A carbon-based negative electrode material with high ramp capacity and a preparation method and use thereof

A negative electrode material, carbon-based technology, applied in the field of materials, can solve the problems of unfavorable full battery performance, low efficiency of carbon-based negative electrode materials in the first week, etc., and achieve the effect of low carbonization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

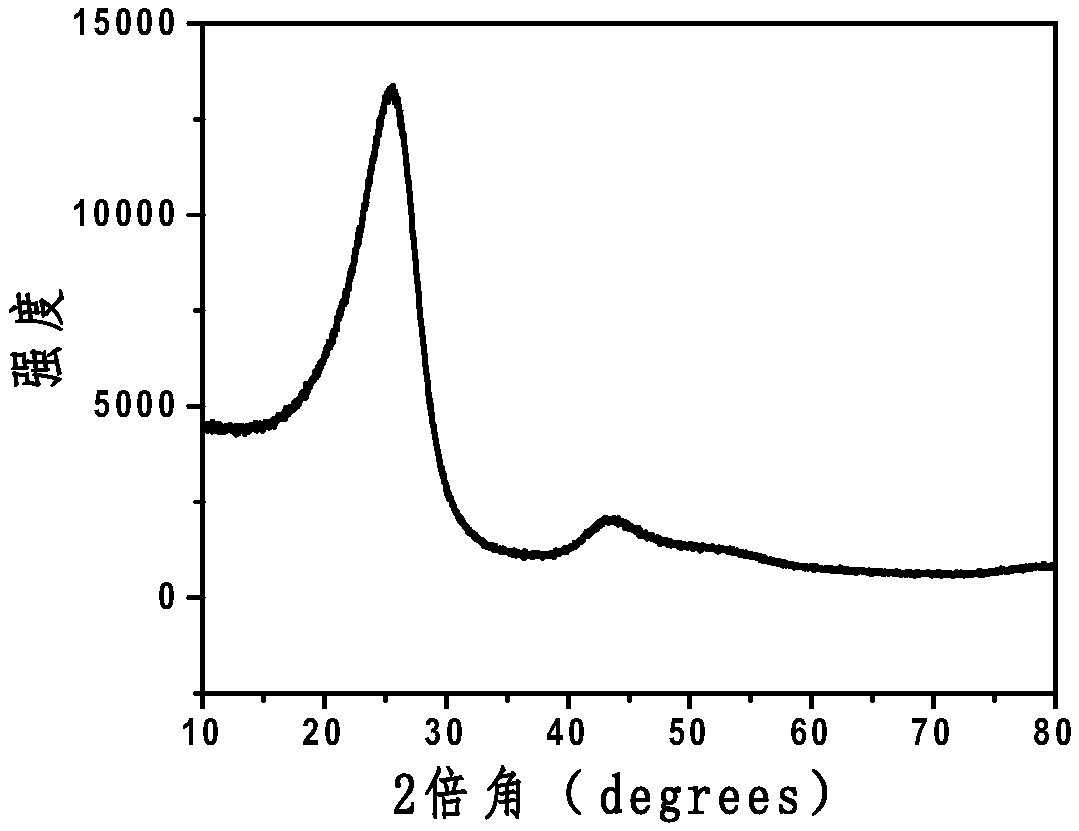

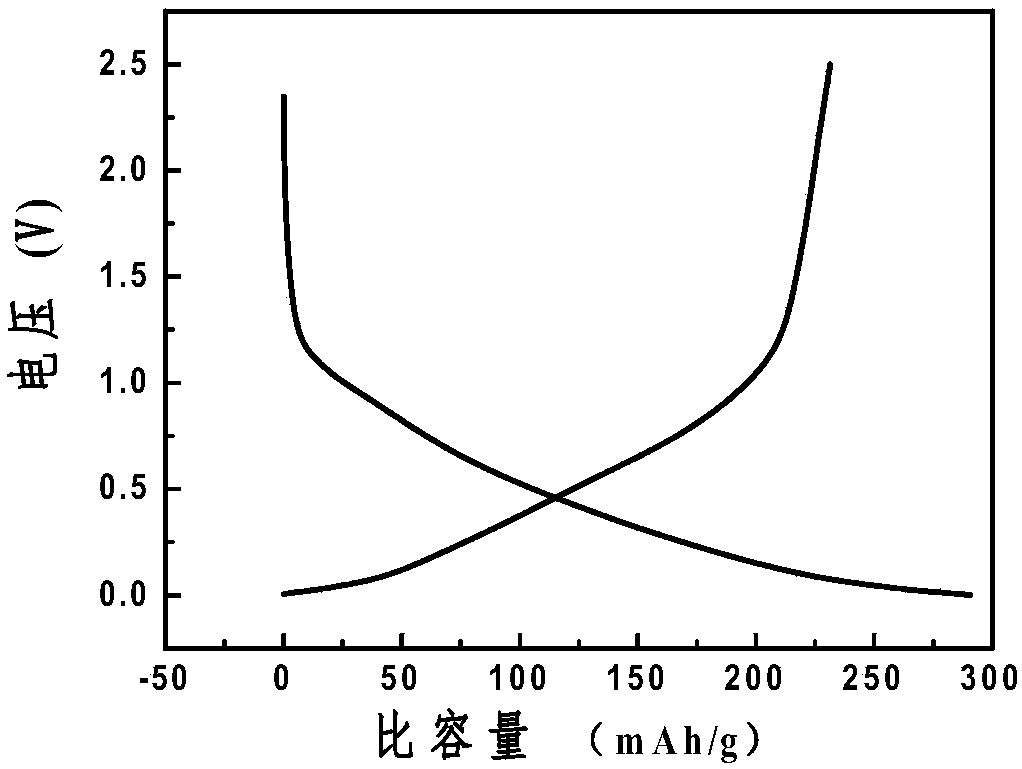

[0063] Put 1 g of pitch into a 20 mL graphite crucible, put it into a tube furnace, and carbonize at 950 °C for 2 hours under an Ar atmosphere to obtain the final carbon-based negative electrode material. Its XRD and SEM are as follows Figure 1-Figure 2 shown. There is no obvious diffraction peak in XRD, indicating that the obtained carbon-based negative electrode material is an amorphous carbon-based negative electrode material. The obtained carbon-based negative electrode material is made into a pole piece, with metallic sodium as the counter electrode, and with 1mol / L NaPF 6 EC / DMC (1:1) is the electrolyte, assembled into a button battery, and its charge and discharge curve is measured at 0.1C, such as image 3 Shown, test result shows: electrochemical curve basically only comprises slope section (referring to comparative example 2 Figure 21 , in comparative example 2, its electrochemical curve includes platform section and slope section simultaneously, in the embodime...

Embodiment 2

