Calibration cable for geological exploration as well as production technology and calibration detection method of calibration cable

A technology of geological detection and calibration, applied in the directions of marking conductors/cables, insulated cables, geophysical measurements, etc., can solve problems such as reducing detection quality and detection efficiency, affecting cable service life, increasing detection costs, etc. performance, extended service life, and the effect of ensuring detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

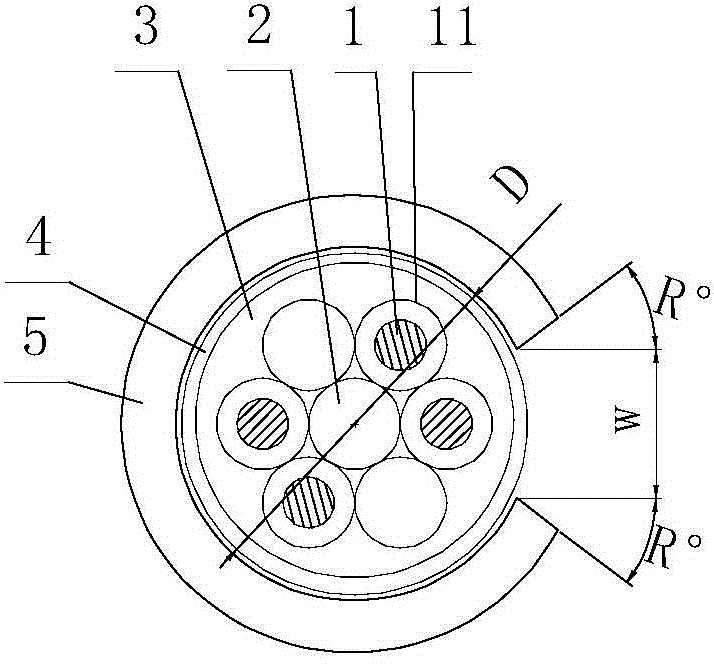

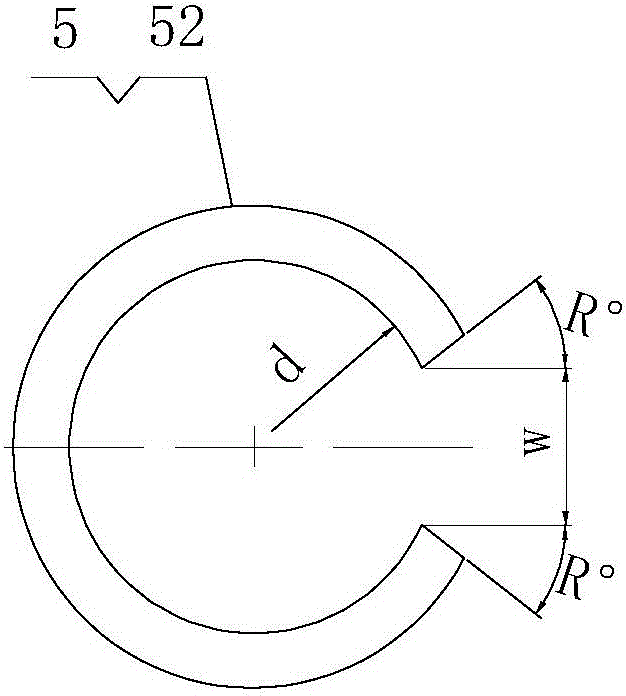

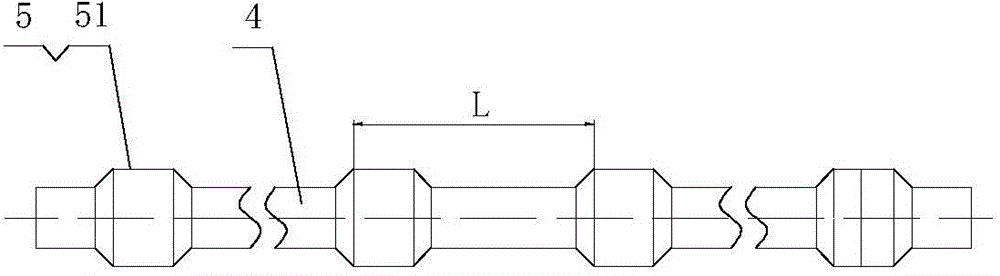

[0054] In conjunction with the accompanying drawings, the structure and principle of the present invention: a calibration cable based on geological exploration, including a conductor 1 made of 19 / 0.16 multi-strand annealed tinned copper strands, the conductor 1 is extruded with an F46 insulating layer 11 and at least three The tensile element 2 of high-strength aramid fiber is mixed to form a cable core wire 3, and the cable core wire 3 is extruded with a polyurethane sheath layer 4, and equidistant L calibration rings 5 are arranged on the sheath layer 4; The jacket layer 4 has an outer diameter D, the calibration ring 5 has an inner diameter d, and the surface is provided with red or other marking colors, and is made of rubber materials; in order to increase the bonding force between the calibration ring 5 and the cable sheath layer 4, the calibration The inner diameter d of the ring 5 should be smaller than the outer diameter D of the sheath layer 4, which is an interferen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com