Patents

Literature

88results about How to "Reduce bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

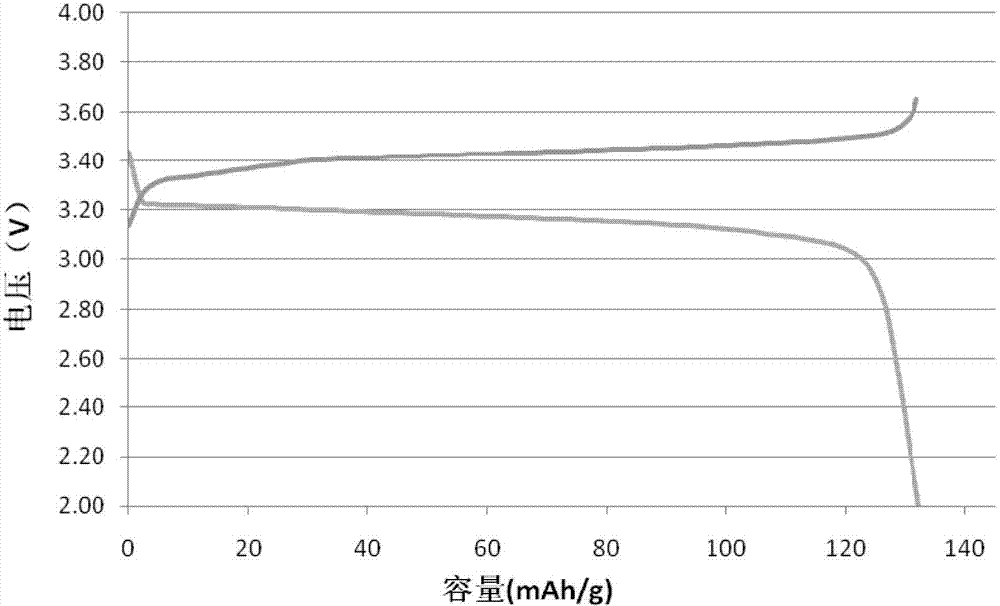

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

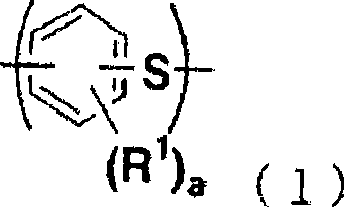

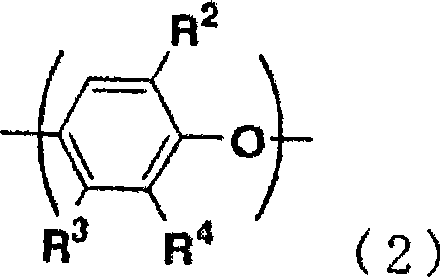

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

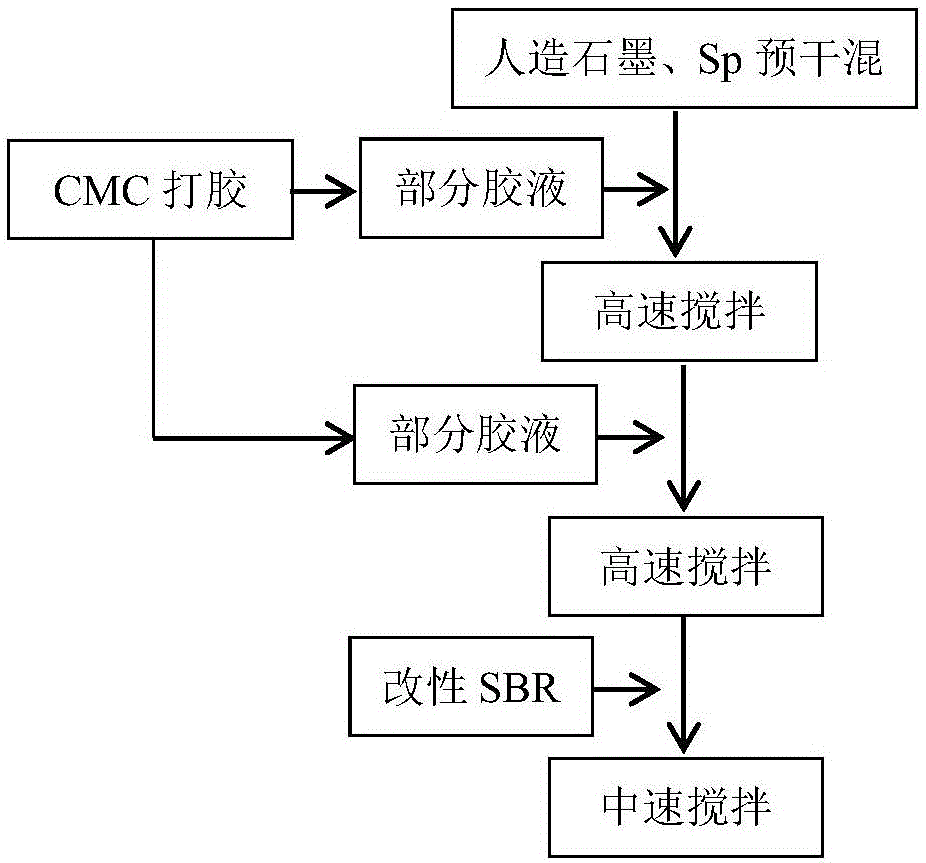

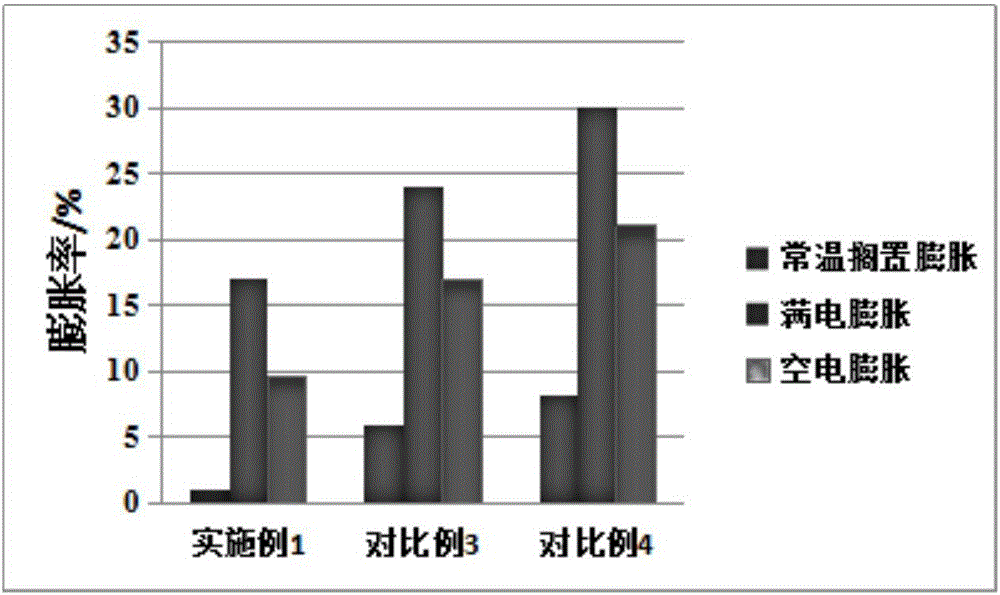

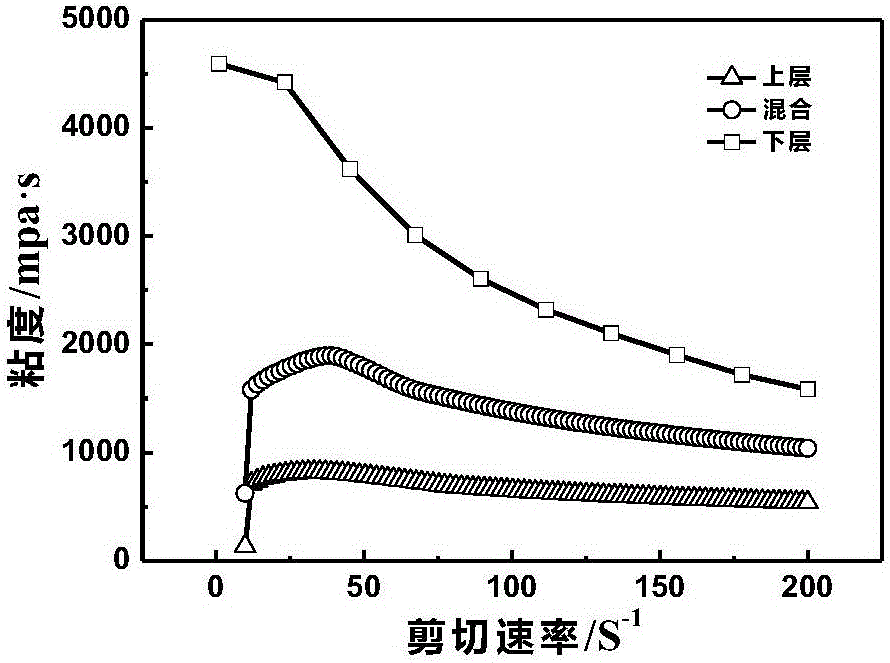

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

Low Surface Friction Proppants

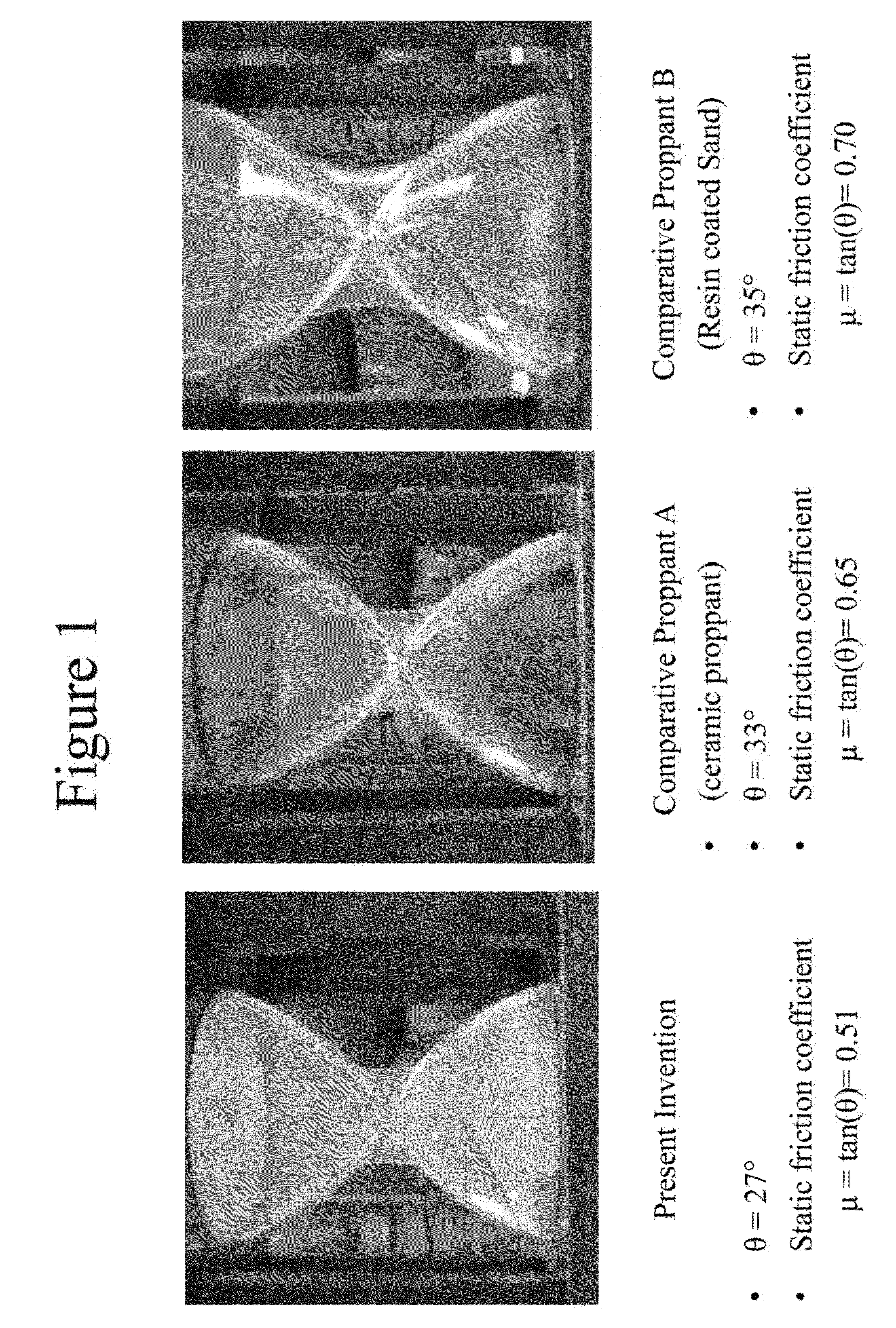

ActiveUS20130014945A1Overcome disadvantagesReduce surface frictionFluid removalFlushingMaterials scienceHydrocarbon

A proppant having low surface friction is described, which is useful in hydrocarbon recovery. Methods of making low surface friction proppants are further described, as well as uses thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

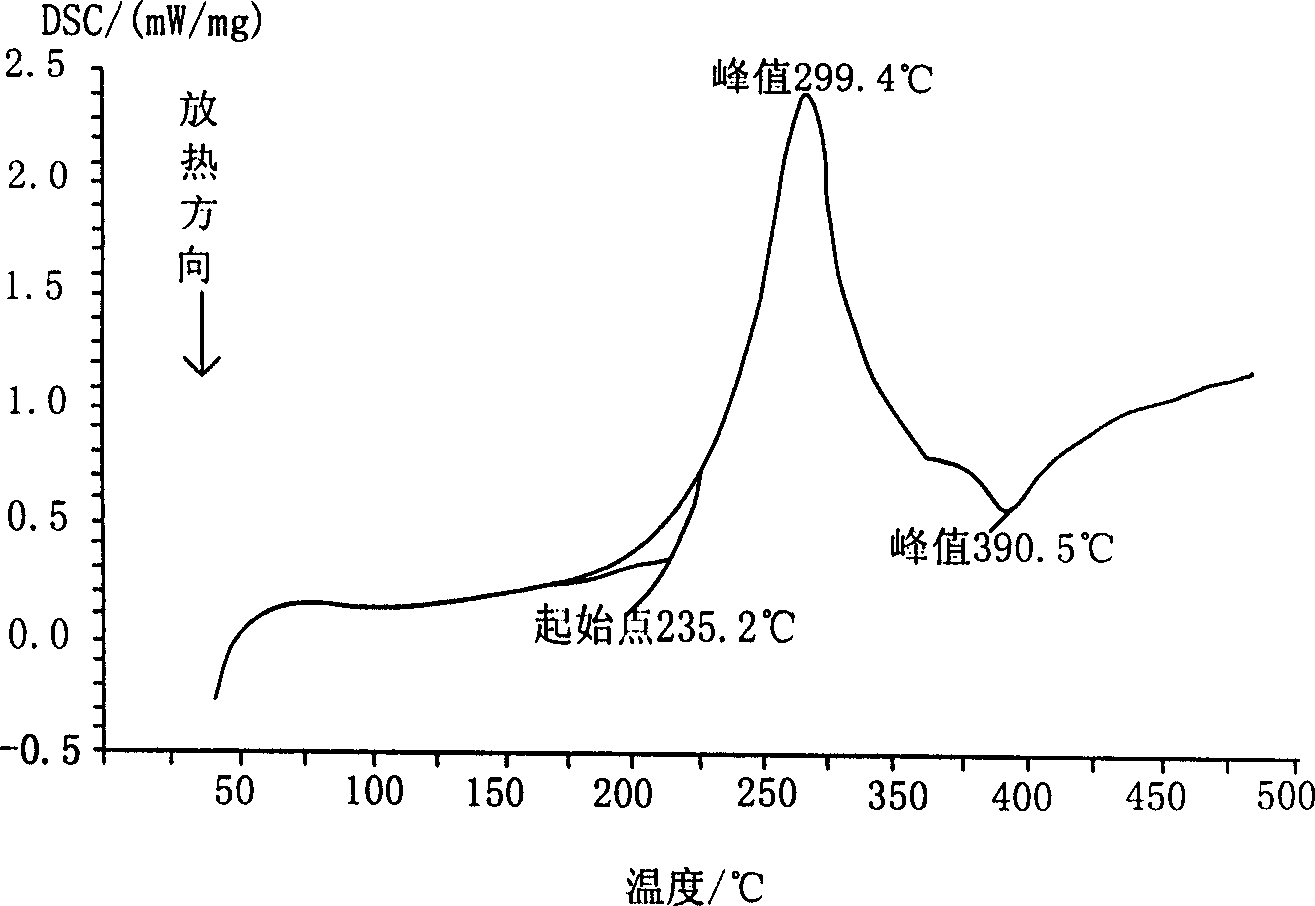

Leadless high-temperature electronic solder and preparation

InactiveCN101239425AHigh melting temperatureImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaRare earthHigh temperature electronics

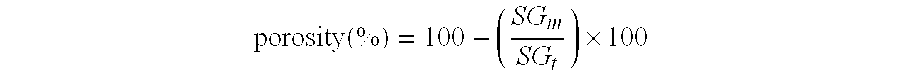

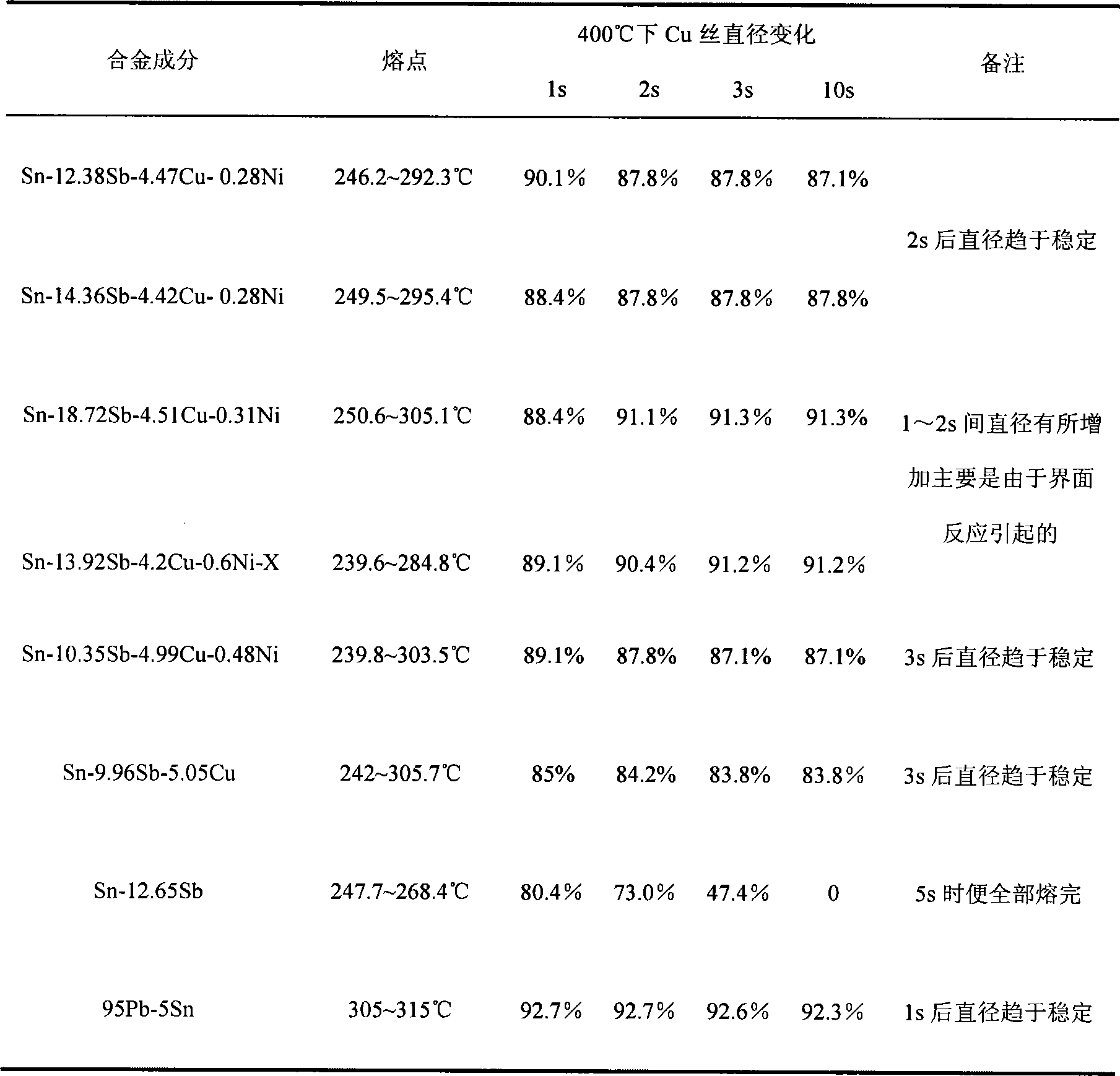

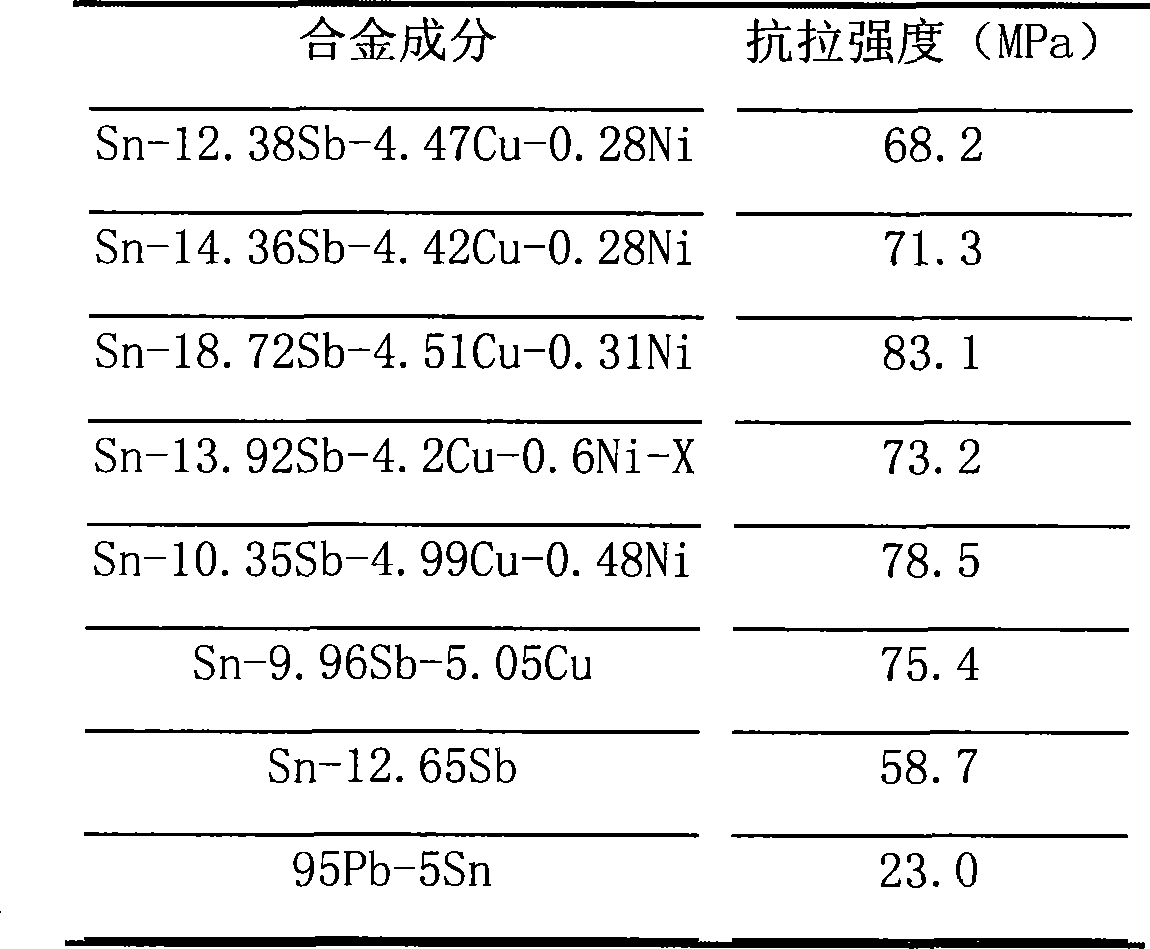

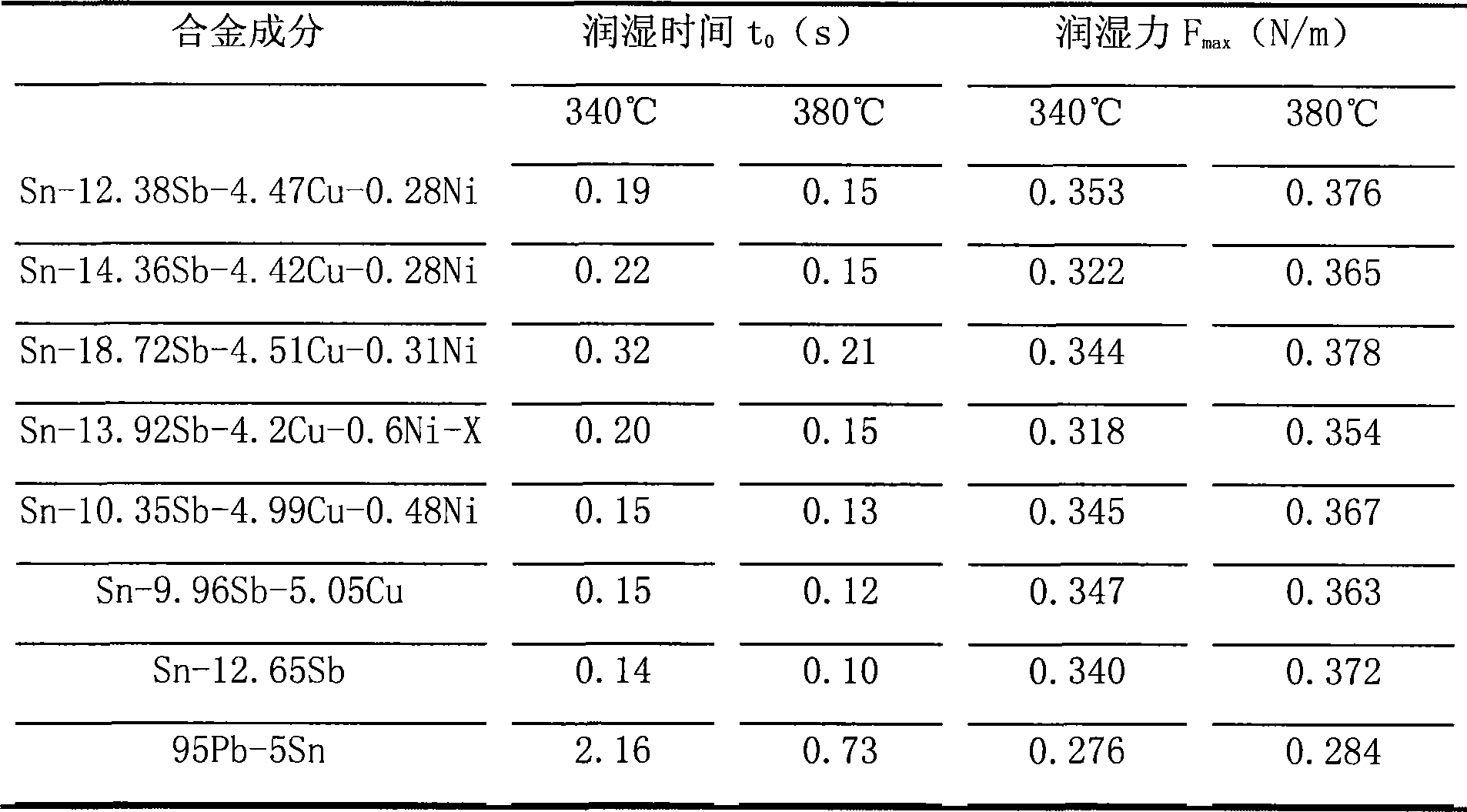

A leadless hyperthermia electronic solder and preparing method thereof are disclosed. The solder is composed of alloy elements according to flowing percentage by weight: 10-224546014f Sb, 1-84550160f Cu, 0.01-224446740f Ni, 0-0.012f X, residue percent of Sn; wherein X represents zero species, one species or composition of optimal several species of Ga, P and mixed rare earth; the fusion point of the solder is between 240 DEG C to 320 DEG C, the tensile strength is 58-84MPa; the preparing method of the solder is: thermal insulating the prepared each alloy element at a temperature ranging from 850 DEG C to 900 DEG C for 1-2 hours by using a vacuum melting furnace or an antivacuum smelting furnace to melt them sufficiently, and mixing them sufficiently before discharged from the furnace, pouring, solidifying to obtain the solder; the solder is made into at least one of solder master alloy, solder block, soldered ball, soldering ring, soldering foil, soldering powder or soldering cream; the solder is provided with a higher fusion point to improve the fusion activity of solder, enhanced credibility of device, good antioxidant ability and excellent humectation performance.

