Patents

Literature

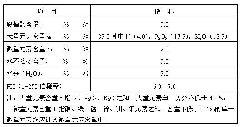

249results about How to "Increase element content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for processing CrNiMo series steel material

ActiveCN102877073AGuaranteed purityHigh strengthSolid state diffusion coatingIngotMaterials processing

The invention discloses a technology for processing a CrNiMo series steel material. The technology comprises the steps of adopting an electroslag remelting technology to obtain a steel ingot which contains 0.14-0.19% of C, 1.5-1.8% of Cr, 0.17-0.35% of Si, 0.4-0.6% of Mn, 0.25-0.36% of Mo, 1.4-1.7% of Ni, 0-0.035% of P and 0-0.030% of S according to percent by weight, forging the steel ingot, then carrying out normalizing and high temperature tempering, carburizing, high temperature tempering and oil quenching, and finally, carrying out low temperature tempering to complete the processing. According to the technology, a heat treatment processing technology which is simple and easy to operate is utilized to ensure the product quality, the problem that a loading part of a coal machine fails to work is solved, the service life of a product is prolonged, and the producing and processing costs are lowered.

Owner:常熟天地煤机装备有限公司

Water-soluble fertilizer by complexing humic acid with plurality of nutrient elements and preparation method thereof

ActiveCN101798246AAvoid fixationFacilitate the operation of transmissionFertilizer mixturesWater insolublePotassium

The invention belongs to the technical field of agriculture, in particular relates to a water-soluble fertilizer by complexing humic acid with a plurality of nutrient elements and a preparation method thereof. The water-soluble fertilizer is prepared by complexing the following raw materials by weight parts: 8 parts of potassium humic acid powder containing more than or equal to 50 percent of humic acid component, more than or equal to 10 percent of potassium oxide component and less than or equal to 2 percent of water-insoluble substances, 42-46 parts of water, 33-38 parts of major element compound, 10 parts of trace element compound, 1.3-1.5 parts of additives and 1.8-2.5 parts of plant growth regulator. The preparation method comprises six steps. The water-soluble fertilizer has the advantages of complete nutrient elements, higher crop absorption utilization rate and stronger directivity.

Owner:陕西赛恩农业科技股份有限公司

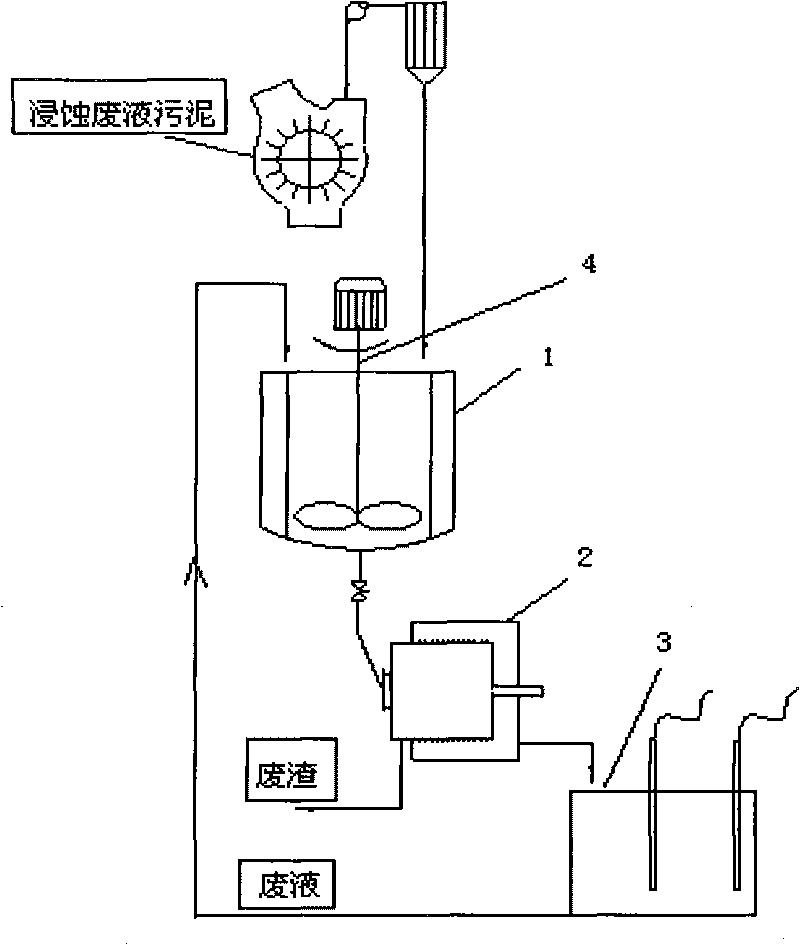

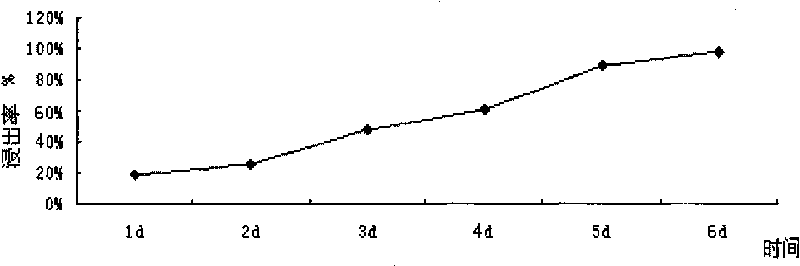

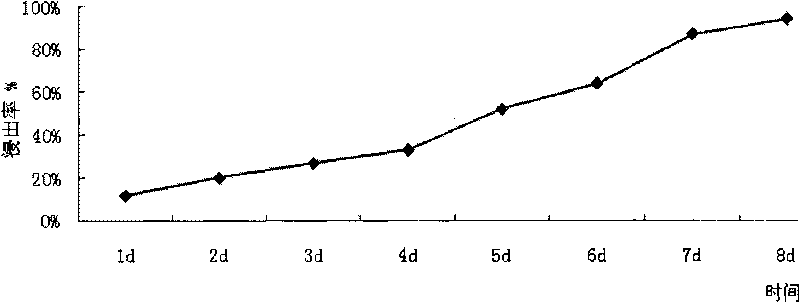

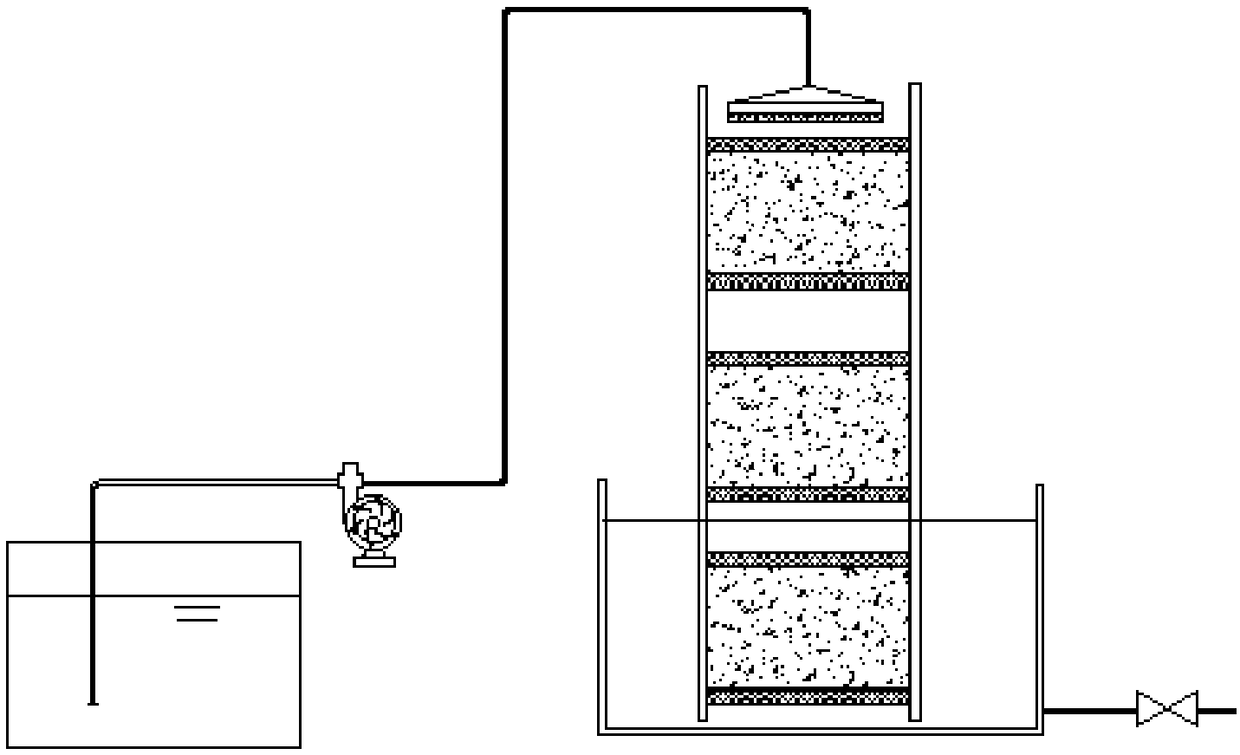

Method for recovering metallic copper in mud by using microorganism and special device

InactiveCN101760619AIncreased content of metal elementsIncrease element contentPhotography auxillary processesProcess efficiency improvementHeating systemMetal leaching

The invention relates to a method for recovering metallic copper in mud generated after production of a circuit board and / or treatment of electroplating rinse-waste water by using a microorganism and a special device. The method comprises the following steps: A, adding a culture medium into a reactor, inoculating a pre-cultured T.f bacteria and T.t bacteria inoculation liquid, starting a heating system and pre-culturing the mixture for 1+ / -0.5 day to obtain a reaction liquid; B, adding the mud into the reaction liquid obtained in the step A with stirring, starting an aeration machine to culture the mixture for 3 to 10 days, opening a valve at the bottom of the reactor, then pumping a leaching agent which contains mud granules from the reactor with stirring, filtering the mud granules with a filter press to obtain the metallic leaching agent; and C, after extracting and condensing the metallic leaching agent obtained in the step B, allowing the metallic leaching agent to enter an electrolytic bath for electrolysis to obtain copper with the purity of over 99 percent, or directly evaporating the concentrated liquor to obtain high-purity CuSO4. The method has the advantages of simple technique, low cost and environmental friendliness.

Owner:惠州市雄越保环科技有限公司

Vegetation protective soil base material activation method

InactiveCN101608446AImprove microbial structureQuick releaseExcavationsSoil preservationActivation methodDecomposition

A vegetation protective soil base material activation method is applied to the fields of ecological slope protection project, ecological restoration project and side slope and landscape garden greening project and the like. The method includes that concrete greening additive, organic matter, cement and activation substance are fully mixed to be uniform and then mixed into soil base material, and a spraying and sowing machine is adopted to spray activation substance on side slope finally, wherein the activation substance is obtained by combination and activation of three microbial inoculum fertilizers of nitrogen-fixing microbial inoculum fertilizer, phosphate-dissolving microbial inoculum fertilizer and silicatebacterium fertilizer. The vegetation protective soil base material activation method provided by the invention provides growth environment for plants in concrete and is beneficial to side slope greening plant growth. Meanwhile quantity of microorganism in slope protection base material is increased, and soil nutrient activation speed is improved by utilizing decomposition of microorganism on organic matter and release action of microorganism on mineral element, thus improving soil aggregate, improving soil fertility and effectively promoting side slope restoration.

Owner:山合林(北京)水土保持技术有限公司

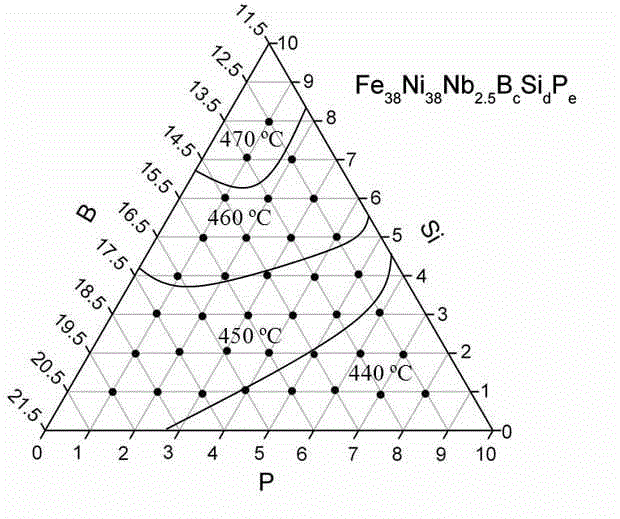

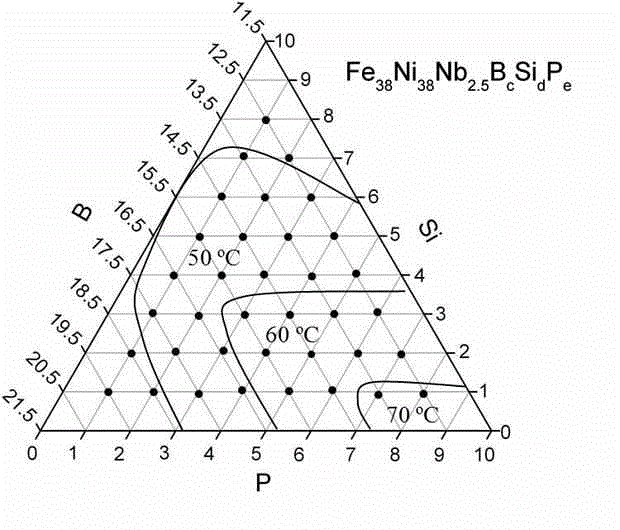

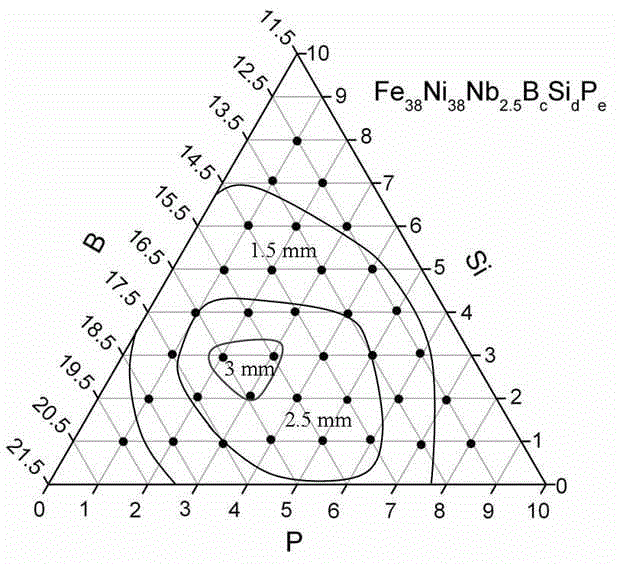

FeNi-based amorphous soft magnetic alloy and preparation method of soft magnetic alloy

ActiveCN102867608AIncrease element contentLarge critical dimensionMagnetic materialsDuctilityPlastic property

The invention discloses a FeNi-based amorphous soft magnetic alloy, of which the formula is FeaNibBcSidPeNbf, wherein a, b, c, d, e and f are atomic percentages; the FeNi-based amorphous soft magnetic alloy is characterized in that a is not less than 10 and not more than 75; b is not less than 5 and not more than 70; c is not less than 4 and not more than 24; d is not less than 0.1 and not more than 15; e is not less than 1 and not more than 14 and f is not less than 0.01 and not more than 6; moreover, the sum of a and b is not less than 72 and not more than 84, and the sum of a, b, c, d, e and f is 100 percent. The FeNi-based amorphous soft magnetic alloy has the characteristics of high content of FeNi elements, large critical dimension, high amorphous formation capacity, excellent soft magnetic performance and mechanical property; the breaking strength is more than 3.3 Gpa and the compressive ductility is more than 7 percent. In addition, the invention further provides a method for preparing FeNi-based amorphous soft magnetic alloy belts or rods.

