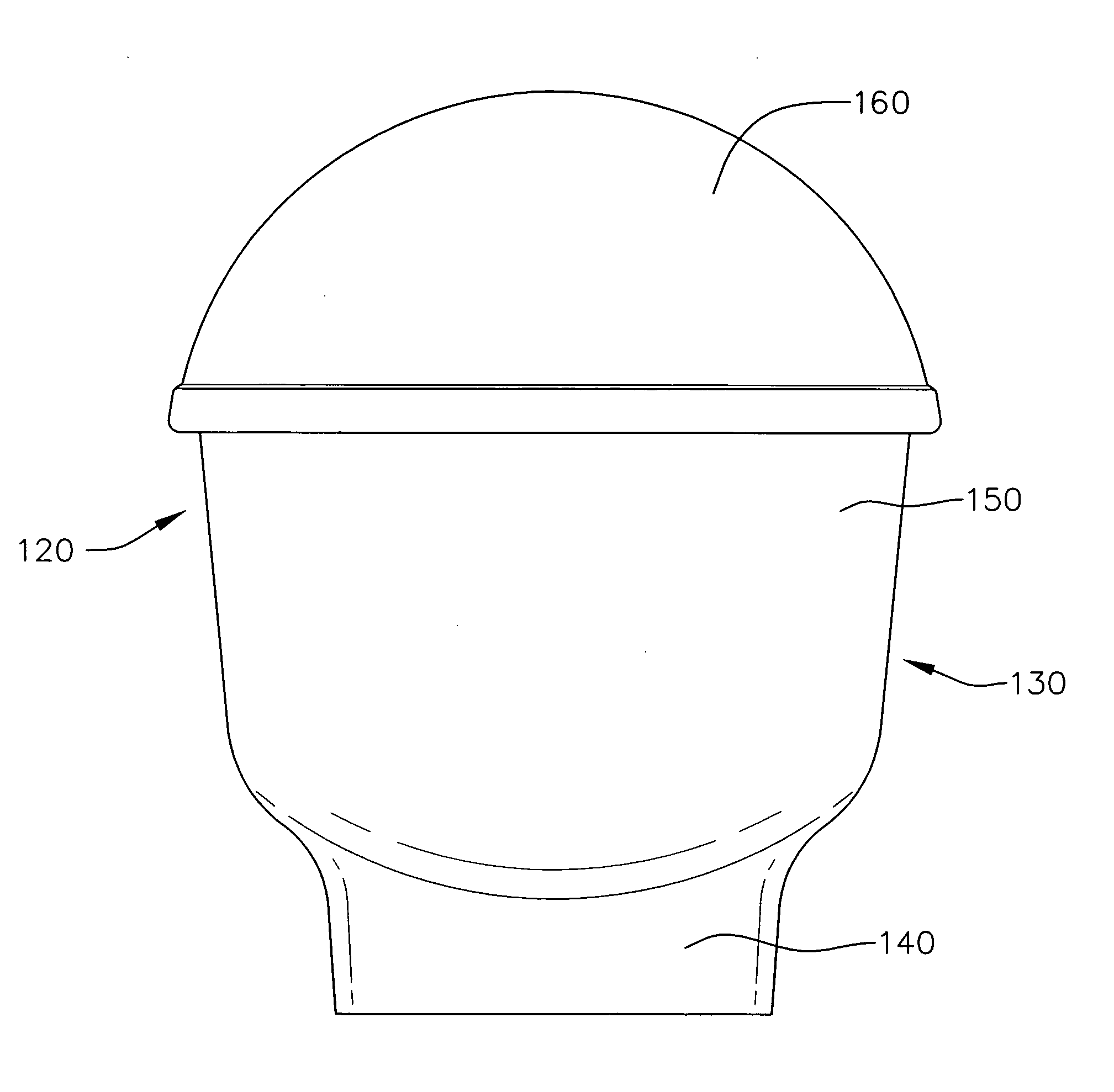

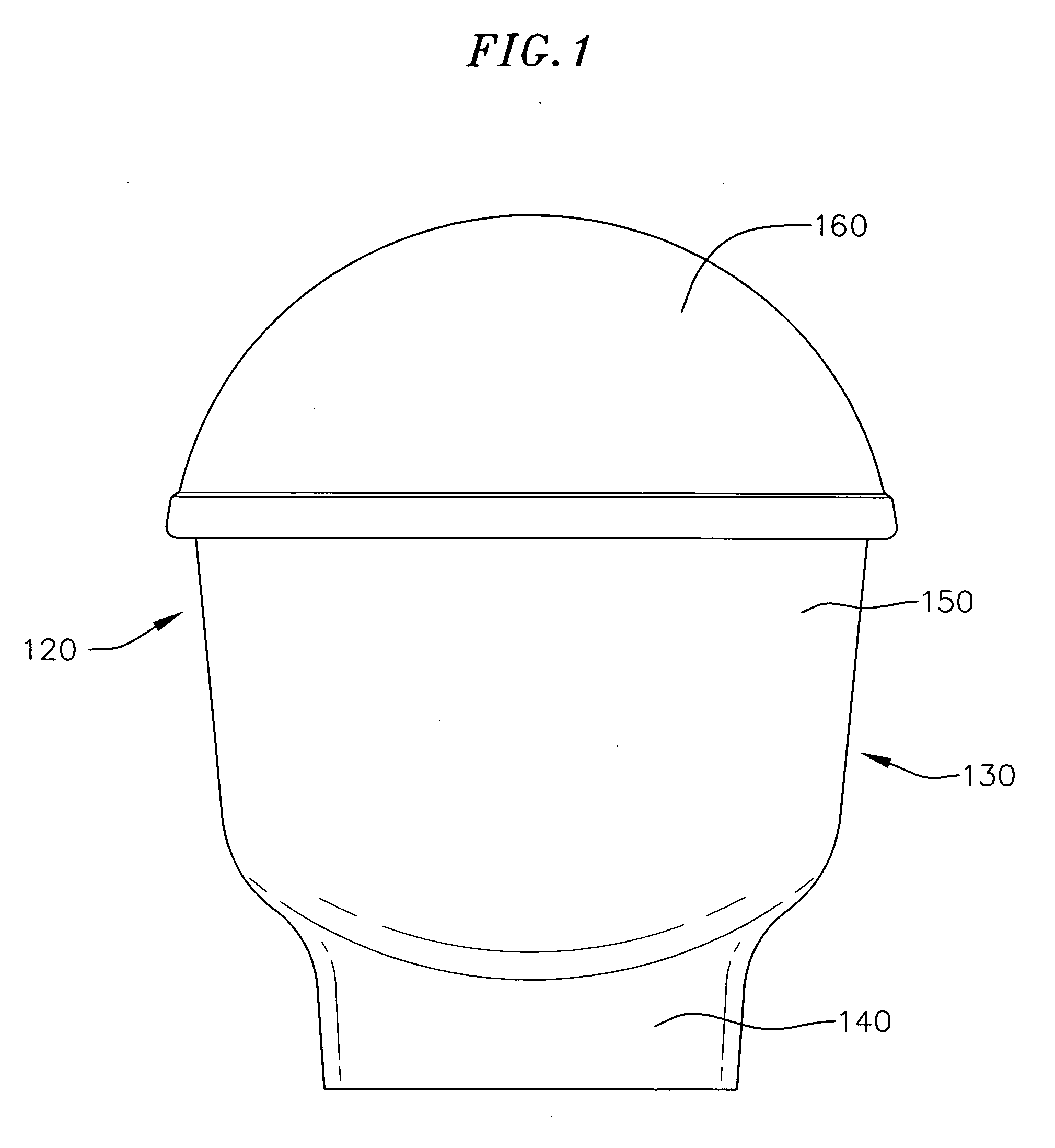

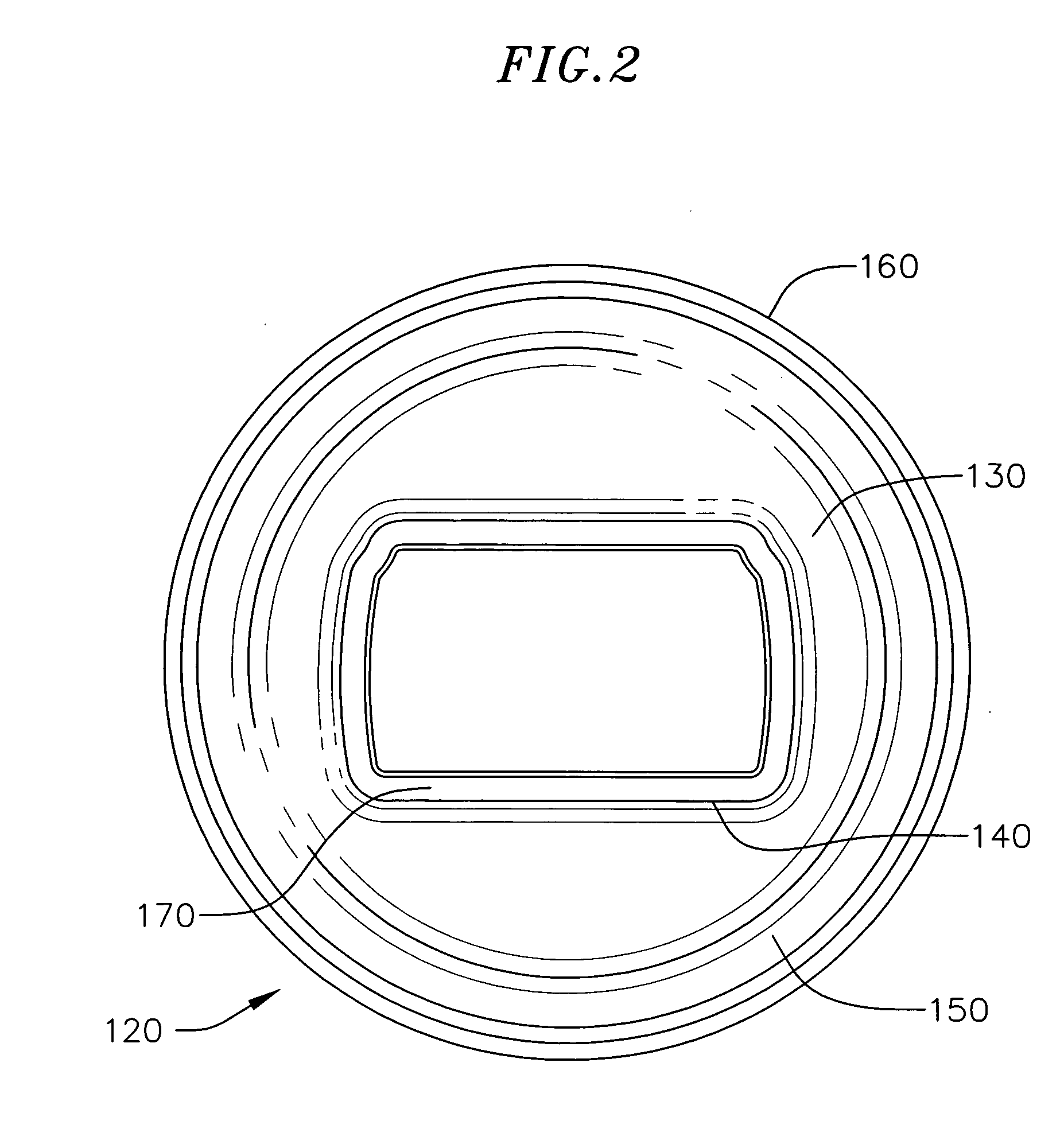

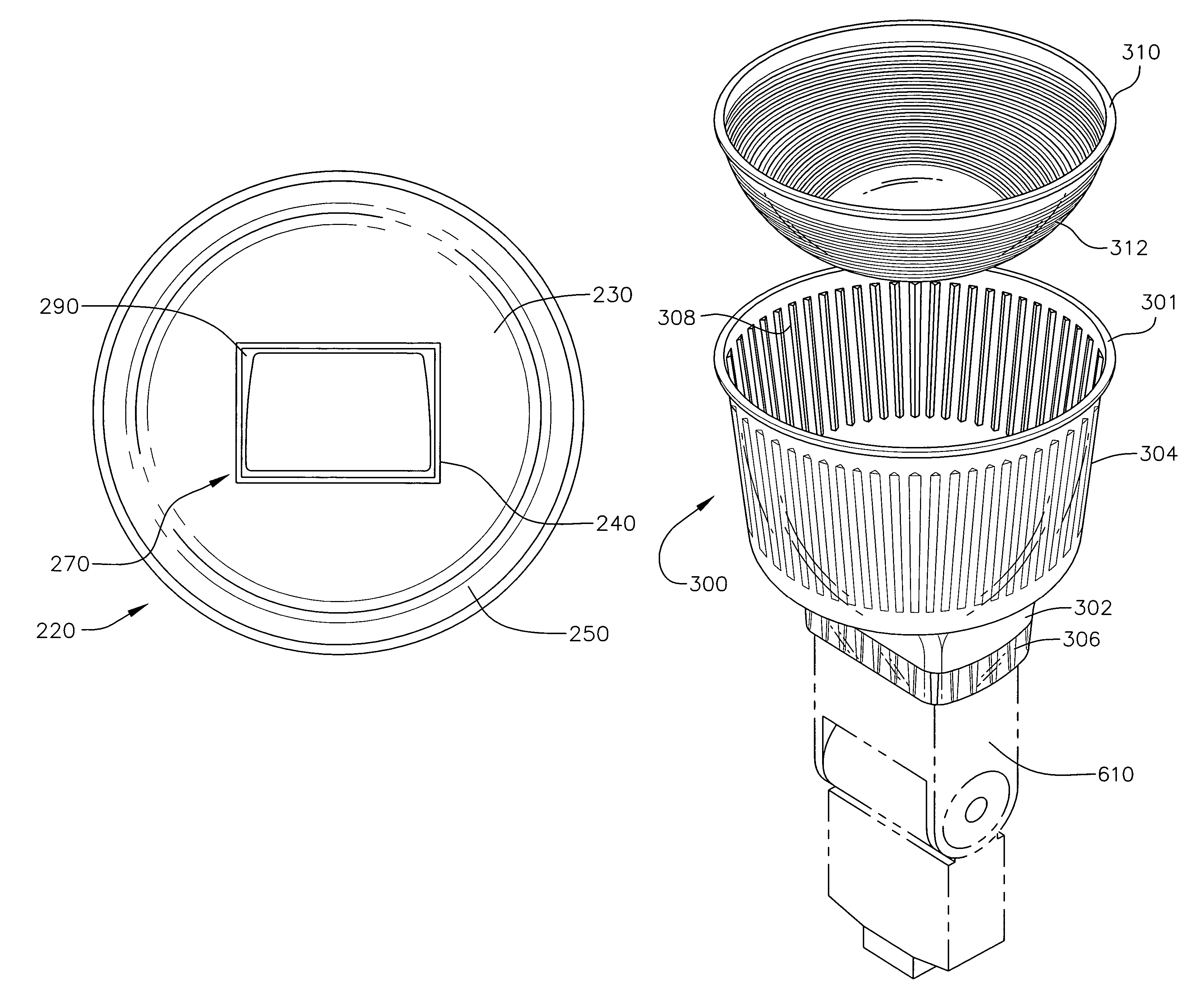

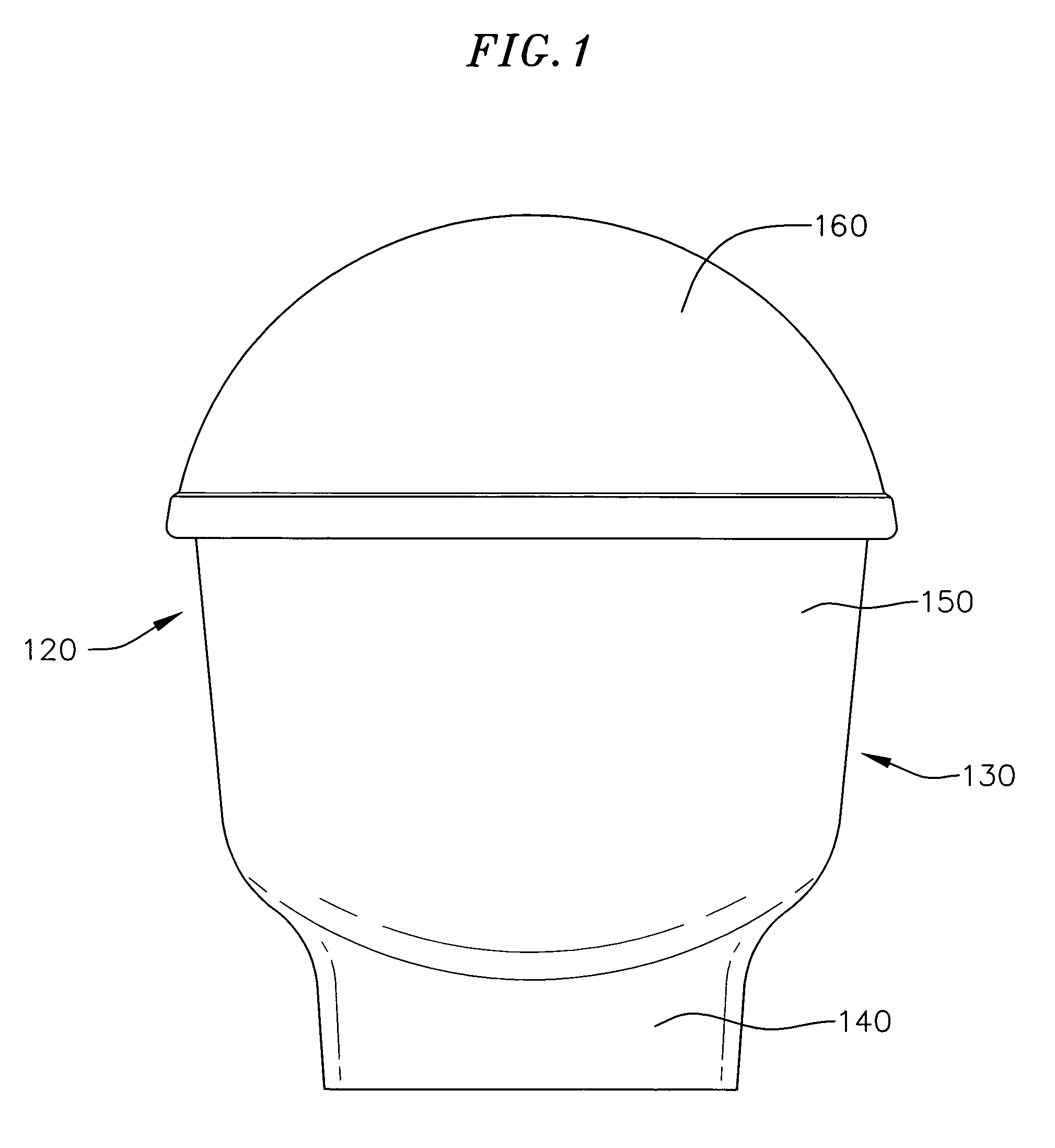

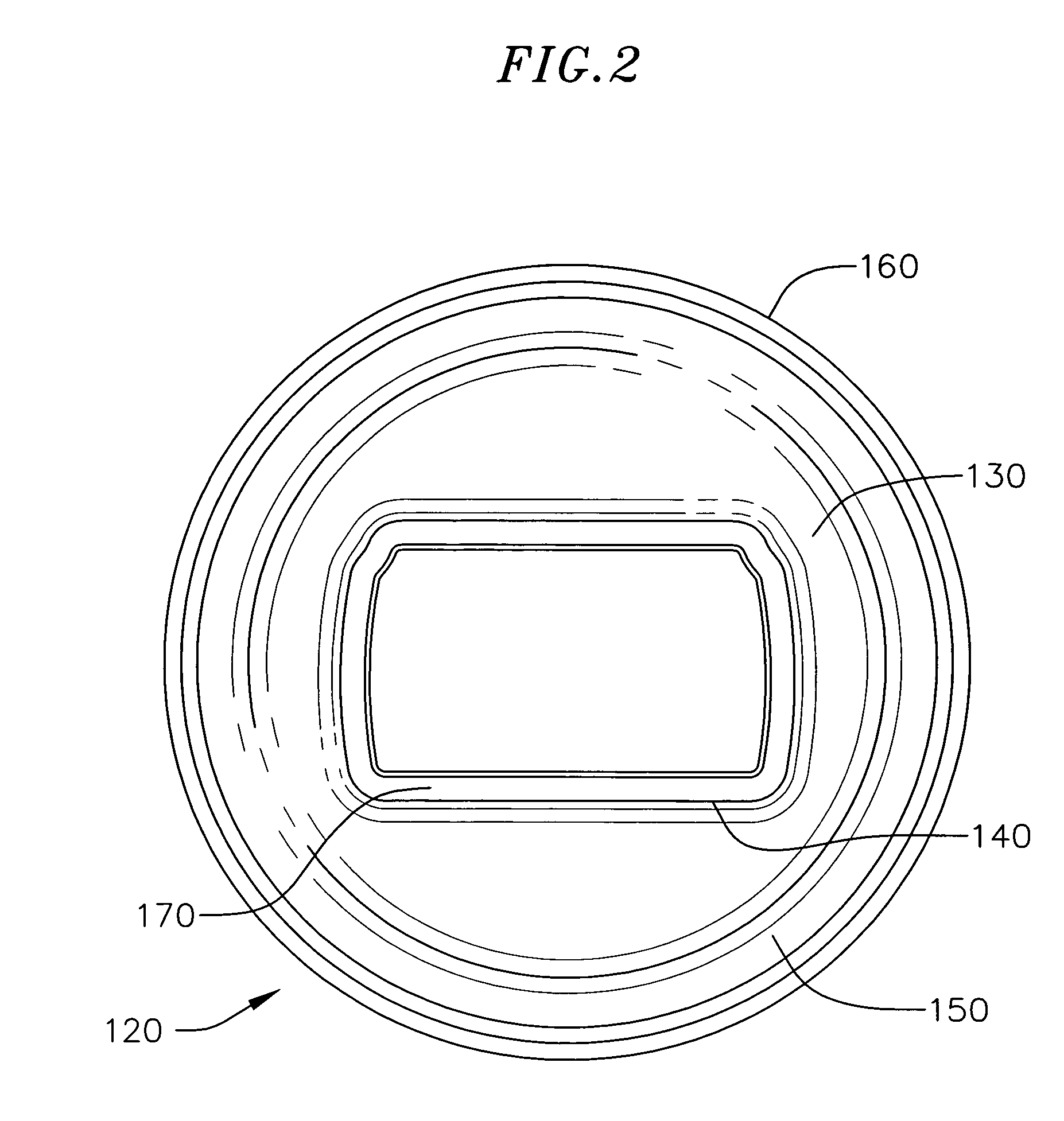

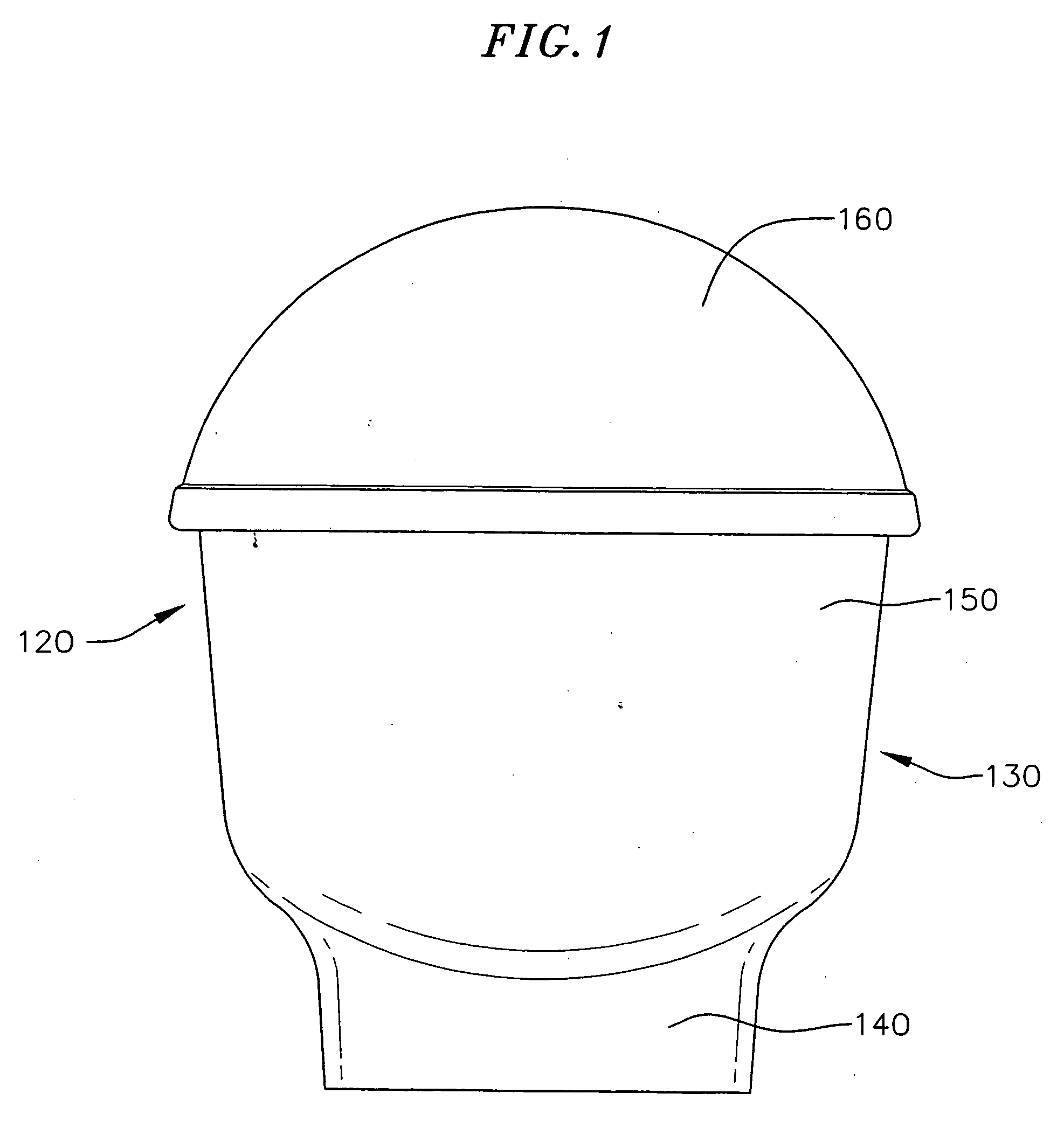

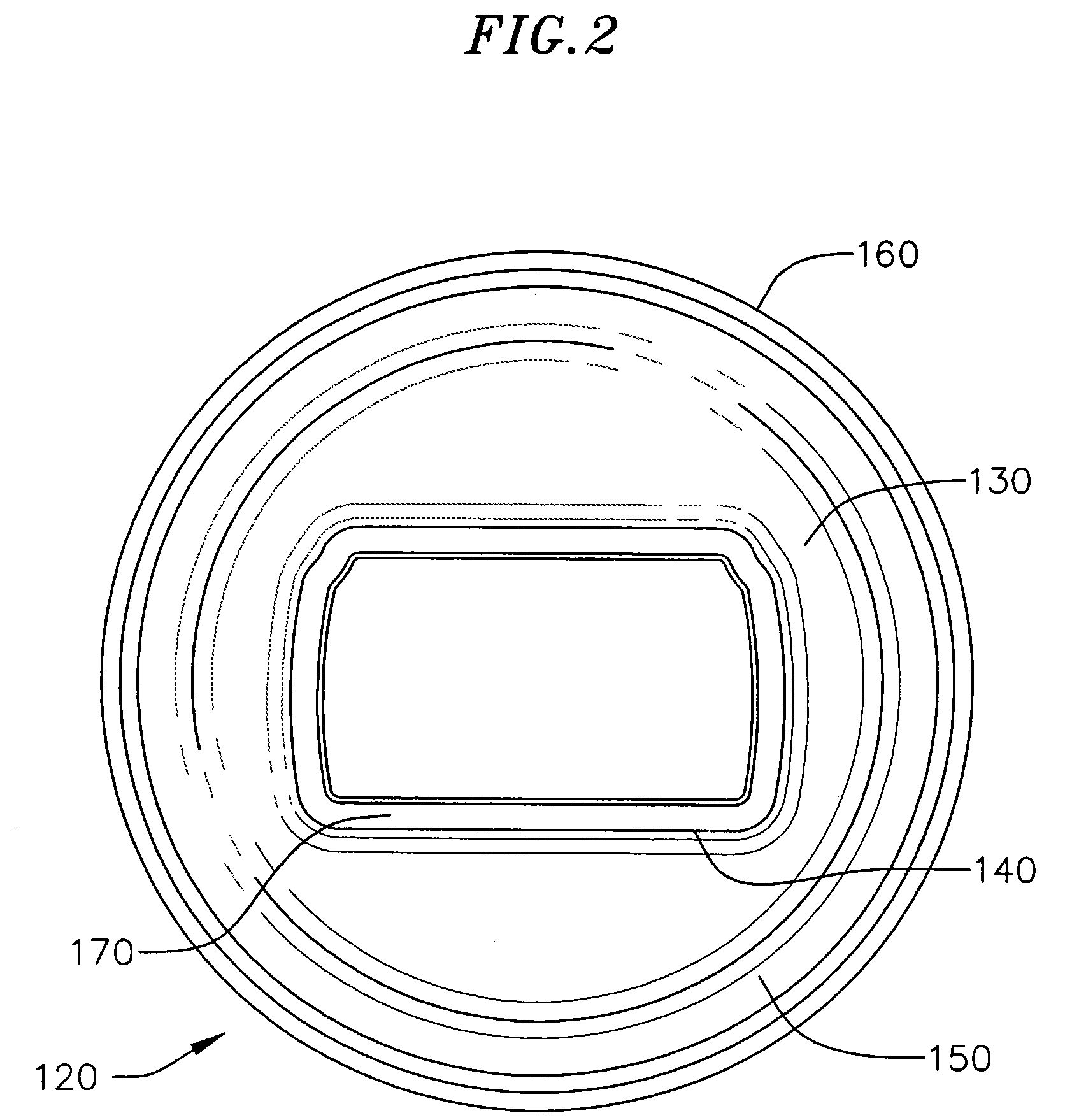

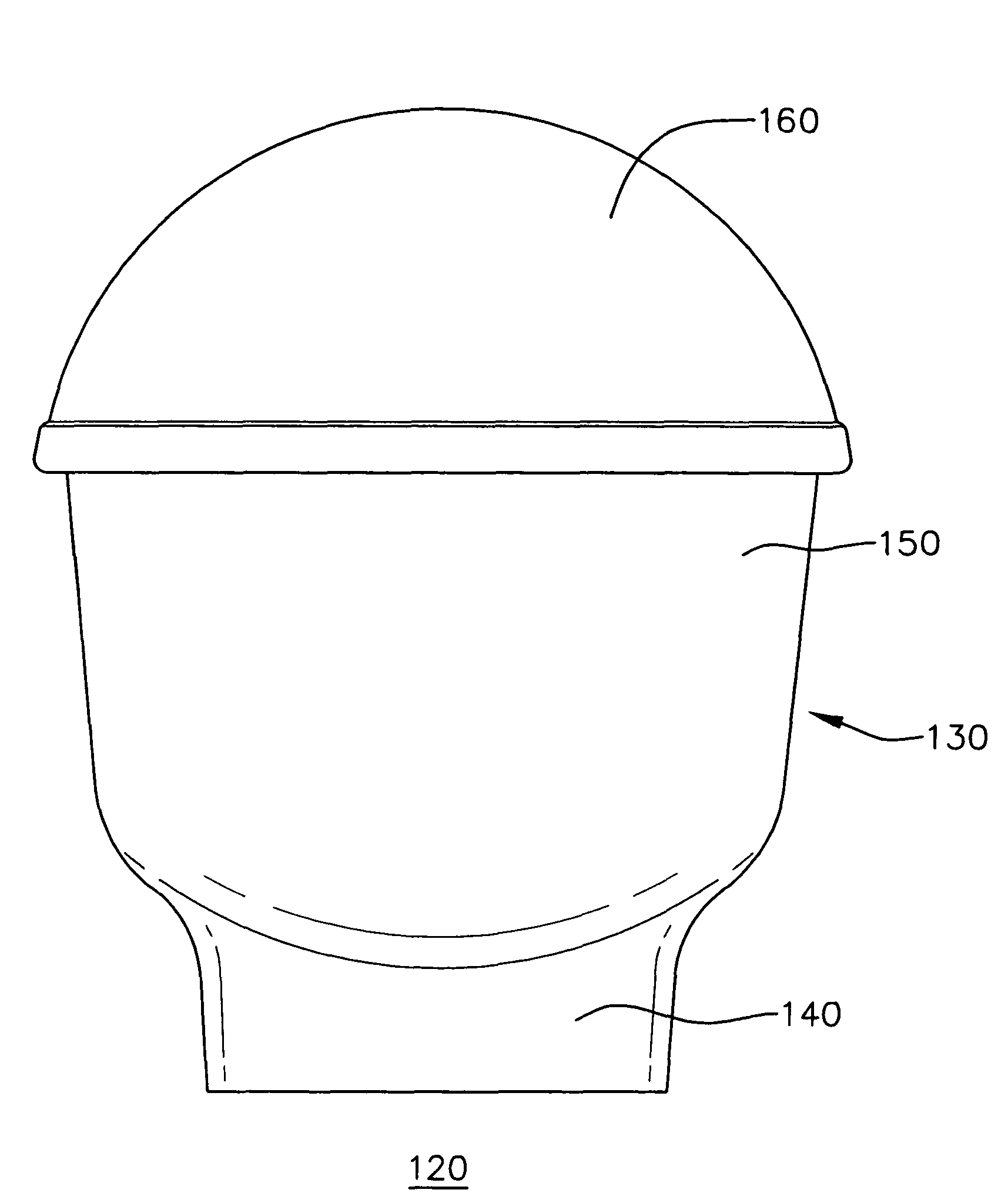

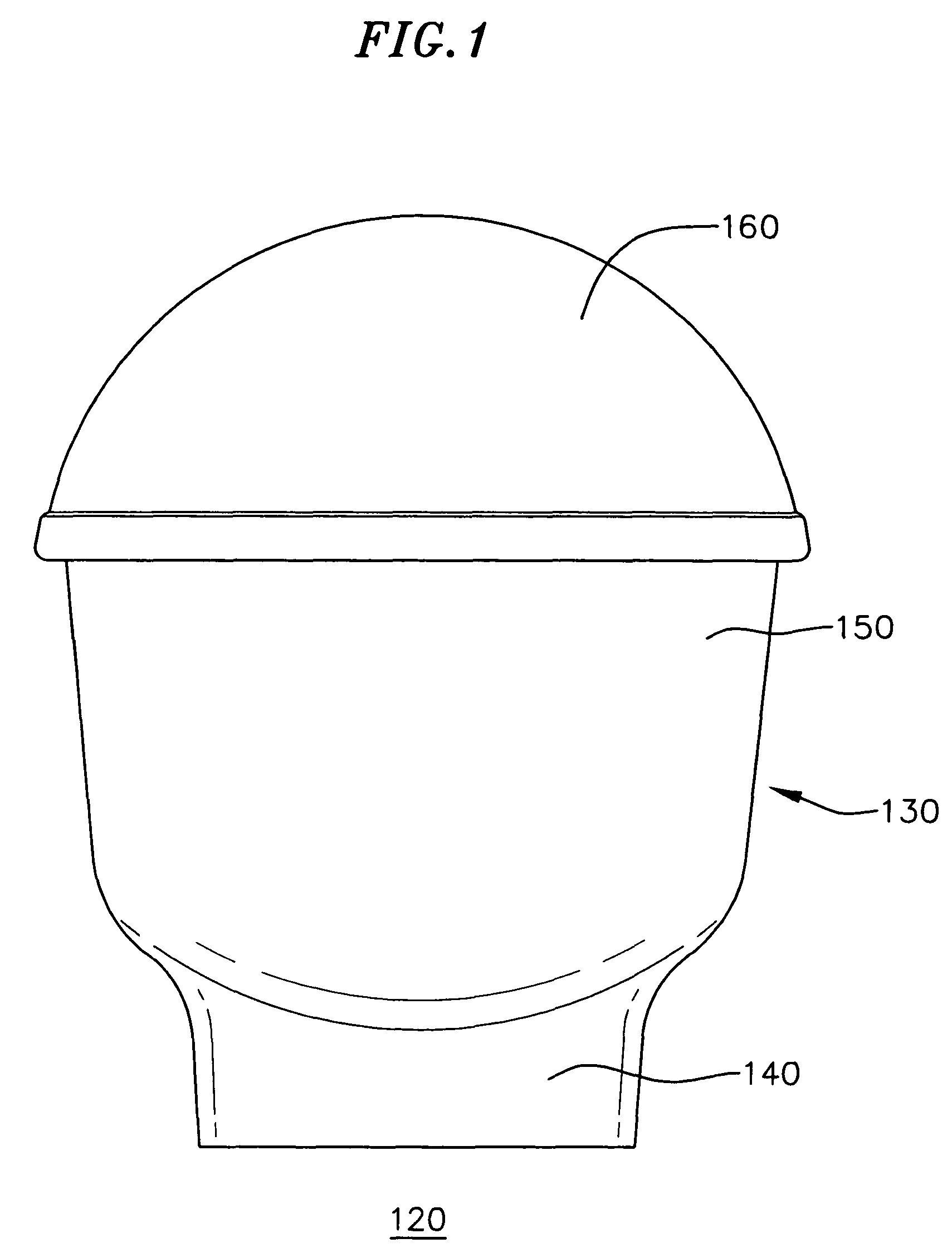

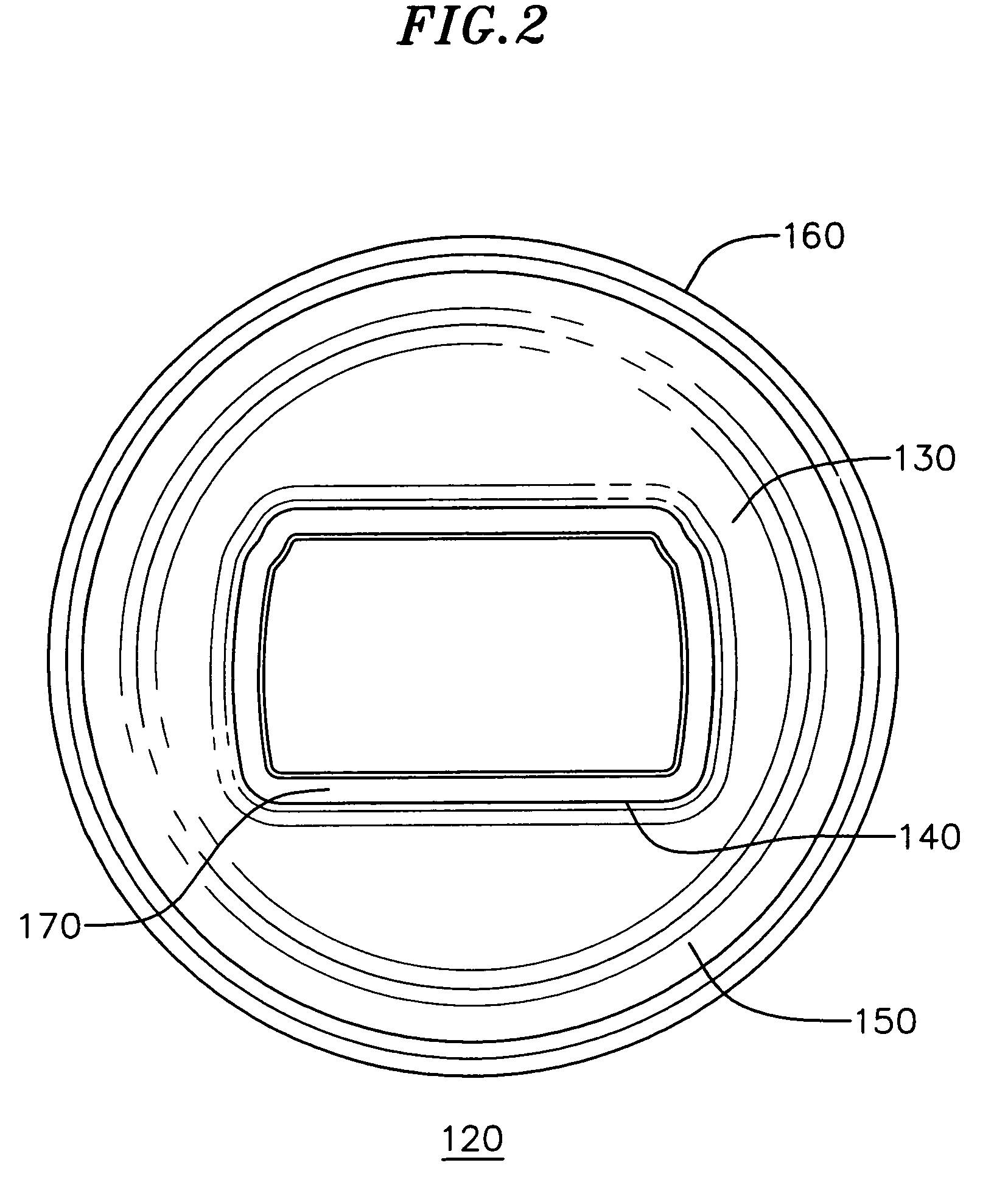

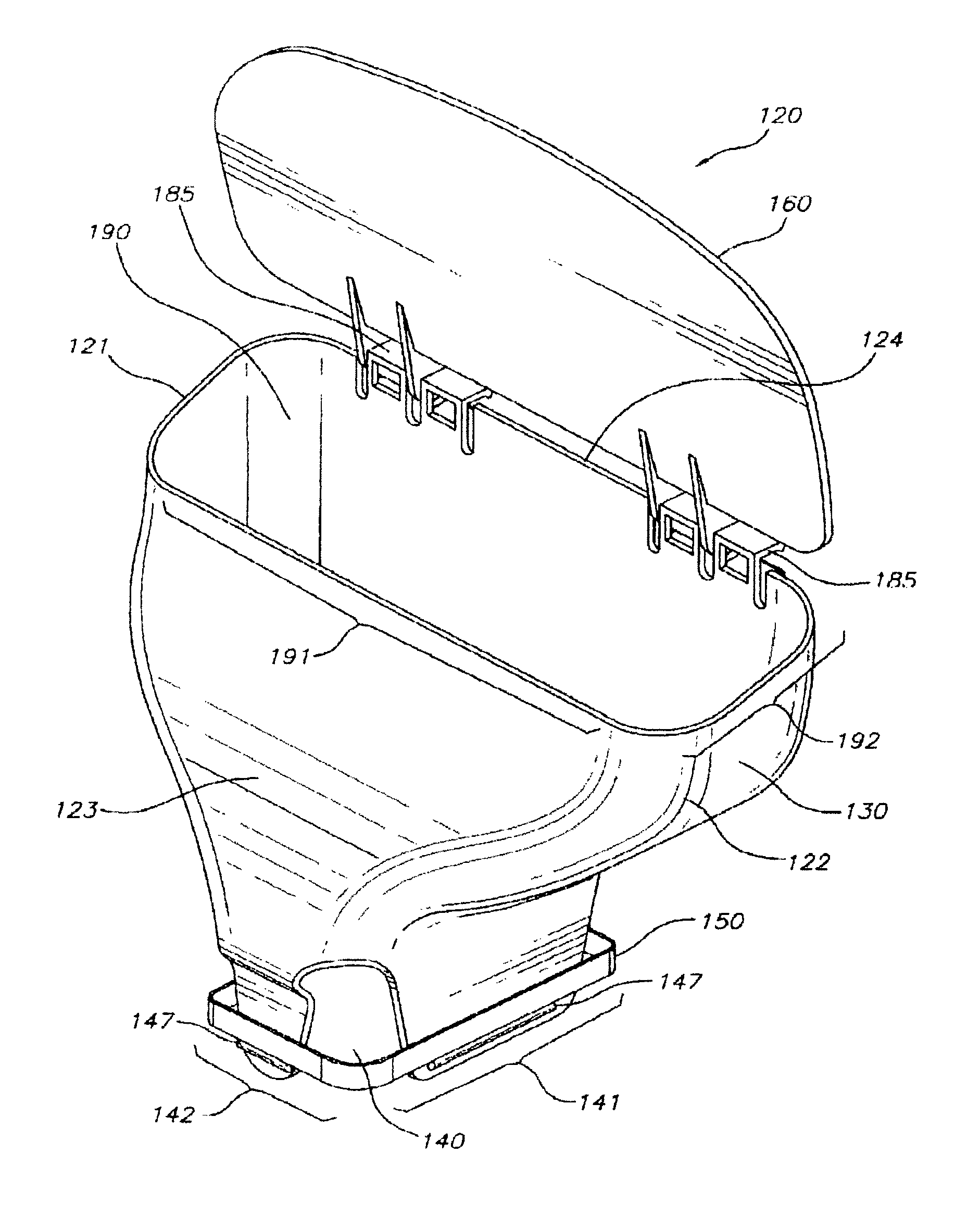

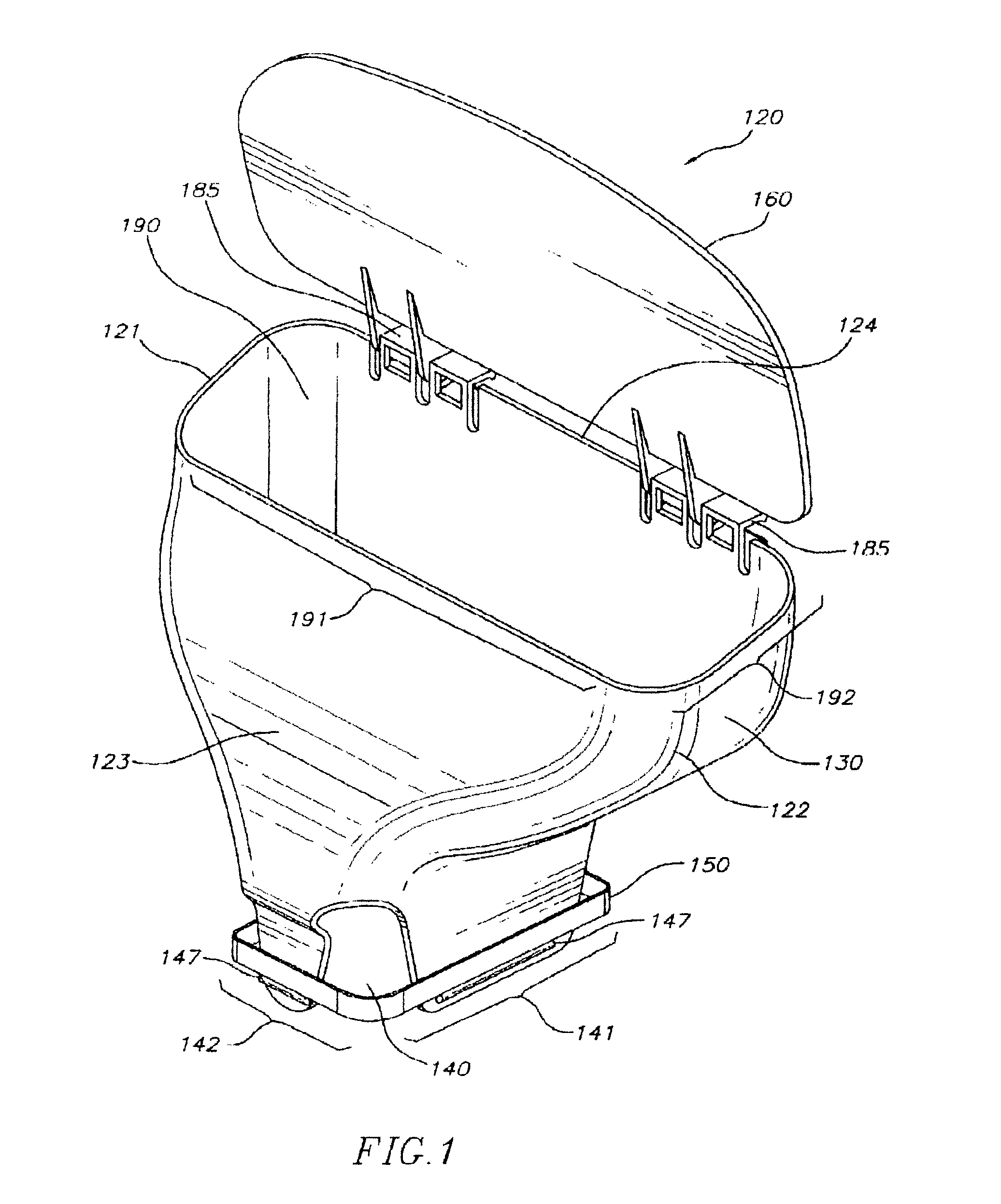

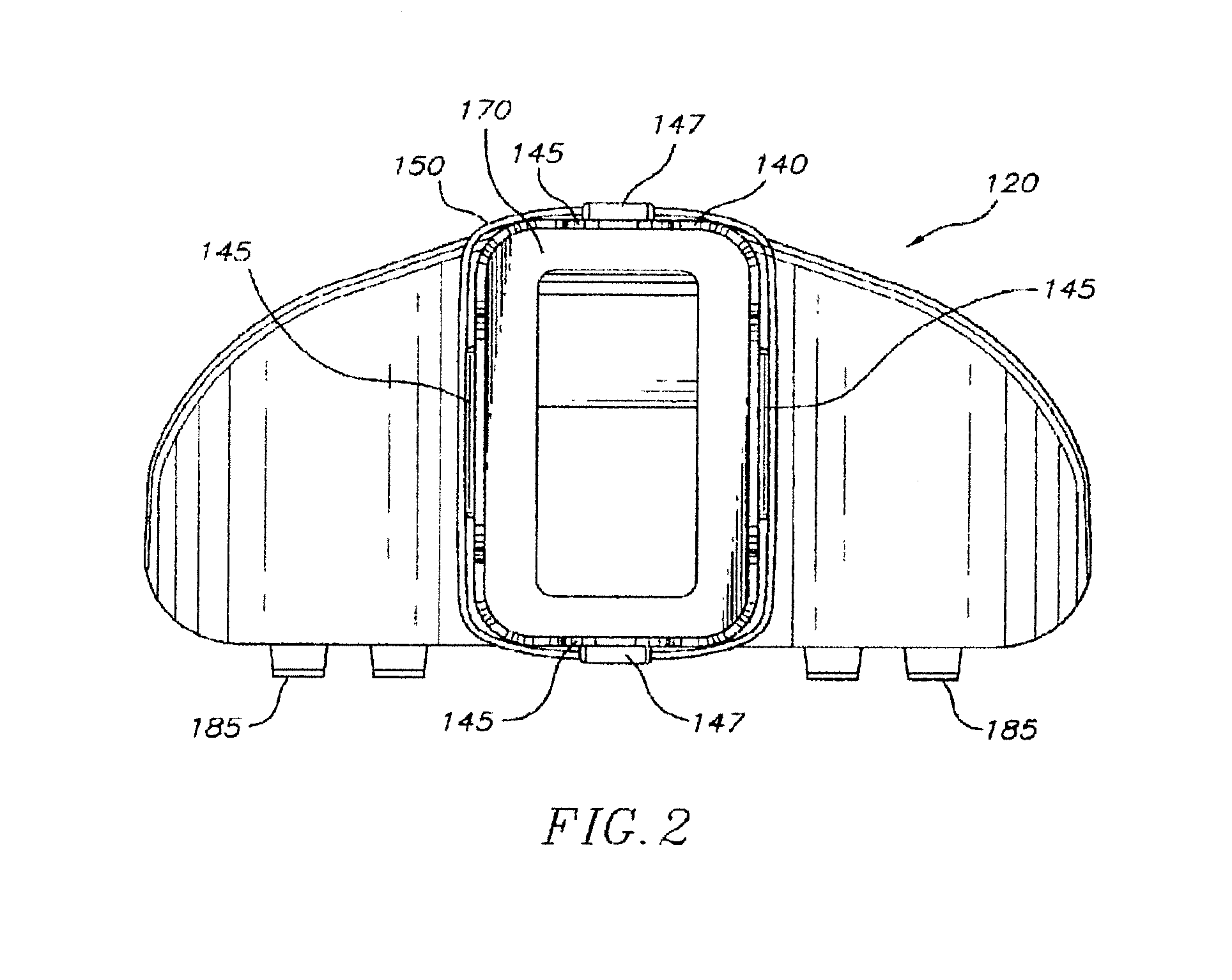

Photographic diffuser

InactiveUS20080204883A1Desirable light balanceGood dispersionDiffusing elementsLight fasteningsPhysicsLight source

A photographic light diffusing device is provided. A cowl is adapted to be mounted on a photographic light source, the cowl including an