Patents

Literature

98results about How to "Low carbonization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

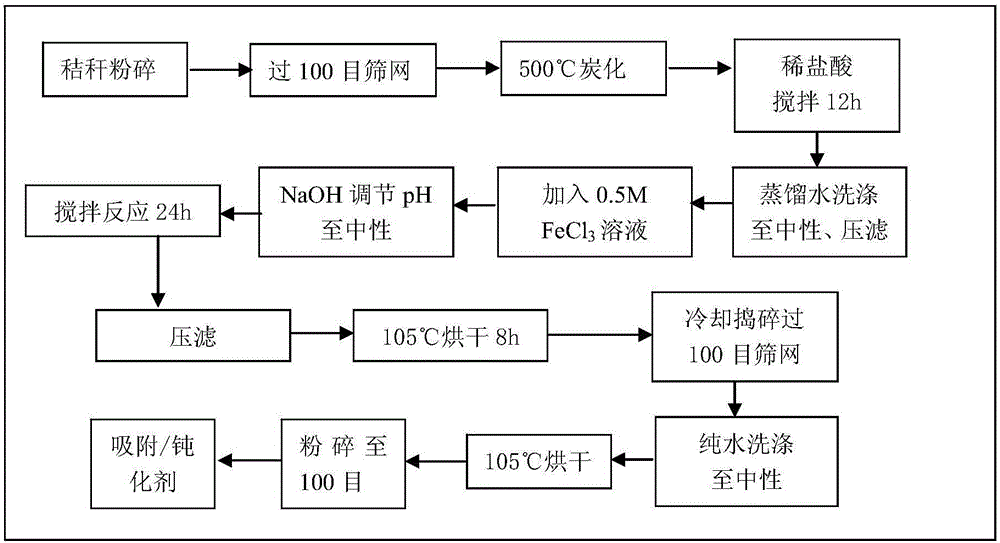

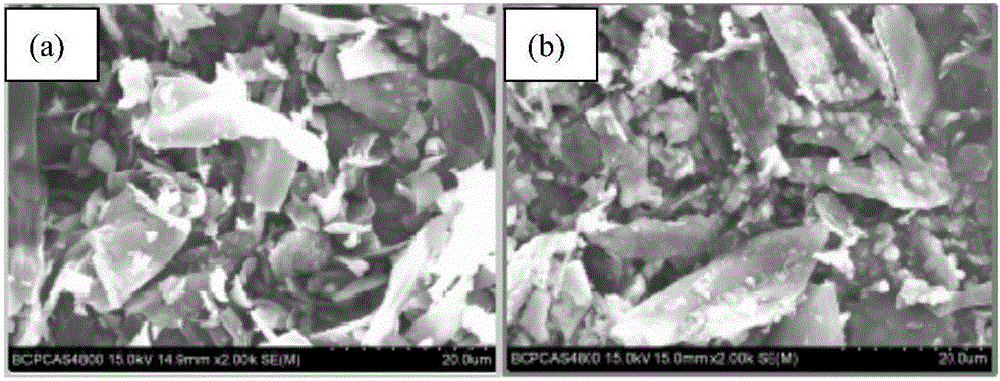

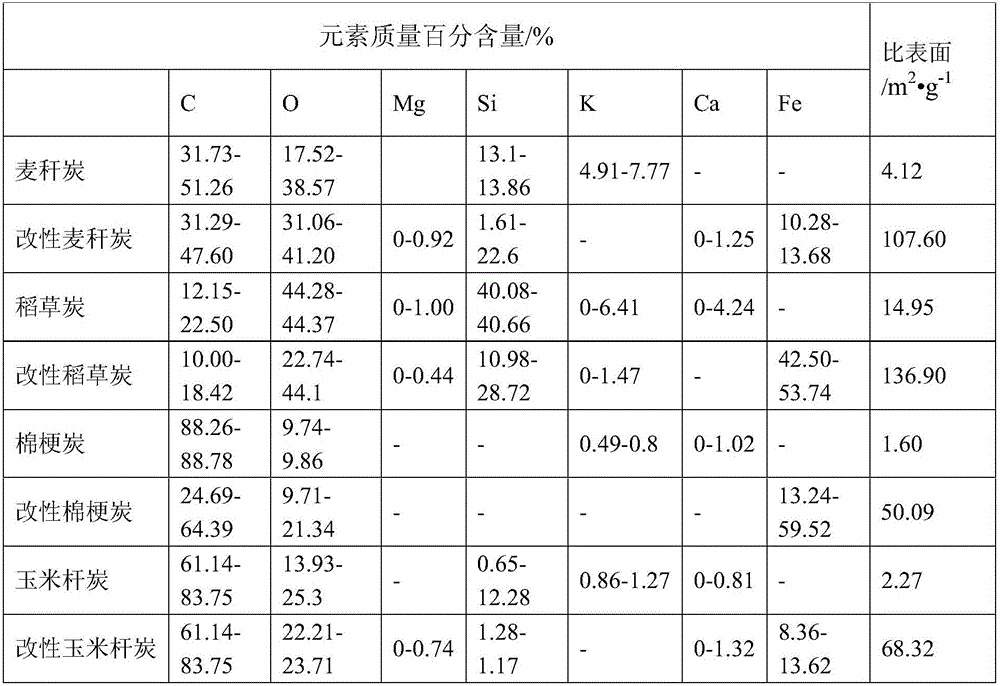

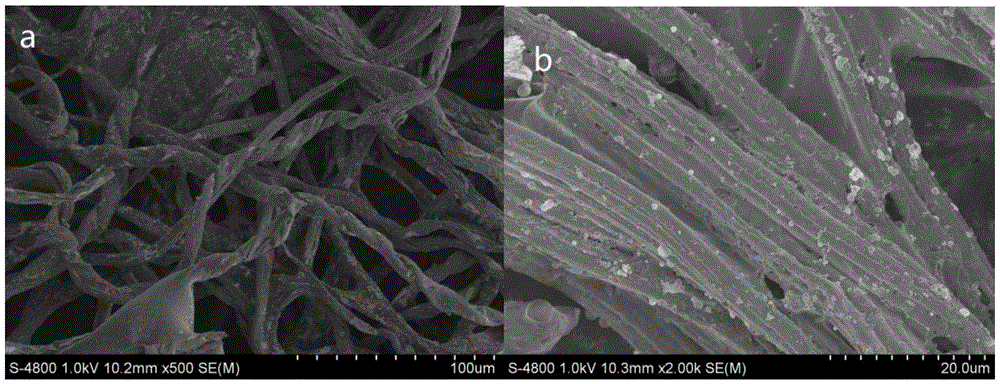

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

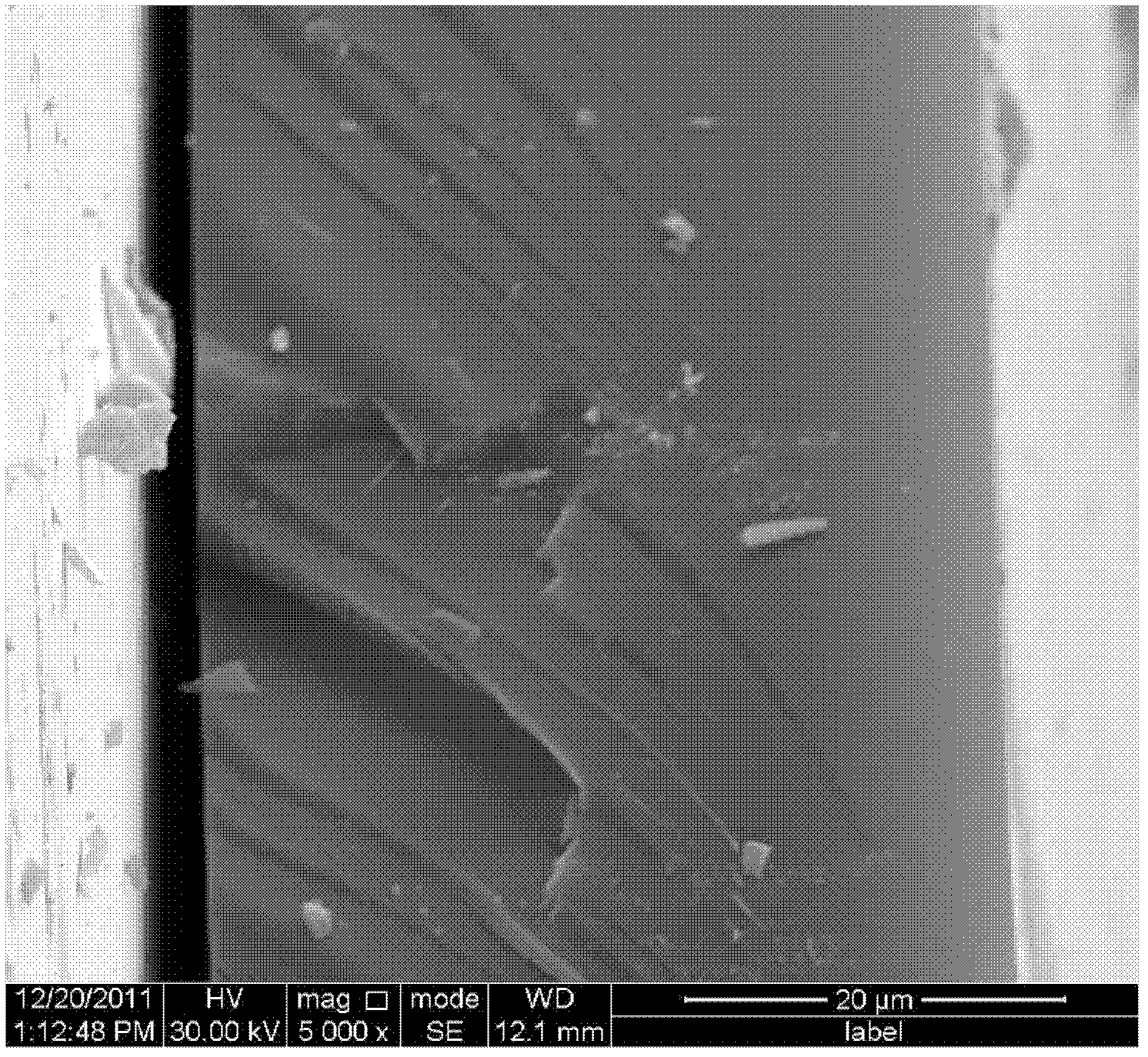

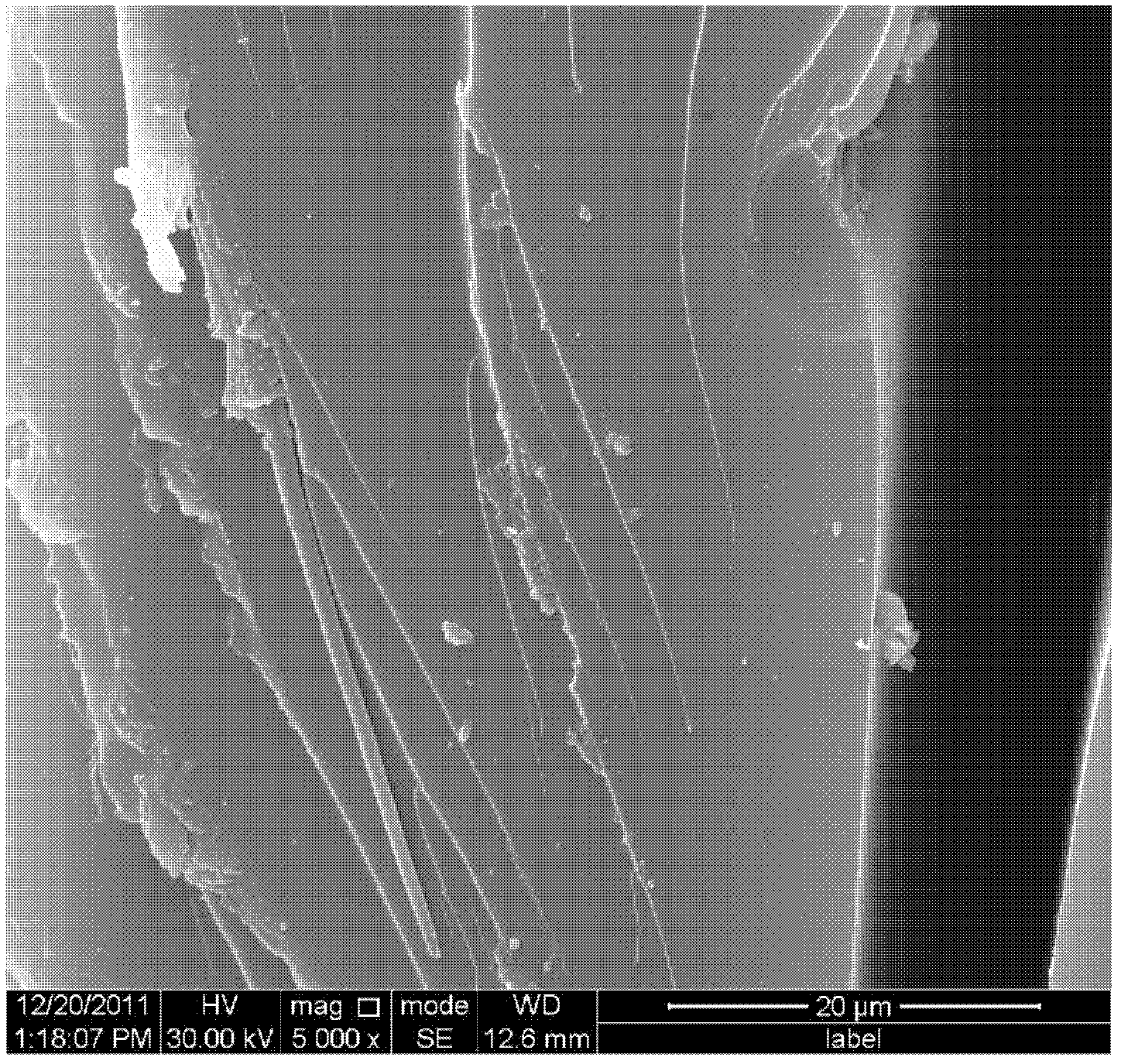

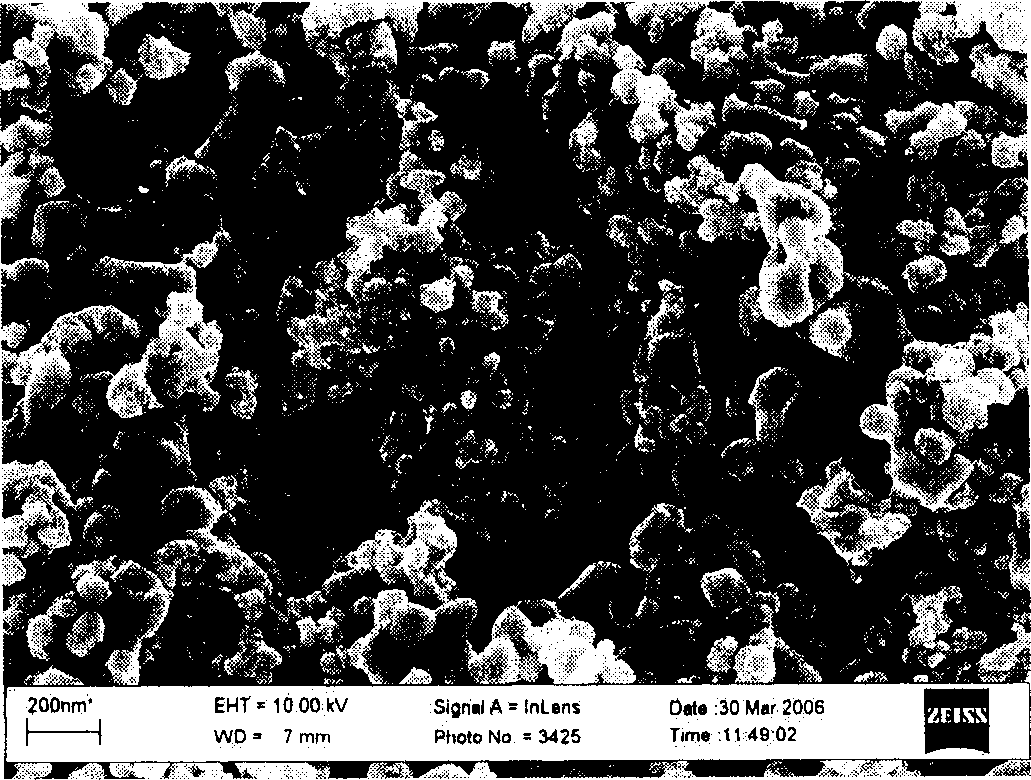

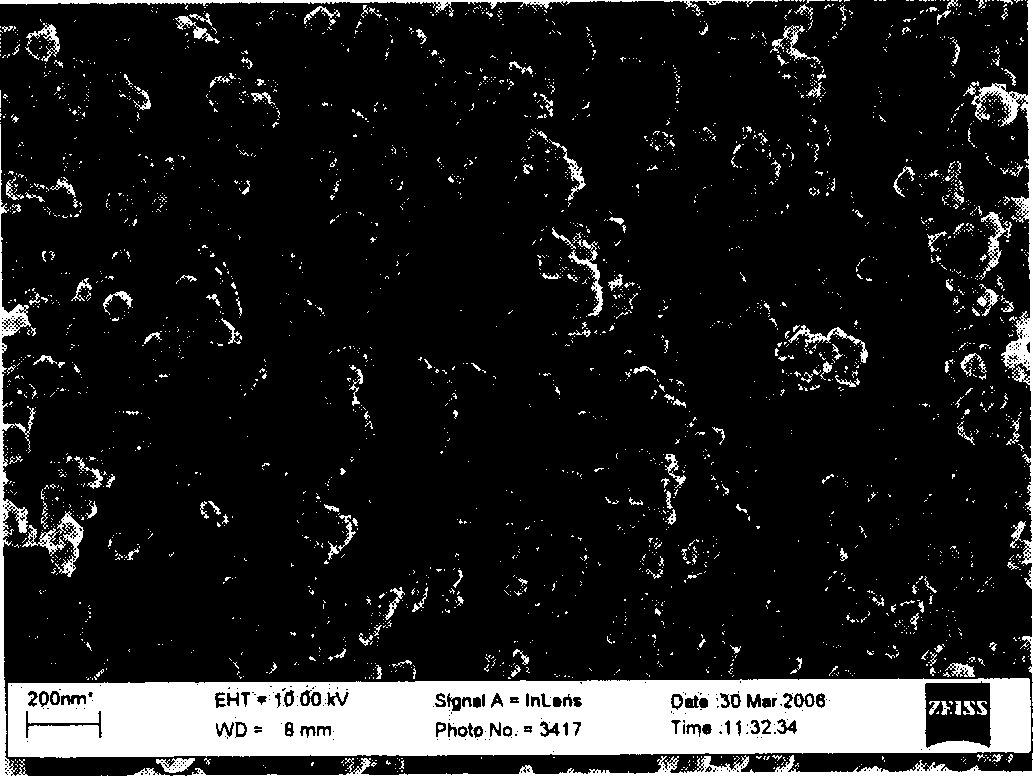

Preparation method and application of hollow tubular biochar

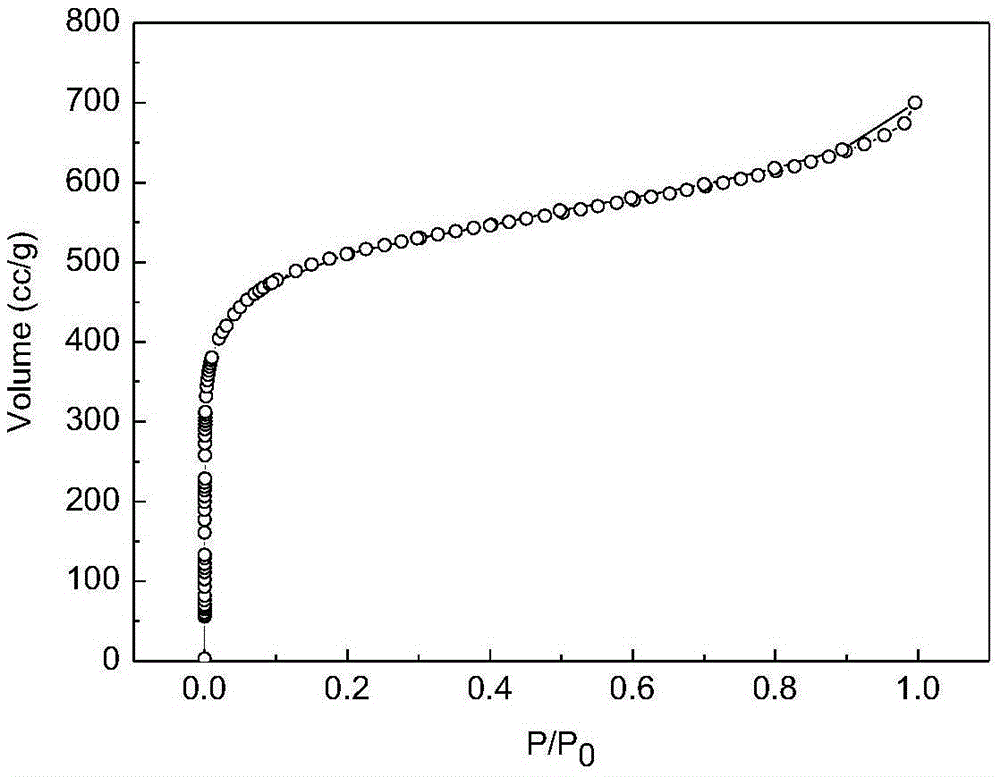

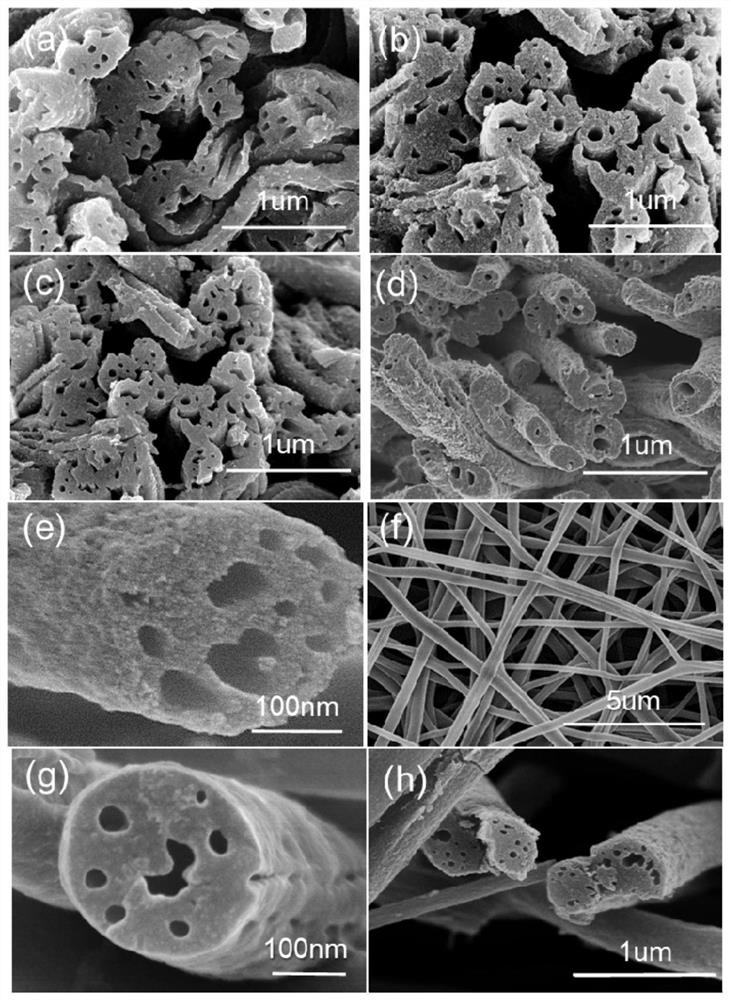

InactiveCN105776182ALow carbonization temperatureLarge specific surface areaHybrid capacitor electrodesCell electrodesSorbentKapok fiber

The invention discloses a preparation method and application of hollow tubular biochar. The preparation method includes: dispersing kapok fiber in a sulfuric acid solution for hydrothermal reaction to obtain carbonized kapok fiber; calcining the carbonized kapok fiber under protection of inert gas, cooling, washing, collecting and drying the calcined kapok fiber to obtain the hollow tubular biochar. The preparation method is simple and easy to control, carbonization and activation of the kapok fiber can be well realized on the premise that original structure of the kapok fiber is maintained, and distribution of balls in the inner surface and the outer surface of a hollow tube can be realized by controlling hydrothermal temperature and calcining temperature. In addition, the biochar prepared by the method can be applied in lithium / sodium ion batteries and supercapacitors and can be used as a carbon matrix in adsorbents, template agents and composite materials. Especially, the hollow tubular biochar presents excellent electrochemical performance when being applied in the lithium / sodium ion batteries.

Owner:SHAANXI UNIV OF SCI & TECH

Method for carbonizing active giantreed carbon and pore-forming