Owner:朗峰新材料启东有限公司

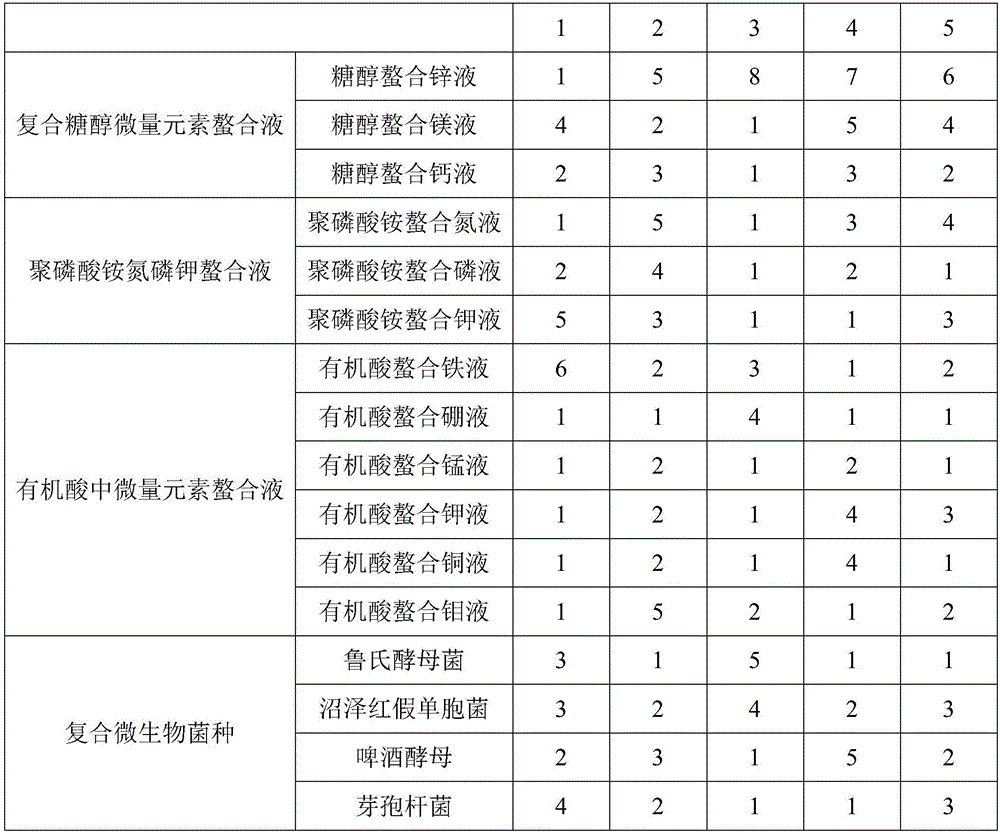

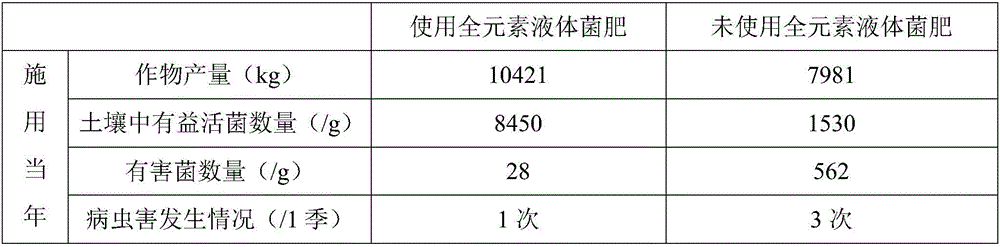

New-generation full-element chelated-state food-grade liquid bacterial fertilizer and preparation method thereof

InactiveCN106316694AFull of nutritionEnough contentCalcareous fertilisersBio-organic fraction processingAmmonium polyphosphateOrganic acid

The invention discloses a new-generation full-element chelated-state food-grade liquid bacterial fertilizer and a preparation method thereof, relates to an organic fertilizer containing bacterial cultures or hyphae, and aims at providing a liquid bacterial fertilizer and a preparation method thereof. Multiple high-salt-resistant strains are reasonably matched and cooperate with multiple chelating solutions, and therefore after the bacterial fertilizer is applied, effective ingredients in the bacterial fertilizer can be efficiently utilized for a long term. The new-generation full-element chelated-state food-grade liquid bacterial fertilizer is prepared from 4-6 parts of composite microbial strains, 4-5 parts of molasses, 0.4-0.6 part of bran, 0.05-0.1 part of carbamide, 0.05-0.1 part of sodium chloride, 0.01-0.02 part of tea leaves, 7-9 parts of a composite sugar alcohol-trace element chelating solution, 20-26 parts of an ammonium polyphosphate-nitrogen-phosphorus-potassium chelating solution, 3-5 parts of an organic acid-medium and trace element chelating solution and 45-50 parts of water. After the liquid bacterial fertilizer is applied, form transformation of soil nutrients can be promoted, plant metabolism can be enhanced, and pathogenic bacteria can be resisted. The liquid bacterial fertilizer is applied to the field of agricultural planting.

Owner:北京百丰生物科技集团有限公司

Method for preparing halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound

ActiveCN102180908APromote low-carbon and high-efficiencyEase of industrial scale productionGroup 5/15 element organic compoundsPolymer scienceHalogen

The invention discloses a method for preparing a halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound. The flame retardant is a pure white crystal product prepared by reacting sodium phenate and hexachlorocyclotriphosphazene serving as raw materials with dioxane serving as a solvent under heating and stirring, filtering and purifying. The preparation method of the flame retardant overcomes the defects of long reaction time, a yellow product color and high production cost existing in the conventional synthesis method commonly. The prepared flame retardant has the characteristics of high efficiency, no halogen, flame retardance, no toxicity, low smoke and the like, has high compatibility with most of organic polymer materials, and has processing stability and using stability.

Owner:JINAN TAIXING FINE CHEM

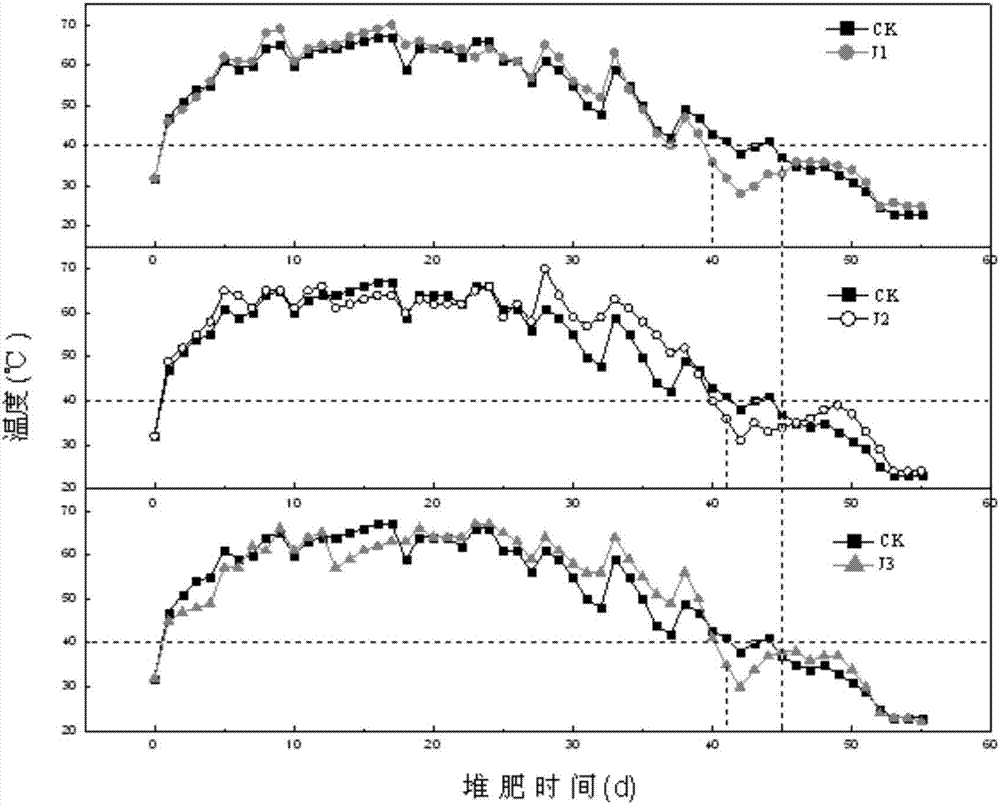

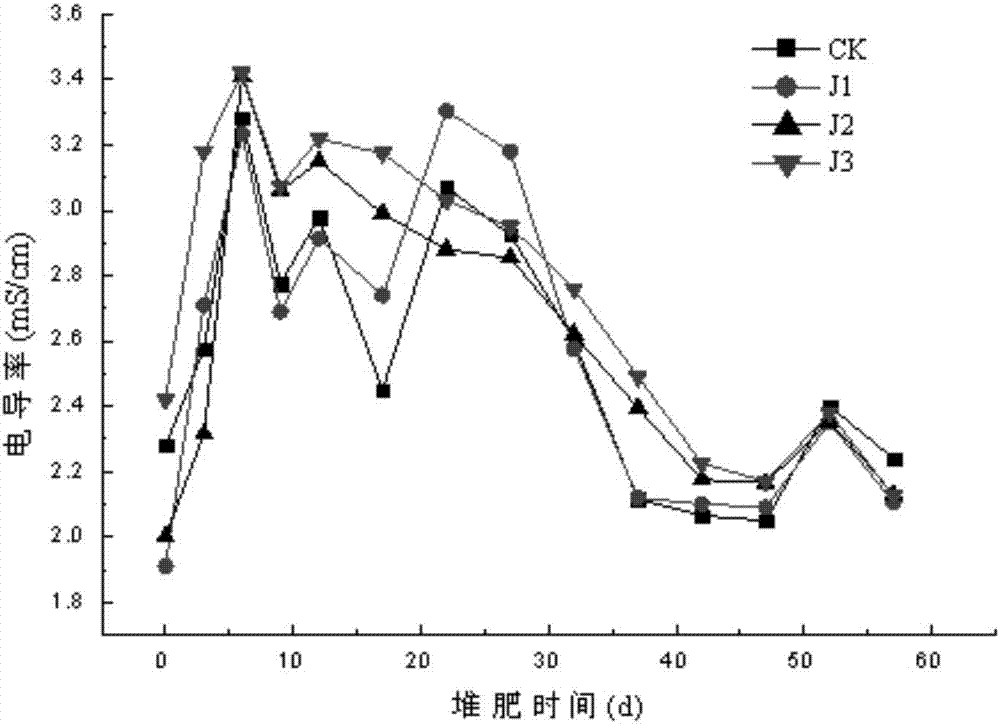

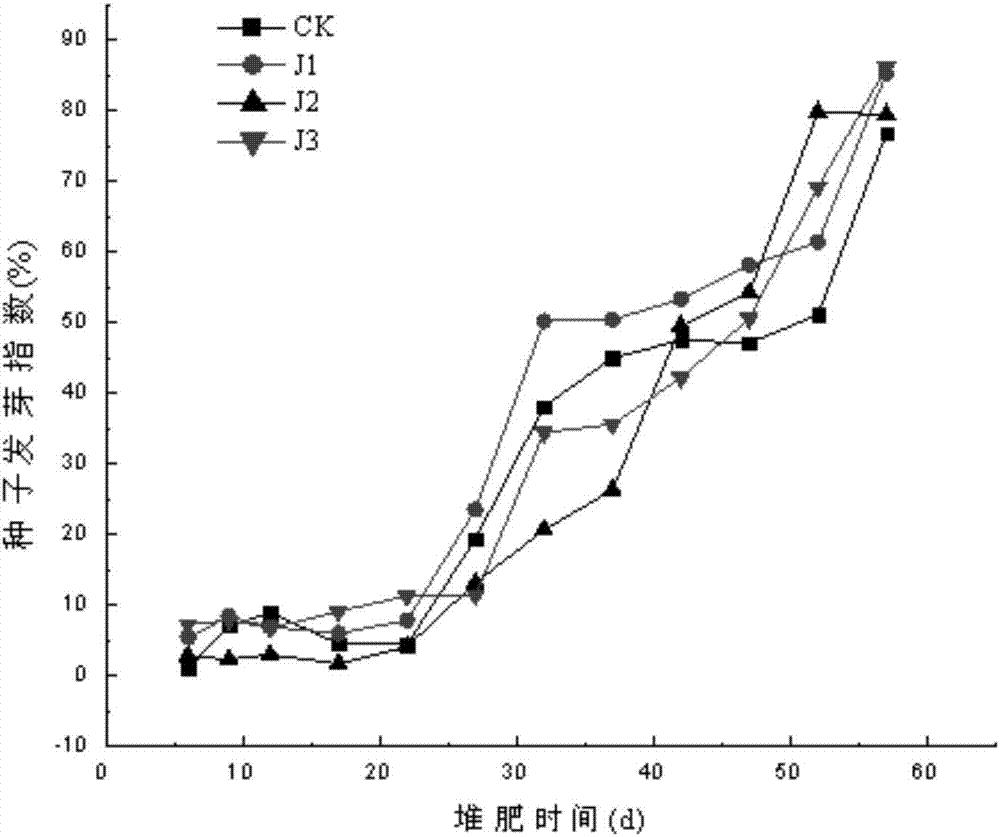

Compound microbial agent for promoting fermentation of pig manure composting

InactiveCN107058179AShort fermentation timeThe promotion effect is obviousBio-organic fraction processingBacteriaBiotechnologyEnterobacter agglomerans

The invention discloses a compound microbial agent for promoting fermentation of pig manure composting. The compound microbial agent is prepared from thermobifida fusca, ureibacillus thermophaericus, pantoea agglomerans, gibsonii, bacillus amyloliquefaciens, bacillus pumilus and a liquid culture medium. Compared with other treatment methods, the fermentation time of the compound microbial agent on the pig manure composting is shorter, and more obvious facilitation effect on fermentation of the pig manure composting is obtained.