Owner:ZHEJIANG METALLURGICAL RES INST

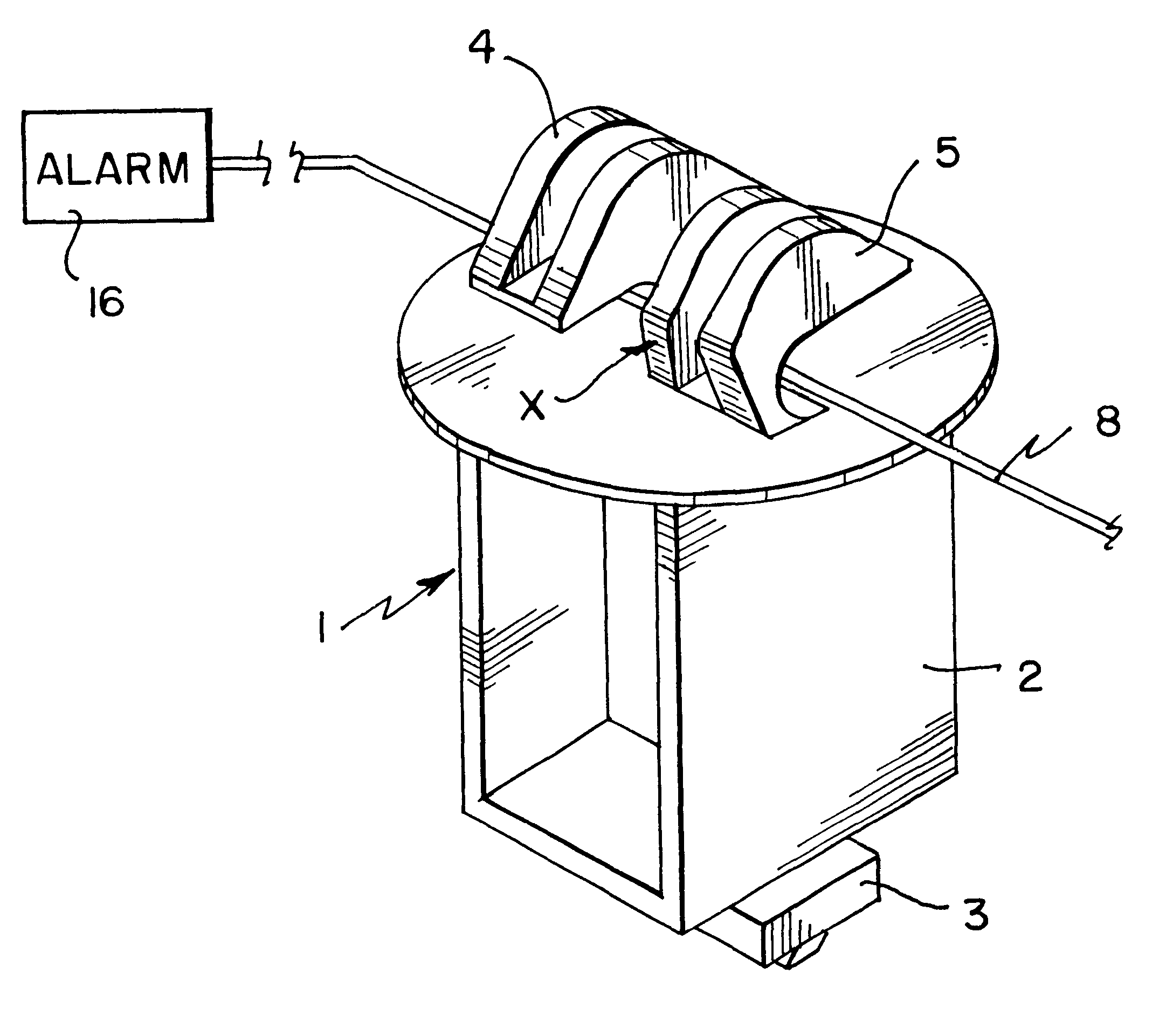

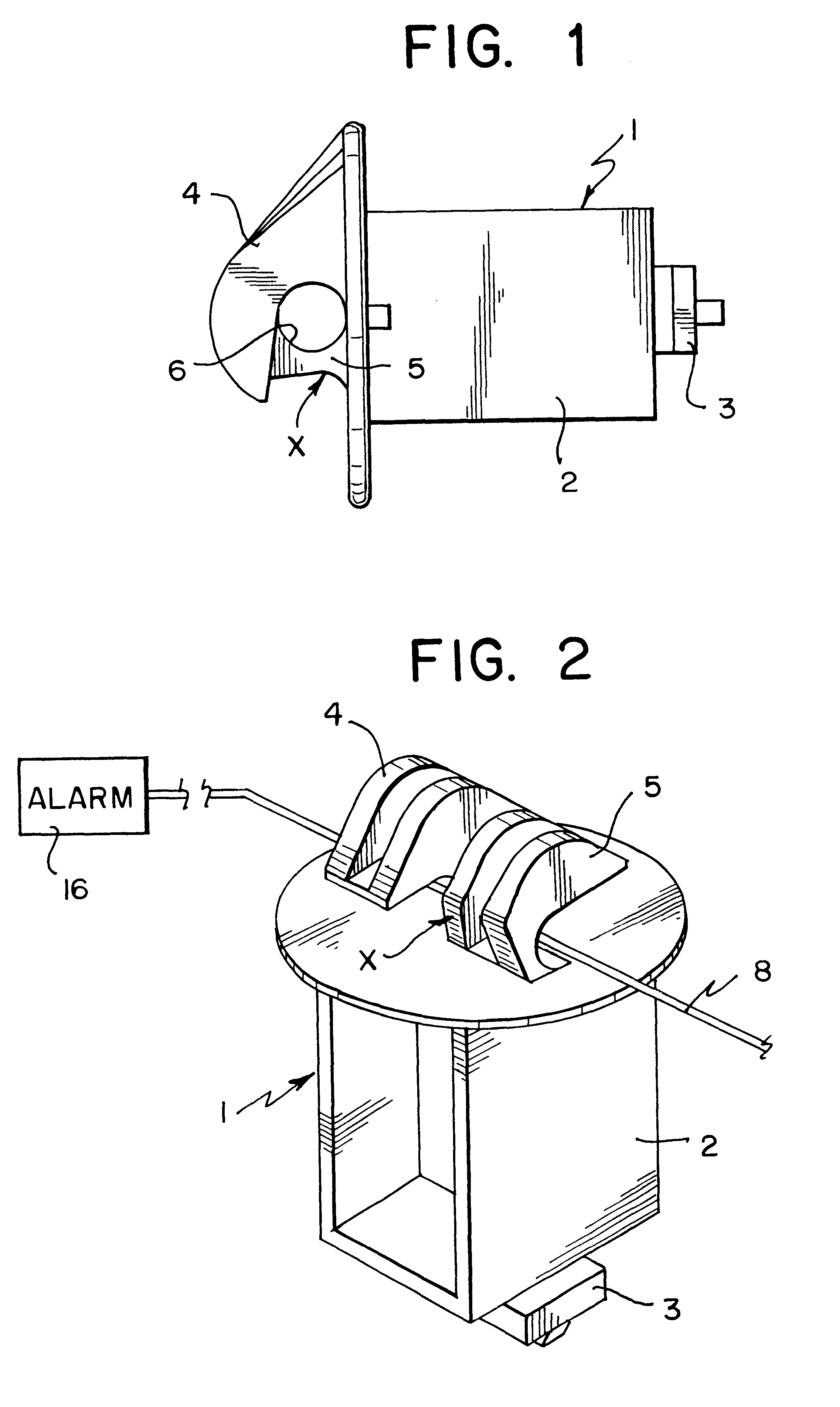

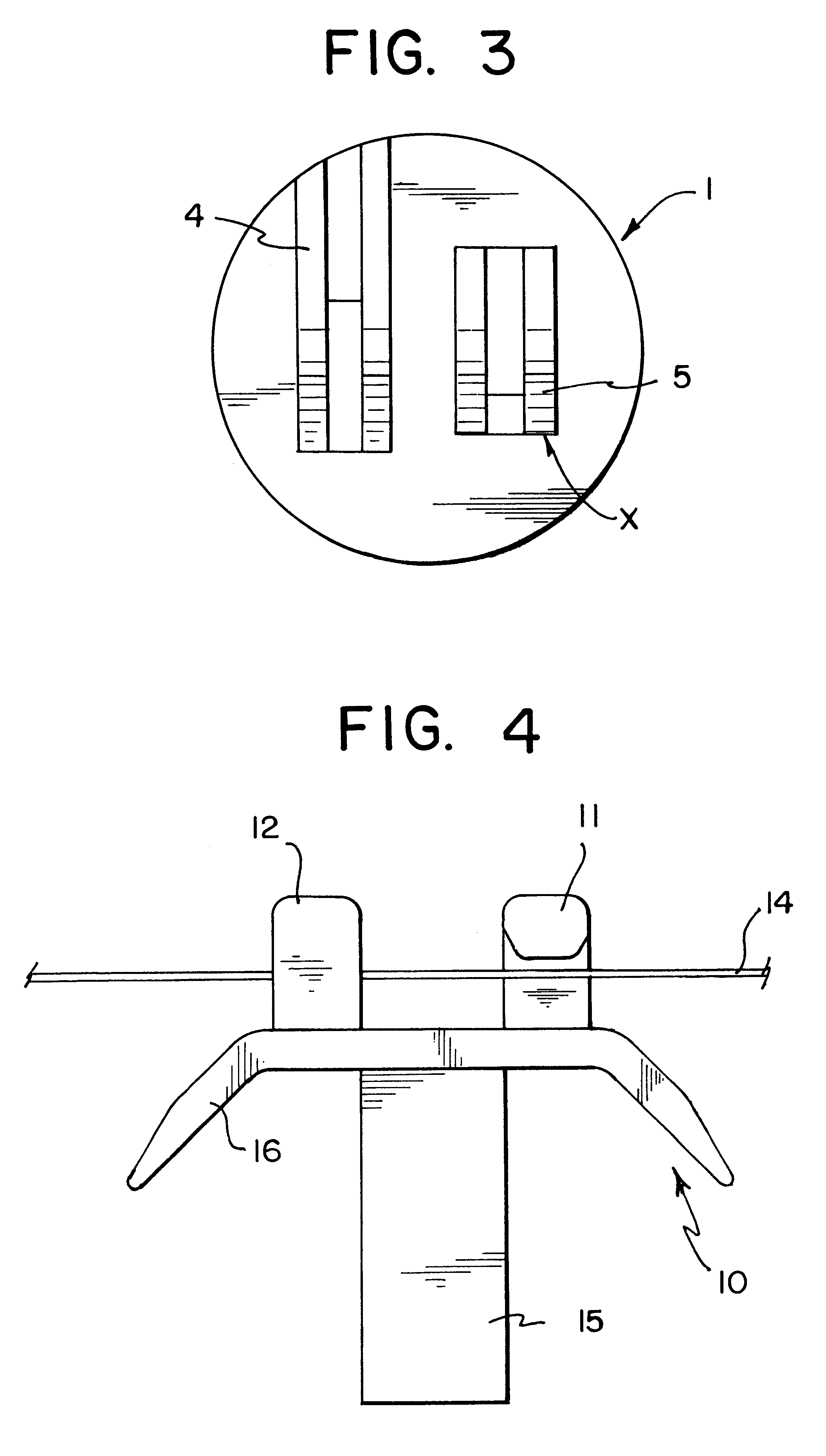

Support device

InactiveUS6290190B1Reduce tooling costsReduce supportPipe supportsPasturing equipmentMechanical engineeringInitial load

A support device (1) for supporting a length of material (8) wherein the support device includes: at least one support finger (4,5) for supporting the length of material (8) which applies an initial load to the support finger (5); the support device characterised in that the support finger (5) no longer supports the length of material (8) when the support finger is placed directly or indirectly under a load substantially greater than the initial load.

Owner:GALLAGHER ELECTRONICS LTD CO

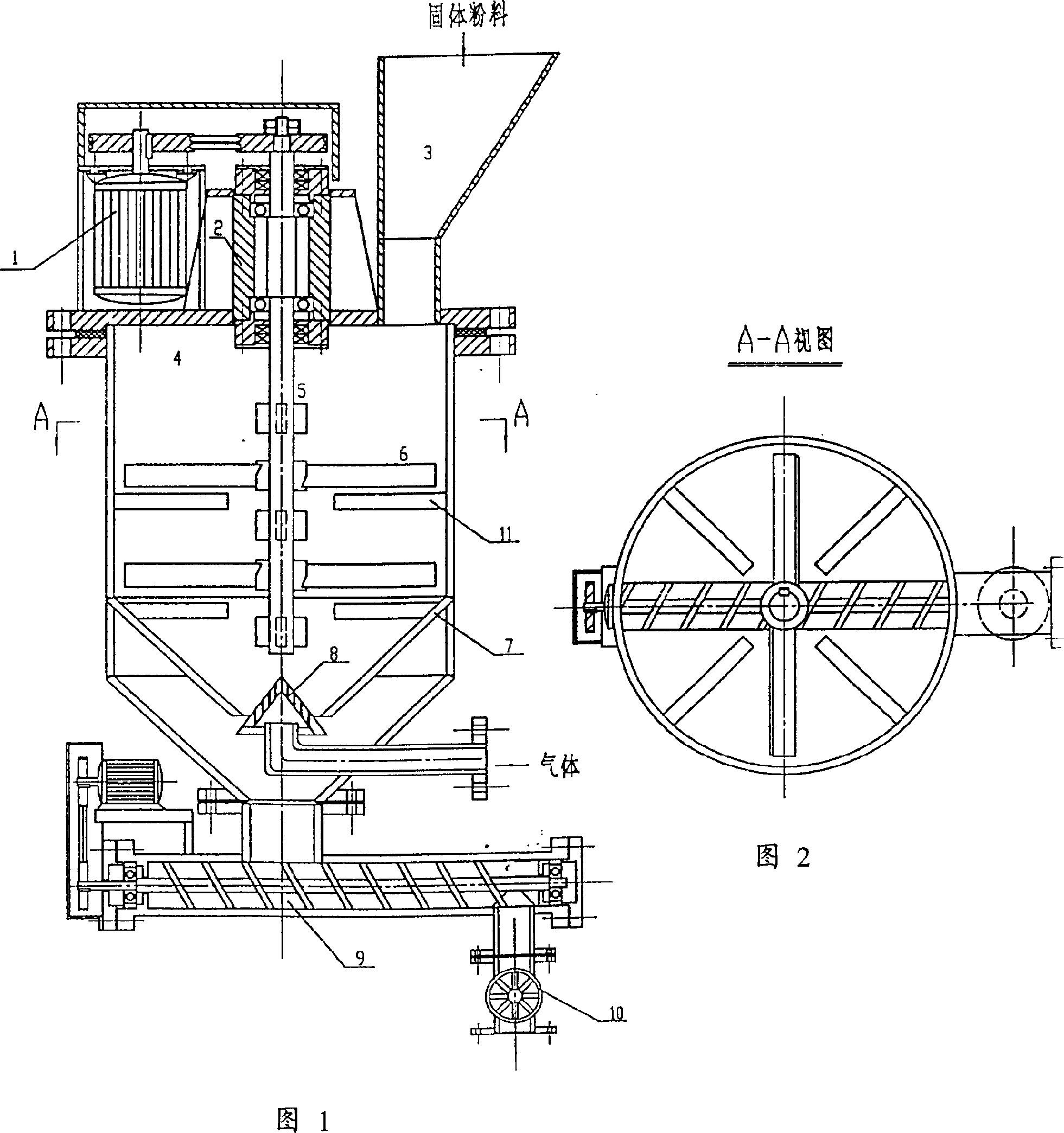

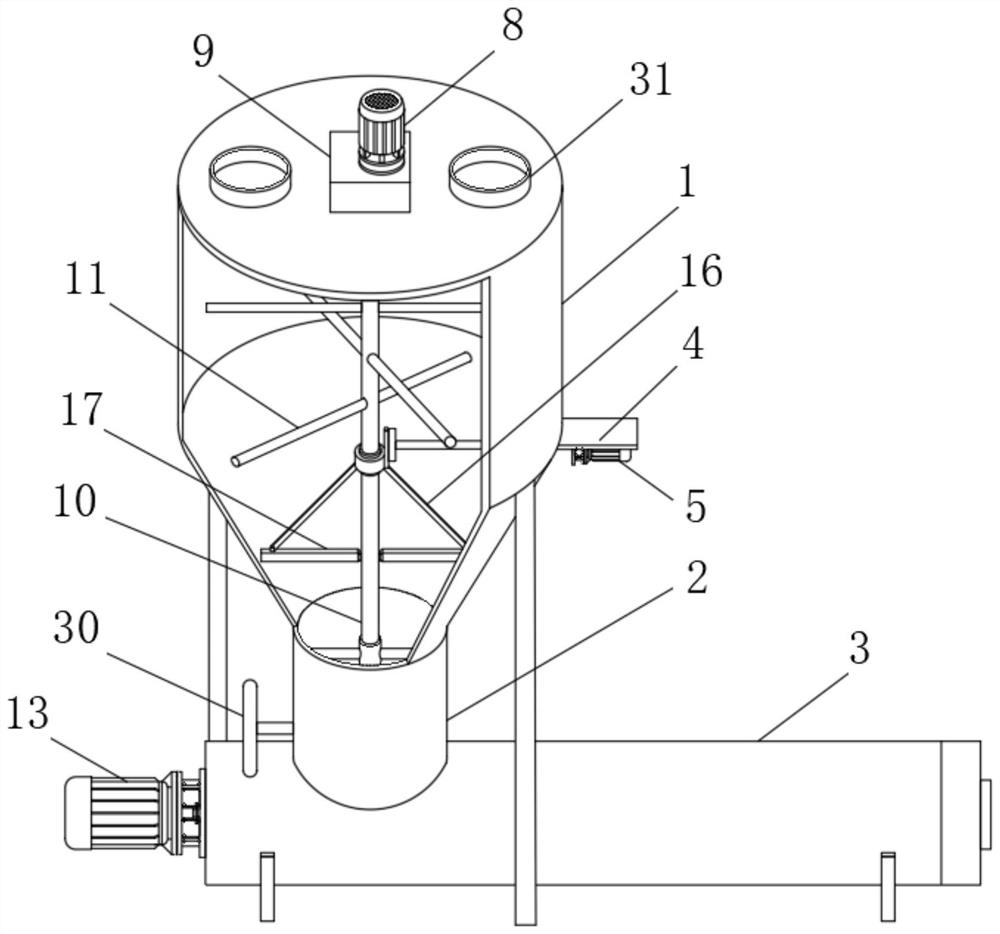

Gas-solid reactor

InactiveCN1448211ATake advantage ofImprove mass transfer conditionsMixing gases/vapours with solidsGas solidSpool valve

The gas-solid reactor includes the main parts of main body, solid feeding port, tail gas exhausting port, stirring shaft, stirring blades, truncated cone solid discharger, turned conic gas distributor, screw conveyor, air sealed slide valve and baffle. The main body includes cylindrical upper part and conic lower part; the solid feeding port and the tail gas exhausting port are in the top of thereactor; the stirring shaft with fixed stirring blades is perpendicular to the central axis of the reactor; the inner wall of the reactor has one or several layers of baffles set; the solid discharger is in the lower part of the reactor; the gas distributor with homogeneously distributed holes is below the solid discharger; and the bottom of the reactor is connected to the screw conveyor; and theslide valve is set on the material discharging pipe of the screw conveyor.

Owner:CHINA PETROLEUM & CHEM CORP +1

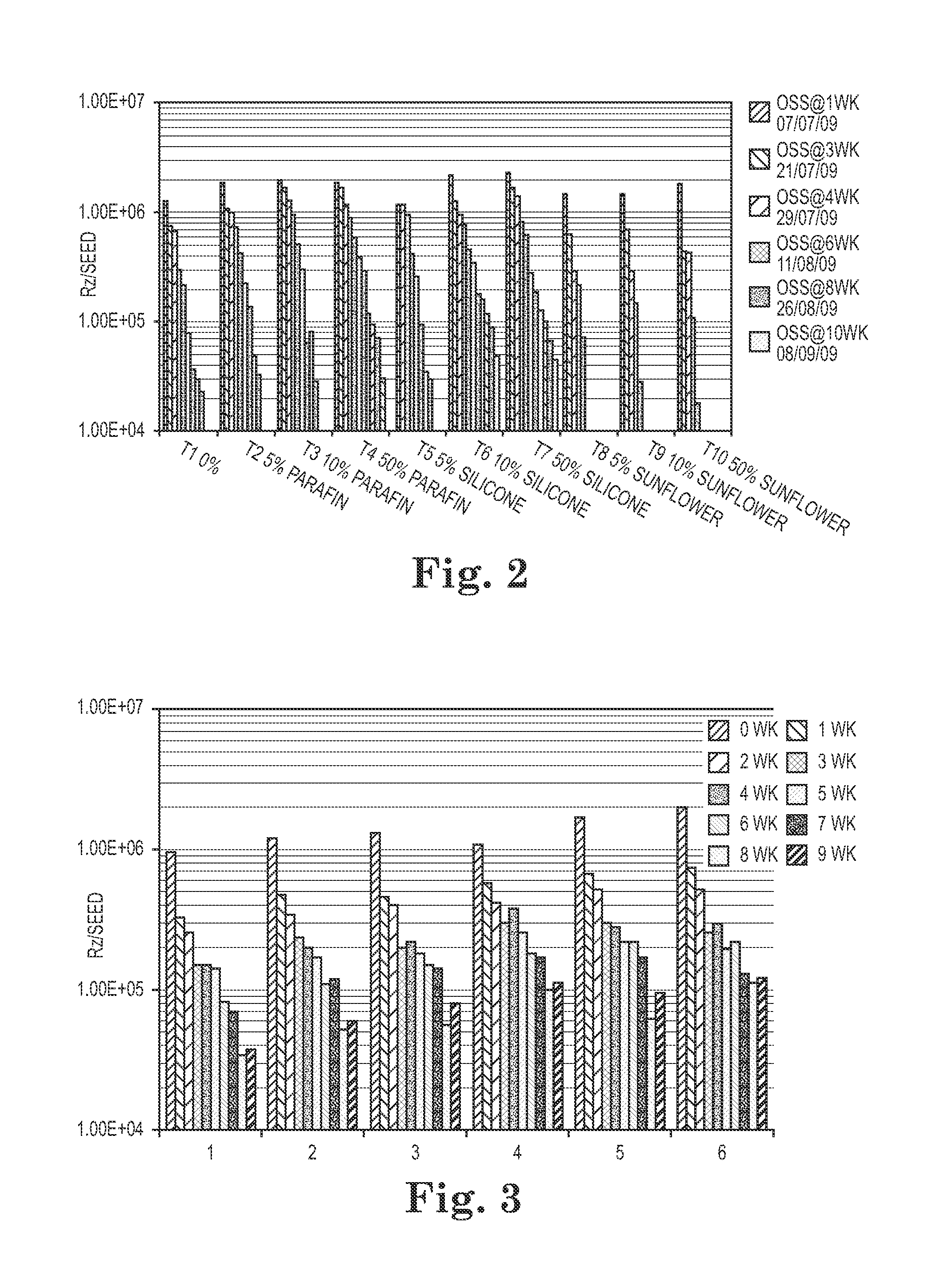

Methods and compositions for reducing seed bridging

ActiveUS20120208699A1Reducing seed bridgingImprove survivabilityBiocidePlant growth regulatorsBiotechnologySurvivability

The various embodiments disclosed herein relate to methods and compositions for reducing the bridging of treated seeds, including some that also enhance the survivability of any beneficial microorganisms included in the composition or mixed therewith and / or enhance the yield of the plants that grow from the seed to which the treatment is applied. The various compositions can include sugar and oil, while other embodiments include sugar, oil, and an emulsifying agent, and certain embodiments include sugar, oil, and at least one microorganism. In various embodiments, the oil can be, for example, a heavy lubricating oil such as mineral oil or silicone oil, and the sugar can be, for example, a non-reducing sugar.