opening through which the photographic light source is visible when the cowl is mounted on the photographic light source. The cowl may also include at least one movable flap and a filter slot for a gel filter.

Owner:GARY FONG PHOTOGRAPHIC

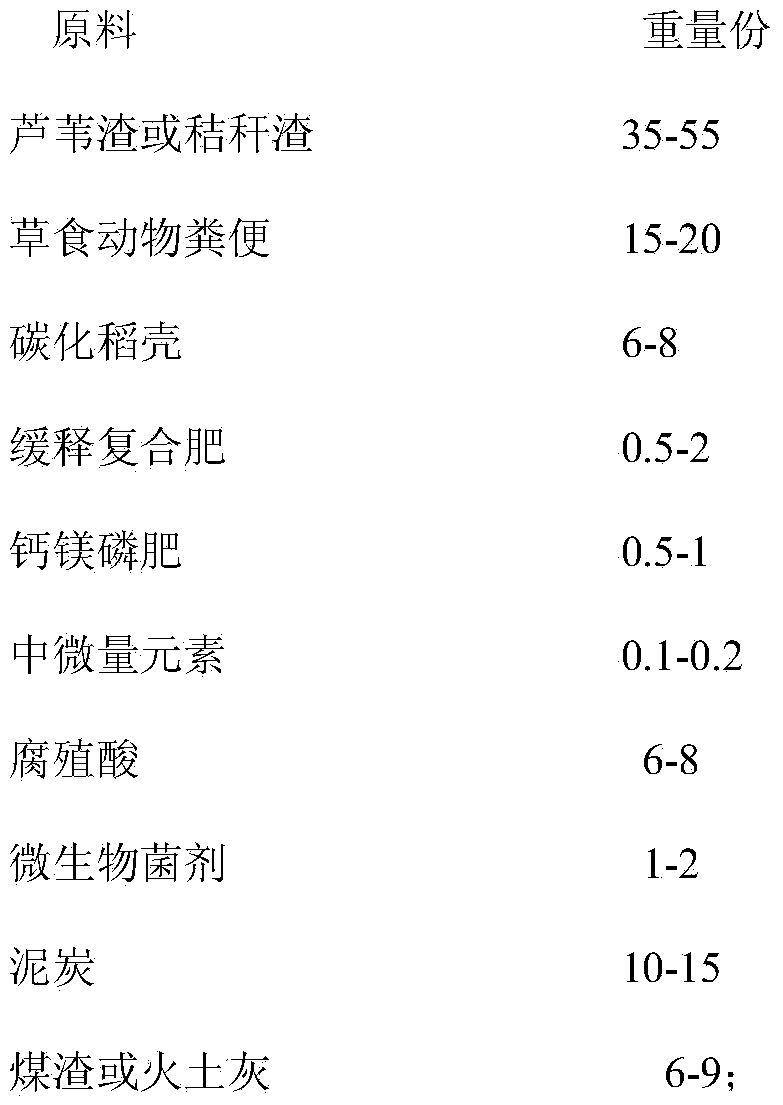

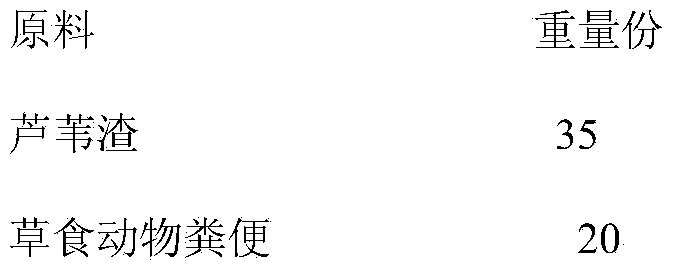

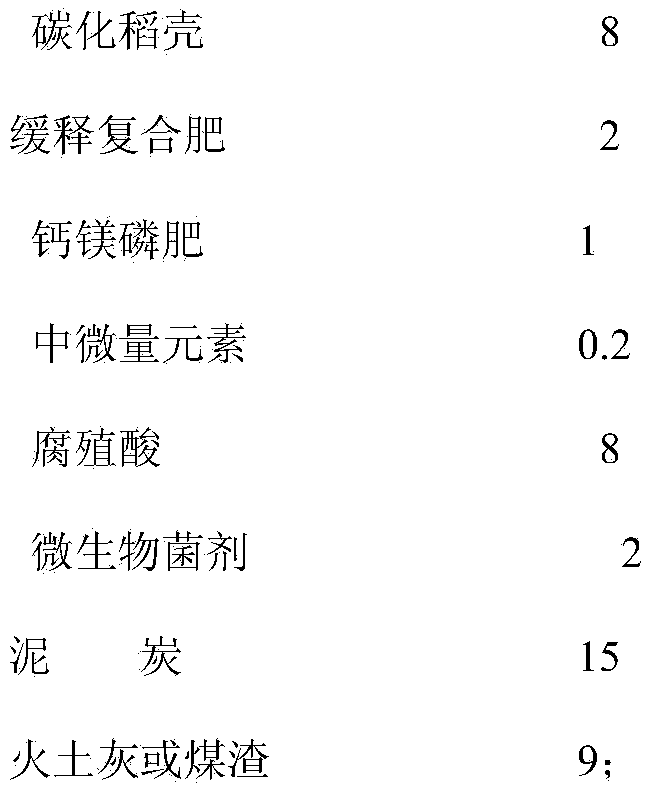

Vegetable and fruit biological activity seedling culture matrix as well as preparation method and application thereof

ActiveCN103626586ASufficient quantityThe source is stable and controllableFertilizer mixturesRoot systemDisease

The invention discloses a vegetable and fruit biological activity seedling culture matrix as well as a preparation method and application of the vegetable and fruit biological activity seedling culture matrix. The vegetable and fruit biological activity seedling culture matrix is prepared by adding auxiliary ingredients such as excrements of plant-eating animals, soil ash or coal slag, peat, a slow-release fertilizer, a calcium-magnesium phosphate fertilizer, medium trace elements and a microbial agent into papermaking wastewater serving as a main ingredient. The matrix is soft, loose, ventilating, water-saving and drought-resisting. The matrix for culturing vegetable and fruit seedlings can achieve the effects of high seedling emerge speed, short seedling age, seedling strengthening, quality improvement, root activity enhancement, disease resistance and improvement on seedling emerge rate and seedling rate; furthermore, the vegetable and fruit biological activity seedling culture matrix is convenient to transplant; the slow seedling period is short; stable yield and high yield of vegetables and fruits are guaranteed.