Owner:HUAZHONG AGRI UNIV

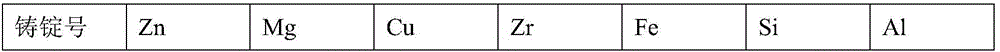

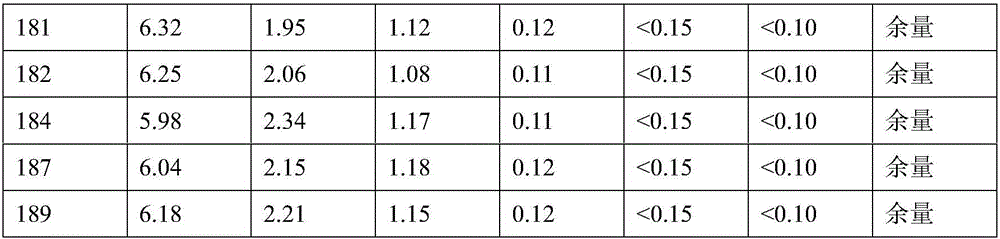

Ultrahigh-strength aluminum alloy with high strength and high hardenability and preparation method of ultrahigh-strength aluminum alloy

The invention discloses ultrahigh-strength aluminum alloy with high strength and high hardenability and a preparation method of the ultrahigh-strength aluminum alloy. The ultrahigh-strength aluminum alloy comprises the components in percentage by weight: 5.8-6.4wt% of Zn, 1.8-2.6wt% of Mg, 1.0-1.2wt% of Cu, 0.06-0.20wt% of Zr, less than or equal to 0.08wt% of Fe, less than or equal to 0.06wt% Si and the balance of Al and unavoidable impurities. Compared with aluminum alloy such as AA7075 and AA7085, the effective strengthening phase of the alloy is remarkably optimized through reasonably controlling the contents of Zn, Mg and Cu, a Zn / Mg value and a Cu / Mg value in the alloy, therefore, the alloy keeps the hardenability of the aluminum alloy AA7085, and meanwhile, the strength of the alloy is obviously higher than the aluminum alloy such as AA7085; and an interdendritic second phase of the alloy is enabled to be sufficiently decomposed through controlling a homogenization heat treatment process, so that the content of elements which can be strengthened in the alloy is increased.

Owner:FOSHAN UNIVERSITY

Fixed-length shear blade and manufacturing method thereof

InactiveCN102644027AImprove toughnessGuaranteed anti-crashing performanceIncreasing energy efficiencyIngot castingShock resistance

The invention discloses a fixed-length shear blade and a manufacturing method of the fixed-length shear blade. The fixed-length shear blade comprises the following components by weight percent: 0.75-1.00% of C, 0.60-1.40% of Si, 0.20-0.50% of Mn, 6.50-8.00% of Cr, 2.50-4.00% of Mo, 1.80-3.50% of V, less than or equal to 0.020% of S, less than or equal to 0.020% of P, the balance of Fe and the unavoidable impurities; and the manufacturing method of the fixed-length shear blade comprises the technological process of: smelting by an induction furnace, electrode bar pouring, electroslag remelting, ingot casting, forging, preheating treatment, rough machining, hardening and tempering heat treatment, semi-finishing, final heat treatment and finish machining. The fixed-length shear blade is high in strength and wear resistance, thus guaranteeing the shock resistance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Three-dimensional porous far-infrared negative ion ceramic body, preparation method thereof, and purpose thereof

InactiveCN102432325AFormulation ScienceReasonable formulaElectrotherapyBathing devicesAdhesiveWater soluble

The invention discloses a three-dimensional porous far-infrared negative ion ceramic body, a preparation method thereof, and a purpose thereof. The three-dimensional porous far-infrared negative ion ceramic body comprises components of, by weight: 20-60 parts of a framework material, 5-30 parts of a far-infrared negative ion mineral material, 0.2-1.5 parts of a water-soluble organic adhesive, 1-10 parts of an inorganic adhesive, 0.5-25 parts of a functional filling material, and 10-68 parts of water. With the method provided by the invention, various defects of existing technologies are overcome. The prepared three-dimensional porous far-infrared negative ion ceramic body is advantaged in large surface area, high strength and good cooperativity with water.

Owner:GUANGDONG JUNFENG BFS TECH

Bearing steel and technology for heating processing

The invention discloses a novel bearing steel and a technology for heating processing, wherein the bearing steel comprises chemical composition (by weight percent): 0.70-0.80% of C, 0.55-0.65% of Si, 1.00-1.10% of Mn, 0.50-0.65% of Cr, not more than 0.10% of Mo, not more than 0.025% of P, not more than 0.025% of S, not more than 0.30% of Ni, not more than 0.25% of Cu, not more than 0.50% of Ni+Cu as well as balance Fe and unavoidable impurities. The technology for heating processing of the bearing steel comprises steel heating processing technique and semi-finished product heating processing technique after mechanical processing of workpieces. The invention can improve the processing accuracy of steel, impact toughness and fatigue life.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Lick brick for treating animal nutrient metabolism disease

InactiveCN101224280AFull of nutritionTargetedMetabolism disorderPharmaceutical delivery mechanismNutrientCalcium

The invention relates to a lick brick used for treating animal nutritional and metabolic diseases, and is characterized in that each kilogram of the lick brick consists of the following components: 250-300g of honey, 100-150g of urea, 200-250g of common salt, 50-70g of calcium oxide, 70-75g of bran, 200-250g of bentonite,125-150g of calcium hydrophosphate, 5.2-7.145g of zinc sulfate, 2-3g of bluestone, 0.7-0.815g of potassium iodide, 0.7-0.87g of sodium selenite, 0.5-0.65g of cobalt chloride, 50g of vitamins and 100g of parasite repelling and stomach strengthening pulvis. Through the reasonable combination of trace elements and mineral elements required by cows, the invention achieves comprehensive nutrition and strong pertinence, and has significant curative effect on animal nutritional and metabolic diseases, blindness and reproductive system diseases of cows and remarkable effect on facilities feeding and the development of animal productivity. The invention can also be used for the treatment of the same diseases of other animals.