[0065] Put 1g of anthracite in a 20mL graphite crucible, put it in a muffle furnace, and heat it at 350°C for 12 hours. The material taken out was treated under Ar atmosphere at 650°C for 24 hours to obtain the final carbon-based negative electrode material. Its Raman spectrum is as Figure 4 As shown, the ID / IG value calculated by Raman spectrum is 2.57, which shows that the prepared carbon-based negative electrode material has a high degree of disorder and small graphitized sheets. The obtained carbon-based negative electrode material is made into a pole piece, with metal sodium as the counter electrode, and 1mol / L NaPF 6 EC / DMC (1:1) is the electrolyte, assembled into a button battery, measured its charge and discharge curve at 0.1C, the charge capacity in the first week is 219.1mAh / g, almost all of the capacity comes from the slope section, and the Coulombic efficiency in the first week Up to 79%.

Embodiment 3

[0067] After crushing 2g of corn stalks, disperse them in 50mL of water, place them in a 100mL beaker, put them in an oven and heat them to 180°C for 24 hours. Then the washed and dried powder was placed in a tube furnace under N 2 Under the atmosphere, treat at 700°C for 10 hours to obtain the final carbon-based negative electrode material. The obtained carbon-based negative electrode material is made into a pole piece, with metal sodium as the counter electrode, and 1mol / L NaPF 6 EC / DMC (1:1) is the electrolyte, assembled into a button battery, and its charge and discharge curve is measured at 0.1C, such as Figure 5 As shown, the test results show that the capacity is as high as 230.5mAh / g, almost all of which comes from the slope section, and the Coulombic efficiency is as high as 75.9% in the first week.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com