Corrosion-resistant high-strength low-alloy steel and preparation method thereof

A high-strength low-alloy steel and corrosion-resistant technology, applied in the field of deep-sea oil production equipment, can solve the problems of low-temperature impact resistance and poor corrosion resistance, low strength and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

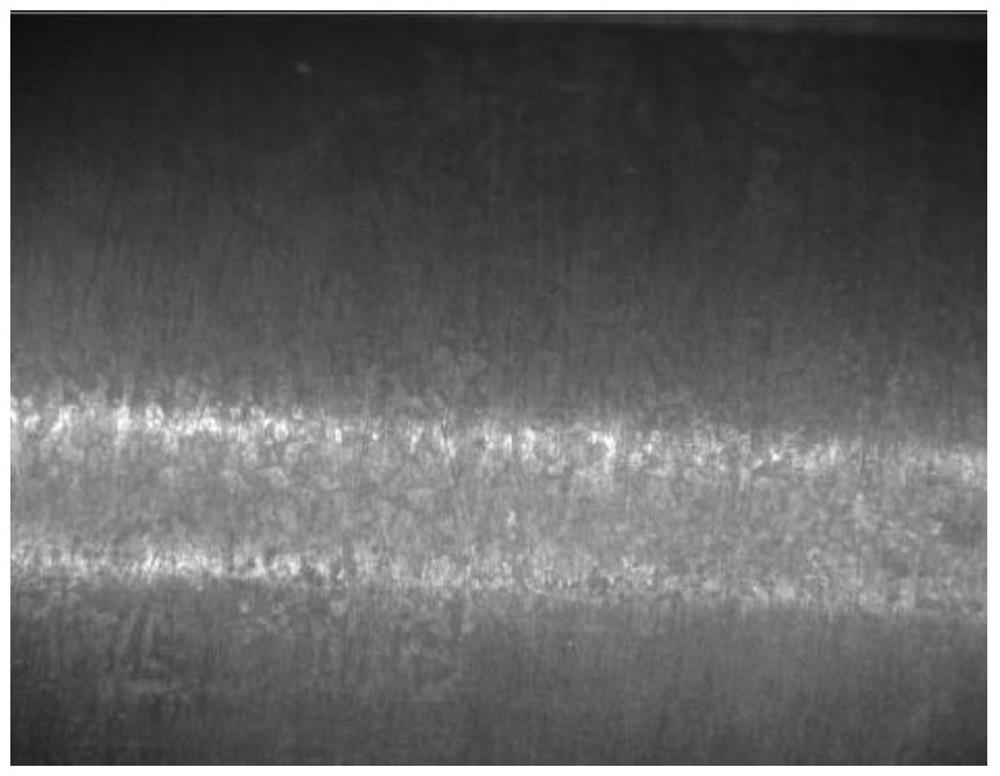

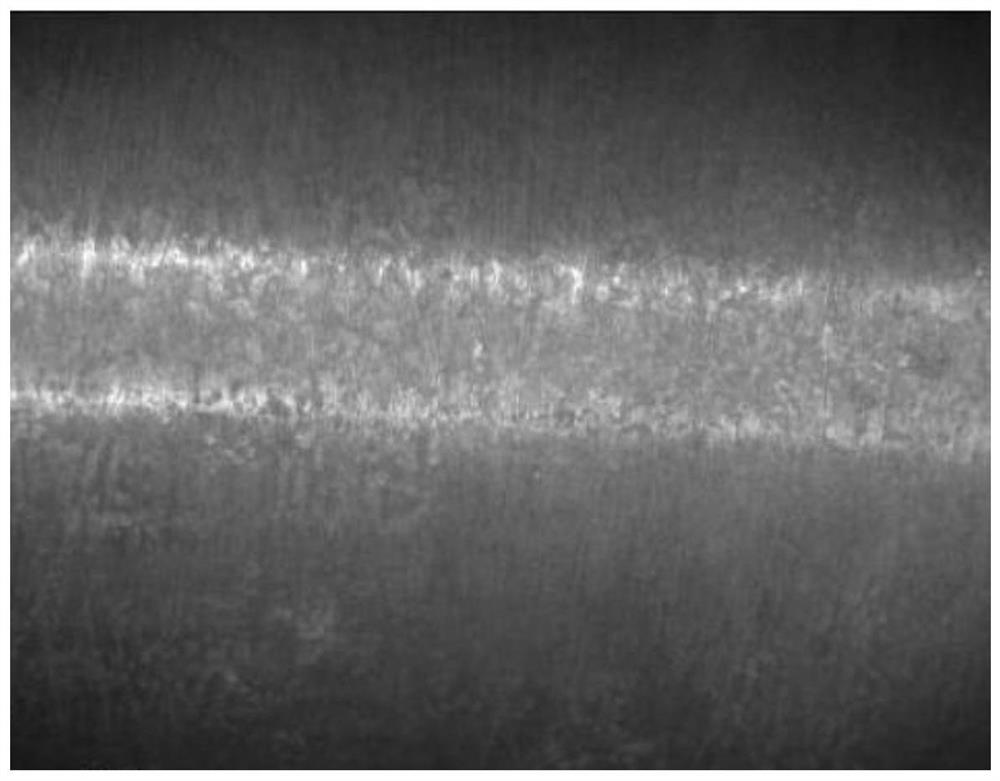

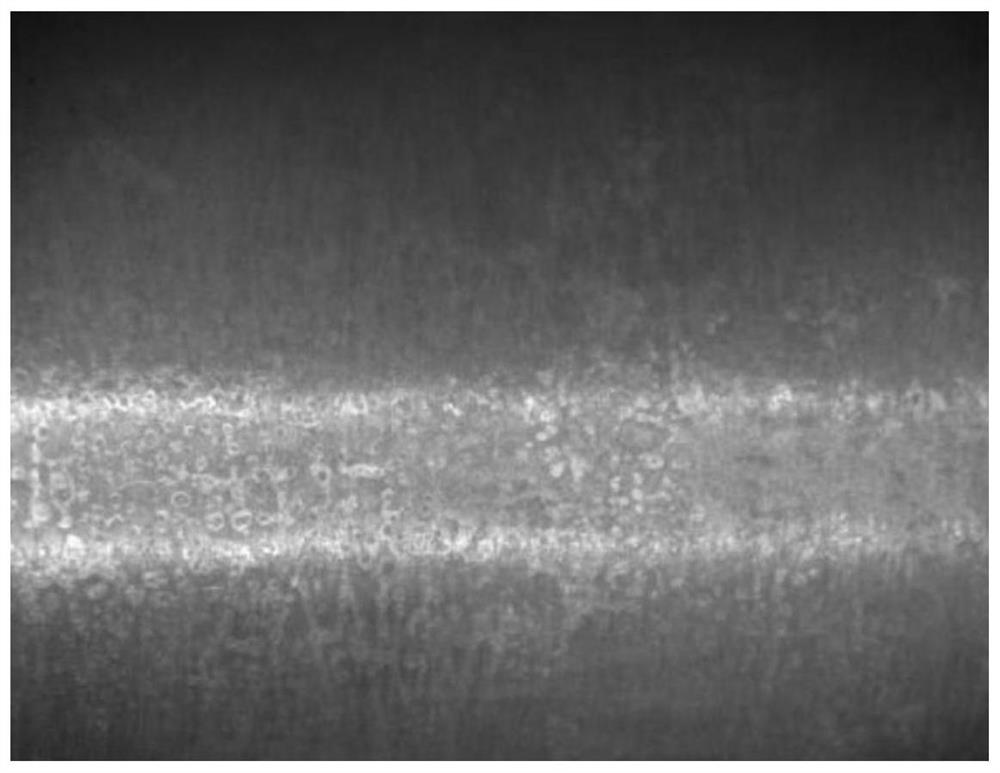

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing corrosion-resistant high-strength low-alloy steel, comprising the following steps:

[0050] Step S1: According to the composition of corrosion-resistant high-strength low-alloy steel, vacuum induction melting is used to smelt the raw materials to obtain ingots, which can ensure the smelting quality of ingots and reduce inclusions;

[0051] Step S2: performing thermal processing on the ingot to obtain a billet;

[0052] Step S3: normalizing the billet to obtain a billet with uniform structure;

[0053] Step S4: performing quenching treatment on the blank to obtain a blank with a martensitic structure;

[0054] Step S5: performing a tempering treatment on the billet to obtain a corrosion-resistant high-strength low-alloy steel with a tempered sorbite structure.

[0055] Compared with the prior art, the beneficial effect of the preparation method of the corrosion-resistant high-strength low-alloy steel provided b...

Embodiment 1

[0074] In a specific embodiment of the present invention, the composition of corrosion-resistant, high-strength and low-alloy steel for deep-sea oil recovery equipment is: C 0.35, Mn 0.95, Si 0.26, Cr 1.05, Mo 0.25, Ni 0.19, V 0.045, Cu 0.015 , P≤0.005, S≤0.003, the balance is Fe and unavoidable impurities.

