Nitraria plant salt and preparation method thereof

A plant salt and technology of Nitraria, applied in the field of Nitraria plant salt and its preparation, can solve the problems of high disease rate, achieve the effects of improving ecological environment, low carbonization temperature, and reducing disease rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

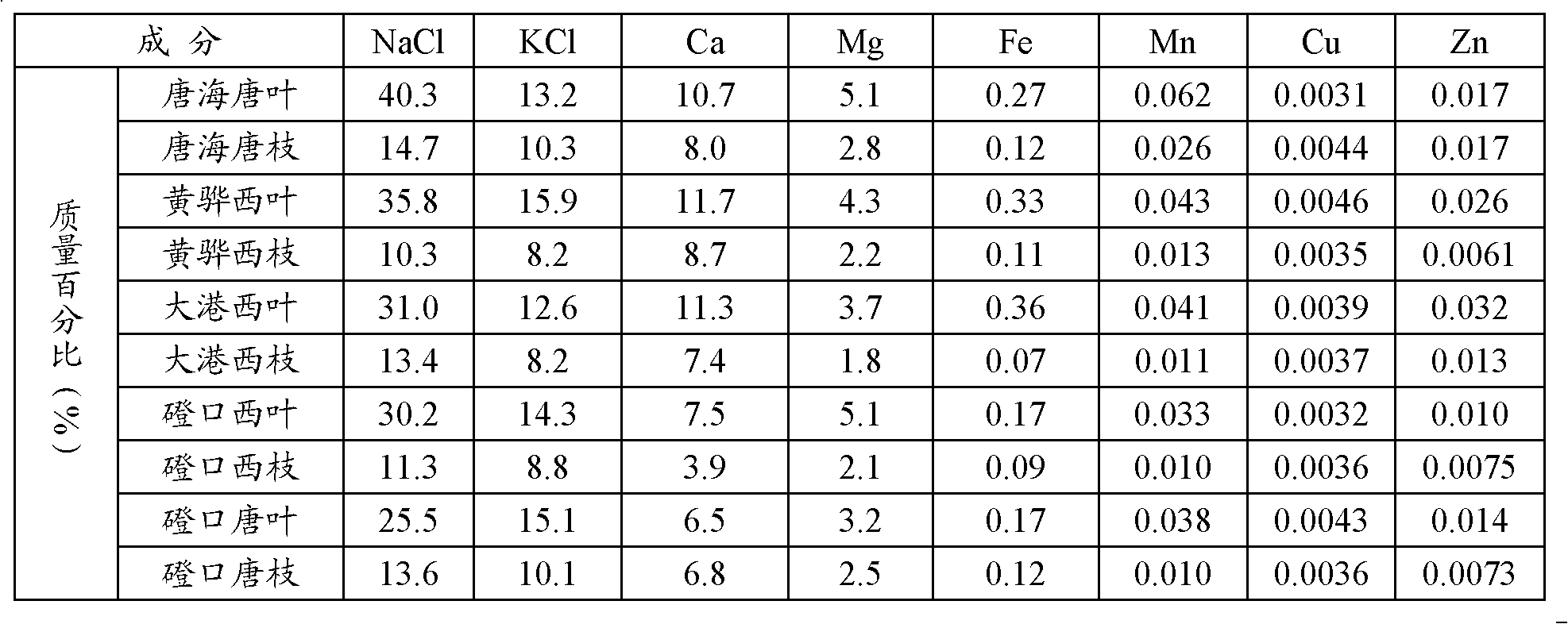

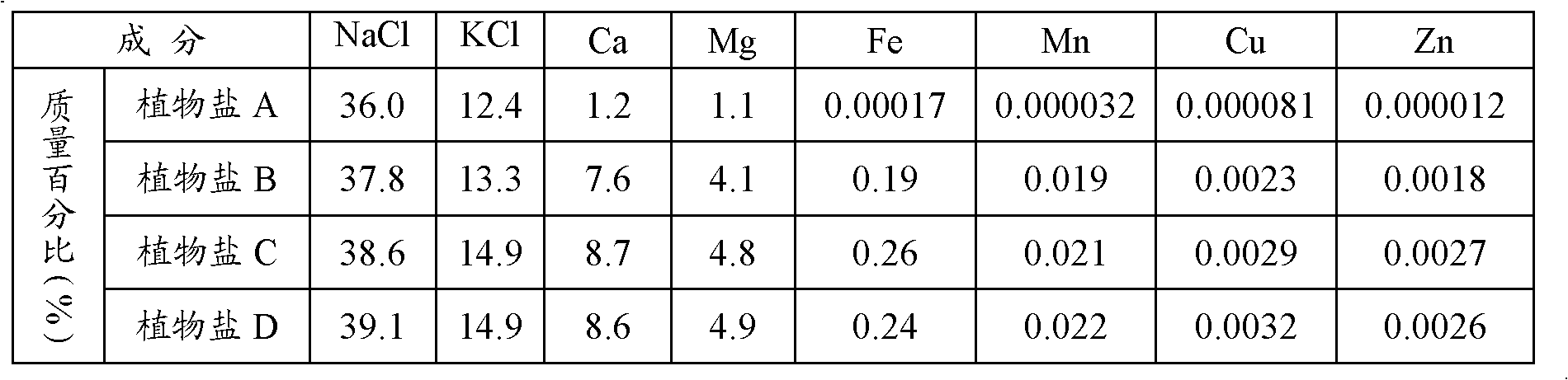

[0029] A total of 6.33 kg of Nitraria siberia leaves and Nitraria tangutica leaves were collected from July to September, and the rotten leaves were removed, washed with water, and then rinsed with deionized water. Then use a centrifuge to centrifuge the leaves at a speed of 2000-5000 rpm (eg 4000 rpm) for 5-10 minutes (eg 10 minutes). Next, dry the centrifuged leaves at a constant temperature at 75°C to 80°C (for example, 80°C), then crush the leaves and pass through a 40-mesh sieve, collect 2.25kg of the crushed leaves that have passed the sieve, put them into a porcelain container and dry them at 200 ℃~300℃ (for example, 250℃) to carry out carbonization while stirring until no black smoke is generated. Add 3L of deionized water to the charcoal, stir well, filter, and collect the filtrate and filter residue respectively.

