A kind of preparation method of superfine tantalum carbide niobium solid solution powder

A tantalum carbide and solid solution technology, applied in the field of new material preparation, can solve the problems of high carbonization temperature, agglomeration, slow diffusion speed, etc., and achieve the effects of low carbonization temperature, small particle size, and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After compressing the purchased slurry-like niobium hydroxide and slurry-like tantalum hydroxide respectively and drying them in an oven at 200°C, 126 kilograms of nanoscale niobium hydroxide and 159 kilograms of nanoscale tantalum hydroxide were obtained; 20nm-90nm.

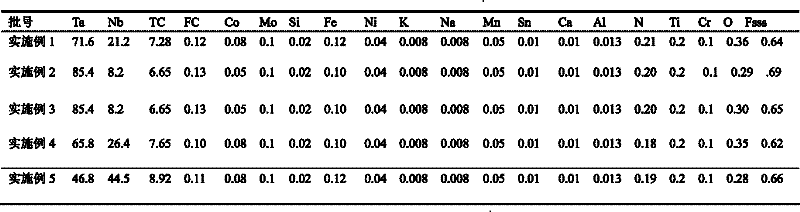

[0028] Get above-mentioned 14.07 kilograms of niobium hydroxide and 36.75 kilograms of tantalum hydroxide and mix with 8.99 kilograms of carbon black again, heat up to 1300 ℃ through slowly 3 hours, high temperature holding time is 11 hours, when vacuum degree reaches 10Pa, end carbonization. Cool with H2 for 14 hours. Ball mill after discharge. The particle size of the Fsss sample was measured to be 0.64 μm, and the chemical composition met the requirements. The specific composition is shown in Table 1.

Embodiment 2

[0030] After compressing the purchased slurry-like niobium hydroxide and slurry-like tantalum hydroxide respectively and drying them in an oven at 200°C, 126 kilograms of nanoscale niobium hydroxide and 159 kilograms of nanoscale tantalum hydroxide were obtained; 20nm-90nm.

[0031] Then 23.45 kg of niobium hydroxide and 28.82 kg of tantalum hydroxide were mixed with 9.95 kg of carbon black, and the temperature was slowly raised to 1320°C for 3 hours, and the high temperature holding time was 12 hours. When the vacuum reached 12Pa, the carbonization was completed. Cool with H2 for 13 hours. Ball mill after discharge. The Fsss particle size of the sample was measured to be 0.69 μm, and the chemical composition met the requirements. The specific composition is shown in Table 1.

Embodiment 3

[0033] After compressing the purchased slurry-like niobium hydroxide and slurry-like tantalum hydroxide respectively and drying them in an oven at 200°C, 126 kilograms of nanoscale niobium hydroxide and 159 kilograms of nanoscale tantalum hydroxide were obtained; 20nm-90nm.

[0034] Mix 5.92 kg of niobium hydroxide and 43.40 kg of tantalum hydroxide with 8.13 kg of carbon black, slowly heat up to 1280° C. for 3 hours, hold high temperature for 13 hours, and finish carbonization when the vacuum reaches 12 Pa. Pass H2 to cool, and the cooling time is 12 hours. Ball mill after discharge. The Fsss particle size of the sample was measured to be 0.65 μm, and the chemical composition met the requirements. The specific composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com