Patents

Literature

58 results about "Hot hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

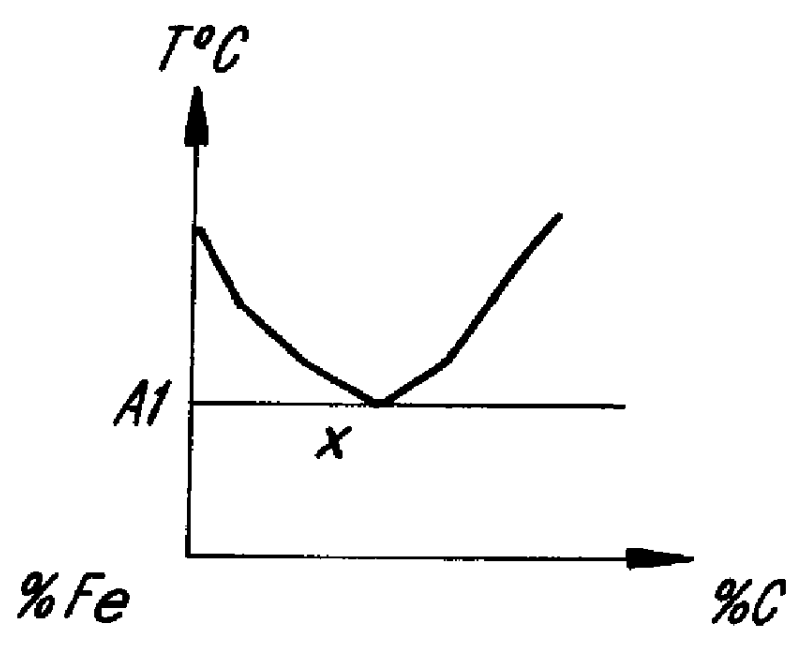

In materials engineering and metallurgy, hot hardness or red hardness (when a metal glows a dull red from the heat) corresponds to hardness of a material at high temperatures. As the temperature of material increases, hardness decreases and at some point a drastic change in hardness occurs. The hardness at this point is termed the hot or red hardness of that material. Such changes can be seen in materials such as heat treated alloys.

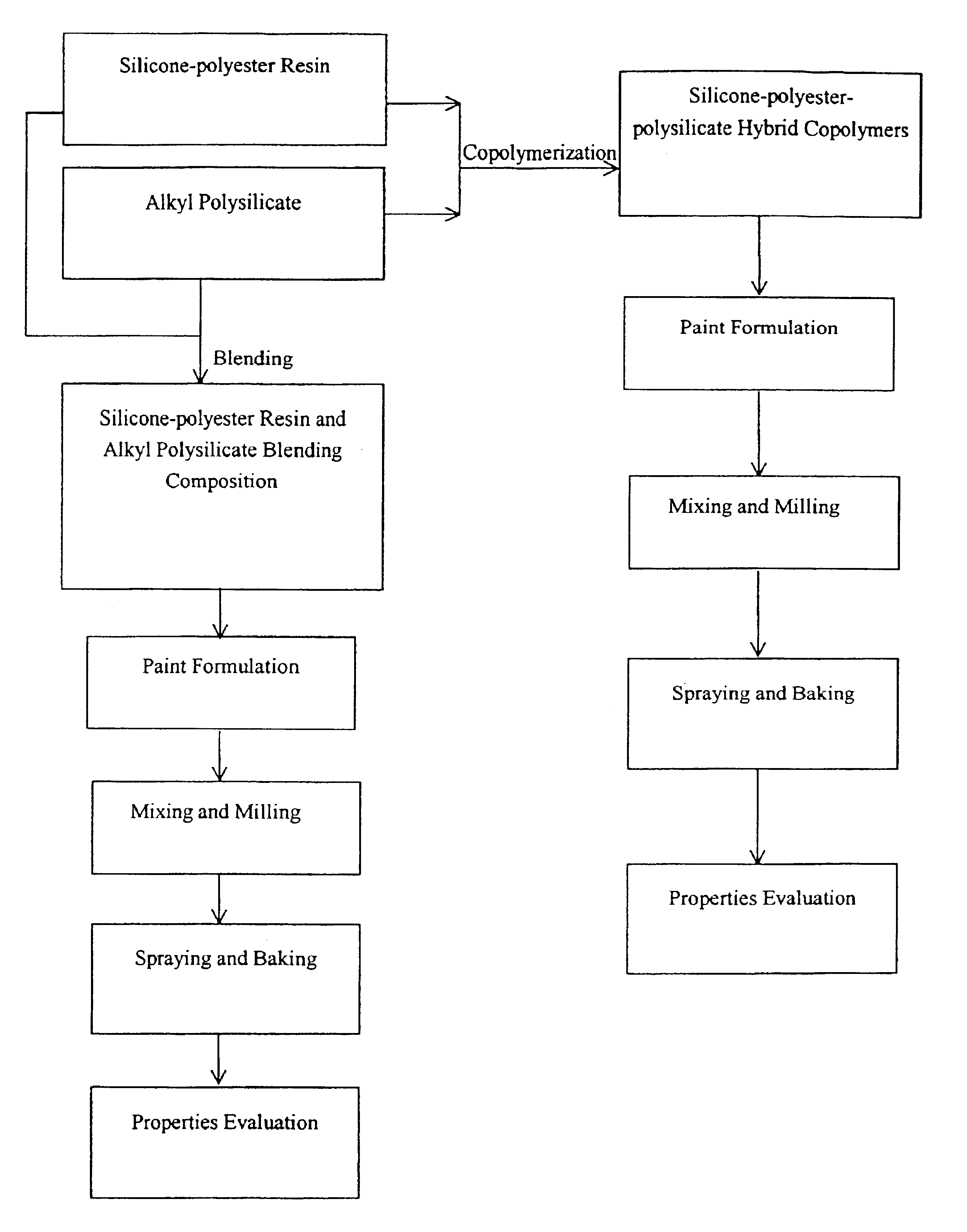

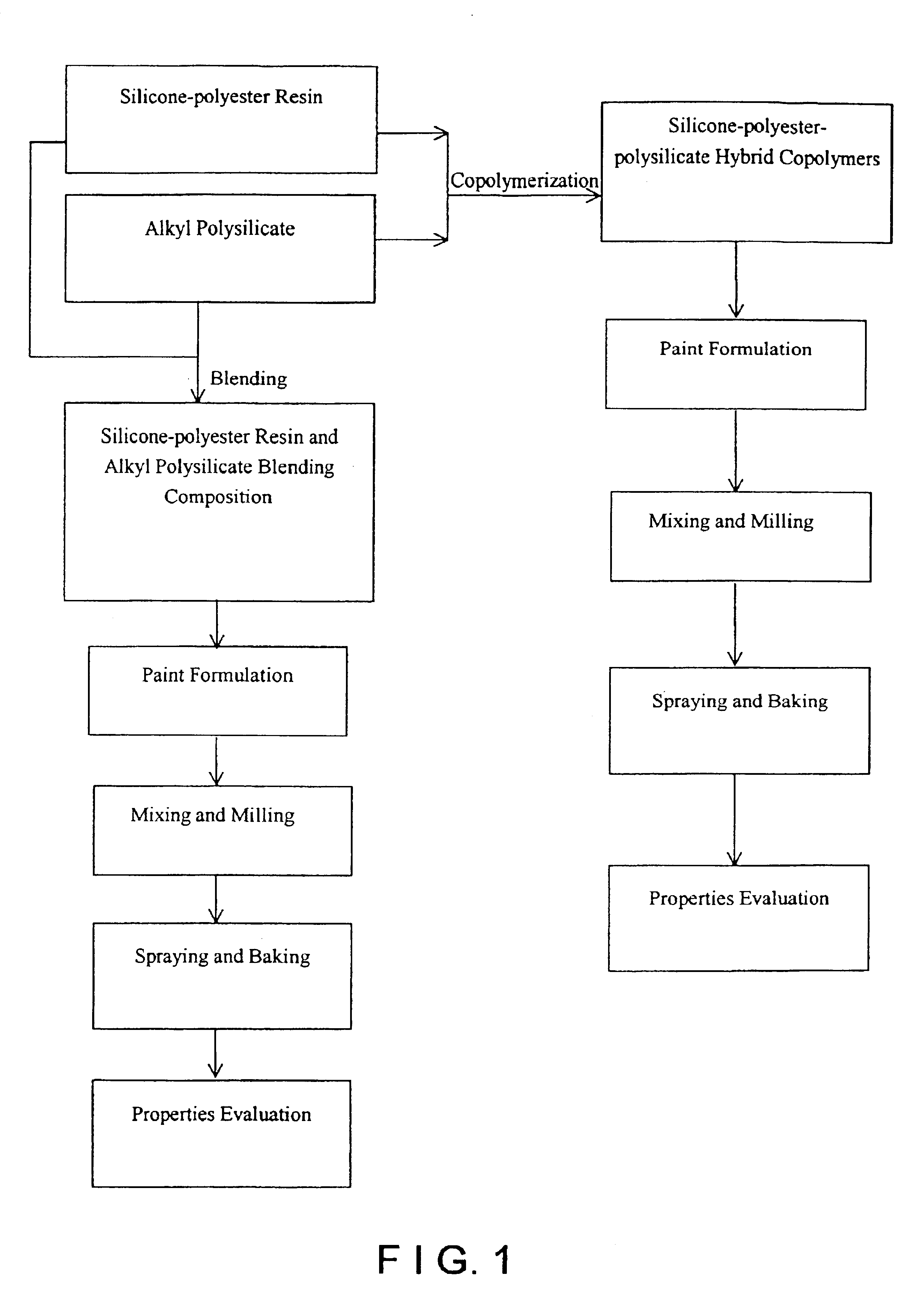

Silicone-polyester-polysilicate hybrid compositions for thermal resistance coating

InactiveUS6893724B2Improve heat resistanceExcellent adhesion to metalGlass/slag layered productsCoatingsCopolymerMaterials science

The present invention employs alkyl polysilicate to form silicone-polyester-polysilicate hybrid compositions with an appropriate proportion to modify silicone-polyester resin, or directly adds the alkyl polysilicate at an appropriate proportion into silicone-polyester resin to produce a hybrid composition. The composition in high baking temperature forms a hybrid structure having good thermal resistance, especially, hot-oil resistance and hot hardness, and good adhesion to metals such as carbon steel, stainless steel and aluminum. The present invention can be used in the field of the protective coating for heat-resistant metal such as frying pans and electric irons to be a kind of novel heat-resistant composition having hybrid structure. The composition in accordance with the present invention comprises (A)silicone-polyester; (B)alkyl polysilicate and the structure thereof comprises (RO)3—Si—O—(Si(OR)2—O)n—R, where n=0˜20 and R represents —CH3, —C2H5, —C3H7, or —C4H9. The composition mentioned above comprises the compounds of (A) and (B) or the copolymer comprised by (A) and (B).

Owner:GRAND TEK ADVANCE MATERIAL SCI

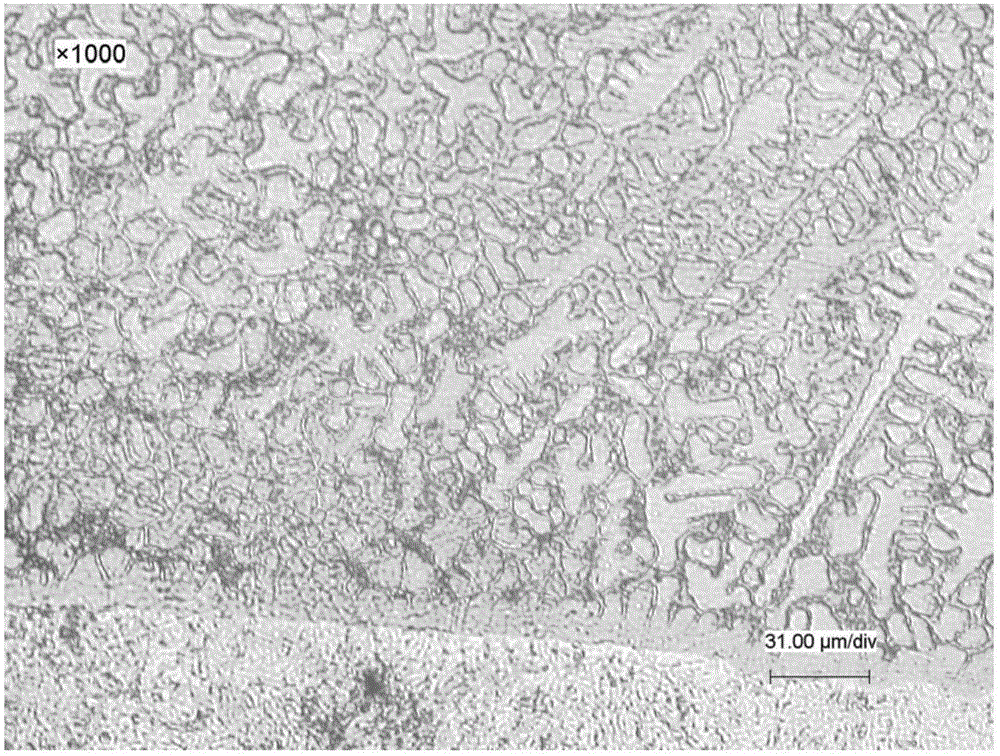

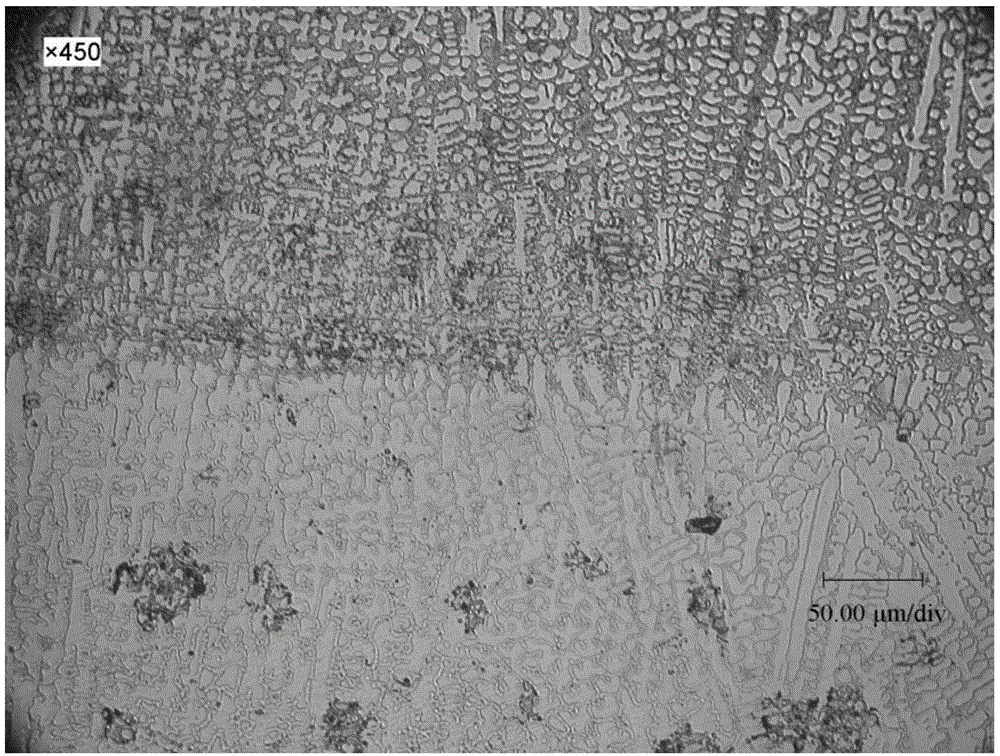

Method for manufacturing high-vanadium, high-cobalt high speed steel

ActiveCN101153376ALow priceSimple processHeat treatment process controlQuenching agentsNumerical controlMilling cutter

The invention provides a manufacturing method of high-vanadium high-cobalt high-speed steel, wherein, the composition weight percent of the high-speed steel is as follows: 1.1 percent to 2.18 percent of C, 5.0 percent to 8.0 percent of W, 4.0 percent to 6.0 percent of Mo, 3.0 percent to 5.0 percent of Cr, 1.2 percent to 8.3 percent of V, 6.5 percent to 11.5 percent of Co and the rest, Fe; the process steps of the high-speed steel includes master alloy preparation, spray forming, hot forging, quench tempering treatment, turning, milling and grinding or TiN / AlTiN coating treatment. The invention omits working procedures such as powder sieving, blending, encapsulation and cold and hot isostatic pressing, etc. and does not need costly equipment investment; moreover, the performance of the invention reaches to or even exceeds that of powder high-speed steel, thereby saving process cost and reducing the applied cost of the high-speed steel. The invention can be widely used in various cutters such as cutting tools for making difficult-to-machining material, and is particularly suitable to make cutters with quick-cutting, high hot hardness and long service life such as large-size broaching tool, gear shaver, hob and gear shaping tool for machining gear and various milling cutters used in digital control machine tool, etc.; moreover, the invention also can be used in making mould, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Corrosion and wear resistant alloy

An iron-based corrosion resistant and wear resistant alloy. The alloy can comprise (in weight percent) 0.005-0.5% boron, 1.2-1.8% carbon, 0.7-1.5% vanadium, 7-11% chromium, 1-3.5% niobium, 6-11% molybdenum, and the balance including iron and incidental impurities. Alternatively, the Nb content can be replaced or combined with Ti, Zr, Hf and / or Ta such that 1%<(Ti+Zr+Nb+Hf+Ta)<=3.5. The alloy has improved hot hardness and high temperature compressive strength and is suitable for use in elevated temperature applications such as in diesel valve seat inserts.