InactiveCN1944246ALow carbonization temperatureReduce energy consumptionOrganic chloride compoundSorbent

The present invention relates to adsorbent, and belongs to the field of technology of treating water and air with active carbon. The present invention prepares active carbon with giant reed root and stem and through crushing, stoving, carbonizing, forming pore and activating. The prepared active carbon may be applied widely in eliminating aromatic compound and organic chloride from waste water, eliminating heavy metal ions, treating atmosphere pollution, etc. The giant reed has low carbonizing temperature and low power consumption.

Owner:SHANDONG UNIV

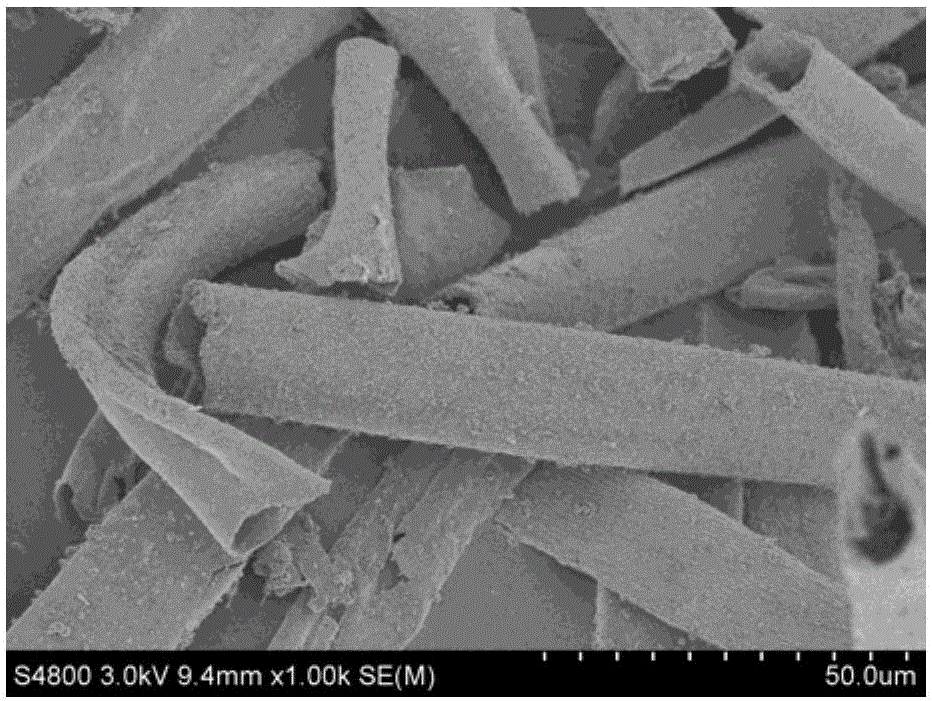

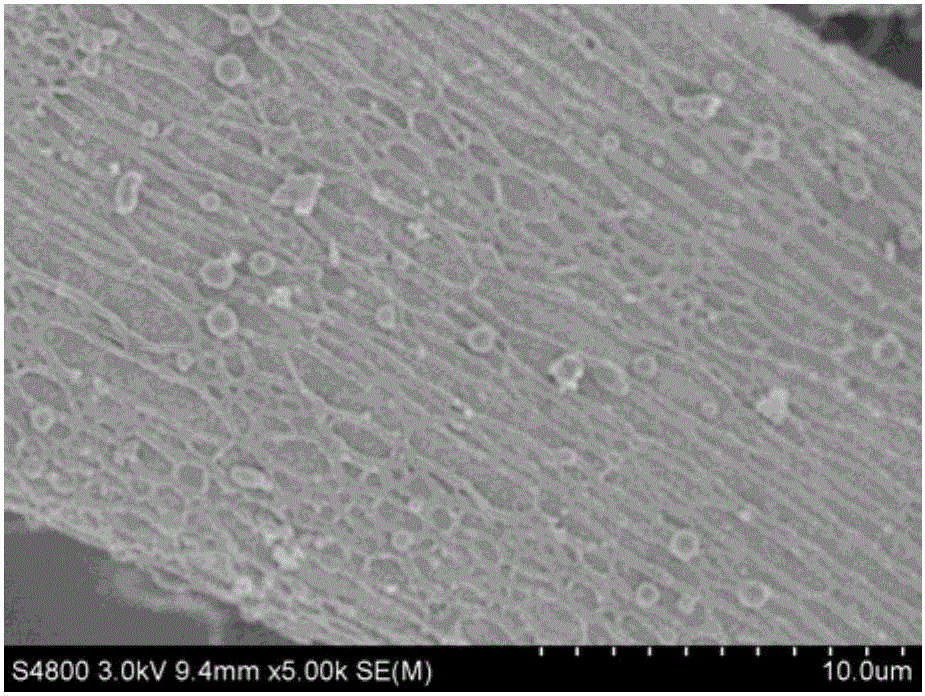

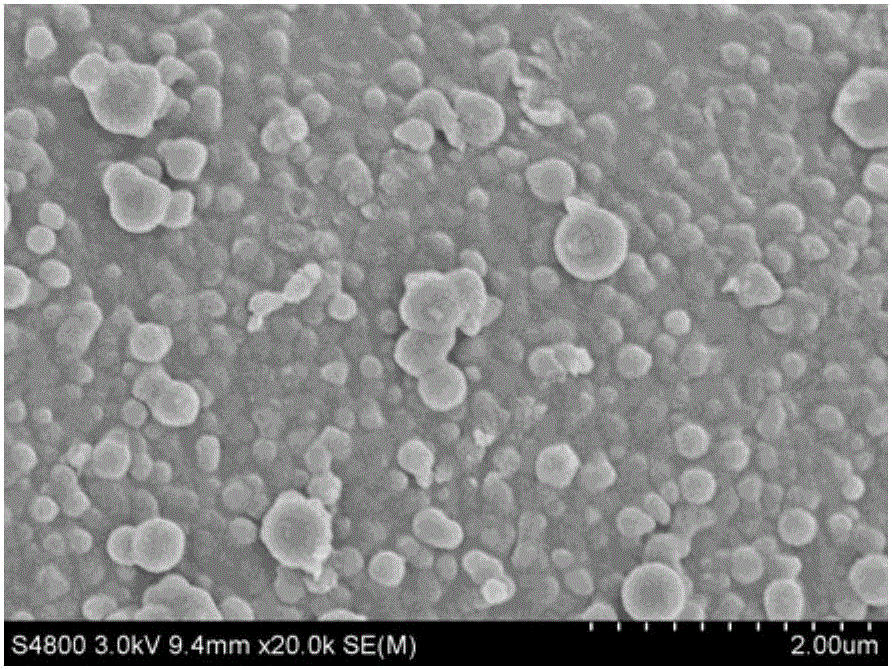

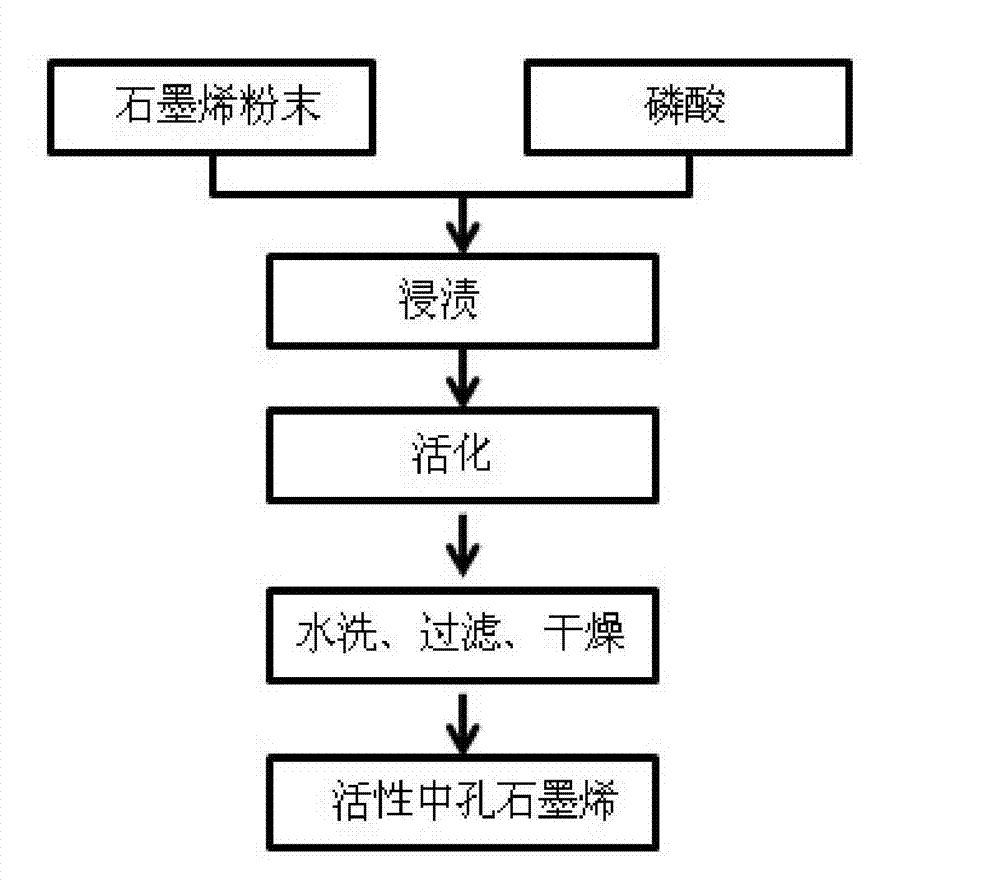

High-specific surface active graphene with mesoporous and preparation method and application thereof

ActiveCN102826542AIncrease productivitySimple operation processMaterial nanotechnologyCarbon compoundsCarbonizationPhosphoric acid

The invention relates to a preparation method of high specific surface active graphene with mesoporous. The method comprises the following steps of: carrying out mixing and impregnation on graphene obtained by stripping graphite oxide and phosphoric acid; then carrying out activation; and by washing, filtering and drying, obtaining the high specific surface active graphene with the mesoporous. The method belongs to the technical field of preparation of a graphene material. The method provided by the invention has simple process, low pollution, low carbonization temperature and low cost and has strong market competitiveness and wide application prospect; the active graphene material provided by the invention has large pore volume and average aperture and has good application prospect on the application aspects of energy storage and the like.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

