A steel and wood composite square wood component

A component and steel frame technology, which is applied in the field of steel and wood composite square wood components, can solve the problems of easy deformation and waste, and achieve the effect of solving the problem of lengthening, improving the utilization rate and solving the problem of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

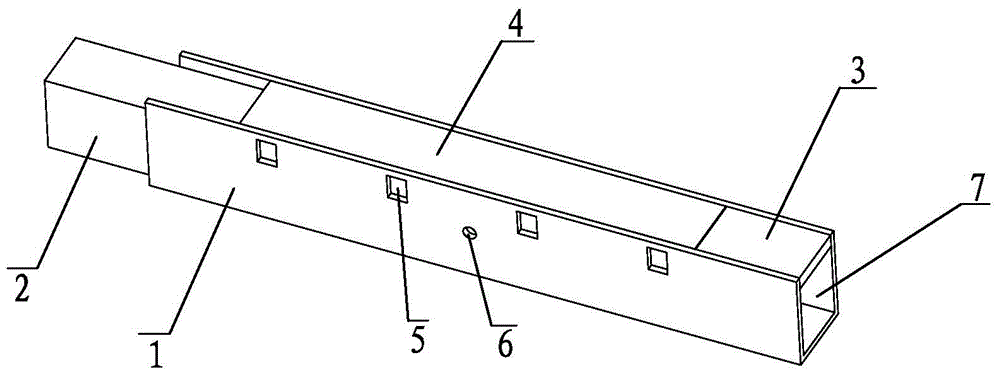

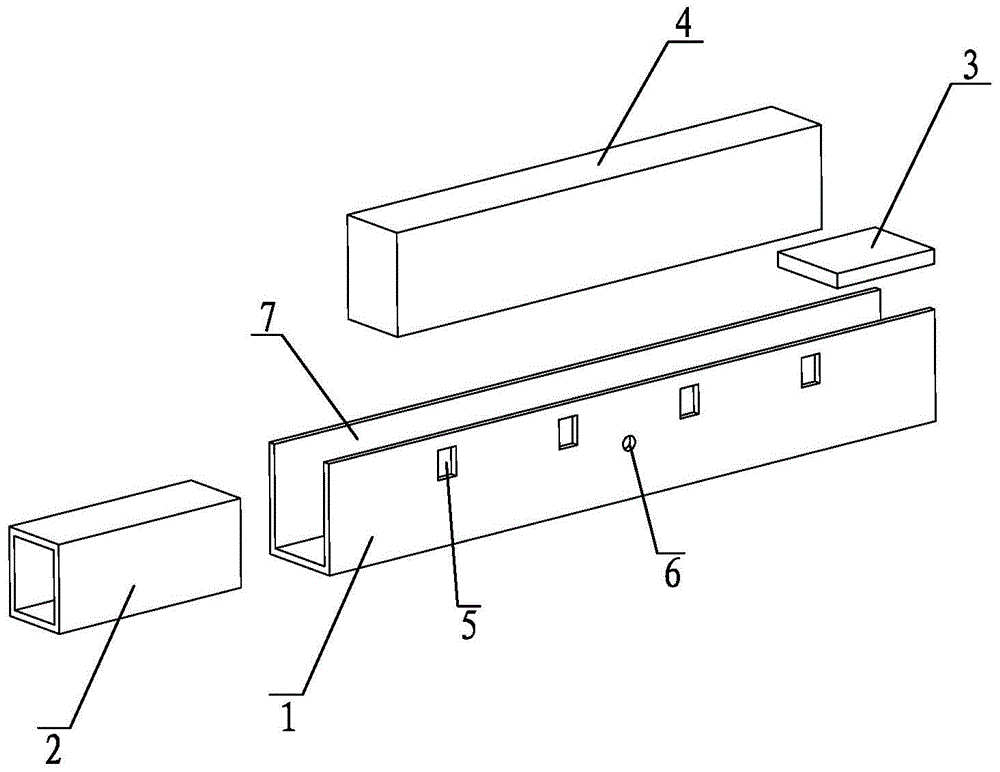

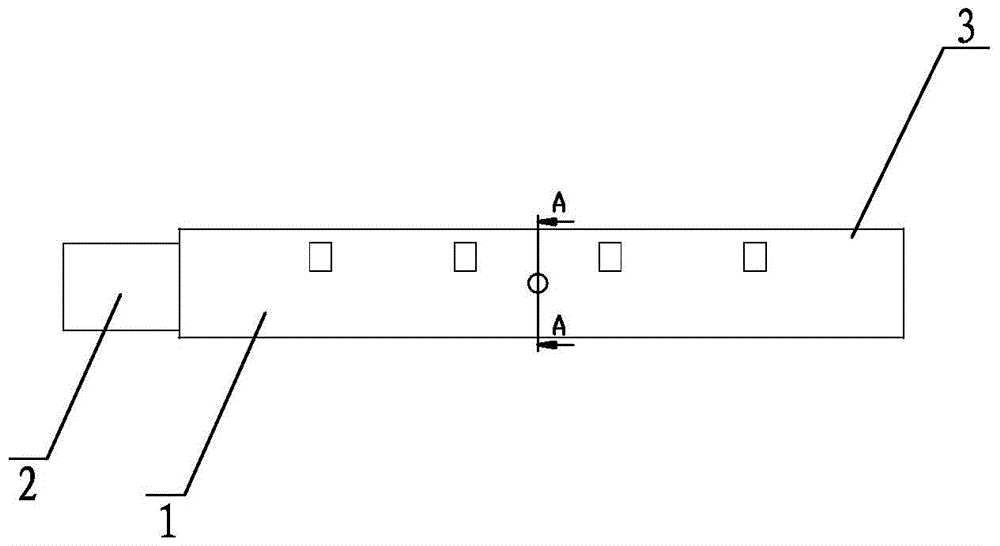

[0015] Such as Figure 1-6 As shown, what the present invention discloses is a steel and wood combined square wood component, comprising a steel frame 1 with a cavity 7, one end of the steel frame 1 is welded with a small square tube 2 by interference fit, the other end of the steel frame 1 A cover plate 3 is fixedly welded on the upper end surface of the upper part, and a square wood 4 is fixed in the cavity 7 of the steel frame 1 and is integrated with the steel frame 1. The square wood 4 is located between the small square tube 2 and the cover plate 3 There are some first nail fixing holes 5 distributed on both sides of the steel frame 1; some second nail fixing holes 6 are also distributed on both sides of the steel frame 1, and the screws 8 in the second nail fixing holes 6 connect the steel frame It is connected with the square wood to form a whole; the thickness of the steel plate of the steel frame 1 is 1.5mm-5mm.

[0016] combine figure 2 , 5 As shown, the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com