Owner:杨奇 +1

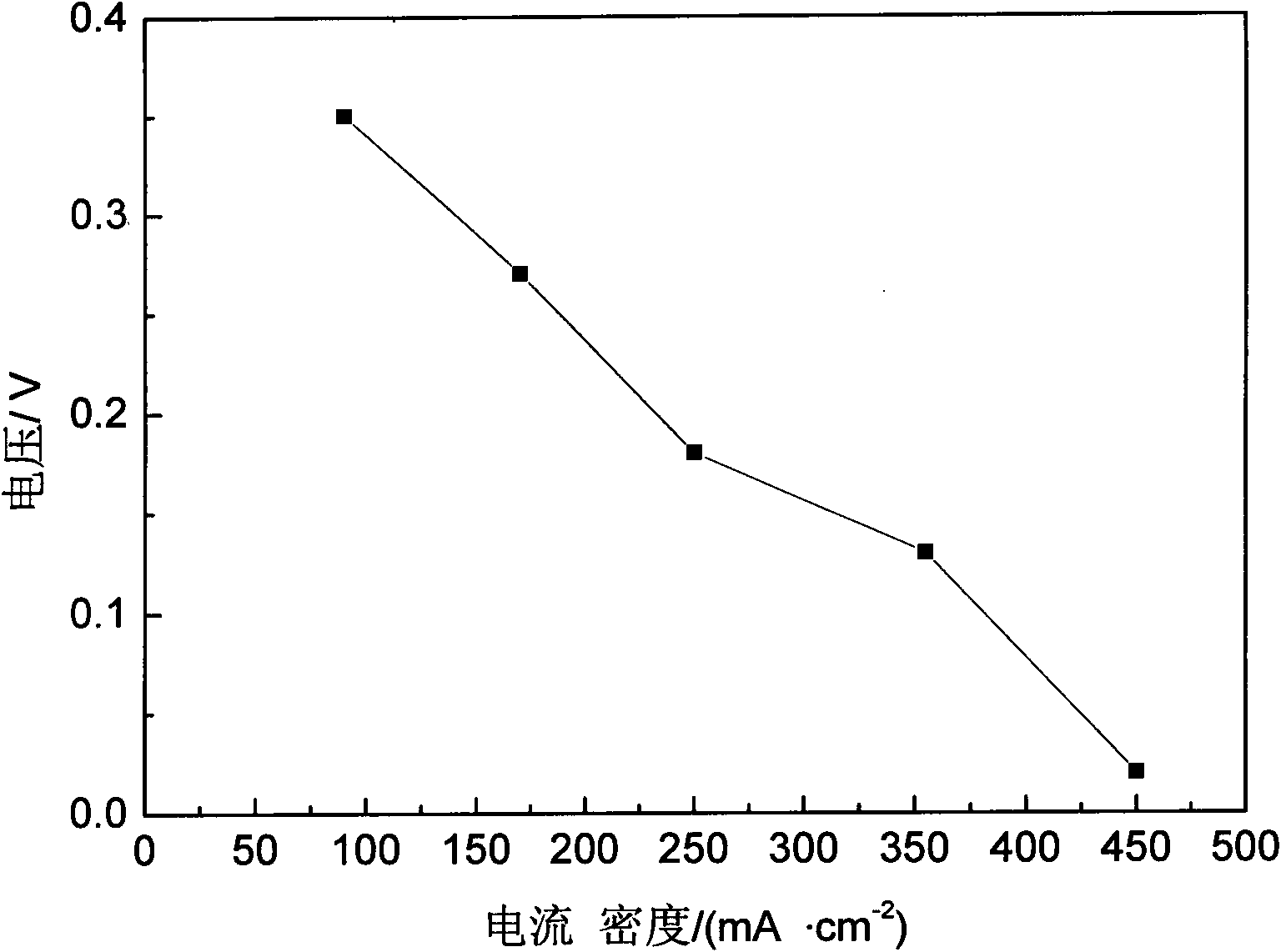

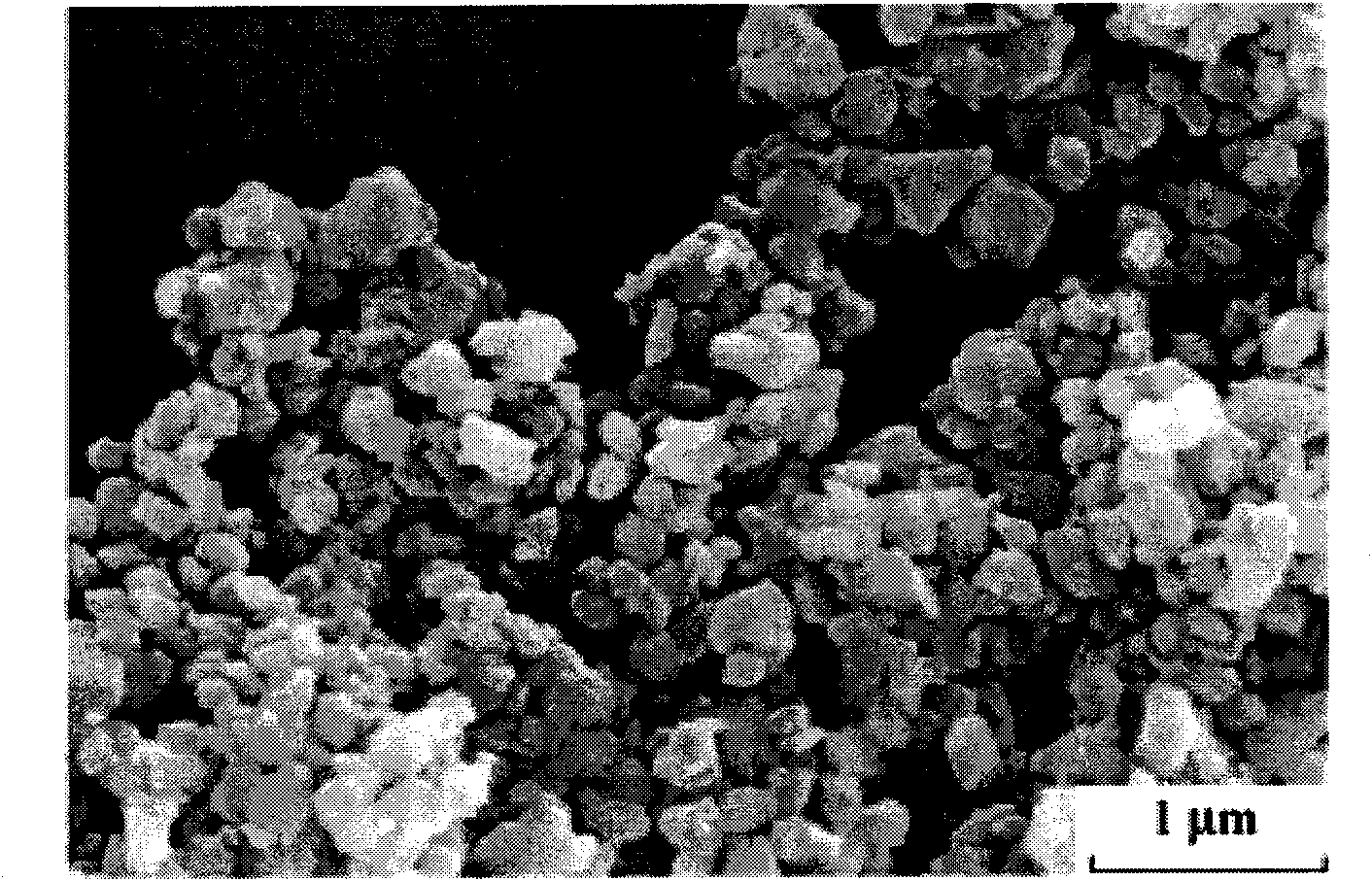

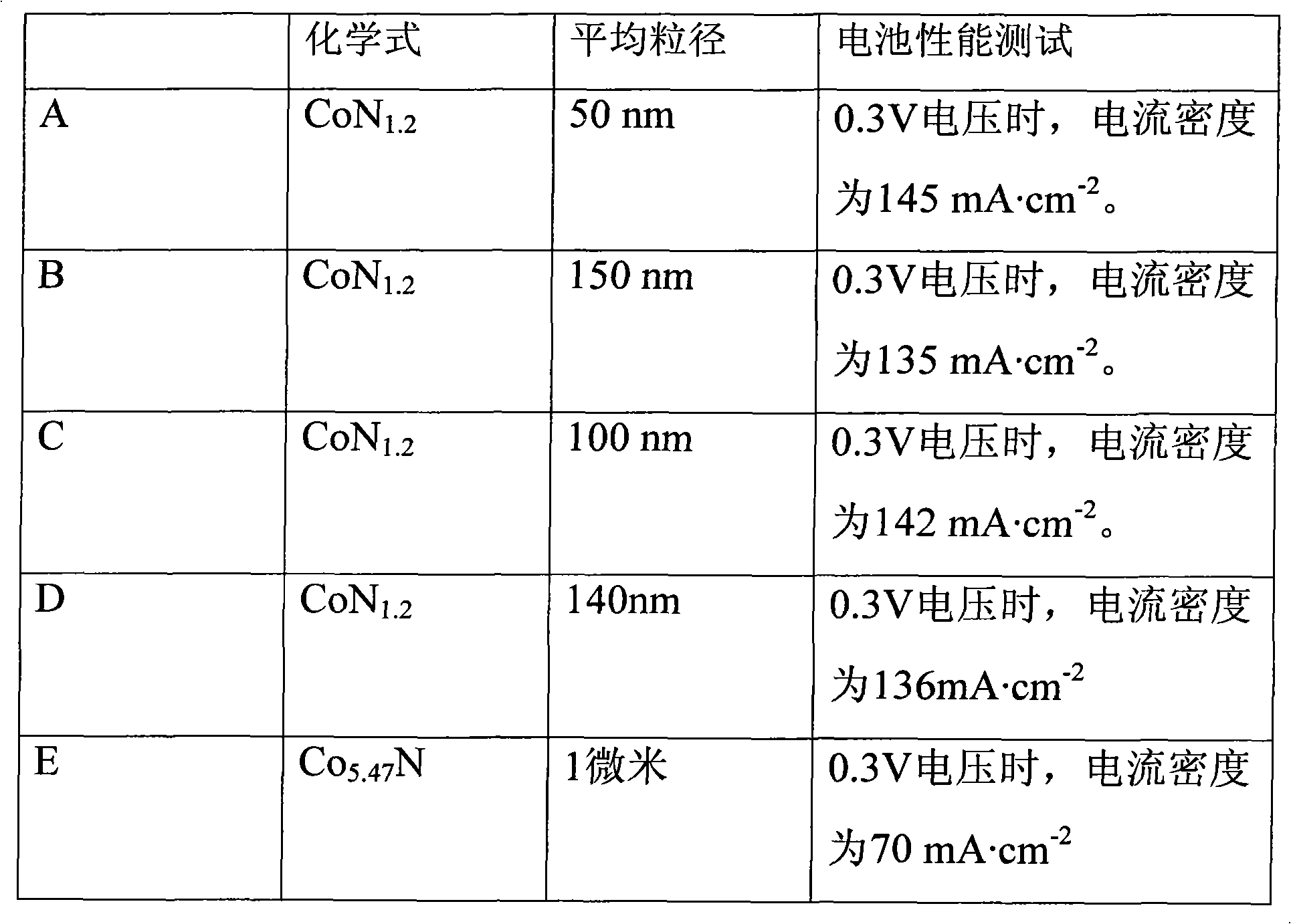

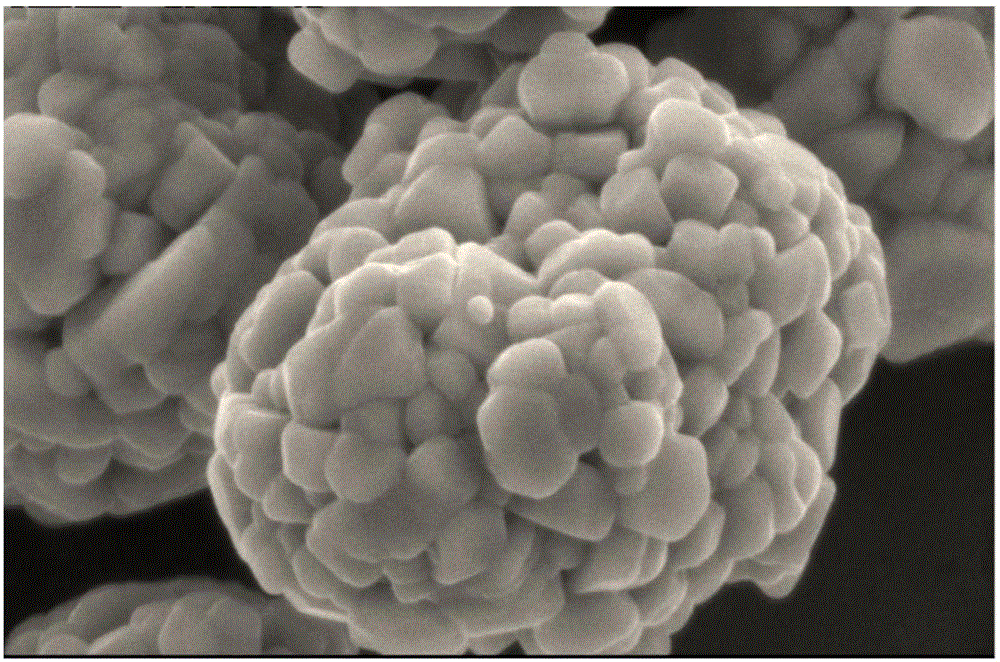

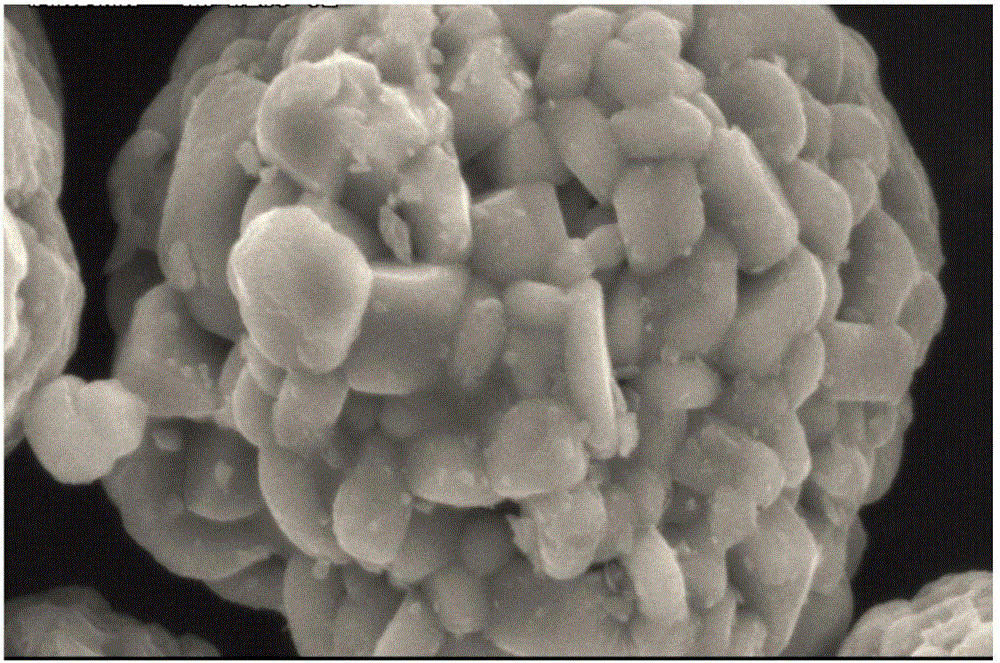

Cobalt nitride compound and preparation method thereof as well as methanol fuel cell catalyst and preparation method thereof

InactiveCN101885476AIncrease element contentRestore fastNitrogen-metal/silicon/boron binary compoundsCatalyst activation/preparationCobalt acetateMethanol fuel

The invention provides a cobalt nitride compound. The chemical formula of cobalt nitride is CoN1.2. The invention also provides a preparation method of the cobalt nitride compound, wherein the average grain size of a reaction raw material namely cobalt acetate is 300 to 500 nanometers, and the cobalt acetate is sintered at a high temperature in the presence of a nitrogen source atmosphere to obtain the cobalt nitride compound. The invention also provides a methanol fuel cell catalyst and a preparation method thereof, wherein the catalyst comprises the cobalt nitride compound and a carrier for loading the cobalt nitride compound. The preparation method of the methanol fuel cell catalyst comprises the following steps of: performing ball milling on the reaction raw material cobalt acetate and the carrier for loading the cobalt nitride compound to ensure that the average grain size is 300 to 500 nanometers; and performing high temperature sintering in the presence of the nitrogen source atmosphere to obtain the catalyst.

Owner:BYD CO LTD

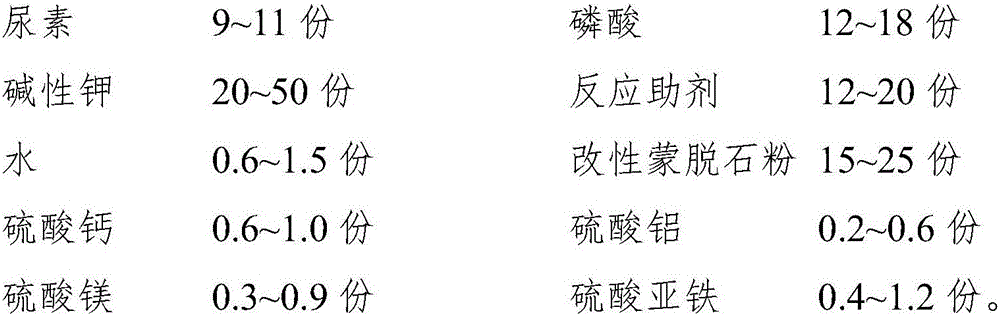

Fertilizer capable of fixing soil heavy metal and preparing method thereof

InactiveCN106631598AMeet growth needsReasonable formulaCalcareous fertilisersMagnesium fertilisersAluminium sulfatePhosphoric acid

The invention relates to the technical field of chemical engineering, and discloses a fertilizer capable of fixing soil heavy metal and a preparing method thereof. The fertilizer is prepared from, by weight, 9-11 parts of urea, 12-18 parts of phosphoric acid, 20-50 parts of alkaline potassium, 12-20 parts of reaction auxiliary, 0.6-1.5 parts of water, 15-25 parts of modified smectite powder, 0.6-1.0 part of calcium sulfate, 0.2-0.6 part of aluminum sulfate, 0.3-0.9 part of magnesium sulfate and 0.4-1.2 parts of ferrous sulfate. The used reaction auxiliary can be used as a catalyst when urea reacts with phosphoric acid and can be used for removing heavy metal ions in soil, impurity removal is omitted, no effluent or waste gas is exhausted, raw materials used in production are fully and reasonably used, and the fertilizer has remarkable environment protection benefits.

Owner:GUIZHOU UNIV

High-strength high-ductility titanium alloy

The invention relates to a high-strength high-tenacity titanium alloy, which is mainly used for manufacturing forged parts in structures of an airframe, airfoils and an undercarriage of an airplane. The high-strength high-tenacity titanium alloy is characterized in that the compositions of each alloy by weight percentage are: 3.5 to 5.5 percent of Al, 4.0 to 8.0 percent of V, 5.0 to 7.0 percent of Cr, 3.0 to 7.0 percent of Mo, and the residual amount of Ti and inevitable impurities. The nominal chemical composition of the high-strength high-tenacity titanium alloy is Ti-4Al-6V-6Cr-5Mo, compared with Ti-1023 titanium alloy and BT22 titanium alloy, the alloy uses Ti-Al-Mo-V-Cr alloy system, so as to increase the content of alloying elements, and reasonably adjusts the proportion of aluminum equivalent and molybdenum equivalent, so that the strength index and the tenacity index of the alloy is obviously improved and the performance of the alloy is more excellent. The obdurability of the high-strength high-tenacity titanium alloy can reach that: the strength sigmab is more than or equal to 1,200MPa, and the fracture toughness K1C is more than or equal to 65MPa m.