Owner:L E JONES CO

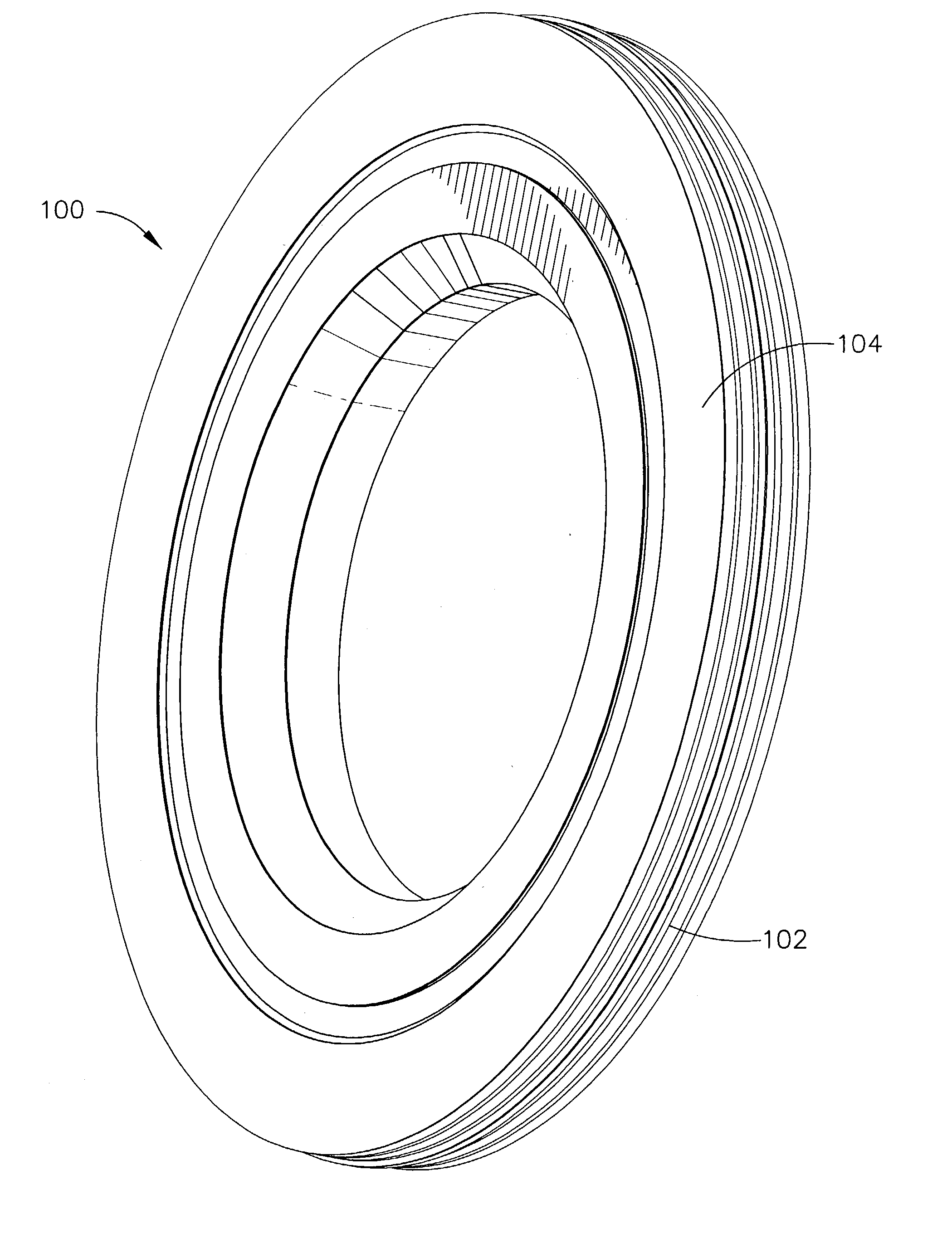

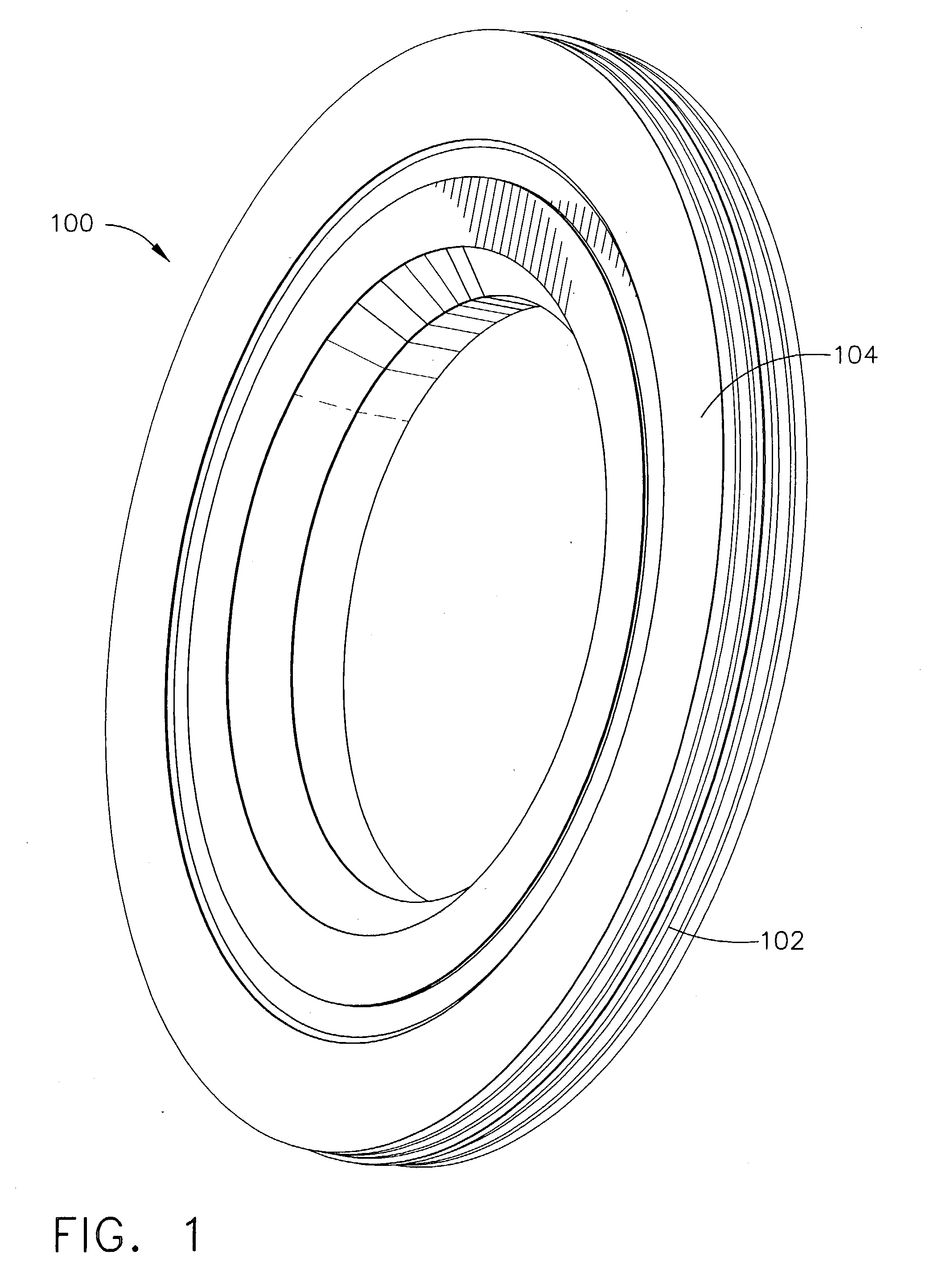

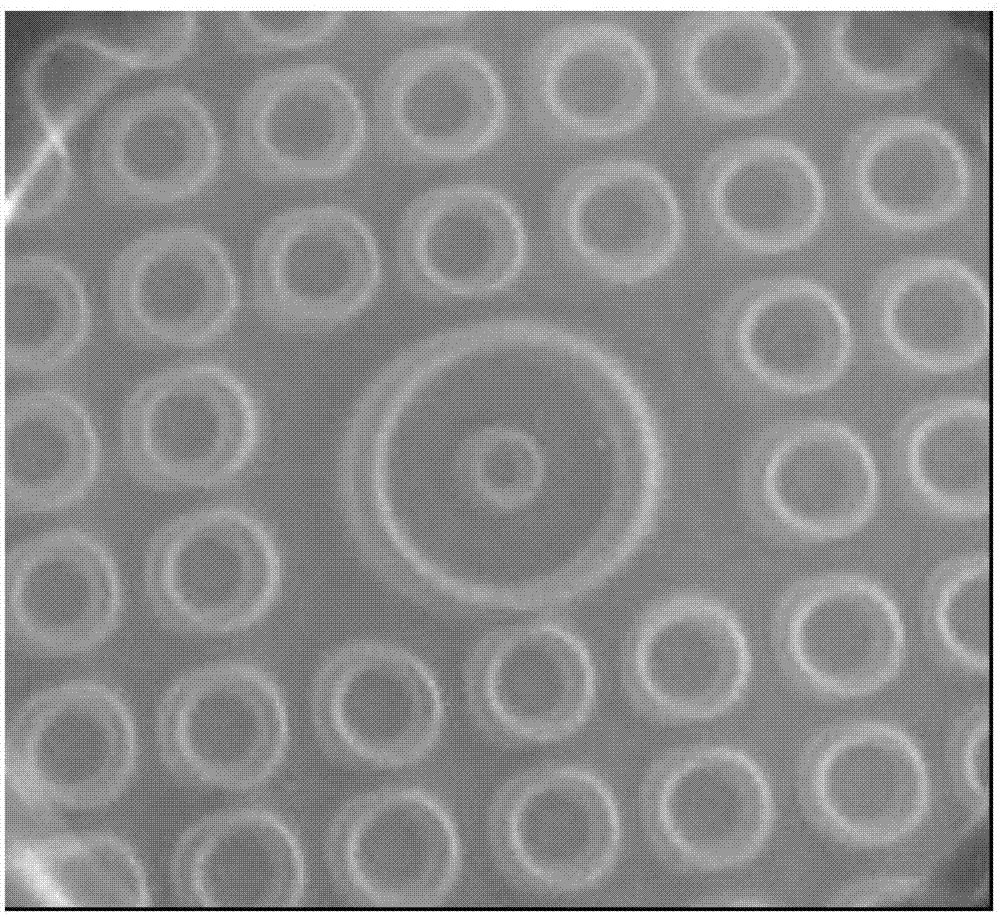

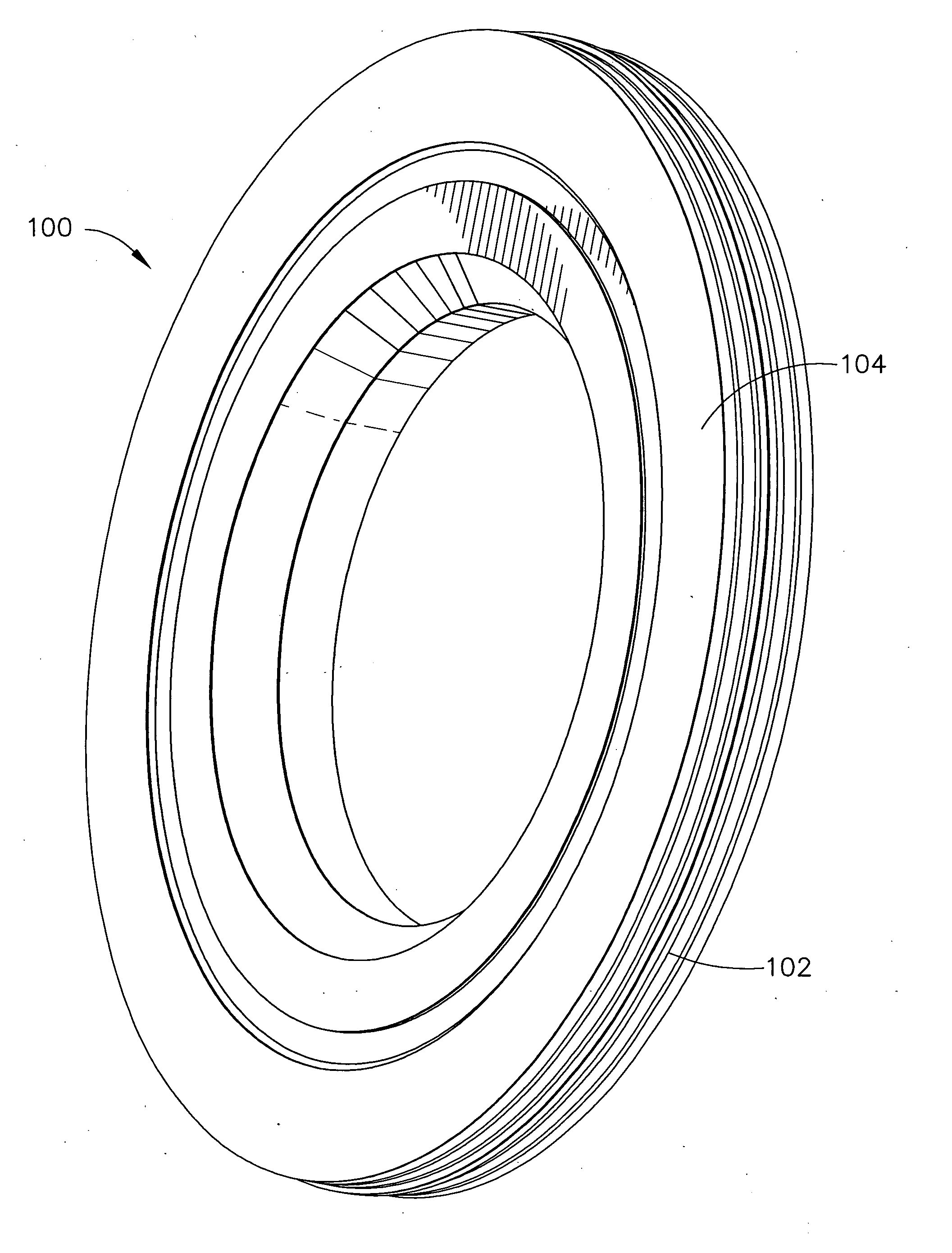

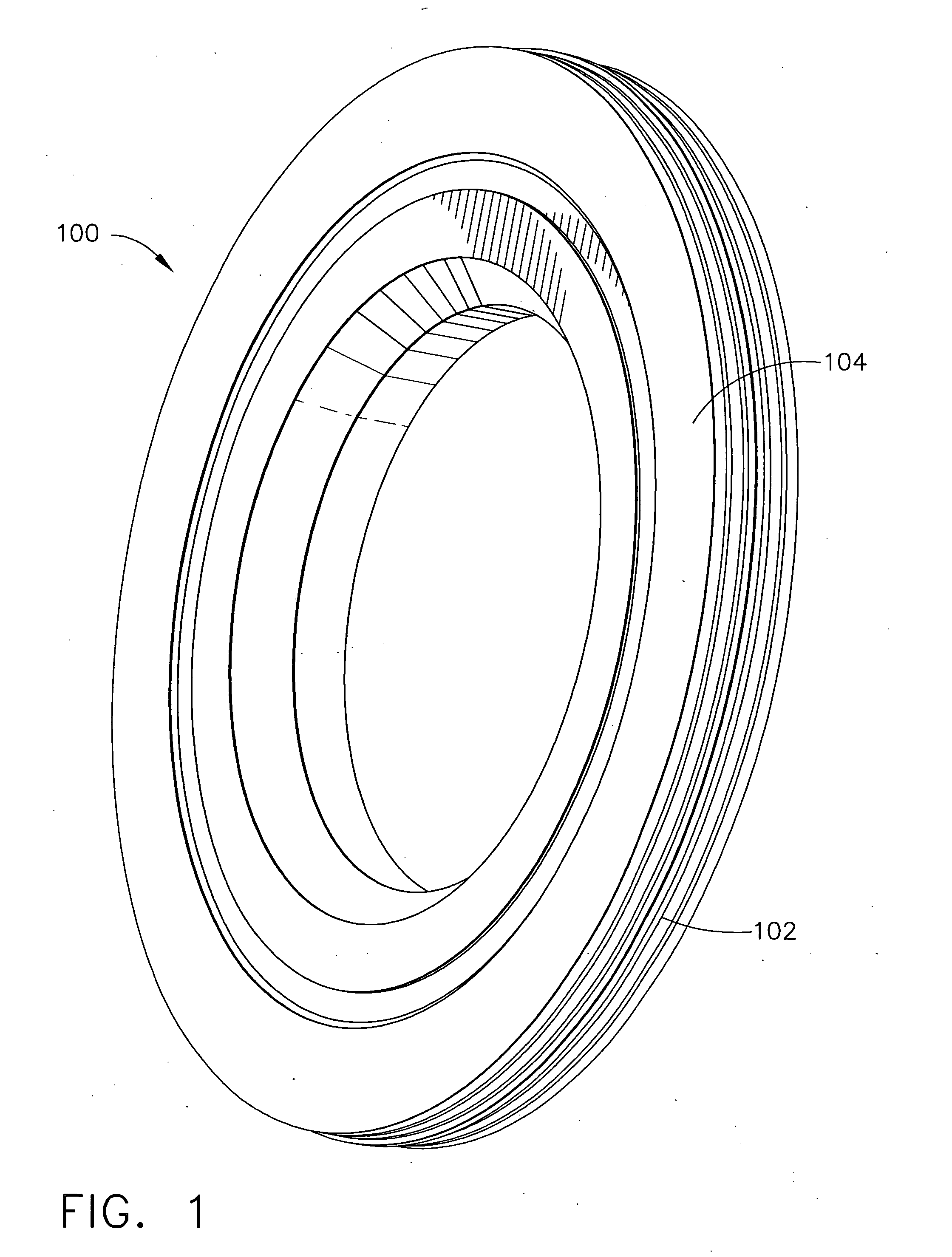

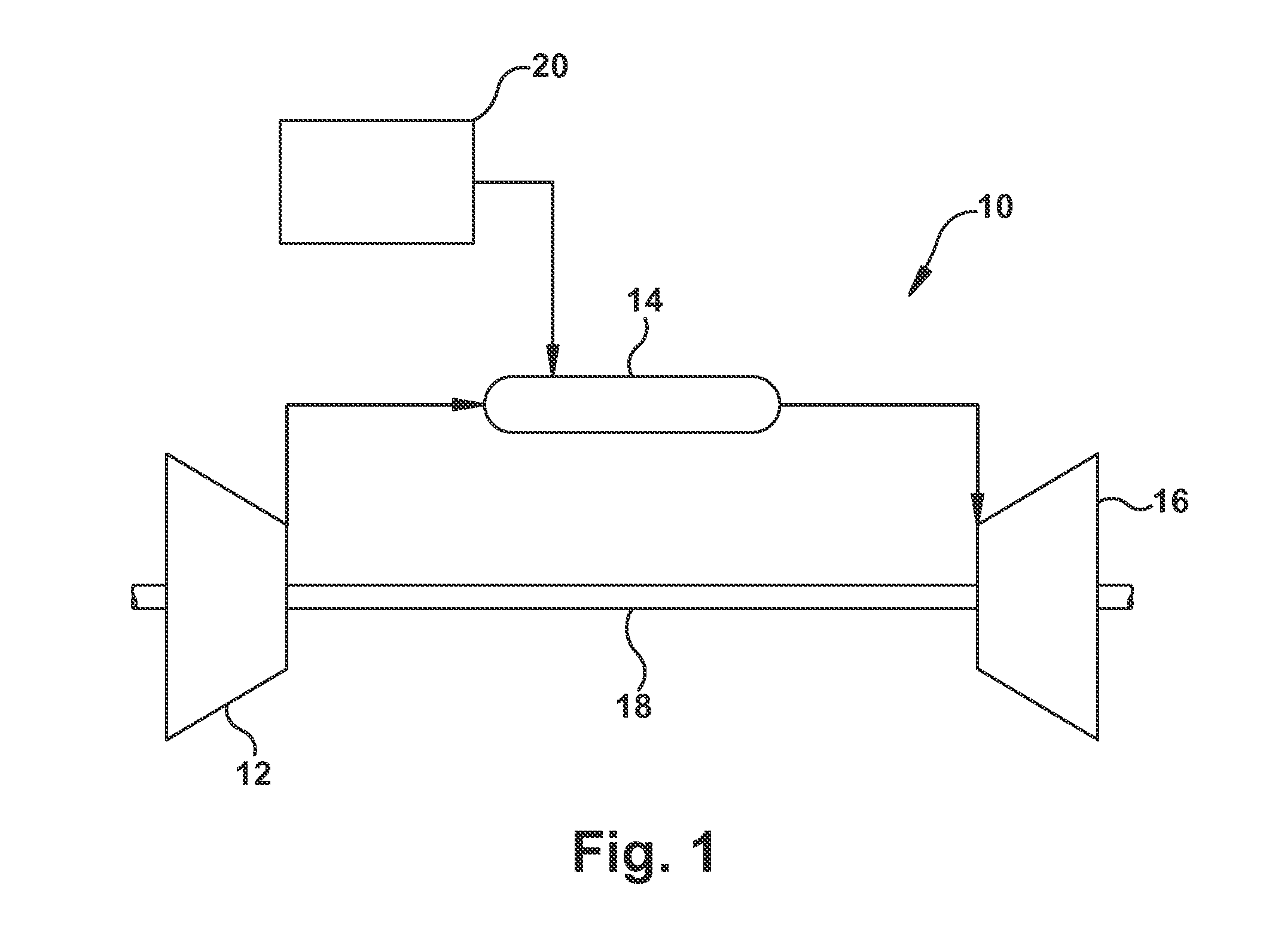

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20030207142A1High to coatingImprove wear resistanceEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