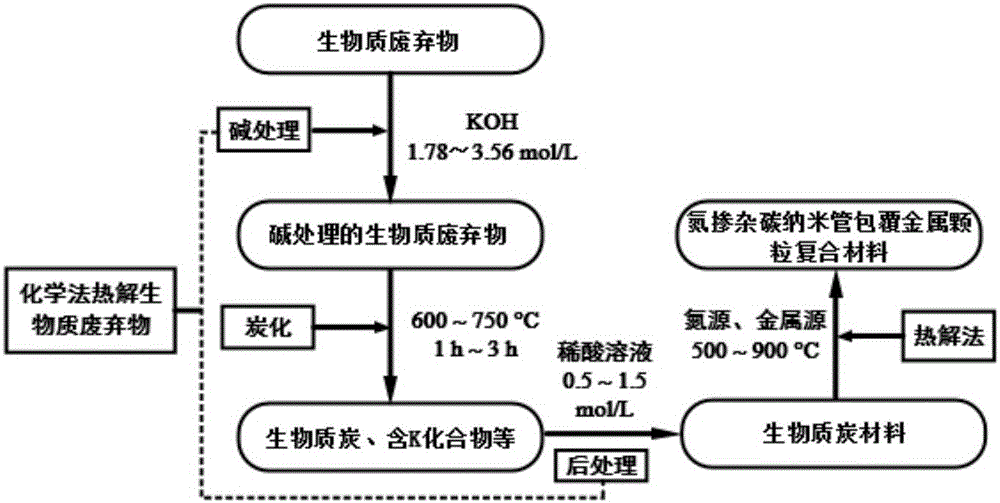

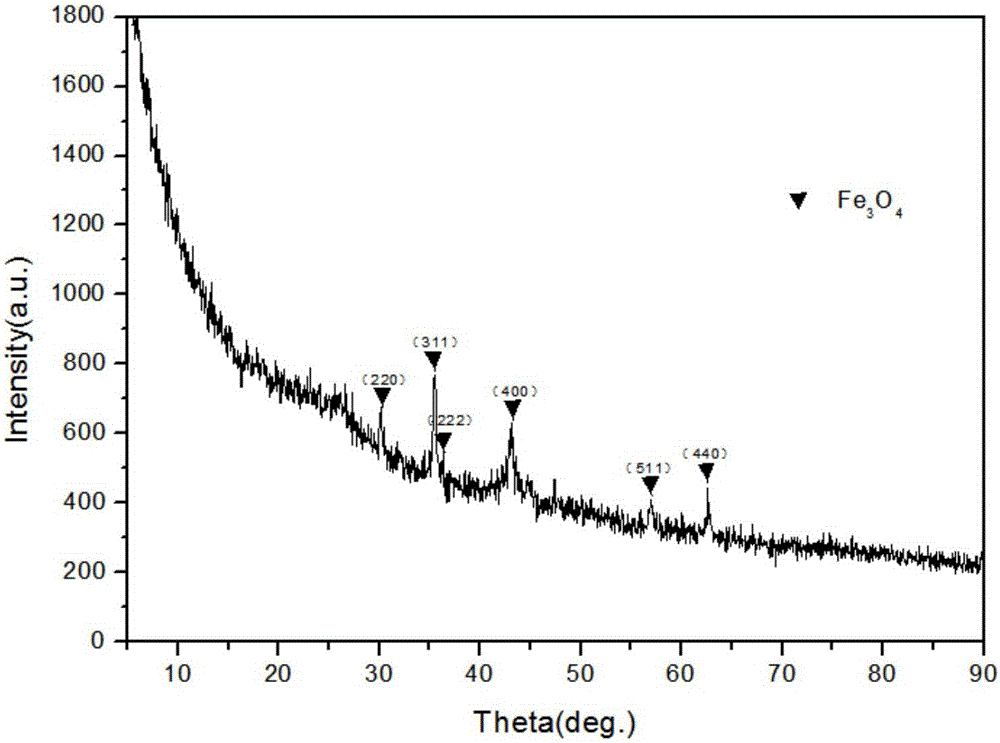

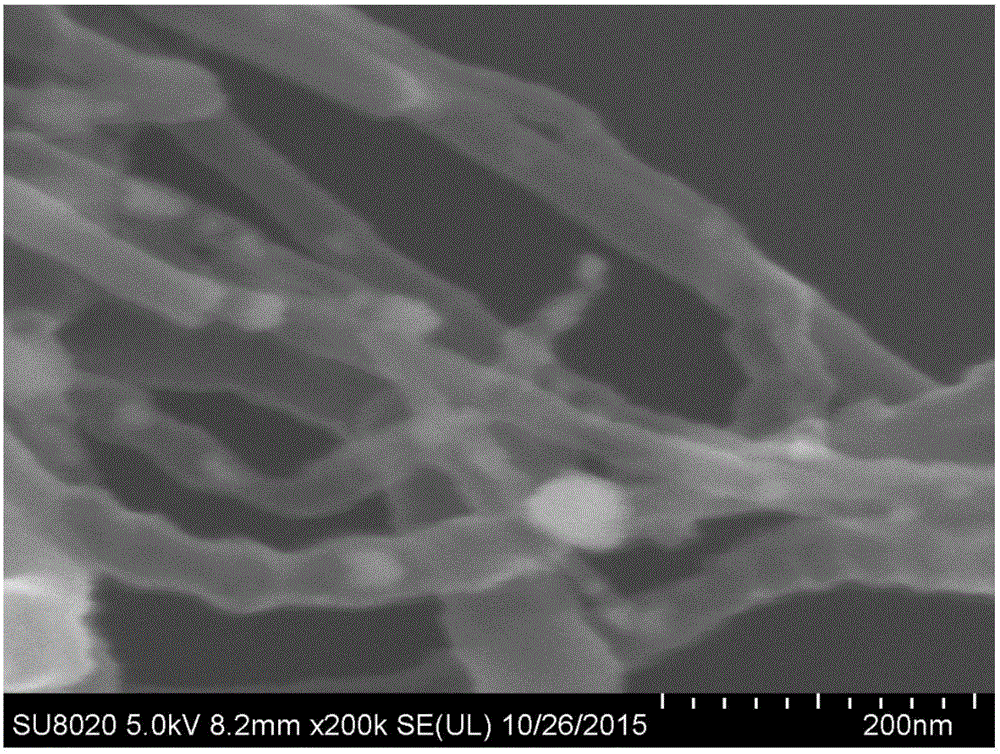

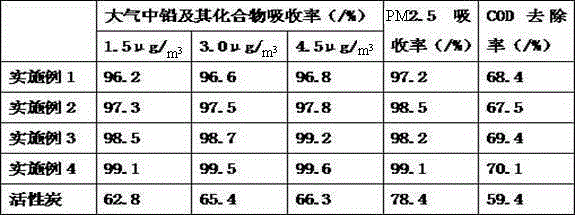

Method for using biomass waste for preparing nitrogen-doped carbon nanotube coated metal particle composite material

ActiveCN105772708AGood dispersionImprove stabilityTransportation and packagingMetal-working apparatusCarbon layerDispersity

The invention discloses a method for using biomass waste for preparing a nitrogen-doped carbon nanotube coated metal particle composite material. The method includes the following steps that firstly, the biomass waste and KOH are evenly mixed in deionized water, an obtained heterogeneous mixture is carbonized under the protection of inert gas, and biomass charcoal is obtained; and then, the biomass charcoal, a nitrogenous nonmetallic compound and water-soluble divalent metal salt are evenly mixed in methyl alcohol, the obtained heterogeneous mixture is subjected to pyrolysis under the protection of the inert gas, and therefore a target product is obtained. By the adoption of the method, a two-step pyrolysis technology is adopted for achieving growth of carbon nanotubes, and dispersion of metal nanoparticles and formation of a cooperative acting mechanism are promoted; the stability of the composite material is reinforced through the structure of carbon nanotube coated metal nanoparticles; the surface activity and dispersity of a carbon layer are improved through in-situ decoration of the nitrogen element; and the contact and active site point number is increased through the formation of a rich pore structure and the high specific surface area.

Owner:安徽皖瑞能源科技有限公司

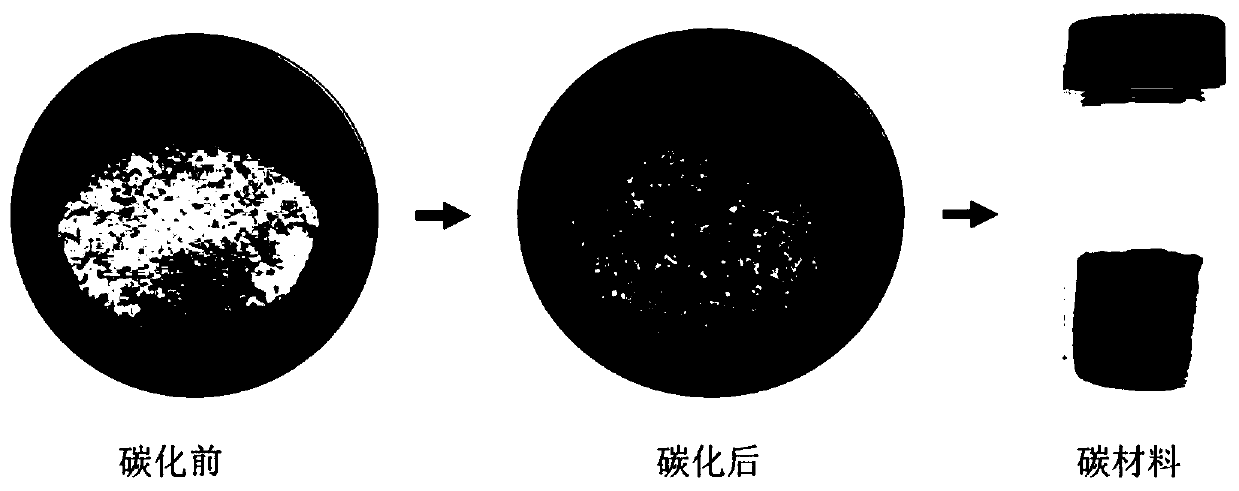

Preparation method of novel biochar

The invention relates to a preparation method of novel biochar, which comprises following steps: (1) crushing plant straws into powder, soaking the plant straws and soaking the plant straws in an ammonium acetate water solution at normal temperature, and cooking the plant straws in a mixed liquid prepared from oxalic acid, sodium nitrate, tannin acid and water; (2) washing filter residue in clear water to remove acid on surface of the plant straw powder; (3) cooking the filtrate; (4) mixing a solid substance obtained in the step (3) with carbon powder according to the weight ratio of 100:2.5 uniformly and performing high-temperature treatment; (5) mixing the treated raw materials with activated charcoal according to the weight ratio of 60:2 uniformly, and performing carbonization treatment with nitrogen gas filled into a quartz tube continuously so that the nitrogen gas is circulated in the quartz tube to prepare the biochar. The method for producing the biochar can reach more than 64.5% in carbonization rate of the plant straws, and is reduced by about 10% in energy consumption during the process.

Owner:QUANJIAO SHENGYUAN BIOMASS ENERGY CO LTD

Process for preparing nano chromium carbide powder

A process for preparing chromium carbide nano-particles includes such steps as dissolving Cr2O3 in organic solution, spray drying to obtain spherical hollow porous particles, calcining at 500-600 deg. C in protecting atmosphere, and carbonizing in H2 / CHCP at 850-1000 deg. C for 40-90 min.

Owner:CENT SOUTH UNIV

Method for preparing vanadium carbide powder

A method for preparing powdered vanadium carbide contains following steps: V#-[2]O#-[5] is dissolved in organic acid solution heated and stirred to obtain clarified and transparent solution of 10-40 % concentration at 60-80 degree centigrade, calcinated under protective atmosphere at 850-1000 degree centigrade and carbonized for 40-90 minute to obtain ultrafine powdered vanadium carbide having 0.1 micrometer average size and 20-60 nanometer grain size. The total carbon content of prepared powdered vanadium carbide is 17.75 % , free carbon is reduced to 0.61 % to satisfy the demand in carbide alloy and special steel production. Said invention also extends the use range of VC and provides ultrafine powdered vanadium carbide for other material production industry.

Owner:CENT SOUTH UNIV

Middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor

The invention discloses a middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor, and belongs to the field of high-performance carbon fiber preparation method. The middle-modulus carbon fiber preparation method comprises following steps: PAN precursor is delivered into a pre-oxidation furnace for pre-oxidation so as to obtain a pre-oxidized fiber body with a density ranging from 1.33 to 1.36g / cm<3>; the pre-oxidized fiber body is delivered into a low temperature carbonization furnace for low temperature carbonization so as to obtain a low temperature carbonized fiber body; the low temperature carbonized fiber body is delivered into a high temperature carbonization furnace for high temperature carbonization, and the carbon fiber with tensile strength ranging from 4500 to 5100MPa, tensile modulus ranging from 270 to 310GPa, and filament diameter ranging from 6 to 10<mu>m is obtained via carbonization. The middle-modulus carbon fiber preparation method is capable of realizing synchronous increasing of carbon fiber tensile modulus and strength, and solving key problems that the tensile strength of middle-modulus carbon fiber is reduced, and cost is high.

Owner:ZHONGFU SHENYING CARBON FIBER +1

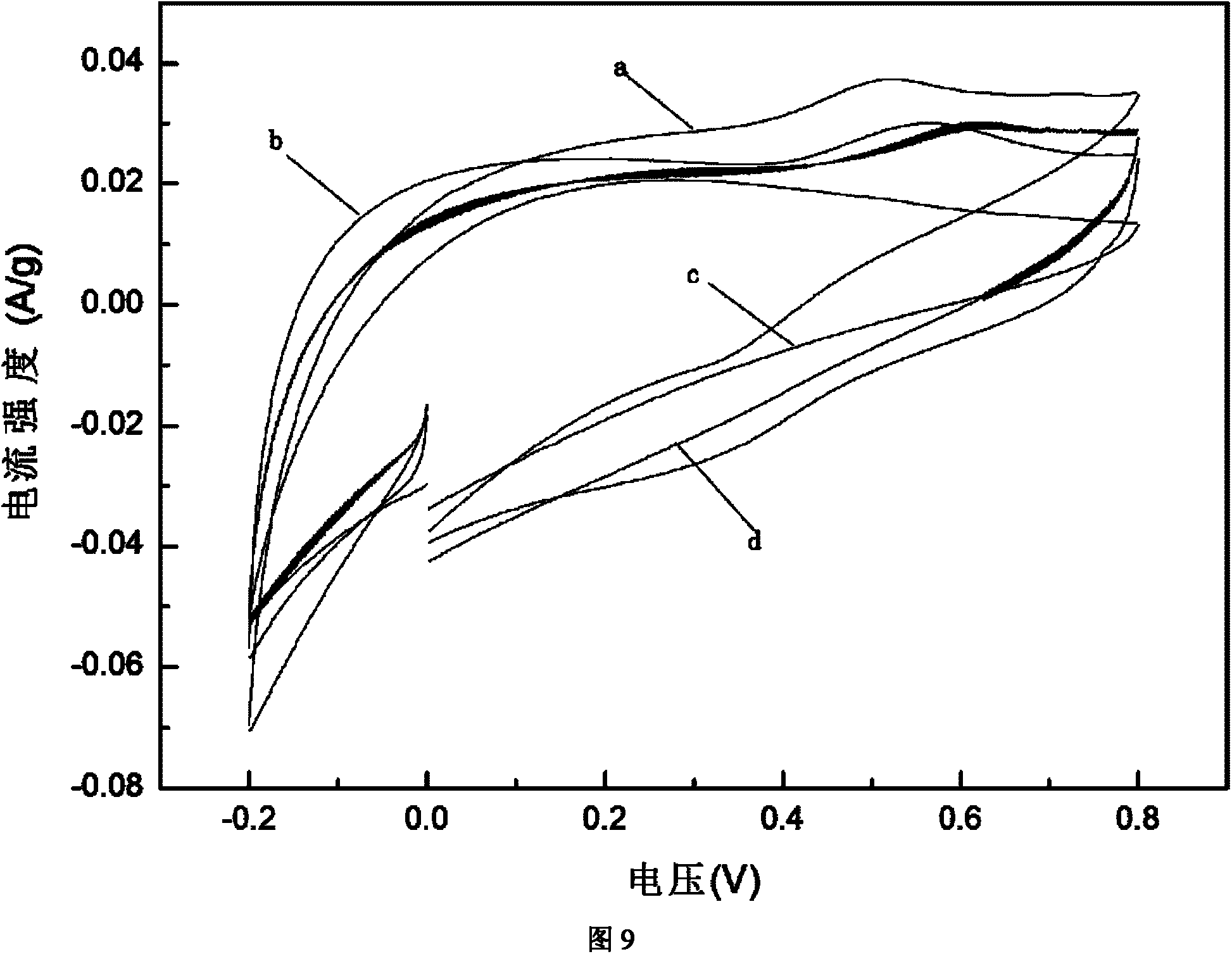

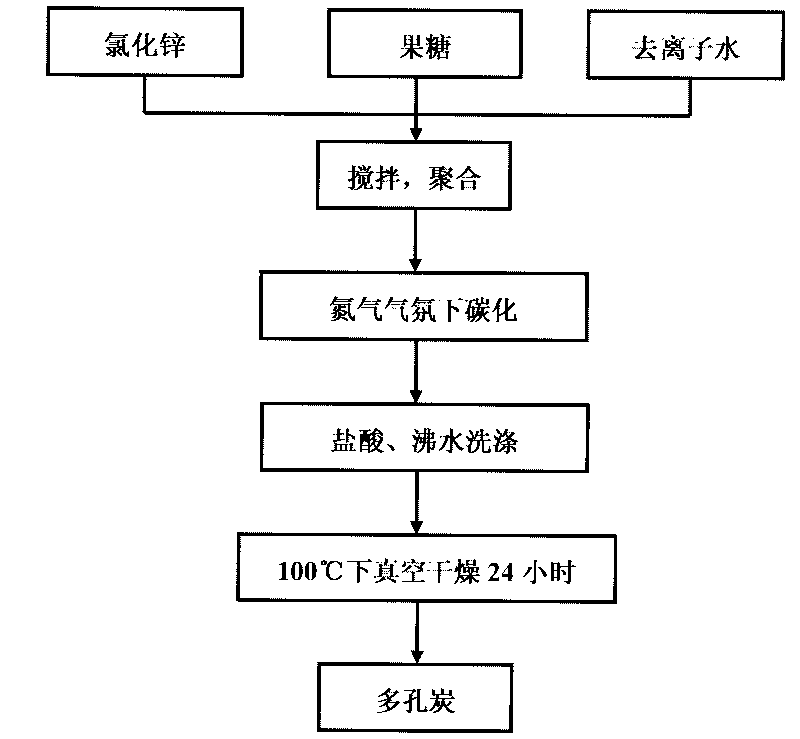

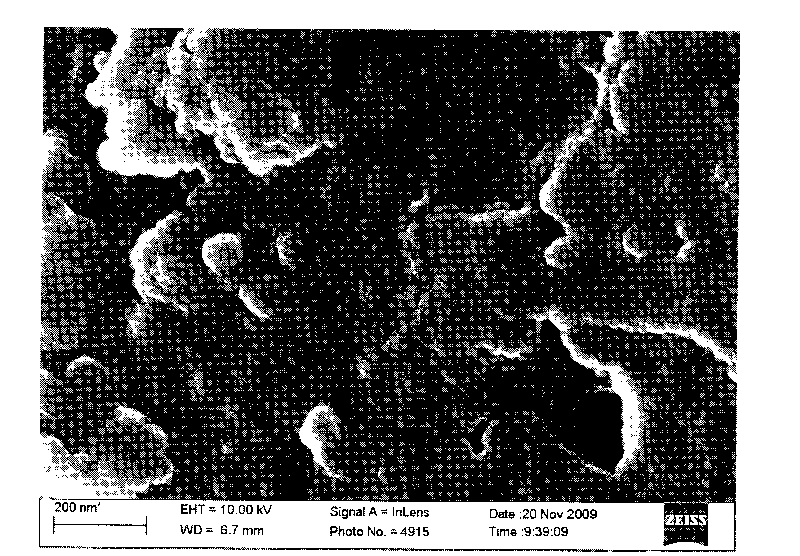

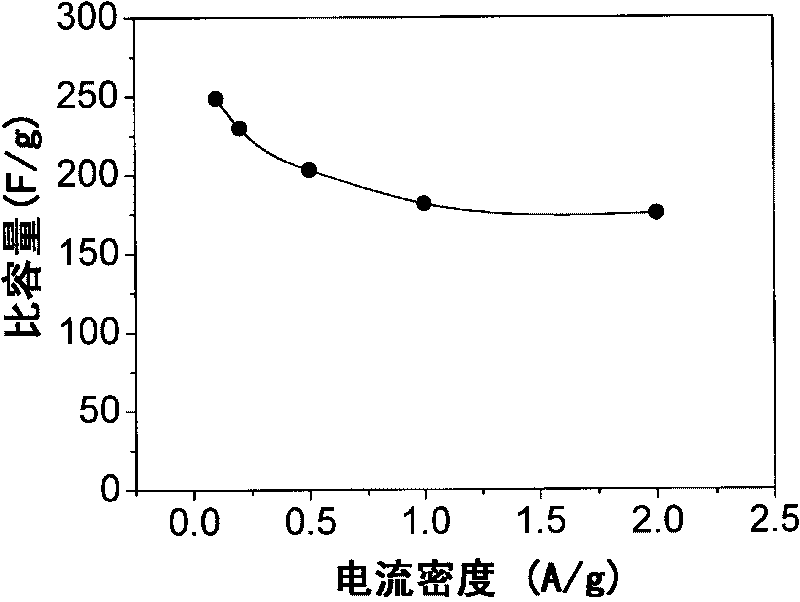

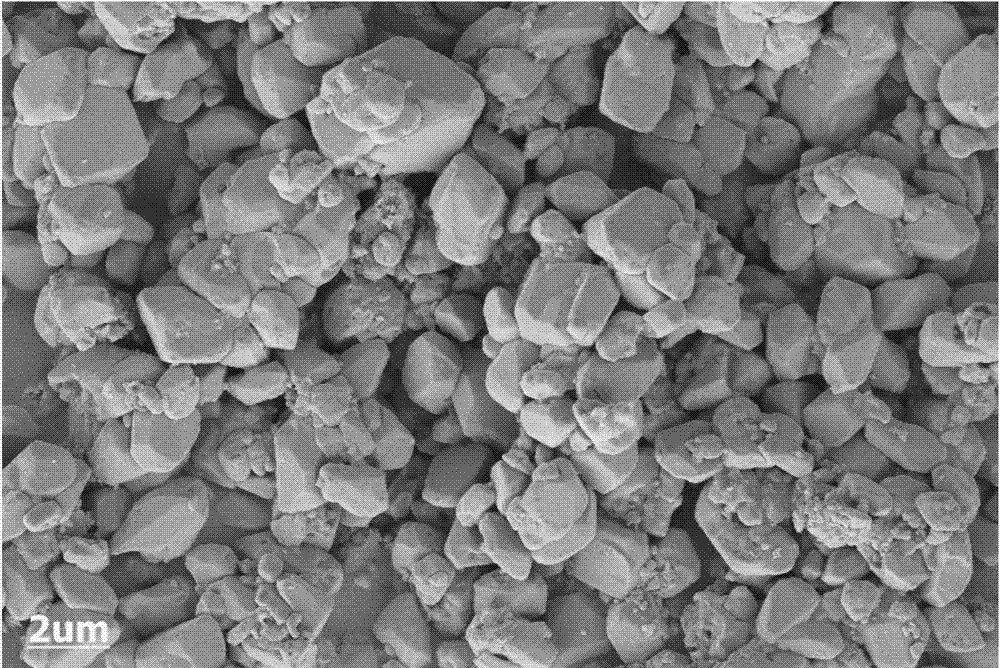

Electrode material of porous charcoal super capacitor and preparation method thereof