Owner:BAOJI TITANIUM IND CO LTD

Konjaku flour walnut sauce with function of health care and preparation method thereof

InactiveCN102018240AIncreased and mineral element contentImprove nutrition and health effectsFood preparationChemistryColloid mill

The invention relates to konjaku flour walnut sauce with the function of health care and a preparation method thereof. The konjaku flour walnut sauce is characterized in that the formulation comprises the following components by weight percent: 77% to 82% of walnut meat, 3% to 10% of konjaku flour, 4% to 6% of white sugar, 0.5% of CMC (Sodium Carboxymethyl Cellulose), 0.2% of edible salt and the balance of water. The preparation method comprises the steps of: baking the walnut meat for 30 minutes to 40 minutes at 135 DEG C to 145 DEG C; cooling; peeling; roughly grinding the walnut meat by a pulverizer or a colloid mill into walnut sauce; baking the konjaku flour for 12 minutes at 125 DEG C until the color is light yellow; grinding the white sugar into powder; adding the powdery white sugar and the edible salt in proportion to the walnut sauce; continuously grinding the walnut sauce until the walnut sauce is fine and smooth; then adding hot water to the CMC to dissolve the CMC; adding CMC to the walnut sauce to continuously grind the walnut sauce; uniformly stirring; canning; and sterilizing at high temperature. The invention keeps the original natural flavor of walnut, contains carbohydrate, dietary fiber and mineral elements, and enhances nutrition and health care function. The konjaku flour walnut sauce has the advantages of fine and sweet mouth feel, no separation of an oil layer, and good application performance and is convenient for eating.

Owner:BEIJING UNION UNIVERSITY

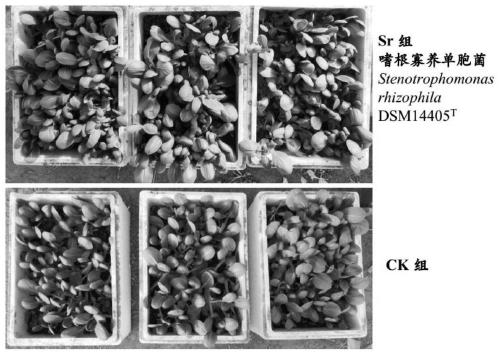

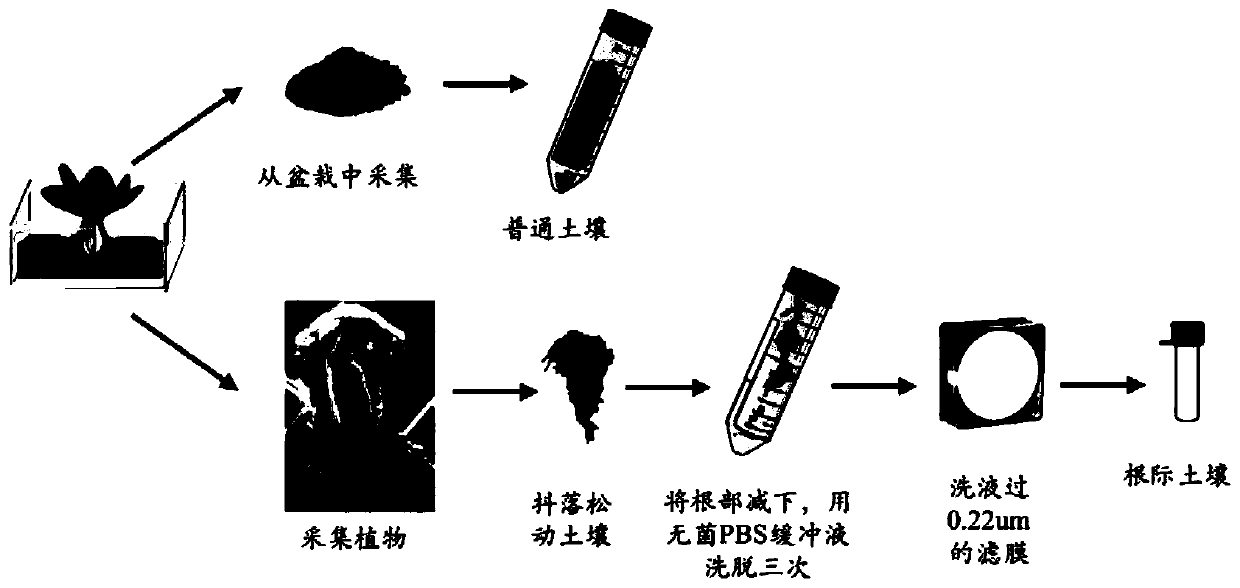

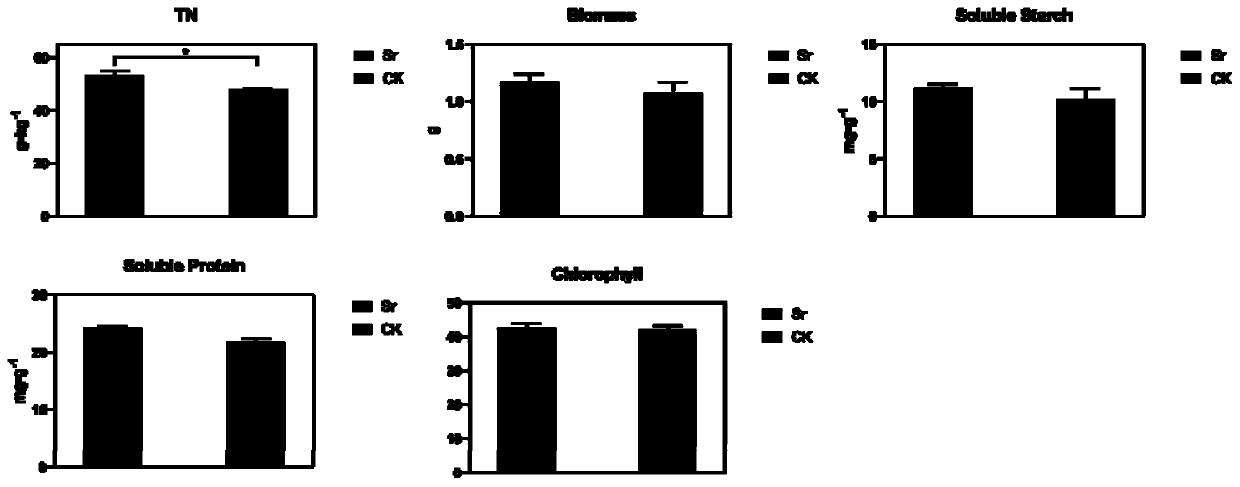

Application of stenotrophomonas rhizophila in improvement of rhizosphere soil and promotion of plant growth

InactiveCN111533585AIncrease contentImprove physical and chemical propertiesOrganic fertilisersSoil-working methodsBiotechnologyNitrate nitrogen

One or more embodiments of the present specification provide an application of stenotrophomonas rhizophila in improvement of rhizosphere soil and promotion of plant growth. One or more embodiments ofthe invention further provide a method for improving rhizosphere soil and promoting plant growth. Stenotrophomonas rhizophila is added into the soil at the early stage of plant growth. The stenotrophomonas rhizophila can increase the content of nitrate nitrogen, phosphorus and other elements in rhizosphere soil, improve the physicochemical properties of the rhizosphere soil and increase the content of nitrogen in plants. Therefore, the stenotrophomonas rhizophila can replace chemical fertilizer to play a role in agricultural production.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

SnZn-based lead-free brazing filler metal containing Cr

InactiveCN102489892AImprove antioxidant capacityImprove wettabilityWelding/cutting media/materialsSoldering mediaCopperElectronic component

The invention belongs to the field of welding material, and particularly relates to a SnZn-based lead-free brazing filler metal containing Cr suitable for reflow soldering and wave soldering in electronic packing. The SnZn-based lead-free brazing filler metal comprises 0.01 to 0.1 percent by weight of Ni, 0.001 to 0.01 percent by weight of P, 0.05 to 0.2 percent by weight of Nd, 0.1 to 0.5 percent by weight of In, 0.01 to 0.5 percent by weight of Cr, 1 to 5 percent by weight of Bi, 7 to 11 percent by weight of Zn, and Sn in balancing amount; and the weight percentage sum of all the components is 100%. The SnZn-based lead-free brazing filler metal has excellent antioxygenic property, wettability and mechanical property, the melting point is equal to that of a conventional SnPb brazing filler metal, copper precipitation is not required, the SnZn-based lead-free brazing filler metal is suitable for reflow soldering and wave soldering, traditional brazing packing devices and electronic components.