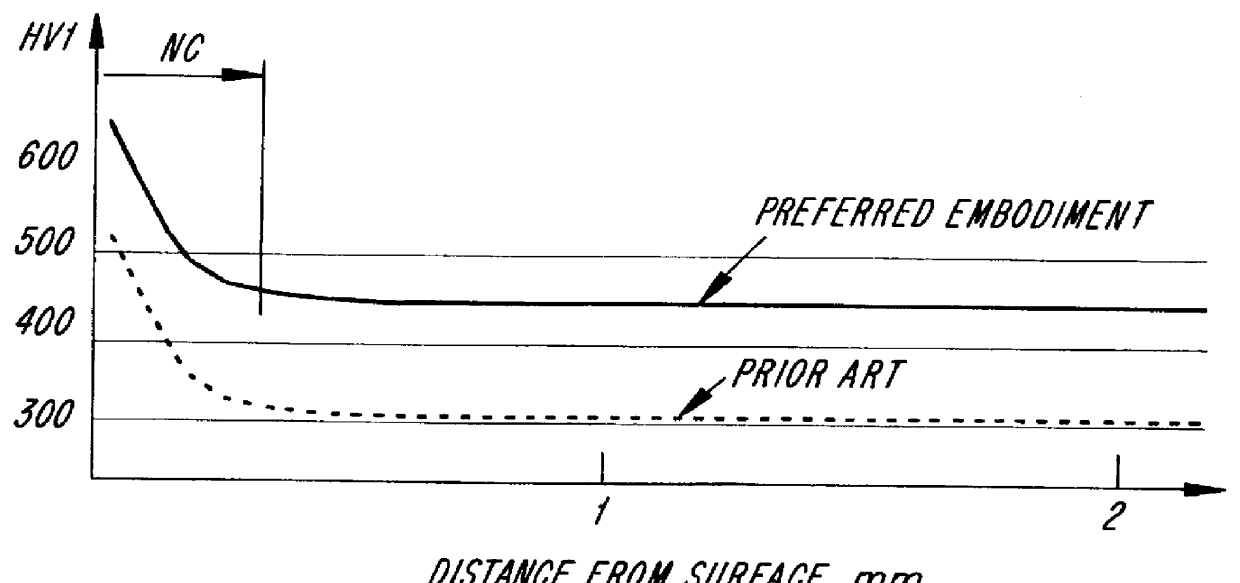

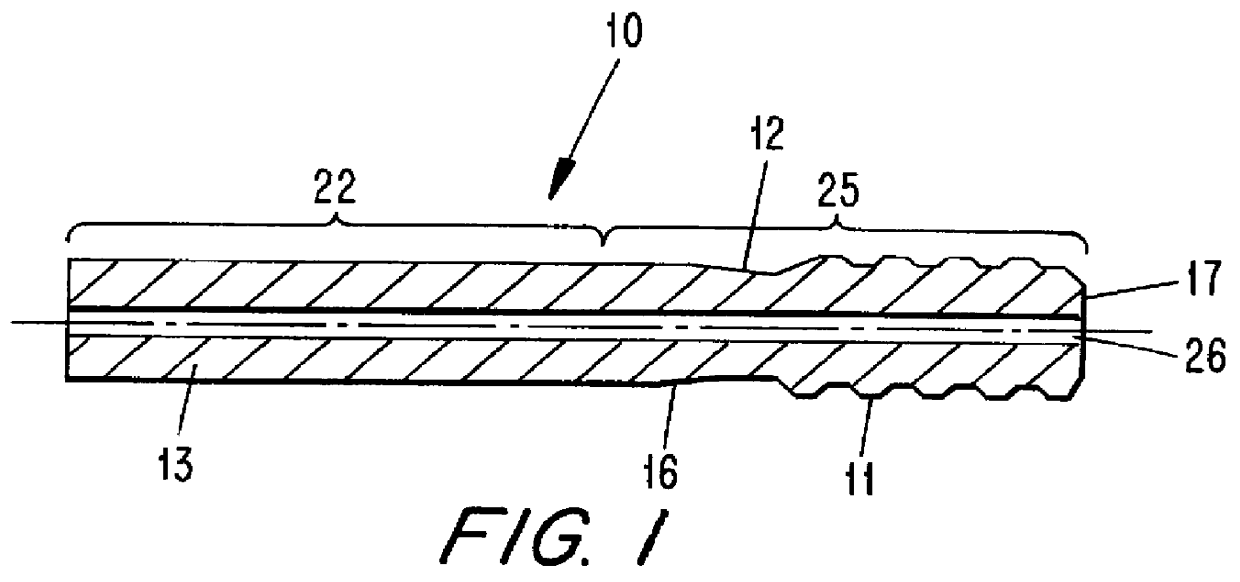

Drill rod and method for its manufacturer

InactiveUS6095266AUnique resistance against corrosion fatigueAbility to withstand high impact loadDrill bitsDrilling rodsFriction weldingAbutment

A rock drilling rod is manufactured by placing free ends of first and second hollow rod components in abutment, and establishing relative rotation between the free ends to friction weld those free ends together. The first component comprises a thread and a clearance portion disposed adjacent the thread. The first component has a hot hardness value of at least about 170 HV1 at 600 DEG C. Prior to friction welding the components together, the thread, clearance portion and central passage of the first component are heat treated against corrosion fatigue. Then, the thread is high frequency hardened to a depth at least as great as the heat treated layer. Following the welding, the weld is cooled while keeping a core hardness of the respective portions of the first and second components disposed immediately adjacent the weld no lower than 390 HV1.

Owner:SANDVIK AB

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS7611590B2Acceptable casting scrap rateGood heat treatment characteristicFurnace typesMachines/enginesWear resistantNiobium

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

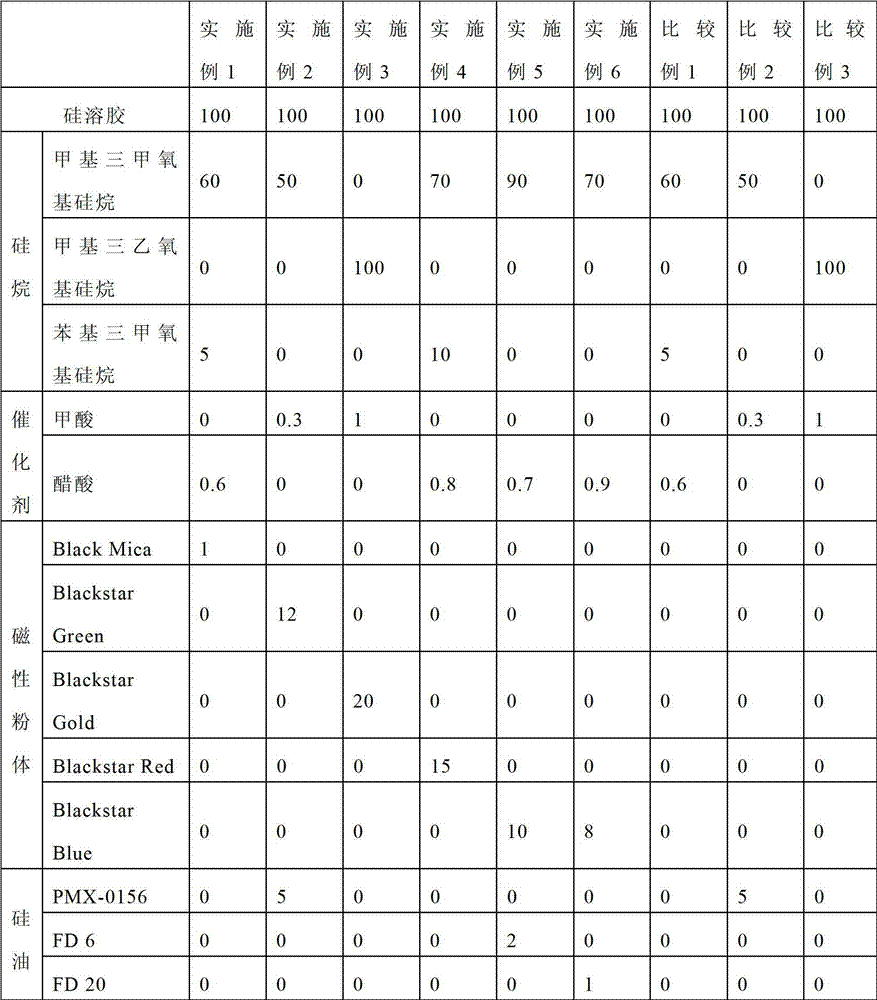

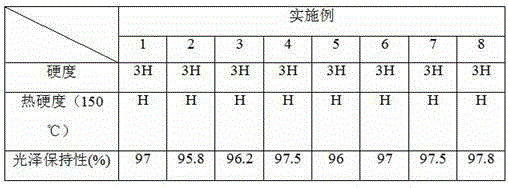

Ceramic paint and coating having stereoscopic effect

The invention relates to ceramic paint having a stereoscopic effect, which is characterized by comprising the following components in parts by weight: 100 parts of silica sol, 50-100 parts of organosilane, 0.3-1 part of catalyst, and 1-20 parts of magnetic powder, wherein the organosilane is methyltrimethoxy silane and / or methyltriethoxy silane; and the catalyst is one or a combination of formic acid, acetic acid, hydrochloric acid, citric acid, methyl formate, ethyl acetoacetate and maleic anhydride. The ceramic paint further comprises 1-5 parts by weight of silicone oil and 5-10 parts by weight of additional organosilane, wherein the additional organosilane is one or a combination of tetramethoxyl silane, tetraethoxy silane, dimethyldimethoxy silane, dimethyldiethoxy silane and phenyltrimethoxy silane. The ceramic paint provided by the invention has favorable cold / hot hardness and wear resistance; and the magnetic powder in the paint can form a coating having multiple stereoscopic patterns, thereby achieving good decorative effect.

Owner:INNOTEK TECH CHINA

Inorganic functional coating for degrading formaldehyde by negative ions and preparation method of coating

ActiveCN103289454AImprove wear resistanceHigh hot hardnessAlkali metal silicate coatingsPhysical chemistryInorganic materials

The invention relates to an inorganic functional coating for degrading formaldehyde by negative ions and a preparation method of the coating. The coating comprises a component A and a component B, wherein the component A contains negative ion powder. The coating is high in abrasion resistance, hardness and high-temperature hot hardness, adhesive force and peeling strength and can be abraded for 9 hours, cross-linking density is greatly enhanced and compactness of the coating is increased as the coating is compounded with inorganic materials with different particle sizes, gaps among large-particle-size raw materials are filled up as the raw materials with different particle sizes are mixed, thermal stress dispersion among the large-particle-size raw materials is absorbed and buffered by small-particle-size raw materials, thermal stress concentration of the small-particle-size raw materials is resisted and isolated by the large-particle-size raw materials, the coating is environment-friendly and green, VOC (volatile organic compound) is avoided, a large number of negative ions can be generated, and the coating is superior to other products in the field.

