Patents

Literature

62results about How to "Improve thermohardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

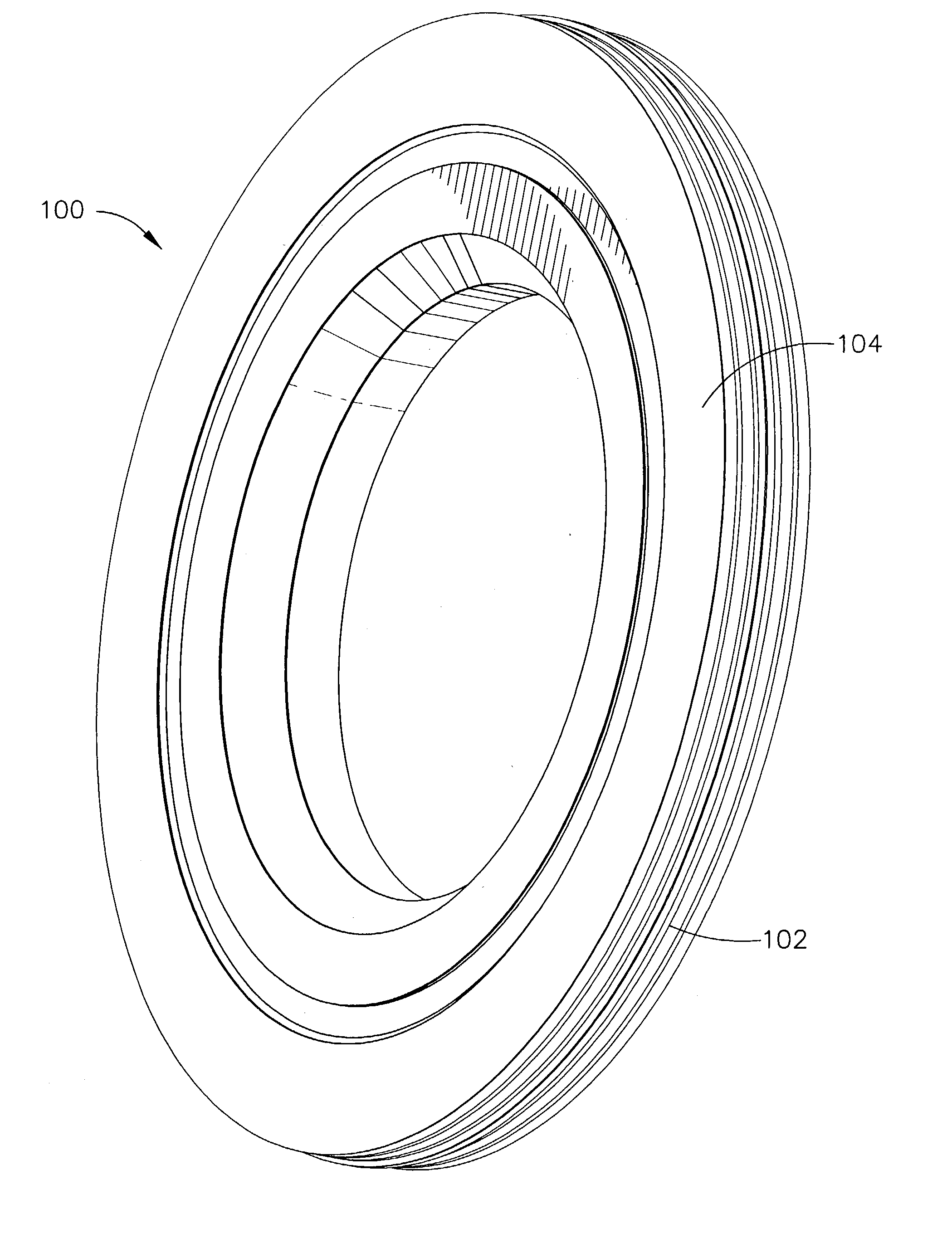

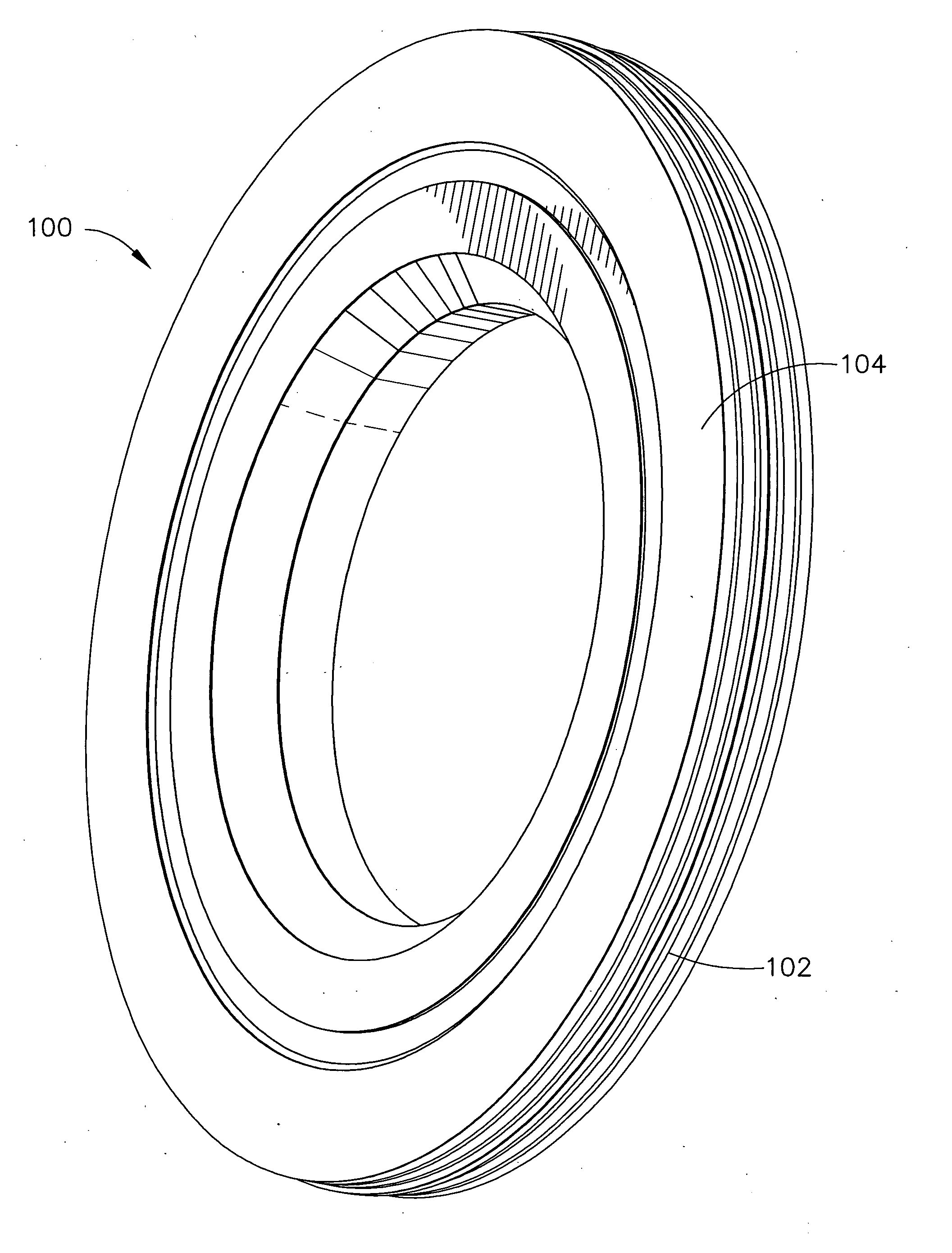

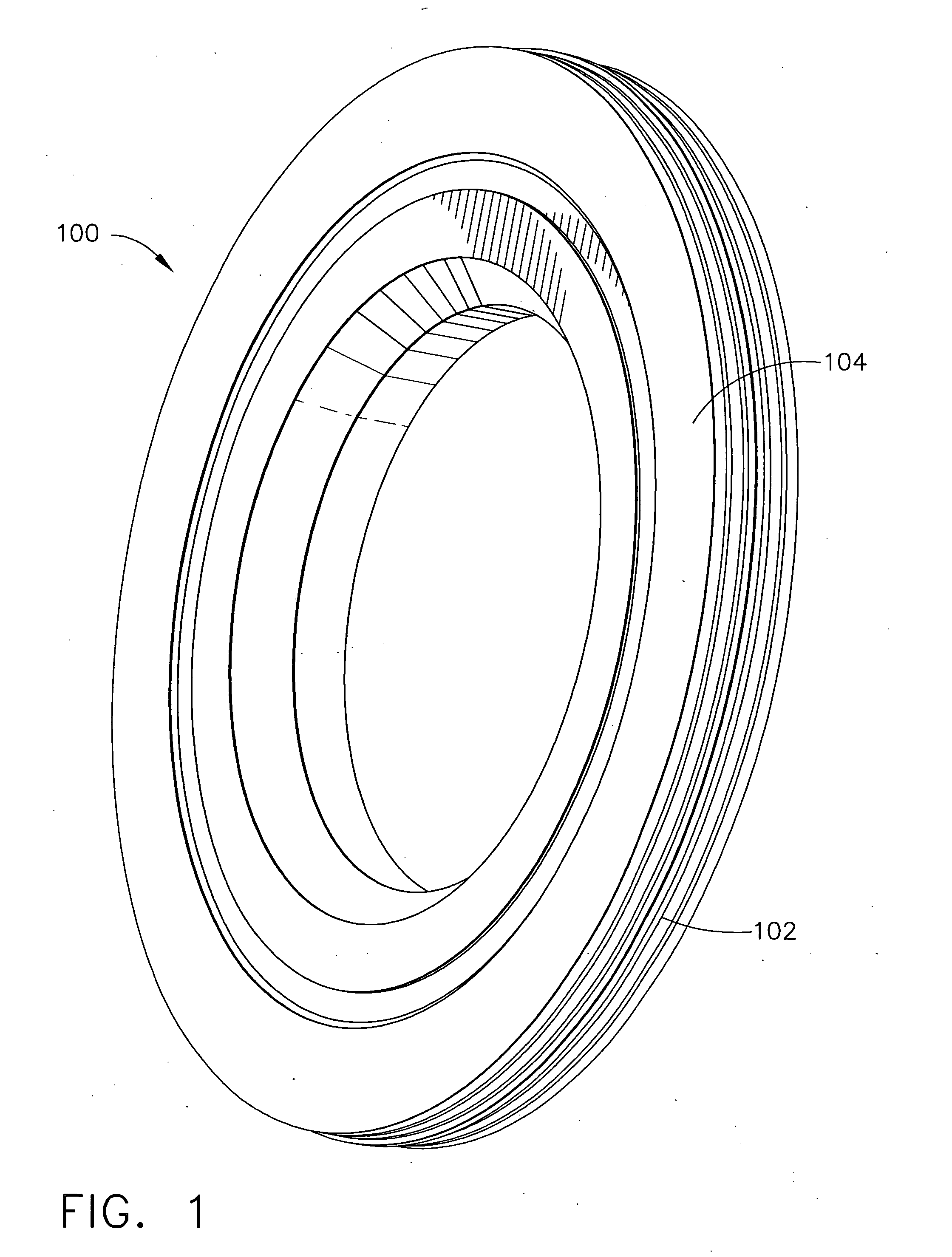

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20030207142A1High to coatingImprove wear resistanceEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

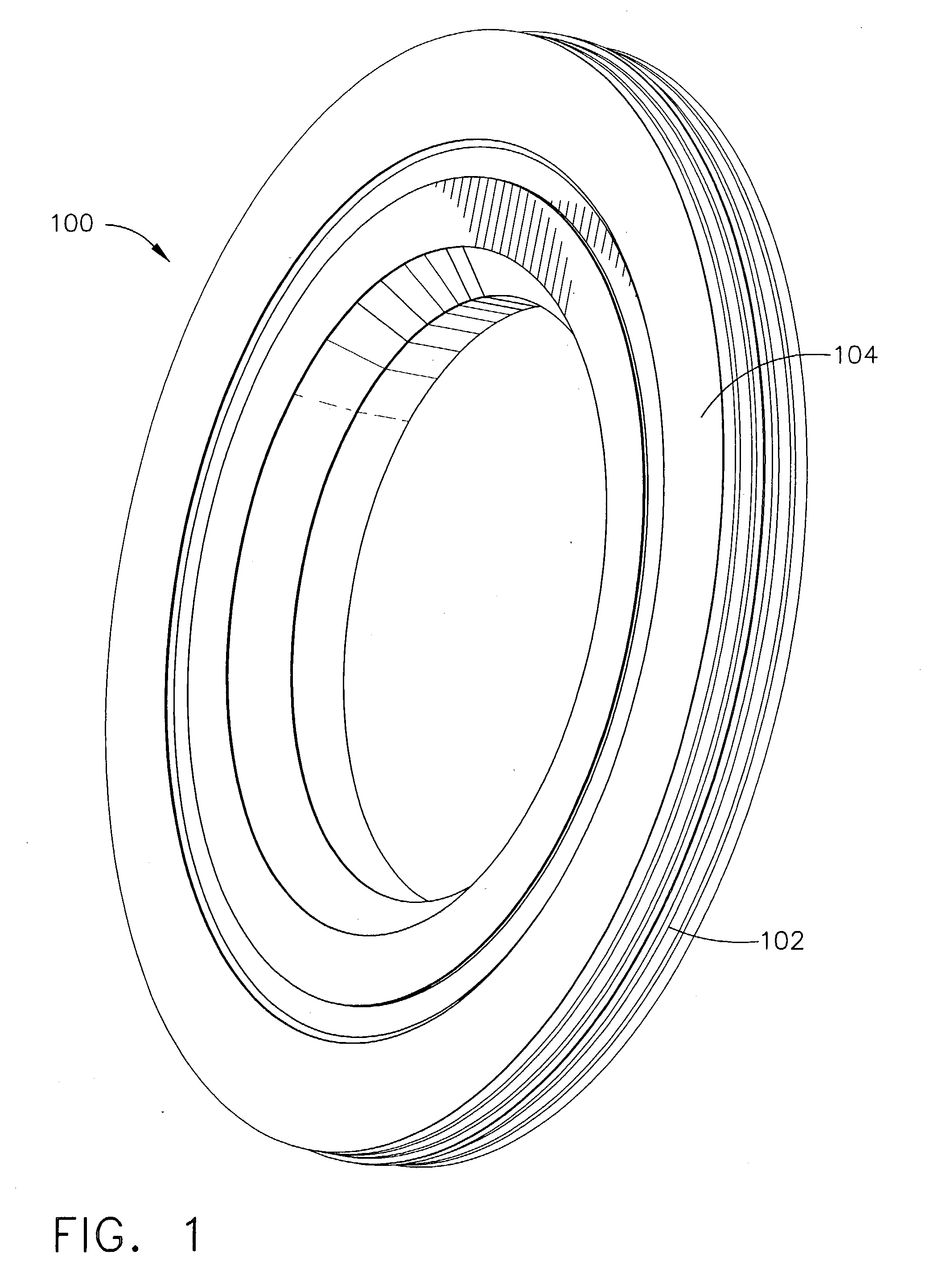

Novel chrome steel high speed steel and heat treatment process thereof

InactiveCN1827825AImprove toughnessImprove wear resistanceHeat treatment process controlQuenching agentsThermal treatmentHigh-speed steel

The invention relates to a novel high-speed alloys steel, in particular a novel chromium series high speed steel and its heat treatment process. The steel comprises the components (by weight percent) of C 0.85%-1.05%, Si 0.2-0.4%, Mn 0.2-0.4%, Cr 9.0-11.0%, W 4.5-6.5%, Mo 0.6-2.0%, V 0.6-2.0%, Ni 0.1-0.3%, Co 0.3-5.0%, Nb 0.8%-1.8%, S <=0.015%, P<=0.02%, and balancing Fe. The high speed steel has enough tenacity and abrasion-resistance, its thermal treatment process is also disclosed.