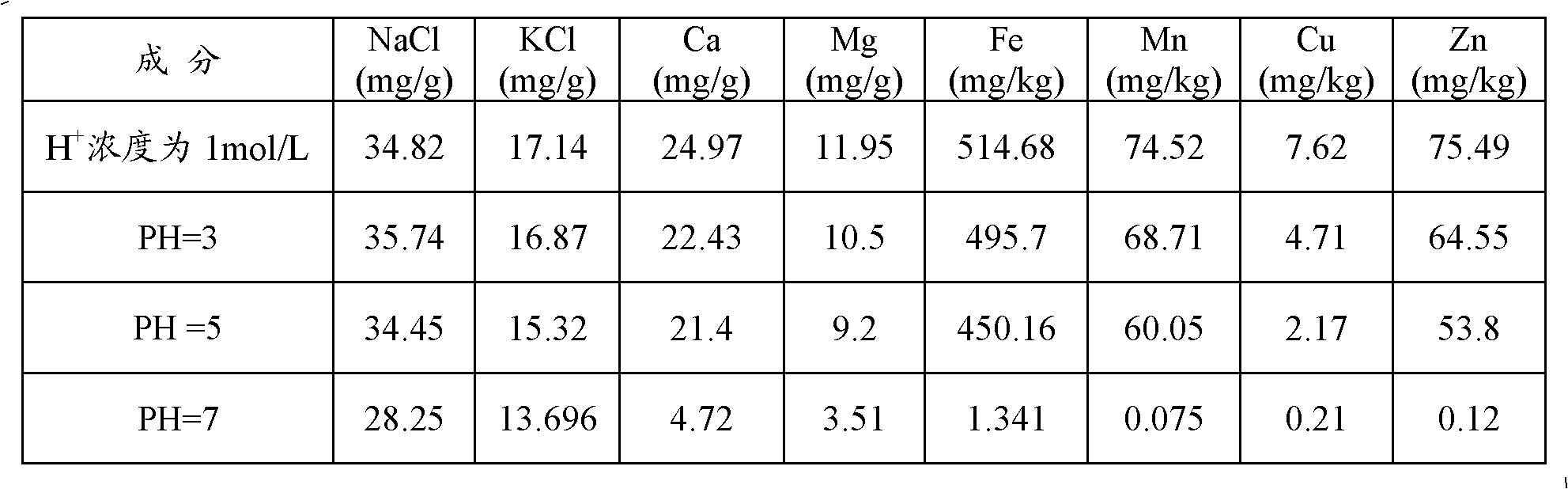

[0030] Add dilute hydrochloric acid to the filter residue to make the pH about 4, stir for 0.5 hour, filter, and collect the filtrate. Then it was combi...

Embodiment 2

[0035] A total of 4.0 kg of Nitraria siberia leaves and Nitraria tangutica leaves were collected from July to September, and the rotten leaves were removed, washed with water, and then rinsed with deionized water. Then use a centrifuge to centrifuge the leaves at a speed of 2000-5000 rpm (eg 3000 rpm) for 5-10 minutes (eg 7 minutes). Next, dry the centrifuged leaves at a constant temperature of 60°C to 80°C (for example, 75°C), then pulverize the leaves and pass through a 40-mesh sieve, collect 1.1kg of crushed leaves that have passed the sieve, put them into a porcelain container at 200 ℃~300℃ (for example, 280℃) to carry out carbonization while stirring until no black smoke is produced. Add 2L of deionized water to the charcoal, stir well, filter, and collect the filtrate and filter residue respectively.

[0036] Add dilute hydrochloric acid to the filter residue to make the pH about 5, stir for 0.5 hour, filter, and collect the filtrate. Then the above filtrates were comb...

Embodiment 3

[0041]A total of 3.8 kg of Nitraria siberia leaves and Nitraria tangutica leaves were collected from July to September, and the rotten leaves were removed, washed with water, and then rinsed with deionized water. The leaves are then centrifuged for 10 minutes with a centrifuge at a rotational speed of 2000-5000 rpm (eg 5000 rpm). Next, dry the centrifuged leaves at a constant temperature at 60°C to 80°C (for example, 60°C), then crush the leaves and pass through a 40-mesh sieve, collect 0.92kg of crushed leaves that have passed through the sieve, put them into a porcelain container and dry them at 200 ℃~300℃ (for example, 300℃) to carry out carbonization while stirring until no black smoke is produced. Add 2L of deionized water to the charcoal, stir well, filter, and collect the filtrate and filter residue respectively.

[0042] Add dilute hydrochloric acid to the filter residue to make the pH about 6, stir for 0.5 hour, filter, and collect the filtrate. Then the above filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com