Owner:华夏贝能(北京)生态科技有限公司

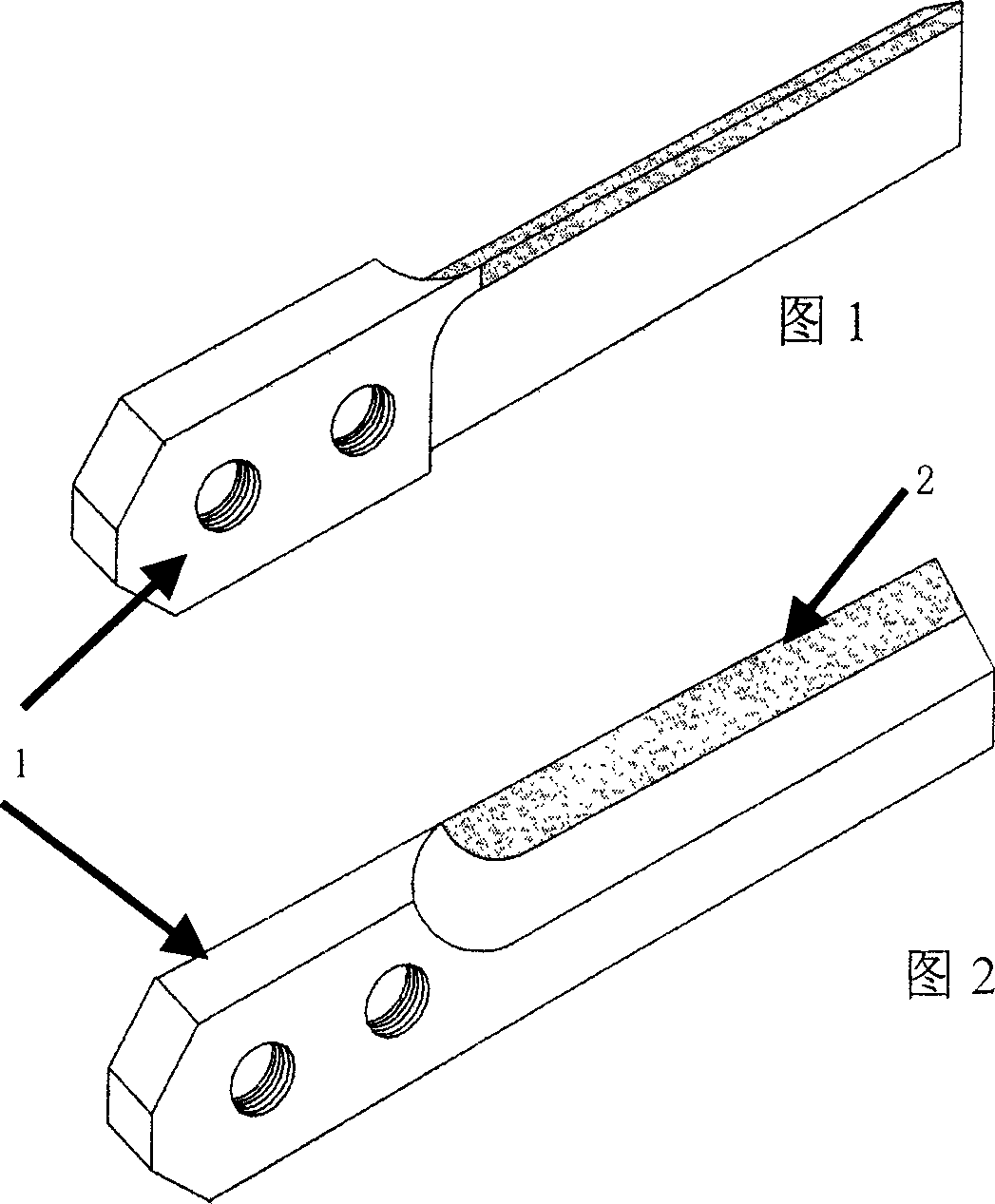

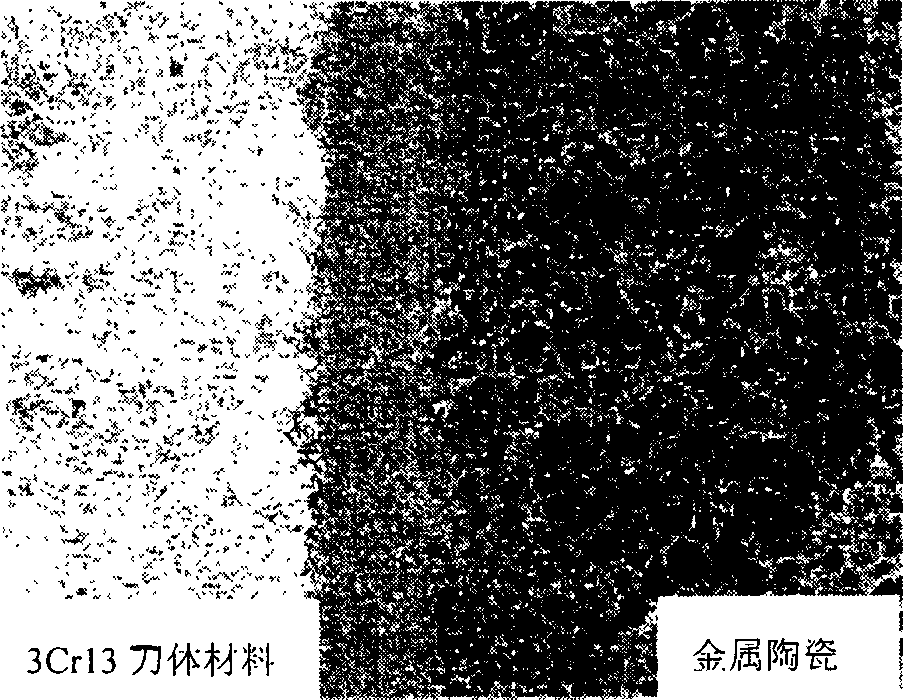

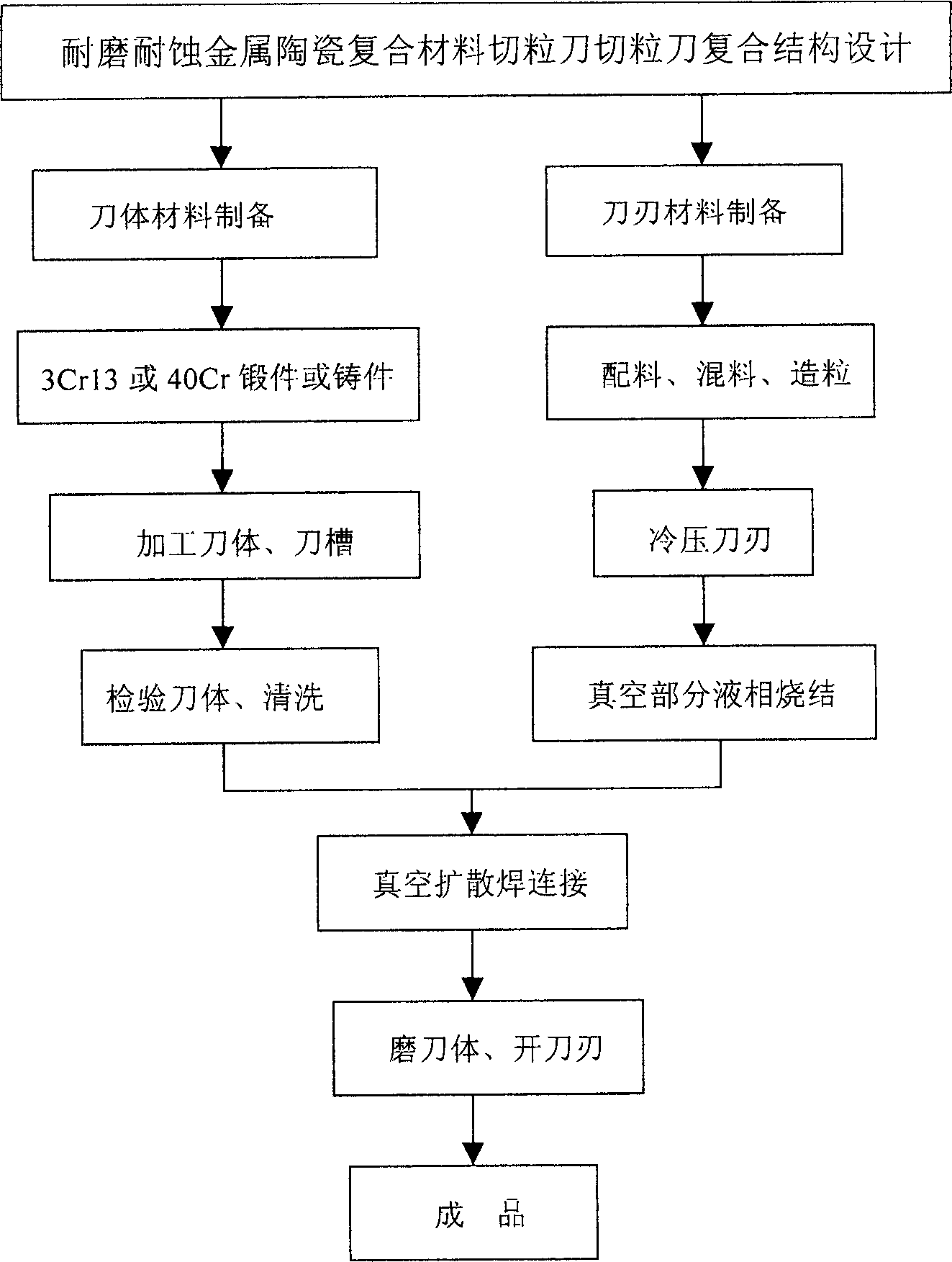

Wear- and corrosion- proof metal ceramic knife edge material

Disclosed is an abrasion-proof anticorrosion ceramic metal cutting edge material, which comprises TiC particles as the base stock, Ni powder 25.0-40.0 wt%, Cr powder 6.0-10.0 wt%, a small amount of Al and Ti powder with a total content of no less than 3.0 wt%. The material ahs good wearing resistance, corrosion stability, oxidation resistance and high hot hardness and strength.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS20060283526A1Acceptable casting scrap rateGood heat treatment characteristicMachines/enginesLift valveNiobiumWear resistant

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

General cold work tool steel

The invention relates to a universal cold work tool steel, which belongs to the technical field of material, wherein the components and the percentage by weight are that C 0.90-1.10, Si 0.70-1.30, Mn 0.30-1.00, P<=0.030, S<=0.030, Cr 4.00-5.50, Mo 0.50-1.00, W 1.00-1.90, V 0.75-1.20 and the allowance is Fe. Compared with cold work die steel of chrome 12 system and chrome 8 system which are extensively used, the universal cold work tool steel has better hardness, better abradability and the matching between and toughness and hot hardness and better comprehensive mechanical properties, which can be used to manufacture alloy tool steel, cutting tool and die. The invention provides a high-performance cold work tool steel, which can be selective to use.

Owner:SHANGHAI JIAO TONG UNIV +1

Anti-wear plastic ramming material dedicated for pure low-temperature waste heat power generation equipment

ActiveCN1994711AHigh strengthImprove adhesionSold ingredients supply apparatusMicrocosmic saltMetallurgy

The invention relates to an abrasion-resistance plastic beater of low-temperature left-heat generator, wherein it uses boule, silica, boule powder, plastic clay, and alumina powder as base material; uses hot hardness microcosmic salt as adhesive; beats and shapes with plastic technique. The inventive product has high strength and abrasion resistance, while its service life can reach 24 month.

Owner:ANHUI RUITAI NEW MATERIALS TECH

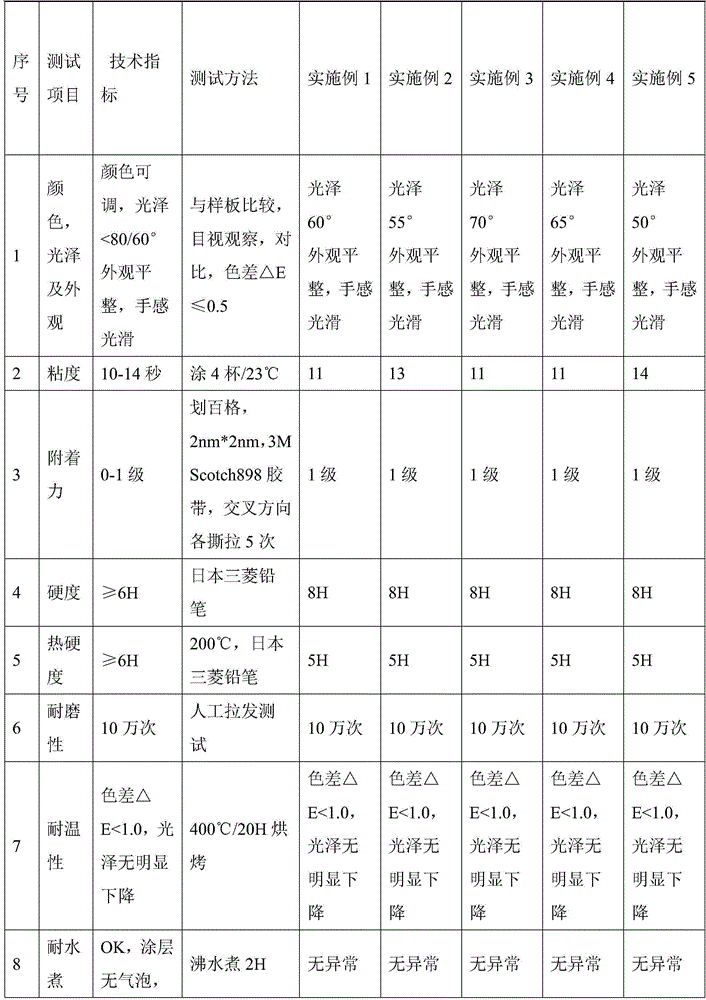

High-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint

The invention discloses high-abrasion-resistance, high-temperature-resistant and water-cooking-resistant aqueous ceramic paint, which is prepared by mixing a component A, a component B and a component C according to a mass ratio of 666: 333: 1, wherein the component A is prepared from the following components in percentages by mass: 26 percent to 30 percent of silica sol, 13 percent to 15 percent of antimony solution, 5 percent to 13 percent of inorganic high-temperature-resistant pigment and 8 percent to 12 percent of silicon dioxide; the component B is prepared from the following components in percentages by mass: 30 percent to 34 percent of silicane, 0.4 percent to 0.6 percent of wetting agent and 0.4 percent to 0.6 percent of flatting agent; the component C is 0.1 percent of catalyst. The paint prepared by the invention not only has the attractive luster and appearance and the nice hand feeling of conventional aqueous ceramic paint, but also has ultrahigh hardness and hot hardness and excellent abrasion resistance, can be up to over 100,000 times in manual hair pulling test, and further has excellent water cooking resistance, temperature resistance and corrosion resistance. The ceramic paint which is provided by the invention and is prepared by adopting a silane coupling agent has many advantages of high temperature resistance, high hardness, noninflammability, no smoke, super weatherability, environment friendliness, nontoxicity, colorfulness and the like.