Owner:长沙浩博生物技术有限公司

Updating ray traced acceleration data structures between frames based on changing perspective

InactiveUS8350846B2Reduce the amount of processingReduce visual acuityImage data processing detailsSpecial data processing applicationsFrame basedGlobal illumination

A method, program product and system for conducting a ray tracing operation where the rendering compute requirement is reduced or otherwise adjusted in response to a changing vantage point. Aspects may update or reuse an acceleration data structure between frames in response to the changing vantage point. Tree and image construction quality may be adjusted in response to rapid changes in the camera perspective. Alternatively or additionally, tree building cycles may be skipped. All or some of the tree structure may be built in intervals, e.g., after a preset number of frames. More geometric image data may be added per leaf node in the tree in response to an increase in the rate of change. The quality of the rendering algorithm may additionally be reduced. A ray tracing algorithm may decrease the depth of recursion, and generate fewer cast and secondary rays. The ray tracer may further reduce the quality of soft shadows, resolution and global illumination samples, among other quality parameters. Alternatively, tree rebuilding may be skipped entirely in response to a high camera rate of change. Associated processes may create blur between frames to simulate motion blur.

Owner:INT BUSINESS MASCH CORP

Photographic light diffuser

ActiveUS20060109640A1Desirable light balanceEasy to shootSpectral modifiersPhotographyEngineeringFlash light

A photographic light diffusing device comprises a semi-transparent cowl which is adapted to be mounted on a photographic light source, the cowl including an opening through which the photographic light source is visible when the cowl is mounted thereon, and a removable semi-transparent cover detachably mounted on the cowl. In another embodiment, a camera flash system comprises a camera flash unit, and a diffuser unit having an adaptor and a tapered cylindrical body. The adaptor is formed to match the shape of the housing of the camera flash unit so that it may be fitted thereto, and the adaptor extends between the camera flash unit and the tapered cylindrical body of the diffuser unit. The diffuser unit widens from the adaptor to meet the tapered cylindrical body.

Owner:GARY FONG PHOTOGRAPHIC

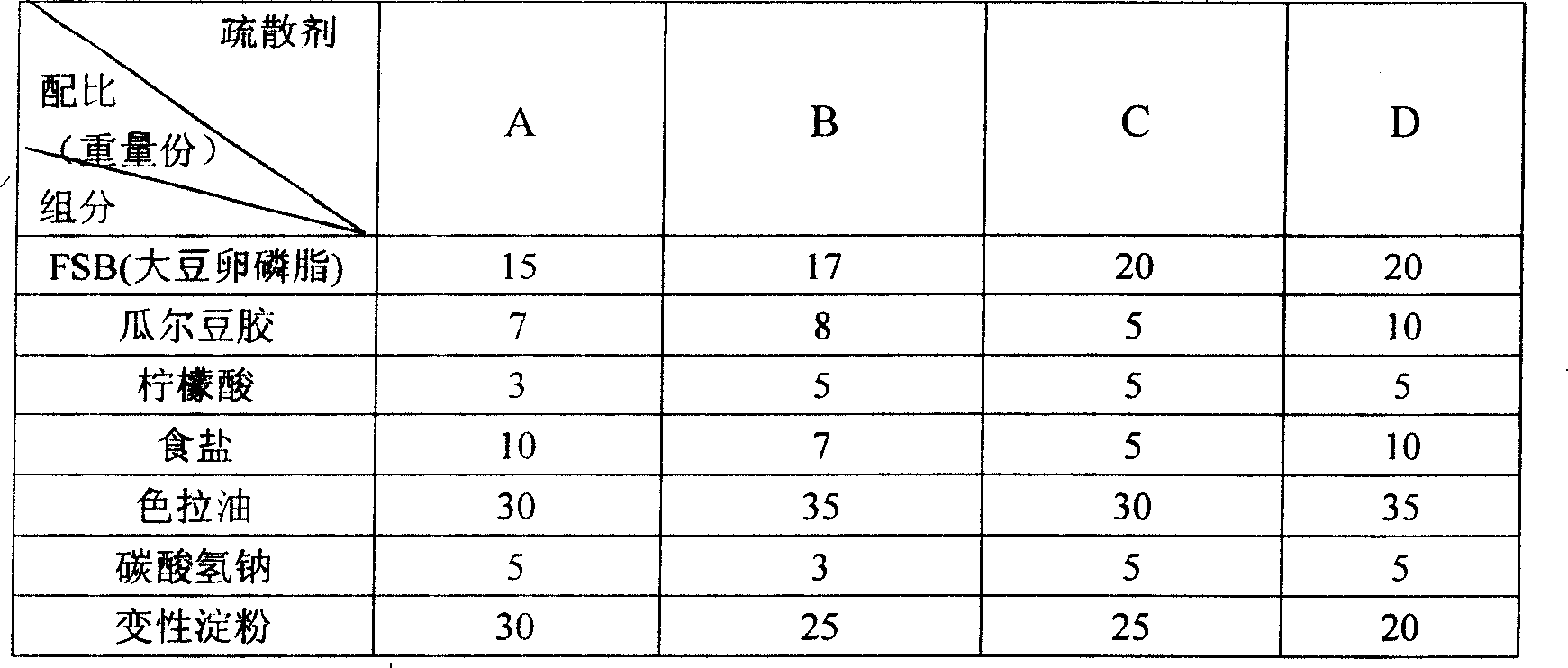

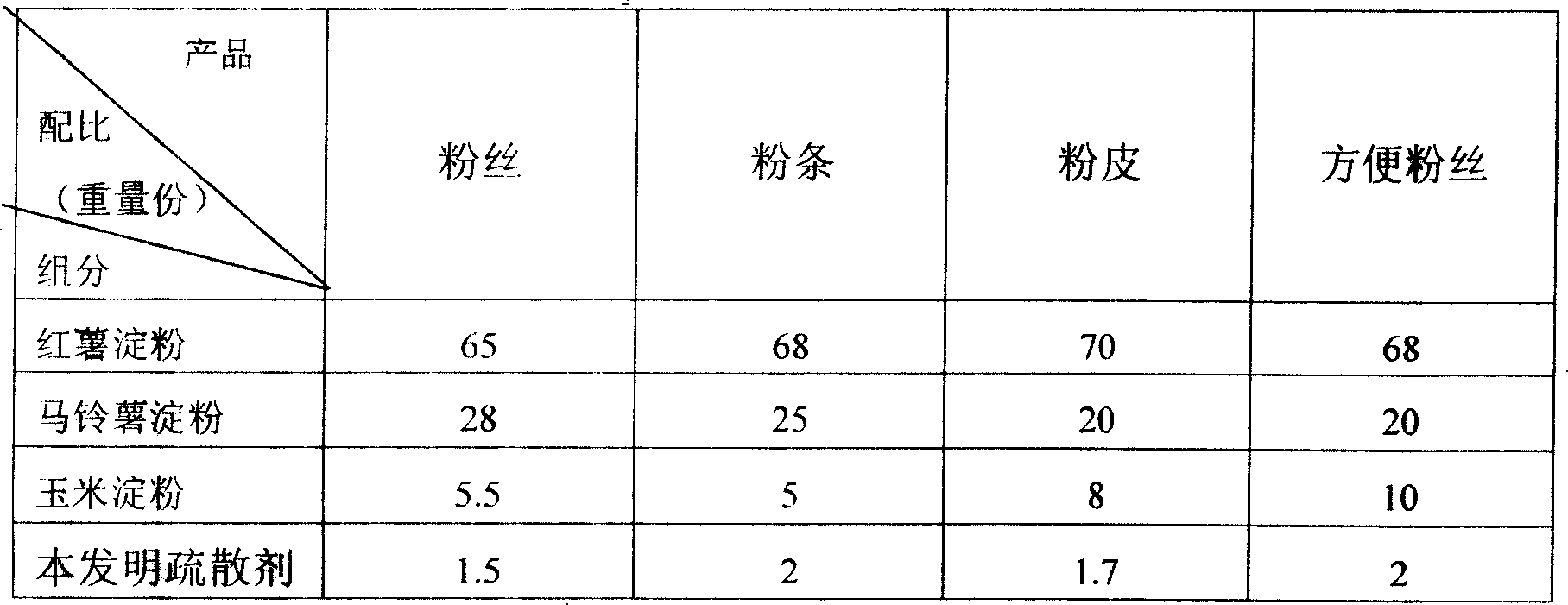

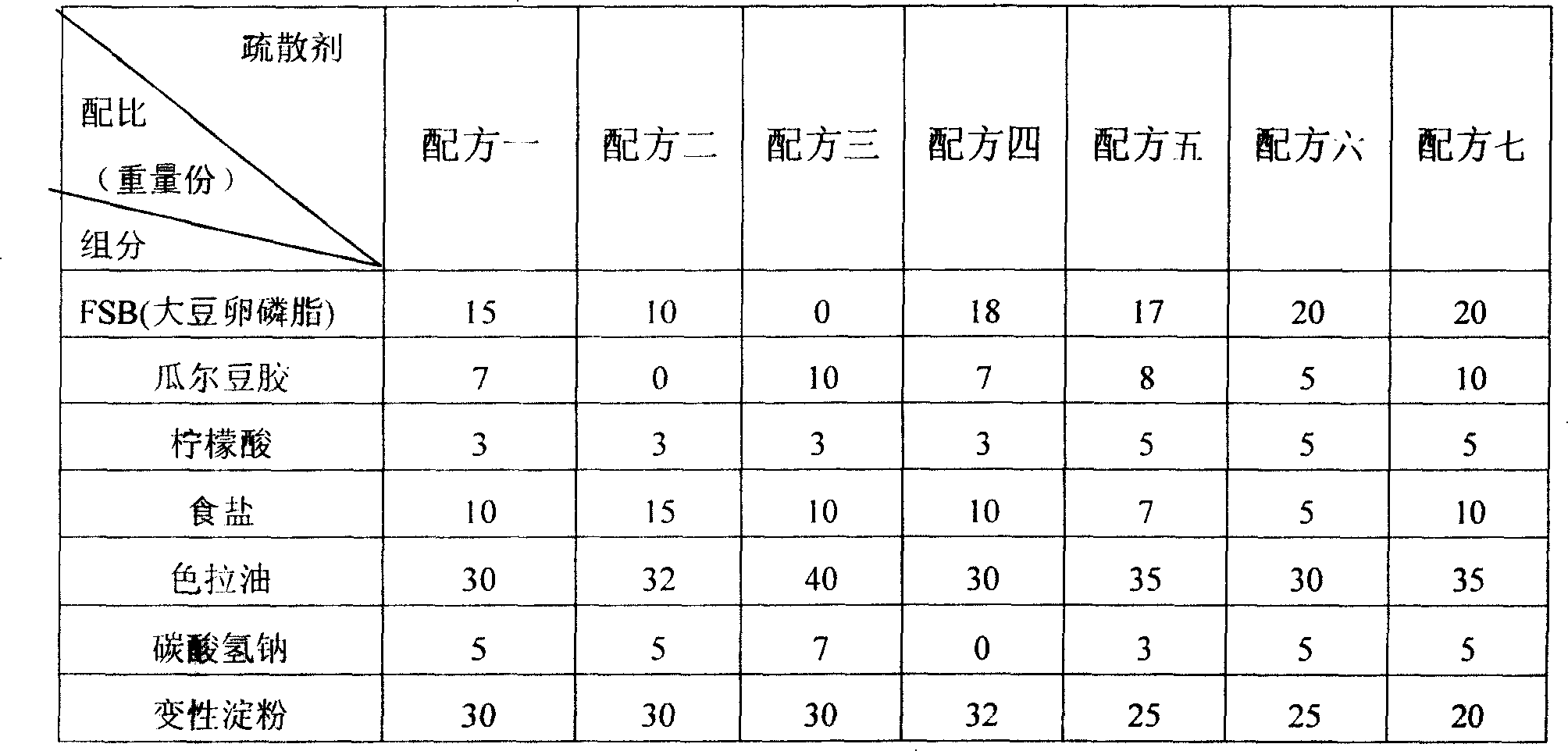

Evacuating agent of vermicelli foodstuff and the vermicelli foodstuff thereof

ActiveCN101081065AEvenly distributedDraw downFood preservationFood preparationSodium bicarbonateAdditive ingredient

The present invention belongs to the field of food producing technology, and is especially one kind of dispersant for vermicelli. The dispersant for vermicelli consists mainly of soybean lecithin 15-25 weight portions, salad oil 20-40 weight portions, sodium bicarbonate 3-8 weight portions, guar gum 5-15 weight portions, citric acid 3-8 weight portions, table salt 5-15 weight portions, and modified starch 15-30 weight portions. The present invention also provides corresponding vermicelli, which consists of the dispersant 1.5-2 weight portions and plant starch 80-120 weight portions. Experiment shows that the dispersant for vermicelli has no harmful matter contained and effect similar to traditional dispersant. The vermicelli with the dispersant is one kind of health food possessing high safety, good look, good taste, physical, chemical and hygienic indexes meeting relevant requirements, balanced and rich nutrients and high marketability.

Owner:四川白家阿宽食品产业股份有限公司

Super white ceramic tile

The invention relates to ultrawhite ceramic tiles wherein the blanks of the tiles are prepared from the following raw materials (by weight portions): clay 25-65 parts, stone fluxing agent 5-20 parts, soil fluxing agent 30-60 parts, siliceous sand 0-15 parts. Compared with the prior arts, The invention has the advantages of higher whiteness, low cost, better mechanical property and environmental protection.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Photographic light diffuser

ActiveUS20060109641A1Easy to shootGood dispersionLighting support devicesLight fasteningsEngineeringCowling

A photographic light diffusing device is provided. A flexible, transparent cowl is adapted to be mounted on a photographic light source, the cowl including a plurality of ribs and an opening through which the photographic light source is visible when the cowl is mounted on the photographic light source. The cowl elastically deforms to fit onto the photographic light source. A removable, flexible cover is placed over the opening of the cowl.

Owner:GARY FONG PHOTOGRAPHIC

Photographic light diffuser

ActiveUS7380966B2Easy to shootGood dispersionLighting support devicesLight fasteningsEngineeringLight source

Owner:GARY FONG PHOTOGRAPHIC

Process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans

ActiveCN103932077AEasy to operateReduce dependenceFood dryingFood preparationBiotechnologyNeutral protease

The invention discloses a process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans. The method comprises the following steps: removing impurities of fresh black beans; soaking; steaming at high pressure to ensure that proteins are denatured properly and cooling; inoculating aspergillus oryzae for enlarge cultivation and uniformly stirring for fermentation starter propagation; naturally cooling prepared cooked yeast, wherein protease activity is 800-1,200 unit / g dry basis (based on neutral protease); adding hot water and stirring; rapidly draining and adding small amount of salt or white spirit; uniformly stirring and compacting and putting into a sealing interlayer tank for heat-preservation fermentation so that fermented amino acid nitrogen is up to more than 0.55 percent; finally, dehydrating and drying by using continuous flow belt type drying equipment so that the water content of the product is less than 15 percent, the amino acid nitrogen is more than 0.85 percent, and the bacterial quantity is less than 103 cfu / g. The quality of the product is stable, the key procedures of each process are controlled in an interlocking mode and have synergistic effects, and the process from material input to acquisition of finished product only needs 15-25 days. The method is short in process period and stable in quality, and a production method and a production process with high efficiency, standardization, large scale, continuity and feasibility are provided for safe and convenient low-salt or salt-free Liuyang salt black bean products.