Owner:广东中实金属有限公司

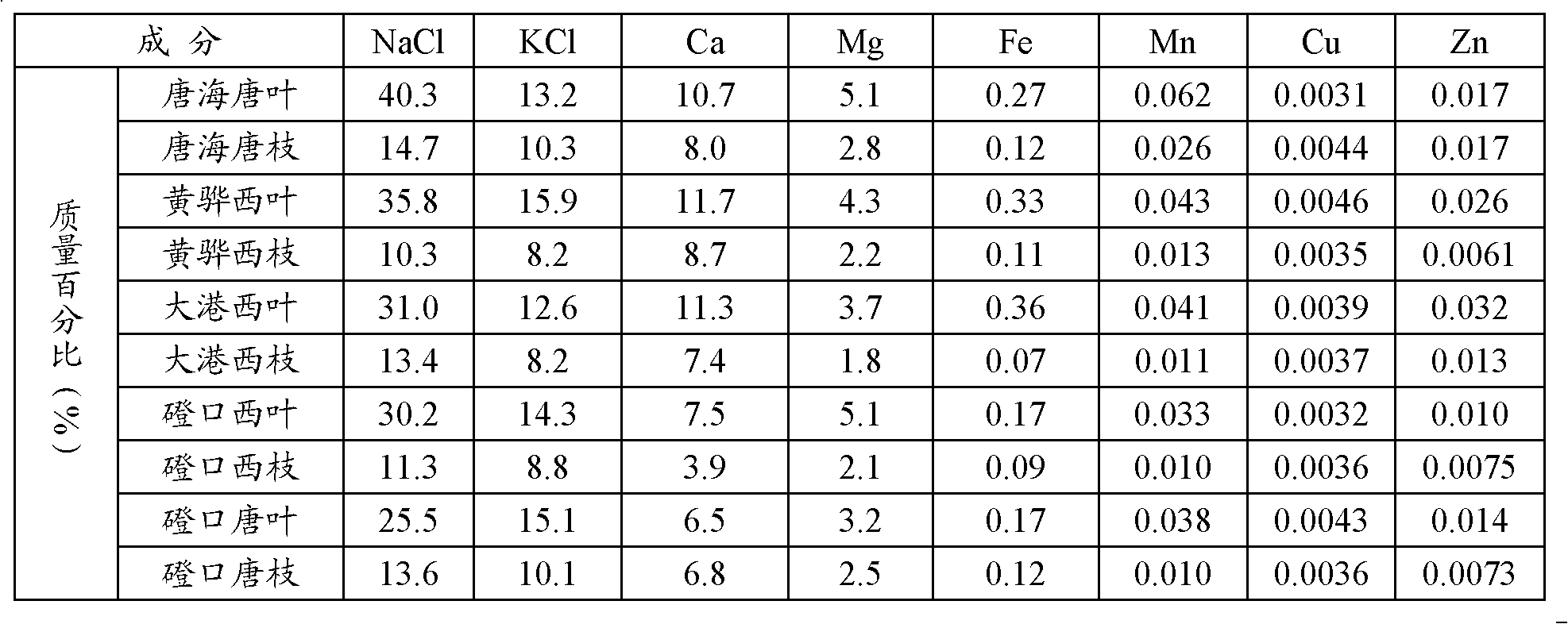

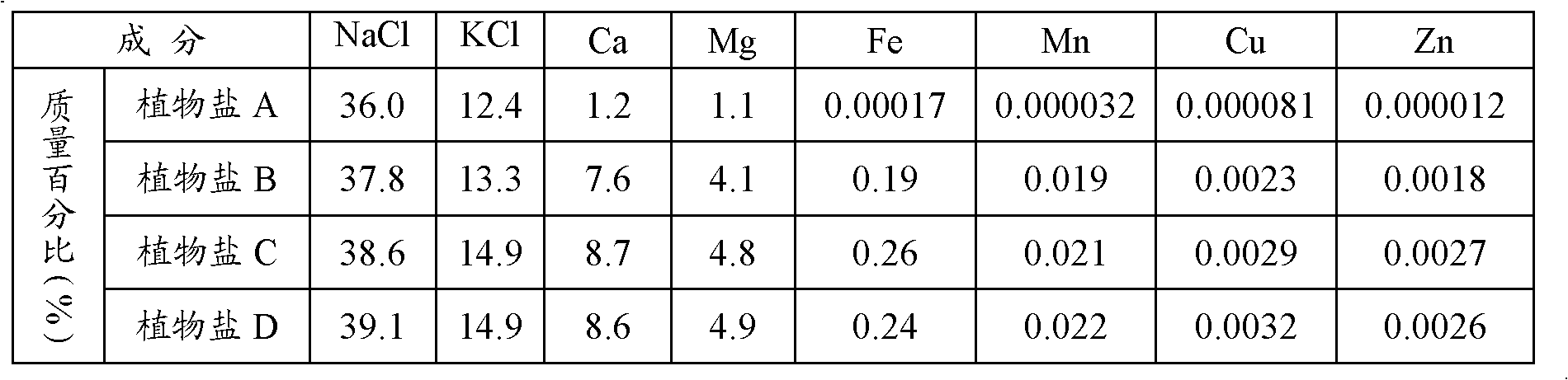

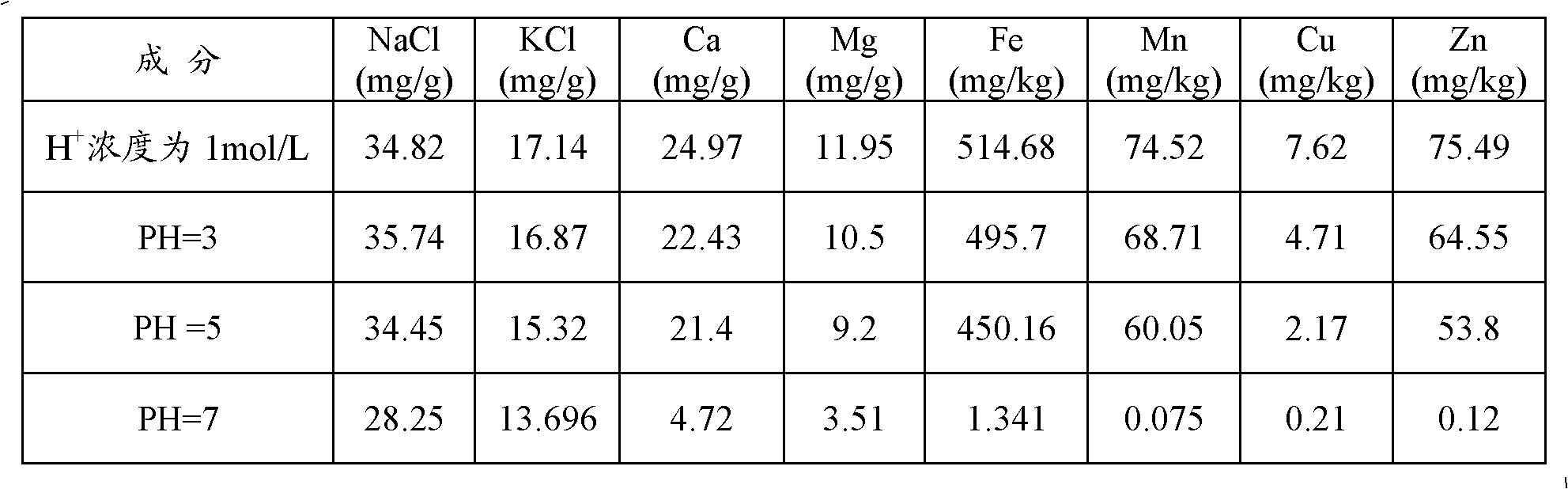

Nitraria plant salt and preparation method thereof

InactiveCN102524740AReduce morbidityLow carbonization temperatureFood preparationChemistryCalcium EDTA

The invention provides Nitraria plant salt and a preparation method thereof. The Nitraria plant salt contains the following components in percentage by weight: 10.3 to 40.3 percent of sodium chloride, 8.0 to 16.0 percent of potassium chloride, 3.5 to 12.0 percent of calcium, 1.5 to 5.5 percent of magnesium, 0.05 to 0.40 percent of iron, 0.010 to 0.065 percent of manganese, 0.0024 to 0.0045 percent of copper, and 0.0010 to 0.035 percent of zinc. The preparation method of the Nitraria plant salt comprises a step of charring a Nitraria plant to obtain a charred material and a step of performing water extraction and acid extraction to the charred material. The preparation method can be adopted to produce Nitraria plant salt which can serve as low-sodium salt and can also utilize Nitraria plants to reduce the salt and alkali contents of soil and improve the ecological environment.

Owner:张华新 +1

Method for producing special multi-element fertilizer for rice from kieselguhr

ActiveCN102775254AHigh content of effective nutrientsReduce usageFertilizer mixturesPorosityDispersity

The invention relates to a method for producing a special multi-element fertilizer for rice from kieselguhr, which belongs to the field of fertilizers and aims to solve the problems of low effective silicon content, poor particle disintegrability, low dispersity and poor water solubility of the existing silicon fertilizer. The method comprises the following steps: evenly mixing kieselguhr and hydroxide, enclosing, and performing hydration reaction in a container at a temperature of 100-1000 DEG C and a pressure of 1.0-1.5 kilograms for 48 hours, wherein the hydroxide includes calcium hydroxide and potassium hydroxide; cooling with more than 3 times of 7 DEG C water until the temperature is below 30 DEG C, precipitating, filtering, baking, and crushing to obtain a mixture; adding magnesium oxide power, wherein the magnesium oxide power accounts for 6% of the mixture; and evenly mixing to obtain the special multi-element fertilizer for rice. The invention is applied to rice planting. The content of silicon, magnesium, calcium and minor elements of the special multi-element fertilizer for rice is about 85%; and the porosity is up to 90%.

Owner:黑龙江华泽农牧发展有限公司

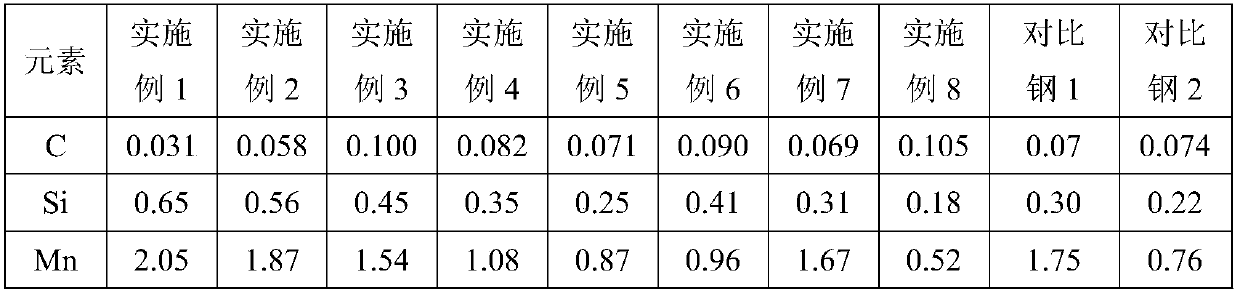

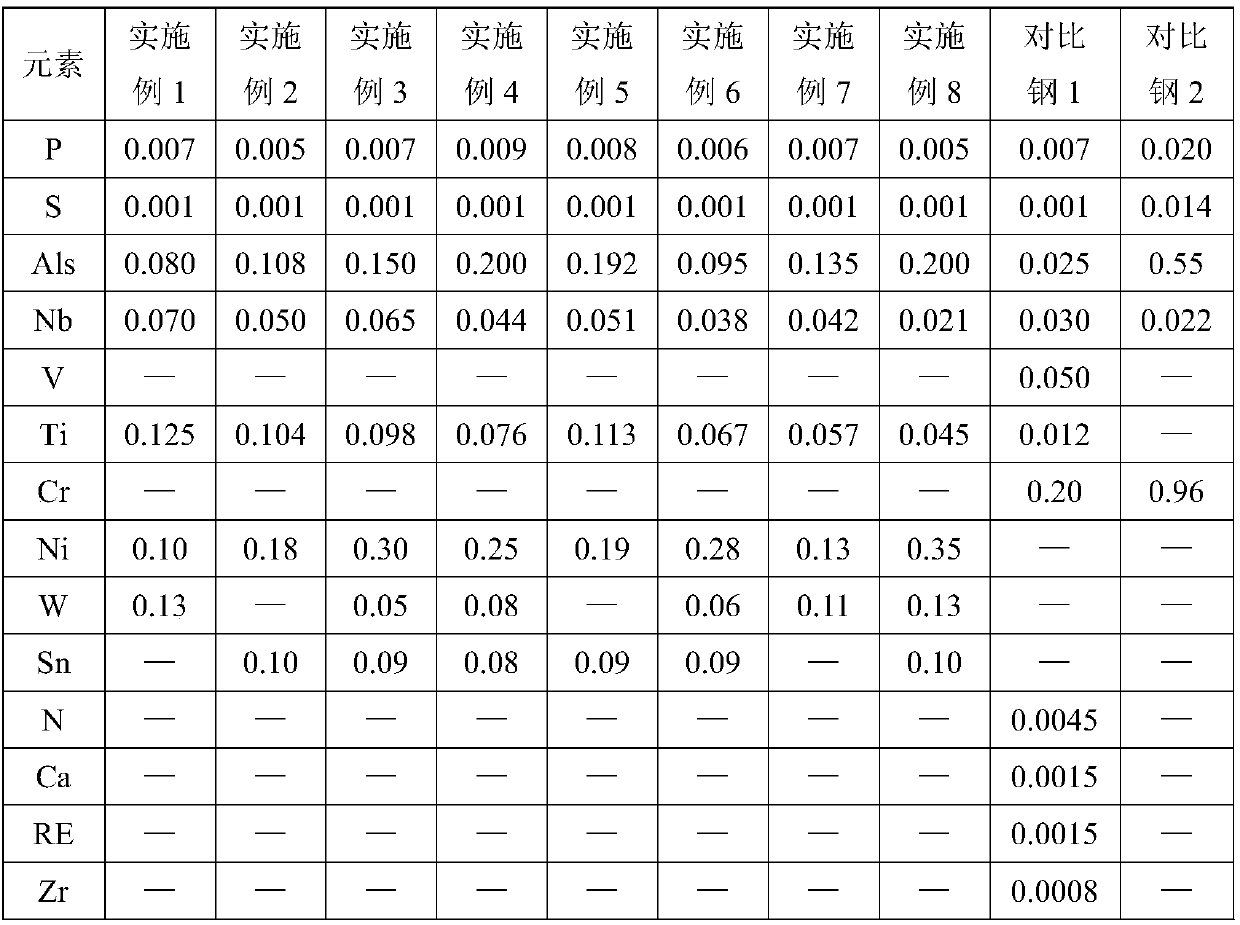

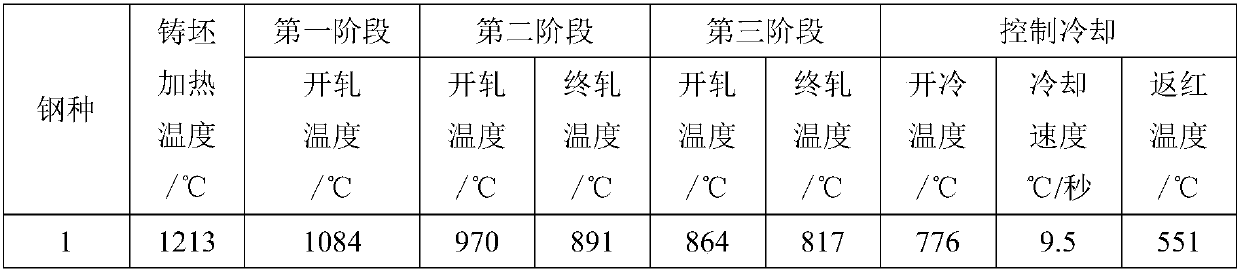

440 MPa corrosion resisting steel for ship at low temperature environment and production method of corrosion resisting steel

The invention discloses a corrosion-resistant steel for 440MPa ships in a low-temperature environment and a production method thereof, belonging to the technical field of material steel. It includes the following components in mass percentage: C: 0.031-0.105%, Si: 0.18-0.65%, Mn: 0.52-2.05%, P≤0.009%, S≤0.001%, Als: 0.080-0.200%, Nb: 0.021 to 0.070%, Ti: 0.045 to 0.125%, Ni: 0.10 to 0.35%, and the balance is Fe and unavoidable impurities. The production method is 1) conventional molten iron desulfurization; 2) converter smelting and RH vacuum treatment; 3) billet continuous casting and heating; 4) section rolling; 5) cooling. The prepared steel plate can be used in an extremely cold and low temperature environment of around ‑80°C. The yield strength of the steel plate is ≥440Mpa, the impact toughness KV2≥100J, and the seawater corrosion performance is better than the traditional seawater corrosion-resistant steel 10CrMoAl.

Owner:武汉钢铁有限公司

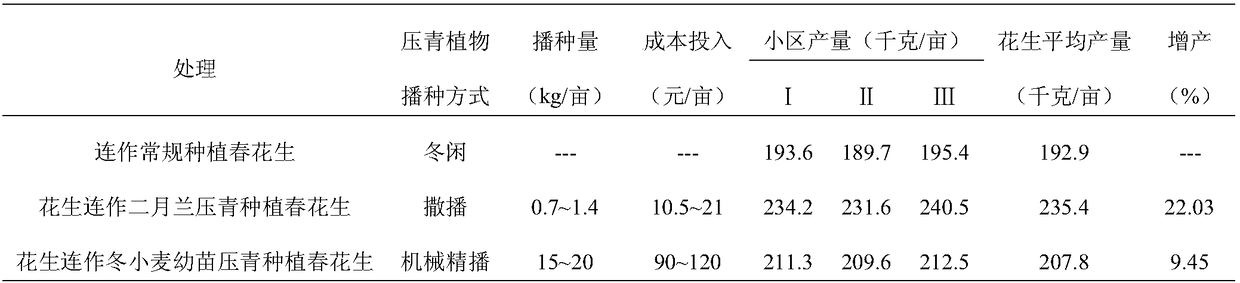

Planting method capable of preventing peanut continuous cropping obstacle

InactiveCN108575640AIncrease contentIncrease element contentFabaceae cultivationGrowth substratesContinuous croppingSoil organic matter

The invention discloses a planting method capable of preventing peanut continuous cropping obstacle and belongs to the technical field of crop planting. According to the planting method capable of preventing the peanut continuous cropping obstacle, orychophragmus violaceus is sowed at land after peanut harvesting and used for turning over of green manure before planting of continuous cropping peanut. The peanut is spring peanut and the land is winter fallowing field. Through turning over of green manure by the orychophragmus violaceus, on one hand, the organic matter content of soil can be increased and organic fertilizer basal application can be reduced; on the other hand, the microbial groups of soil in the continuous cropping peanut field can be changed. By means of the planting method,manpower and material resource consumption caused by intensive cultivation of soil can be substantially reduced, the transpiration of the soil can be reduced, the utilization rate and productivity ofthe soil can be increased, and the peanut yield can be increased.