Owner:DONGGUAN RUNTIAN CHEM CO LTD

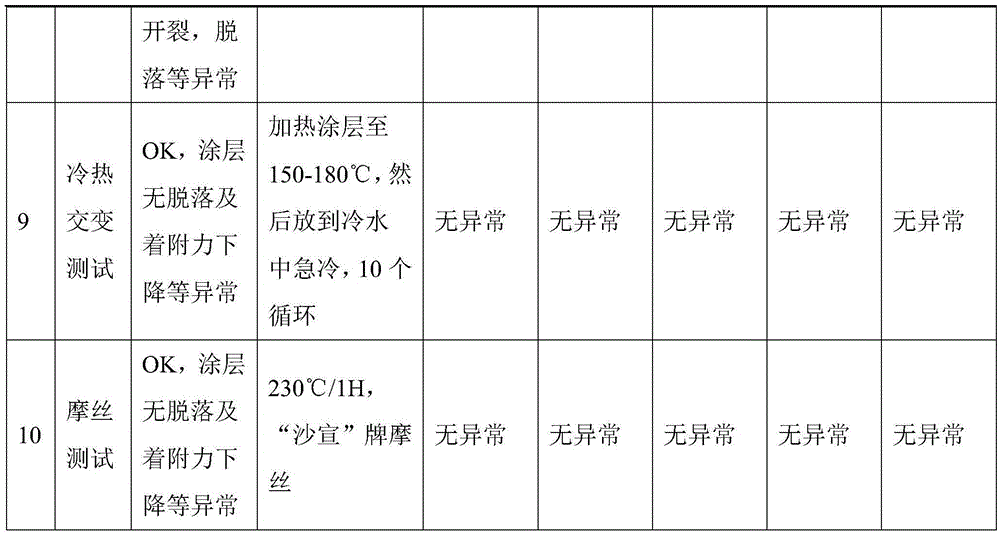

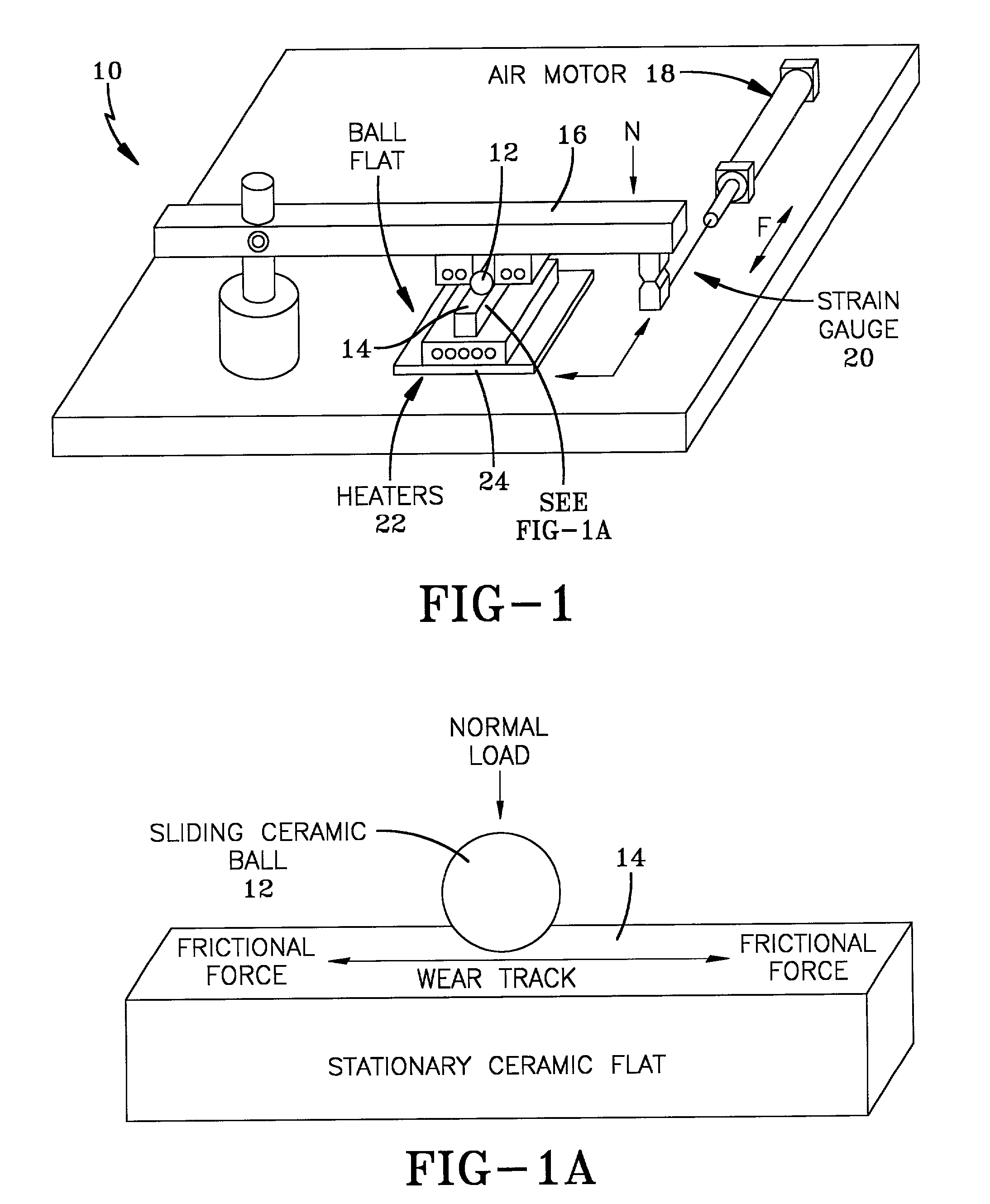

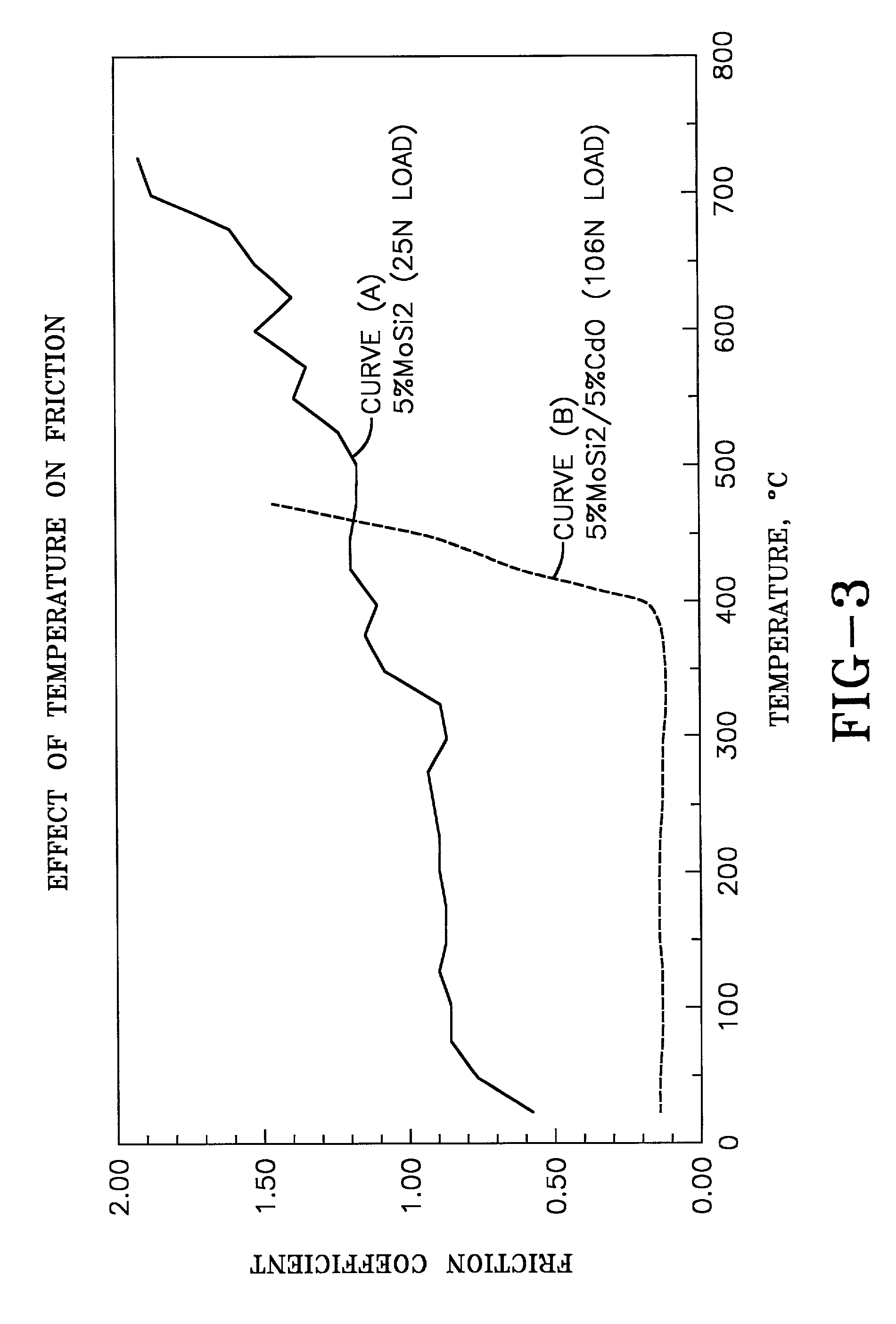

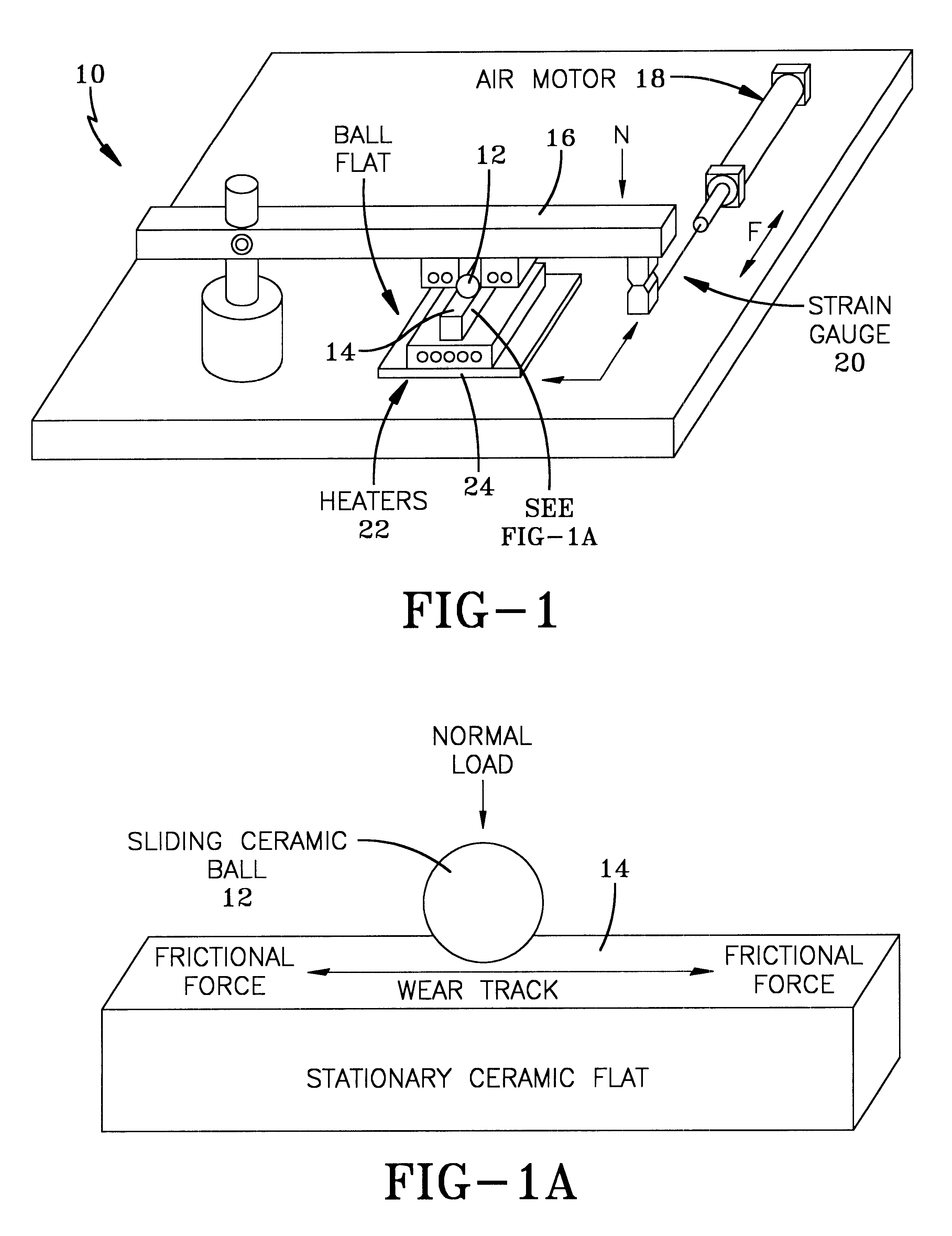

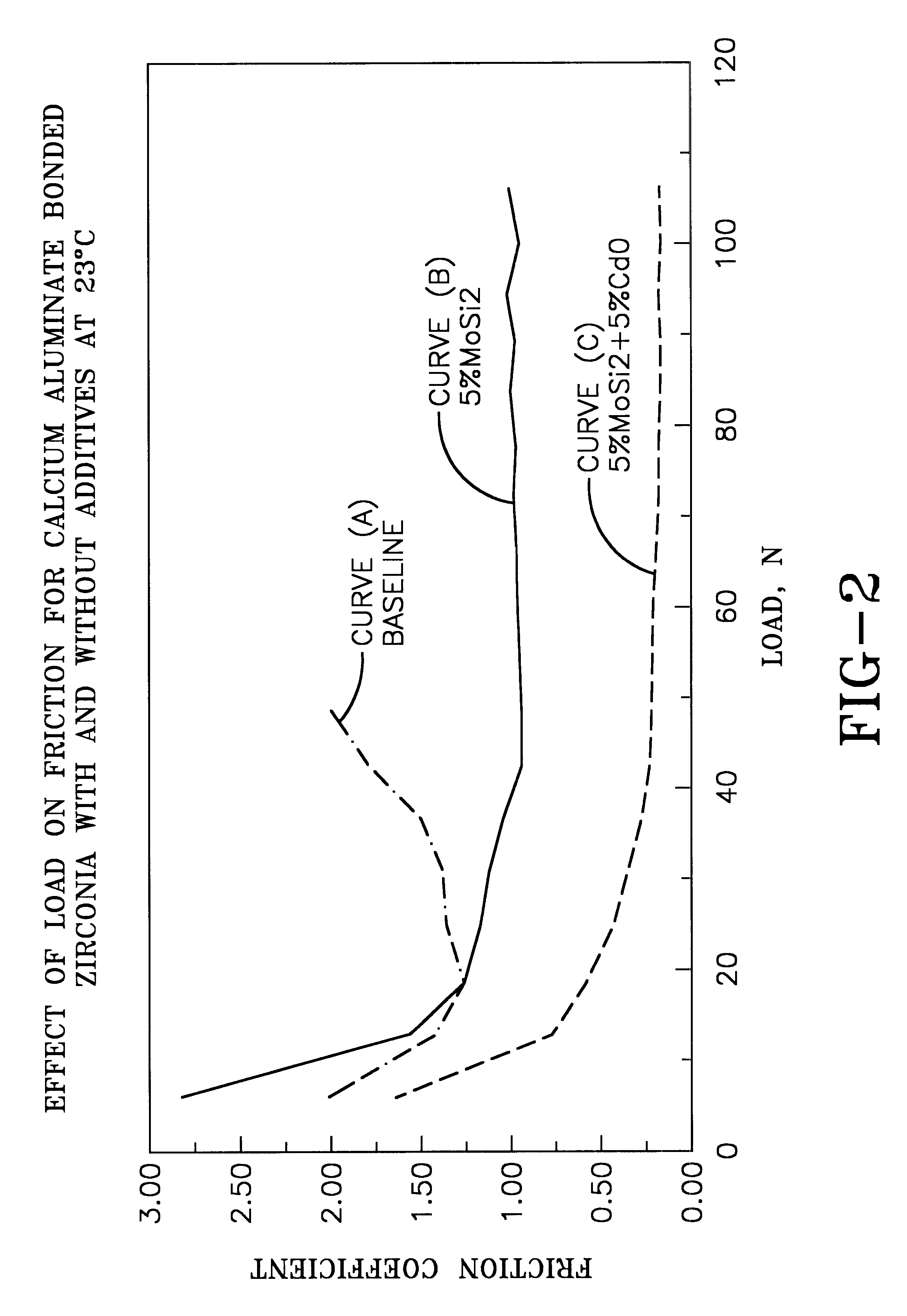

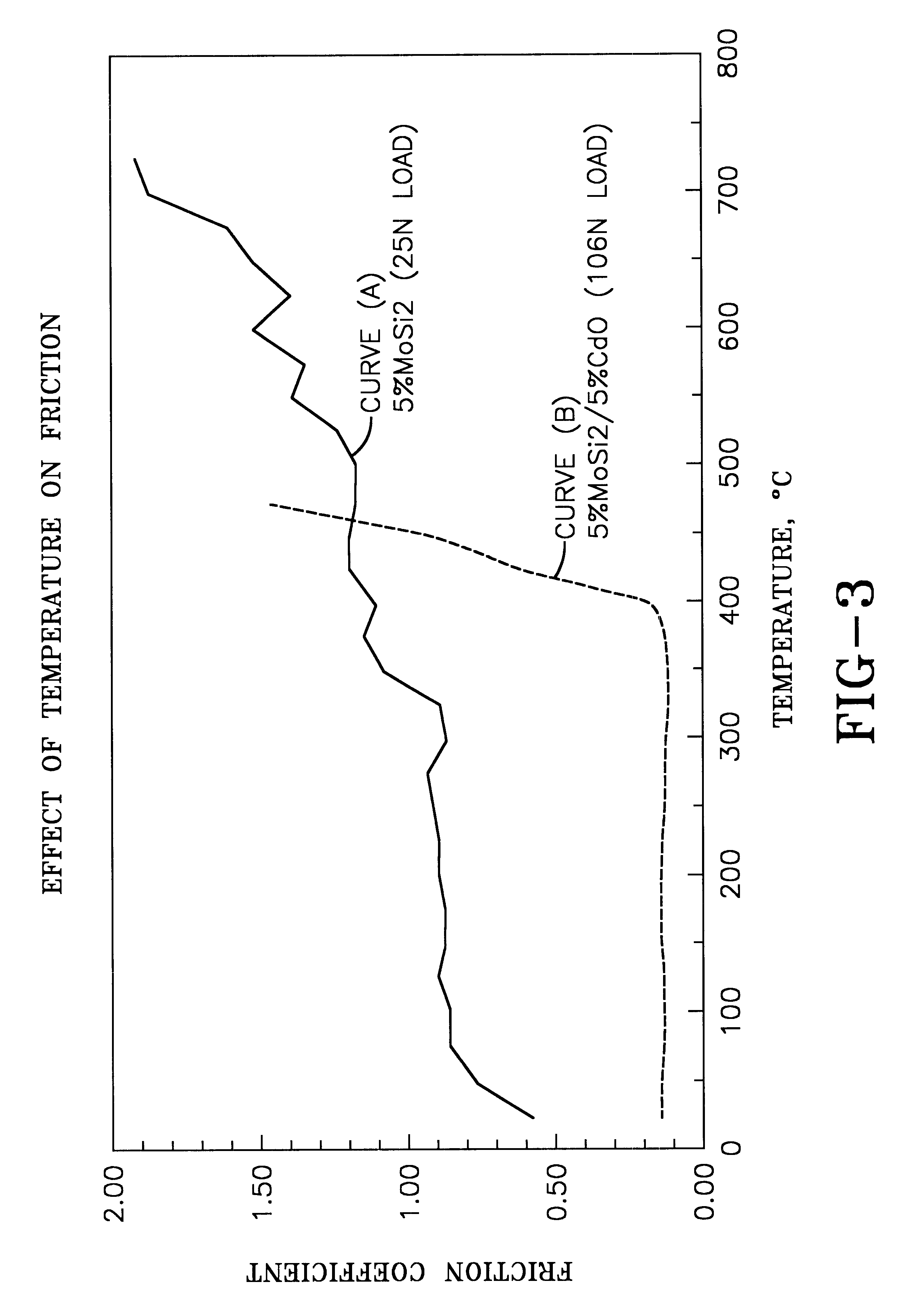

Self-lubricating ceramic composites

The invention comprises a self-lubricating ceramic composite characterized as having a low porosity derived from a mixture of at least one ceramic powder preferably selected from the group consisting of silicon nitride, silicon carbide, zirconia, alumina, zirconium nitride, tungsten carbide, and titanium carbide; a cemetitious binder, effective amounts of at least one metal silicide, and at least one metal oxide. The ceramic powder mixture can be slurried with sufficient amounts of water and subsequently subjected to pressures of about 6.0 to 7.0 MPa in a mold at temperatures of about 125° to 175° C. to form a self-lubricating ceramic composite capable of maintaining hot-hardness temperatures above 750° C. These self-lubricating ceramic composites are particularly useful in the manufacture of high-performance turbine engines, including engine parts, bearings, gears, rotors and in other areas where high-heat lubricating properties of the ceramic composite are required.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Coating material with high adhesion with matrix

The invention discloses a coating material with high adhesion with a matrix. The coating material is prepared from the following raw materials (by weight): 12-15 parts of glass glaze, 70-80 parts of alumina ceramic powder, 3-4 parts of carboxymethylcellulose sodium, 4-5 parts of sodium silicate, 1.6-2 parts of tin dioxide, 0.6-0.8 part of boron glass powder, 4-6 parts of silica sol, 2-3 parts of copper-nickel alloy, 0.6-0.9 part of cobalt oxide, 1.2-1.5 parts of sodium carbonate, 6-8 parts of titanium carbide, a proper amount of anhydrous ethanol and a proper amount of deionized water. The ceramic coating provided by the invention has a simple preparation process, is low-cost and is convenient to coat. The prepared coating has good cold and hot hardness and wear-resistance, has high adhesion with a matrix, is not easy to fall off, and is worth of promotion.

Owner:MAANSHAN JINSHENG IND DESIGN

Self-lubricating ceramic composites

The invention comprises a self-lubricating ceramic composite characterized as having a low porosity derived from a mixture of at least one ceramic powder preferably selected from the group consisting of silicon nitride, silicon carbide, zirconia, alumina, zirconium nitride, tungsten carbide, and titanium carbide; a cemetitious binder, effective amounts of at least one metal silicide, and at least one metal oxide. The ceramic powder mixture can be slurried with sufficient amounts of water and subsequently subjected to pressures of about 6.0 to 7.0 MPa in a mold at temperatures of about 125° to 175° C. to form a self-lubricating ceramic composite capable of maintaining hot-hardness temperatures above 750° C. These self-lubricating ceramic composites are particularly useful in the manufacture of high-performance turbine engines, including engine parts, bearings, gears, rotors and in other areas where high-heat lubricating properties of the ceramic composite are required.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

3Cr2Mo die steel heat treatment process

The present invention discloses a 3Cr2Mo die steel heat treatment process which is characterized by comprising the following steps, to be more specific, (1) forging; (2) annealing, to be more specific, heating to the temperature of 850 DEG C, performing thermal insulation for 2-4h, at isothermal temperature of 720 DEG C, performing thermal insulation for 4-6h, then cooling in a furnace to 500 DEG C, and taking out of the furnace to cool in the air; (3) quenching and tempering, to be more specific, at the quenching heating temperature of 860-870 DEG C, performing oil quenching, and at 540-580 DEG C performing tempering, wherein the surface hardness is 30-35HRC; and (4) carburizing process, to be more specific, heating at 900 DEG C for (6-8) h, after infiltration, at 850-870 DEG C performing oil quenching, and then performing low temperature tempering at 200-250 DEG C for (2-3) h. The 3Cr2Mo die steel heat treatment process can improve organizational stability of 3Cr2Mo die steel, and has high hot hardness, wear resistance and toughness and other overall performances.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