InactiveCN101710540ASimple preparation processLow costElectrolytic capacitorsHybrid/EDL manufactureNew energyNitrogen gas

An electrode material of porous charcoal super capacitor and a preparation method thereof belong to the field of electrochemistry and new energy materials. The electrode material of porous charcoal super capacitor is prepared by using zinc chloride as template agent and catalyzer, using fructose as progenitor, solving the fructose and zinc chloride having a weight ratio of 50:1 to 1:99 in deionized water, stirring in oil bath at 10 to 300 DEG C, putting into an oven at 20 to 200 DEG C for 1 to 50 hours, roasting under the protection of argon, nitrogen or helium, heating with a temperature rate being 1 to 20 DEG C per minute, charring at 450 to 1200 DEG C, keeping temperature for 0.5 to 5 hours, washing with hydrochloric acid and water till no chloride ion exists tested by using silver nitrate, and then drying. The preparation process of the electrode material is simple, low-cost and fit for industrializing production.

Owner:UNIV OF SCI & TECH BEIJING

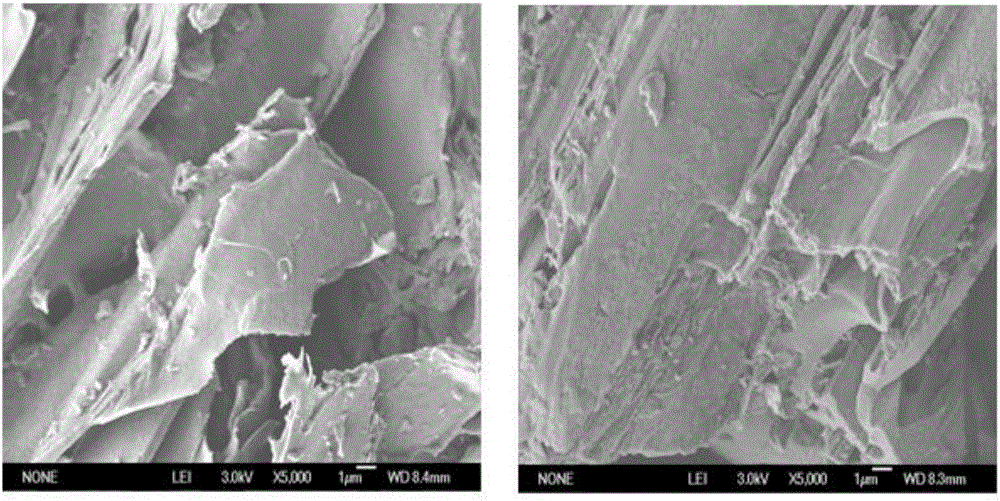

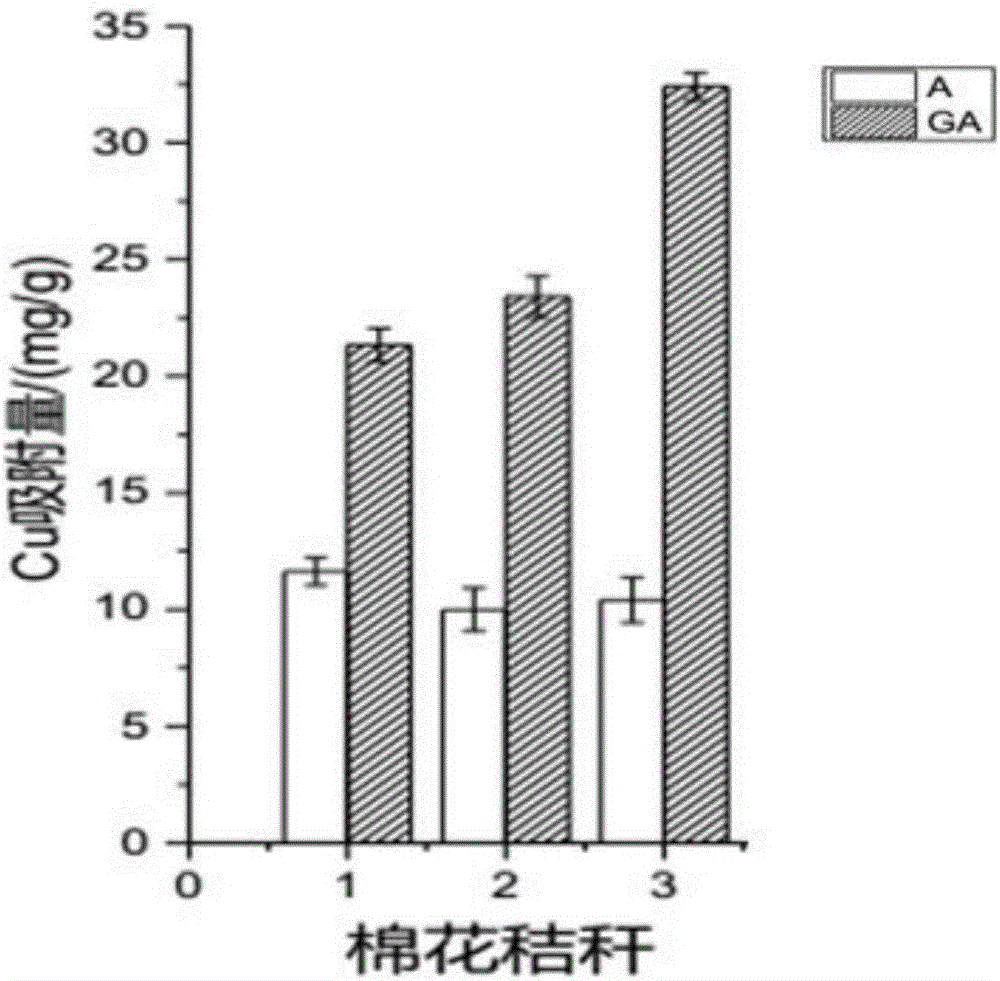

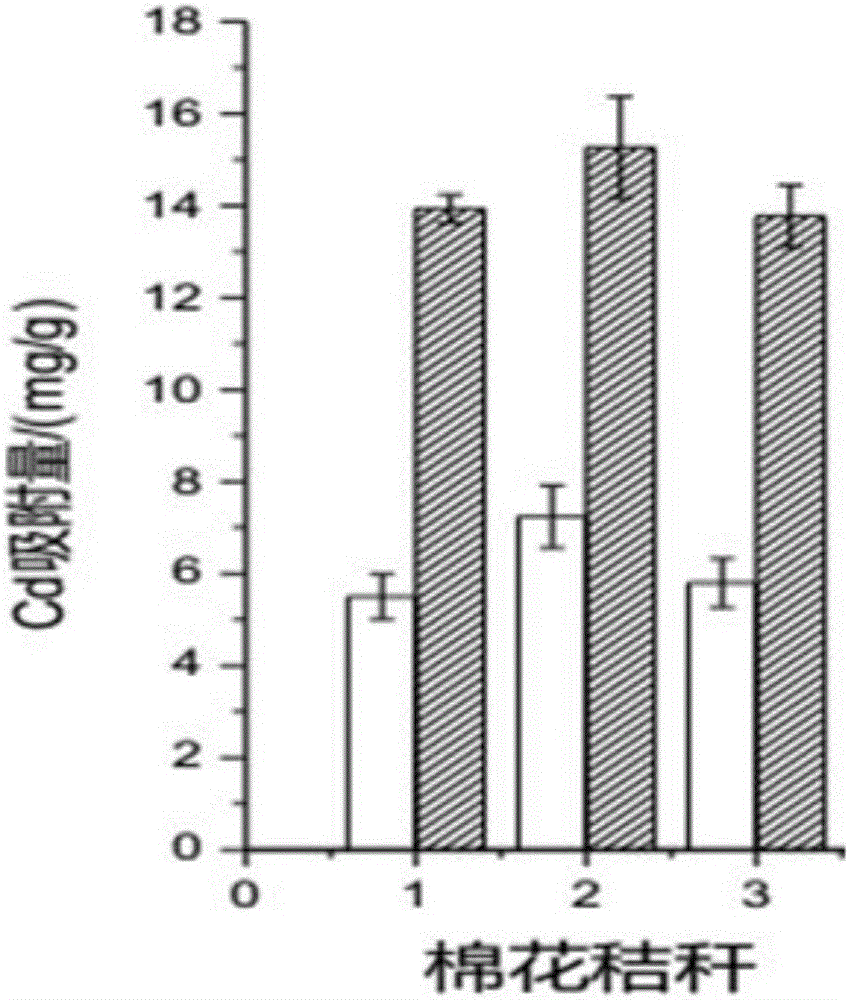

Method for preparing efficient heavy metal adsorbent from modified cotton stalk biomass charcoal

InactiveCN105879838ABiomass carbon pores increaseImprove adsorption capacityOther chemical processesBiomass carbonSorbent

The invention discloses a method for preparing a high-efficiency heavy metal adsorbent by modifying cotton stalk biomass charcoal. Carbonization at 300°C for 3‑6h; (2) Add 0.3mol / L KMnO to the cotton biochar prepared in step (1) 4 solution, and then add a mass fraction of 60% HNO 3 solution, heated at 85-95°C for 2.5-3.5h, filtered, washed, and dried to obtain a modified product, the biochar and KMnO 4 solution and HNO 3 The dosage ratio of the solution is 1g: (7-7.8)ml: (3.3-4.0)ml. The pore volume of the biomass charcoal obtained by carbonizing the cotton stalks prepared by the method of the invention is obviously increased, and can efficiently adsorb heavy metal copper and cadmium at the same time.

Owner:SHANDONG NORMAL UNIV

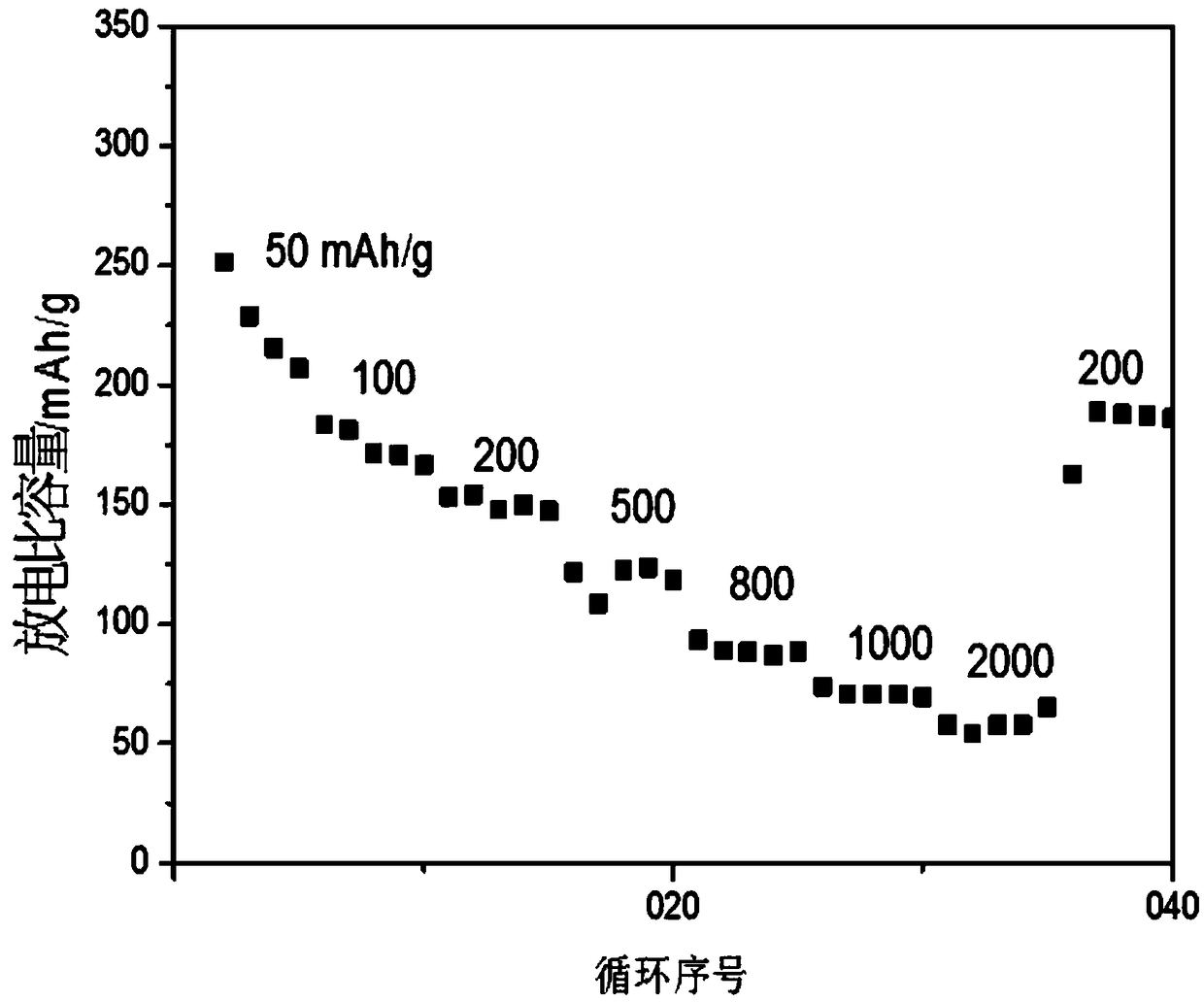

Selenium-doped ferrous disulfide carbon-coated composite material and preparation and application methods thereof

ActiveCN109437123AHigh activityImprove electrochemical activityCell electrodesSecondary cellsSodium-ion batteryCarbon coated

The invention discloses a selenium-doped ferrous disulfide carbon-coated composite material. The composition of the selenium-doped ferrous disulfide carbon-coated composite material is FeSe*S2-*@C, wherein x is 0.1-1.9. When applied to sodium ion batteries, the selenium-doped ferrous disulfide carbon-coated composite material can effectively inhibit volume expansion effects and increase actual specific capacity, rate capability and cycling performance. The invention also discloses preparation and application methods of the selenium-doped ferrous disulfide carbon-coated composite material.

Owner:中山高容新能源科技有限公司

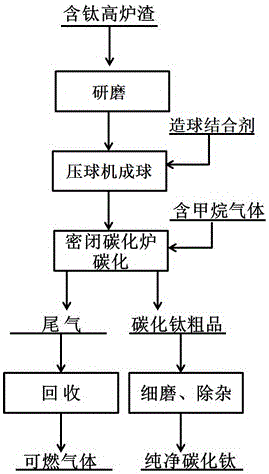

Titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag

The invention provides a titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag. The method comprises the steps that the titanium-bearing blast furnace slag serves as the raw material, grinding and balling are conducted, heating is conducted to 1,100 DEG C to 1,300 DEG C, methane is decomposed into hydrogen and carbon black, and a titanium carbide crude product is obtained after reduction and carbonization are conducted; the titanium carbide crude product is subjected to levigating treatment and purifying, and a more pure titanium carbide product can be obtained; the processes of the method are simple and easy to operate, due to the fact that methane is decomposed to obtain hydrogen and carbon black with high activity, hydrogen and the titanium-bearing blast furnace slag are subjected to a gas-solid reaction, and the reduction efficiency is high; meanwhile, by means of the carbon black with the high activity, the carbonization efficiency is greatly improved, the overall reaction efficiency is improved, the carbonization temperature is decreased, tail gas obtained from the reaction is used as gas fuel supply for heating of a closed-type carbide furnace, therefore, energy consumption is effectively reduced, an existing titanium-bearing blast furnace slag resource is better utilized, the added value of the titanium-bearing blast furnace slag is increased, and good industrial application value is achieved.

Owner:CHONGQING UNIV

Method for preparing nanopowder of tungsten carbide

InactiveCN1843908AFine and uniform particle sizeLow carbonization temperatureTungsten/molybdenum carbideHydrogen atmosphereCarbide

The invention relates to a method for preparing nanometer tungsten carbide, belonging to field of preparing nanometer metallic carbide powder. The method employs formaldehyde-phenol resin as carbon source and demolding agent, and prepares mixture of nanometer W particle covered by formaldehyde-phenol resin, then gets nanometer WC powder through vacuum carbonization, and finally removes free carbon through heating treatment in hydrogen atmosphere. The invention is characterized by fine and homogenous WC powder, simple process and device and low cost.