Owner:BECKER UNDERWOOD

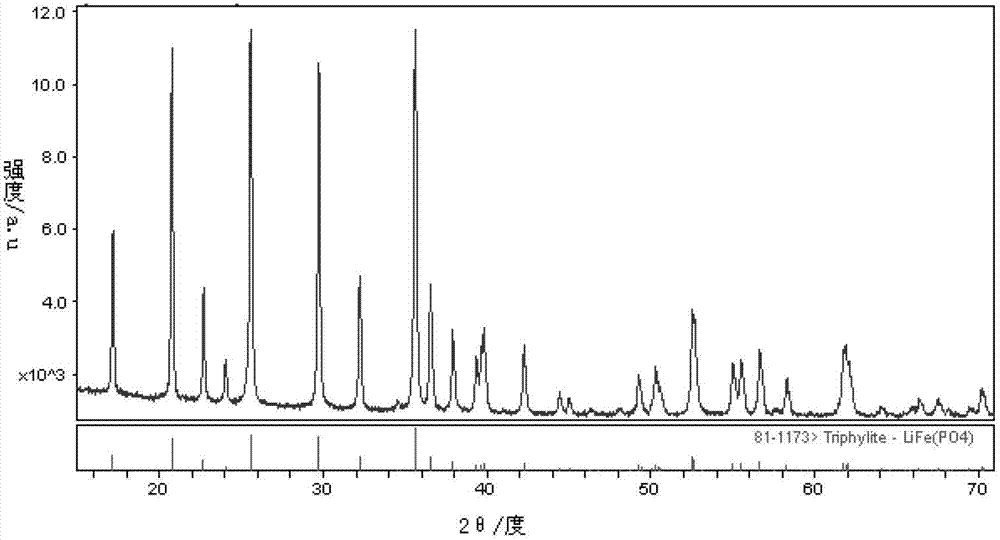

Preparation method of high-vibration-compaction low-specific-surface-area lithium iron phosphate made by positive pole material

ActiveCN102969502AHigh bulk densitySmall specific surface areaCell electrodesPhosphorus compoundsDoped oxideMaterials processing

The invention relates to a preparation method of high-vibration-compaction low-specific-surface-area lithium iron phosphate made by a positive pole material, and relates to lithium ion. The preparation method comprises the following steps of: mixing a lithium source compound, an iron source compound and a phosphorus source compound according to stoichiometric proportion by a watering wet method according to 70%-85% of solid content, adding a metal-ion-doped oxide, a primary carbon source and a dispersant agent, uniformly mixing, and carrying out spray granulation after a ball mill treatment, thus obtaining a dry powder body; pretreating the dry powder body in an inert atmosphere, adding water according to 70%-85% of solid content after cooling the dry powder body, meanwhile, adding a secondary carbon source and the dispersant agent, and uniformly stirring, thus obtaining the dry powder body through the ball mill treatment and the spray granulation; and carrying out the first heat treatment on the dry powder body in the inert atmosphere, and carrying out high temperature treatment and air flow classification, thus obtaining the high-vibration-compaction low-specific-surface-area lithium iron phosphate made by a positive pole material. The processing property of the positive pole material of lithium iron phosphate is obviously improved without influencing other electrochemistry properties.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

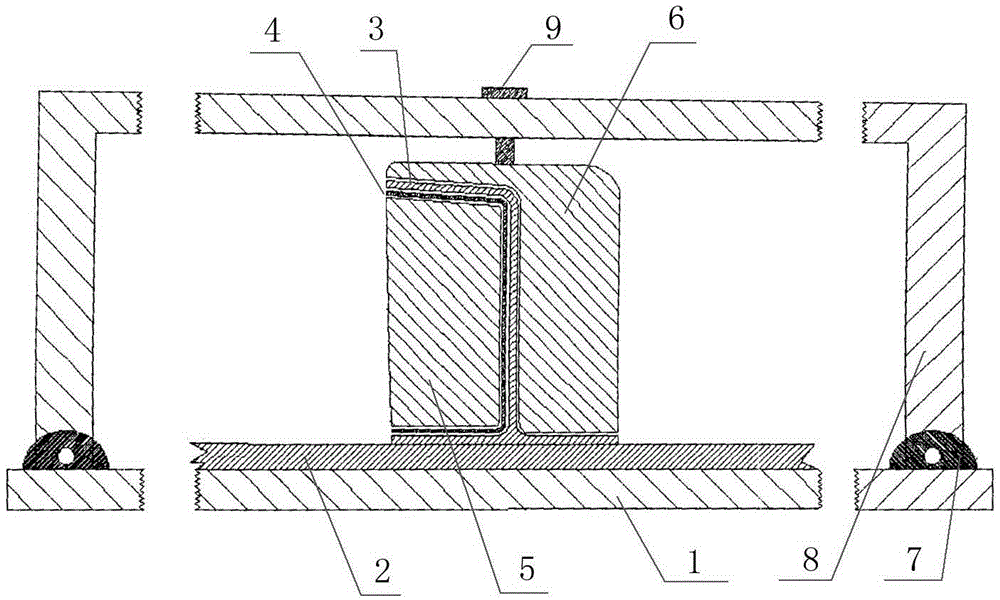

Composite material J type longitudinal wall positioning integral forming tool and forming method thereof

The invention relates to a composite material J type longitudinal wall positioning integral forming tool. A foundation coating is arranged on a coating forming tool. A J type longitudinal wall is arranged in the designated position on the upper surface of the foundation coating. An inner longitudinal wall forming tool is arranged on the inner surface of the J type longitudinal wall through a rubber compensation layer, and the inner form of the J type longitudinal wall is completely filled with the inner longitudinal wall forming tool. The outer surface of the J type longitudinal wall is coated with an outer longitudinal wall forming tool. A cuboid structure without a cavity is formed through the outer longitudinal wall forming tool, the inner longitudinal wall forming tool and the J type longitudinal wall. A positioning beam is connected with the coating forming tool through positioning lug pieces. The positioning beam stretches across the outer longitudinal wall forming tool. The top of the positioning beam is connected with the upper surface of the outer longitudinal wall forming tool through a fixing member. Specific to the structural characteristics of a carbon fiber composite material J type wall, the problems of excursion of the longitudinal wall axis size, rib-line size and longitudinal wall shape in the manufacturing process of the J type wall are solved through the optimal design of an existing tool structure.

Owner:SHENYANG AIRCRAFT CORP

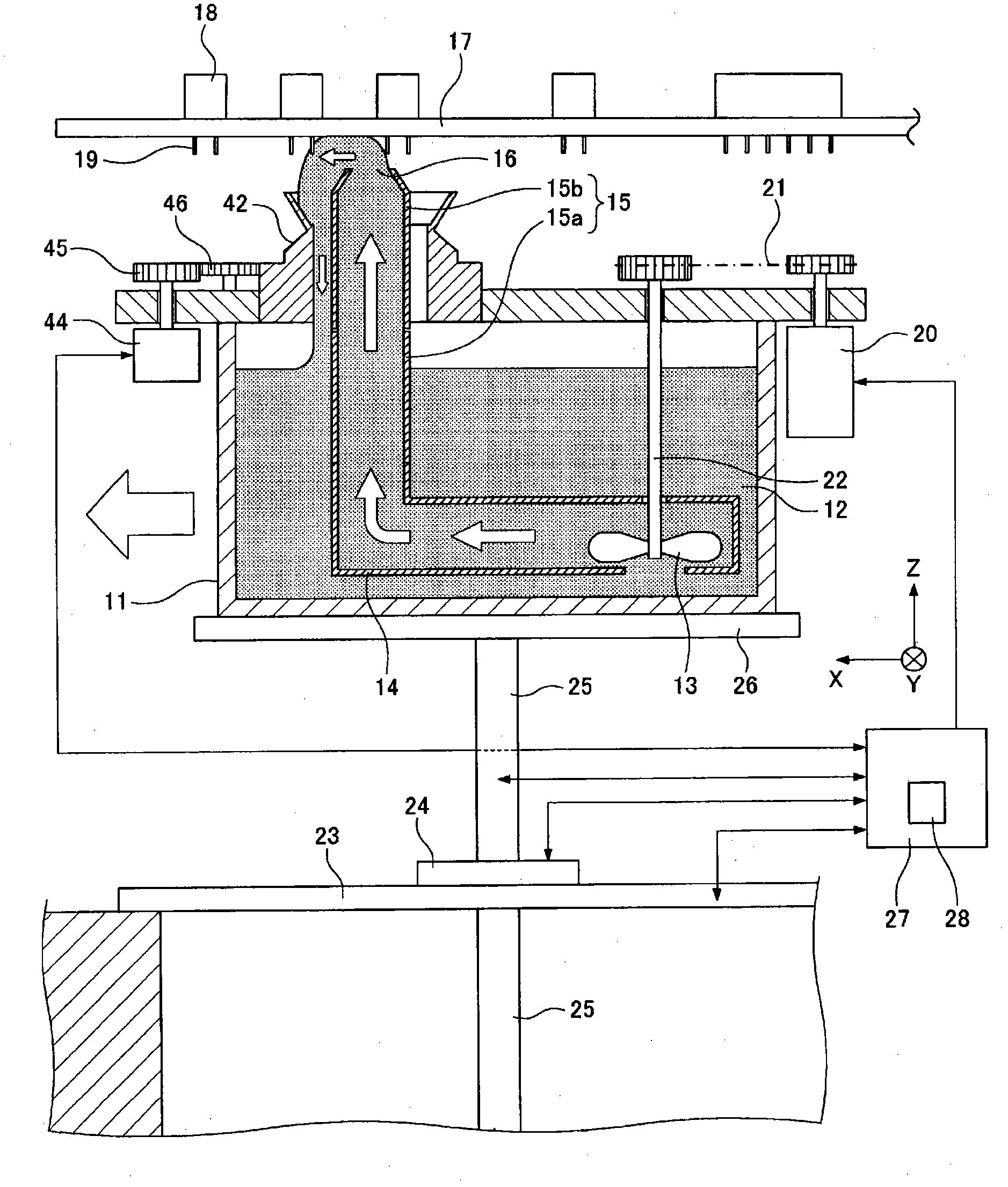

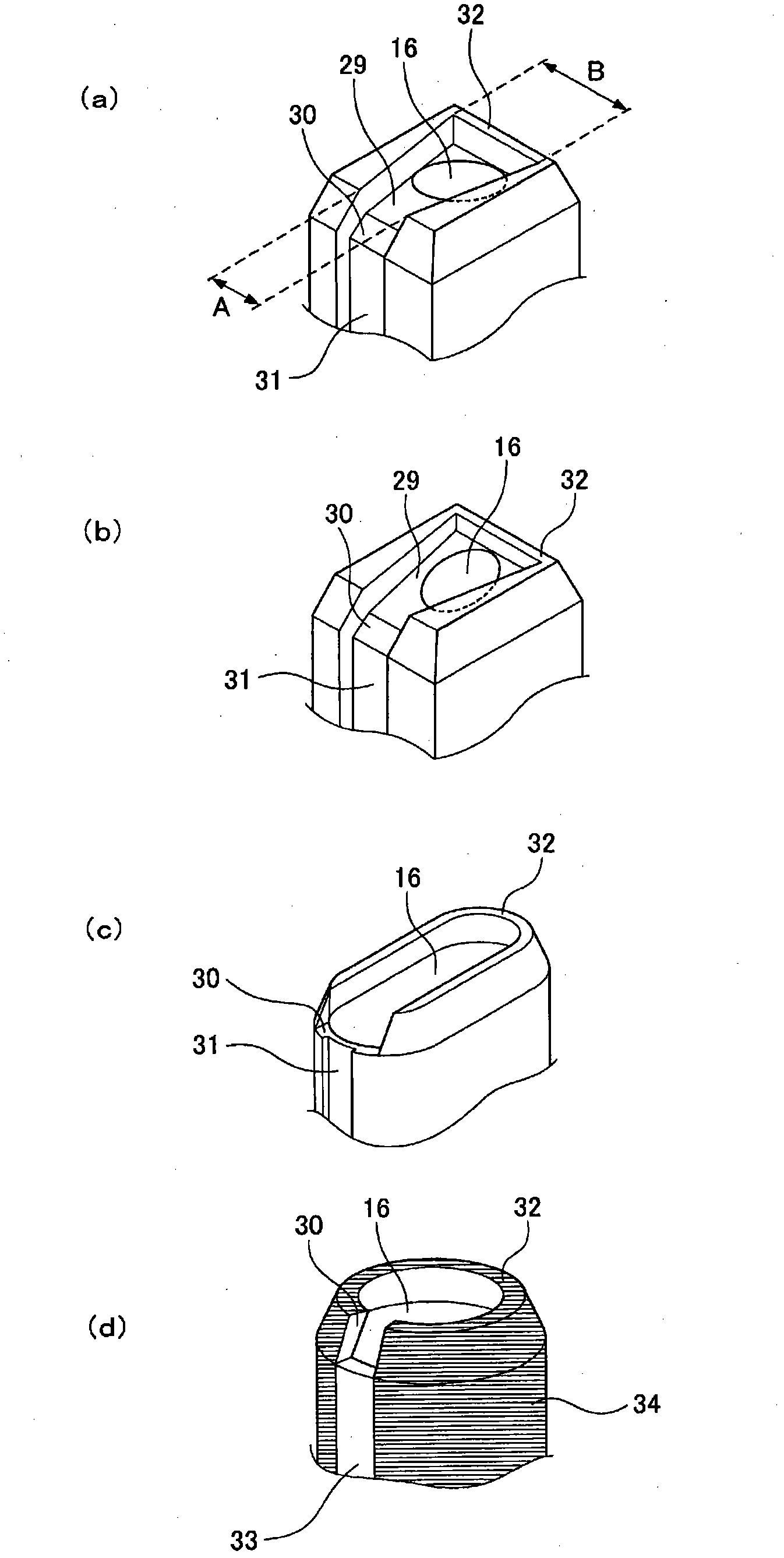

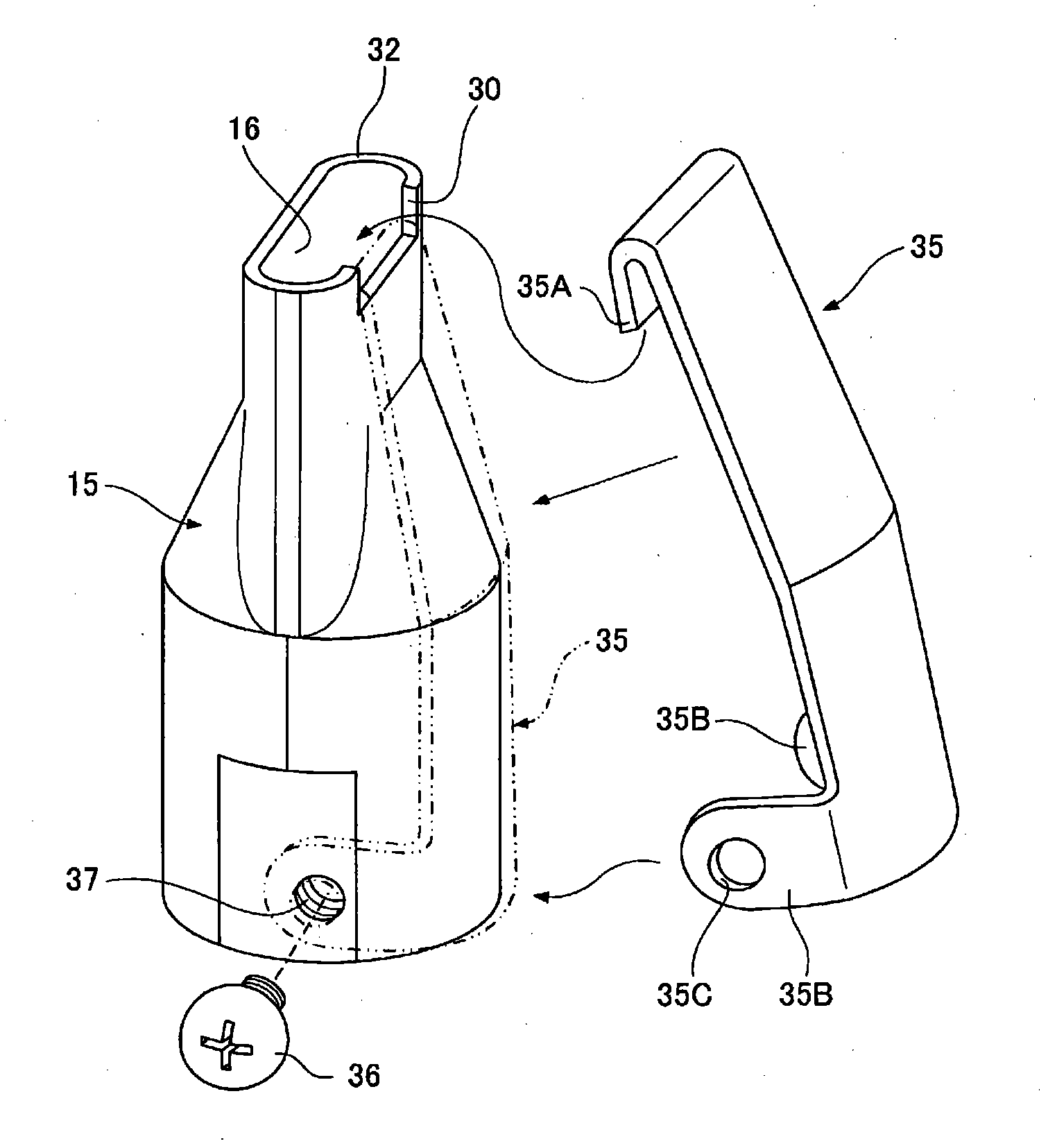

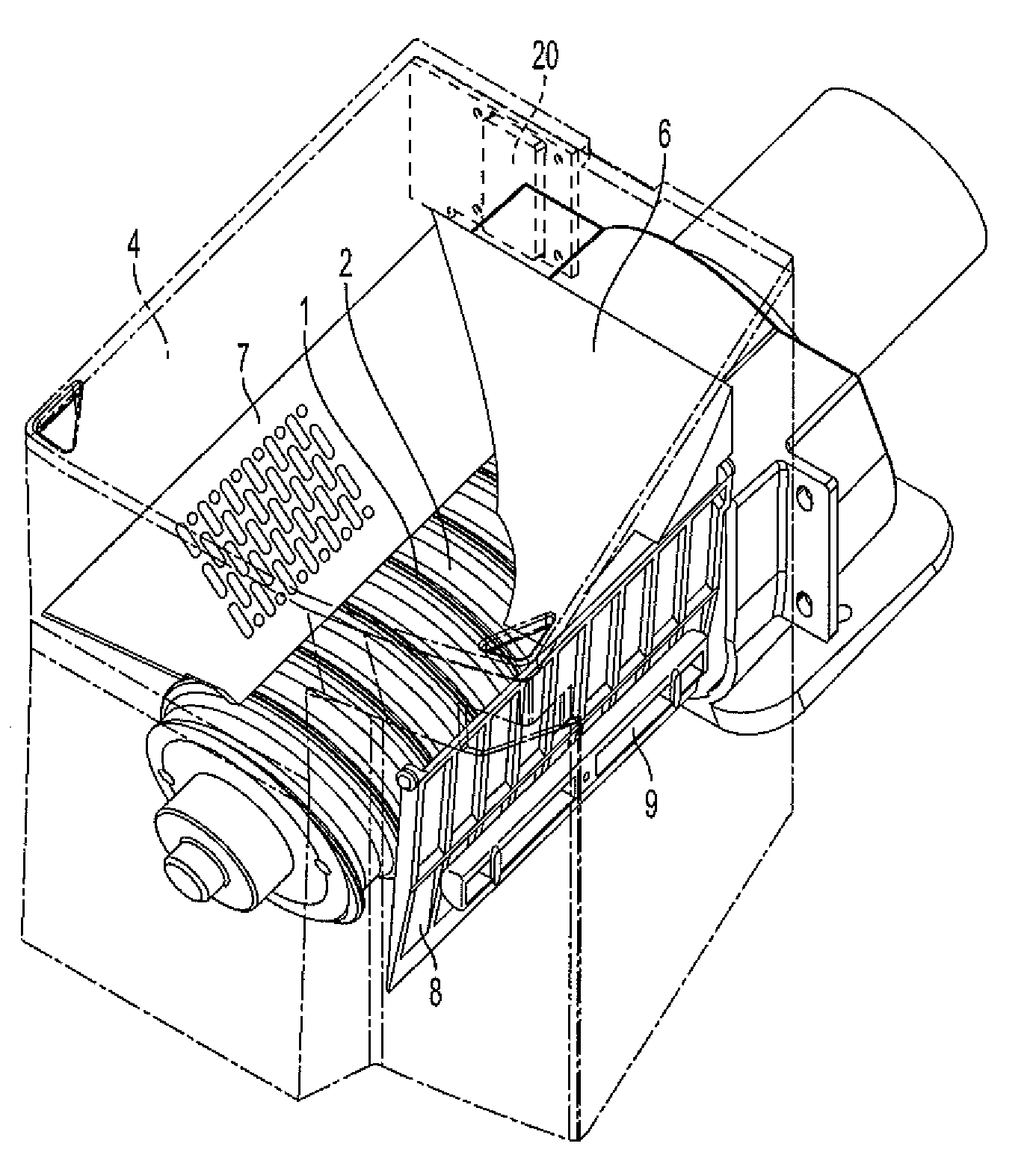

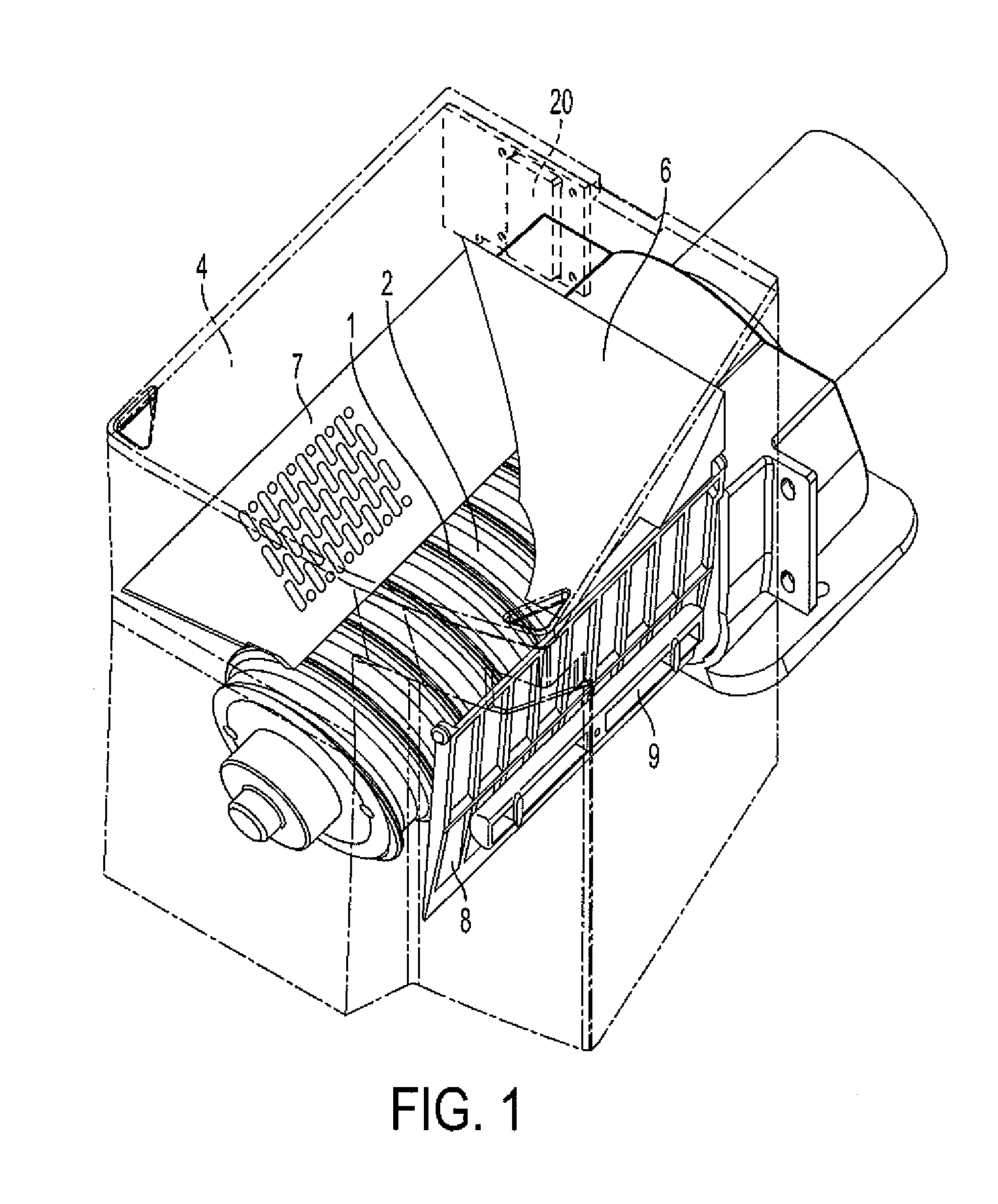

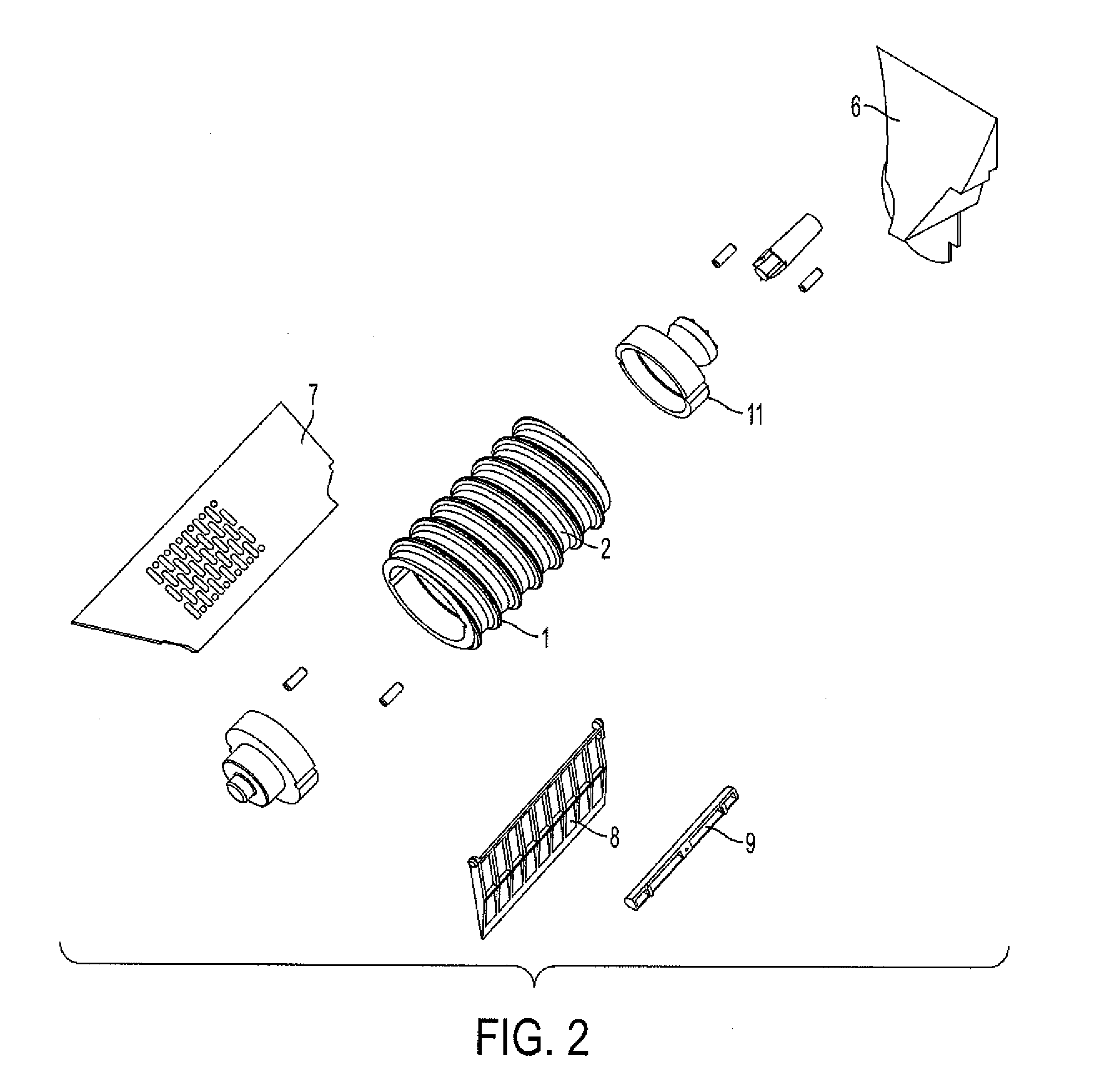

Jet soldering device and soldering method

InactiveCN102326462AReduce bridgingReduce poor brazingPrinted circuit assemblingSolder feeding devicesEngineeringSoldering

Provided is a jet soldering device with which it is possible to reduce problems associated with soldering such as bridging and protrusion formation. The disclosed jet soldering device is characterized by having: a solder bath (11) that stores melted solder; a jet nozzle (15) that comprises an end surface from which the melted solder is ejected, a cutout (30) provided in the aforementioned end surface, and a recovery wall (32) provided in the aforementioned end surface; a solder feeding mechanism (13, 20, 21, 22) that feeds the melted solder stored in the solder bath (11) to the jet nozzle (15); a tank driving mechanism (23, 24, 25, 26) that moves the solder bath (11); a solder receiving wall (42) that surrounds the jet nozzle (15) with a prescribed space therebetween and is connected to the jet nozzle (15); and a rotating mechanism (44, 45, 46) that transmits a drive force from the outside of the solder receiving wall (42) and rotates the solder receiving wall (42) and the adhesion nozzle (15).