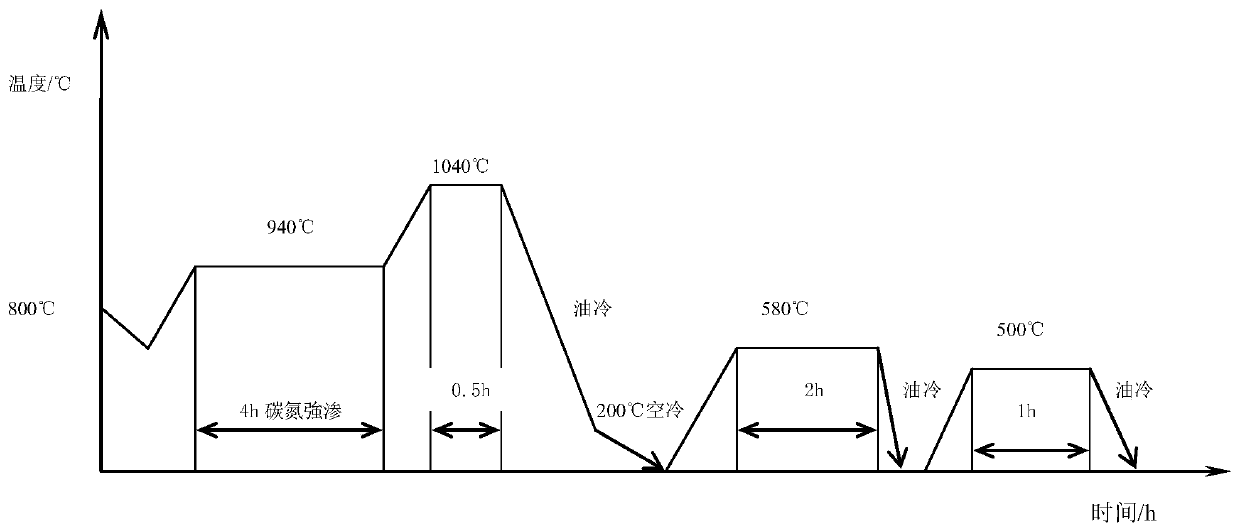

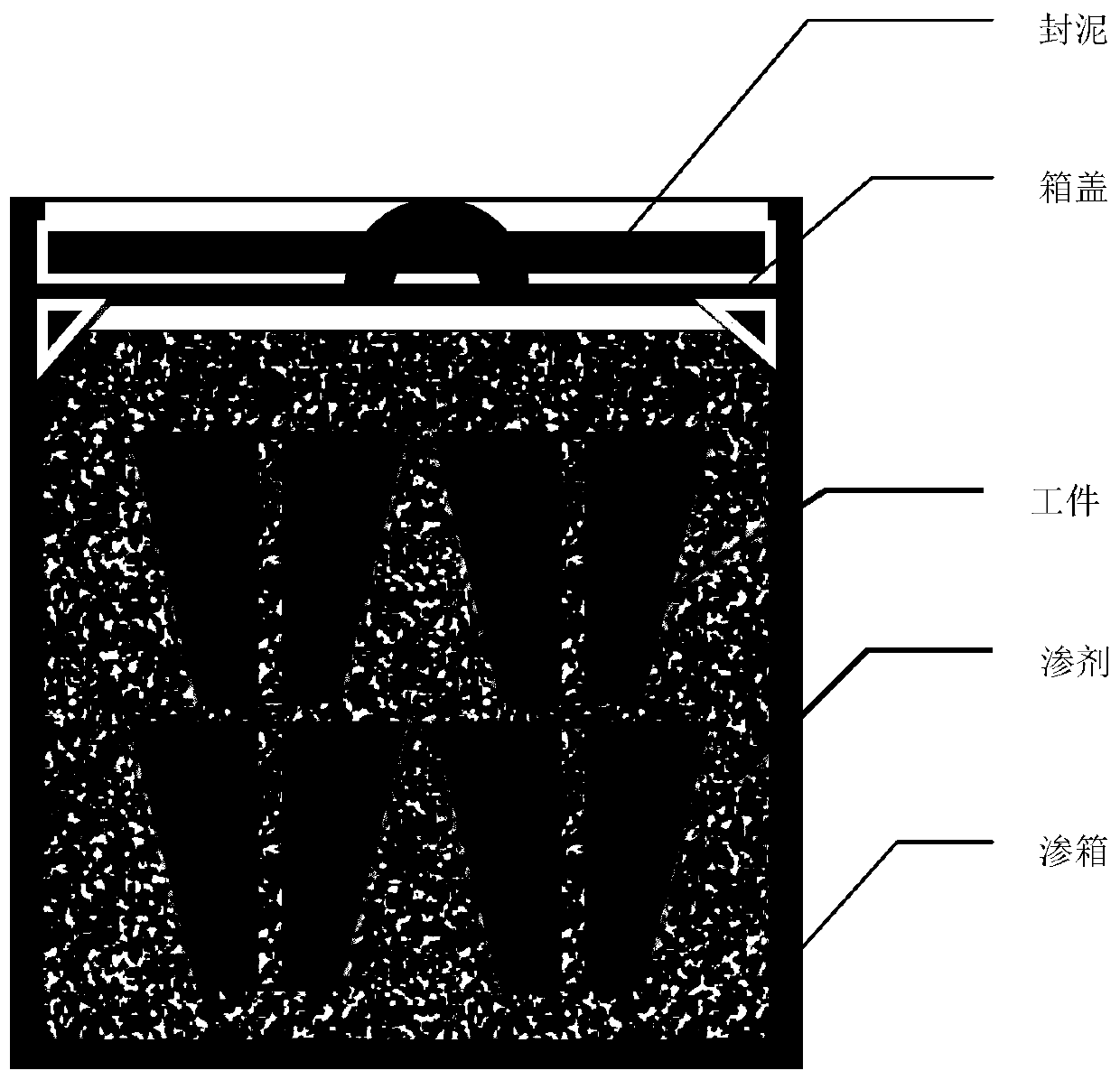

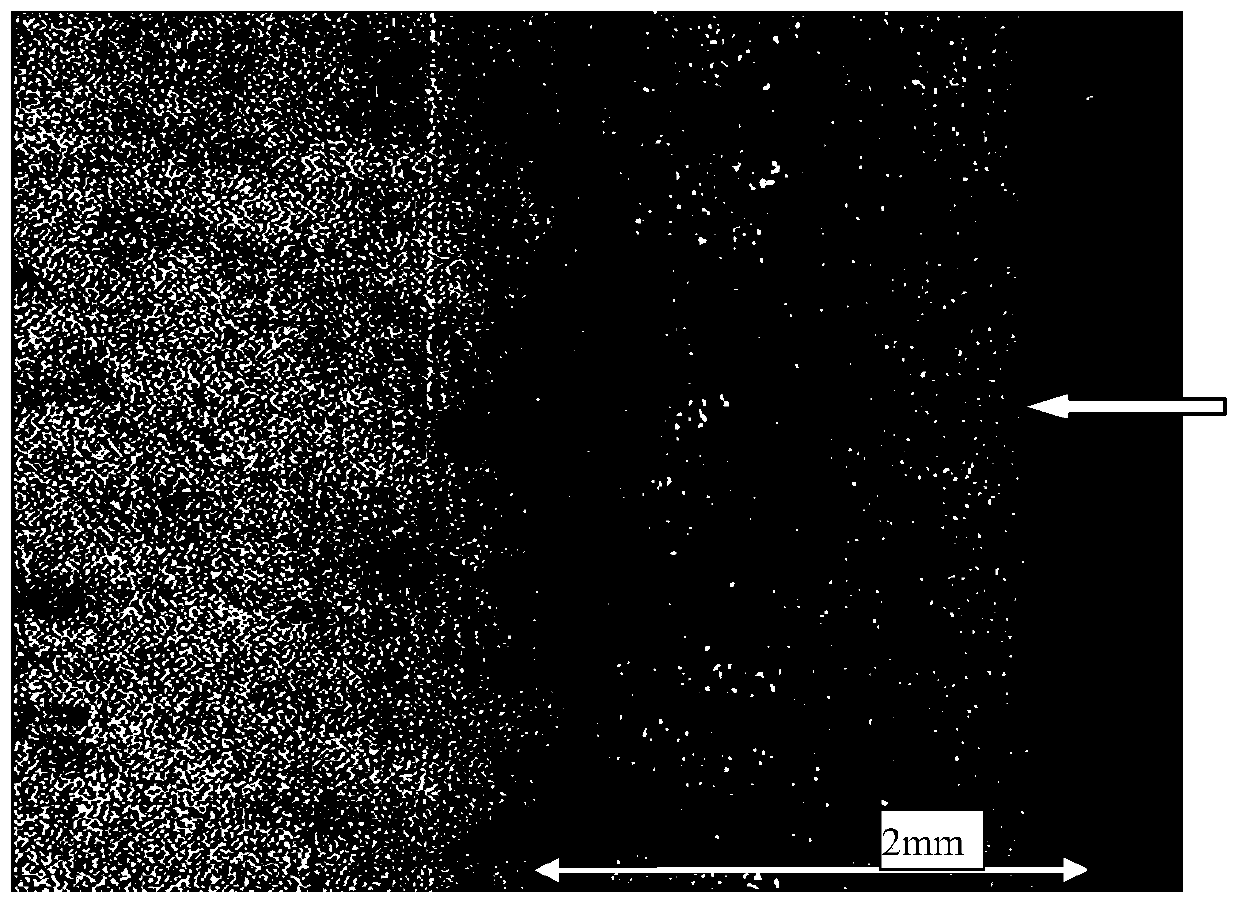

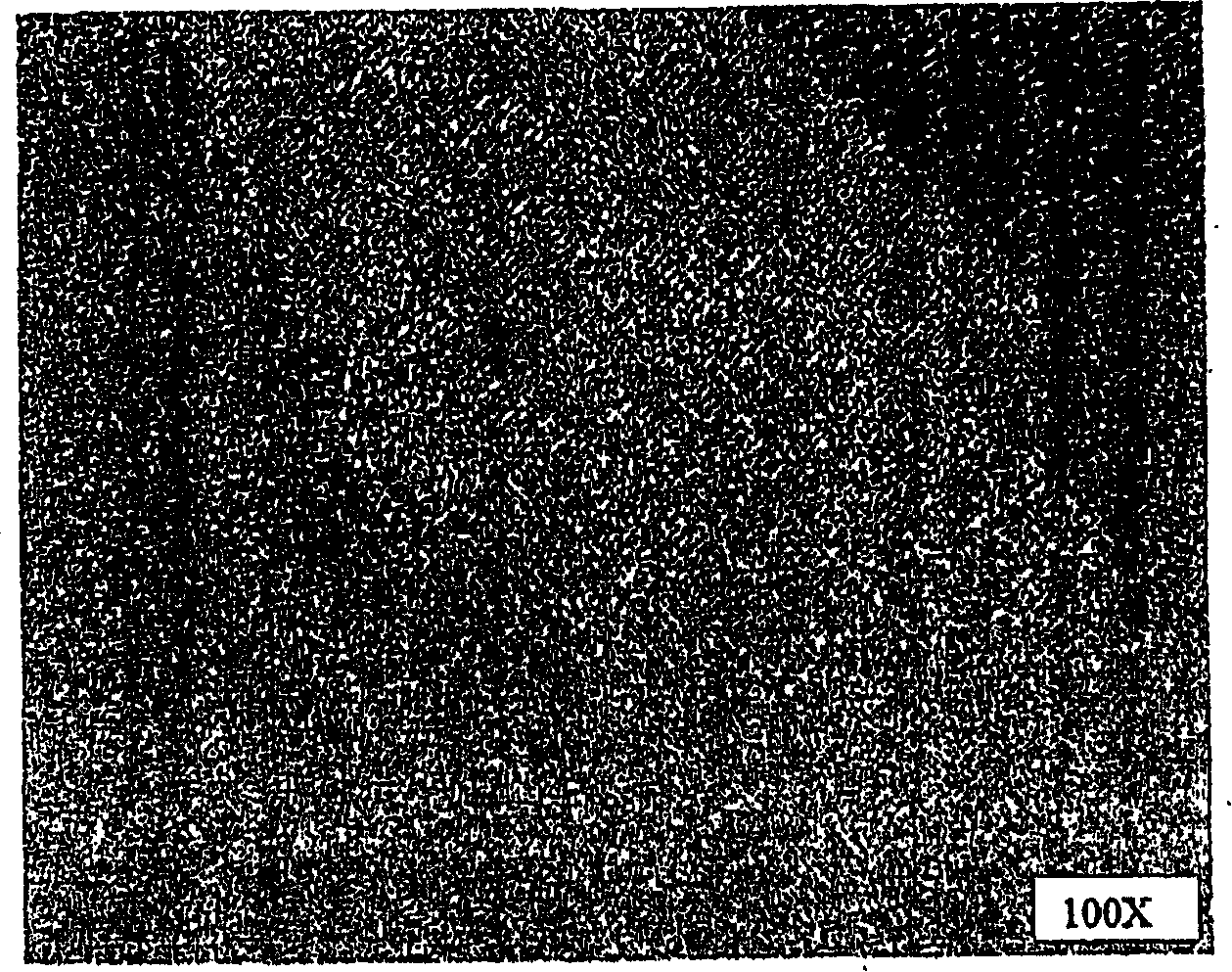

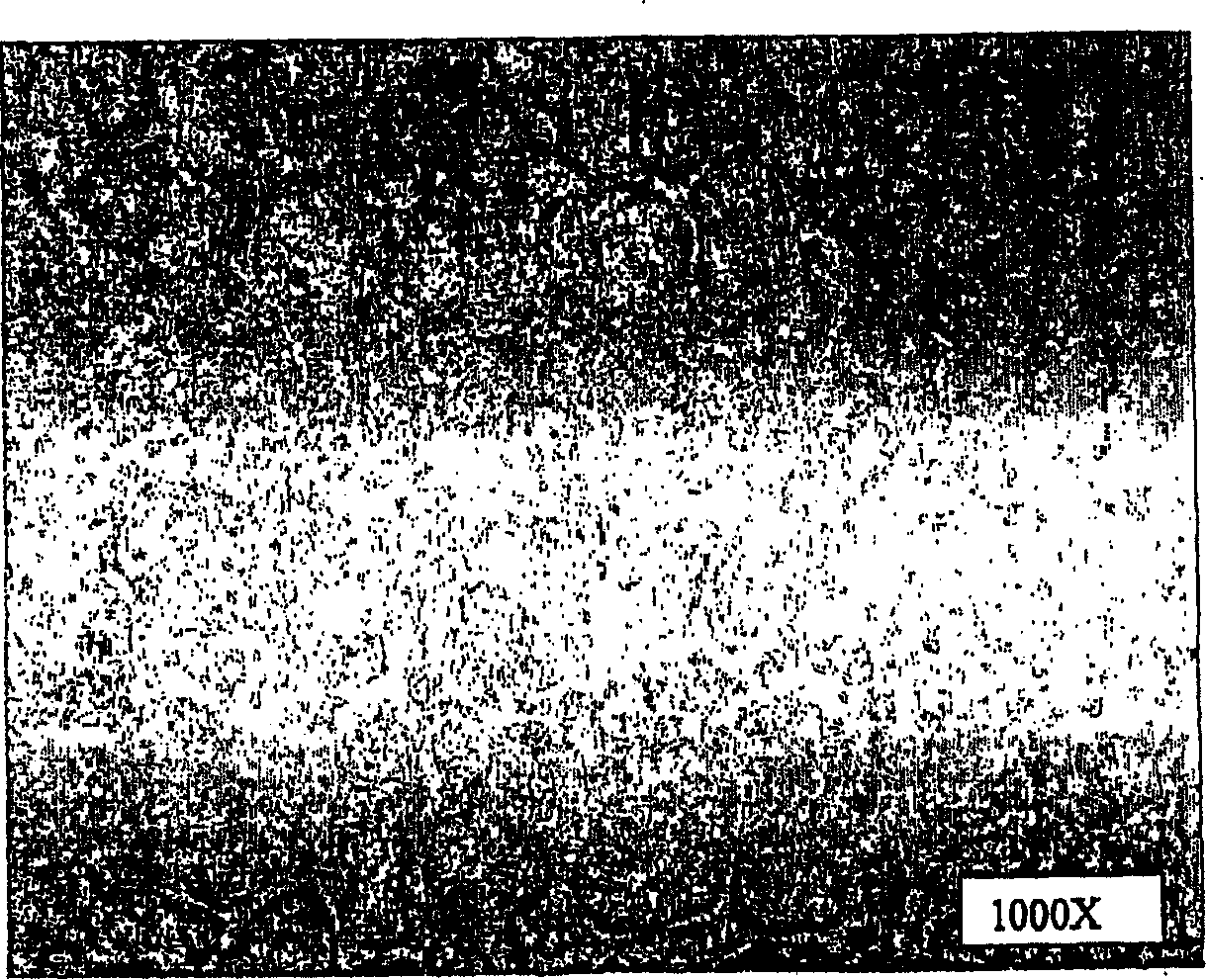

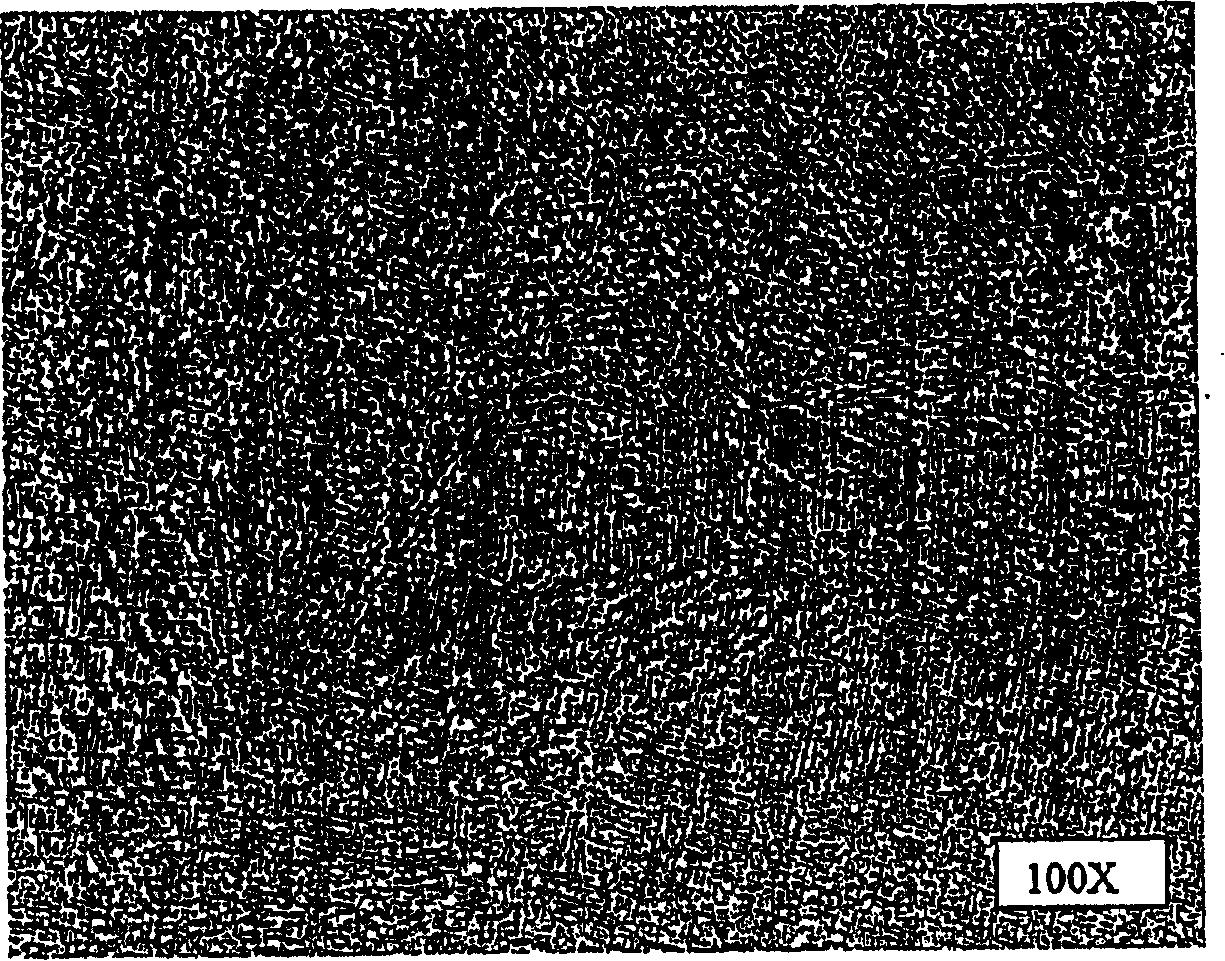

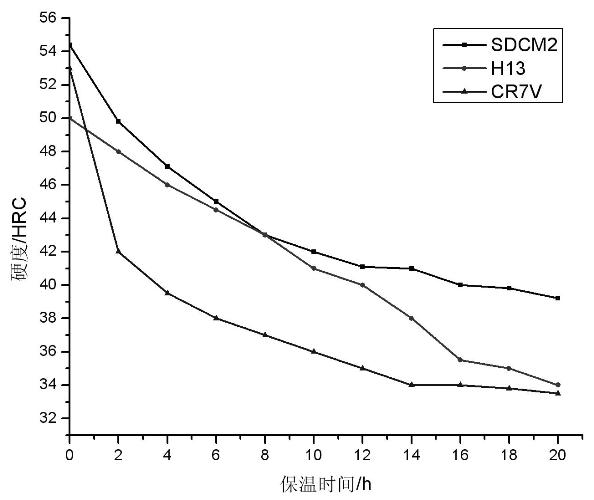

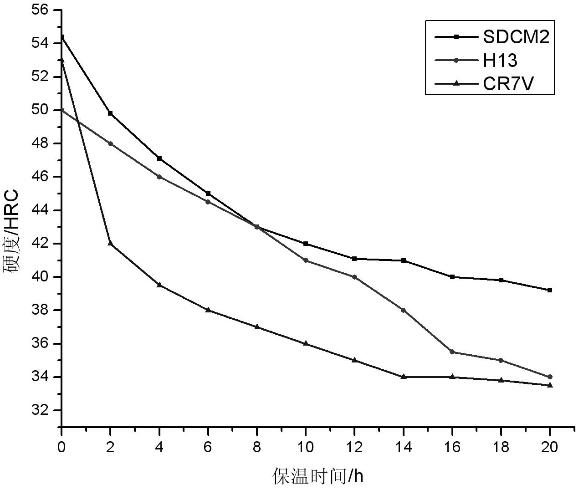

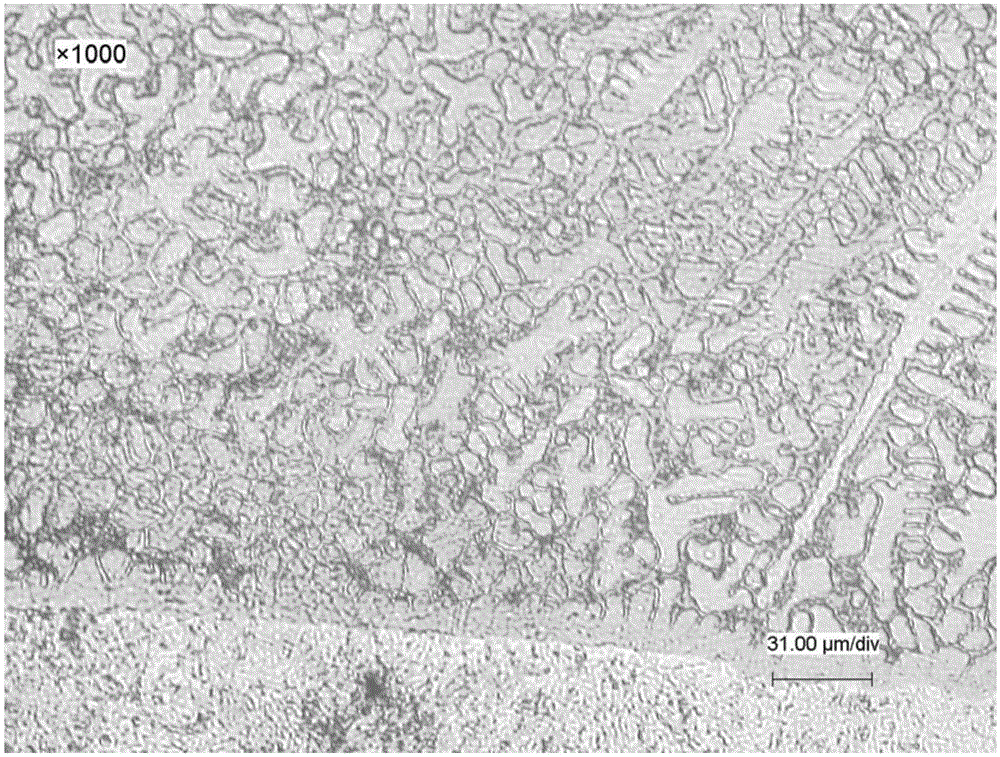

Heat treatment process improving hot hardness and high temperature abrasion resisting performance of hot mold steel

ActiveCN110565048AExtend high temperature service lifeSimple methodSolid state diffusion coatingHigh-temperature corrosionHeat treated

The invention provides a heat treatment process improving the hot hardness and the high temperature abrasion resisting performance of hot mold steel. Charcoal, urea particles, sodium carbonate powderand chromic anhydride are mixed to obtain a carbon-nitrogen strong permeating mixture; a hot mold steel workpiece and the carbon-nitrogen strong permeating mixture are installed in a permeating box atthe same time, and a box cover of the permeating box is sealed; the permeating box is placed into a crucible type electric furnace to be subjected to constant temperature carbon-nitrogen strong permeating at 850-950 DEG C; after quenching treatment, the hot mold steel workpiece is directly immersed into quenching oil to be cooled; and after air cooling, placing into a box type intermediate temperature tempering furnace for tempering twice is performed, and the hot mold steel workpiece high in hot hardness and high in high temperature abrasion resisting performance is obtained. The heat treatment process has the advantages of being easy and convenient to operate, low in cost and obvious in effect, the surface hardness of the obtained hot mold steel can reach 62 HRC or above, the high temperature abrasion resisting performance under the temperature of 600 DEG C exceeds that of a same hot mold steel conventional heat treatment piece twice or above, and the service life of a hot working mold can be effectively prolonged.