Owner:HUNAN AGRICULTURAL UNIV

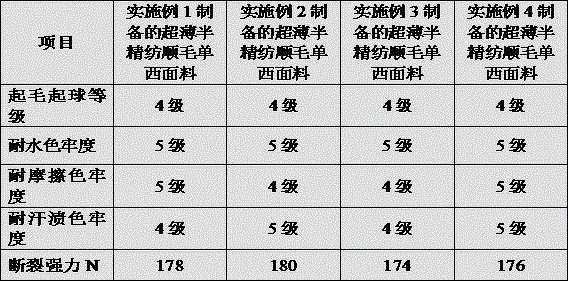

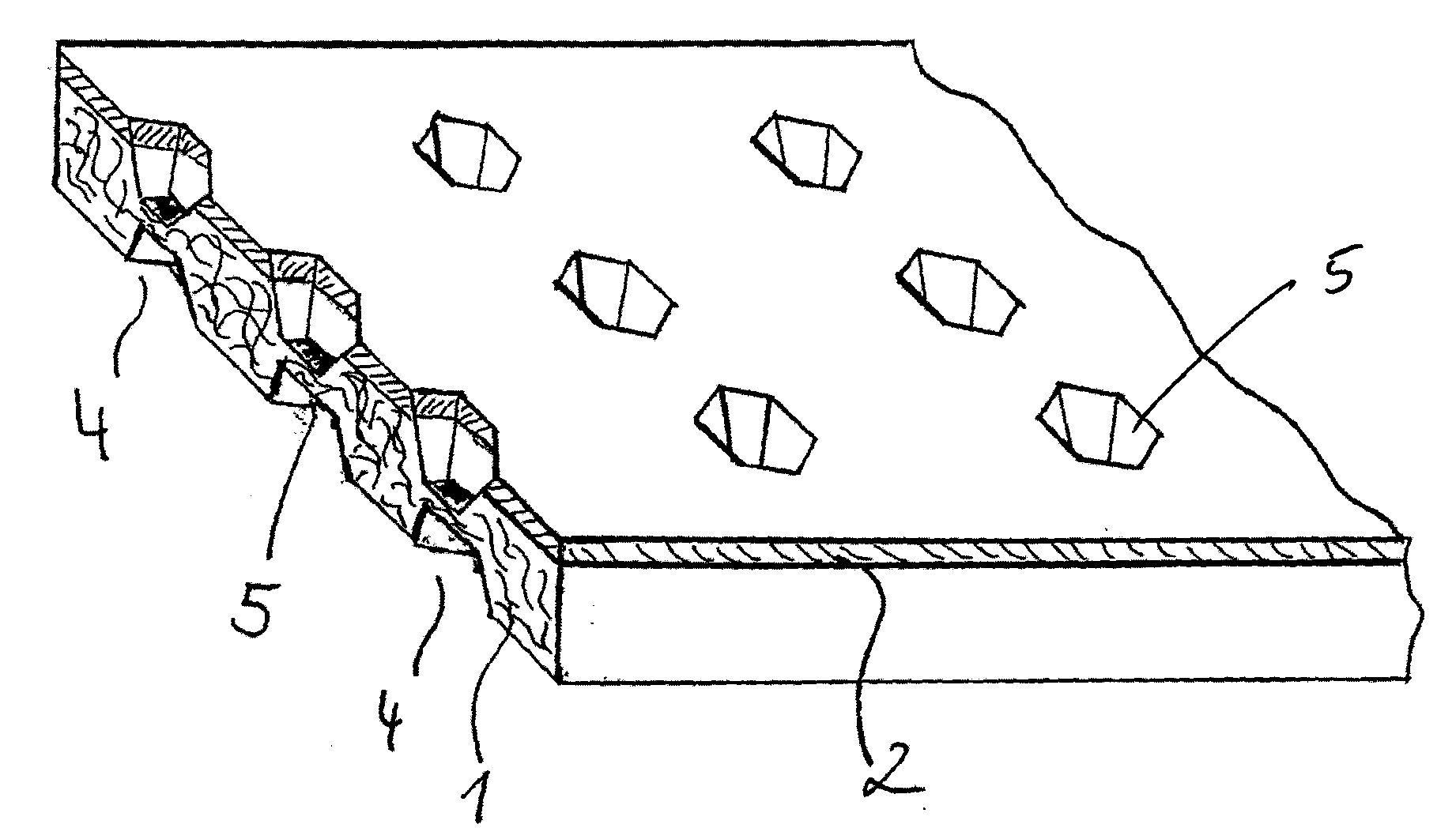

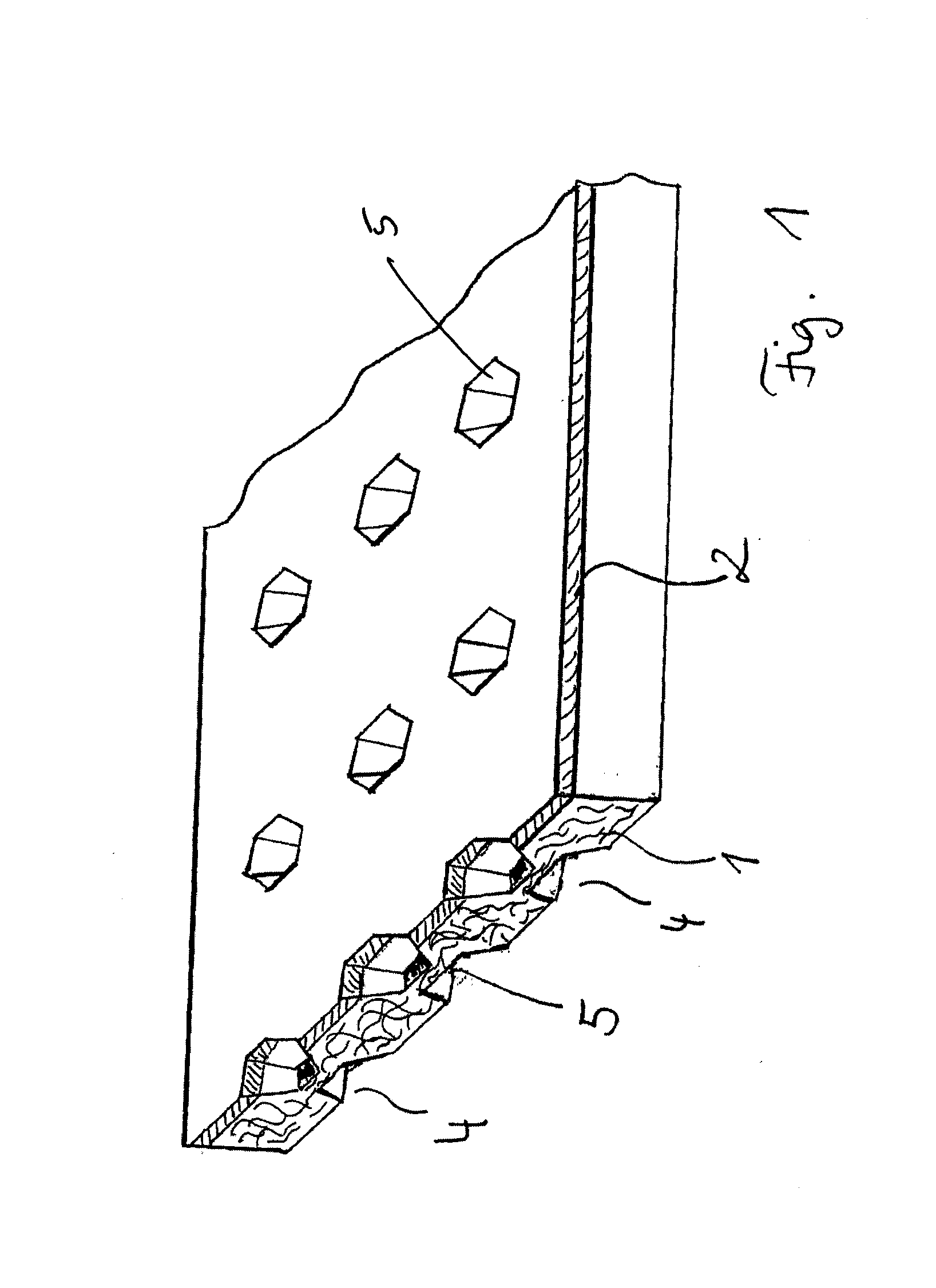

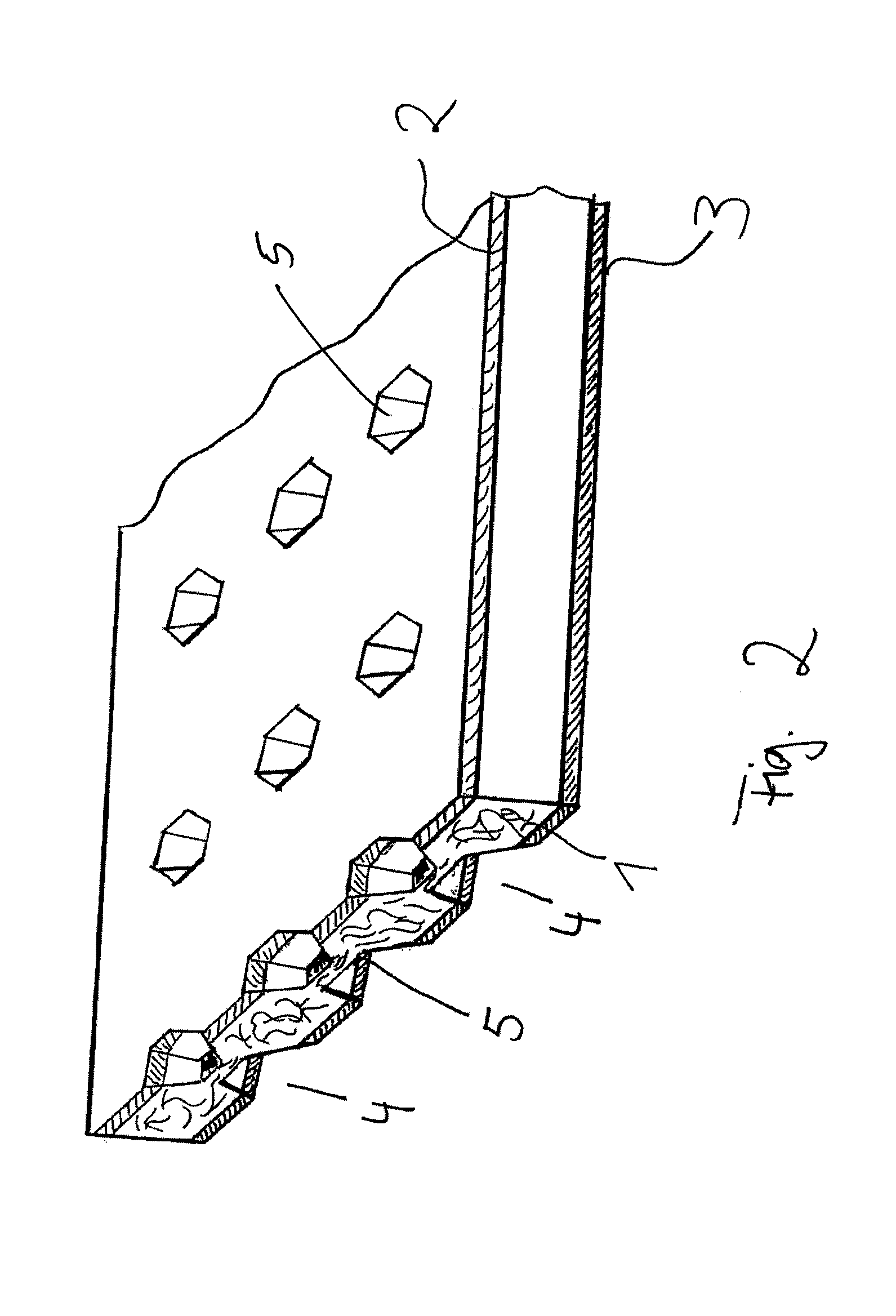

Ultrathin semi-worsted nap up blazer fabric and preparation process thereof

ActiveCN106757613AImprove qualitySoft qualityHeating/cooling textile fabricsWoven fabricsPolyesterFiber

The invention discloses an ultrathin semi-worsted nap up blazer fabric and a preparation process thereof. The fabric comprises Australian wool short cutting, cotton cashmere, polyester loose fiber and modal lose fiber; the preparation method comprises the steps that raw materials are dyed, opened, blended and stuffed by wool loosing and dyeing processes; then, roving is prepared by carding and two wool line blending by a carding machine and the roving is spun into a single yarn by a spinning frame; after being automatic winding, the single yarn is doubling and then is twisted into semi-worsted double yarn; by the adoption of same longitude and latitude mode, the semi-worsted double yarn is woven into gray fabric on a weaving machine; the step gray fabric is put into water to wash for the first time, and then put into a scouring and milling combined machine to mill, the gray fabric after the milling is placed into a steel-wire napper to nap, and then, is set and dried after being brushed by a damping brushing machine, the dried gray fabric is lustered and sheared, and finally, the ultrathin semi-worsted nap up blazer fabric is obtained by decating. The ultrathin semi-worsted nap up blazer fabric and the preparation process thereof use semi-worsted spinning, are combined with a roving fabric nap up process and prepare the ultrathin semi-worsted fabric which is good in quality, soft, comfortable and warm-keeping.

Owner:LILANG CHINA

Cellulose Cloth

InactiveUS20100159207A1Soft qualityPromote absorptionSynthetic resin layered productsNon-woven fabricsCellulose fiberMaterials science

A cellulose cloth has a fiber layer of cellulose fibers that absorb liquids as well as a second layer bonded thereto, wherein the second layer has a different color or a different color pattern than the fiber layer, and wherein the fibers of the fiber layer are bonded to one another by partial press-bonding with compression of the cellulose fibers in the press-bonded areas.

Owner:MCAIRLAIDS VLIESSTOFFE GMBH & CO KG

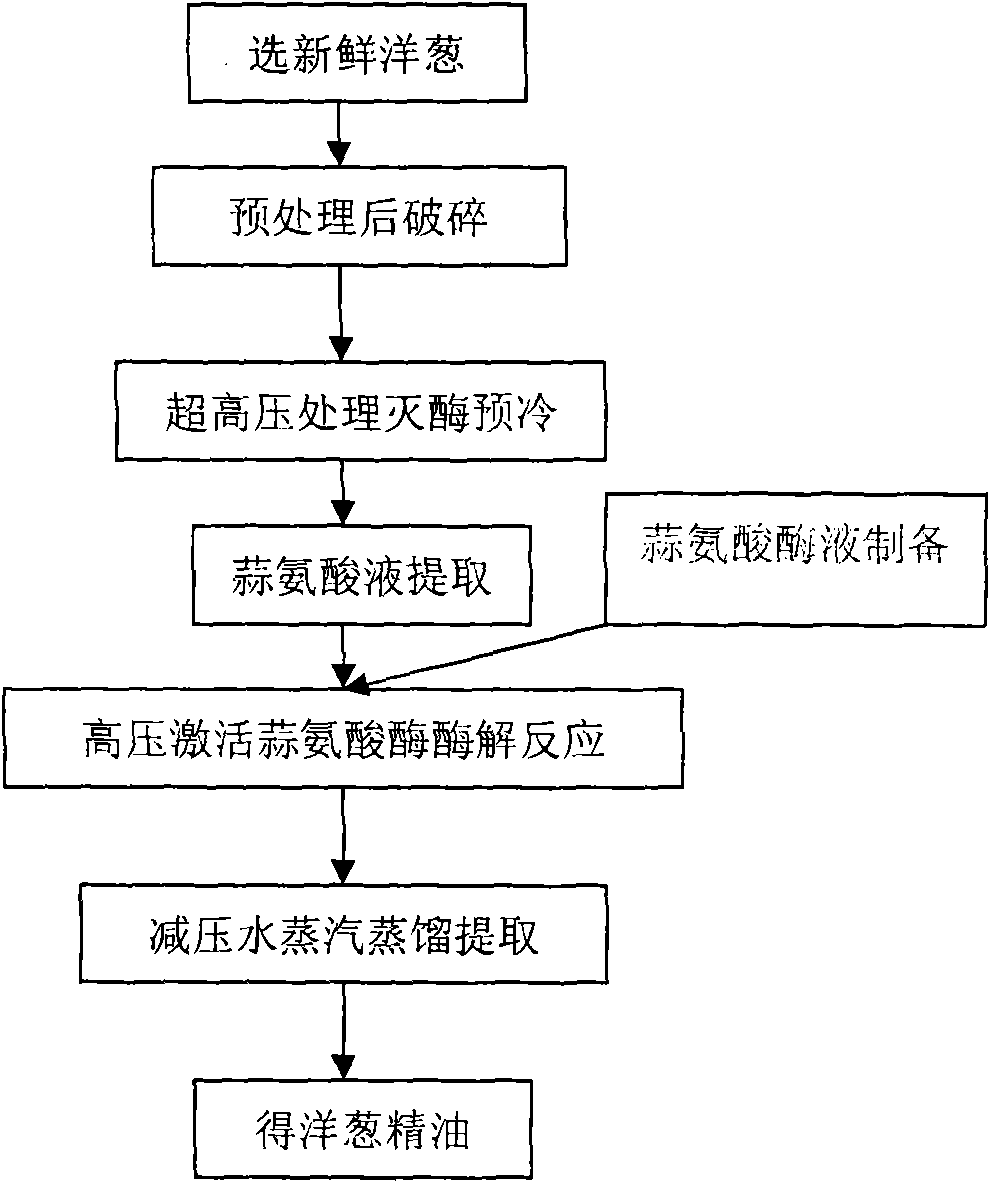

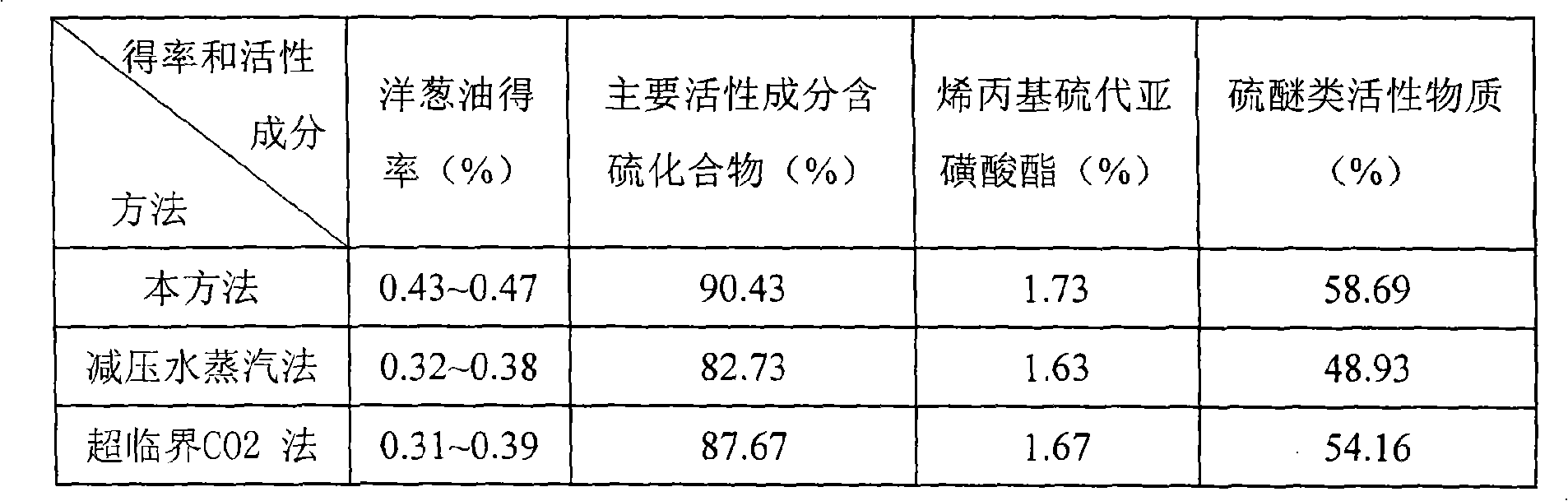

Method for extracting onion essential oil through ultrahigh pressure regulation of alliinase reaction

InactiveCN101591587AAvoid interferenceAvoid residueEssential-oils/perfumesFermentationWater vaporAlliinase

The invention discloses a method for extracting onion essential oil through ultrahigh pressure regulation of alliinase reaction, and belongs to fine and deep processing technology for farm products. The method is carried out according to the following steps: (1) pretreating onion under ultrahigh pressure; (2) preparing onion alliin solution; (3) preparing onion alliinase solution; (4) catalyzing alliinase zymolysis reaction under the ultrahigh voltage; and (5) decompressing water vapor to distill and extract the onion essential oil. The method is easier to control the production process, thereby improving the yield and the quality of the onion essential oil. Under the process condition, the yield of the onion essential oil is between 0.43 and 0.47 percent. The quality of the essential oil and the content of active substances are also improved; and the essential oil has wide market development prospect.

Owner:JIANGSU UNIV

Photographic light diffuser

ActiveUS20080259588A1Easy to shootGood dispersionNon-electric lightingPoint-like light sourceEngineeringCowling

A photographic light diffusing device is provided. A flexible, transparent cowl is adapted to be mounted on a photographic light source, the cowl including a plurality of ribs and an opening through which the photographic light source is visible when the cowl is mounted on the photographic light source. The cowl elastically deforms to fit onto the photographic light source. A removable, flexible cover is placed over the opening of the cowl.

Owner:GARY FONG PHOTOGRAPHIC

Light weight nonwoven fire retardant barrier

ActiveUS20060093870A1Low average denierLight weightLayered productsSeating furnitureNonwoven fabricFire retardant

A non-woven flame retardant barrier can be prepared from low denier, charring fibers and substantially free of polymers made from halogenated monomers. The charring fibers can be modified viscose fibers, for example Visil®. The blend of low denier fibers can be, for example, a blend of 1.5 denier fibers and 3.0 denier fibers.

Owner:WM T BURNETT IP

Lightweight nonwoven fire retardant barrier

ActiveUS7410920B2Light weightSoft qualityLayered productsSeating furniturePolymer scienceFire retardant

A non-woven flame retardant barrier can be prepared from low denier, charring fibers and substantially free of polymers made from halogenated monomers. The charring fibers can be modified viscose fibers, for example Visil®. The blend of low denier fibers can be, for example, a blend of 1.5 denier fibers and 3.0 denier fibers.

Owner:WM T BURNETT IP

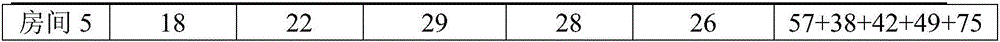

Puffed potato whole meal and preparation method of puffed potato whole meal

The invention discloses puffed potato whole meal and preparation method of the puffed potato whole meal. The puffed potato whole meal is prepared by the following steps: cleaning potatoes; stewing; feeding the stewed potatoes at a cold outdoor air temperature, and freezing; transferring the thoroughly frozen potatoes inside, unfreezing, peeling and dewatering; and airing the dewatered potatoes on a heated brick bed, and preparing powder. The process disclosed by the invention is simplified; the production cost is low; the method is easy to popularize; the prepared puffed potato whole meal product is soft in texture, easy to dry, easy to crush, free of caking when being kneaded, and easy to knead, not easy to go bad and long in retention period and has the relatively white color.

Owner:全洪范

Polyurethane hot melt adhesive and preparation method thereof for seamless integrated vamps

ActiveCN104212404AExcellent Adhesive PropertiesAdhesivelyFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to the technical field of polyurethane hot melt adhesives, in particular to a polyurethane hot melt adhesive and a preparation method thereof for seamless integrated vamps. The polyurethane hot melt adhesive comprises, by weight, 60-90 parts of polyester polyol, 20-30 parts of diisocyanate, 2-5 parts of chain extenders and 0.1-2 parts of anti-aging auxiliaries. The polyurethane hot melt adhesive has the advantages that the high-strength bonding characteristic is achieved, materials such as leather and flocking materials can be connected with mesh cloth or other materials in a thermal fusing mode, thereby, seamless integrated shoe making technology can be achieved, bonding between the vamps is quite firm and stable, the appearance is attractive, the melting point of the polyurethane hot melt adhesive is low, the fluidity is good at the hot melting state, the film-forming property is good, cold resistance and bending resistance are good, an adhesive film touches soft, sewing machine staff can be greatly reduced, production processes are reduced, and the production costs are lowered. The preparation method is simple and mature, the production efficiency is high, and general popularization and application can be facilitated.

Owner:东莞宏石功能材料科技有限公司

Mosquito-repelling wet tissue and preparation method thereof

InactiveCN106265097AWide range of applicationsGentle on skinCosmetic preparationsToilet preparationsSolventWoven fabric

The invention discloses mosquito-repelling wet tissue. The mosquito-repelling wet tissue is prepared from a mosquito-repelling liquid and no-woven fabric carrying the mosquito-repelling liquid; the mosquito-repelling liquid is prepared from components in parts by weight as follows: 1-5 parts of a wetting agent, 0.05-0.5 parts of a chelating agent, 5-30 parts of a mosquito repellent, 5-35 parts of a solvent, 0.05-0.5 parts of an aromatic essential oil, 0.3-1.0 part of a preservative, 0.1-2 parts of a pH regulator and 26-89 parts of deionized water. The mosquito-repelling wet tissue is convenient to carry and use and has a good mosquito-repelling effect and high comfort after being used by a user. The invention further discloses a preparation method of the mosquito-repelling wet tissue. The preparation method adopts a simple process and is convenient to operate, high in safety coefficient, high in operability and efficiency and low in cost.