Owner:周向儒

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS7611590B2Acceptable casting scrap rateGood heat treatment characteristicFurnace typesMachines/enginesWear resistantNiobium

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

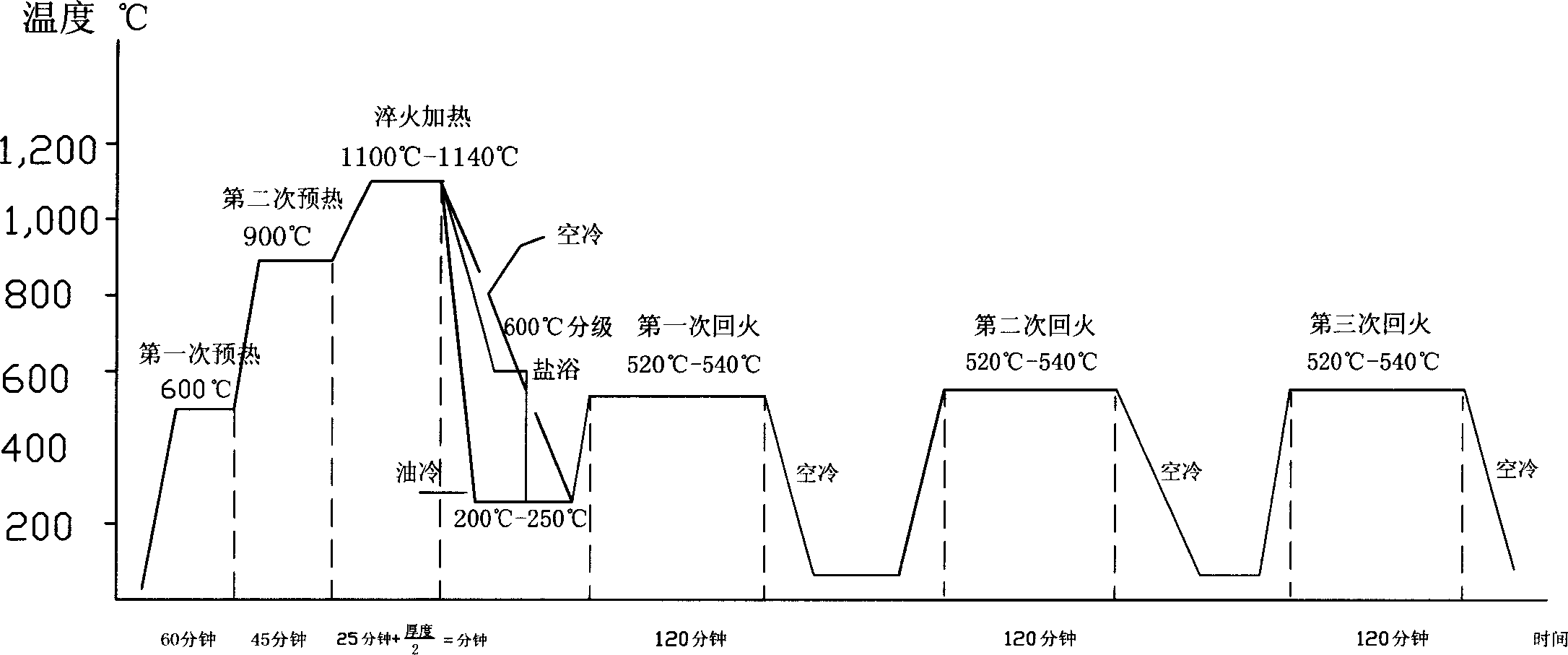

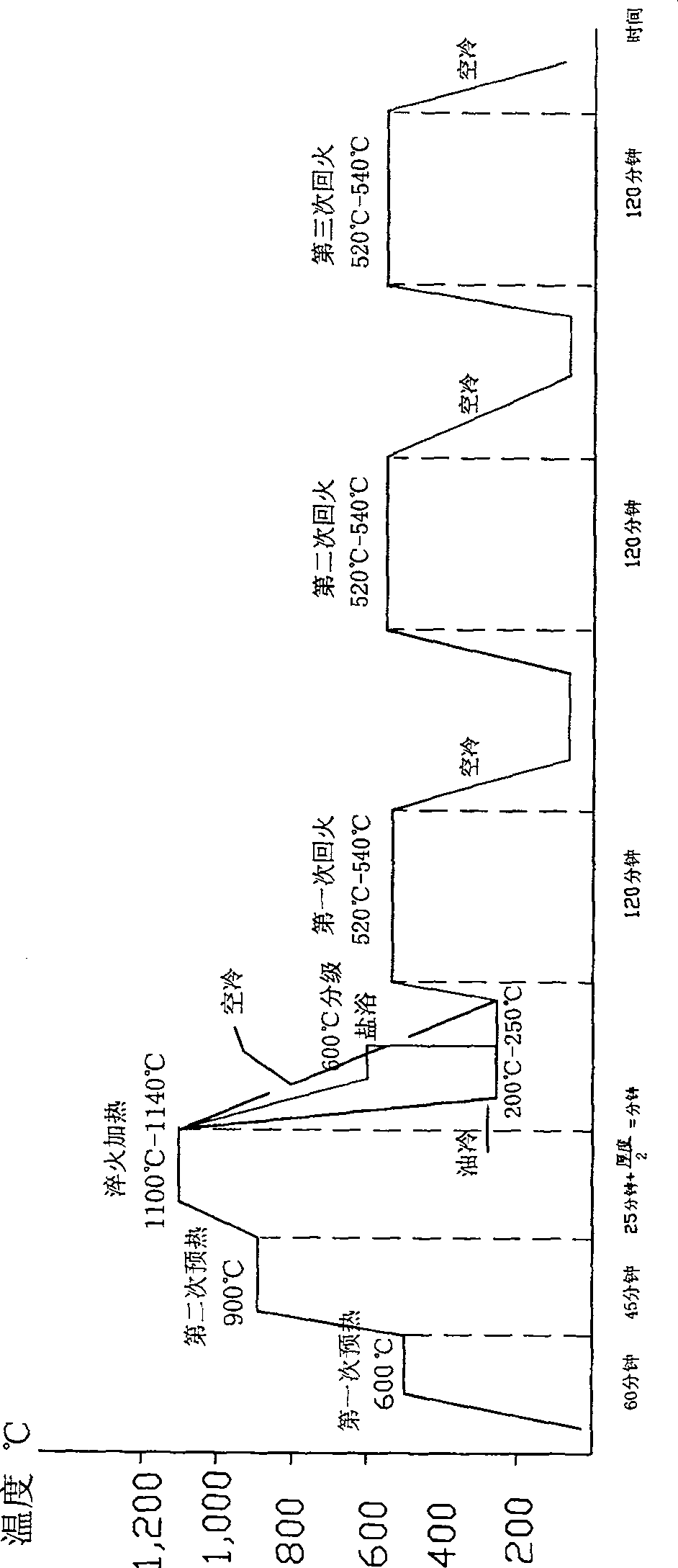

Heat treatment process of high speed steel for cutting tool

The invention discloses a heat treatment process of high speed steel for a cutting tool. The heat treatment process comprises the following steps: (1) heating in stages, to be more specific, in the first stage, heating to the temperature of 550-560 DEG C with the holding time of 20-30 minutes; in the second stage, heating to the temperature of 820-840 DEG C with the holding time of 30-40 minutes, in the third stage, heating to quenching temperature of 1070-1090 DEG C with the holding time of 60-90 minutes; (2) quenching by oil cooling; (3) tempering with the tempering temperature of 505-515 DEG C with the holding time of 90-120 minutes, then cooling by air to room temperature; and performing the tempering treatment for two times by the process.

Owner:WUXI XINSANZHOU STEEL

Wear resistant alloy for valve seat insert used in internal combustion engines

ActiveUS20060283526A1Acceptable casting scrap rateGood heat treatment characteristicMachines/enginesLift valveNiobiumWear resistant

This invention related to a high carbon and high molybdenum / tungsten martenisitic type iron base alloy with excellent hot hardness and wear resistance for making valve seat insert. The alloy comprises of 2.05-3.60 wt % carbon, 0.1-3.0 wt % silicon, 0-2.0 wt % manganese, 3.0-10.0 wt % chromium, 11.0-25.0 wt % molybdenum and tungsten, 0.1-6.5 wt % nickel, 0-8.0 wt % vanadium, 0-6.0 wt % niobium, 0-8.0 wt % cobalt, and the balance being iron with impurities.