Owner:锦州捷通铁路机械股份有限公司

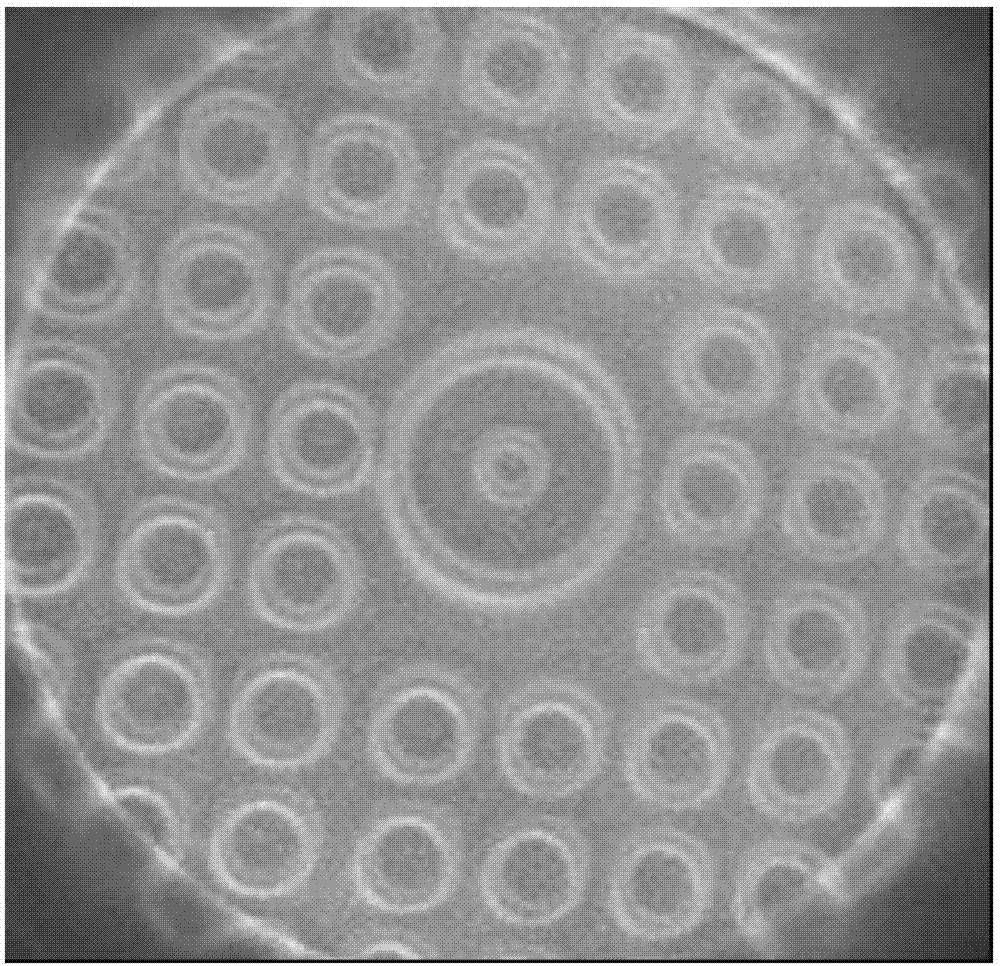

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20050175840A1Improve thermal conductivityHigh stressEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

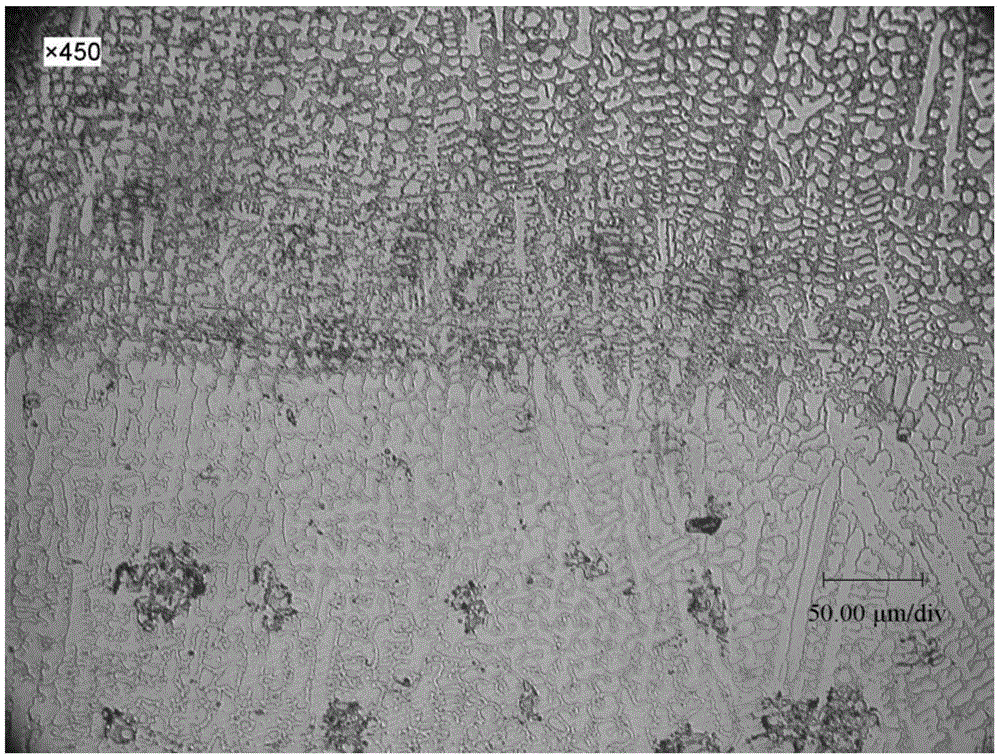

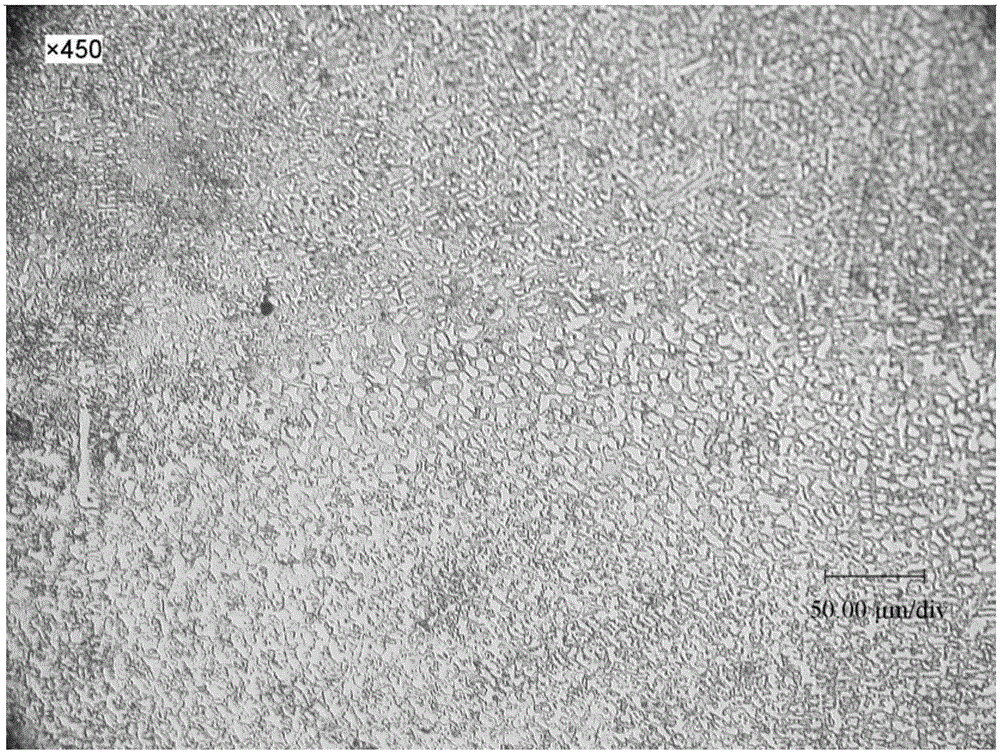

Method for electroforming Co-Ni alloy coating on copper plate for continuous casting crystallizer

The invention discloses a method for electroforming a Co-Ni alloy coating on a copper plate for a continuous casting crystallizer. The method comprises the steps of polishing, oil removing, water scrubbing, back engraving and Co-Ni electroforming. By adopting the method, the electroformed layer is exquisite, the coating is high in hardness and better in hot hardness, and because the coating is high in hardness and good in hot hardness, the abrasion resistance of the copper plate at high temperature is greatly improved, and the steel loading capacity of the copper plate can reach 0.15-0.20 million tons. Besides, the electroforming solution is good in dispersibility, so that the coating is strong in covering capacity and good in leveling performance. Moreover, the copper alloy electrolysis etching solution is an alkalescent solution, and the surface of a chromium-zirconium-copper alloy part can obtain sand-like pearly luster with a uniform color through anode electrolysis etching, so that the bonding force of the coating is improved, the electroformed layer can not generate dross easily, the electroformed layers on high and low areas are relatively uniform, machining wastes of the coating are reduced, and the utilization ratio of raw materials is improved. The method is suitable for electroforming the Co-Ni alloy coating on the copper plate for the continuous casting crystallizer.

Owner:QINHUANGDAO SHOUGANG CHANGBAI MOLD

Corrosion and wear resistant alloy

Owner:L E JONES CO

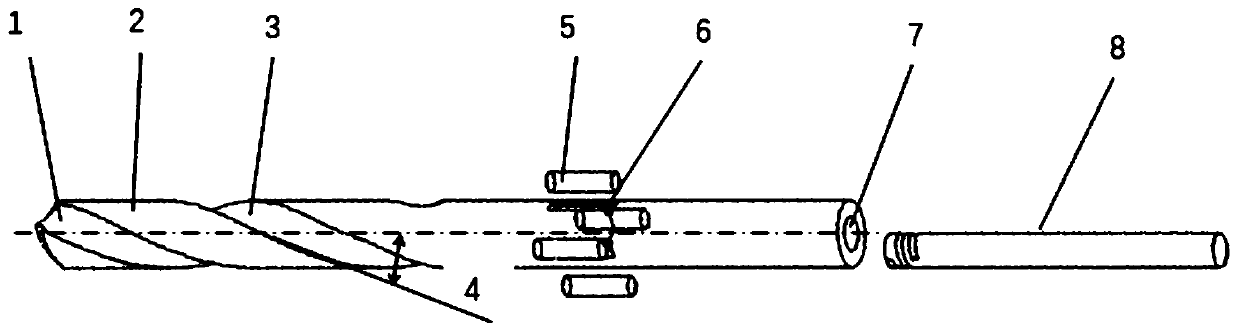

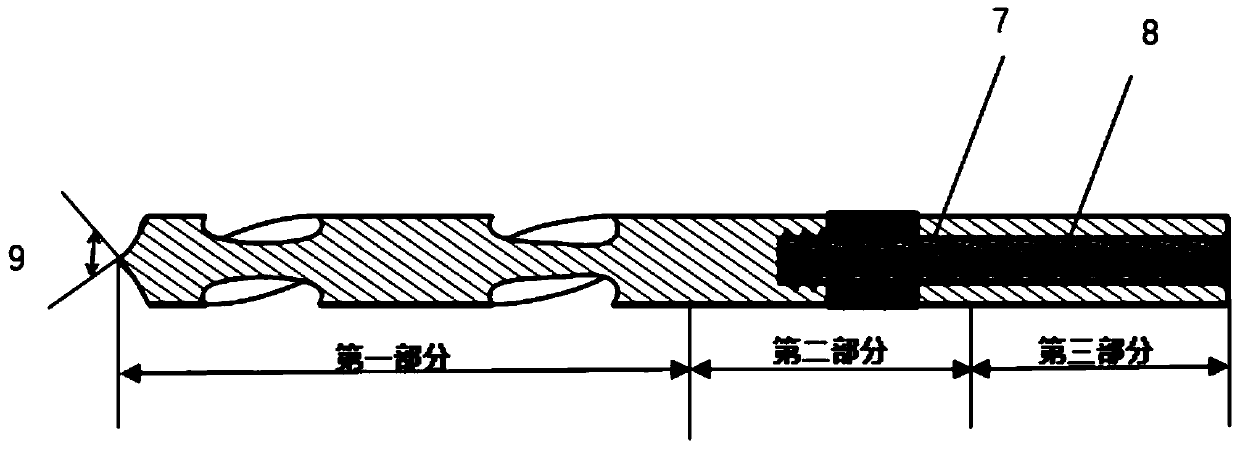

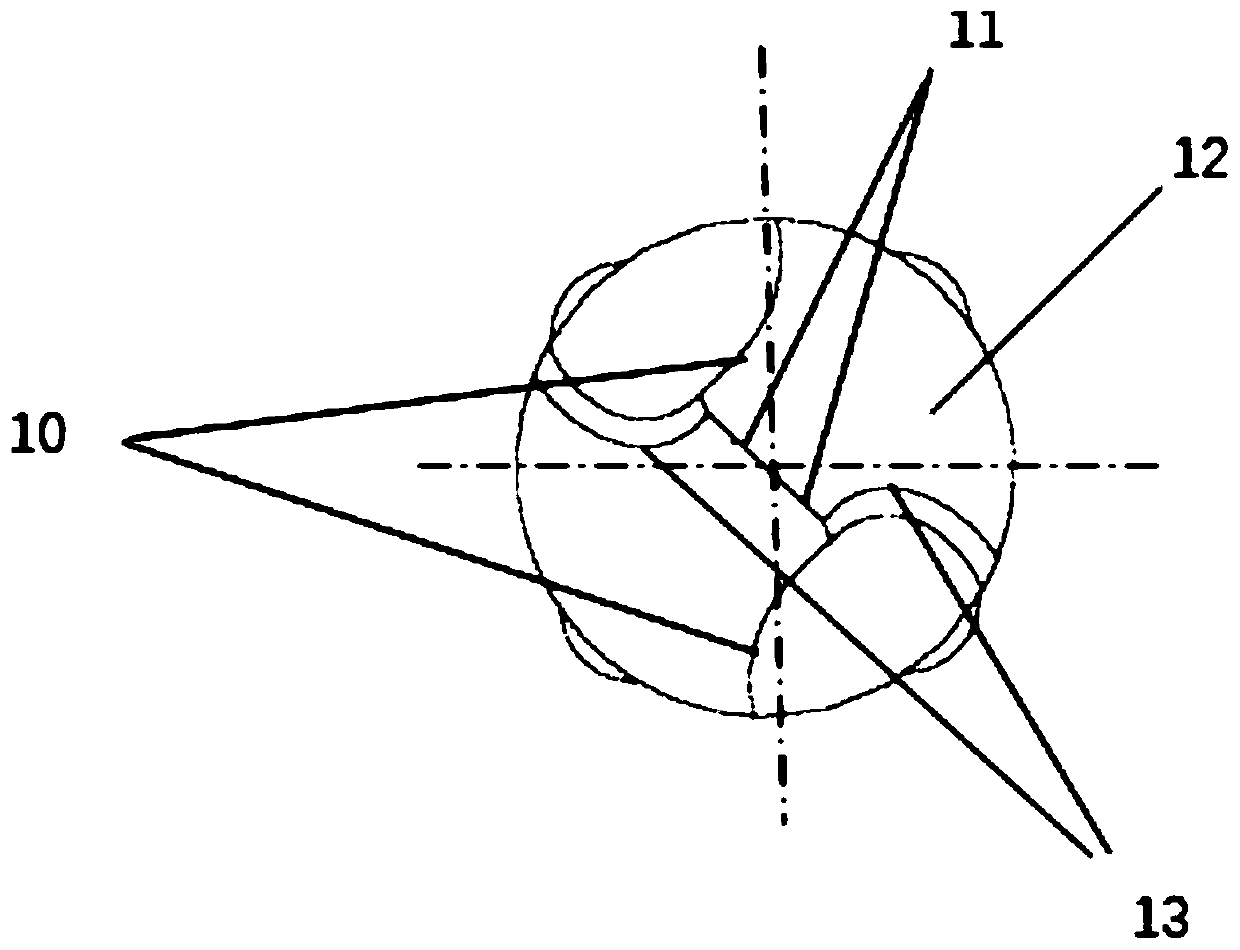

Drilling and rolling combined forming cutter

InactiveCN110560753AImprove wear resistanceEffective protectionTransportation and packagingWorkpiecesFeeding forceWave shape

