Corrosion and wear resistant alloy

A technology of alloy and iron-based alloy, which is applied in metal material coating process, furnace, heat treatment equipment, etc., can solve the problems of decreased matrix strength and hardness, high price of cobalt-based alloy, accelerated wear and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

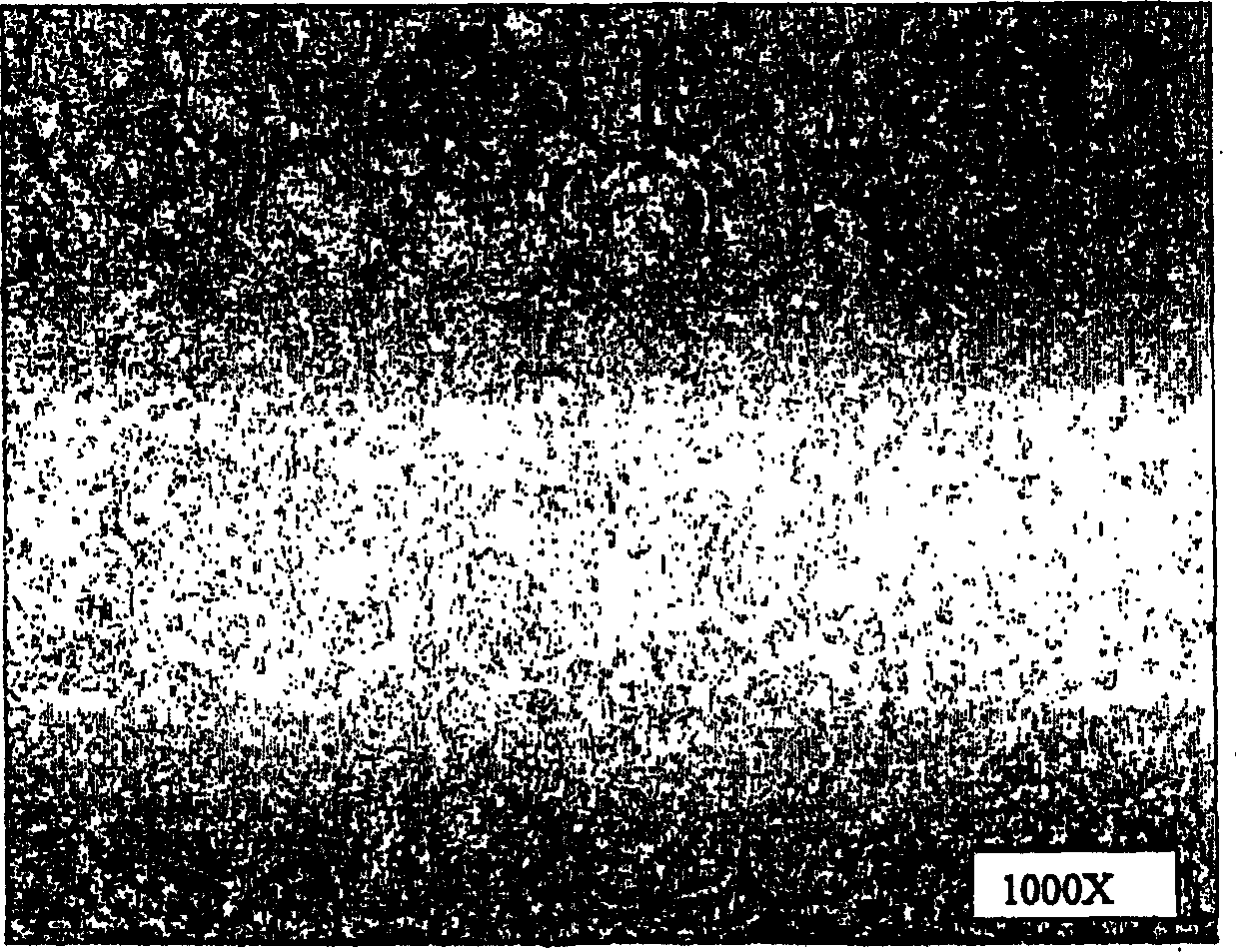

[0050] Alloys having the compositions shown in Table I were cast according to standard casting techniques. Alloy casting into 50 lbs using standard pouring head (3 / 4″ diameter) with SiMn (2 oz / 100 lbs), FeV (3 oz / 100 lbs) and / or CeLa (1 oz / 100 lbs) inoculants Each batch (heat). Experimental Heat A was cast at 2882°F. In the hardened and tempered condition, the microstructure of Heat A included martensite and pearlite. Heat A was cast at 1600°F Hardened at F for about 3 hours, quenched in flowing air and tempered at 1200°F for about 3.5 hours. To improve the oxidation resistance of Heat A, experimental Heat B was prepared with lower C and Mo content (Pouring at 2850°F). Heat B also contains B and Nb to increase hardness after hardening and tempering. In order to obtain an alloy with better toughness than Heat B, a third alloy, the present invention Heat C (cast at 2850°F). Heat C exhibits improved hardness and improved toughness. Heat C is characterized as a low B, high Cr, hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com