Owner:WINSERT

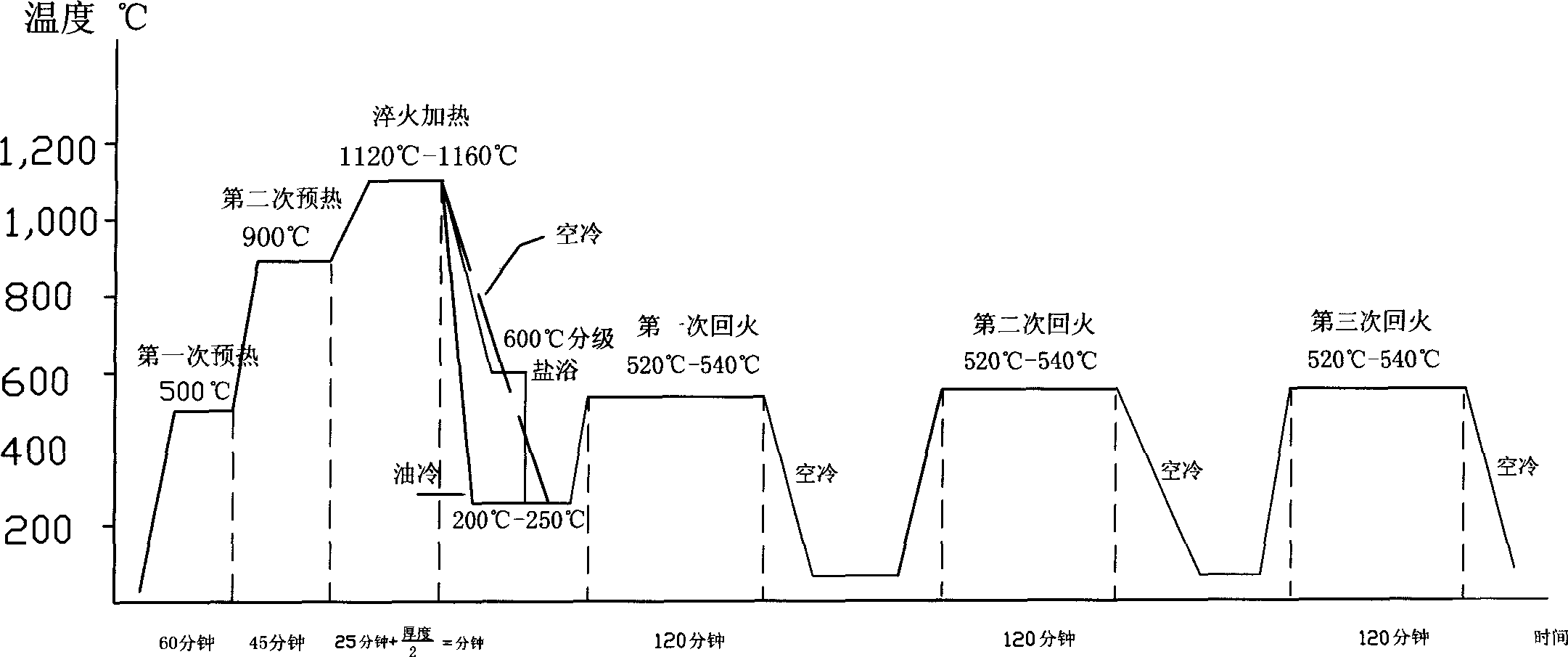

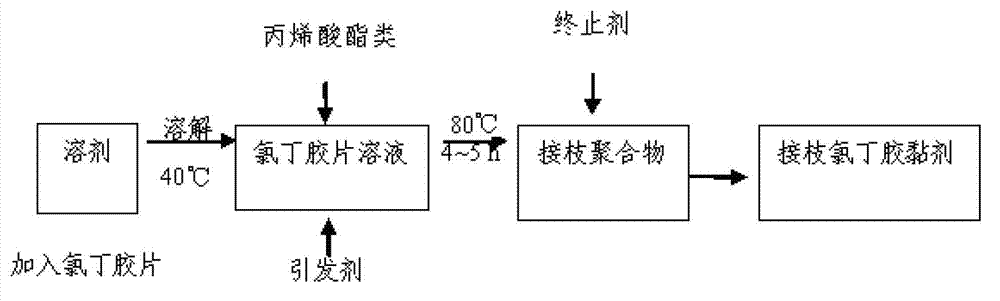

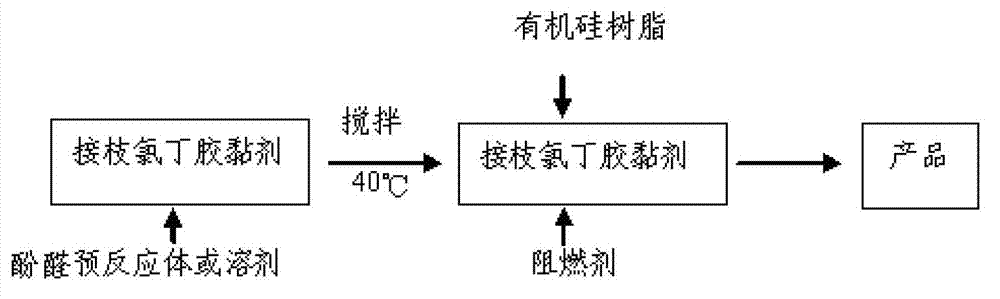

Shield adhesive and preparation method thereof

ActiveCN102898983AGood adhesionImprove high temperature resistanceUnderground chambersAldehyde/ketone condensation polymer adhesivesPolymer scienceAdhesive

The invention relates to a shield adhesive and a preparation method thereof. The shield adhesive comprises the following raw materials by weight: 90 to 110 parts of a chloroprene rubber adhesive, 50 parts of acrylic acid ester, 1 to 3 parts of organosilicon, 40 parts of a phenolic resin, 4 to 8 parts of nanometer magnesium oxide, 100 parts of a solvent, 0.22 to 0.44 part of a catalyst, 1 to 1.5 parts of an initiator, 1 to 1.5 parts of a terminator and 20 to 40 parts of a fire retardant. According to the invention, A90 and A30 are added into the sliced chloroprene rubber adhesive for blending to improve heat resistance of the sliced chloroprene rubber adhesive, and then an obtained mixture and acrylate undergo ternary polymerization. The shield adhesive provided by the invention has high bonding strength and strong high temperature resistance and is applicable to subways, underground roads and tunnels at the bottom of a sea (a river or a lake).