[0075]Smelting 40kg recast ingots in a vacuum induction furnace;

[0076] The ingot is homogenized and then heated for forging to obtain a 80×80×550 mm forging billet with a total forging ratio of ≥6.

[0077] Normalizing the forging billet: normalizing temperature (T 1 ) is controlled at 880°C, and the holding time (t 1 ) for 2 hours, air-cooled to 675°C, then isothermal for 5 hours, and then air-cooled to room temperature; in the normalizing heating process, two-stage heating is adopted, namely "room temperature-700°C, 700-880°C", of which "room temperature-700°C stage" adopts Rapid heating, the heating rate is about 350°C / h; "700-880°C" adopts slow heating, and the ...

Embodiment 2

[0082] In a specific embodiment of the present invention, the composition of corrosion-resistant, high-strength and low-alloy steel for deep-sea oil production equipment is: C 0.34, Mn 0.96, Si 0.29, Cr 1.15, Mo 0.26, Ni 0.22, V 0.050, Cu 0.015 , P≤0.005, S≤0.003, the balance is Fe and unavoidable impurities.

[0083] Smelting 40kg recast ingots in a vacuum induction furnace;

[0084] The ingot is homogenized and then heated for forging to obtain a 80×80×550 mm forging billet with a total forging ratio of ≥6.

[0085] Normalizing the forging billet: normalizing temperature (T 1 ) is controlled at 920°C, and the holding time (t 1 ) for 2 hours, air-cooled to 690°C, then isothermal for 5 hours, and then air-cooled to room temperature; in the normalizing heating process, two-stage heating is adopted, namely "room temperature-700°C, 700-920°C", of which "room temperature-700°C stage" adopts Rapid heating, the heating rate is about 350°C / h; "700-920°C" adopts slow heating, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com