Owner:HANGZHOU GUOGUANG TOURING COMMODITY

Wet tissue for relieving hemorrhoid symptoms and preparation method of wet tissue

InactiveCN106265295AEasy to usePromote healingCosmetic preparationsToilet preparationsWound healingAlcohol

The invention discloses a wet tissue for relieving hemorrhoid symptoms. The wet tissue consists of a conditioning liquid and non-woven fabric bearing the conditioning liquid, wherein the conditioning liquid is prepared from components in parts by weight as follows: 30-60 parts of a witch hazel extracting solution, 0.05-0.1 parts of glucose chlorhexidine, 0.01-0.05 parts of borneol, 2-5 parts of dealdehyding alcohol, 2-8 parts of propylene glycol, 0.3-1 part of a preservative, 0.05-0.3 parts of a pH regulator and 26-66 parts of deionized water. The wet tissue can effectively relieve the hemorrhoid symptoms, perform sterilization, disinfection and detumescence, reduce exudation and promote wound healing, is mild and safe, has no side or toxic effects and is convenient to use. The invention further discloses a preparation method of the wet tissue for relieving the hemorrhoid symptoms. The preparation method adopts a simple process and is convenient to operate, high in security coefficient, operability and efficiency and low in cost.

Owner:HANGZHOU GUOGUANG TOURING COMMODITY

Infantile hand-mouth wet wipe and production method thereof

InactiveCN106176482AHigh acceptancePH reliefInorganic/elemental detergent compounding agentsCosmetic preparationsPreservativeWet wipe

The invention discloses infantile hand-mouth wet wipe, made with a detergent and nonwoven bearing the detergent; the detergent comprises the following components, by weight: 0.1-8 parts of a sweetener, 0.2-5 parts of a deterging agent, 0.2-8 parts of a plant extract, 1-5 parts of a moisturizer, 0.3-1.0 part of a preservative, 0.1-3 parts of a pH regulator and 90-99 parts of deionized water. The Infantile hand-mouth wet wipe is nontoxic, non-irritating, highly safe to use, soft and comfortable, suitable for wiping sensitive parts of a baby such as hand and mouth, also suitable for cleaning baby supplies such as nipples and feeding bottles. The invention also discloses a production method of the infantile hand-mouth wet wipe. The preparation method is simple, high in operational safety and high in efficiency.

Owner:HANGZHOU GUOGUANG TOURING COMMODITY

Antistatic polyester false twisted yarn, process for its production, and antistatic special conjugated false twisted yarn comprising antistatic polyester false twisted yarn

InactiveUS20090308048A1Low friction resistanceSoft qualityYarnMonocomponent polyesters artificial filamentMethyl methacrylatePolyester

An unstretched filament composed of a PET-based aromatic polyester multifilament comprising a polyoxyalkylene-based polyether and an organic ionic compound is subjected to simultaneous stretching and false twisting under specified conditions to produce a polyester false twisted yarn, whereby rapid and stable false twisting can be accomplished without section deformation or fluff generation during false twisting, and the resulting yarn has a highly satisfactory hand quality and a fibrillation resistant fiber structure, while also exhibiting a highly durable antistatic property.Interlacing of the unstretched filament with an unstretched polyester filament comprising a polymethyl methacrylate-based polymer and / or polystyrene-based polymer and stretching / false twisting thereof under specified conditions allows rapid and stable production of conjugated false twisted yarn exhibiting highly satisfactory bulkiness and a spun feel with the absence of fluff, as well as a highly durable antistatic property. The finished yarn is particularly useful for purposes that require static electricity to be inhibited, such as student wear, uniforms, dustproof clothing and the like.