Owner:UNIV OF SCI & TECH BEIJING

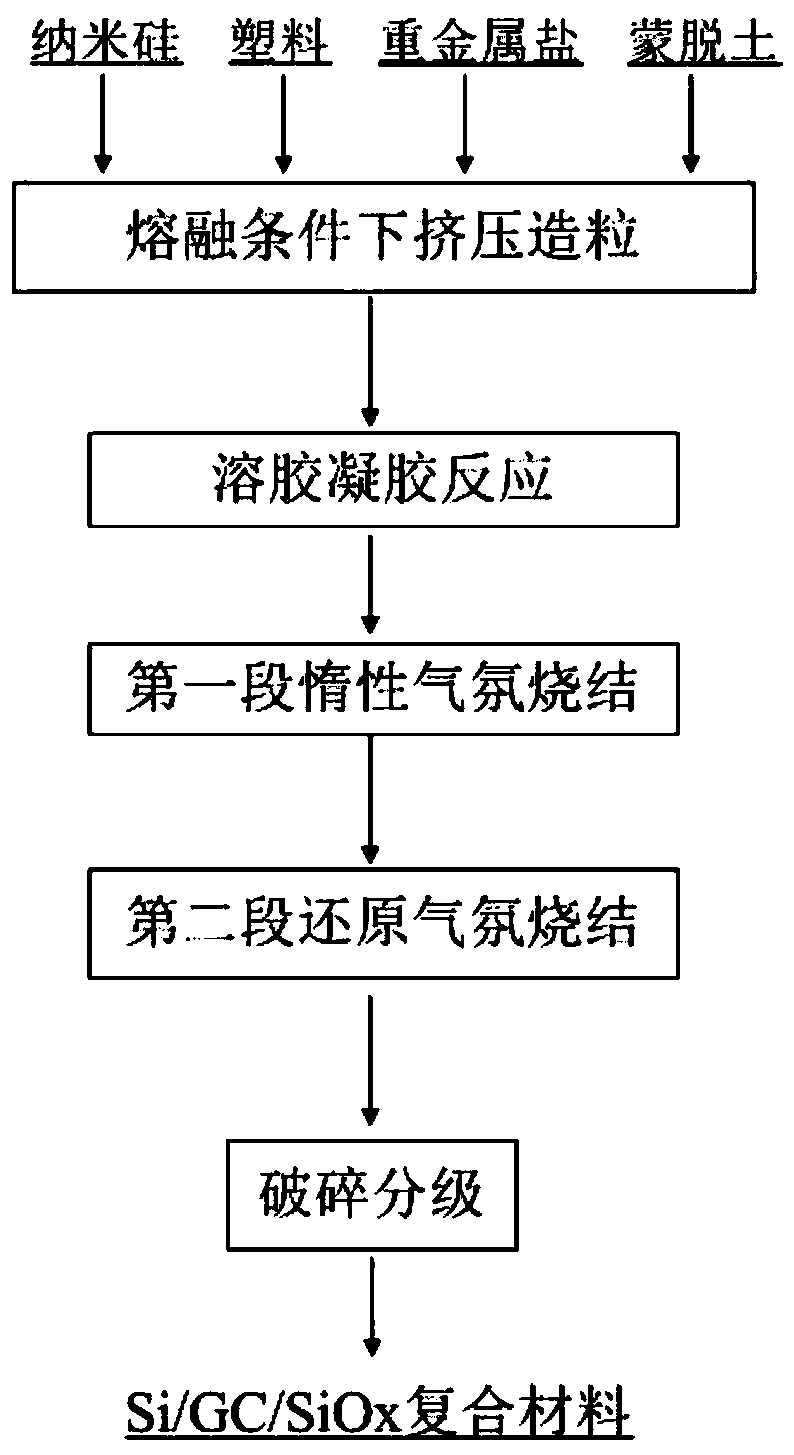

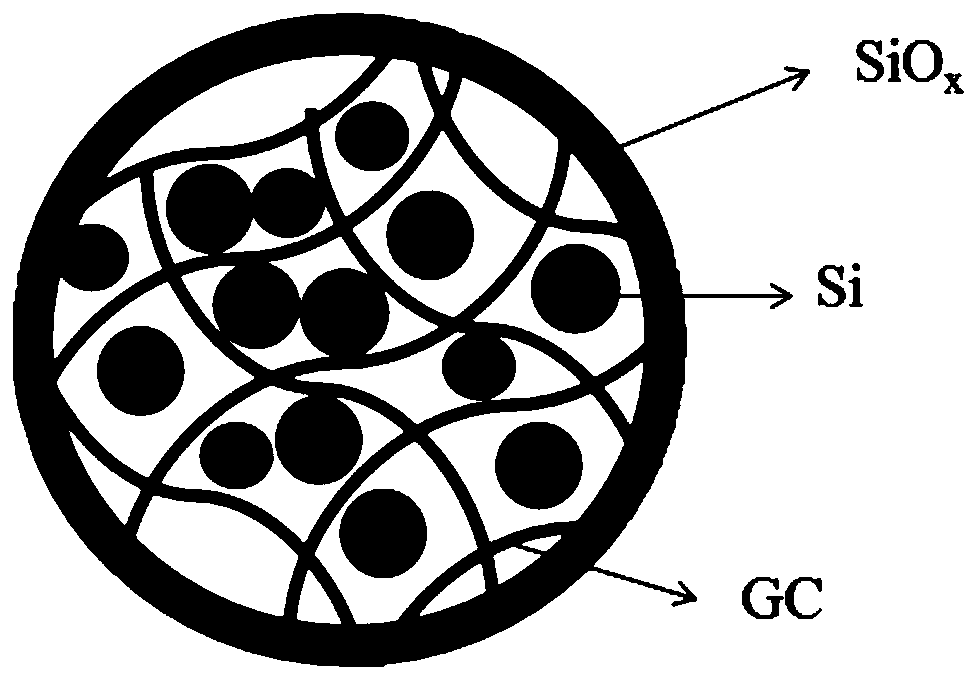

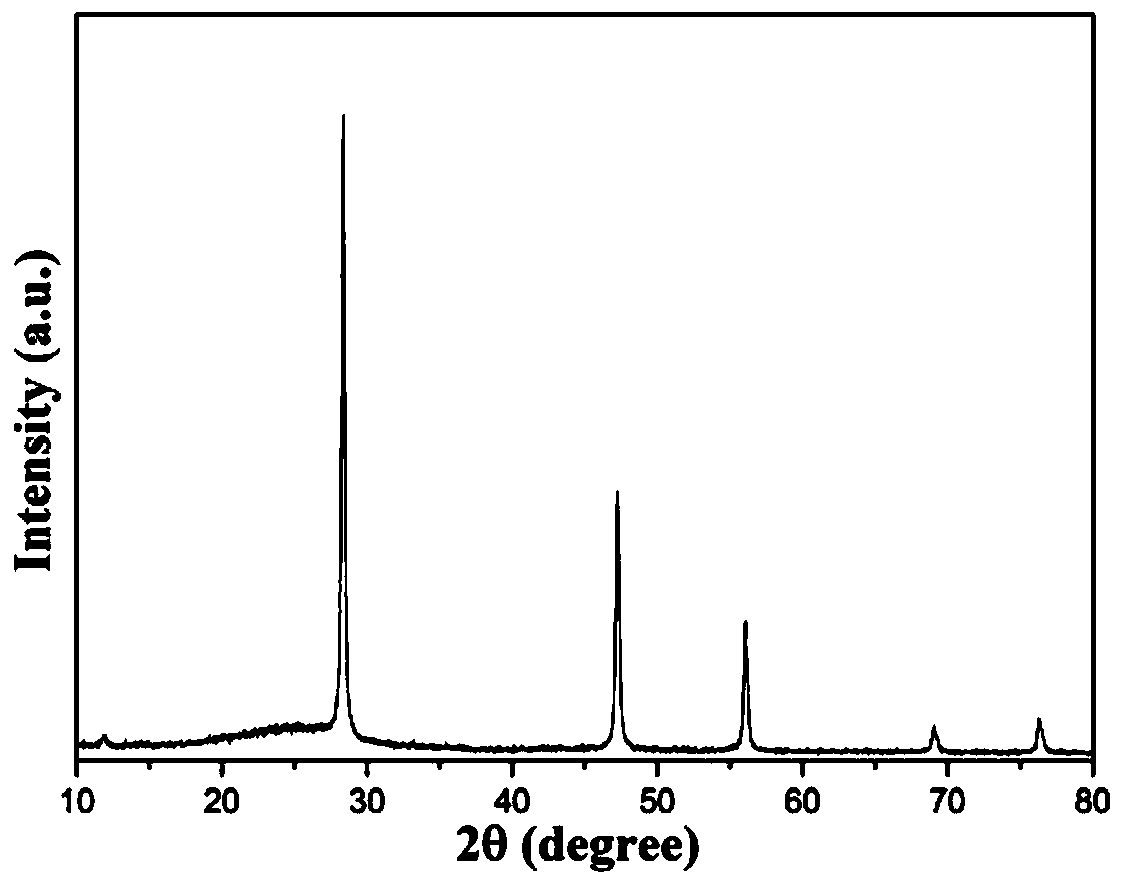

Preparation method of silicon-based composite material for lithium ion power battery

ActiveCN109755546AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsElectrical batterySilicon dioxide

The invention discloses a preparation method of a silicon-based composite material for a lithium ion power battery, belonging to the field of negative electrode materials for lithium ion batteries. The method comprises the steps of mixing the raw materials for extrusion and granulation under molten conditions by using nano silicon, plastic and montmorillonite as raw materials and adding heavy metal salt as a catalyst to obtain a nano-silicon / plastic / montmorillonite composite material; adding a nonionic surfactant and a cationic surfactant to the hydrochloric acid solution to obtain a mixed solution, adding the nano-silicon / plastic / montmorillonite composite material to the mixed solution to carry out a sol-gel reaction to obtain a nano-silicon / plastic / silica composite material; and obtaining the silicon-based composite material by subjecting the nano-silicon / plastic / silica composite material to carbothermal reduction. The preparation method provided by the invention, by utilizing the characteristics of inducing catalytic plastics and catalytic graphitization in heavy metal salts, realizes low temperature graphitization and graphitized carbon uniformly coating nano silicon particlesby using plastic as a carbon source, thereby improving electrochemical performance of silicon anode materials.

Owner:湖南宸宇富基新能源科技有限公司

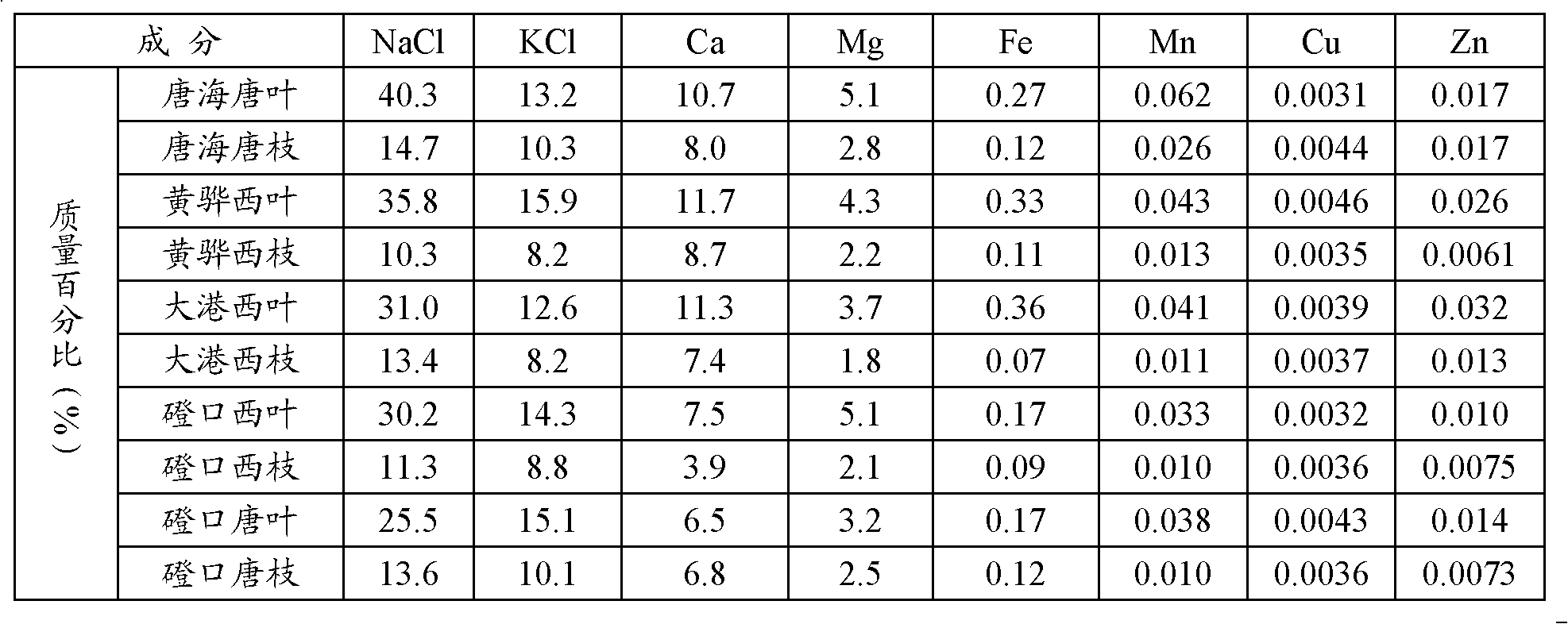

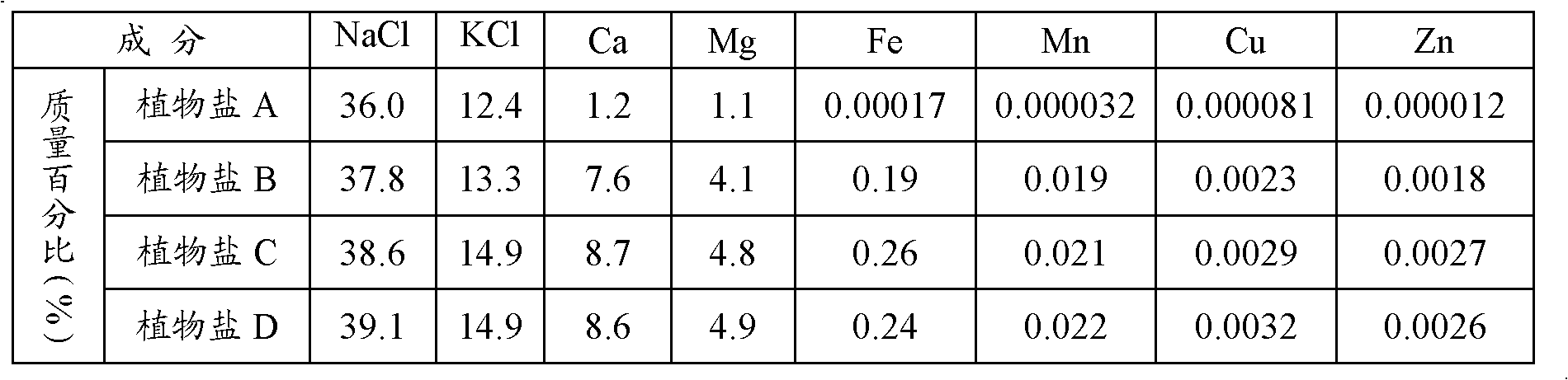

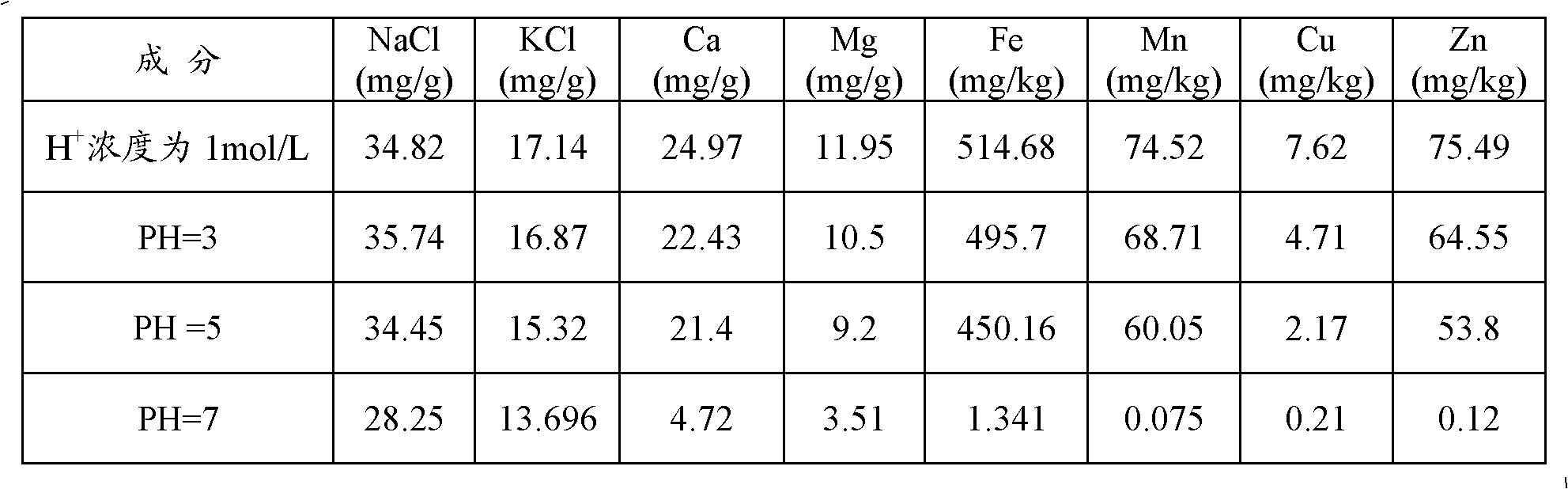

Nitraria plant salt and preparation method thereof

InactiveCN102524740AReduce morbidityLow carbonization temperatureFood preparationChemistryCalcium EDTA

The invention provides Nitraria plant salt and a preparation method thereof. The Nitraria plant salt contains the following components in percentage by weight: 10.3 to 40.3 percent of sodium chloride, 8.0 to 16.0 percent of potassium chloride, 3.5 to 12.0 percent of calcium, 1.5 to 5.5 percent of magnesium, 0.05 to 0.40 percent of iron, 0.010 to 0.065 percent of manganese, 0.0024 to 0.0045 percent of copper, and 0.0010 to 0.035 percent of zinc. The preparation method of the Nitraria plant salt comprises a step of charring a Nitraria plant to obtain a charred material and a step of performing water extraction and acid extraction to the charred material. The preparation method can be adopted to produce Nitraria plant salt which can serve as low-sodium salt and can also utilize Nitraria plants to reduce the salt and alkali contents of soil and improve the ecological environment.