Owner:PANASONIC CORP

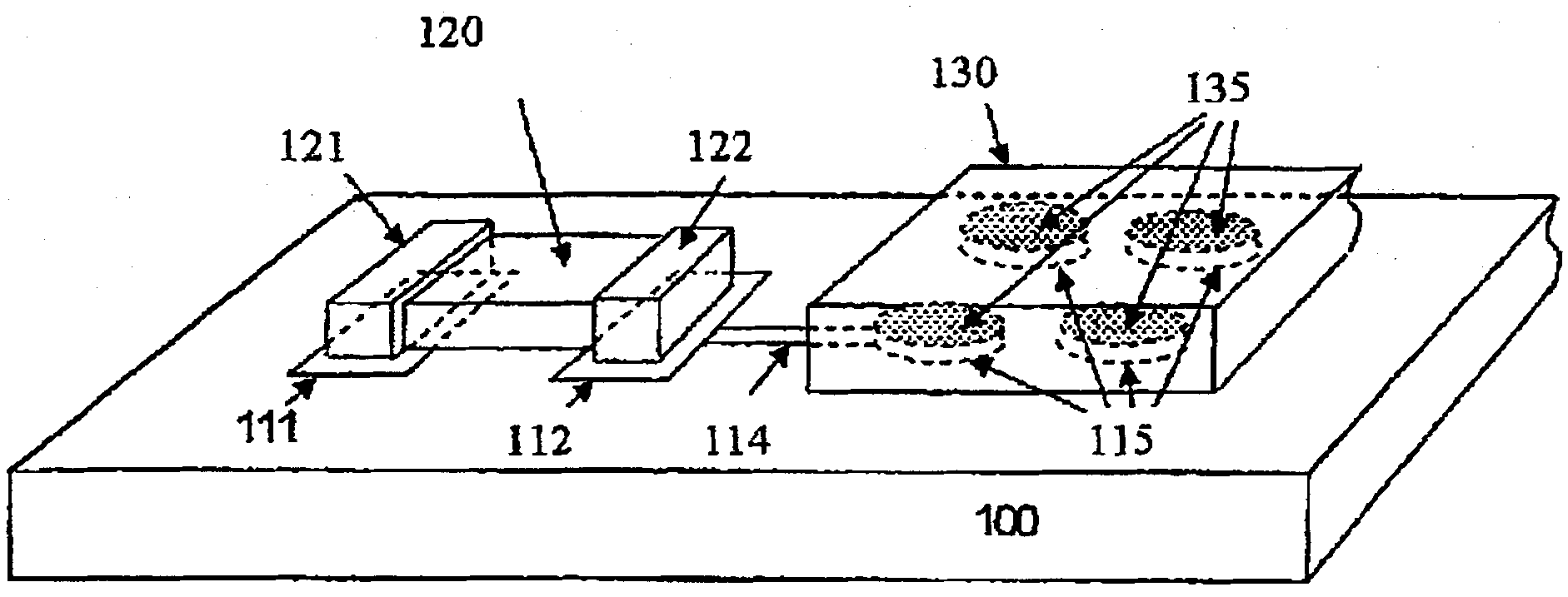

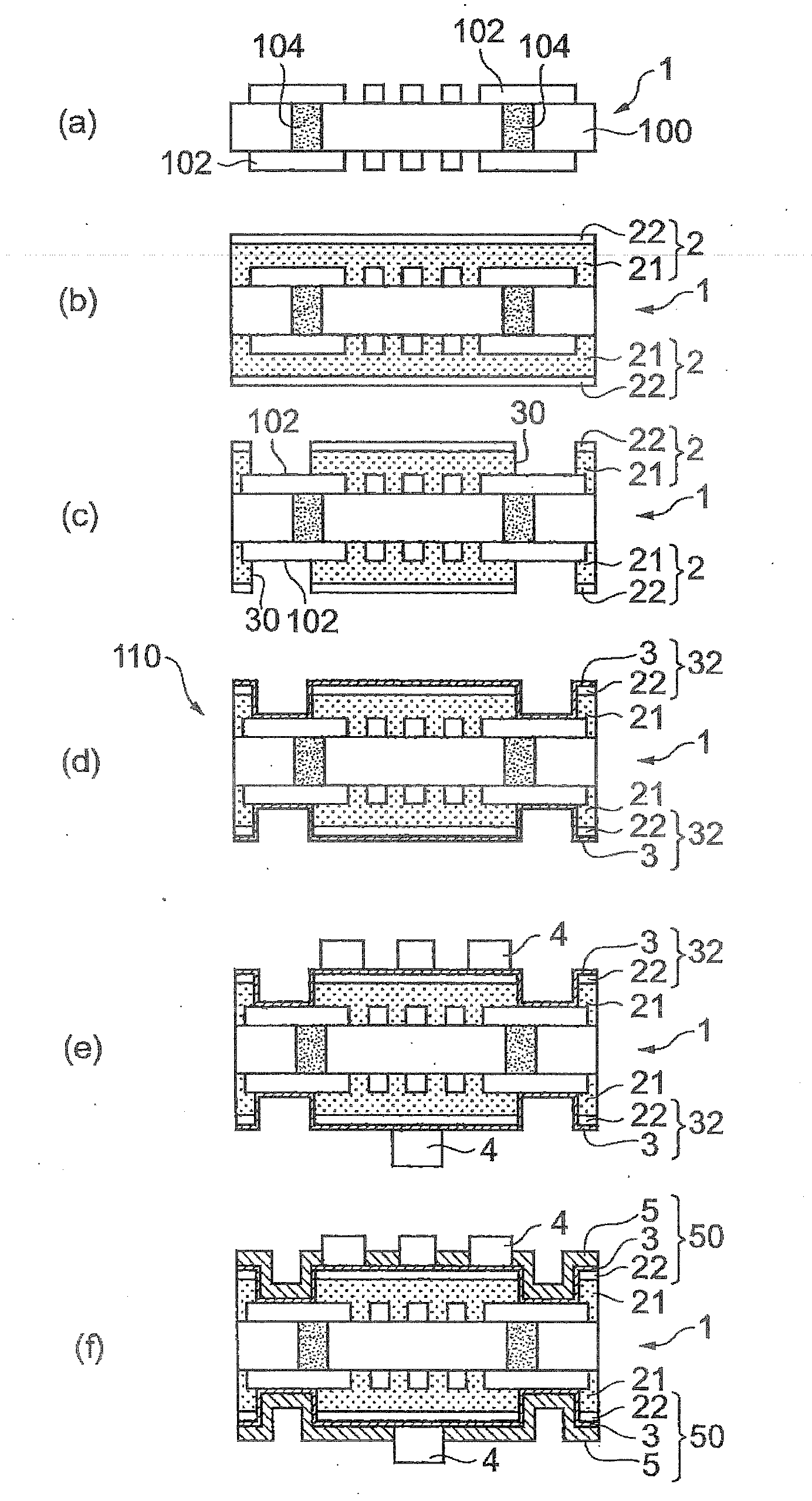

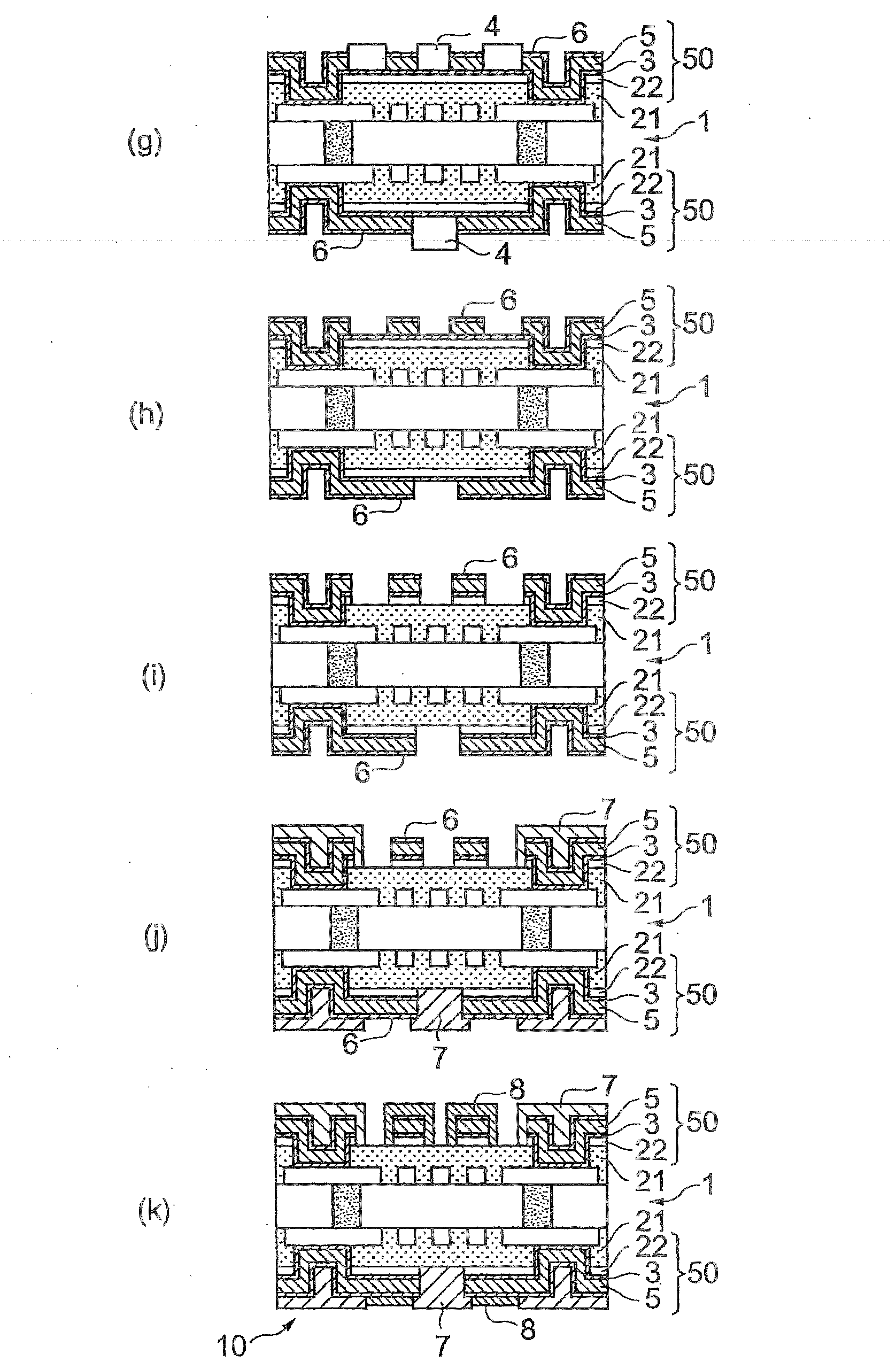

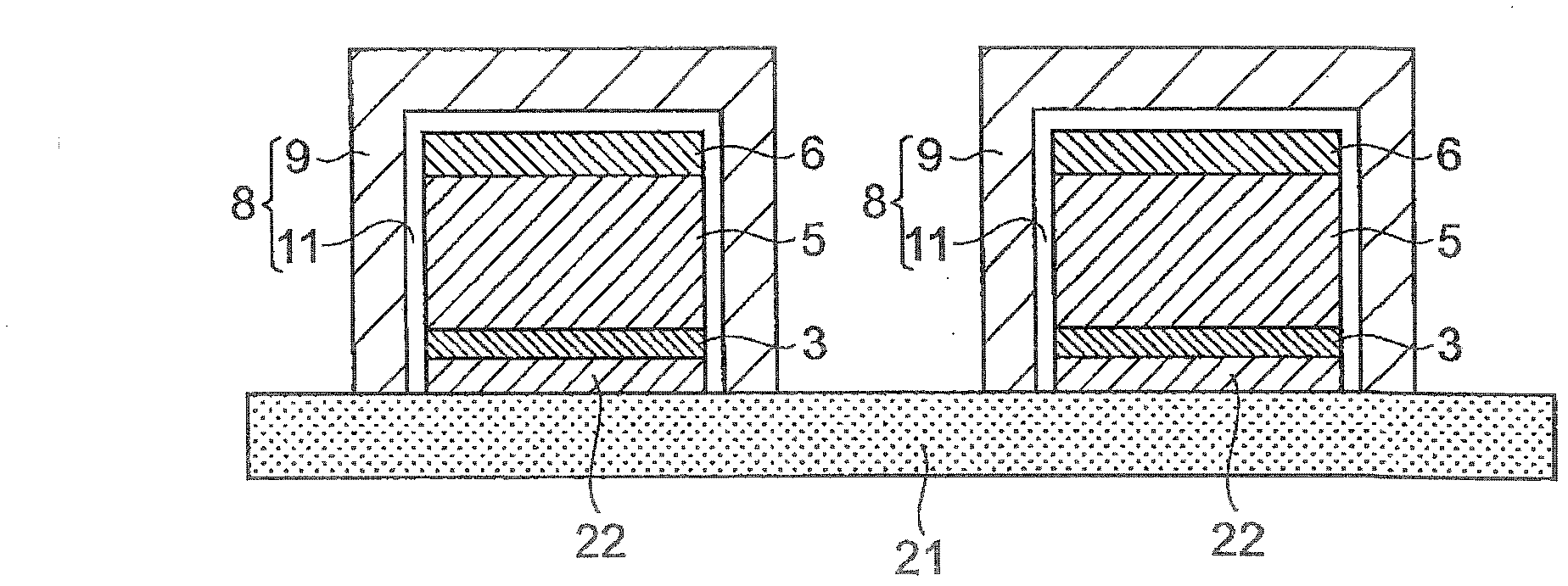

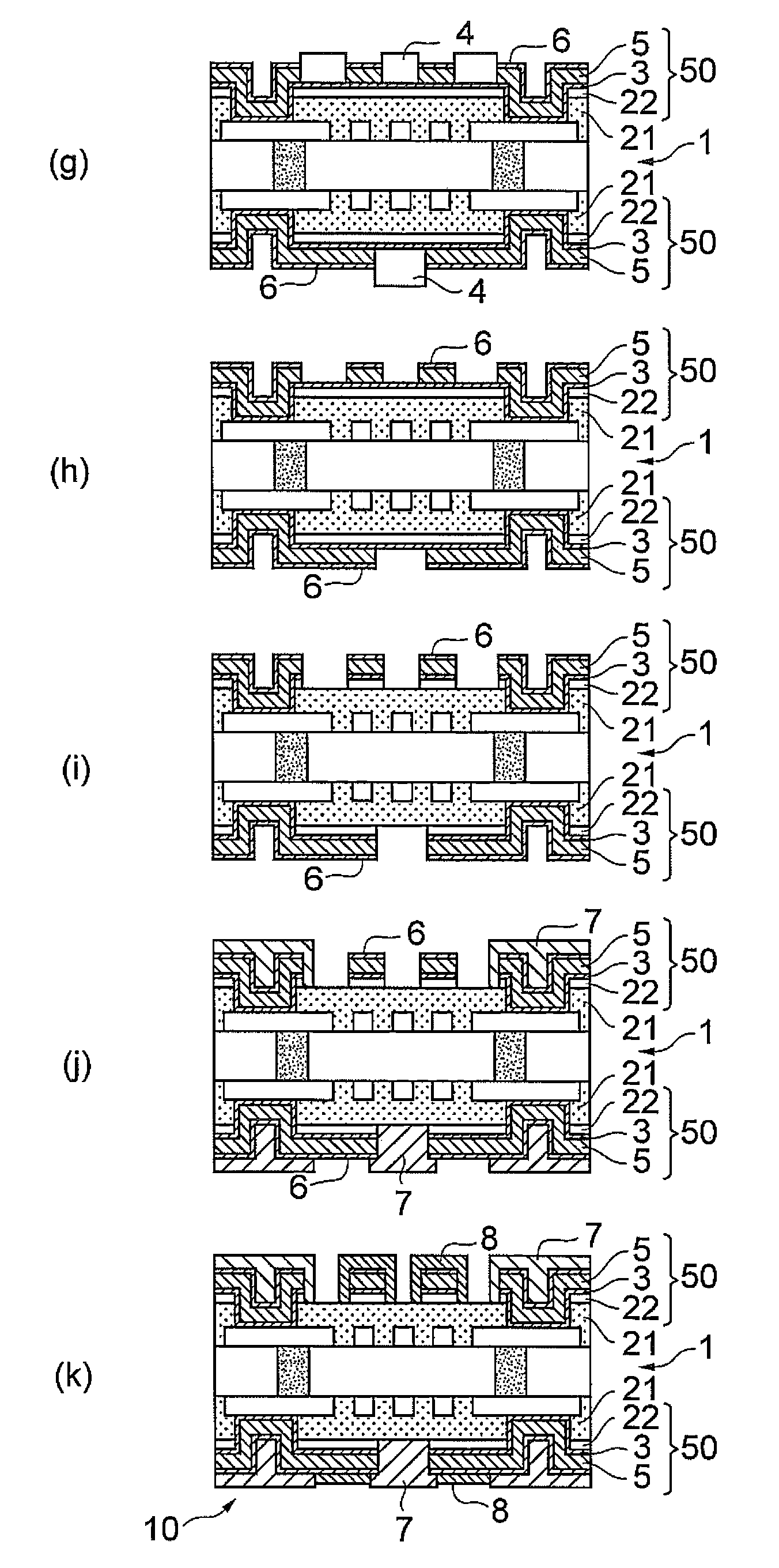

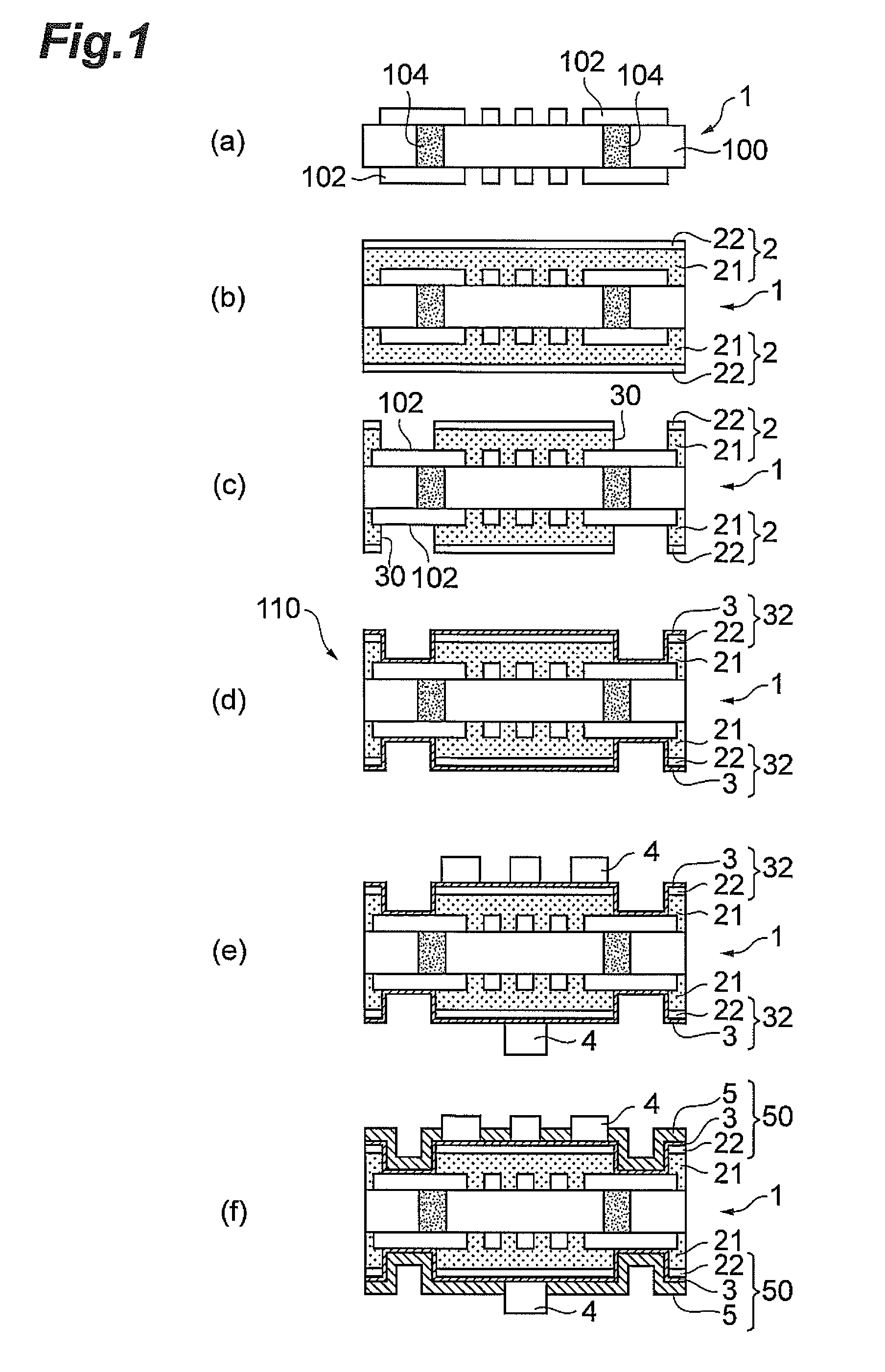

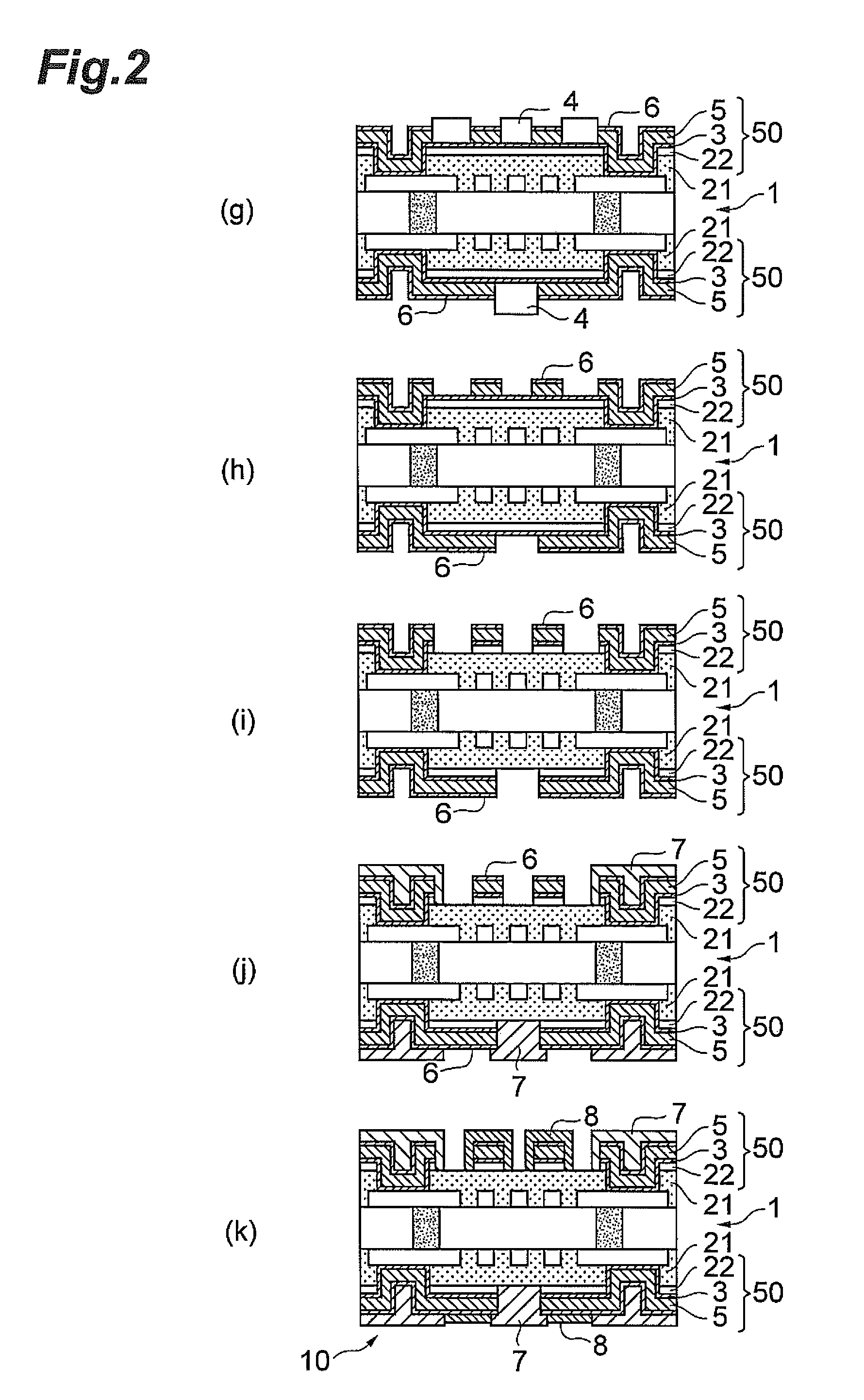

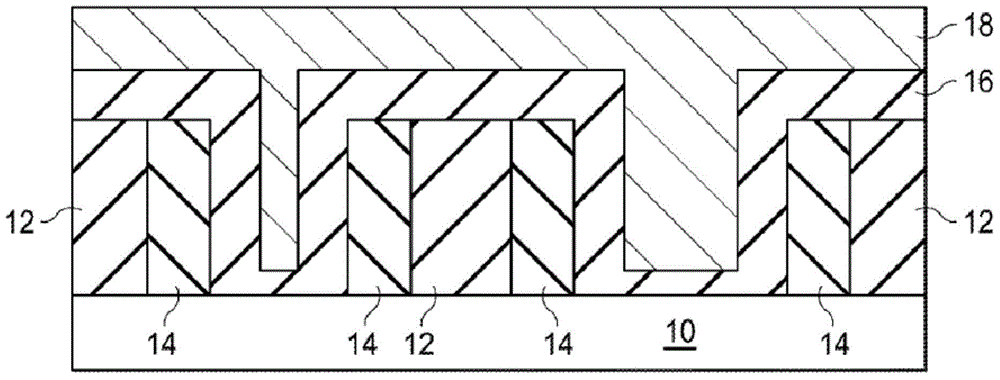

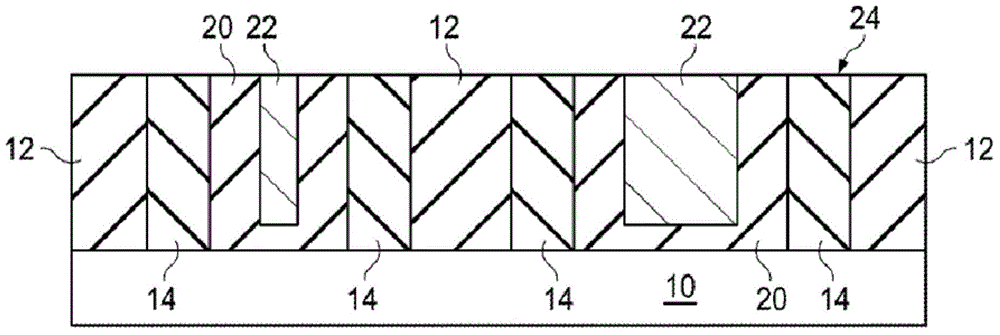

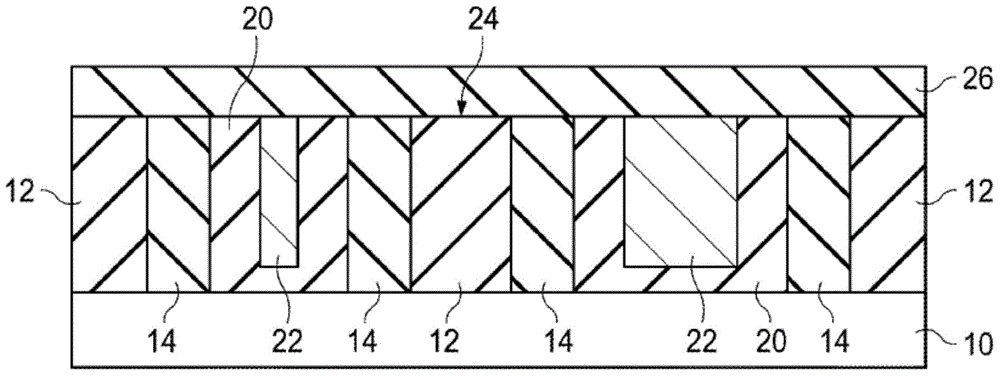

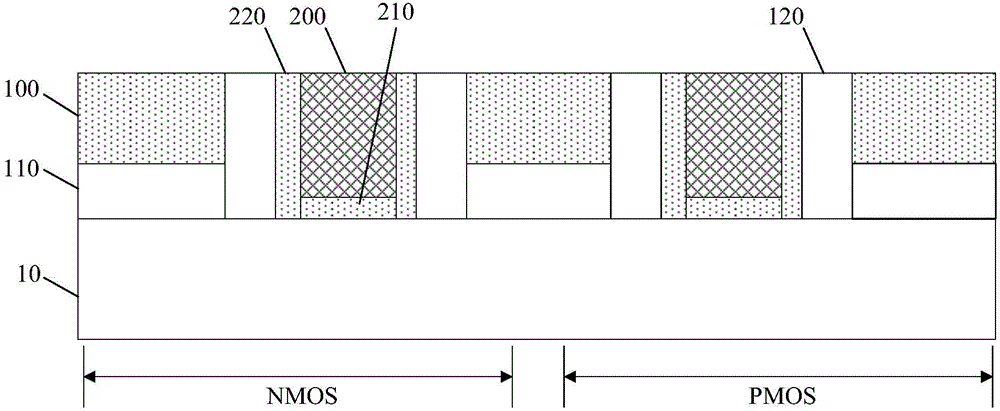

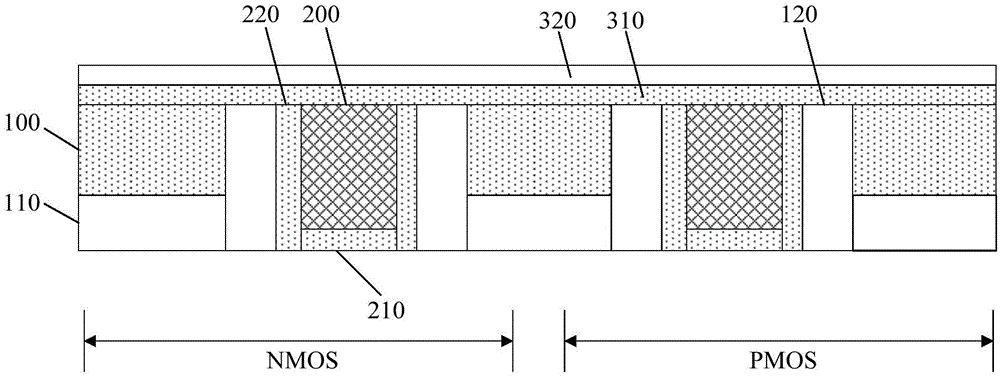

Apparatus and method for vertically-structured passive components

ActiveCN102044531AReduce areaReduces bridging and/or undersolderingSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

A manufacturing technique for constructing passive electronic components in vertical configurations is disclosed. Electrically passive components are constructed in a structure that is substantially perpendicular to target platform including a first plane to provide a larger electrode contact area and a smaller physical dimension. Passive components structured to be substantially perpendicular toa plane associated with a target platform can be directly connected to pad contacts of an integrated circuit or substrate or can be embedded in a package to reduce the area overhead of a passive component while improving the effectiveness of the passive components in their applications.

Owner:WINTEC IND INC

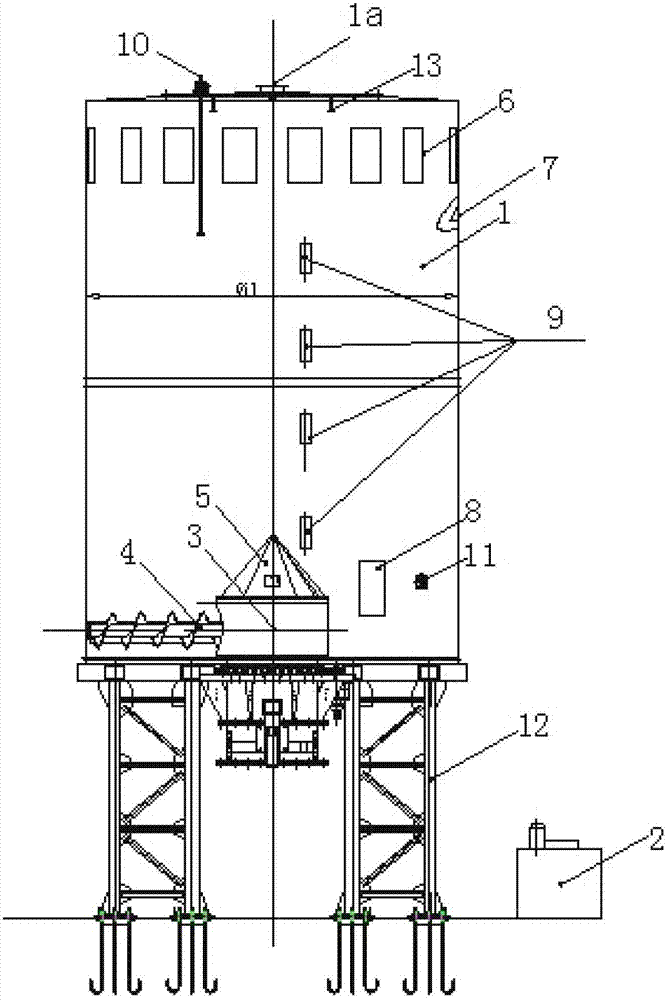

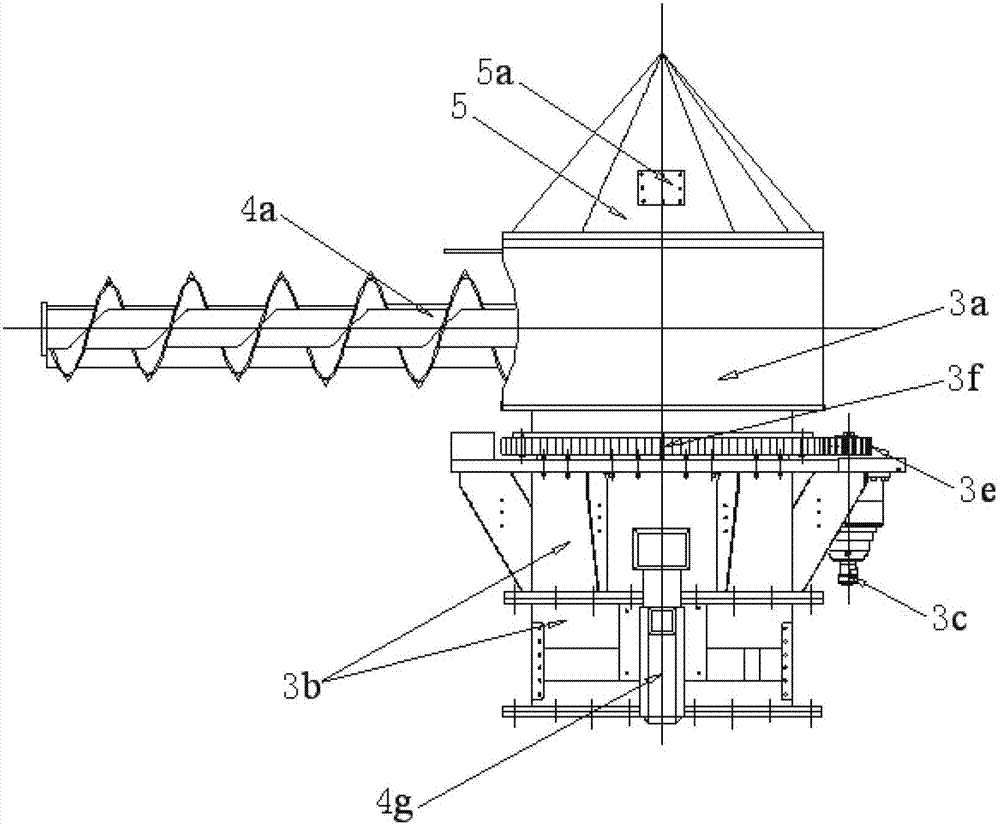

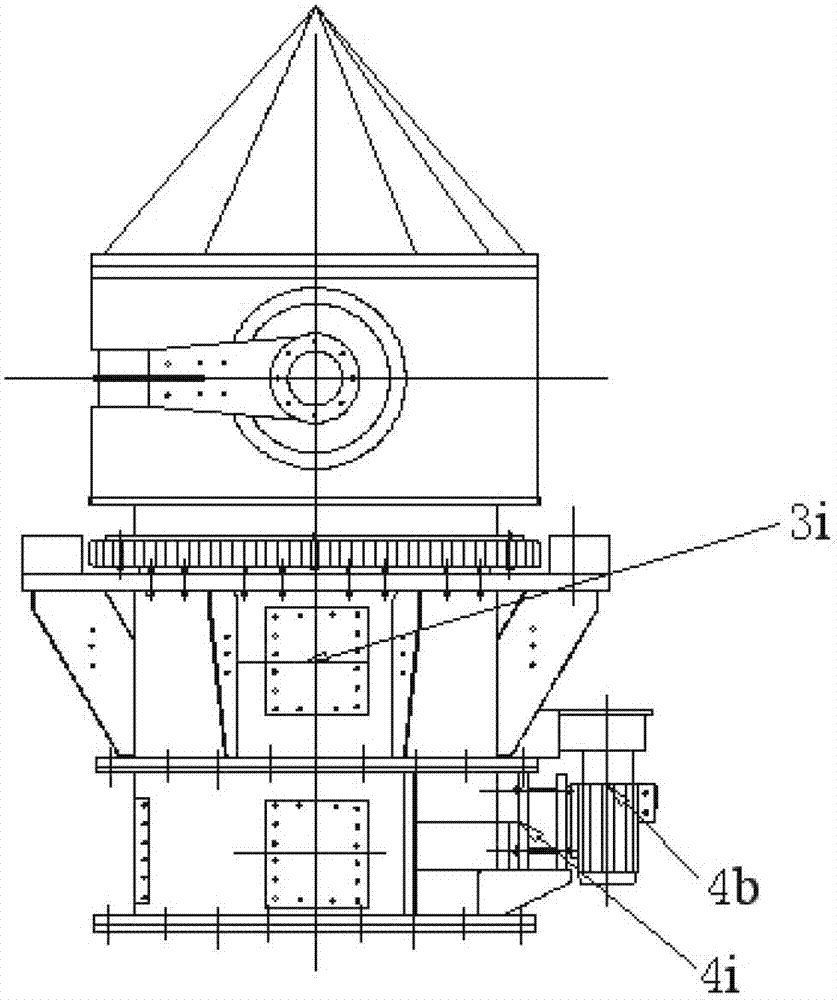

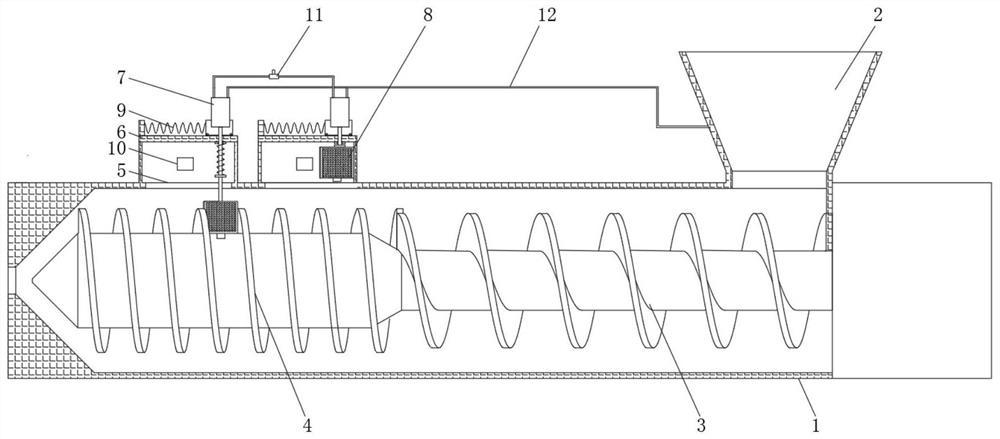

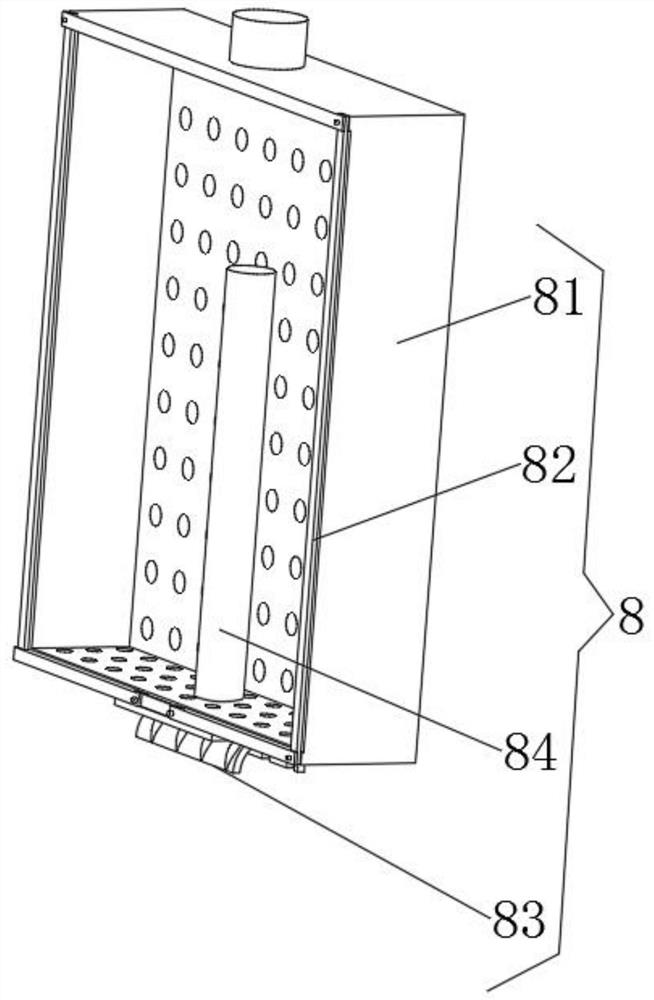