Owner:TEJIN FIBERS LTD

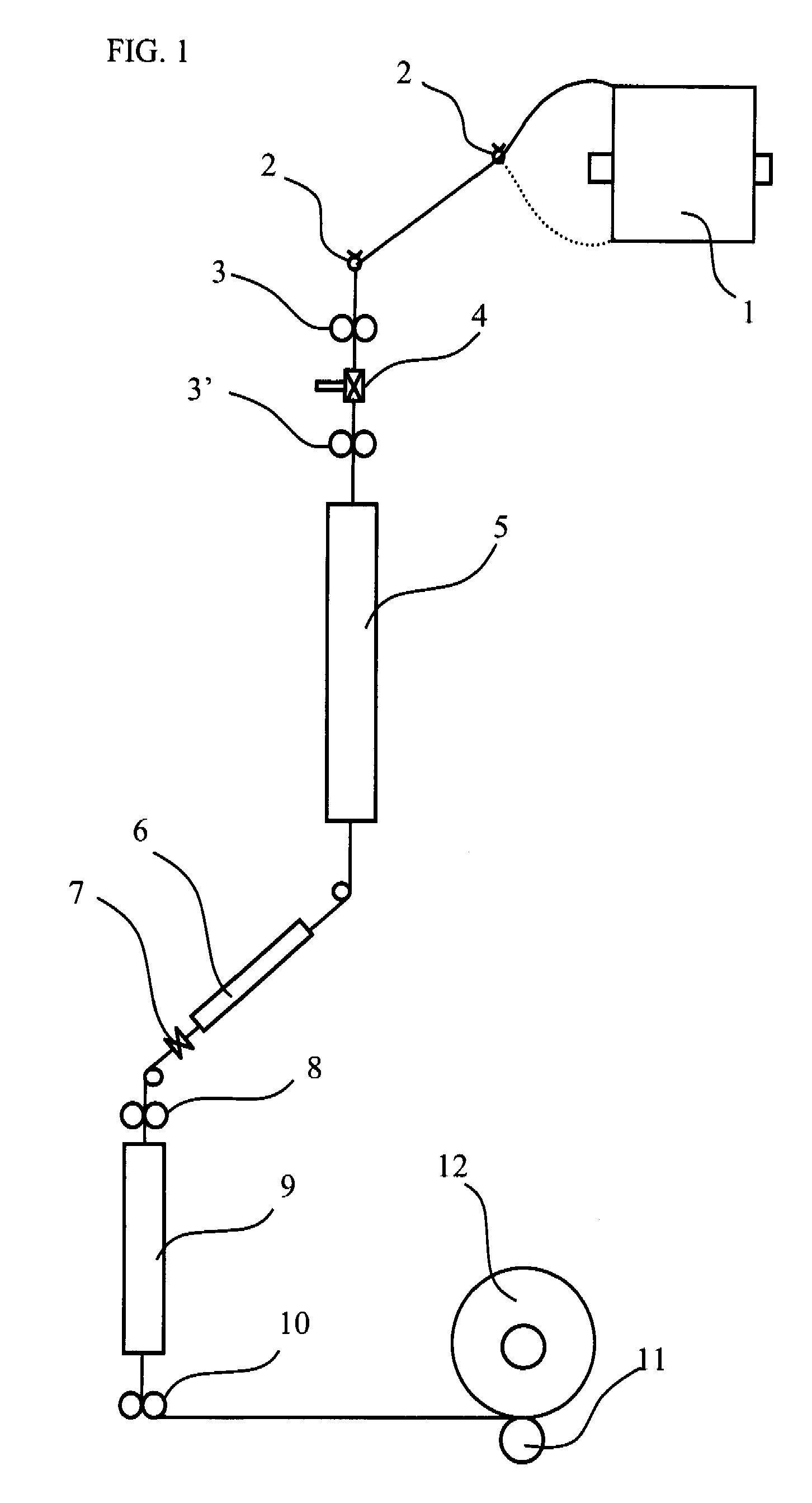

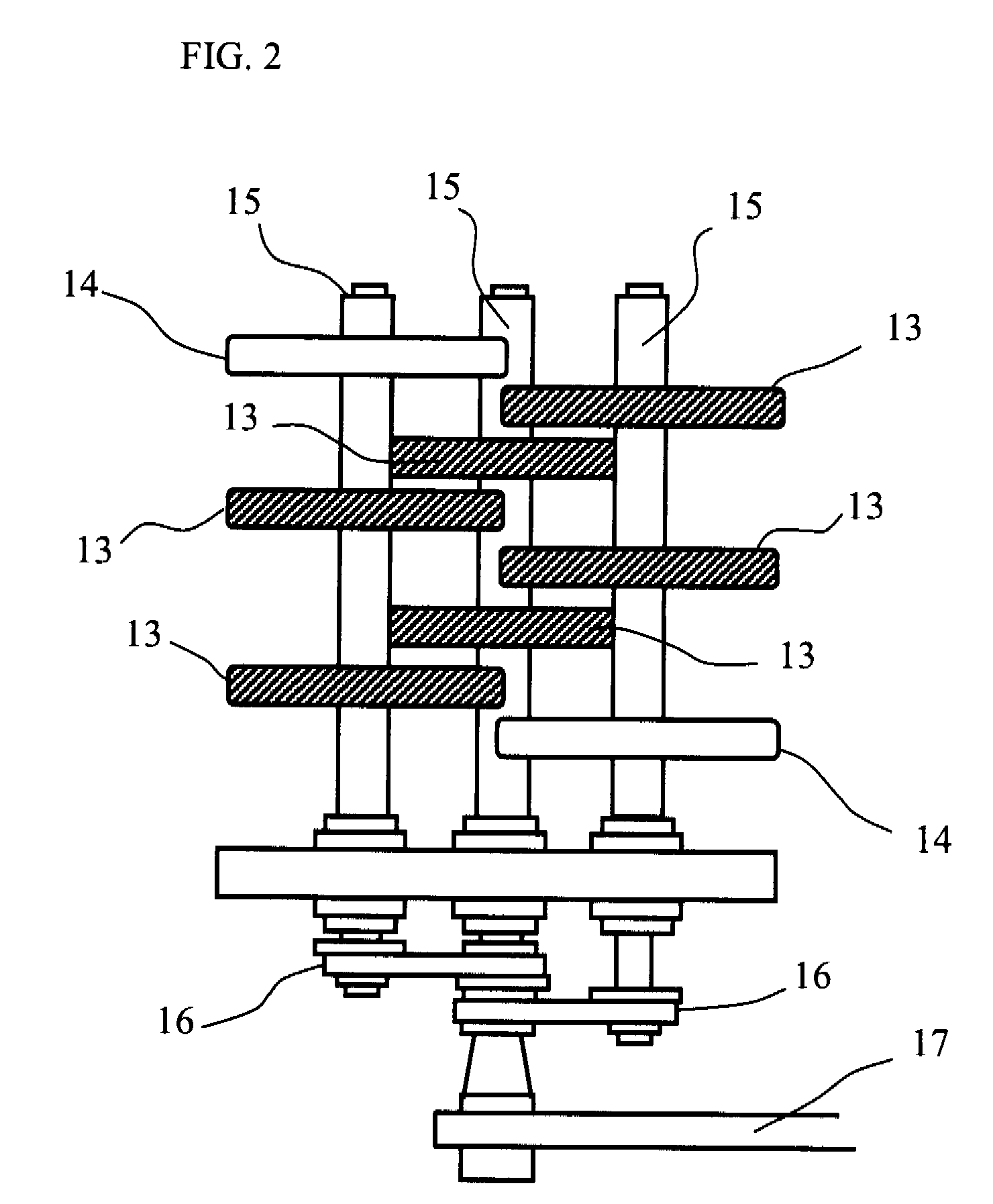

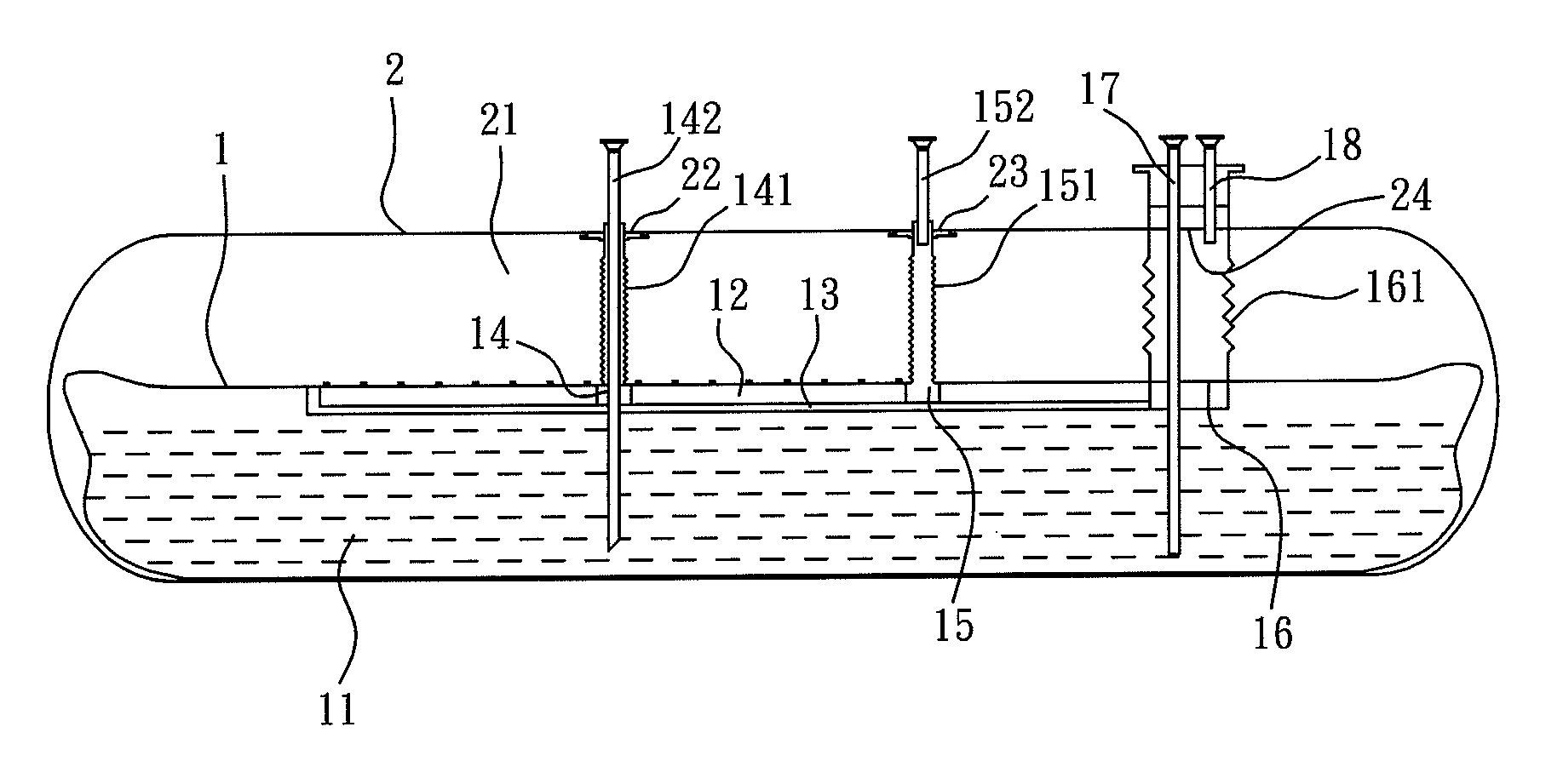

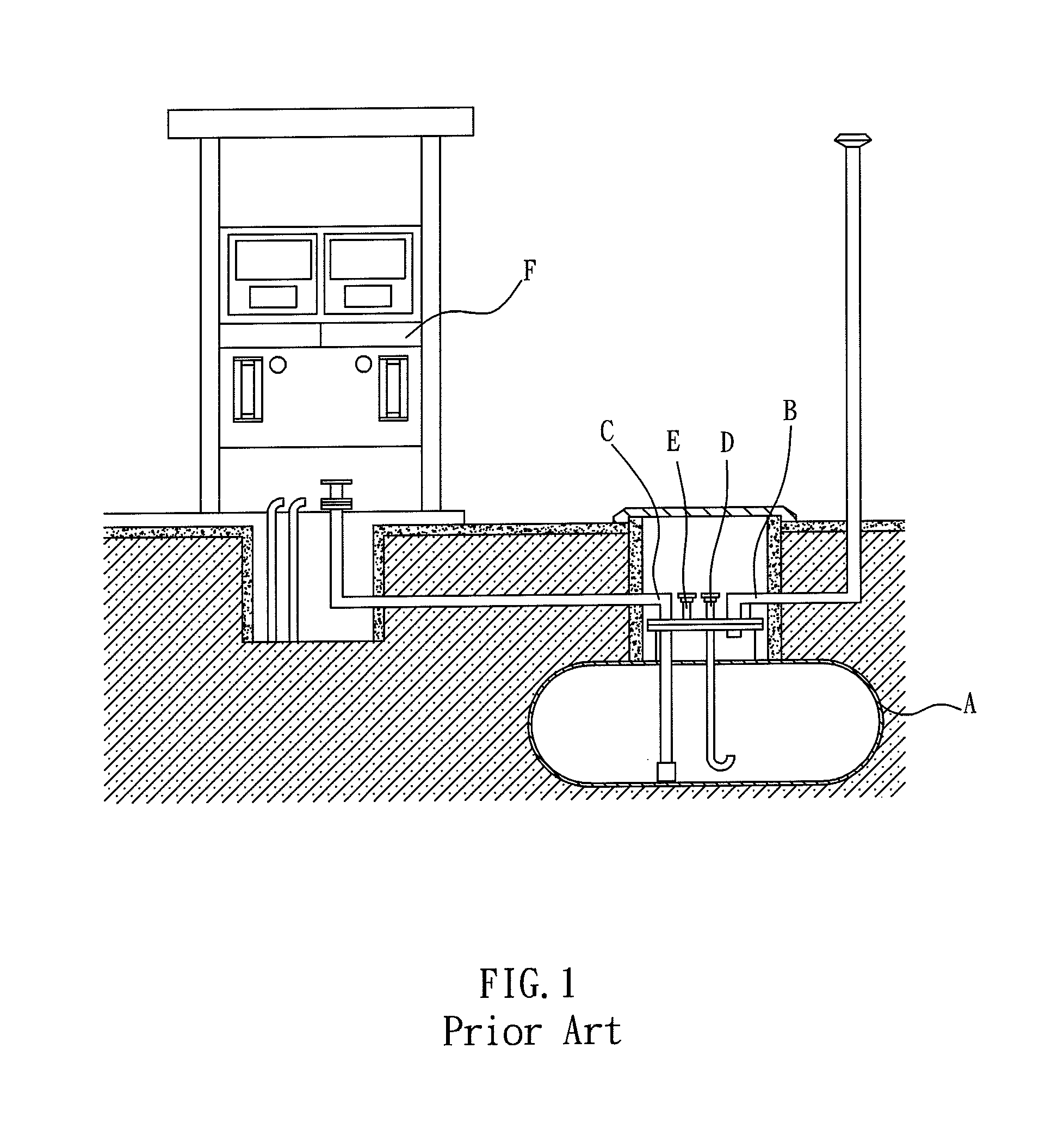

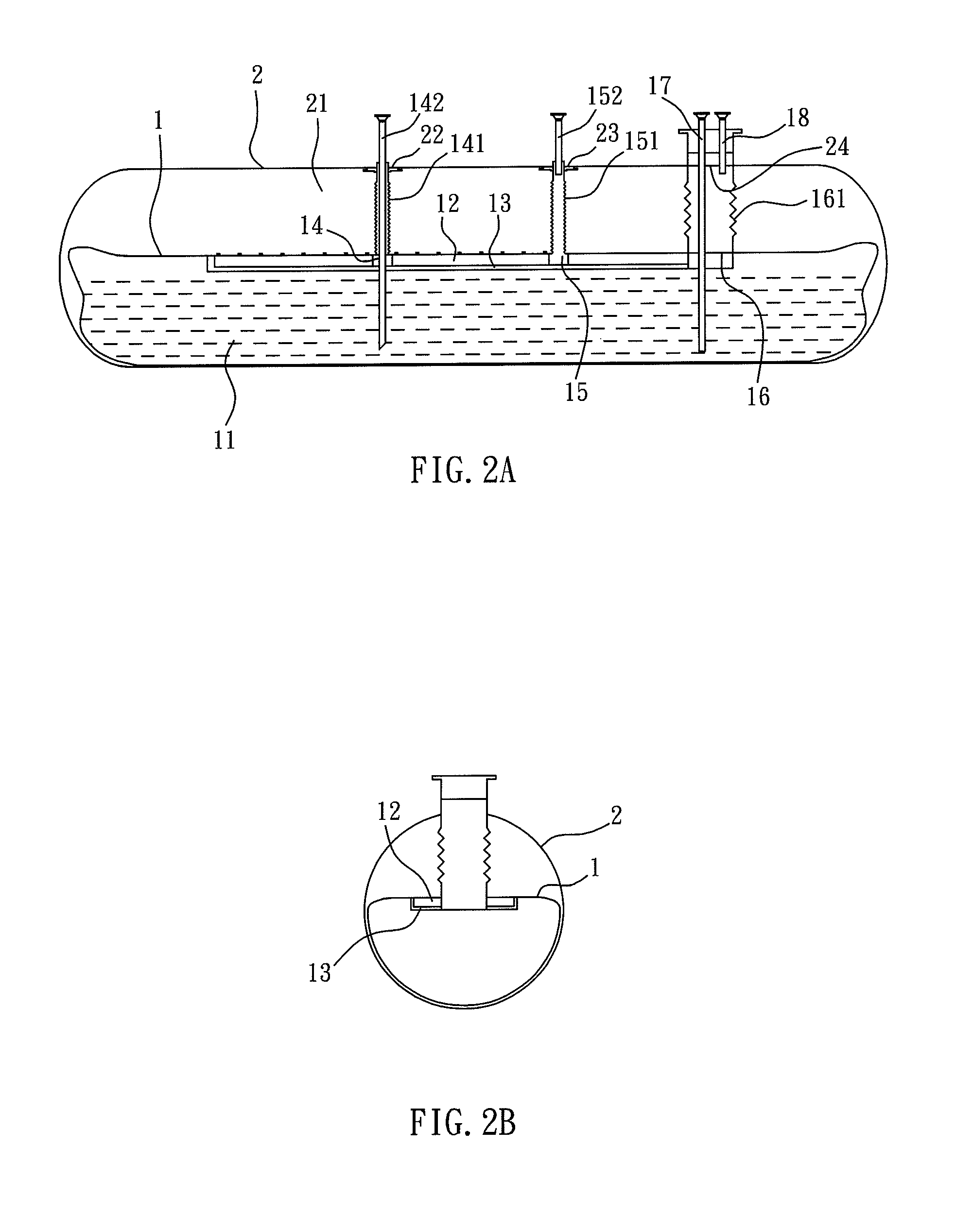

Gasoline storage device

A gasoline storage device, which is regulated to prevent gasoline from vaporizing, and is fabricated from a soft gasoline bag made from soft material that has been processed and coated on both sides so as to be resistant against gasoline and the majority of chemical liquids. The soft gasoline bag can be folded into a small size, directly disposed into a steel gasoline tank and allowed to unfold. Expandable hoses are used to respectively connect to the existing gasoline inlet pipe, gasoline-measuring pipe and manhole of the steel gasoline tank. The soft properties of the soft gasoline bag are used to isolate the gasoline stored within the steel gasoline tank from the air, thereby reducing vaporization of gasoline, pollution and wastage.

Owner:FULL MOST

Photographic light diffuser

A photographic light diffusing device comprises a semi-transparent cowl which is adapted to be mounted on a photographic light source, the cowl including an opening through which the photographic light source is visible when the cowl is mounted thereon, and a removable semi-transparent cover detachably mounted on the cowl. In another embodiment, a camera flash system comprises a camera flash unit, and a diffuser unit having an adaptor and a tapered cylindrical body. The adaptor is formed to match the shape of the housing of the camera flash unit so that it may be fitted thereto, and the adaptor extends between the camera flash unit and the tapered cylindrical body of the diffuser unit. The diffuser unit widens from the adaptor to meet the tapered cylindrical body.

