Oxygen-free steam carbonization method for cotton straws

A cotton stalk and carbonization technology, applied in the field of resource utilization of agricultural waste, can solve the problems of poor nitrogen fixation and fertilizer efficiency, metal ion pollution, poor soil compatibility, etc., to improve soil organic carbon and total nitrogen content, carbonization Effect of low temperature and reduced nitrogen nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

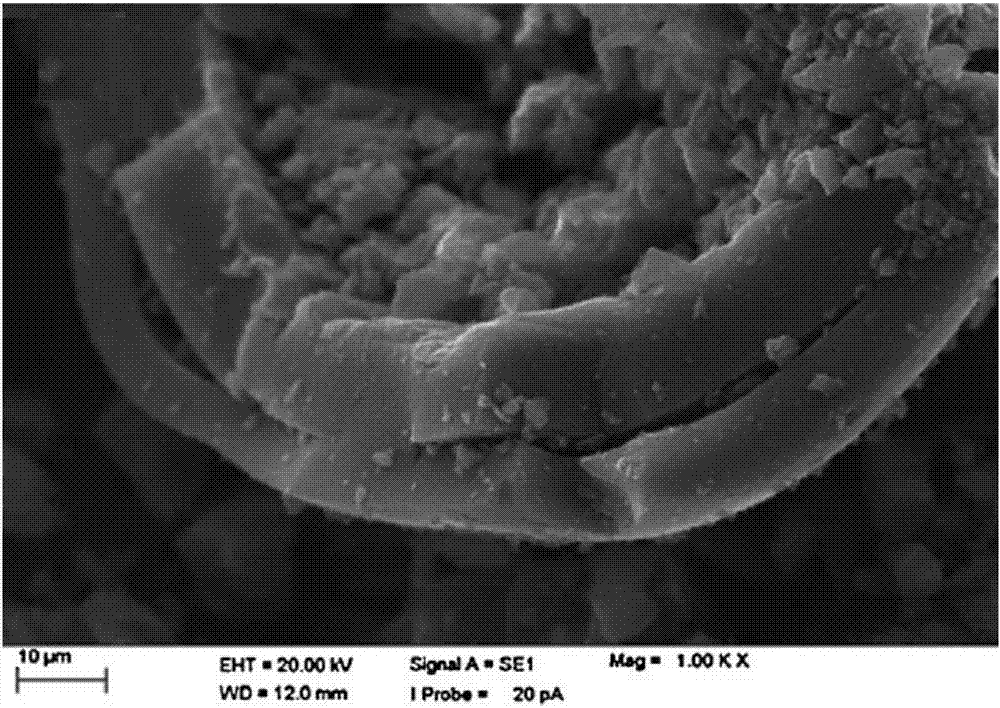

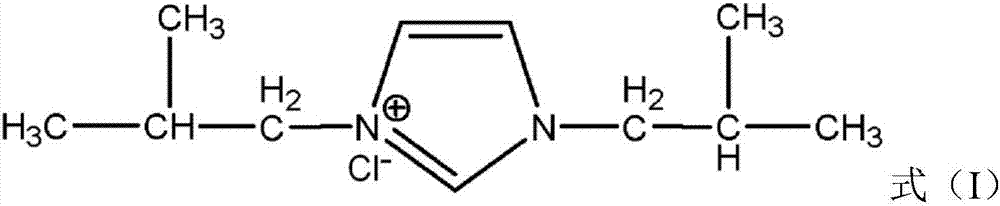

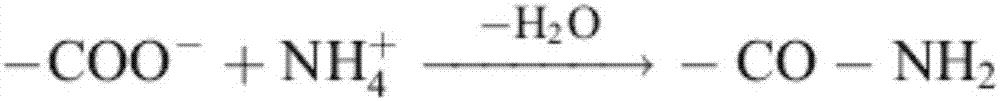

[0046] Cotton stalks were taken from Shanghe County, Jinan City. Mature cotton stalks harvested in 2015 were taken. Leaves and shells were removed, and side branches were not removed. They were stored in a ventilated and cool laboratory for later use. Cut the cotton stalks into sections with an average length of 0.8 cm, soak the cut cotton stalks in NH 4 Cl solution, soaked at 60°C for 3h, then took out the soaked cotton stalks and drained them, and placed the drained cotton stalks in a tubular heater (from Lihua Machinery Co., Gongyi City) at a temperature of 350 ℃ water vapor, pressure 0.3MPa, heating for 5h, then cooling to room temperature, taking out, fully washing the product with 35% hydrochloric acid solution, and then washing with distilled water until the pH of the washing solution is between 6-7, then drying, That is, biochar.

[0047] After testing, the SBET of the biochar = 1401m 2 / g, at P / P 0 The measured total pore volume V total = 0.91cm 3 / g, the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com