Owner:SUZHOU JINQIANG NEW MATERIALS

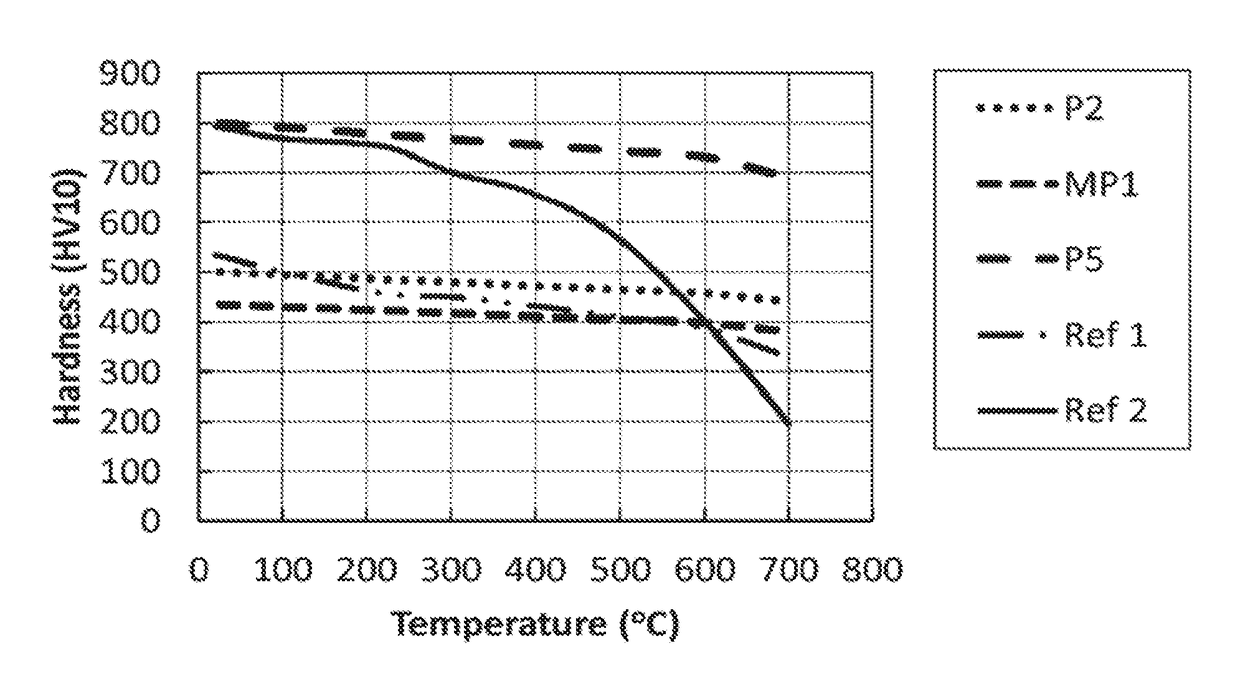

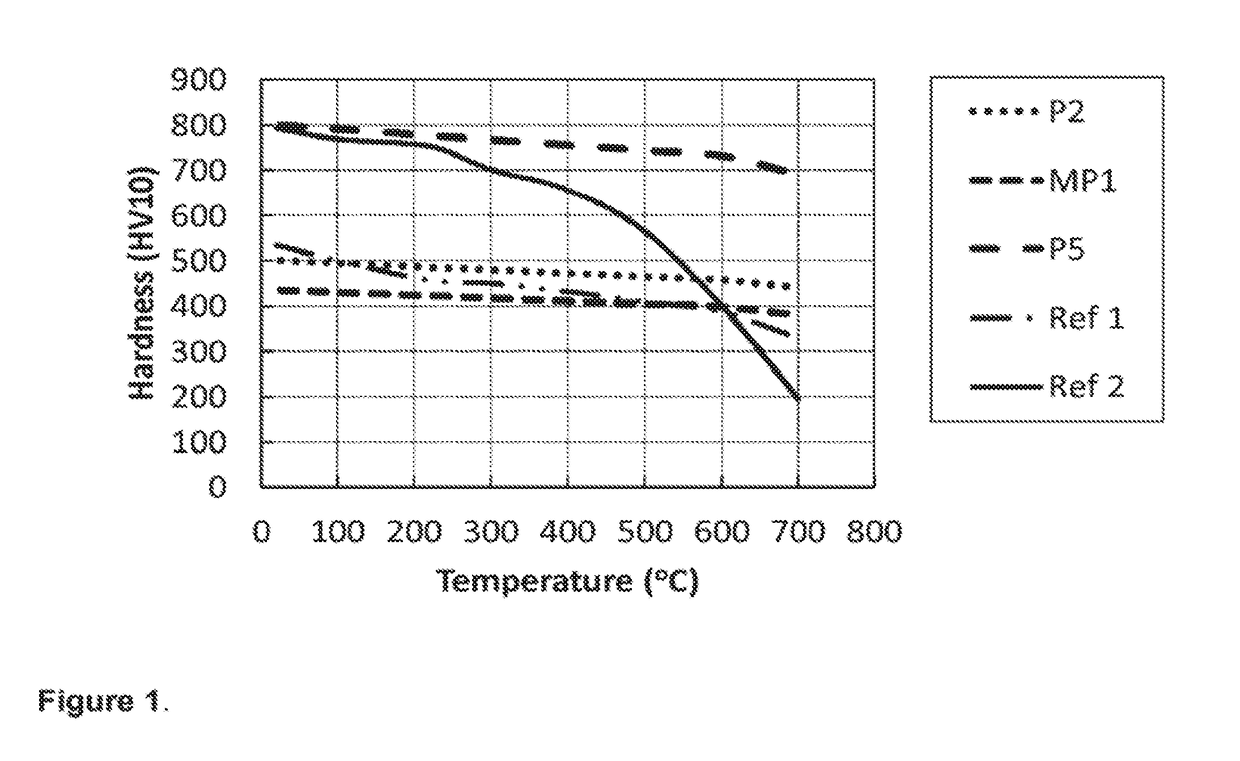

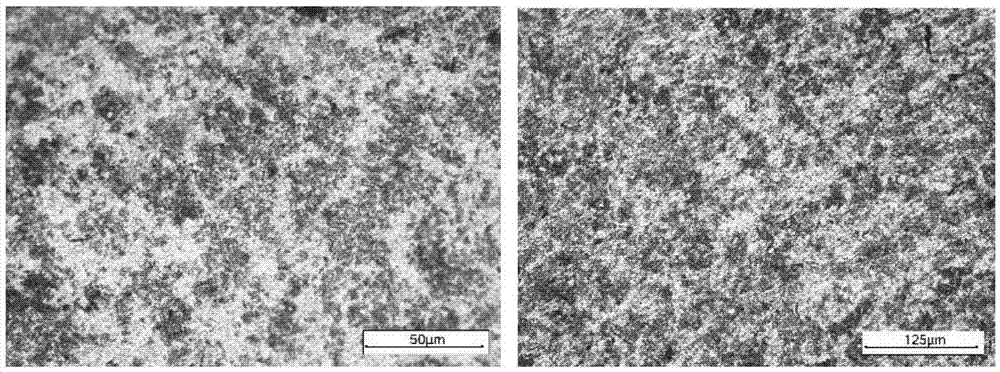

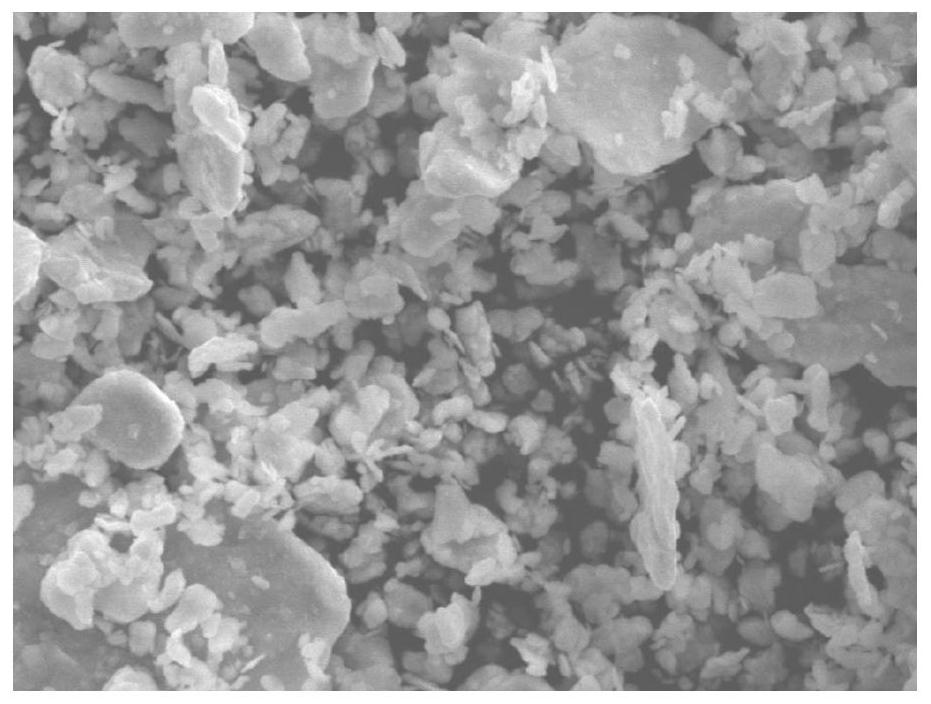

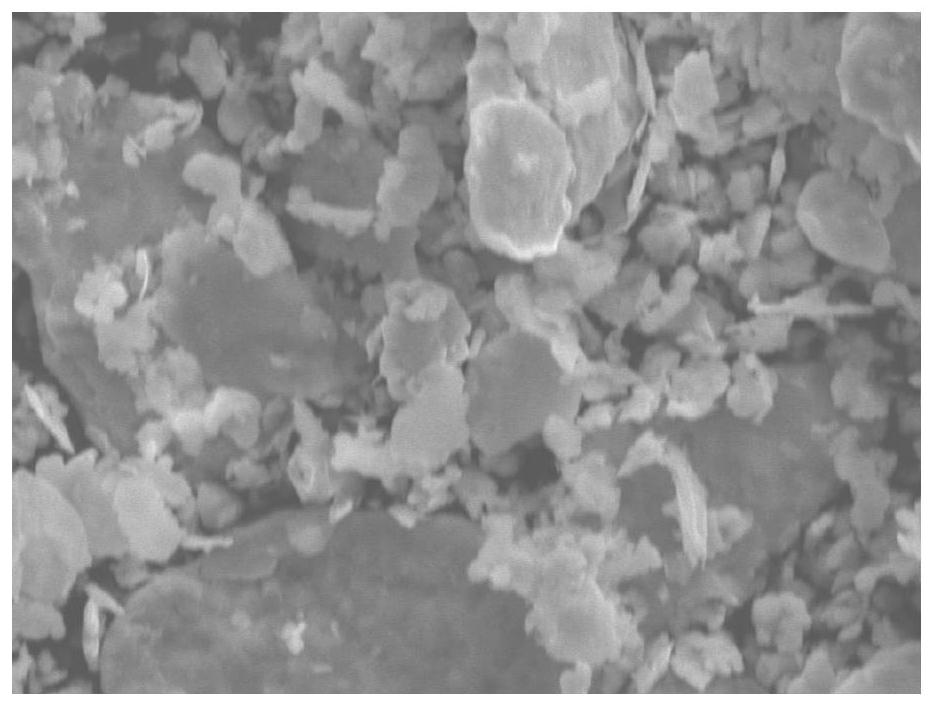

New powder composition and use thereof

ActiveUS20180066343A1Improve thermohardnessHigh heat intensityArc welding apparatusMetallic material coating processesThermal sprayingAlloy

A laser cladding or plasma transferred arc overlay welding process may be used advantageously to apply and to control the material properties of a coating designed for protecting the substrate against wear, corrosion and oxidation at elevated temperature. Furthermore, a laser cladding or plasma transferred arc overlay welding process may be used to apply the coating alloy materials in applications where traditional thermal spray or weld-applied coatings are not practical. By using these welding methods very good bonding is achieved by fusion during welding. At the same time the properties of the clad layer is preserved by the limited dilution typical of these two welding methods compared traditional overlay welding, by e.g. Gas Tungsten Arc Welding and the like.

Owner:HOGANAS AB

Production technique of antifatigue aluminum alloy section

The invention discloses a production technique of an antifatigue aluminum alloy section. The alloy comprises the following elements in percentage by mass: 3.5-4.2% of Cu, 1.2-1.8% of Mg, 0.4-0.8% of Mn, 0.10-0.15% of Zn, 0.1-0.2% of,Sb0.2-0.3% of Ti, 0.35-0.45% of Zr, 0.08-0.12% of Fe, 0.04-0.06% of Si, 0.03-0.05% of Ge, 0.02-0.03% of Bi, 0.04-0.08% of