Owner:GARY FONG PHOTOGRAPHIC

Portable photographic diffuser

Owner:GARY FONG PHOTOGRAPHIC

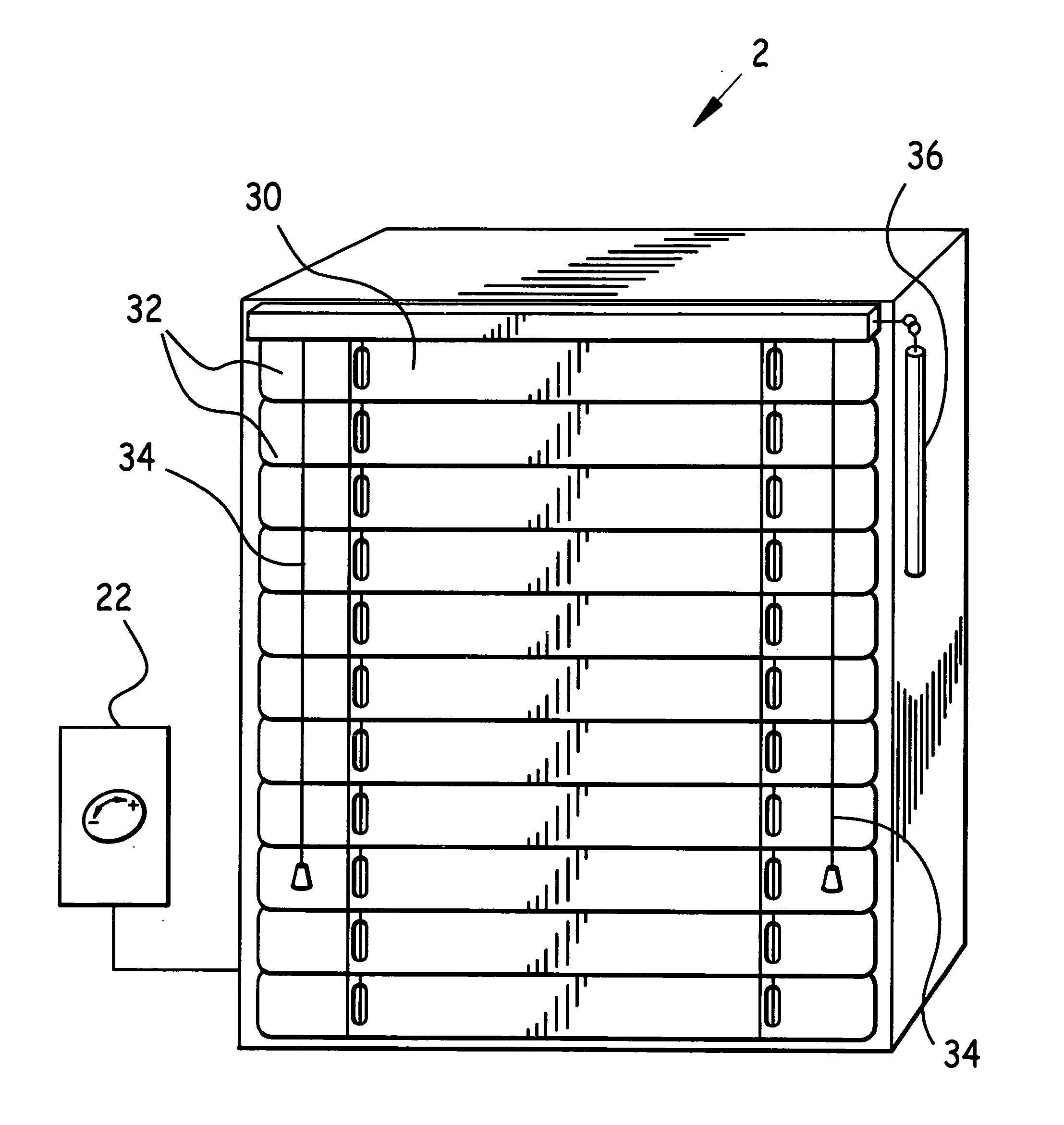

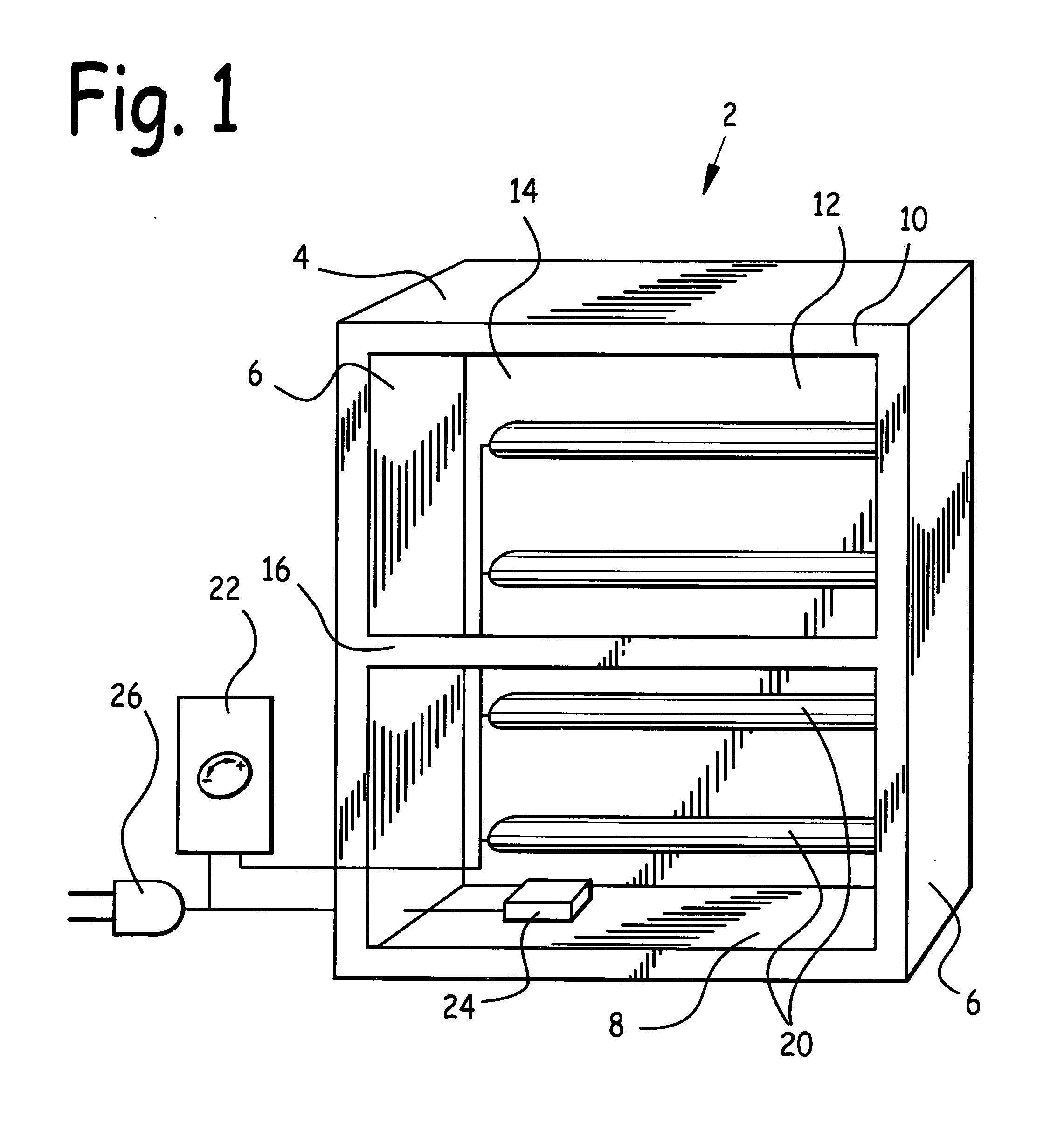

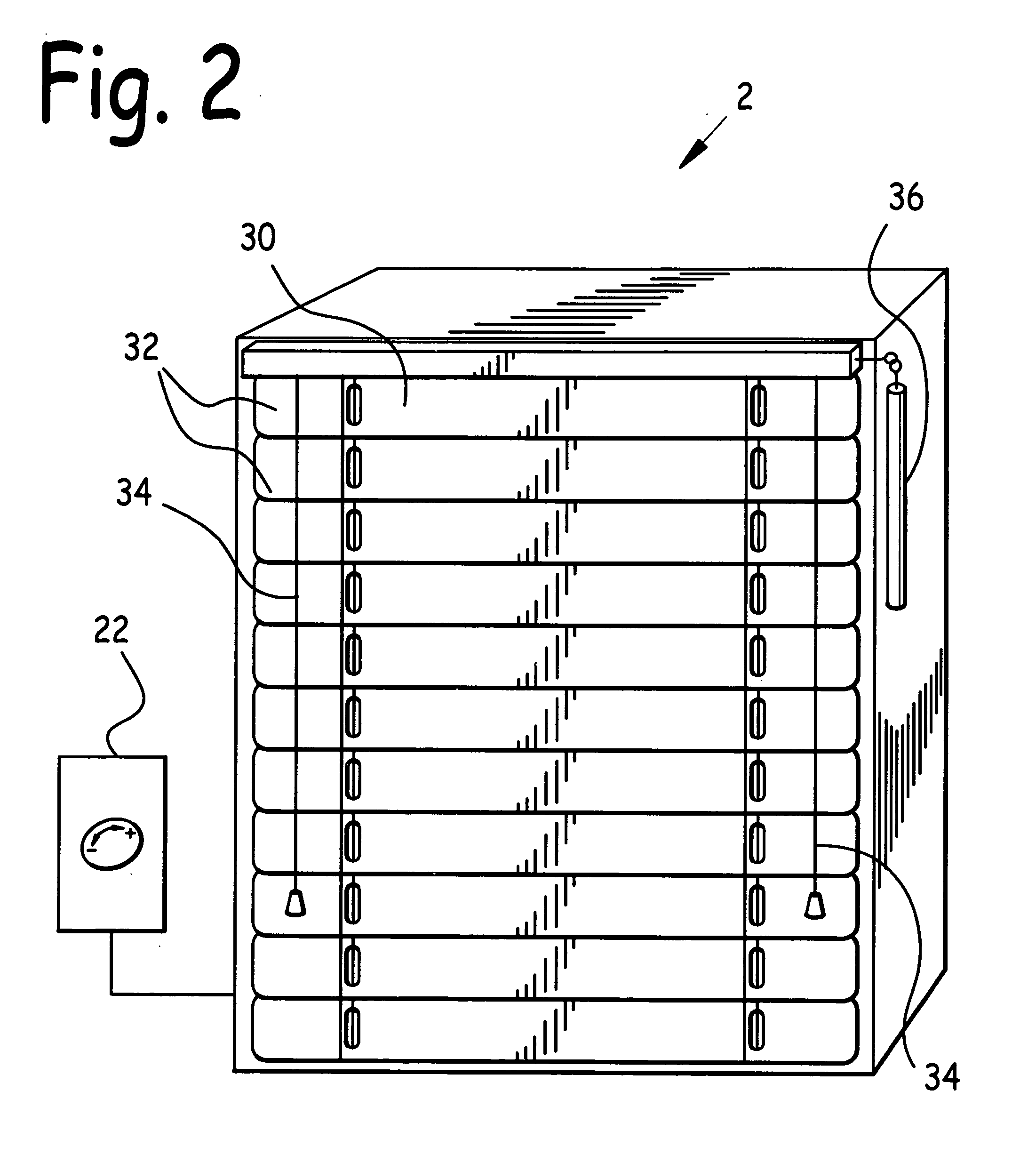

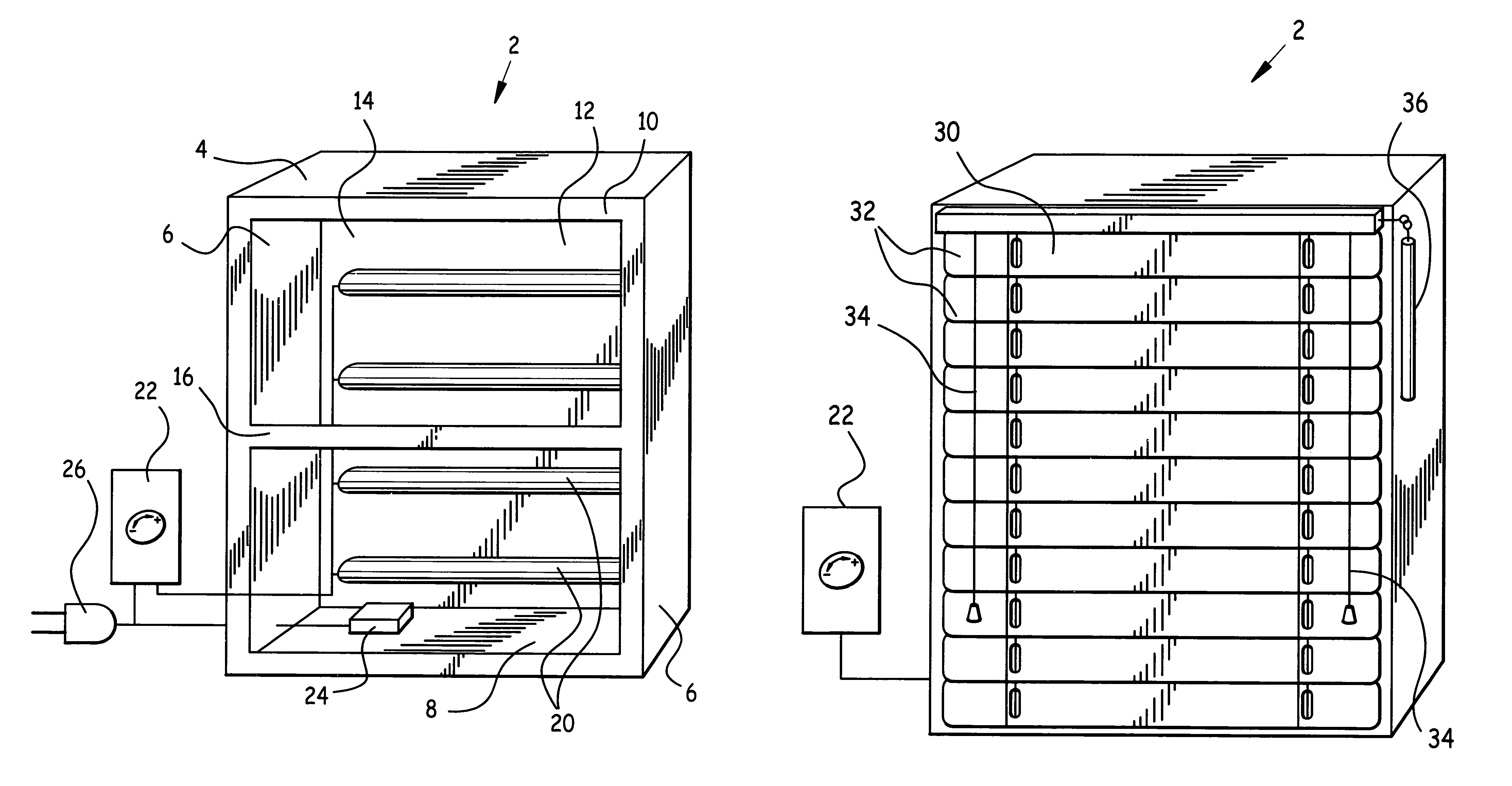

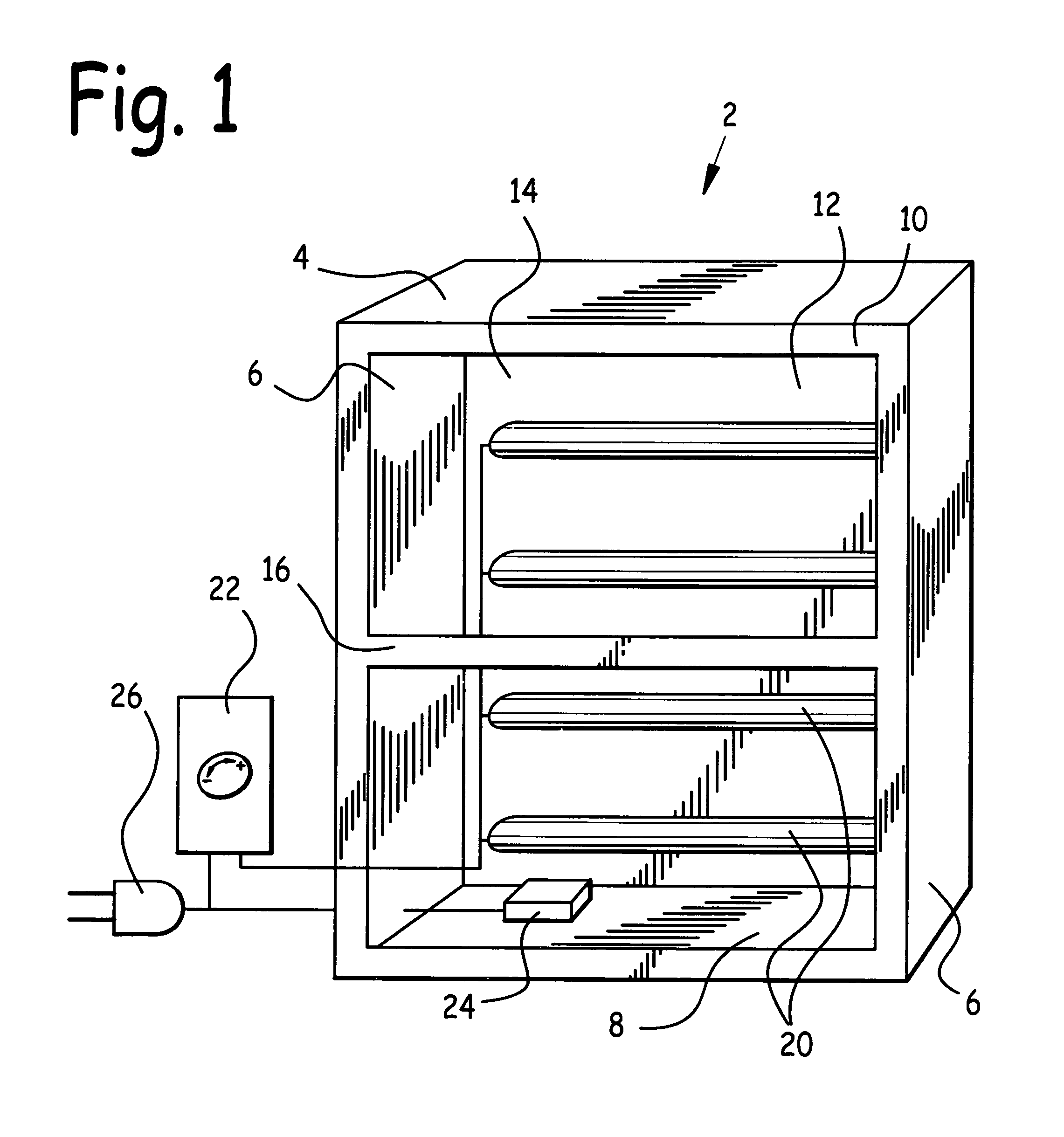

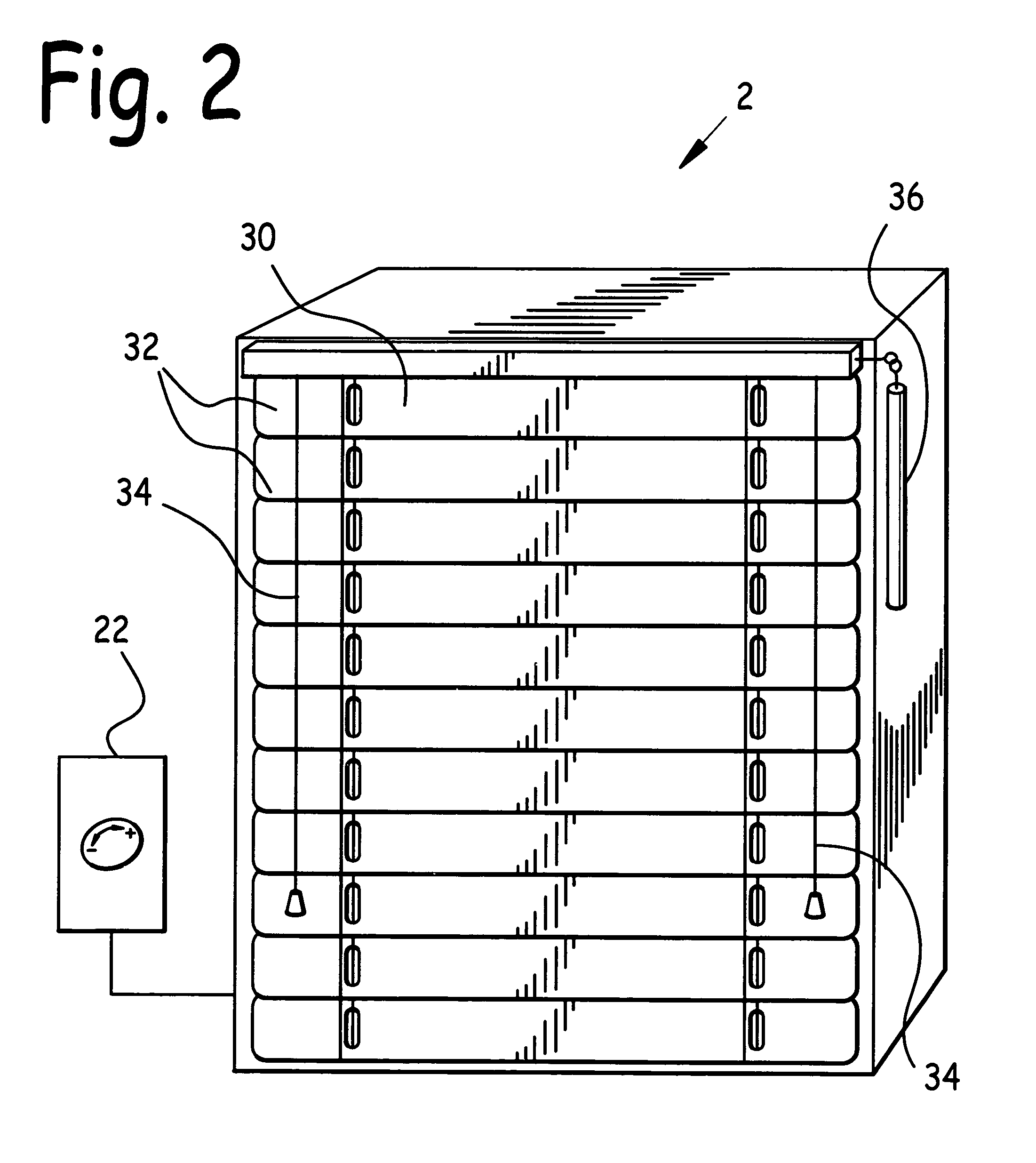

Window light box with blind

InactiveUS20100259915A1Increased aesthetic appealCheerful ambianceShow cabinetsElongate light sourcesElectricityWindow shutter

A window light box with blind. A light source within the light box provides light through a front aperture. A blind is mounted to a light box front, and is extendable over the front aperture. The blind and / or light source may be colored; the blind may be opaque, translucent, or transparent. The light source is electrically connected to a power source through a switch, which may be an ON / OFF dimmer switch. An alternate embodiment is disclosed wherein the light source is electrically connected to a power source through a switching receiver, and a remote controls the receiver. A battery back-up is disclosed to power the light source in the event of power source interruption. The light source may be fluorescent, incandescent, serpentine lighting, a Christmas light string, LED, or other appropriate light source.

Owner:HUBBS IRMA

Passion fruit beverage and making method thereof

The invention discloses a passion fruit beverage. The passion fruit beverage comprises passion fruit pulp, passion fruit juice, passion fruit seeds, liquorice and the like. The invention further discloses a making method of the passion fruit beverage. The making method comprises the following steps of (1) peeling the passion fruit and taking a mixture of the passion fruit pulp, the passion fruit juice and the passion fruit seeds; (2) grinding the mixture of the passion fruit pulp, the passion fruit juice and the passion fruit seeds to obtain a serosity of the passion fruit pulp, juice and seeds; and (3) adding a natural sweetener and water into the serosity of the passion fruit pulp, juice and seeds, and evenly mixing to obtain the passion fruit beverage. The characteristics that the passion fruit seeds are rich in dietary fiber and are hard to separate from the pulp are utilized, the passion fruit pulp and the passion fruit seeds are grinded together and are combined with the liquorice and the like, the taste is good, the passion fruit seeds are fully utilized, the appearance of the product is attractive, the process is simple, the dietary fiber, the vitamins and the like are supplemented for the human body, and the passion fruit beverage and the making method of the passion fruit beverage are suitable for large-scale industrialized production.

Owner:HEYUAN XINGRUI FOOD TECH DEV CO LTD

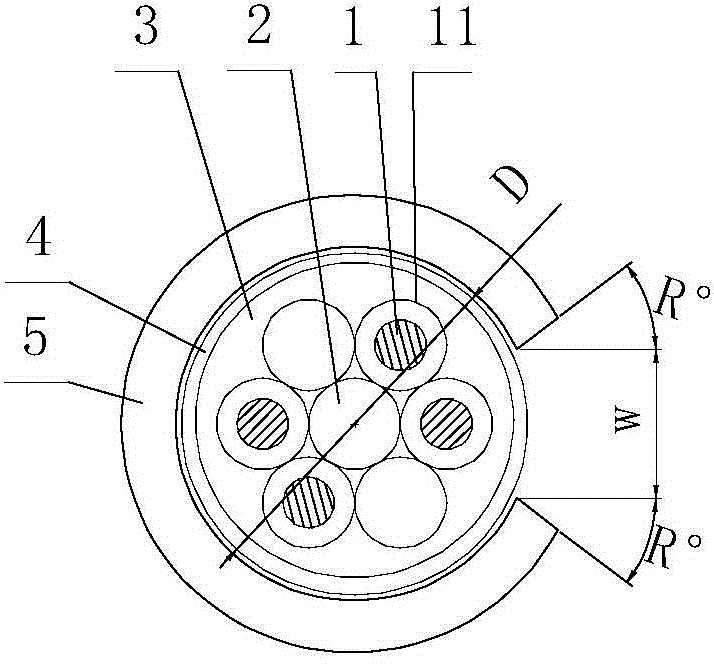

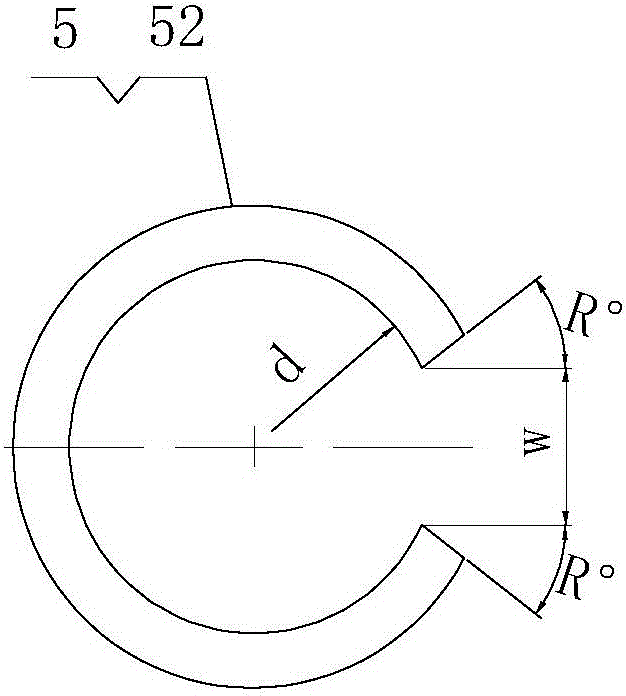

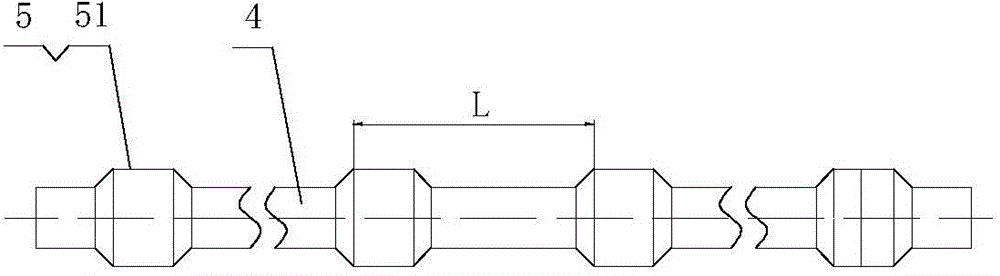

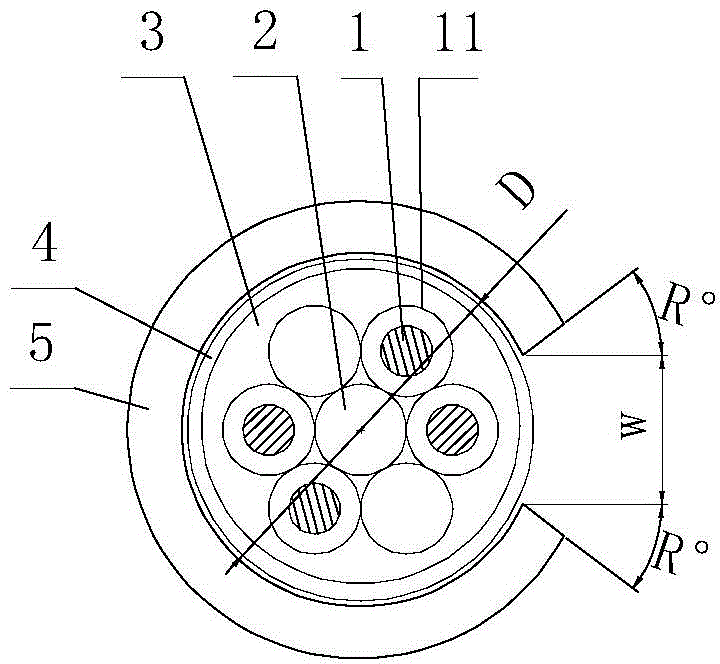

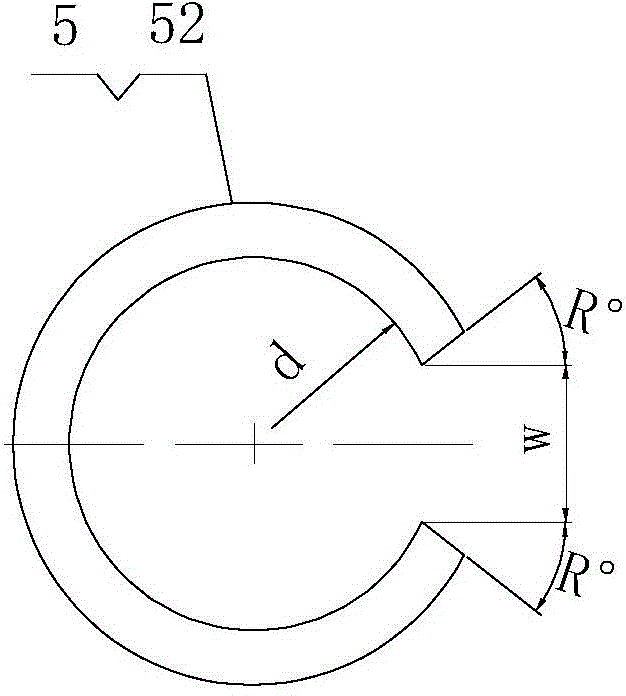

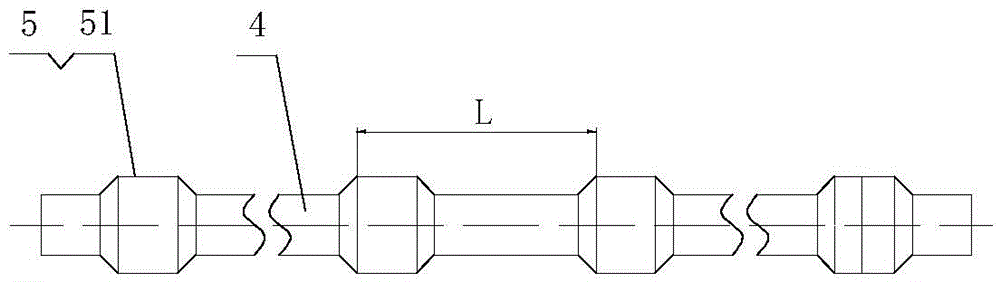

Calibration cable for geological exploration as well as production technology and calibration detection method of calibration cable

InactiveCN104409151ASolve the difficult problem of length calculationSolve the length problemInsulated cablesGeological measurementsNatural disasterElectrical conductor

The invention provides a calibration cable for geological exploration as well as a production technology and a calibration detection method of the calibration cable. The calibration cable for geological exploration comprises a cabled core formed by mixing a plurality of conductors and tensile components, a sheathing layer is extruded on the outer side of the cabled core, calibration rings with equal intervals L are arranged on the sheathing layer, the outer diameter of the sheathing layer is set as D, the inner diameter of each calibration ring is set as d, the surface of each calibration ring is set as red or other marking colors, and the calibration ring is made of rubber. When a product is produced according to an operation process of the production technology, the technical scheme that a section of the calibration cable is selected randomly from a finished cable for detection is adopted. The defects that the conventional exploration cable does not have calibration intervals, is not suitable for exploration of deeper geological condition, cannot finish a geological exploration task precisely, especially when the deeper geological condition is explored, design calculation on the cable length is required, the service life of the cable is influenced, and the exploration cost is increased are overcome, and the calibration cable is particularly suitable for an instrument and equipment for exploration of geological conditions with frequent natural disasters such as earthquake, debris flow, landslide and the like.

Owner:湖南华菱线缆股份有限公司

Calibration cable for geological exploration

InactiveCN105761821ASolve the difficult problem of length calculationSolve the length problemCommunication cablesInsulated cablesNatural disasterElectrical conductor

The invention discloses a calibration cable for geological exploration. A plurality of conductors and a tensile element are mixed to from a cable core. The cable core is wrapped by a sheath layer in an extruding manner, and the sheath layer is provided with calibration rings at equal intervals of L. The external diameter of the sheath layer is set as D, and the internal diameter of each calibration ring is set as d. The surface of the calibration ring is provided with a red mark or a mark with another color, and is made of rubber. The cable is manufactured according to a technological operation flow, and one calibration cable segment is selected from the finished cable for detection. The cable irons out the defects that there is no calibration interval in conventional cable detection, the conventional cable detection is not suitable for deeper geological conditions and cannot precisely complete a geological exploration task, the service life of the cable is affected when the length of the cable needs to be designed and calculated for the detection of the geological conditions at one depth and the detection cost is increased. The cable is especially suitable for the detection of the geological conditions of places with the frequent natural disasters, such as earthquake, mud-rock flow and landslide.

Owner:湖南华菱线缆股份有限公司

Window light box with blind

InactiveUS7887213B2Increased aesthetic appealCheerful ambianceShow cabinetsElongate light sourcesElectricityRemote control

A window light box with blind. A light source within the light box provides light through a front aperture. A blind is mounted to a light box front, and is extendable over the front aperture. The blind and / or light source may be colored; the blind may be opaque, translucent, or transparent. The light source is electrically connected to a power source through a switch, which may be an ON / OFF dimmer switch. An alternate embodiment is disclosed wherein the light source is electrically connected to a power source through a switching receiver, and a remote controls the receiver. A battery back-up is disclosed to power the light source in the event of power source interruption. The light source may be fluorescent, incandescent, serpentine lighting, a Christmas light string, LED, or other appropriate light source.

Owner:HUBBS IRMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com