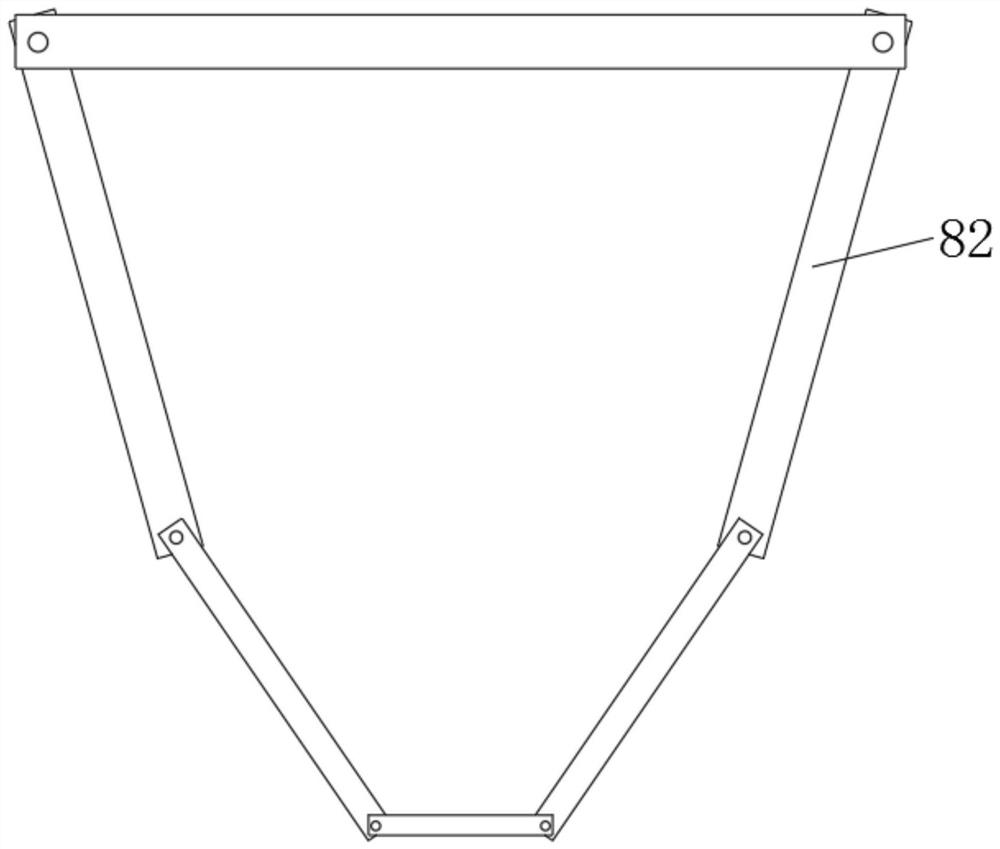

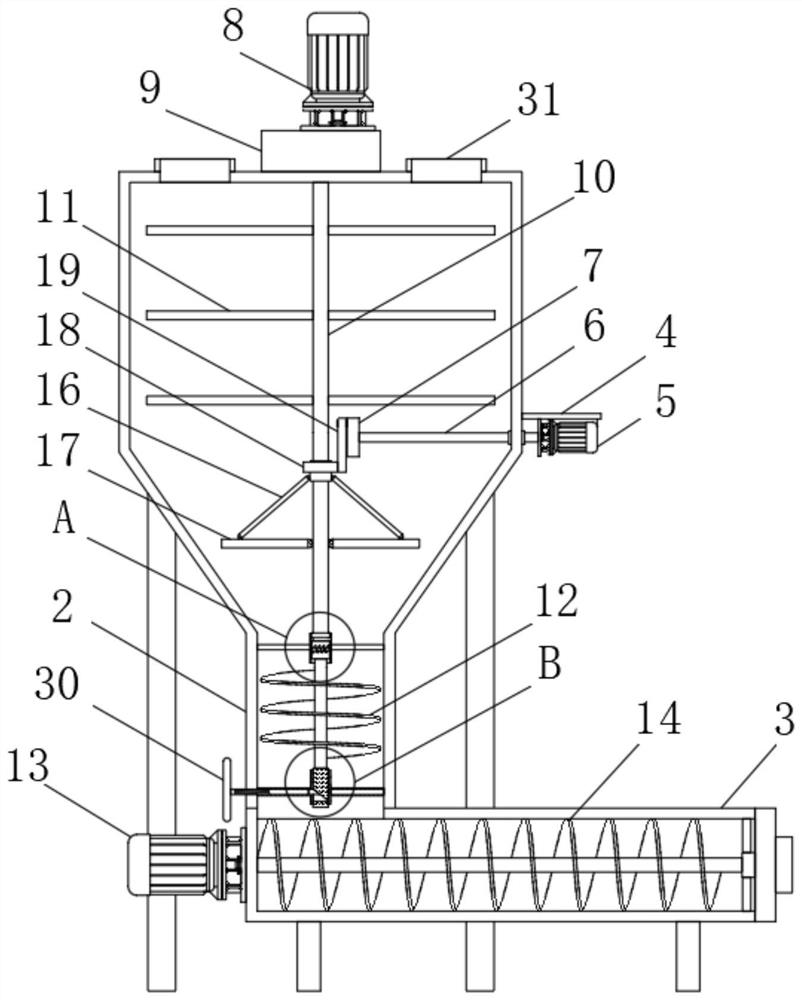

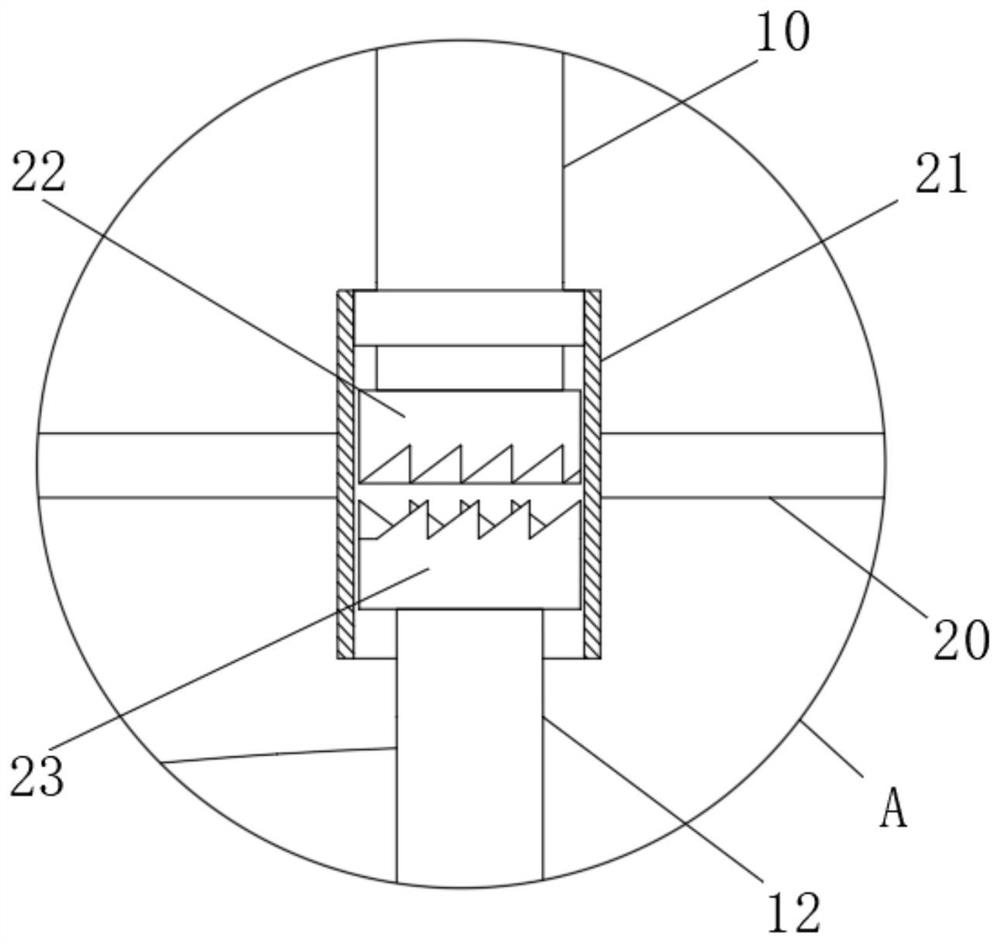

Spiral discharging bin capable of rotating in two directions

ActiveCN102765612AImprove stabilityReduce vertical pressureLarge containersLoading/unloadingFailure rateEngineering

The invention relates to a bin, in particular to a spiral discharging bin capable of rotating in two directions. The bin comprises a feed cylinder, a spiral conveying machine, a rotary discharging cylinder and a hydraulic station; the hydraulic station is arranged on the ground; the top of the feed cylinder is provided with a feed port; the bottom of the feed cylinder is provided with the rotary discharging cylinder; the rotary discharging cylinder comprises an upper cylinder body, a lower cylinder body and a slewing mechanism which is connected with the hydraulic station; the lower cylinder body is fixed with the feed cylinder; the upper cylinder body is arranged on the lower cylinder body through the slewing mechanism; the slewing mechanism drives the upper cylinder body to rotate; the side of the upper cylinder body is provided with a feed hole; the spiral conveying machine passes through the feed hole, and is connected with the upper cylinder body and used for conveying materials; and the spiral conveying machine and the upper cylinder body rotate. According to the spiral discharging bin, materials are discharged by the two-direction rotation structure of the rotary discharging cylinder and the spiral conveying machine, so that the stability of the discharging amount of the bin is improved, and failure rate of equipment is reduced.