Owner:张华新 +1

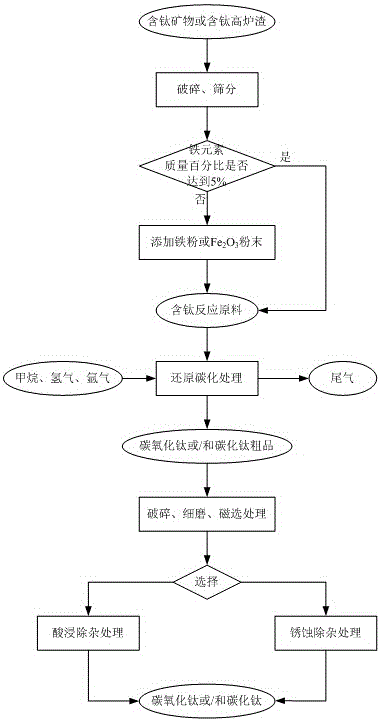

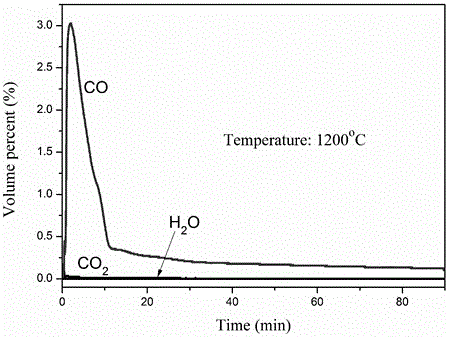

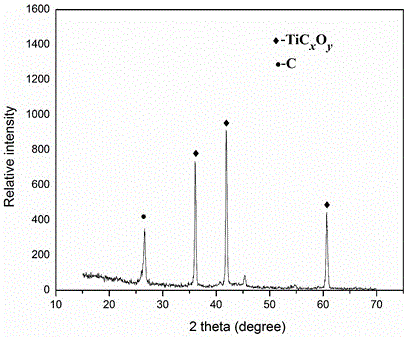

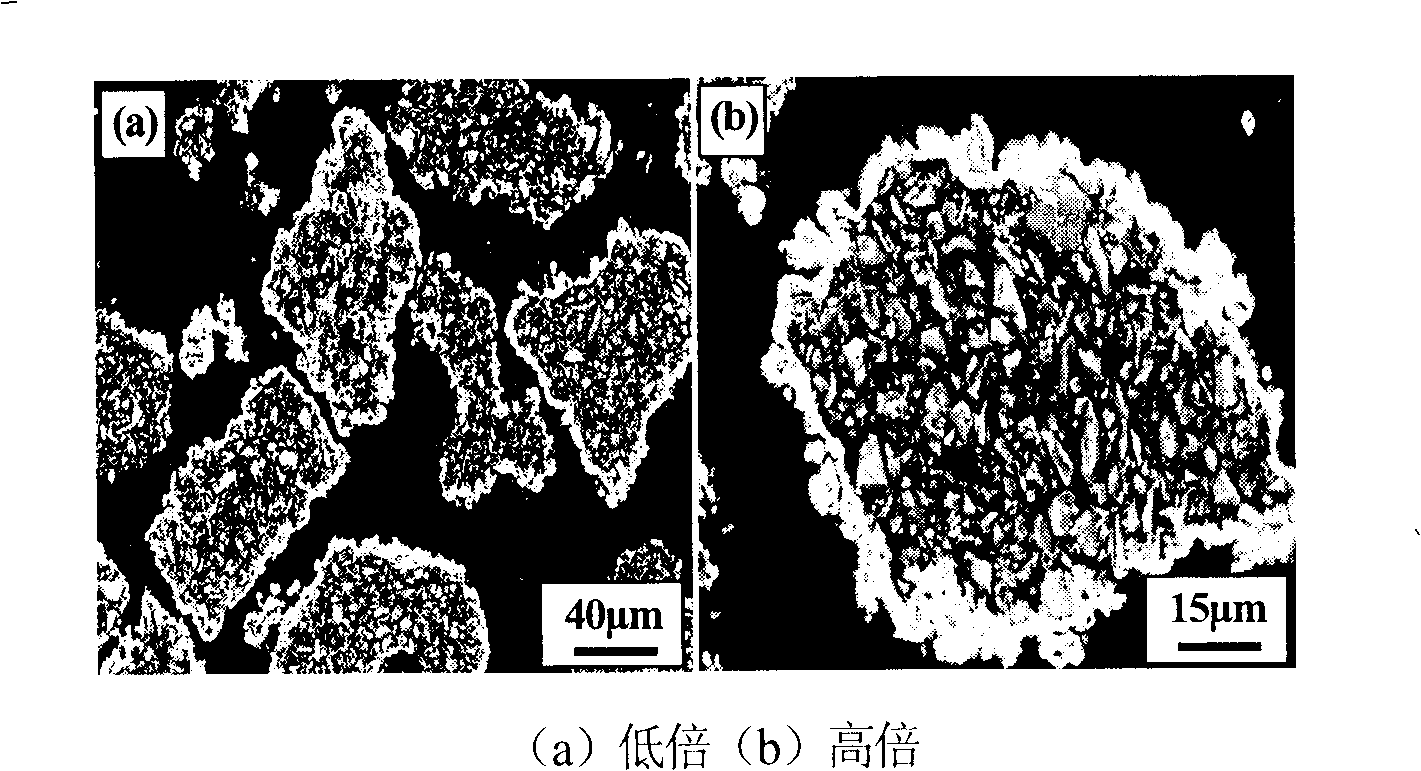

Method for preparing carbon-doped titanium oxide or/and titanium carbide from titanium-containing mineral or slag

InactiveCN106315584ALow costShort production processHydrogen separationTitanium carbideSlagReaction rate

The invention provides a method for preparing carbon-doped titanium oxide or / and titanium carbide from titanium-containing mineral or slag. According to the method, the cheap titanium-containing mineral or slag is adopted as a donor of the titanium element, and hydrogen and methane are selected to serve as a reducing agent and a carbonization agent respectively, so that raw material cost is saved; moreover, the processing only needs to reach the low temperature of 1,200-1,400 DEG C, meanwhile, reforming of methane is realized in the process of preparing carbon-doped titanium oxide or / and titanium carbide, hydrogen and carbon black are obtained through methane splitting, hydrogen and the titanium-containing material are subjected to a gas-solid reduction reaction, and reduction efficiency is high; meanwhile, the carbon black obtained through splitting greatly improves carbonization efficiency, carbonization temperature is low, the carbonization rate is high, energy consumption cost is saved, therefore, production cost is lowered, the production reaction rate is increased, the recovery rate of the titanium element in the raw material is raised, and the problems that in an existing carbon-doped titanium oxide and titanium carbide production process, preparation temperature is high, production efficiency is low, and cost is high are well solved.

Owner:CHONGQING UNIV

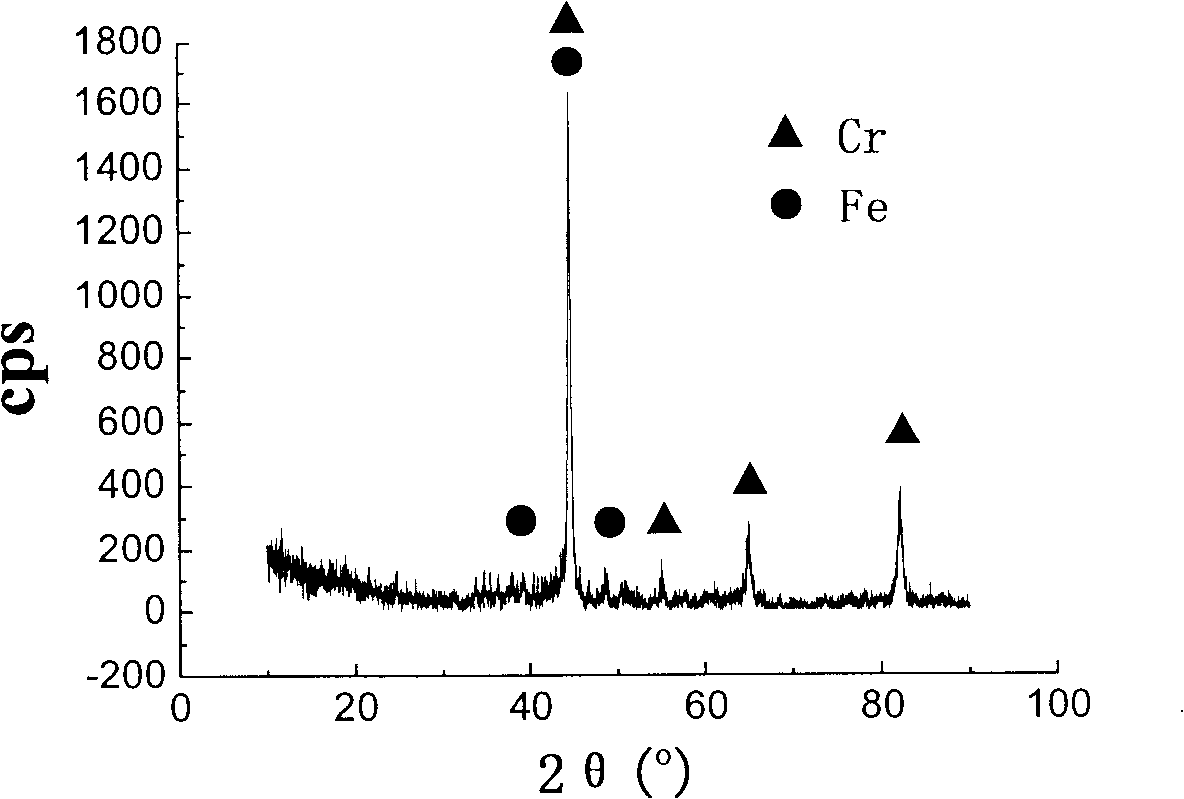

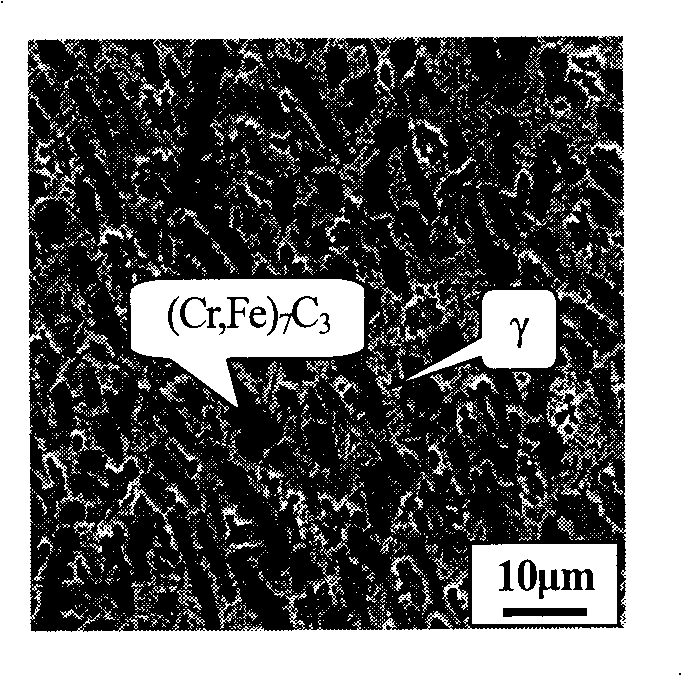

Synthetic reaction plasma cladding powder and preparation technique thereof

InactiveCN101255557AHigh bonding strengthAvoid easy separationMetallic material coating processesSucroseGranularity

The invention discloses a chromium-ferrum-carbon- tungsten-nickel synthetic reaction plasma cladding powder and the preparing process thereof. With sucrose as the precursor of carbon, by carbonizing under a specific temperature, a chromium-ferrum-carbon- tungsten-nickel plasma cladding composite power coated with carbon is formed. The process is as follows: mixing the raw materials powder(except the sucrose) in accordance with the granularity requirement in proportion, wet grinding, drying the mixed slump powder, carbonizing the mixture of the dried powder and the sucrose by step, and crushing and screening the carbonized block-like substance. The invention solves the problem that reaction components are separated in plasma cladding powder when preparing carbide metal composite coating by plasma cladding in current technology, besides, sucrose is the precursor of carbon, which has low carbonizing temperature, the produced carbon has high purity, the carbonizing process has low pollution, and the industrial feasibility is high.

Owner:WEIFANG UNIVERSITY

Biomass porous carbon/prussian blue composite material and preparation method thereof

ActiveCN110436484AIncrease the areaHigh porosityCarbon compoundsCyanic/isocyanic acidPorous carbonCarbonization

The invention provides a biomass porous carbon / prussian blue composite material and a preparation method thereof. The composite material mainly comprises C, N, O, K, Fe and Cl, main organic functionalgroups comprise cyano, hydroxyl, alkyl, benzene ring, a benzene ring substituent and the like, biomass porous carbon serves as a main body of the composite material, and prussian blue substances areattached to the surface layer and pores of the biomass porous carbon. The preparation method mainly comprises the following steps: (1) conducting pickling to remove metal ions; (2) conducting swellingmodification on biomass; (3) loading a porous carbon pore-forming agent and a Prussian blue reactant; (4) conducting drying and dehydrating; and (5) conducting controllable preparation of the biomassporous carbon / prussian blue composite material. The method can obviously lower the carbonization temperature in the process of preparing the functional material from the biomass, widens the raw material source of the biomass, saves the energy, and has the advantages of low cost and low pollution.

Owner:HUNAN UNIV OF SCI & TECH

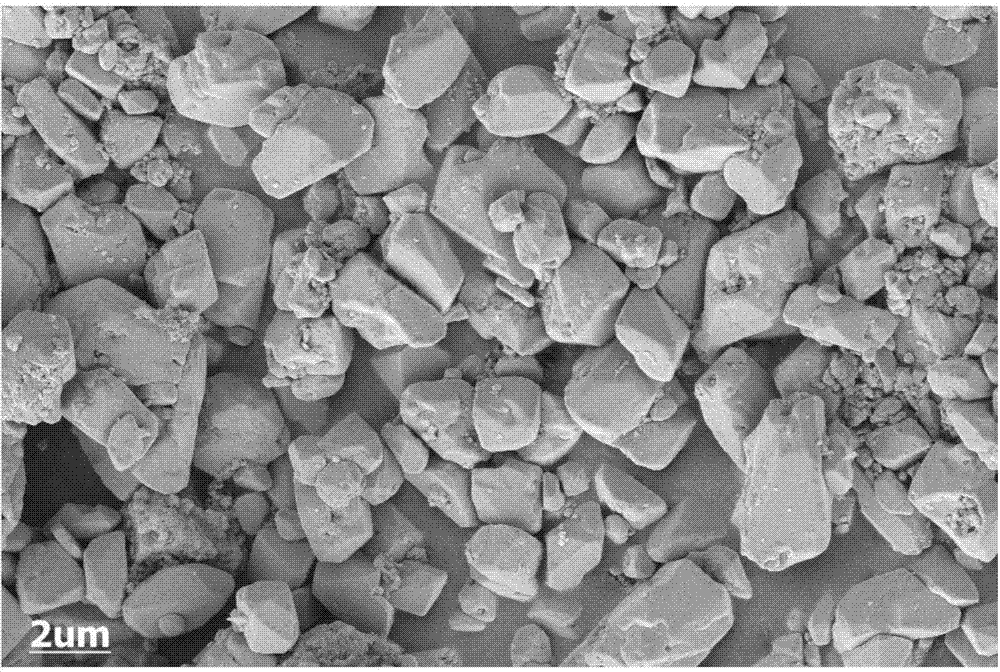

Preparation method of ultrafine tantalum carbide powder

ActiveCN102134073ASimple procedureLow carbonization temperatureChemical industryChemical compositionGranularity

The invention relates to a preparation method of ultrafine tantalum carbide powder. The technical scheme is as follows: the preparation method comprises the steps of: drying pulpy tantalum hydroxide bought in a baking oven at the temperature of 180-250 DEG C, obtaining nano-level tantalum hydroxide, then mixing the nano-level tantalum hydroxide and carbon black, increasing the temperature slowly to be 1200-1300 DEG C, carrying out vacuum carbonization for 6-14 hours and obtaining the ultrafine tantalum carbide (TaC) powder of which the powder granularity is less than 0.6mum and the chemical compositions conform to the requirements of preparing hard alloy. The preparation method of the ultrafine tantalum carbide powder provided by the invention has the advantages that the process is short, the operation is easy to be realized and the energy is saved.

Owner:长沙伟徽高科技新材料有限公司

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

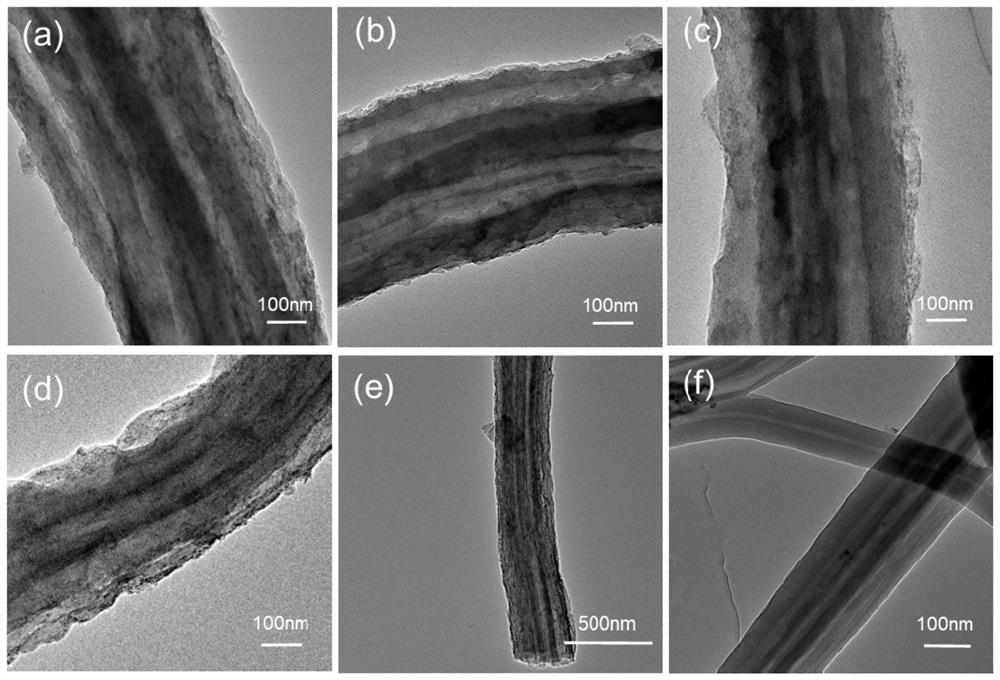

ActiveCN113073426AImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. According to the method, a porous multi-hollow flexible composite nanofiber membrane is prepared through coaxial electrostatic spinning, wherein an outer layer solution for coaxial electrostatic spinning consists of a sacrificial high-molecular polymer, a retained high-molecular polymer and a solvent A, and an inner layer solution for coaxial electrostatic spinning is composed of a sacrificial high-molecular polymer, a material capable of generating a substance with semiconductor characteristics and low surface energy in the spinning process, and a solvent B; and then the sacrificial high-molecular polymer in the porous multi-hollow flexible composite nanofiber membrane is removed to obtain the membrane material formed by stacking porous multi-hollow nanofibers, wherein the porous multi-hollow nanofibers are provided with a plurality of hollow pipelines and three-dimensional penetrating through hole micro-nano structures with the hollow surfaces. The membrane material disclosed by the invention has relatively high flexibility and mechanical strength, and the problems of fragility, low mechanical strength and the like of a porous composite fiber material and a single hollow fiber material are solved.