Owner:SHANDONG PEANUT RES INST

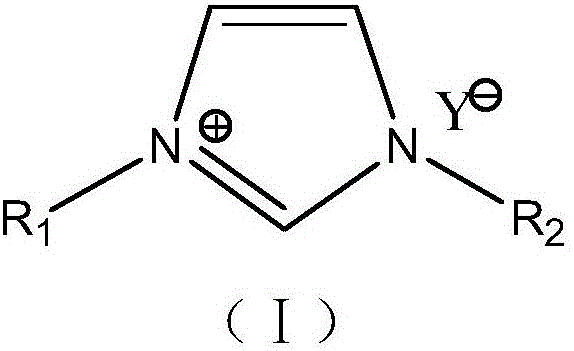

Positive pole piece and lithium ion battery containing pole piece

InactiveCN106252649AHigh tap densityIncrease gram capacityCell electrodesSecondary cellsPhysical chemistryPole piece

The invention relates to the field of lithium ion batteries, and particularly relates to a positive pole piece and a lithium ion battery containing the pole piece. The positive pole piece provided by the invention comprises a positive pole current collector, and a positive pole active material adhered to the positive pole current collector, the positive pole active material contains a modified ternary material with a coating layer on the surface, the structural formula of the modified ternary material is LiCo(1-x-y)MnxNiyO2, wherein x is more than 0 and is less than or equal to 0.3, y is more than 0 and is less than or equal to 0.3, and x+y is more than 0 and is less than or equal to 0.6, and the coating layer contains imidazole ion liquid. According to the invention, the proportion of the contents of Ni element and Mn element in the ternary material can be optimized, meanwhile, the imidazole ion liquid is added in the positive pulping process, the direct contact of an active material and the electrolyte can be blocked to avoid corrosion, and the stability of the battery is improved.

Owner:NINGDE AMPEREX TECH

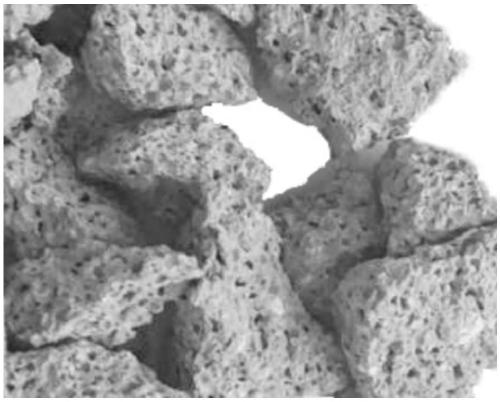

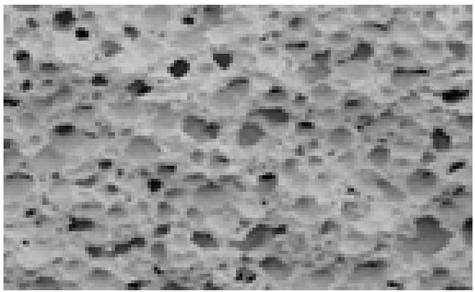

Porous dephosphorization filter material based on kieselguhr and silicon earth and preparation method thereof

PendingCN109225126ALower isoelectric pointGood removal effectOther chemical processesWater contaminantsWater qualitySewage

The invention relates to the technical field of sewage treatment, in particular to a porous dephosphorization filter material based on kieselguhr and silicon earth and a preparation method thereof. The porous dephosphorization filter material is prepared from the following ingredients in parts by weight: 20 to 30 percent of kieselguhr, 45 to 55 percent of silicon earth, 8 to 11 percent of cement,6 to 10 percent of lime, 2 to 4 percent of gypsum and 1.5 to 2 percent of aluminum powder. The invention also discloses the preparation method of the porous dephosphorization filter material. The method comprises the following steps of (A) crushing the kieselguhr and silicon earth; (B) uniformly mixing kieselguhr powder, silicon earth powder, cement, lime, gypsum and aluminum powder according to the mixture ratio; adding water; performing stirring; then pouring the materials into a mold; (C) after demolding, performing natural caring for 3 to 5 days in the normal temperature state; (D) after the caring, crushing the materials into particles with the diameter being 1 to 3cm to obtain the filter materials. The porous dephosphorization filter material provided by the invention has the advantages that the removal rate of phosphorus in tail water in sewage treatment plants and surface non-point sourcearea sewage can be greatly improved; the water quality stability of the outlet water can bemaintained.

Owner:YUNNAN ZHAOHONG ENVIRONMENTAL ENG CO LTD

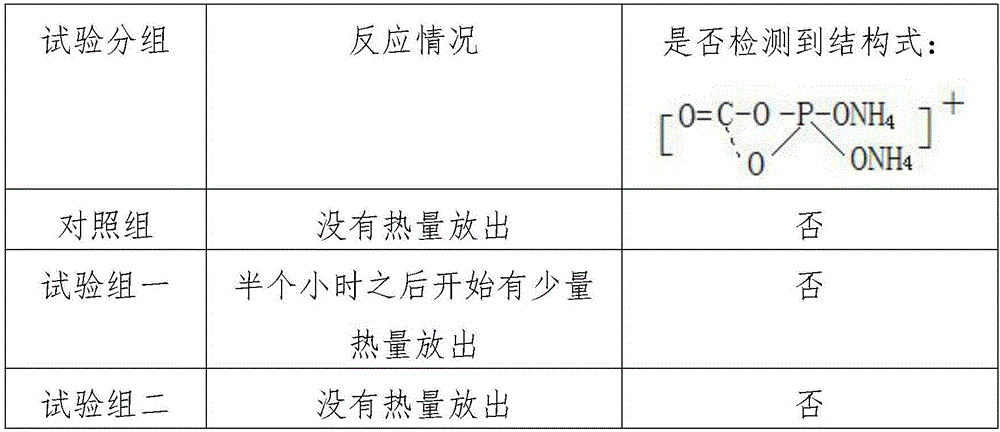

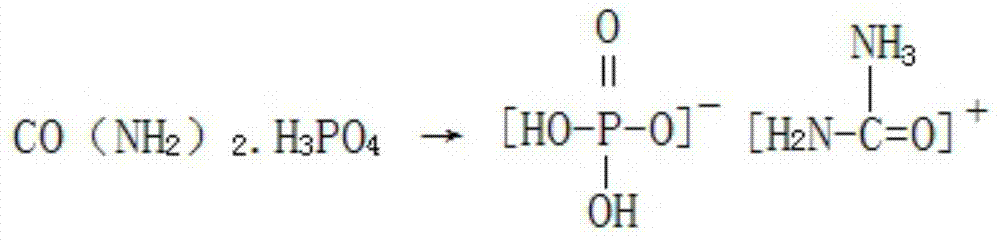

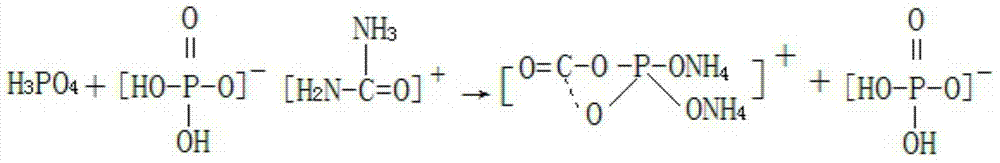

Method for preparing dendrobium officinale nutrient fertilizer

InactiveCN104291903AReduce the degree of crystallizationHigh purityCalcareous fertilisersMagnesium fertilisersChemical industryAmmonia production

The invention relates to the technical field of chemical industry, and discloses a method for preparing a dendrobium officinale nutrient fertilizer. The method comprises the following steps: determining the proportion of nutritive elements in the dendrobium officinale nutrient fertilizer by analyzing various nutritive elements absorbed in a growth process of dendrobium officinale, reacting phosphoric acid with carbamide to generate an intermediate, then introducing ammonia gas into the intermediate to produce ammonium dihydrogen phosphate, separating part of ammonium dihydrogen phosphate by crystallization so as to control the content of nitrogen and phosphorus in a solution to meet the proportion required by the growth of dendrobium officinale, and then adding potassium and other medium trace element compounds into the solution to prepare a fertilizer special for dendrobium officinale. According to a production method disclosed by the invention, raw materials can be fully used, produced ammonium dihydrogen phosphate is relatively good in quality, and the prepared fertilizer special for dendrobium officinale is relatively low in cost.