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

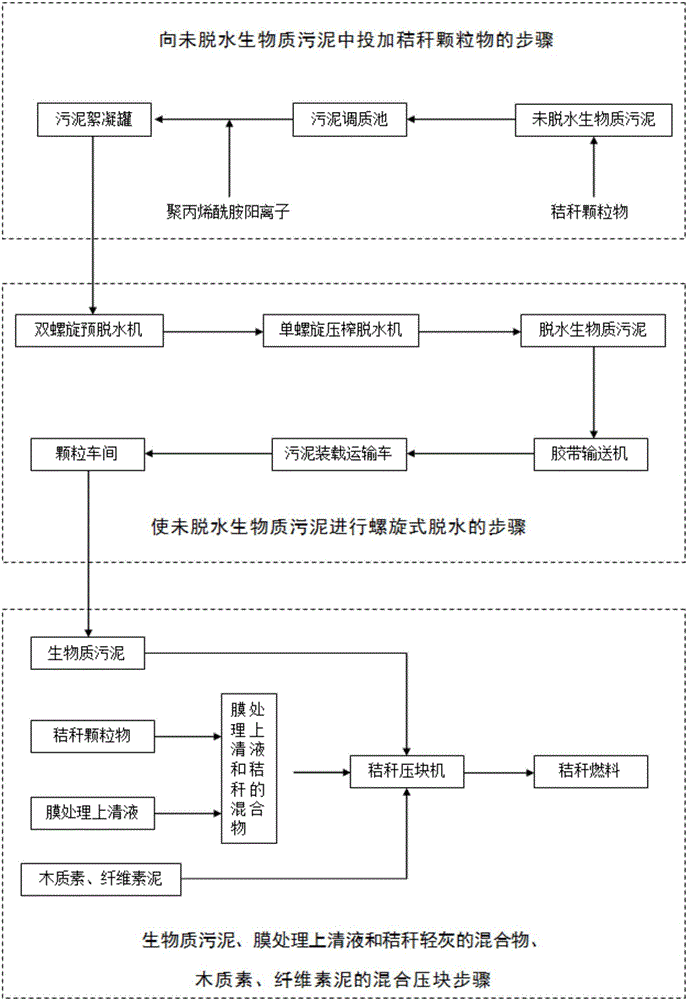

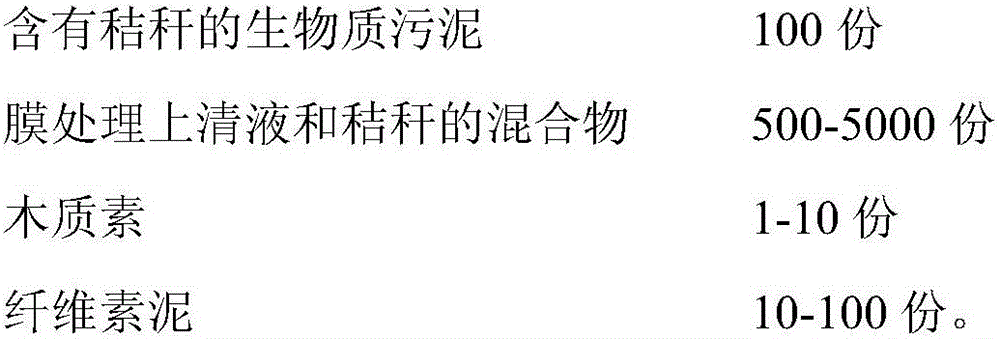

Straw fuel containing biomass sludge and preparation method of straw fuel

The invention belongs to the technical field of fuel preparation, and particularly relates to straw fuel containing biomass sludge and a preparation method of the straw fuel. The straw fuel containing the biomass sludge is prepared from the biomass sludge containing straw, a mixture of membrane treatment supernate and straw, lignin and cellulose mud. According to the straw fuel, organic waste obtained through biomass resource treatment is fully utilized, and great economic benefits and environmental friendliness benefits are achieved. In addition, straw particles and other plant materials are added into sludge which is not dewatered, and the thermal value of the dewatered sludge can be increased; due to the fact that the straw particles and other plant fibers are mixed in the sludge, the friction force of the pre-dewatered sludge in a spiral squeezing dehydrator is increased, then the operation frequency of the spiral squeezing dehydrator can be improved, and the operation efficiency and output sludge dryness of the machine are effectively improved.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