RE, 0.002-0.003% of B and the balance of Al. The contents of Fe, Si and other impurity elements are lowered to improve the fracture toughness, fatigue resistance and stress corrosion resistance of the alloy; and the rare earth metal elements, including Pr, Nd and La, in the modifier can form high-thermohardening-property complex component compounds in the aluminum alloy which are reticularly distributed on the grain boundary or among the dendrite, thereby refining the structure, effectively preventing the base transformation and movement of crystal boundaries, and further obviously enhancing the high temperature properties of the alloy.

Owner:ANHUI HUANYU ALUMINUM

High-speed steel and heat treatment technique thereof

InactiveCN1824821AImprove toughnessImprove wear resistanceHeat treatment process controlQuenching agentsNiobiumManganese

This invention relates to new style alloy high-speed steel, especially relates to new style chrome steel system high-speed steel and its heat treatment technique. The weight percentage of the elements is that carbon 0.85-1.05%, silicon 0.2-0.4%, manganese 0.2-0.4%, chrome 9.0-11.0%, tungsten3.5-4.5%, molybdenum 0.6-2.0%, vanadium 0.4-2.0%, nickel 0.1-0.3%, cobalt 0.3-5.0%, niobium 0.8-1.8%, sulfur not more than 0.015%, phosphor not more than 0.02%, the rest is iron. Compared to home made die steel, the toughness and wear resistance of the high-speed steel in this invention is enough, it can be used to make all kinds of cold die, cutting tool, cutlery, and the production cost is low. This invention also provides the heat treating technique of the high-speed steel.