Owner:GUIZHOU UNIV +2

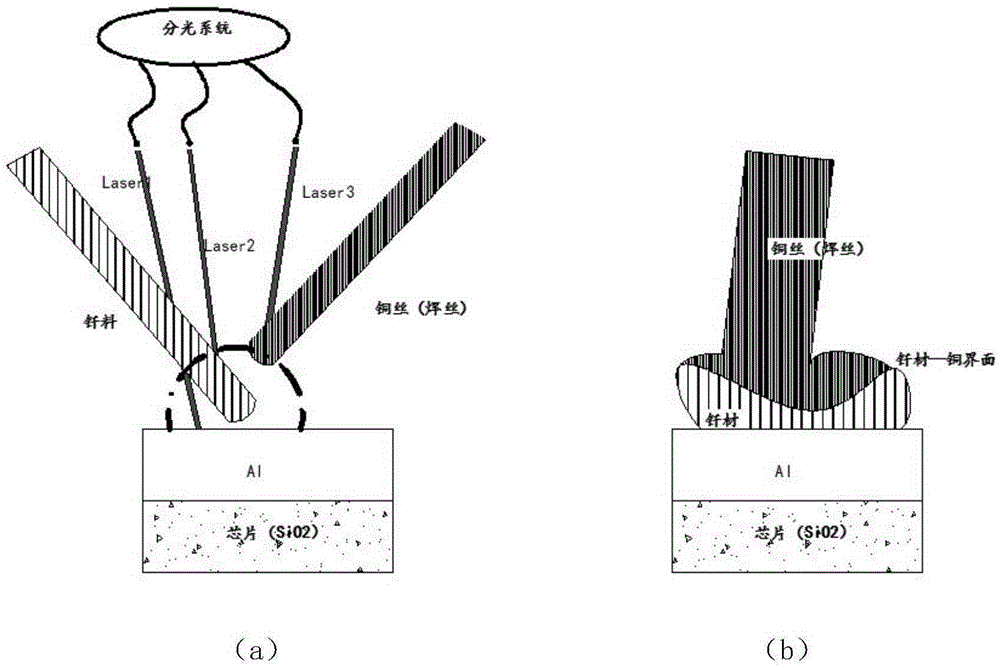

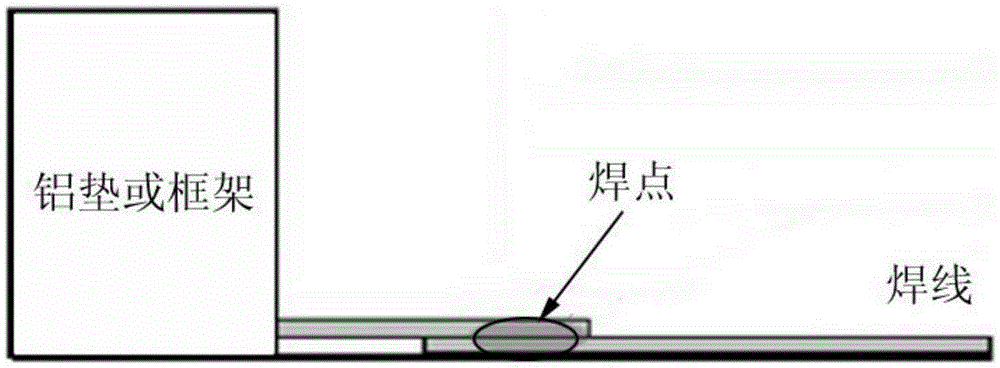

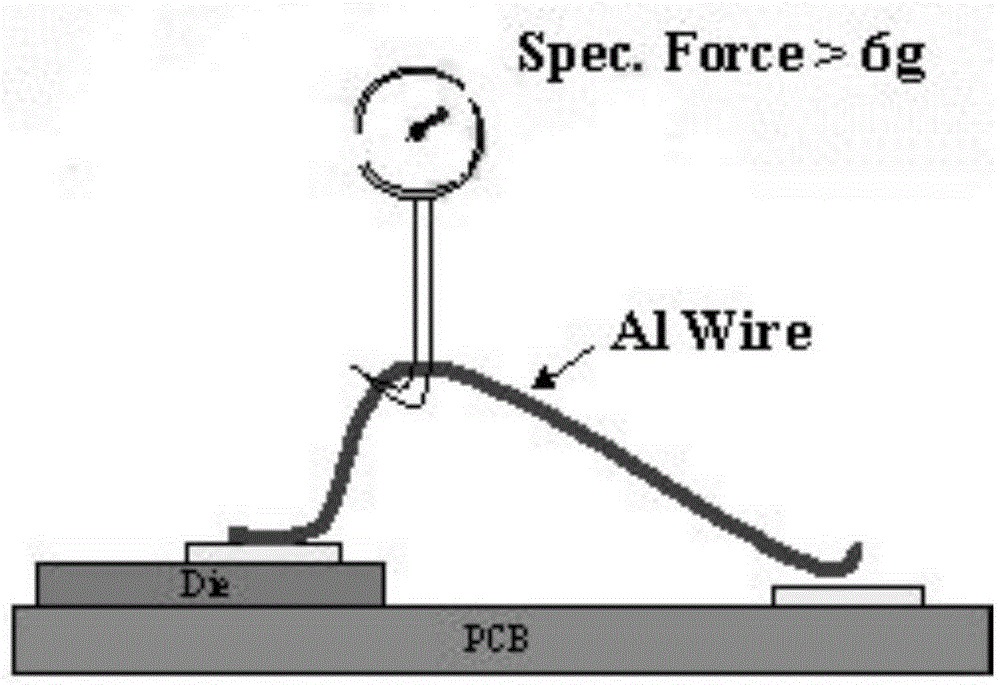

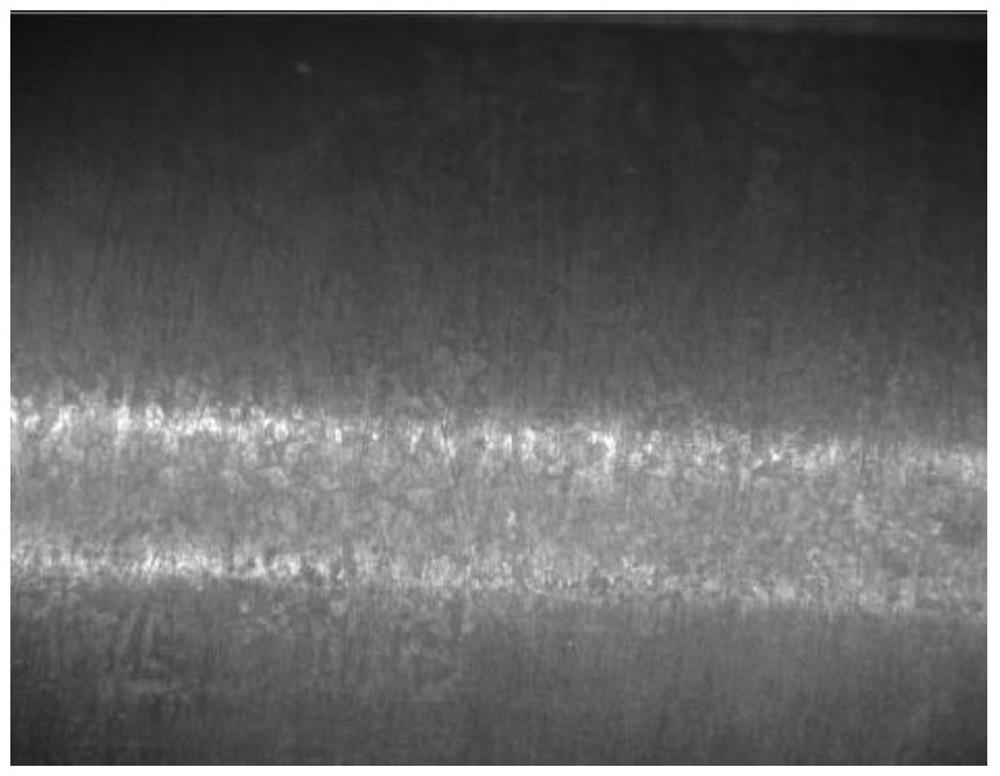

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

Corrosion-resistant high-strength low-alloy steel and preparation method thereof

The invention discloses corrosion-resistant high-strength low-alloy steel and a treatment process thereof, and belongs to the technical field of deep sea oil extraction equipment. The problems of low strength and toughness, poor low-temperature impact resistance and poor corrosion resistance of seabed wellhead and oil extraction equipment materials in the prior art are solved. The corrosion-resistant high-strength low alloy steel comprises the following components of, in percentage by mass, 0.33-0.38 of C, 0.90-1.00 of Mn, 0.26-0.35 of Si, 0.95-1.20 of Cr, 0.21-0.30 of Mo, 0.16-0.25 of Ni, 0.04-0.08 of V, 0.010-0.020 of Cu, less than or equal to 0.01 of P, less than or equal to 0.01 of S, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps of smelting raw materials to obtain a cast ingot; carrying out hot working on the cast ingot to obtain a blank; and sequentially carrying out normalizing treatment, quenching treatment and tempering treatment on the blank to obtain the corrosion-resistant high-strength low-alloy steel with a tempered sorbite structure.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

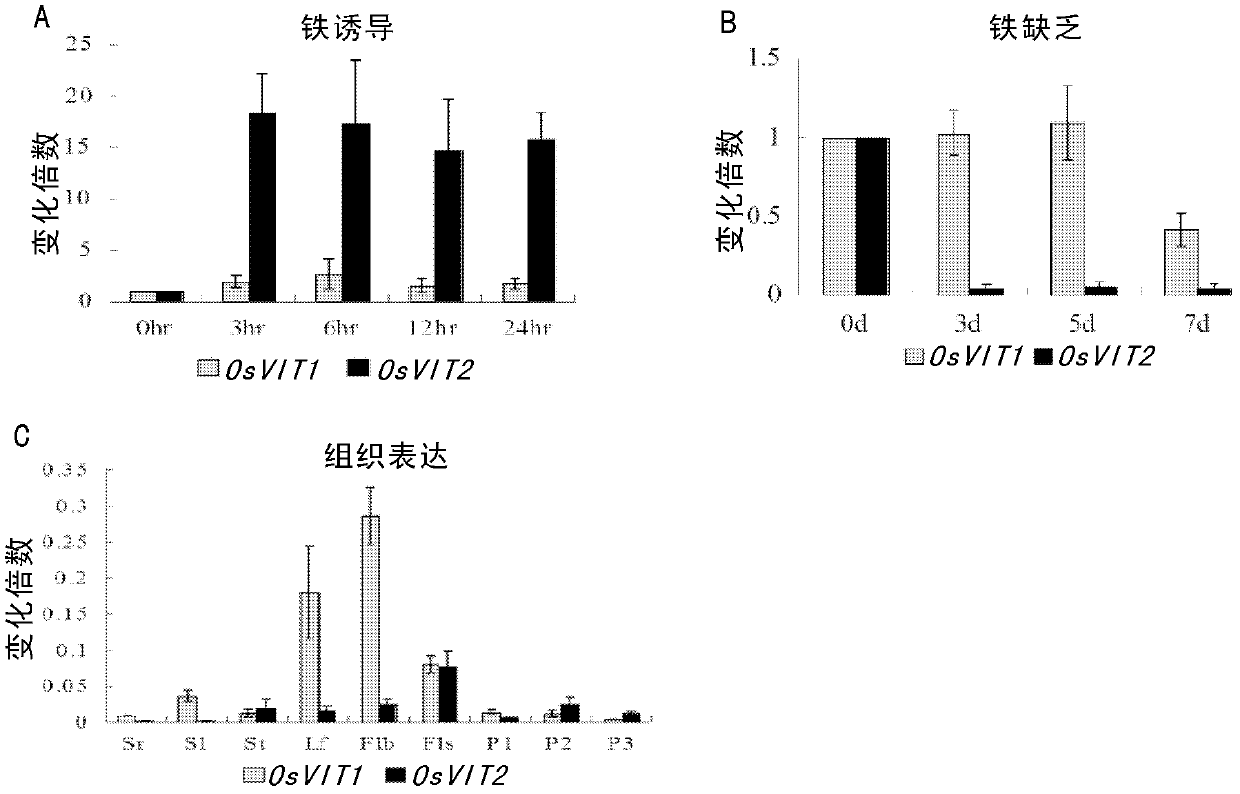

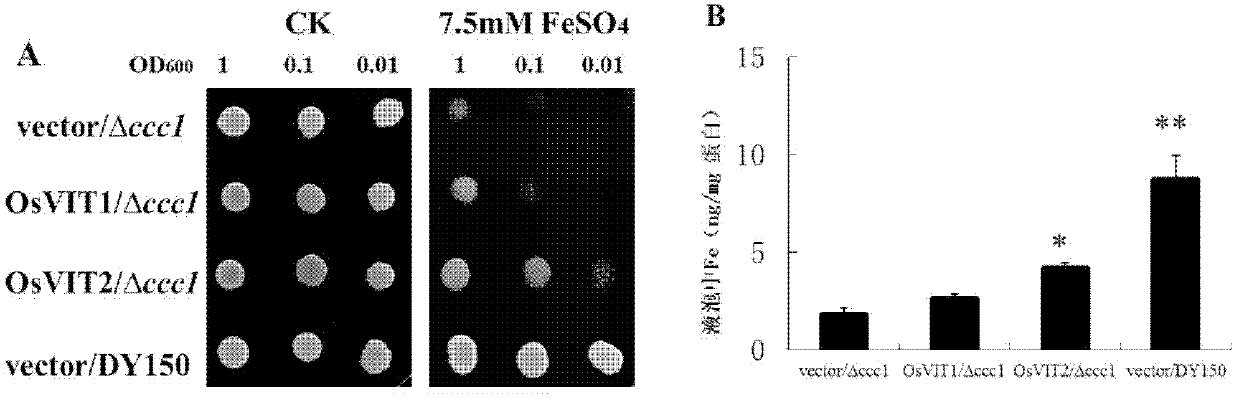

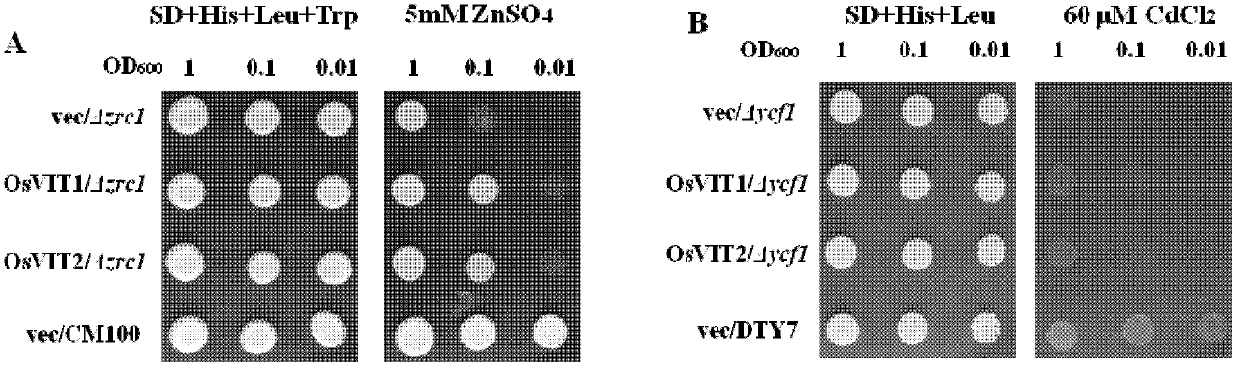

Metal transporter protein and encoding gene and application thereof

The invention relates to a metal transporter protein and an encoding gene and an application thereof. The invention discloses a new gene; and polypeptide encoded by the new gene has a metal transporter function. The gene can be greatly applied to the improvement of plant varieties and also can be used for increasing the content of iron and / or zinc in edible parts of a plant. The invention provides a valuable gene resource for developing a new crop variety with higher nutritive value.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

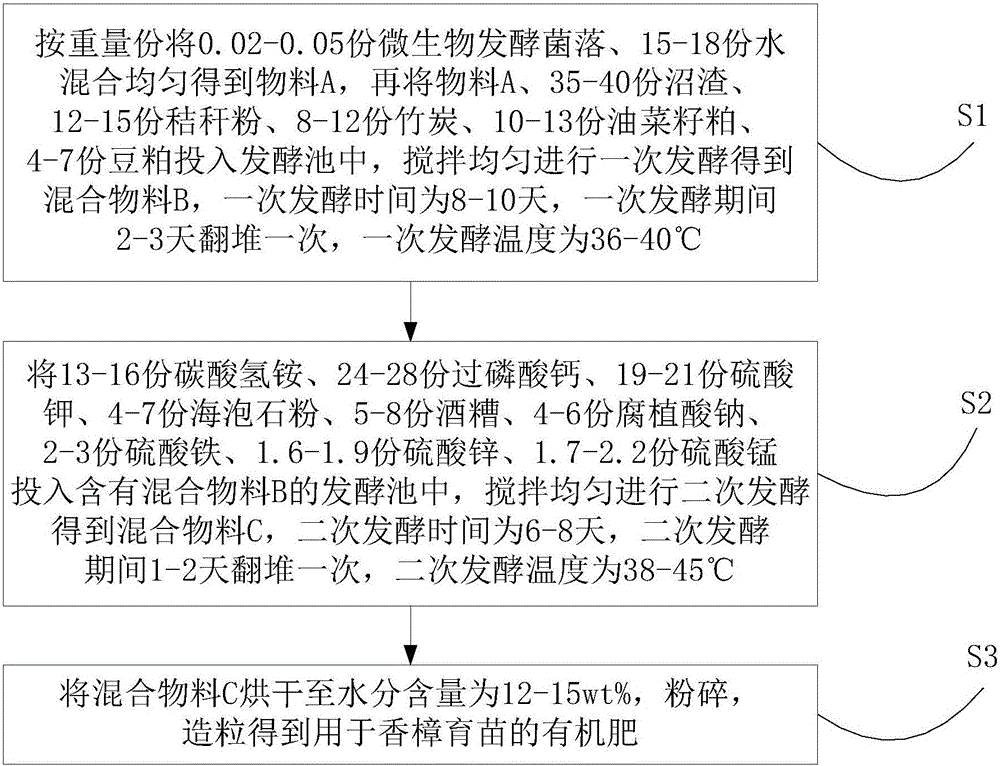

Method for preparing cinnamomum camphora seedling raising organic fertilizer

InactiveCN105732227AFully absorbedImprove disease resistanceSuperphosphatesBio-organic fraction processingDecompositionMixed materials

The invention discloses a method for preparing a cinnamomum camphora seedling raising organic fertilizer. The method comprises the following steps: uniformly mixing microbial fermentation bacterial colony and water to obtain a material A, adding the material A, biogas residues, straw powder, bamboo charcoal, rapeseed dregs and bean dregs into a fermenting tank, uniformly stirring, performing primary fermentation, so as to obtain a mixed material B after primary fermentation; adding ammonium bicarbonate, calcium superphosphate, potassium sulfate, sea-foam stone powder, distillers' grains, sodium humate, ferric sulfate, zinc sulfate and manganese sulfate into the fermenting tank containing the mixed material B, uniformly stirring for secondary fermentation, so as to obtain a mixed material C after secondary fermentation; drying the mixed material C, crushing, granulating, thereby obtaining the organic fertilizer used for cinnamomum camphora seedling raising. The method for preparing the cinnamomum camphora seedling raising organic fertilizer provided by the invention is simple, and due to thorough decomposition and fermentation, the obtained organic fertilizer contains rich organic matters, is high in nutrient content and good in fertilizer efficiency, meets the nutrient requirement of cinnamomum camphora in the seedling raising period and can promote growth of cinnamomum camphora seedlings.

Owner:WANGJIANG TANSHI PARK & GARDEN CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com