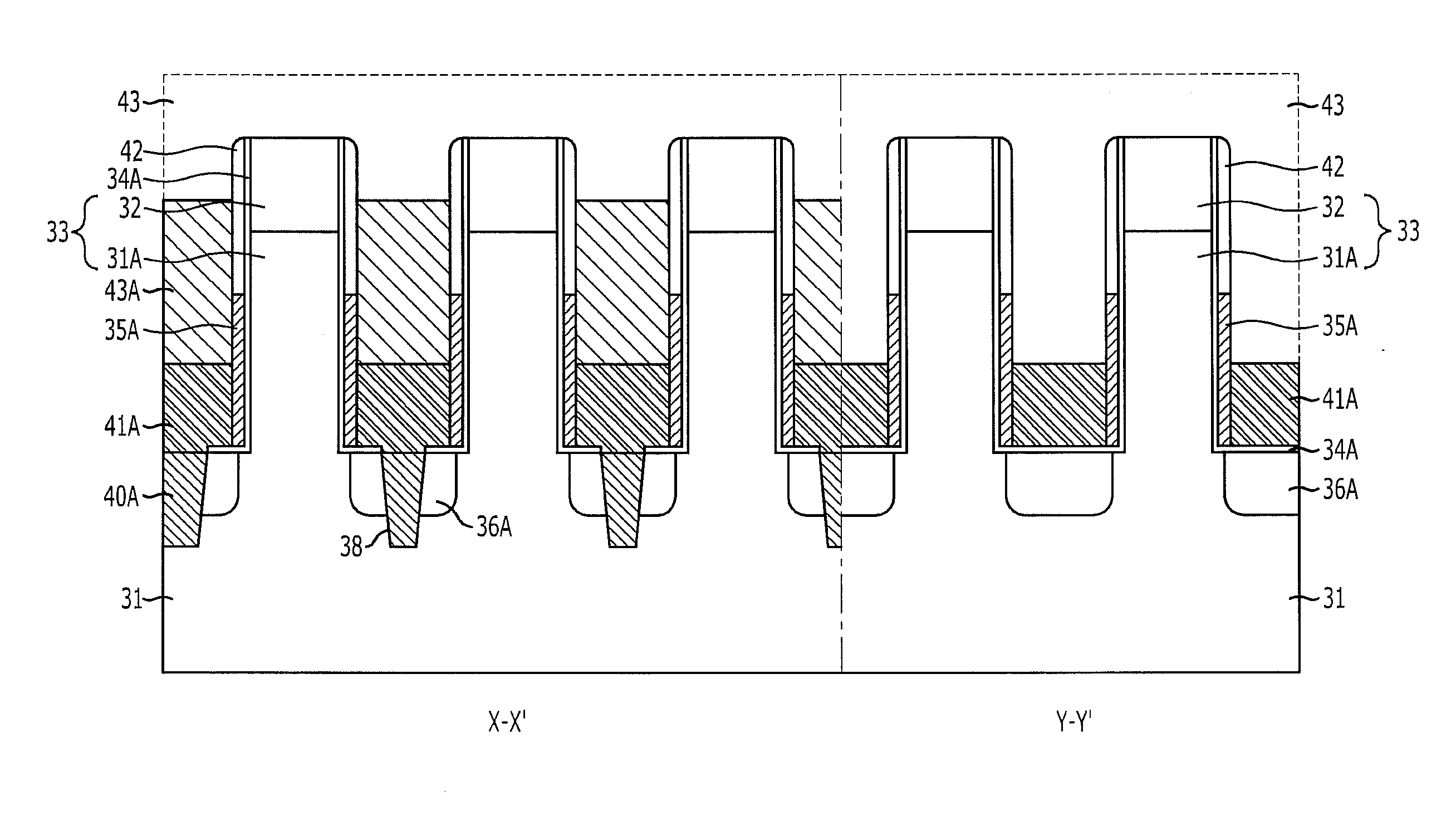

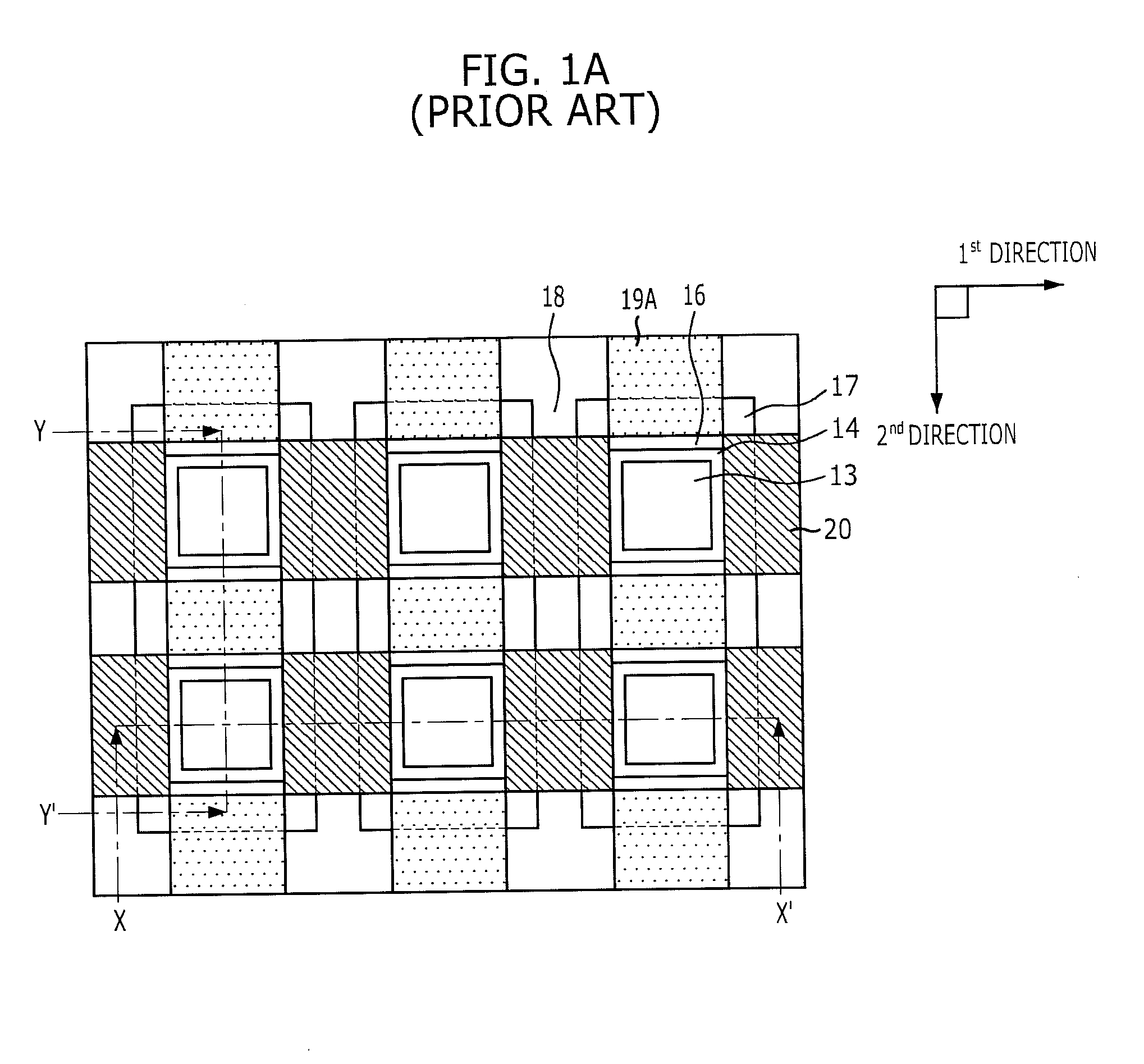

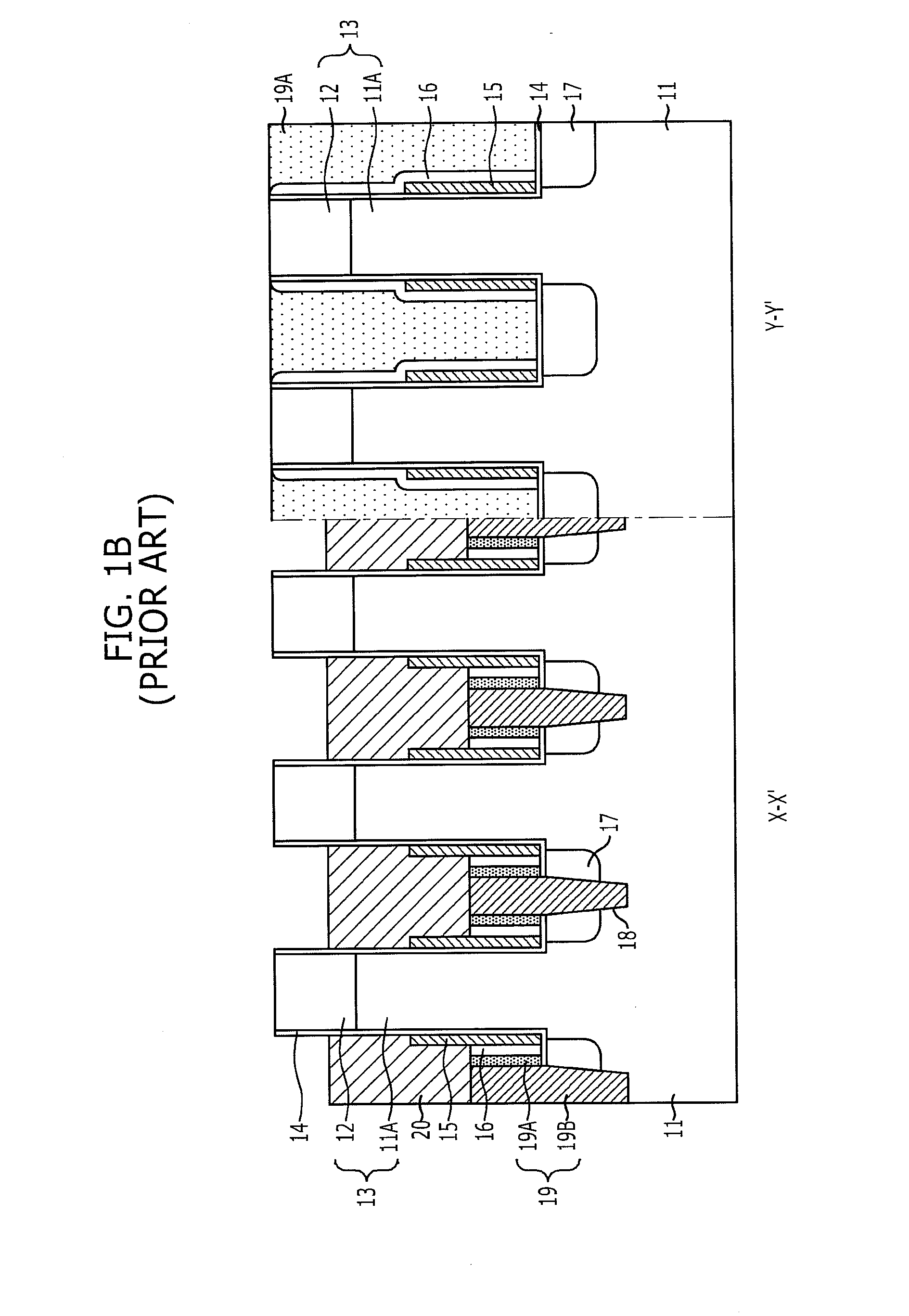

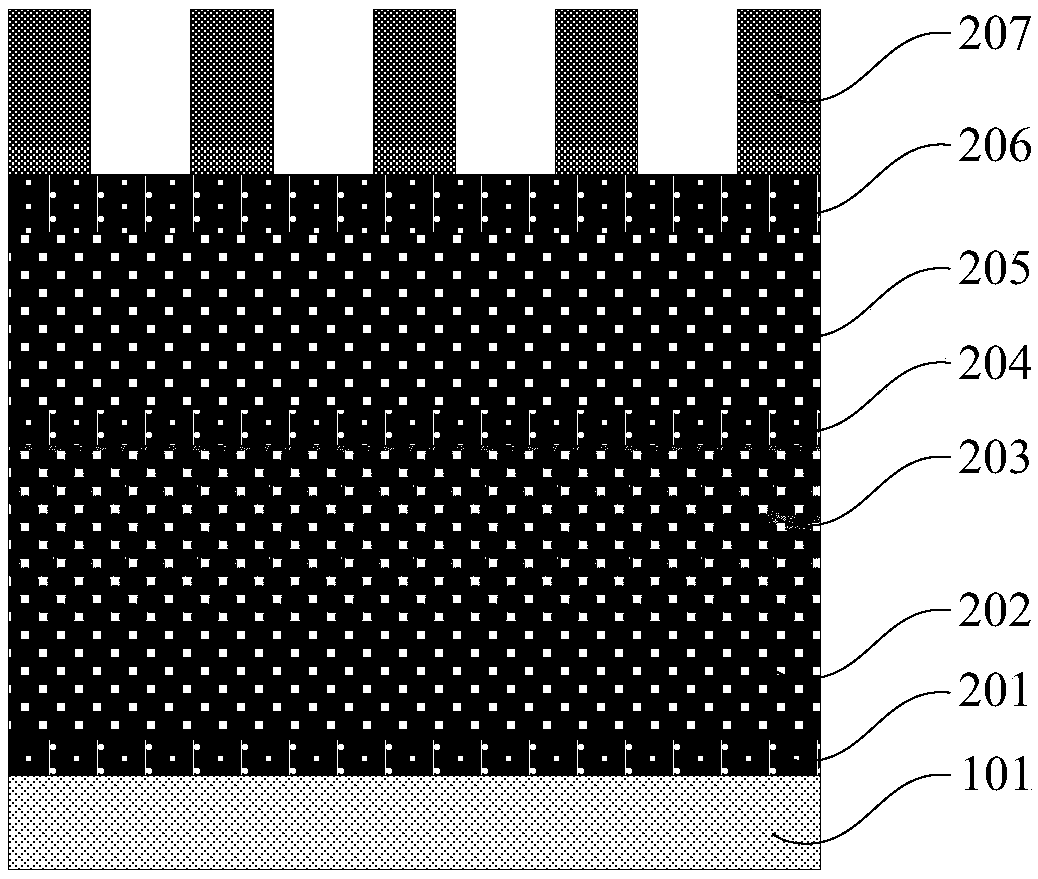

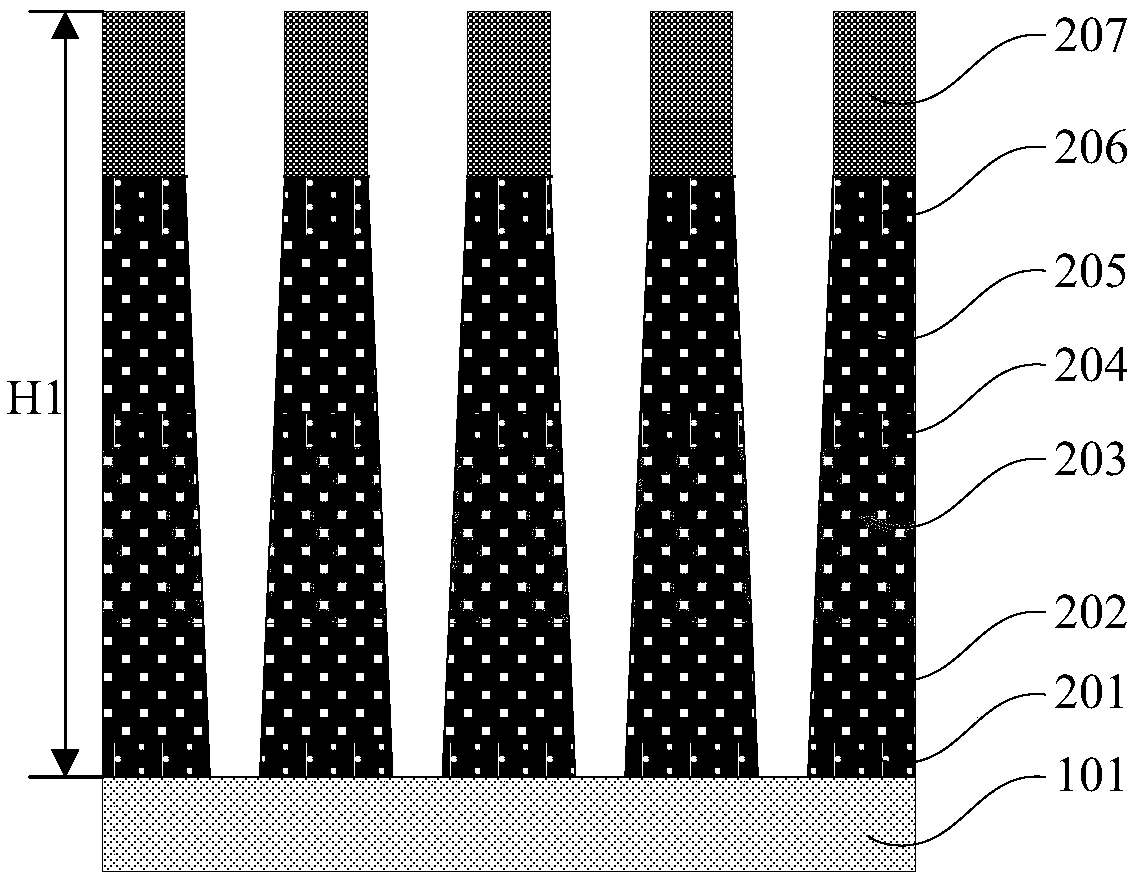

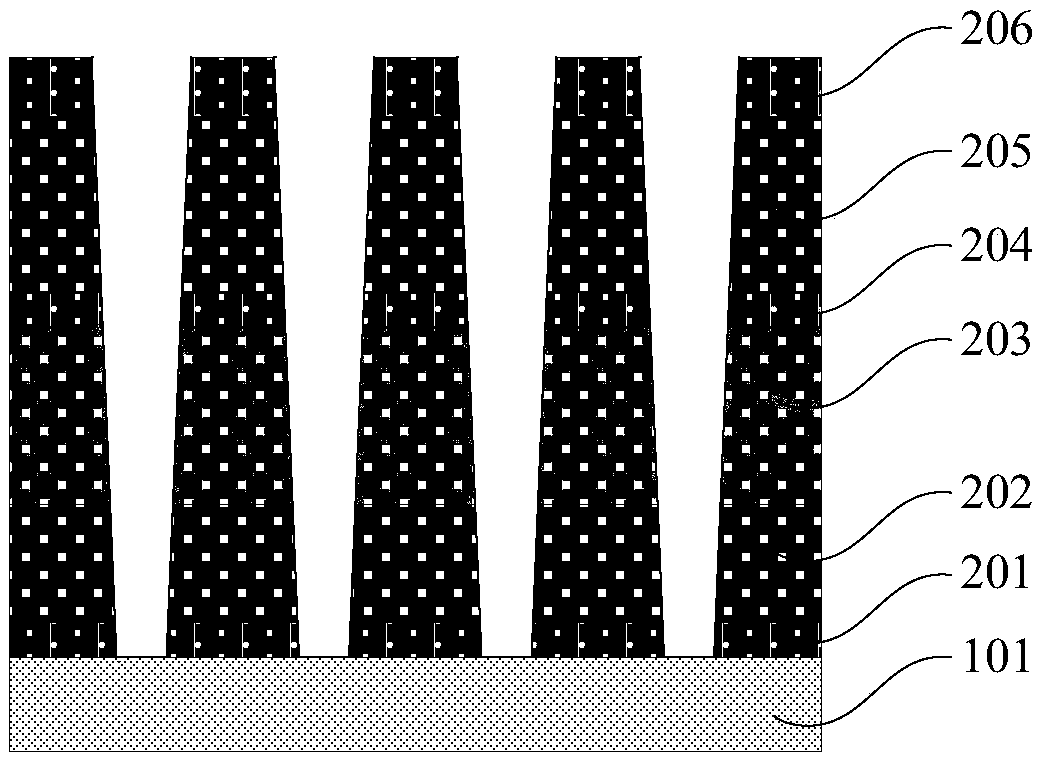

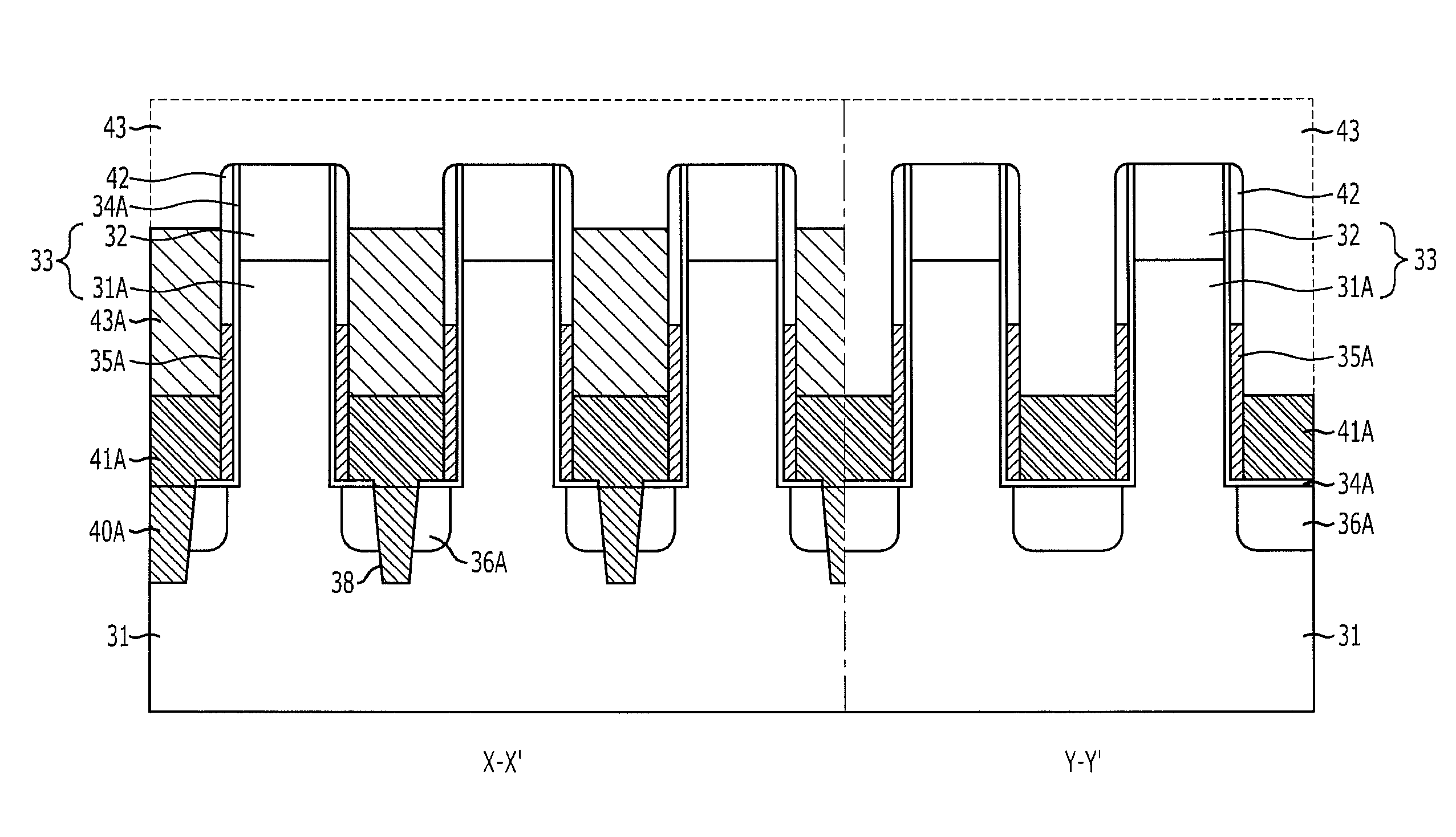

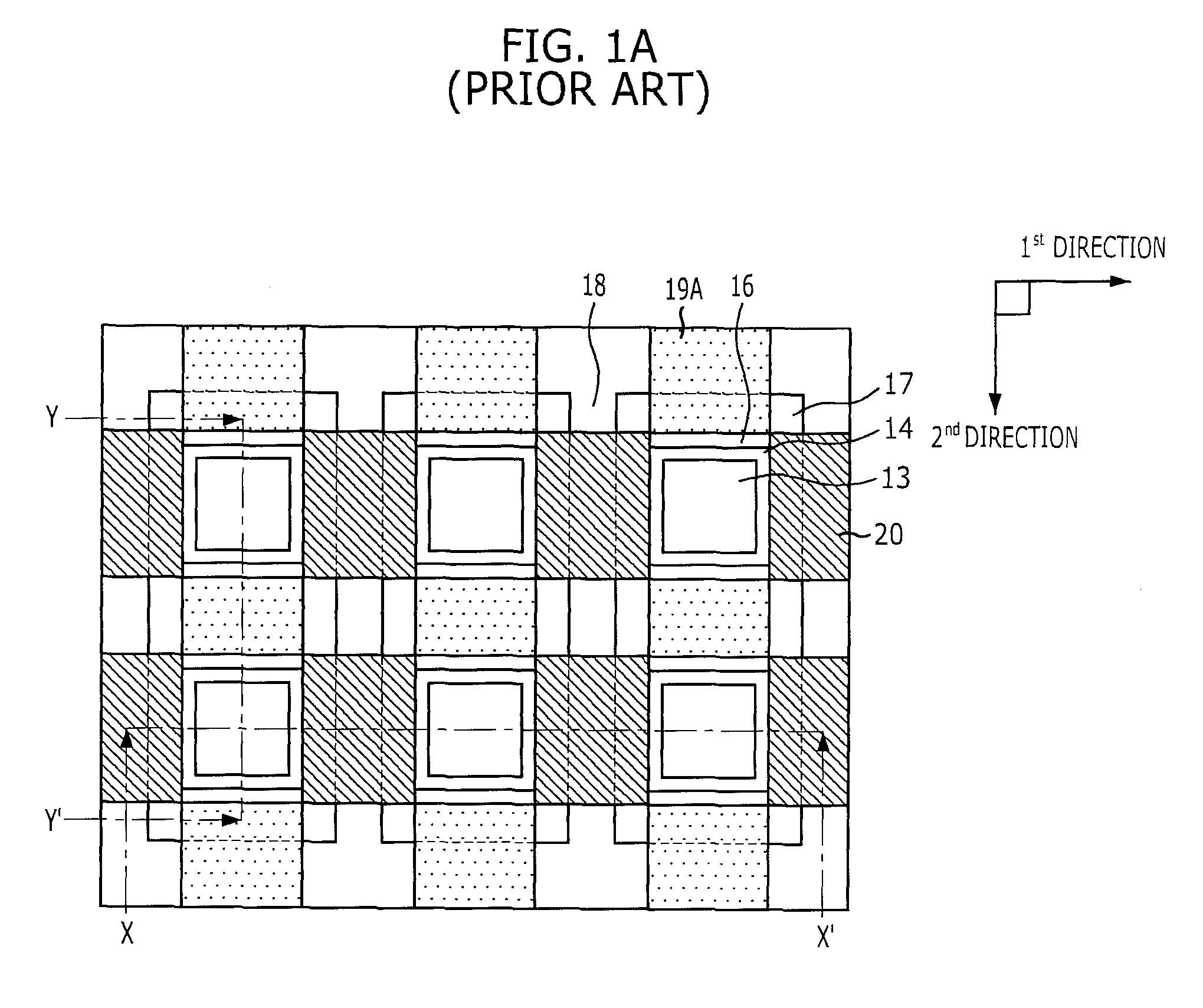

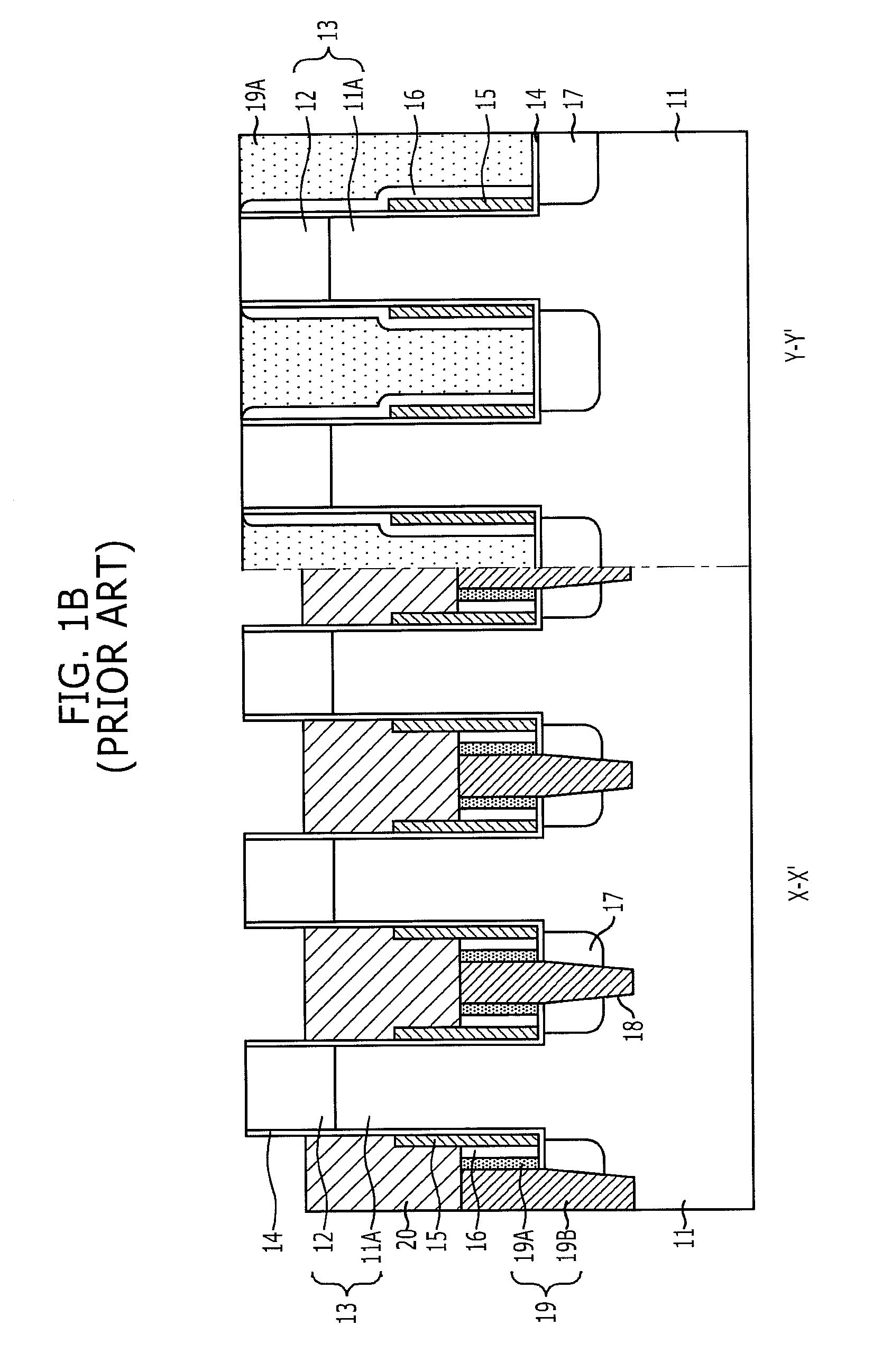

Method for fabricating semiconductor device including vertical channel transistor

ActiveUS20100120221A1Degradation may occurReduce bridgingSemiconductor/solid-state device manufacturingSemiconductor devicesInter layerEngineering

A method for fabricating a semiconductor device includes forming a plurality of pillar structures over a substrate, forming gate electrodes over sidewalls of the pillar structures, forming a sacrificial layer buried between the pillar structures, etching the sacrificial layer and the substrate to form trenches in the substrate, forming first inter-layer insulation patterns buried over the trenches and removing the remaining sacrificial layer at substantially the same time, and forming second inter-layer insulation patterns over the first inter-layer insulation patterns and buried between the pillar structures.

Owner:SK HYNIX INC

Sizing agent for NFC magnetic sheet, preparing method of sizing agent and NFC magnetic sheet

InactiveCN103632795AReduce bridgingHigh resistivityLayered productsMagnetic liquidsMagnetic effectNano al2o3

The invention provides a sizing agent for an NFC magnetic sheet and a preparing method of the sizing agent. The sizing agent comprises magnetic powder and an organic carrier, and further comprises nanometer alumina powder, wherein the mass ratio of the nanometer alumina powder to the magnetic powder is 0.0005: 0.005. The invention further provides the NFC magnetic sheet prepared through the sizing agent. By means of the added nanometer alumina, the number of bridge connection among the magnetic powder is effectively reduced, the specific resistance rate of the magnetic sheet is increased, the imaginary part, namely the magnetic loss, of the complex permeability is obviously reduced within the range allowed by the reducing of the real part of the complex permeability, accordingly the quality factor of the whole magnetic sheet is improved, and the magnetic effect of the magnetic sheet is improved.

Owner:BYD CO LTD

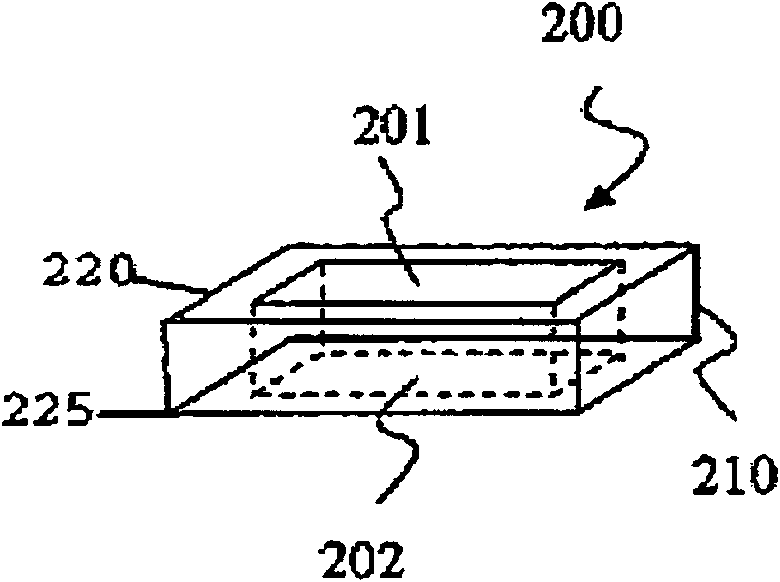

Substrate for mounting semiconductor chip and method for producing same

InactiveCN102576693AImprove reliabilityReduce bridgingSemiconductor/solid-state device detailsSolid-state devicesResistCopper plating

Disclosed is a method for producing a substrate for mounting a semiconductor chip, by which the formation of bridges can be reduced and excellent wire bonding performance and excellent solder joint reliability can be achieved even in cases when fine wiring is formed. Specifically disclosed is a method for producing a substrate for mounting a semiconductor chip, which comprises: a resist formation step wherein a resist is formed on a first copper layer of a laminate, which comprises an inner layer plate having an inner layer circuit on the surface and the first copper layer that is formed on the inner layer plate with an insulating layer therebetween, in regions other than the region that is to be a conductor circuit; a conductor circuit formation step wherein a conductor circuit is obtained by forming a second copper layer on the first copper layer by electrolytic copper plating; a nickel layer formation step wherein a nickel layer is formed on at least a part of the conductor circuit by electrolytic nickel plating; a resist removal step wherein the resist is removed; an etching step wherein the first copper layer is removed by etching; and a gold layer formation step wherein a gold layer is formed on at least a part of the conductor circuit by electroless gold plating.

Owner:RESONAC CORP

Substrate for mounting semiconductor chip and method for producing same

InactiveUS8997341B2Reduce bridgingExcellent bondabilitySemiconductor/solid-state device detailsSolid-state devicesResistElectrical conductor

It is an object of the invention to provide a method for producing a substrate for mounting a semiconductor chip, that can reduce bridging and allows excellent wire bondability and solder connection reliability to be obtained, even when forming fine-pitch wirings. The method for producing a substrate for mounting a semiconductor chip according to the invention comprises a resist-forming step in which a resist is formed on the first copper layer of a stack comprising an inner board with an inner layer circuit on the surface and a first copper layer formed on the inner board separated by an insulating layer at the sections other than those that are to constitute a conductor circuit, a conductor circuit-forming step in which a second copper layer is formed by electrolytic copper plating on the first copper layer to obtain a conductor circuit, a nickel layer-forming step in which a nickel layer is formed by electrolytic nickel plating on at least part of the conductor circuit, a resist removal step in which the resist is removed, an etching step in which the first copper layer is removed by etching, and a gold layer-forming step in which a gold layer is formed by electroless gold plating on at least part of the conductor circuit.

Owner:RESONAC CORPORATION

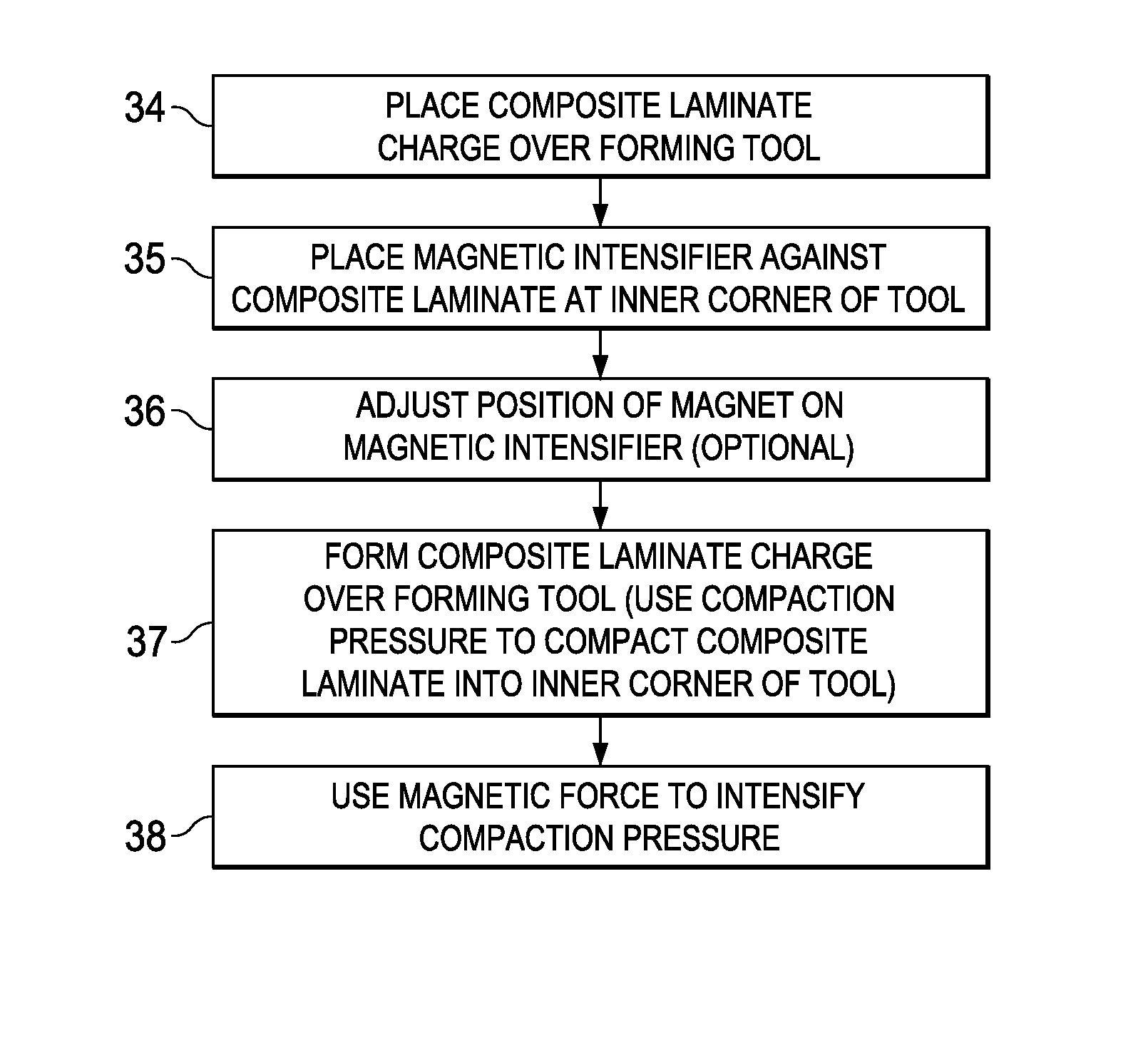

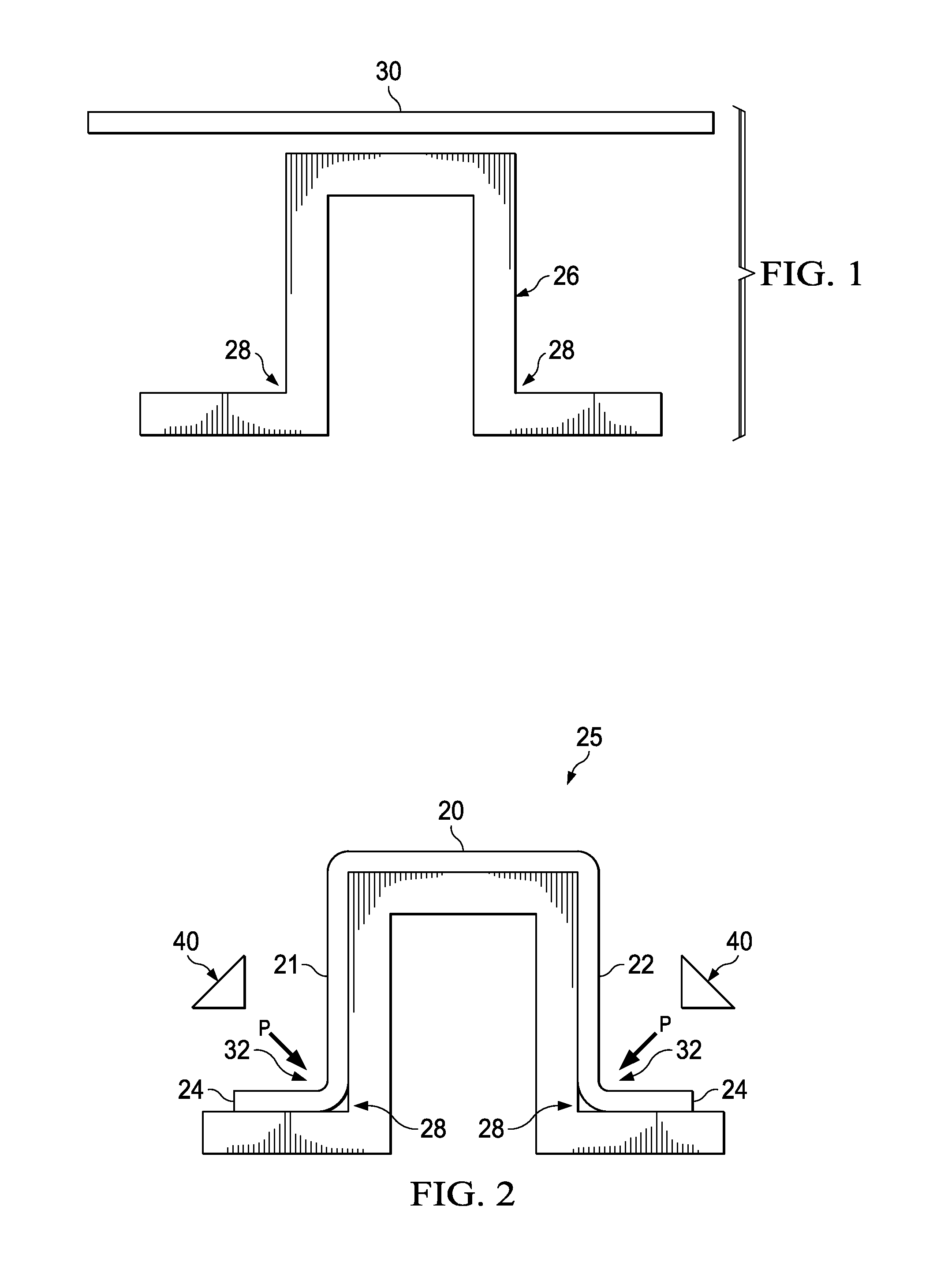

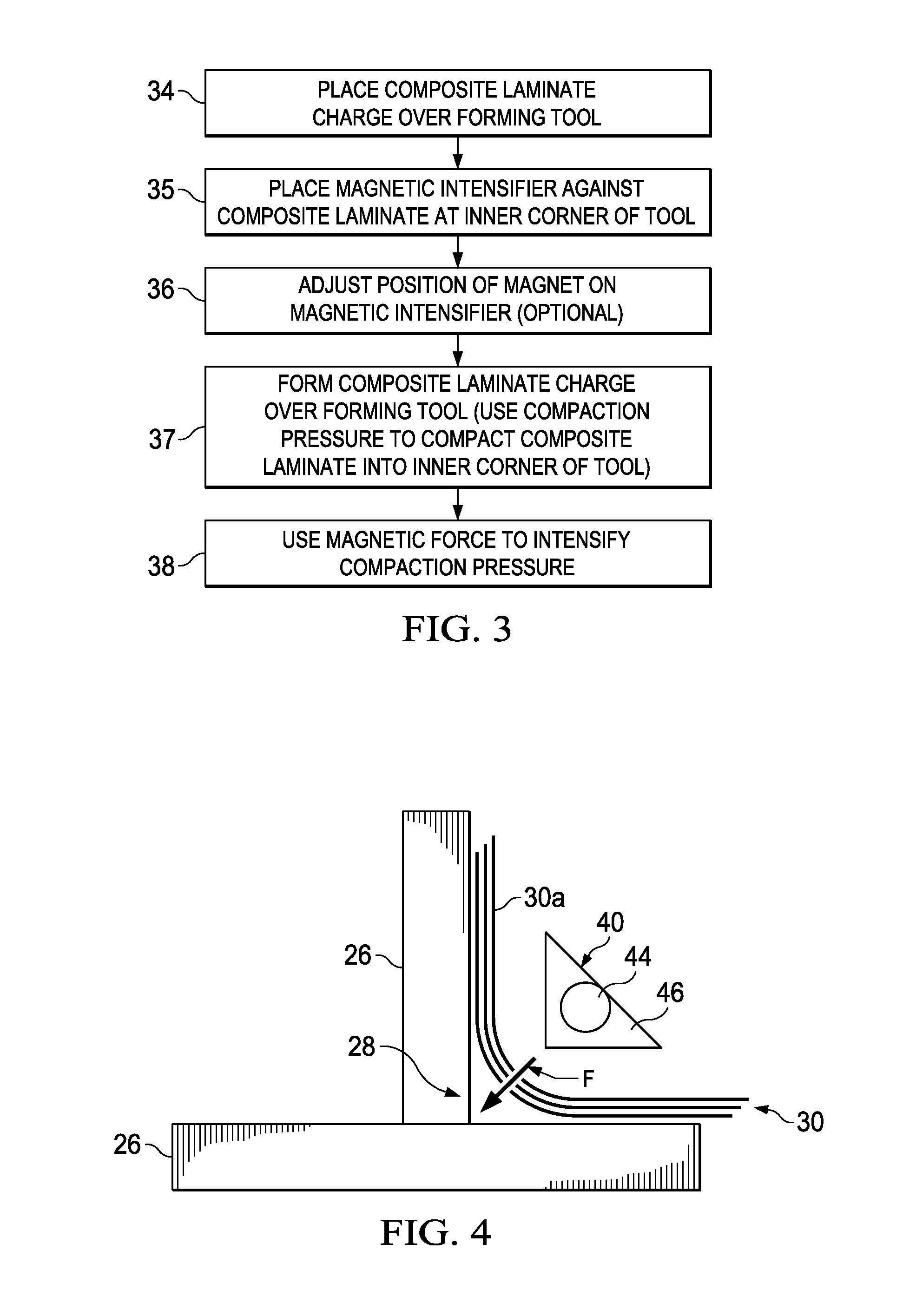

Laminate Compaction Using Magnetic Force

ActiveUS20140216642A1Easy constructionEasy to installMechanical working/deformationLamination ancillary operationsMagnetic tension forceComposite laminates

A device uses magnetic force generated by a magnet to intensify compaction pressure applied to a composite laminate.