Owner:周向儒

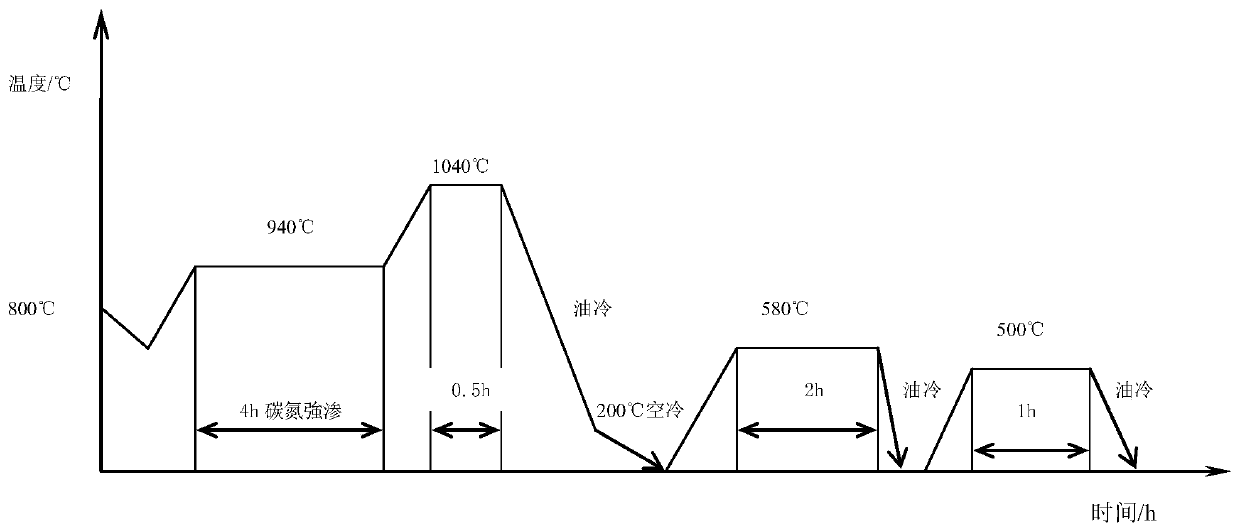

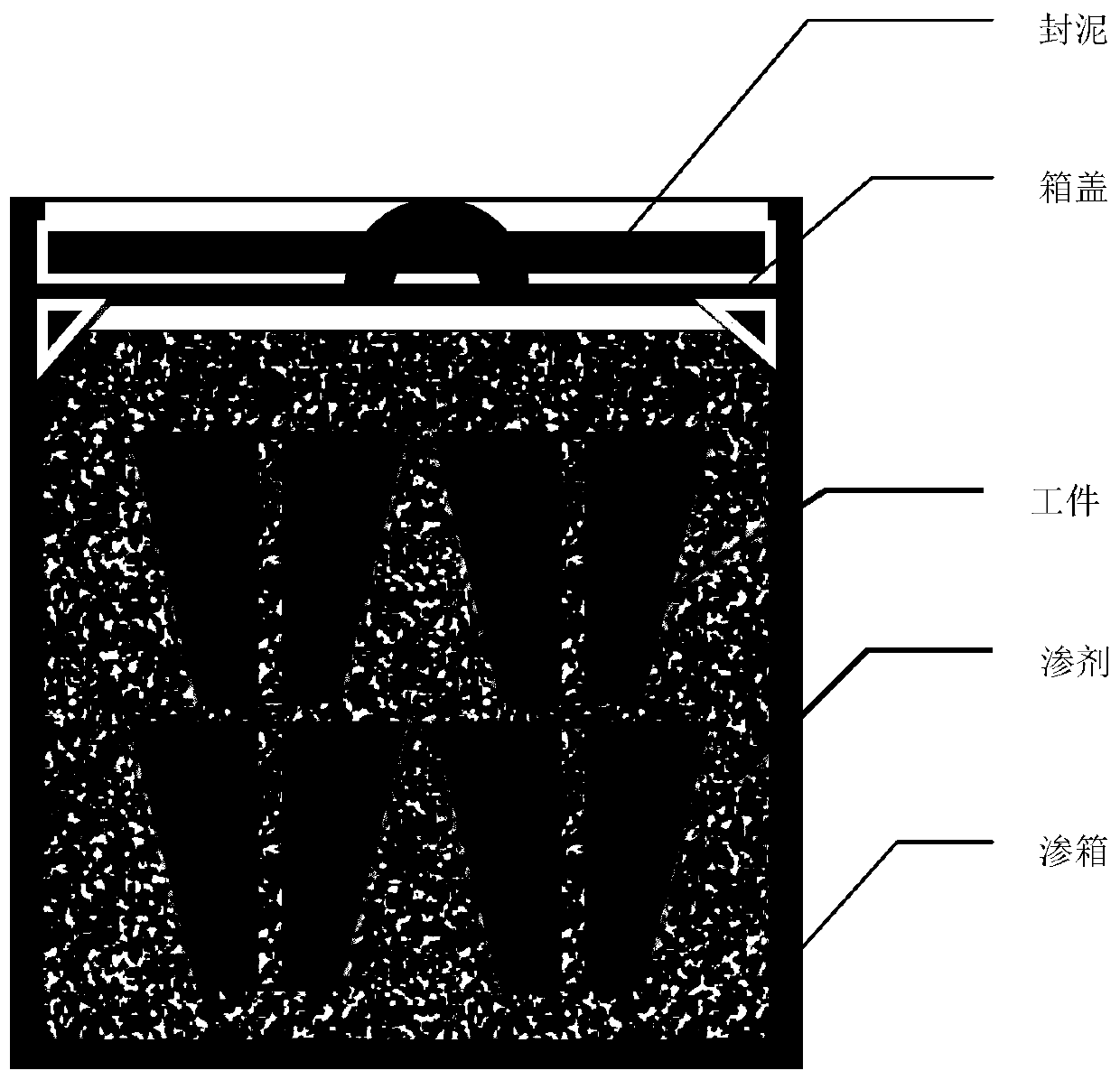

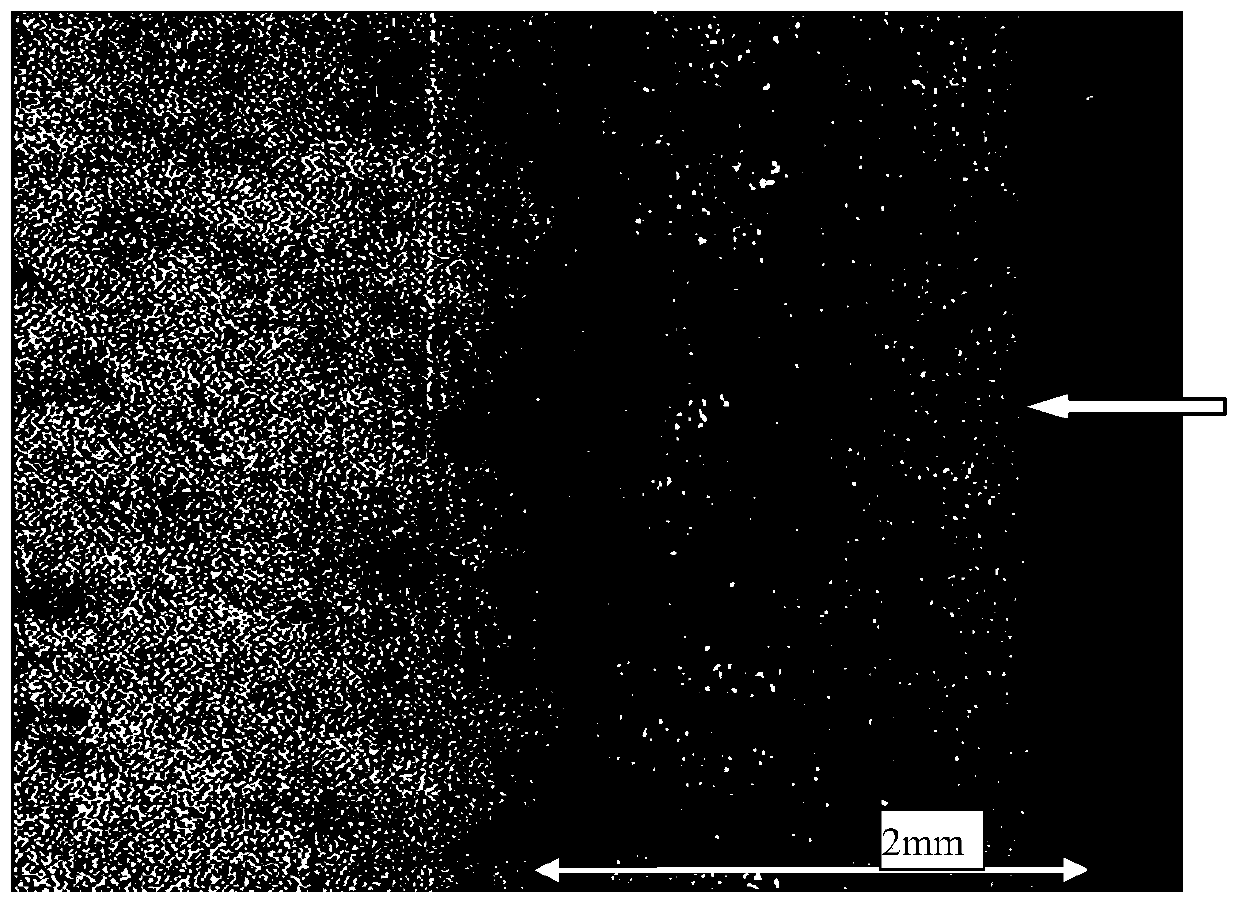

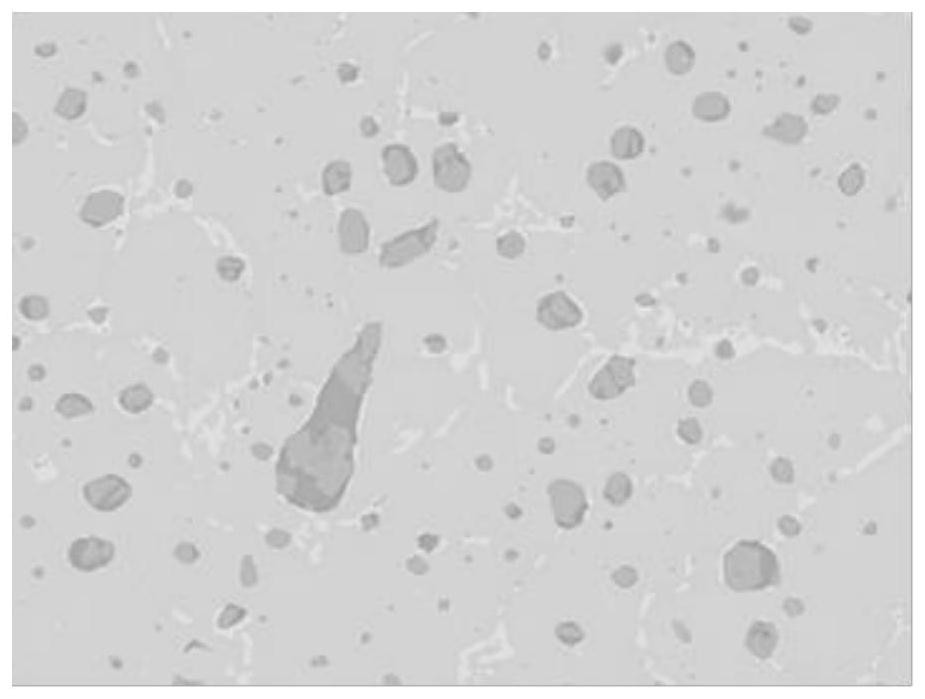

Heat treatment process improving hot hardness and high temperature abrasion resisting performance of hot mold steel

ActiveCN110565048AExtend high temperature service lifeSimple methodSolid state diffusion coatingHigh-temperature corrosionHeat treated

The invention provides a heat treatment process improving the hot hardness and the high temperature abrasion resisting performance of hot mold steel. Charcoal, urea particles, sodium carbonate powderand chromic anhydride are mixed to obtain a carbon-nitrogen strong permeating mixture; a hot mold steel workpiece and the carbon-nitrogen strong permeating mixture are installed in a permeating box atthe same time, and a box cover of the permeating box is sealed; the permeating box is placed into a crucible type electric furnace to be subjected to constant temperature carbon-nitrogen strong permeating at 850-950 DEG C; after quenching treatment, the hot mold steel workpiece is directly immersed into quenching oil to be cooled; and after air cooling, placing into a box type intermediate temperature tempering furnace for tempering twice is performed, and the hot mold steel workpiece high in hot hardness and high in high temperature abrasion resisting performance is obtained. The heat treatment process has the advantages of being easy and convenient to operate, low in cost and obvious in effect, the surface hardness of the obtained hot mold steel can reach 62 HRC or above, the high temperature abrasion resisting performance under the temperature of 600 DEG C exceeds that of a same hot mold steel conventional heat treatment piece twice or above, and the service life of a hot working mold can be effectively prolonged.