The invention belongs to the field of drilling tools, and relates to a drilling and rolling combined forming cutter. The drilling and rolling combined forming cutter comprises three parts, wherein thefirst part is a drill bit, the second part is a rolling cutter, the third part is a handle, and the three parts are sequentially connected; a drill tip part of the drill bit is provided with two transverse edges; a main cutting edge of the drill tip is a wave-shaped edge, preeminent sharpness and strength are achieved, and chips are discharged more smoothly; two auxiliary cutting edges are arranged on the main rear cutter surface; and two cutting grooves with cylindrical spiral structures are formed in a drill bit body. According to the drilling and rolling combined forming cutter, drilling and rolling are simultaneously machined, so that the number of the machining procedures is reduced, the machining time is shortened, and the machining efficiency is greatly improved; through the optimized groove-shaped structure and the wave-shaped cutting edges, the preeminent sharpness and strength are achieved, and the chips are discharged more smoothly; and the top angle of 140 degrees reducesthe feeding force at the initial stage of drilling and provides excellent self-centering capability, so that the hole machining quality is improved, the hot hardness is improved, and the chip accumulation is prevented.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

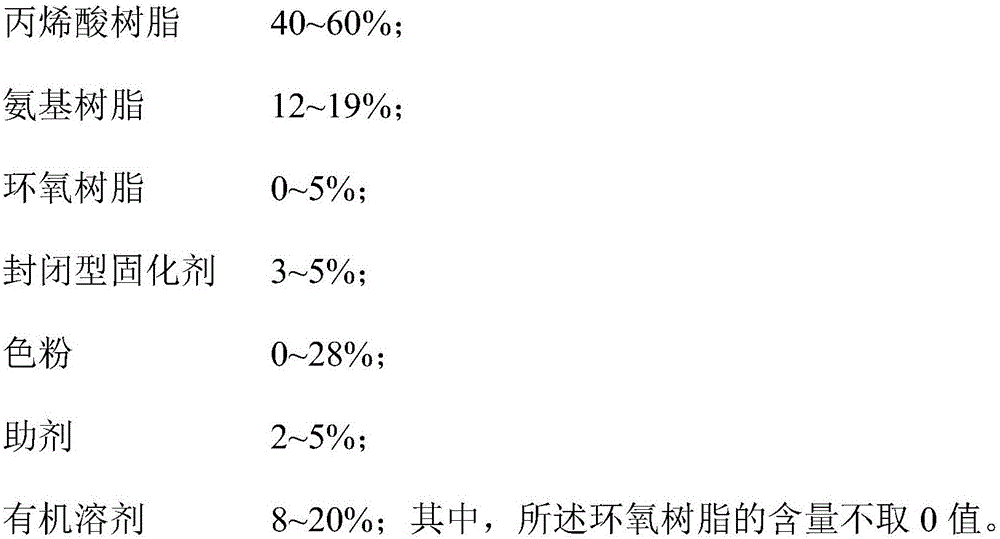

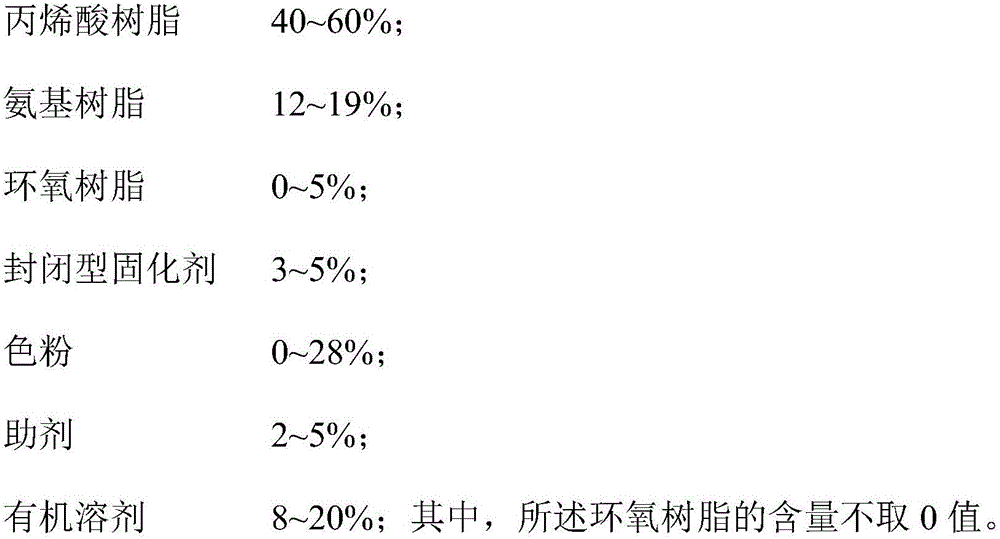

Paint for electric irons, and preparation and application method thereof

ActiveCN106085056AImprove spraying effectFlat surfaceFireproof paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention provides a paint for electric irons, and a preparation and application method thereof. The paint at least comprises the following components in percentage by weight: 40-60% of acrylic resin, 12-19% of amino resin, 0-5% of epoxy resin, 3-5% of enclosed-type curing agent, 0-28% of toner, 2-5% of aid and 8-20% of organic solvent. The content of the epoxy resin is not 0. The paint is a single-component acrylic amino baking varnish, and has the advantages of favorable spraying effect, smooth surface, high gloss and uniform color. More importantly, the paint film formed by drying at the temperature of lower than 160 DEG C has favorable hardness, and especially can still have higher hot hardness, favorable adhesion to the substrate, excellent damp heat resistance and excellent wear resistance in a 120-DEG C environment.

Owner:CHINA PAINT MFG CO SHENZHEN

Material for hot stamping mould and preparation method thereof

The invention relates to a novel steel product for a hot stamping mould. The novel steel product is applicable to the hot stamping mould having requirements on high abrasive resistance and high cold and heat fatigue resistance and belongs to the technical field of hot stamping mould material manufacture processes. The material provided by the invention for the hot stamping mould comprises the following chemical components in percentage by weight: 0.40-0.50% of C, 0.7-0.9% of Si, 0.65-0.85% of Mn, 0.025% of P, 0.005% of S, 2.5-2.7% of Cr, 2.1-2.4% of Mo, 0.8-1.0% of V, and the balance ofl Fe and micro impurities. After being subjected to inductive smelting, electro-slag re-smelting, annealing, homogenizing at high temperature, forging and annealing, the material has a good machining performance. After being subjected to quenching at 1020 degrees centigrade and tempering at 550 degrees centigrade, the material has the advantages of good hot strength, hot hardness, high abrasive resistance and fatigue resistance, good weldability, higher heat conductivity coefficient and lower thermal expansion coefficient. The material is applicable to the hot stamping forming mould.

Owner:SHANGHAI UNIV

Laser repairing method for hot roller with toughness and strength

InactiveCN106567068ASmall amount of deformationExtended service lifeMetallic material coating processesUltimate tensile strengthWear resistance

The invention relates to a laser repairing method for a hot roller with toughness and strength. A transitional alloy layer, an intermediate alloy layer and a surface alloy layer are arranged on the surface of the hot roller layer by layer in a laser cladding manner; alloy powder adopted by the transitional alloy layer is prepared from the following components in percentage by mass: 0.2 to 0.3 percent of C, 3.2 to 3.6 percent of Si, 1.2 to 1.8 percent of B, 2.2 to 2.6 percent of Fe, 7 to 8 percent of Cr and the balance being Ni; alloy powder adopted by the intermediate alloy layer is prepared from the following components in percentage by mass: 0.4 to 0.5 percent of C, 3.8 to 4.3 percent of Si, 11.2 to 11.93 percent of B, 2.5 to 3.2 percent of Fe, 10 to 12 percent of Cr and the balance being Ni; and alloy powder adopted by the surface alloy layer is prepared from the following components in percentage by mass: 0.05 to 0.1 percent of C, 3.0 to 3.16 percent of Si, 2 to 4 percent of Fe, 16 to 19 percent of Cr, 27 to 30 percent of Mo and the balance being Co. The surface of the hot roller repaired by adopting the laser repairing method for the hot roller has good wear resistance, corrosion resistance and hot hardness; and in addition, the inner part of the hot roller has the toughness and the strength, and a good laser cladding effect is realized.

Owner:DANYANG HONGTU LASER TECH

Production method of cold-rolled bright strip steel

The invention discloses a production method of cold-rolled bright strip steel. The production method of the cold-rolled bright strip steel comprises the following steps: (1) batching, (2) smelting, (3) compression molding, (4) annealing treatment, (5) cold-rolling, (6) uncoiling, (7) welding, and (8) cleaning and drying to obtain the cold-rolled bright strip steel. The cold-rolled bright strip steel produced by the invention not only has high dimensional accuracy, bright surface, high magnetic induction, low iron loss, low surface roughness, uniform thickness, high lamination factor and good blanking property, but also has excellent hardness, good stretching resistance, good hot hardness, high hardenability, difficulty in deformation and cracking, high plasticity, toughness and elasticity, high strength of a welded joint and the like, and can replace a thick hot-rolled strip for the same purpose so as to reduce the use amount of steel, and the economic significance is large.

Owner:HUAIBEI YUANLI METAL PROD CO LTD

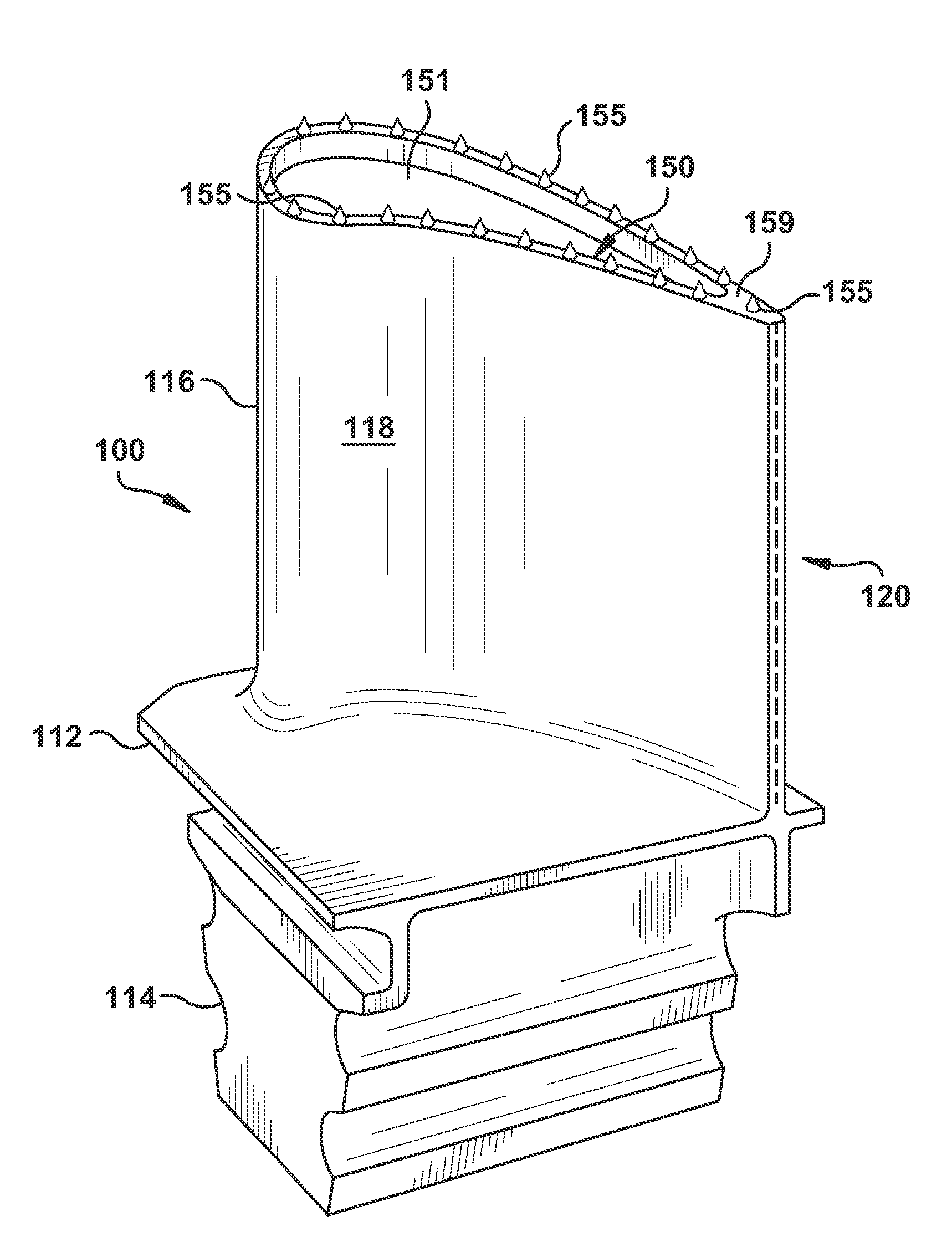

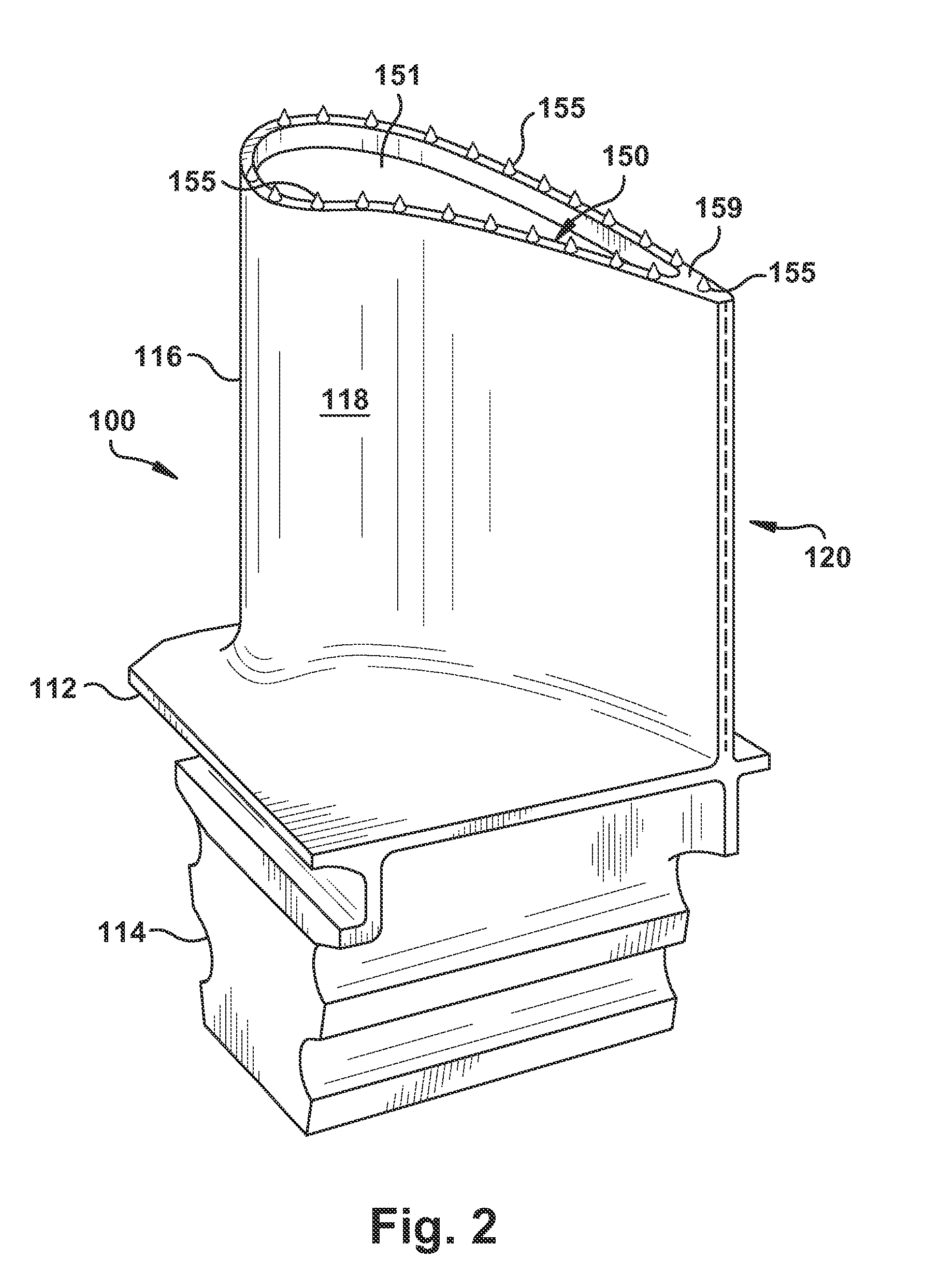

Turbine buckets wtih high hot hardness shroud-cutting deposits

Turbine buckets include a pressure side, a suction side opposite the pressure side, and a bucket squealer tip attached to the pressure side and the suction side. The bucket squealer tip includes a plurality of high hot hardness shroud-cutting deposits deposited on its exterior surface that have a hardness of at least about 1100 kg mm−2 and a melting temperature of at least about 1500° C.

Owner:GENERAL ELECTRIC CO

Heat-resisting steel plate

InactiveCN104449260AExcellent heat resistance temperatureGood solvent resistanceAnti-corrosive paintsPolyester coatingsSurface layerHeat resistance

The invention discloses a heat-resisting steel plate. The heat-resisting steel plate is prepared by sequentially coating a pre-coated steel plate with a base-layer coating and a surface-layer coating and baking, wherein the surface layer of the pre-coated steel plate is coated with the base-layer coating and a base-layer film is formed; and the surface layer of the base-layer film is coated with the surface-layer coating and a surface-layer film is formed. The base-layer coating and the surface-layer coating used in the heat-resisting steel plate are formed by combining organosilicone-modified polyester resin as base materials and other additives; in the heat-resisting steel plate, since the organosilicone-modified polyester resin has the advantages of excellent heat resistance temperature, excellent adhesion and workability to a metal material, excellent solvent resistance and good hot hardness, the organosilicone-modified polyester resin can be sprayed on the surface of the pre-coated metal such as an iron material, an aluminum material or stainless steel and can be widely applied in heat-resistant materials such as baking trays, electric frying pans and barbecue set.

Owner:CHENGDU JINHUI TECH

A hot roller laser restoration method allowing surface hardness after restoration to be 58 HRC or above

InactiveCN106567063APositive effectSmall amount of deformationMetallic material coating processesRestoration methodUltimate tensile strength

The invention relates to a hot roller laser restoration method allowing surface hardness after restoration to be 58 HRC or above. A transition alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of a hot roller. Alloy powder adopted by the transition alloy layer includes components by mass: 0.12-0.19% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5% of C, 3.8-4.3% of Si, 12-13% of B, 2.0-2.45% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.0-3.6% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Carbon-free high-speed steel and preparation method thereof

The invention discloses carbon-free high-speed steel and a preparation method thereof. According to the carbon-free high-speed steel provided by the invention, iron powder is introduced to replace molybdenum powder and cobalt powder, and a small amount of LaB6 is introduced to improve the tempering resistance and red hardness of the material; and through joint addition of La and B, strengthening is caused, austenite transformation is delayed, structure coarsening and desolvation of alloy elements during tempering are inhibited, so that the red hardness and the hot hardness of the Fe-Co-Mo material are improved. Meanwhile, a preparation process is simple, the cost of the raw materials is reduced, the excellent cutter material performance is shown, and a prepared cutter can keep high hardness and is not sticky under the long-time cutting action, and important application value in the industry is achieved.

Owner:XIANGTAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com