Owner:THE BOEING CO

Waste plastic recycling and granulating production equipment

The invention relates to the technical field of environmental protection equipment, and discloses waste plastic recycling and granulating production equipment, which comprises an extruder, a hopper, amelting screw and an extrusion screw, two groups of sliding chutes and slideways are arranged at positions, corresponding to the upper part of the hopper, of the extruder, and the slideways are movably connected with an air cylinder through sliding blocks. According to the waste plastic recycling and granulating production equipment provided by the invention, when molten plastic rotates and movesalong with the extrusion screw, the two filtering pieces are inserted into a groove of the extrusion screw in turn to filter out incompletely molten plastic or impurities, so that the purity of meltis improved, and the quality of regenerated plastic is improved; and secondly, plastic on the inner wall of a hopper body is extruded through airflow generated when the air cylinder moves, one side ofthe plastic where bridging occurs is suspended, movement of plastic fragments in the hopper is assisted, then disturbance of the plastic fragments can be increased through rapid pulse airflow, the bridging probability is further reduced, the conveying speed of the broken fragments is increased, so that the conveying speed is matched with the processing speed of a granulator.

Owner:常丹阳

Method for improving morphology of capacitor holes

ActiveCN110943163AGood lookingReduce difficultySolid-state devicesCapacitorsCapacitanceMiniaturization

Owner:CHANGXIN MEMORY TECH INC

Method for fabricating semiconductor device including vertical channel transistor

ActiveUS7964463B2Reduce bridgingLess bendingSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceInter layer

Owner:SK HYNIX INC

Granulated flaky titanic acid salts, process for production thereof, resin compositions containing the salts

InactiveCN101490157AReduce bridgingReduce cloggingAlkaline earth titanatesAlkali titanatesPotassium octatitanateTitanic acid

The invention provides granulated flaky titanic acid salts which little cause bridging or clogging in kneading and which bring about improvement in the manufacturing environment; a process for production of the salts; and resin compositions containing the salts. The granulated titanic acid salts can be produced by a process characterized by shaping a flaky titanic acid salt with a binder. The flaky titanic acid salt may be a layer titanic acid salt, flaky potassium octatitanate, a composite flaky metal titanate, or the like.

Owner:OTSUKA CHEM CO LTD

Carbon nano-crystal hydrogen-storage material and preparation method

InactiveCN1912164AAbundant resourcesLow priceOther chemical processesFinal product manufactureCoalAcid washing

The invention discloses a carbon nanometer crystal hydrogen storage material and the making method. The constituents of the material includes 60-90wt% coal based carbon with hexagonal net grid layer crystal structure and the particle diameter is 20-100nm, 10-40wt% of one or several metal from Na, Al, Ti, V, Cr, Fe, Ni, Zn, Mo, and Pd. The method includes the following steps: taking alkali washing and acid washing to coal, after 1000-1600 degree centigrade carbonization, adding the metal powder, under 0.5-3MPa hydrogen pressure, taking ball milling for 0.5-8h. It has the advantages of large hydrogen storage density, low raw material cost, simple technology, etc.

Owner:SHANDONG UNIV OF SCI & TECH

Dispensing canister for delivery of solid medication

InactiveUS20120095593A1Easy configuration and recalibrationExpensive costsSmall article dispensingCoin-freed apparatus detailsOral medicationCoupling

The apparatus and process of the present invention provides for the automated, singulated dispensing of articles, particularly solid oral medication in predetermined quantities. The apparatus of the invention is a canister which houses a screw having a channel of a certain width and depth that corresponds to the dimensions of a particular pill type. The screw is removably mounted within a canister, such that screws having channels of various dimensions, corresponding to a particular pill to be dispensed, can be substituted into the canister. Upon rotation of the screw, the articles to be dispensed travel along a sidewall, pass under a singulation ramp, and exit from an aperture on the proximal end of the canister. A rotational driver-coupling is mounted to the proximal end of the screw, allowing for activation of the canister by engaging the screw. The present invention further describes methods of dispensing articles.

Owner:TRANSLOGIC

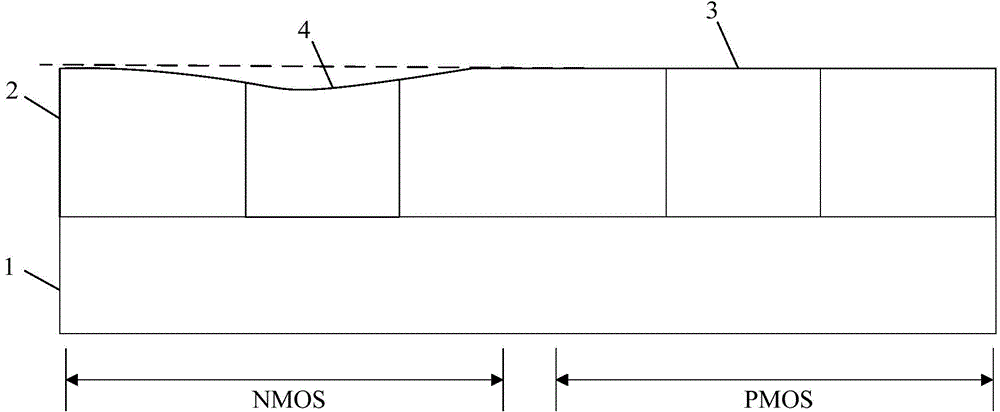

Gate Protection Caps and Method of Forming the Same

ActiveCN104659083AReduce bridgingSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMiddle line

A structure includes a substrate, a gate structure over the substrate, a dielectric layer over the substrate, and a cap over a gate electrode of the gate structure. Top surfaces of the dielectric layer and gate electrode are co-planar. The gate structure extends a gate lateral distance between first and second gate structure sidewalls. The cap extends between first and second cap sidewalls. A first cap portion extends from a midline of the gate structure laterally towards the first gate structure sidewall and to the first cap sidewall a first cap lateral distance, and a second cap portion extends from the midline laterally towards the second gate structure sidewall and to the second cap sidewall a second cap lateral distance. The first cap lateral distance and the second cap lateral distance are at least half of the gate lateral distance.

Owner:TAIWAN SEMICON MFG CO LTD

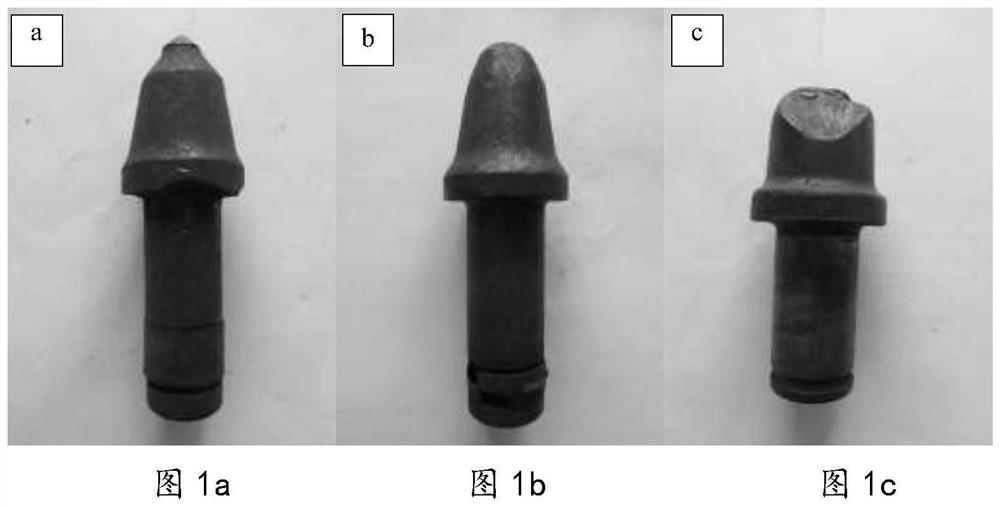

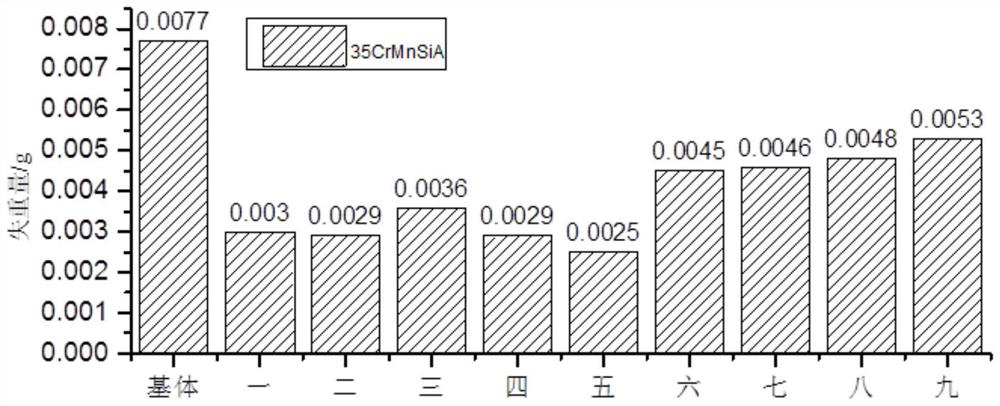

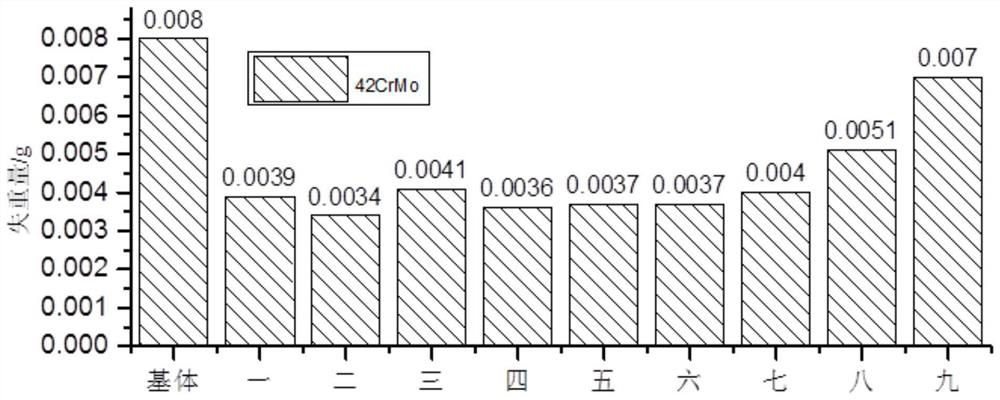

Material suitable for remanufacturing of 35CrMnSiA and 42CrMo cutting teeth and laser cladding method

ActiveCN111719147AImprove wear resistanceUniform hardnessMetallic material coating processesCarbideSingle crystal

The invention provides a material suitable for remanufacturing of 35CrMnSiA and 42CrMo cutting teeth and a laser cladding method. The material for remanufacturing of the cutting teeth is laser cladding powder and is composed of iron-based alloy powder, sintered tungsten carbide WC or cast tungsten carbide WC or a mixture of cast tungsten carbide WC and single-crystal tungsten carbide, nickel Ni and CeO 2, wherein the iron-based alloy powder is composed of C, Cr, Si, B, Al and Fe. The hardness of a cladding layer reaches about 53HRC, good abrasion resistance is achieved, the microstructure is ferrite and carbide distributed on the grain boundary, and the abrasion resistance can be improved by taking the carbide as a framework. A three-dimensional diagram of the abraded surface shows that furrows of the abraded surface are slight, and only little pitting corrosion and peeling exist.

Owner:INNER MONGOLIA UNIV OF TECH

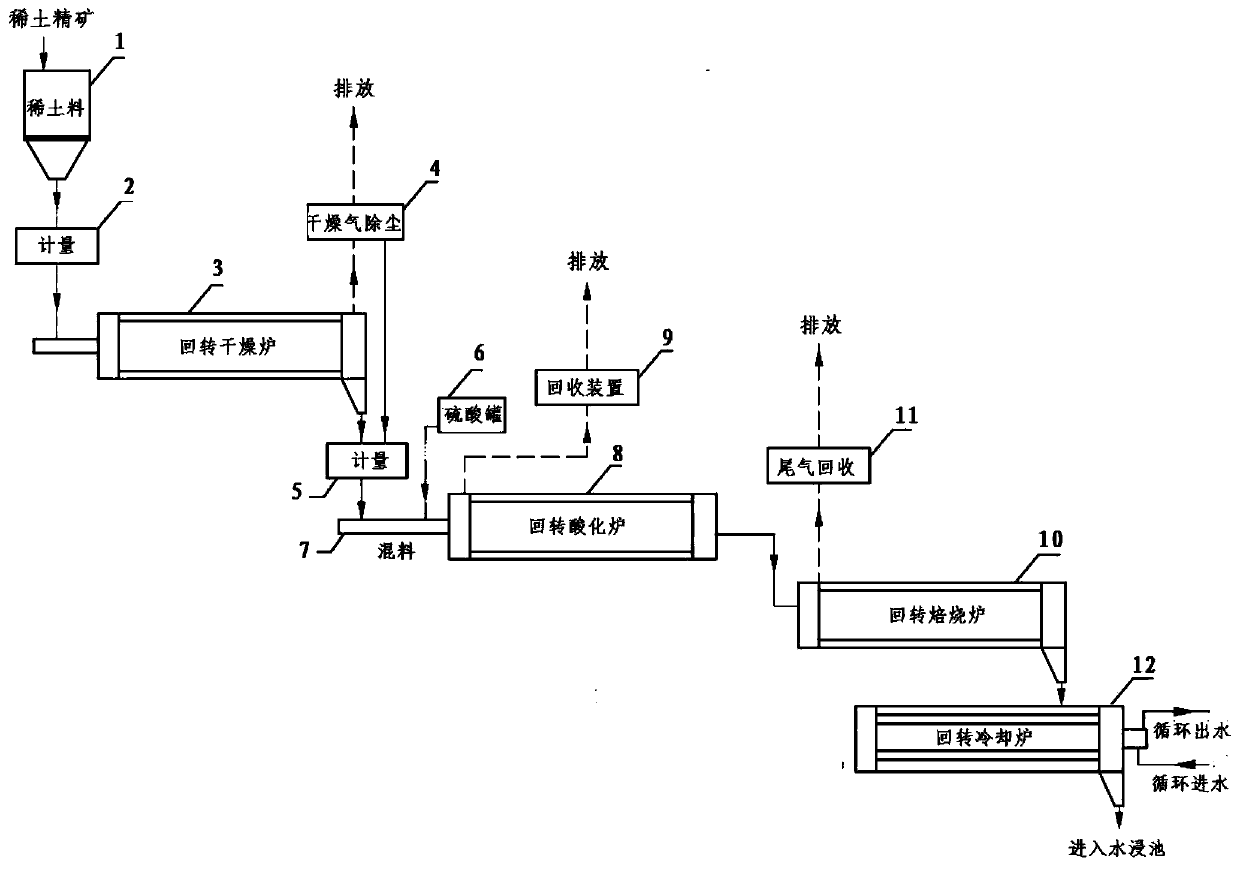

System and method for acidizing and roasting rare earth concentrate through multi-section external heating rotary furnace

The invention discloses a method and system for acidizing and roasting rare earth concentrate through a multi-section external heating rotary furnace. The method comprises the following steps of metering and putting the rare earth concentrate into an external heating rotary drying furnace, controlling heating temperature of materials and staying time in the furnace, exhausting tail gas, conveyingdust and sulfuric acid into a rotary acidifying furnace, and controlling the temperature of the materials and the staying time in the furnace; exhausting the tail gas entering an acidified tail gas recovery device after the tail end reaches the standard; enbaling acidified materials to enter a rotary roasting furnace to be roasted, controlling the temperature of the materials and the staying timein the furnace, and exhausting roasted tail gas entering a roasting tail gas recycling device after the roasted tail gas reaches the standard; and enabling high-temperature roasted materials to entera rotary cooling furnace to be cooled and be conveyed to a water leaching procedure so as to obtain the acidified roasted rare earth concentrate with the roasted material leaching rate being 93%-98%.According to the method, the tail gas treatment amount and operation cost are greatly reduced, the fluidity of the dried rare earth concentrate is good, the corrosion rate of equipment and pipelines is reduced, and equipment pipeline blockage is reduced.

Owner:西安三瑞实业有限公司

Method for forming grid

ActiveCN105448684AReduce saggingReduce bridgingSemiconductor/solid-state device manufacturingSemiconductor devicesDielectric layerMetal

Owner:SEMICON MFG INT (SHANGHAI) CORP

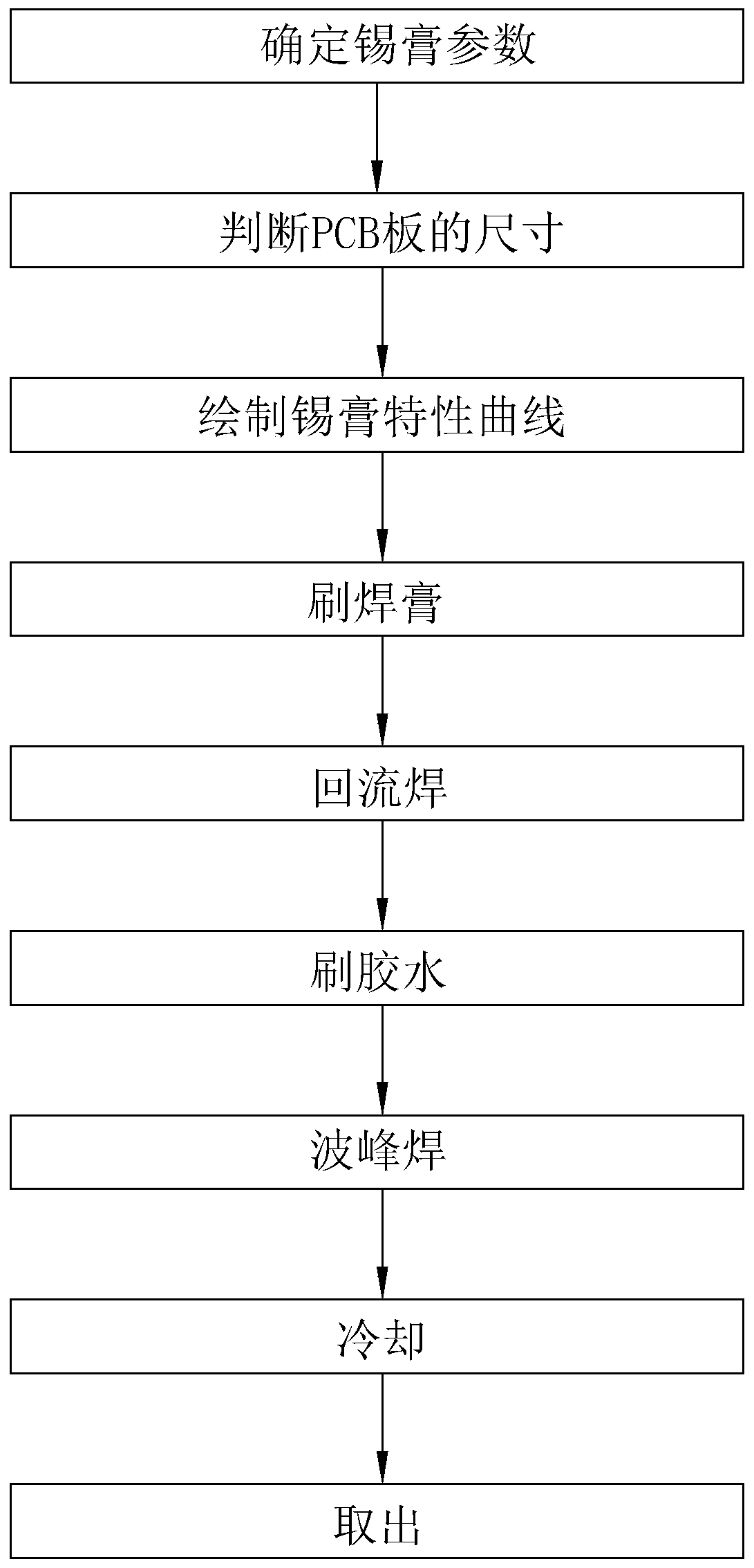

Solder paste reflow soldering and glue fixing process

InactiveCN110248495AReduce crackingWeak tensile strengthPrinted circuit assemblingSurface mountingSolder paste

The invention discloses a solder paste reflow soldering and glue fixing process, belonging to the technical field of surface mount. The key point of the technical solution is that the process includes the steps of determining solder paste parameters, judging the size of a PCB, drawing a solder paste characteristic curve, applying solder paste, performing reflow soldering, applying glue, performing wave soldering, cooling and taking. According to the process, the technical problem that the bridging is easily generated between pins of a device in the prior art is solved, the effect of reducing the probability of generating bridging between the pins of the device is achieved, and the process is applied to the soldering of the PCB.

Owner:深圳市英创立电子有限公司

Anti-blocking type mixing and discharging device of screw extruder

The invention relates to the technical field of extruders, and discloses an anti-blocking type mixing and discharging device of a screw extruder. The anti-blocking type mixing and discharging device comprises a hopper, a connecting pipe and a conveying pipe, wherein the connecting pipe is fixedly arranged at the bottom of the hopper, the conveying pipe is fixedly arranged at the bottom of the connecting pipe, a mounting plate is fixedly connected with the side face of the hopper, the bottom of the mounting plate is fixedly connected with a first motor, and an output shaft of the first motor isfixedly connected with a transverse shaft. According to the anti-blocking type mixing and discharging device of the screw extruder, the first motor and a second motor are started in the mixing process, the second motor operates to drive a movable rod, a connecting rod and an inner sleeve to rotate around a rotating shaft, meanwhile, the second motor can drive a disc to rotate, and a vertical roddrives the outer sleeve ring and the inner sleeve ring to move up and down in a reciprocating mode, therefore, the movable rod swings up and down while rotating, the stirring effect is improved, the materials at the bottom of the hopper are stirred more loosely, and the probability of blockage or bridging is reduced.

Owner:李强

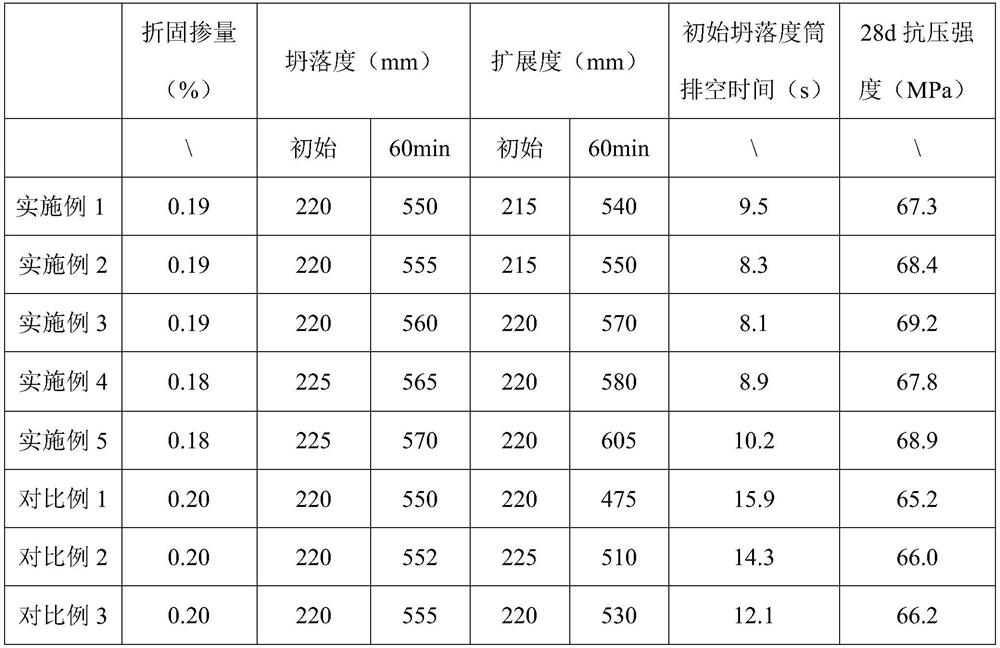

Viscosity reduction type polycarboxylate superplasticizer and preparation method thereof

The invention discloses a viscosity reduction type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is prepared from unsaturated vinyl ether, an unsaturated carboxylic acid monomer and a derivative thereof, an unsaturated phosphonic acid monomer and an unsaturated sulfonic acid monomer through free radical polymerization. The unsaturated vinyl ether with long-chain alkyl is used as a preparation raw material of the polycarboxylate superplasticizer, so that the HLB value of a side chain of the polycarboxylate superplasticizer is reduced, the rigidity of the side chain is enhanced, the adsorption effect of the side chain on water molecules is reduced, and the side chain can be more stretched in a cement pore solution, the cladding effect of the side chain on the water molecules is reduced, so that the consumption of water by the polycarboxylate structure is reduced. The polycarboxylate superplasticizer has excellent viscosity-reducing performance in high-strength concrete with low water-binder ratio; and the preparation method of the viscosityreduction type polycarboxylate superplasticizer is simple, rapid and suitable for large-scale production.

Owner:武汉优城科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com