Owner:DONGHUA UNIV

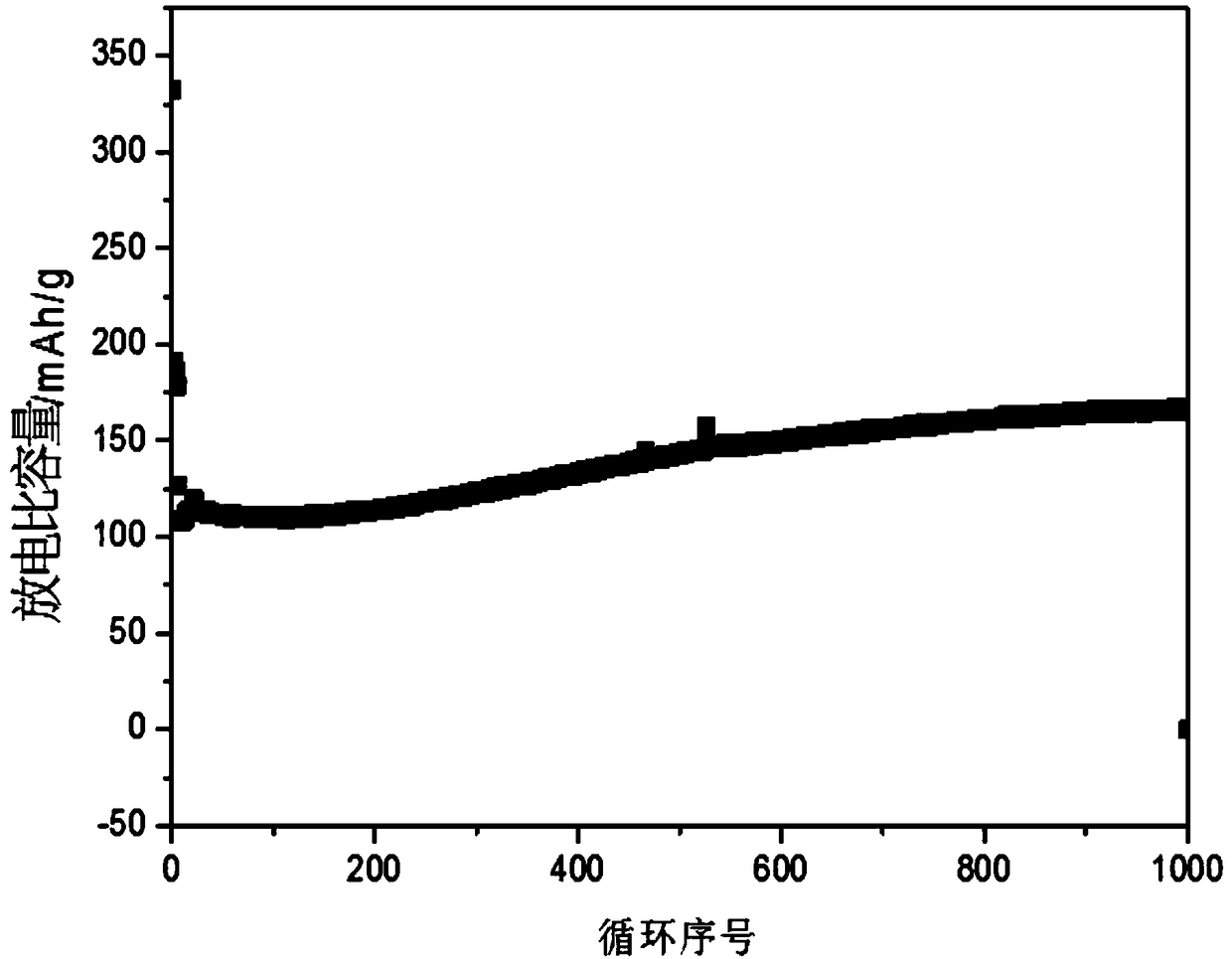

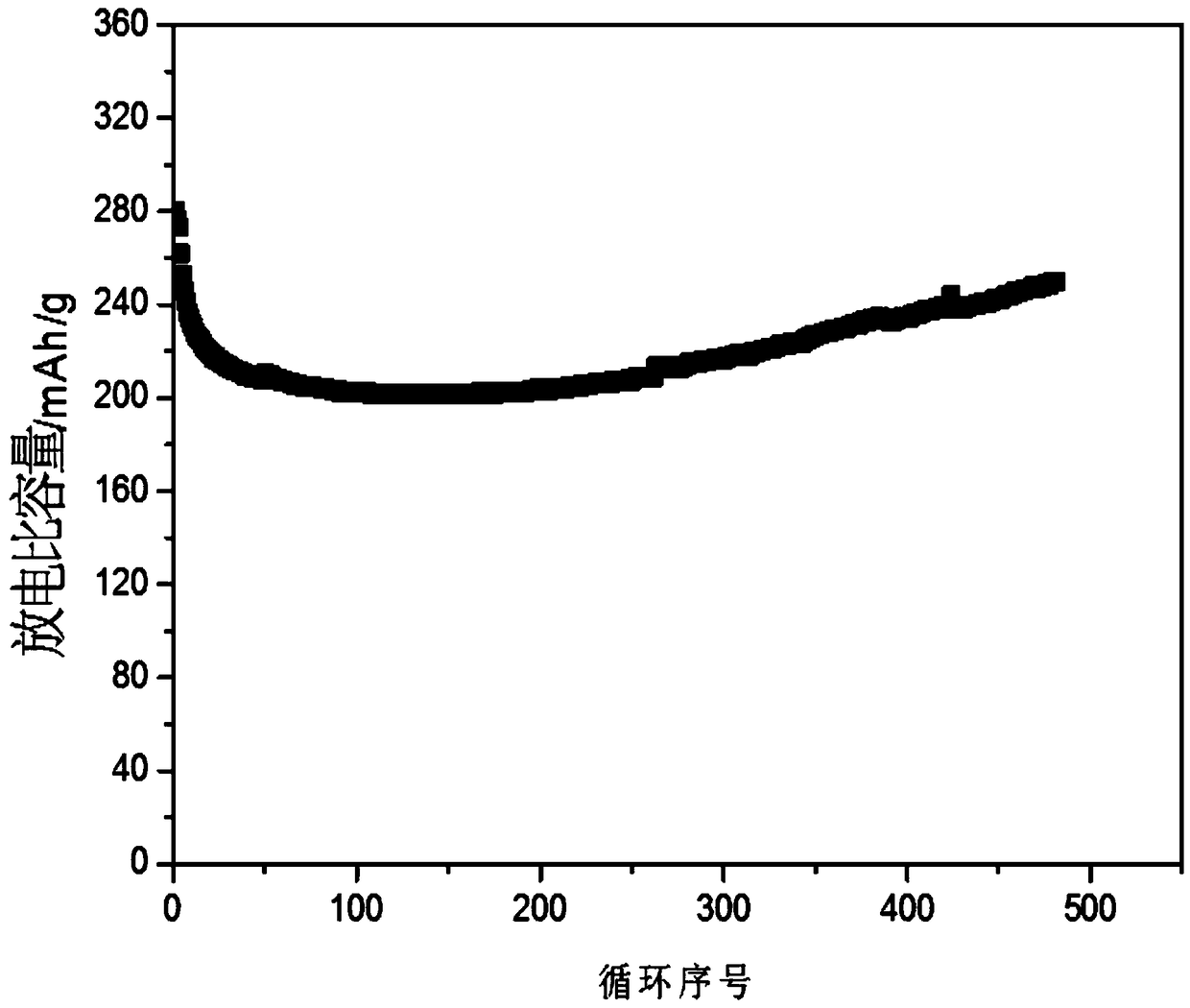

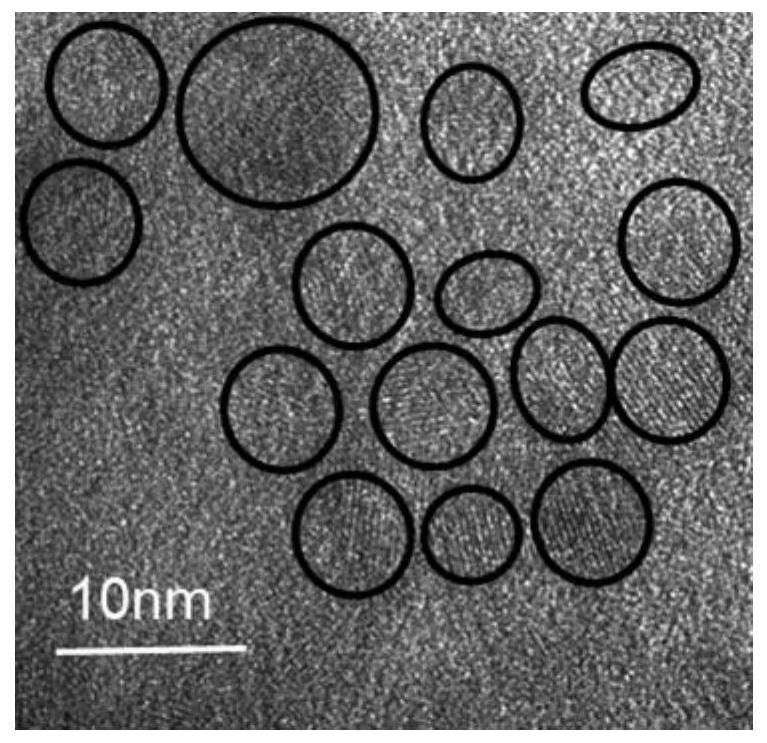

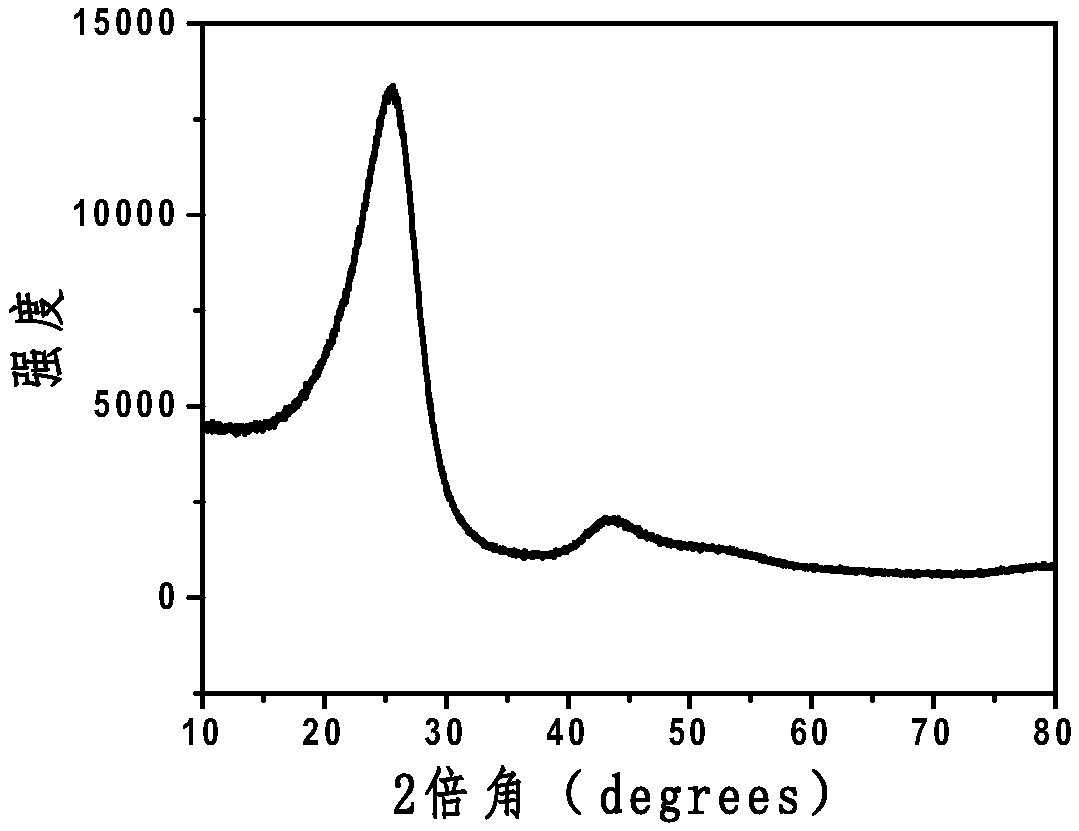

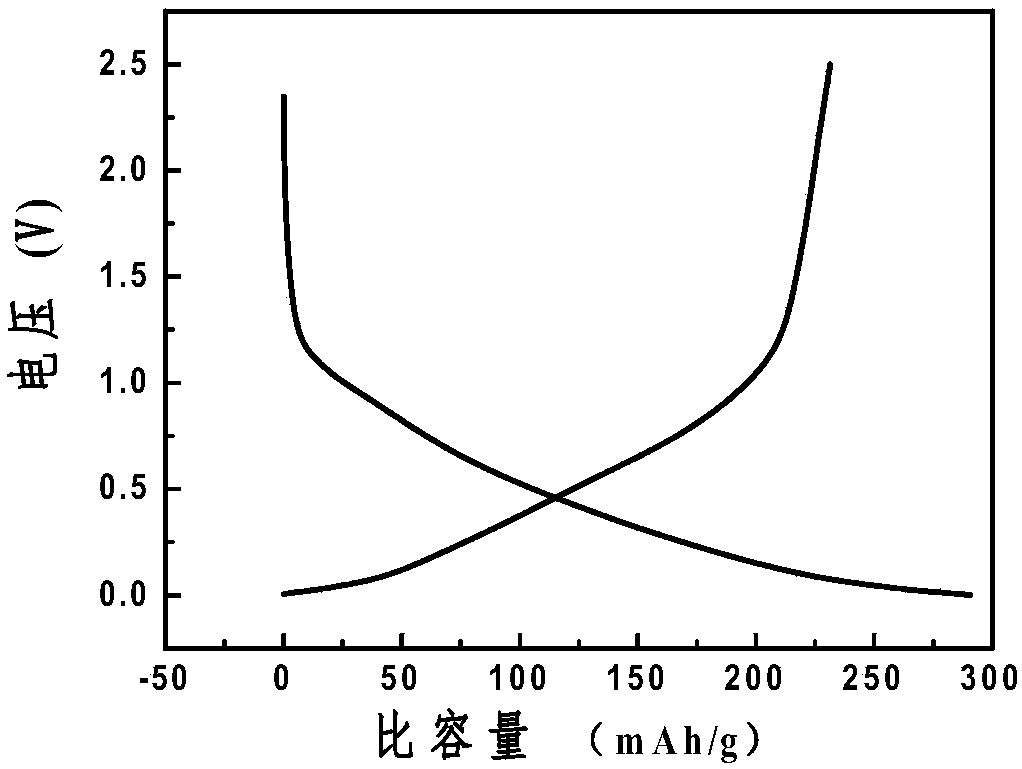

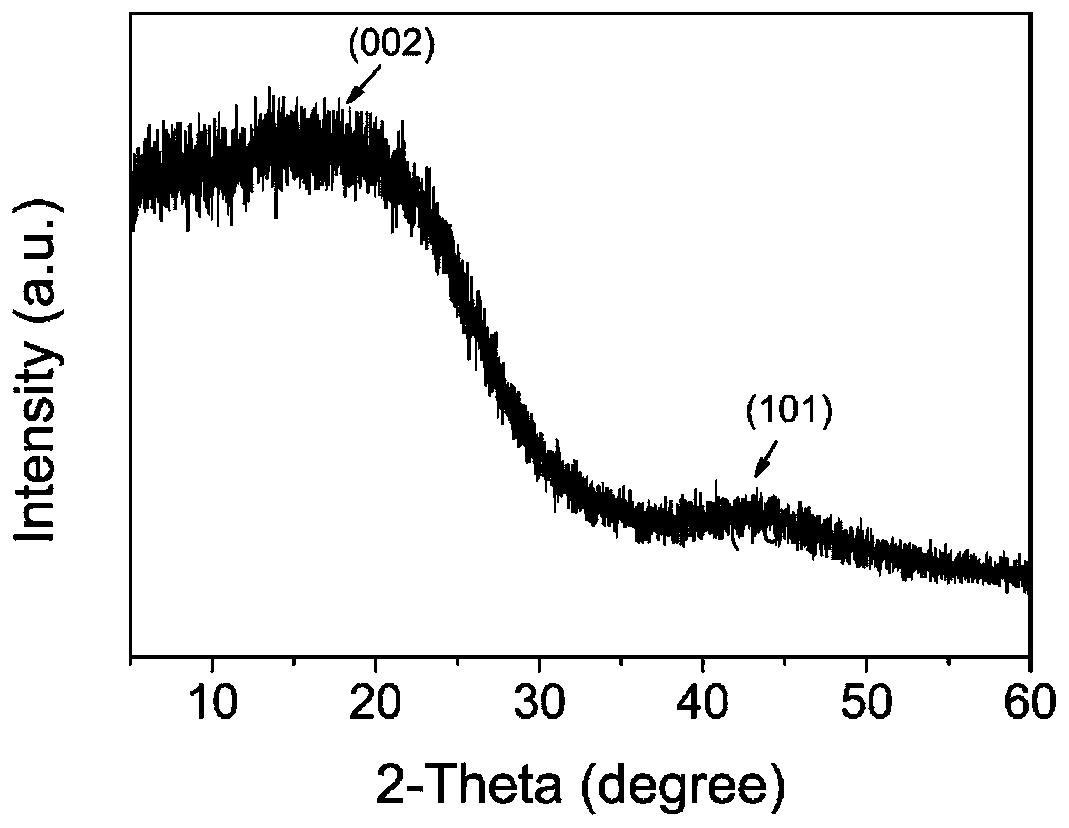

A carbon-based negative electrode material with high ramp capacity and a preparation method and use thereof

ActiveCN109148884ALow carbonization temperatureShort processing timeNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryCycle efficiency

