Carbon nano-crystal hydrogen-storage material and preparation method

A technology of hydrogen storage materials and carbon nanocrystals, which is applied in chemical instruments and methods, fuel cells, and final product manufacturing, can solve the problems of high hydrogen depletion temperature, low ball milling efficiency, and high raw material cost, and achieve low hydrogen depletion temperature, The effect of short milling time and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

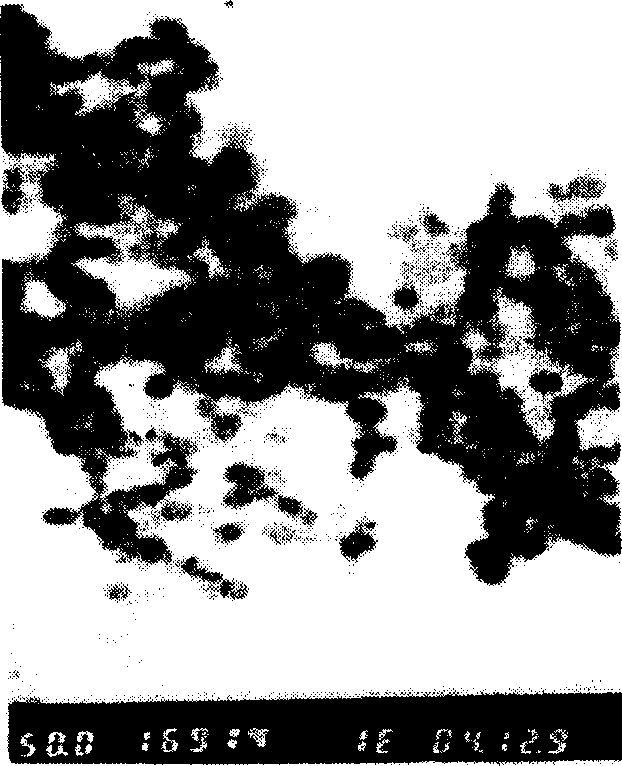

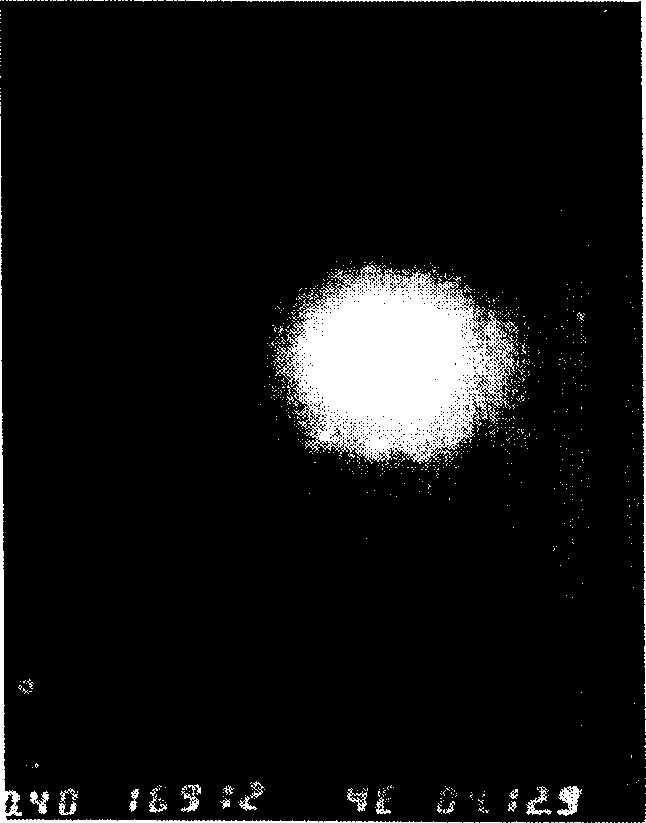

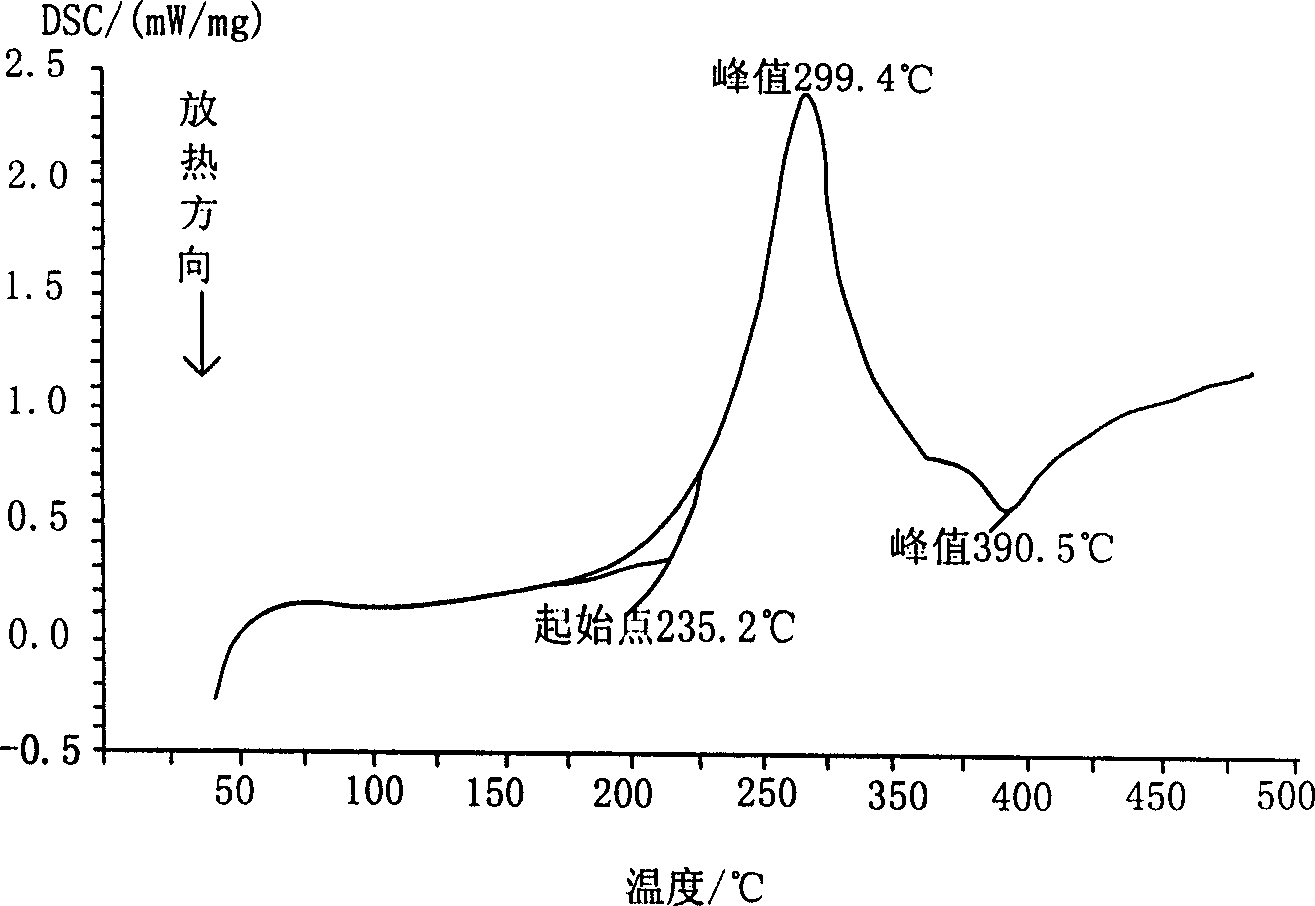

[0016] A Vietnamese Hongji anthracite sample (dry basis ash content 6.02%) was coarsely crushed with a jaw crusher and vibrating mill until the particle size was 99%) to 2MPa, and put it into an ND7-2 type frequency conversion planetary ball mill for ball milling for 1 hour to obtain a hydrogen storage material. Its transmission electron microscope pictures are as figure 1 As shown, it shows that its particle size is 20-100nm; its electron diffraction photo is as figure 2 As shown, it shows that it is a nanocrystalline structure; its differential scanning calorimetry curve is as follows image 3 As shown, it shows that the starting temperature of hydrogen desorption is 235°C, and the main peak temperature of hydrogen desorption is 299°C. The amount of hydrogen released (mass percentage of released hydrogen to material) at 300°C for 20 minutes was 5.45wt% by water drainage method.

Embodiment 2

[0018] The difference from Example 1 is that the mass ratio of coal soda for deashing coal is 1:6, the concentration of hydrochloric acid is 10%, the acid leaching time is 8 hours, and the coal ash content is reduced to 0.05%. The X-ray diffraction curve is as follows: Figure 4 As shown, it shows that no obvious mineral exists, and the hydrogen desorption amount of the obtained hydrogen storage material is 5.48wt%.

Embodiment 3

[0020] The difference from Example 1 is that the mass ratio of soda coal for coal deashing is 1:2, the concentration of hydrochloric acid is 2%, the acid leaching time is 2 hours, the ash content of the coal is reduced to 1.36%, and the hydrogen release capacity of the obtained hydrogen storage material is 5.30%. wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com