An embodiment of the invention relates to a carbon-based negative electrode material with high ramp capacity and a preparation method and use thereof. The method comprises: placing a carbon source precursor in a crucible, placing the precursor in a heating device, and heating the precursor in an inert atmosphere at 0.2 DEG C / min to 30 DEG C / min to 400 DEG C to 1000 DEG C; wherein the carbon sourceprecursor comprises any one or a combination of at least two of fossil fuel, biomass, resin, and organic chemical; the carbon source precursor is subjected to heat treatment at low temperature at 400DEG C to 1000 DEG C for 0.5 to 48 hours, carbonizing that precursor of the carbon source to obtain a carbon-based negative electrode material; The specific surface area of carbon-based cathode material obtained by low temperature heat treatment is less than 10m2 / g. The carbon-based negative electrode material is assembled into the sodium ion battery, and then is charged and discharged between 0 to 2.5 V, and the voltage curve with high ramp capacity is obtained. The ramp capacity is above 180 mAh / g and the first-cycle Coulomb efficiency is above 75%. By coating the surface, the specific surface area can be further reduced, and the first-cycle efficiency and reversible specific capacity can be improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

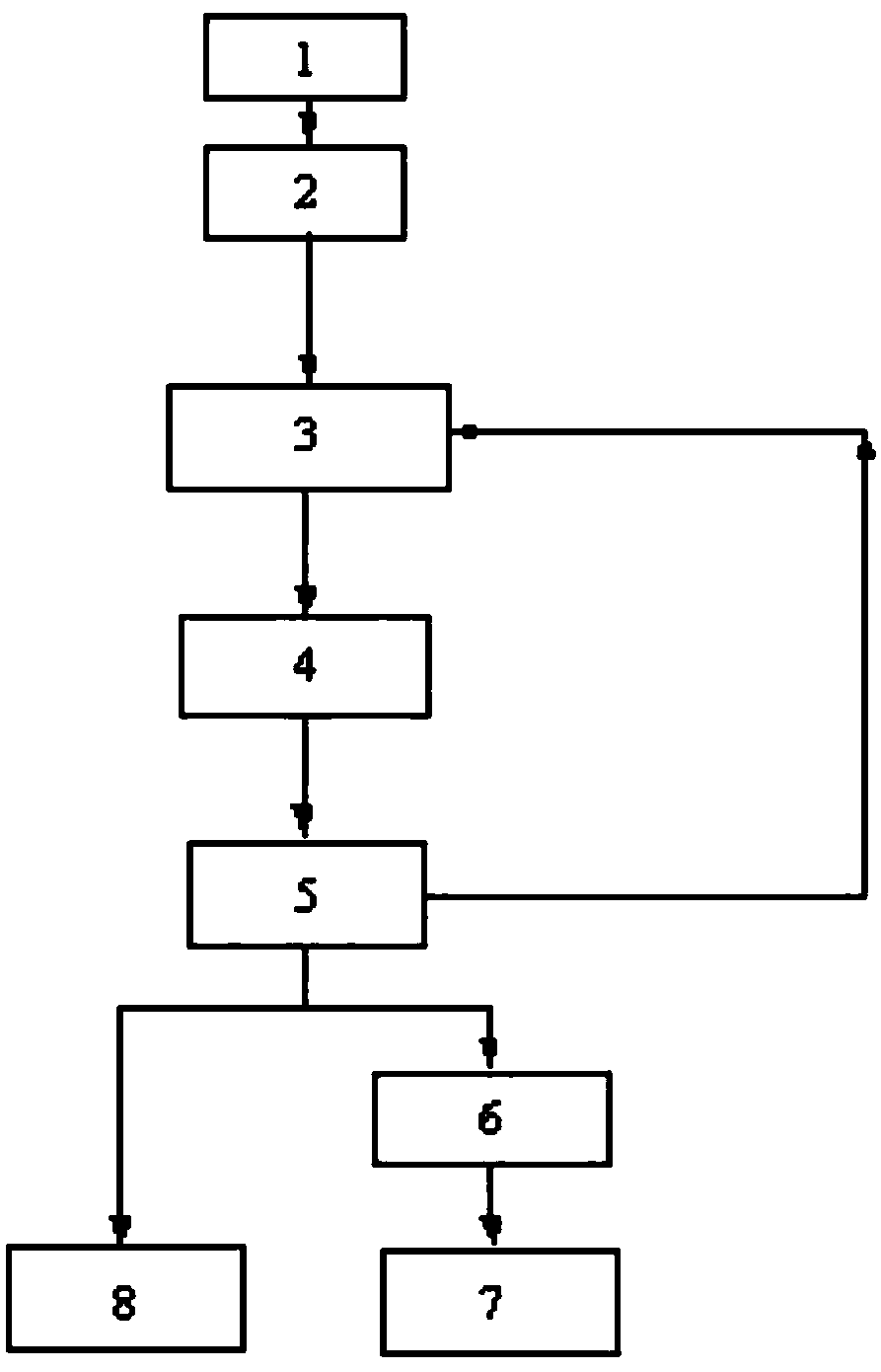

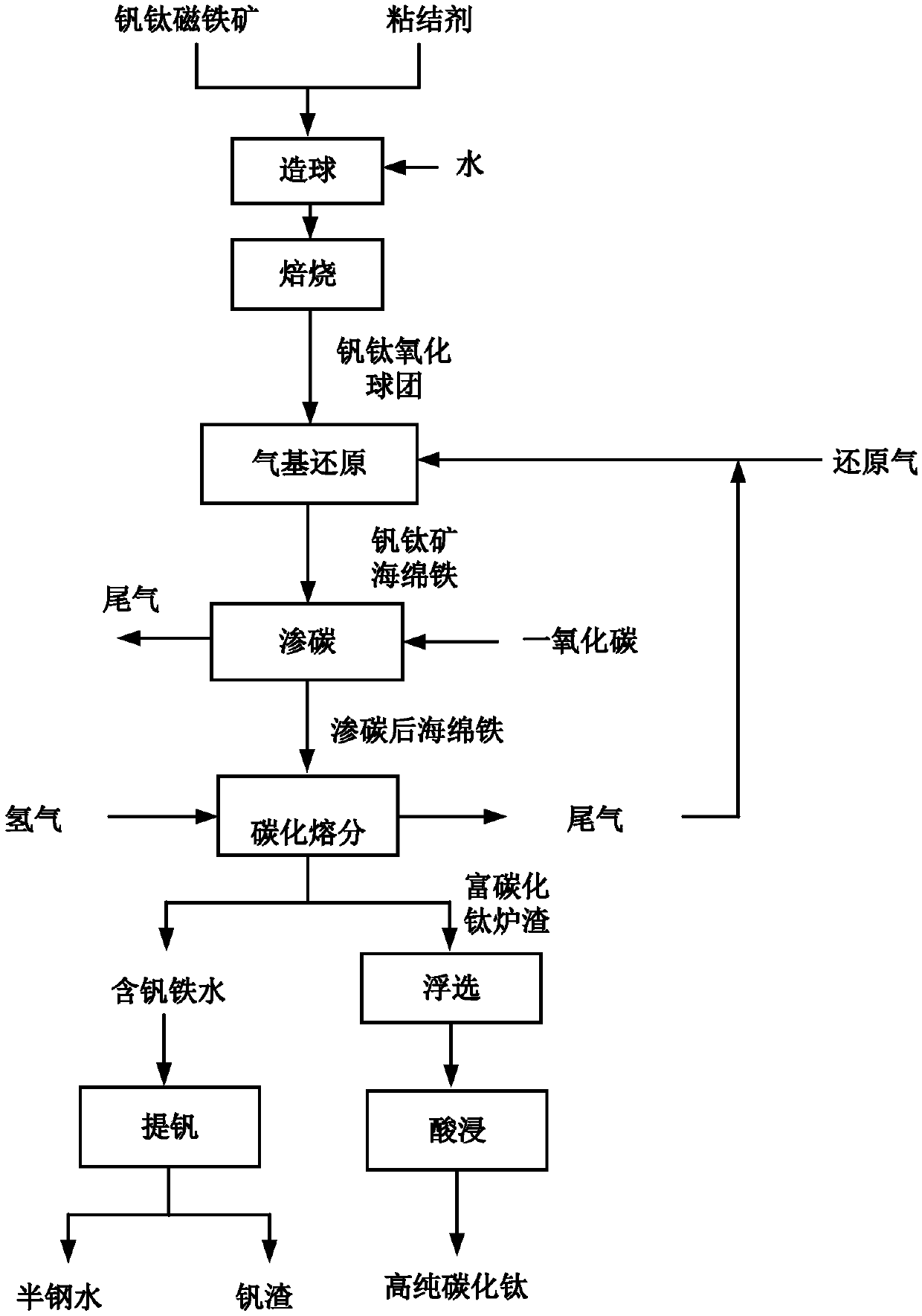

System and method for preparing titanium carbide from vanadium titano-magnetite comprehensively

PendingCN107653353AIncrease product valueEnvironmentally friendlyTitanium carbideShaft furnaceExhaust gasTitanium carbide

The invention relates to a system for comprehensively utilizing vanadium-titanium-magnetite to prepare titanium carbide, wherein the system includes a gas-based shaft furnace, a melting separator and a separation and purification system, and the gas-based shaft furnace includes an inlet of vanadium-titanium-magnetite oxidation pellets , reducing gas inlet and vanadium-titanium ore sponge iron outlet, melting separator includes vanadium-titanium ore sponge iron inlet, hydrogen inlet, tail gas outlet, vanadium-containing molten iron outlet and titanium carbide-rich slag outlet, and the separation and purification system includes titanium carbide-rich slag inlet And the titanium carbide outlet, the vanadium-titanium ore sponge iron outlet of the gas-based shaft furnace is connected to the vanadium-titanium ore sponge iron inlet of the melter, the tail gas outlet of the melter is connected to the reducing gas inlet of the gas-based shaft furnace, and the carbonization of the melter The titanium carbide slag outlet is connected to the titanium carbide-rich slag inlet of the separation and purification system. The invention also relates to a method of producing titanium carbide using the system. The system adopts the short-process smelting process of vanadium-titanium magnetite gas-based direct reduction-melting separation, which can make full use of TiO2 in the slag, and the obtained products have high value and are environmentally friendly.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Oxygen-free steam carbonization method for cotton straws

InactiveCN106865543ARich pore structureImprove fertilizer efficiencyCarbon compoundsOrganic fertilisersWater vaporCarbonization

The invention provides an oxygen-free steam carbonization method for cotton straws. The method comprises the following steps: cutting the cotton straws into section materials, immersing the cotton straw section materials in an NH4Cl solution, taking out the immersed cotton straw section materials, draining off the section materials, putting the drained-off cotton straw section materials into a container, carrying out steam heating for carbonization, cooling to room temperature, washing and drying, thus obtaining biomass charcoal. The biomass charcoal obtained through the method is large in specific surface area, good in pore structure and high in organic carbon content, and has a good improvement effect when used for soil improvement.

Owner:北京联绿生态环境有限公司

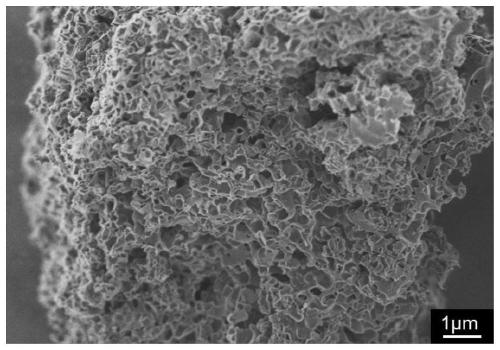

Method for preparing porous carbon material through polyester low-temperature carbonization

ActiveCN111410184ALow carbonization temperatureIncrease profitCarbon preparation/purificationPolyesterPolymer science

The invention belongs to the technical field of polymer carbonization, and particularly relates to a method for preparing a porous carbon material through polyester low-temperature carbonization. A mixture of polyester and transition metal oxide is heated and carbonized at the temperature not higher than 500 DEG C, and a porous carbon material is prepared after aftertreatment. The transition metaloxide is used for promoting decarboxylation reaction of polyester in the heating carbonization process, eliminating weak oxygen-containing chemical bonds in the polyester and generating an intermediate degradation product, and the intermediate degradation product is used for constructing a carbon material skeleton through crosslinking, cyclization and / or aromatization reaction to form the porouscarbon material. The porous carbon material with high specific surface area is prepared by adopting a one-step carbonization method and utilizing the transition metal oxide to promote the carbonization of the waste polyester at a lower temperature, and a new method is provided for converting a large amount of cheap urban and industrial waste polyester into the porous carbon material with high additional value.

Owner:HUAZHONG UNIV OF SCI & TECH

Lead-carbon composite material, and preparation method and application thereof

ActiveCN103943859AFix production issuesGood capacitance characteristicsHybrid capacitor electrodesCell electrodesCarbon compositesCarbonization

The invention discloses a lead-carbon composite material, and a preparation method and an application thereof. The preparation method comprises the following steps: processing an organic carbon source to prepare a solution, adding lead powder, grinding, uniformly mixing, and drying to obtain mixed powder; and adding concentrated sulfuric acid to the mixed powder under stirring, allowing the obtained solution to stand for carbonization for a period of time, washing, and drying to prepare the lead-carbon composite material, wherein the mass fractions of carbon and lead in the lead-carbon composite material are 0.1-25% and 75-99.9% respectively. The invention also discloses the lead-carbon composite material prepared through the preparation method, and the application of the composite material. The method has the advantages of simplicity, low cost and low energy consumption, and lead carbon batteries made by using the composite material have substantially longer heavy current charge and discharge life and higher mass specific power than present lead acid storage batteries.

Owner:TIANNENG BATTERY GROUP +1

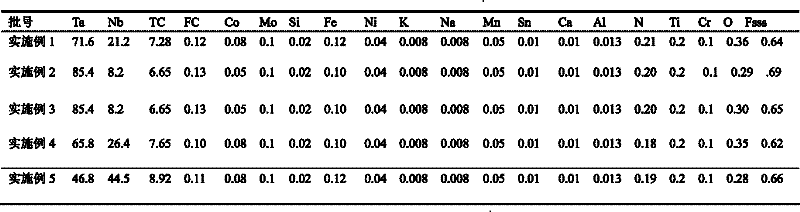

A kind of preparation method of superfine tantalum carbide niobium solid solution powder

The invention belongs to the field of new material preparation and particularly provides a preparation method of superfine tantalum-niobium carbide solid solution powder. The preparation method comprises the following specific steps: a, separately compressing slurry-shaped niobium hydroxide and tantalum hydroxide, and then drying at the temperature of 180-250 DEG C for 6-12 hours to remove water, thus obtaining niobium hydroxide powder and tantalum hydroxide powder with the particle size of 20-90 nm; and b, uniformly mixing the niobium hydroxide powder and tantalum hydroxide powder with carbon black based on the condition that the mass ratio of carbon black to niobium hydroxide powder to tantalum hydroxide powder is 1:(0.72-2.75):(2.24-5.29), carbonizing in a vacuum furnace while controlling the carbonization temperature at 1250-1350 DEG C, continuously vacuumizing, and terminating the carbonization process when the vacuum degree reaches 10-12 Pa; and then cooling for 12-16 hours, and after discharging the material, ball-milling to obtain the tantalum-niobium carbide powder with the Fsss particle size less than 0.7 mu m. The preparation method provided by the invention has low carbonization temperature, the prepared niobium carbide powder has small particle size, and the operation process is simple and easy to implement.

Owner:长沙伟徽高科技新材料有限公司

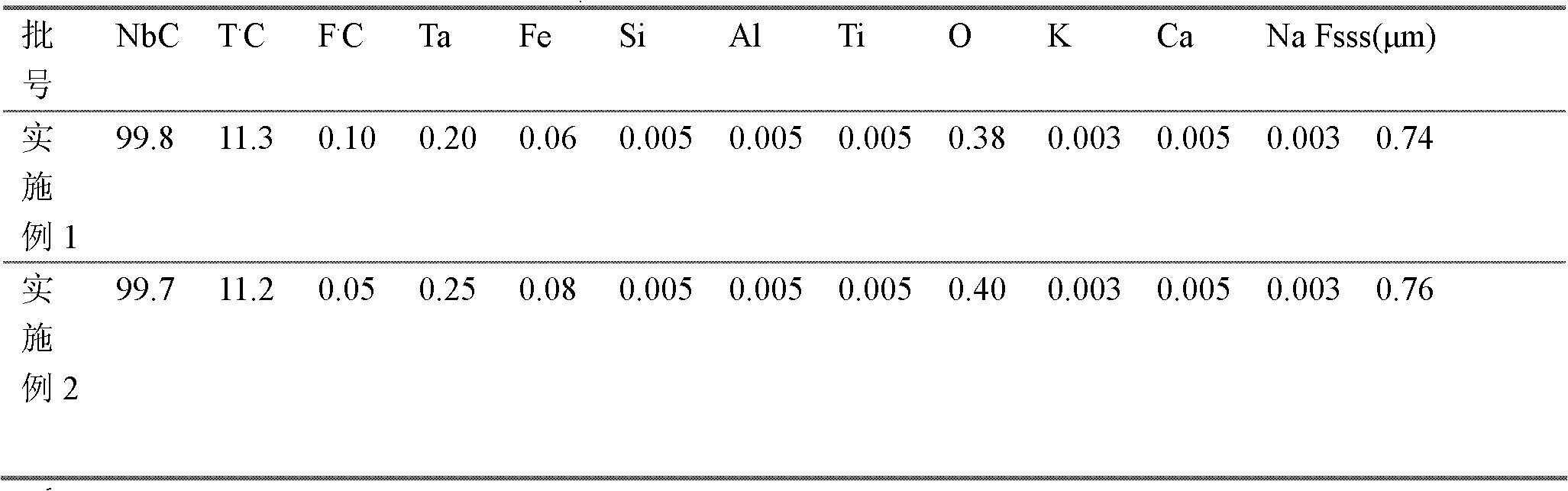

A kind of preparation method of superfine niobium carbide powder

ActiveCN102275919ALow carbonization temperatureSmall granularityNanotechnologyVacuum pumpingTemperature control

Belonging to the field of new material preparation, the invention specifically provides a preparation method of superfine niobium carbide powder. The method comprises the steps of: a. drying the compressed slurry niobium hydroxide at a temperature of 180-250DEG C for 6h-12h so as to remove moisture, thus obtaining niobium hydroxide powder with a granule size of 20nm-90nm; b. mixing the niobium hydroxide powder and carbon black uniformly in a mass ratio of 1:0.225-0.235, conducting carbonization in a vacuum furnace, with the carbonization temperature controlled from 1280DEG C to 1350DEG C, carrying out vacuum-pumping continuously, ending the carbonization process when the vacuum degree reaches 10Pa-12Pa, then conducting cooling for 12h-16h, and performing ball milling after discharging, thus obtaining the niobium carbide powder with a Fsss granule size less than 0.8micrometer. With low carbonization temperature and simple and easily realizable operation process, the method provided in the invention can prepare niobium carbide powder of small granule size.

Owner:长沙伟徽高科技新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com