Owner:锦州捷通铁路机械股份有限公司

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20050175840A1Improve thermal conductivityHigh stressEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

Heat-resistant aluminum alloy containing Mo-Be and preparation method of heat-resistant aluminum alloy containing Mo-Be

The invention discloses a heat-resistant aluminum alloy containing Mo-Be and a preparation method of the heat-resistant aluminum alloy containing Mo-Be and belongs to the field of metal material engineering. The heat-resistant aluminum alloy containing Mo-Be is prepared from, by mass percent, 6%-7% of Cu, 0.5%-0.7% of Mn, 0.5%-0.7% of Ni, 0.3%-0.4% of Cr, 0.3%-0.4% of Be, 0.3%-0.4% of Mo, 0.2%-0.3% of V, 0.15%-0.25% of Ti, 0.01%-0.015% of B, 2.5%-3% of Ce, 1.5%-2% of La and the balance Al and inevitable impurities. The preparation method includes the steps that firstly, an aluminum and chromium intermediate alloy is molten, after other intermediate alloys and aluminum are added, a covering agent is added, slag is pushed aside after heat preservation, an aluminum refining agent is added, and slag is separated after heat heat preservation; secondly, casting is performed; and thirdly, cast blanks are subjected to solid solution and aging treatment. According to the alloy, due to multi-element alloying, the component range of the alloy is adjusted, high-temperature strength and high-temperature lasting performance of the alloy are remarkably improved after heat treatment, and the highest transient tensile strength reaches 260 MPa-270 MPa at 250 DEG C. Tensile strength ranges from 233 Mpa to 238 Mpa after heating is performed at 200 DEG C for 200 h, and tensile strength ranges from 187 Mpa to 195 Mpa after heating is performed at 250 DEG C for 200 h.

Owner:LIAONING TECHNICAL UNIVERSITY

Iron-based powder metallurgy self-lubricating CNG engine valve seat ring high in tensile strength and manufacturing method thereof

InactiveCN106623906AHigh strengthIncrease frictionTransportation and packagingMetal-working apparatusFiberMetal particle

The invention discloses an iron-based powder metallurgy self-lubricating CNG engine valve seat ring high in tensile strength. The iron-based powder metallurgy self-lubricating CNG engine valve seat ring is prepared from, by weight, 6.3-6.5 parts of chrome, 4.3-4.5 parts of cobalt, 0.6-0.9 part of nickel, 1.6-1.9 parts of zirconium, 2.8-3.2 parts of vanadium, 15-18 parts of copper, 0.9-1.2 parts of nanometer molybdenum disulfide, 0.5-0.7 part of tungsten disulfide, 0.3-0.6 part of carbon nano tubes, 1-2 parts of silica fume, 0.1-0.3 part of sodium pyrosulfite, 1.6-1.8 parts of steel fibers, 3-4 parts of polyimide resin powder, 2-3 parts of micro wax powder and 66-69 parts of iron. According to the iron-based powder metallurgy self-lubricating CNG engine valve seat ring, a layer of copper film is laid on the surface of the modified nanometer molybdenum disulfide, the modified nanometer molybdenum disulfide coated with the copper film serves as a solid lubricating agent and is added into a base material, meanwhile, the tungsten disulfide, the zirconium, the vanadium and the like are added, the metal particle phase change is changed through sintering, cast infiltration and the hot treatment technique, and the obtained product is high in tensile strength and fatigue resistance, resistant to oxidation and low in cost.

Owner:安徽马仪科技股份有限公司

Powder-metallurgic valve seat ring of CNG engine

InactiveCN106567005AHigh densityOptimizing Metal Phase TransitionsFurnace typesMachines/enginesNitrogen gasWear resistance

The invention discloses a powder-metallurgic valve seat ring of a CNG engine, which is composed of, by mass, 3.5-4.5% of Co, 12-15% of Cu, 6-7.5% of Mo, 0.5-1.2% of Ni, 4.5-5.5% of Cr, 2.5-3.5% of W, 0.2-0.3% of Y2O3, and the balanced being a base material, iron. The valve seat ring is produced through the process of solid phase alloying sintering, wherein nitrogen gas and cracked ammonia gas are fed as a protective atmosphere. A copious cooling tempering process is used in thermal treatment. The valve seat ring is improved in toughness, wear resistance, thermal hardening property, thermal conductivity and coefficient of linear expansion under constant high temperature. Density of the valve seat ring is improved by controlling effective sintering temperature and sintering rate.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

High-conductivity abrasion-resistant coating for guide rail and preparation technology thereof

ActiveCN106282884AImprove thermohardnessHigh hardnessMolten spray coatingFailure rateChemical composition

The invention relates to a high-conductivity abrasion-resistant coating for a guide rail and a preparation technology thereof. The coating comprises the following chemical components by content: 45 to 55% of Mo, 15 to 25% of Cu, 6 to 10% of Cr, 1 to 3% of B and 2 to 4% of Si, and the balance being Ni. The preparation technology comprises the steps like surface down cutting of the to-be-coated guide rail, surface cleaning of the guide rail, shield protection, sand-blasting roughening, coating preparation and coating grinding processing. The preparation technology is characterized in that a high-speed plasma spraying technology is adopted, a uniform and compact large-thickness, high-conductivity and abrasion-resistance coating can be prepared on the surface of an electromagnetic railgun launching guide rail, the thickness of the grinded coating is 1.0 to 1.1 mm, the bonding strength of the coating and the guide rail is 20 to 35 MPa, the microhardness of the coating is 450 to 600 HV, and the electric conductivity is 5 to 12% IACS. The obtained high-conductivity abrasion-resistant coating is mainly used in special parts like the electromagnetic railgun launching guide rail, the surface hardness, abrasion resistance and electrical erosion resistance of the guide rail can be effectively improved, the service life is prolonged, the thermal hardness of the surface of the guide rail is improved, the failure rate of grinding is decreased, and the coating has important engineering application value.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

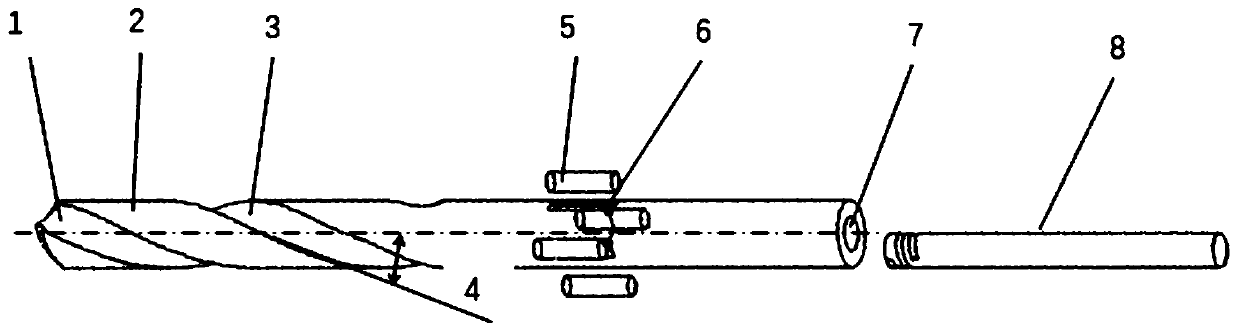

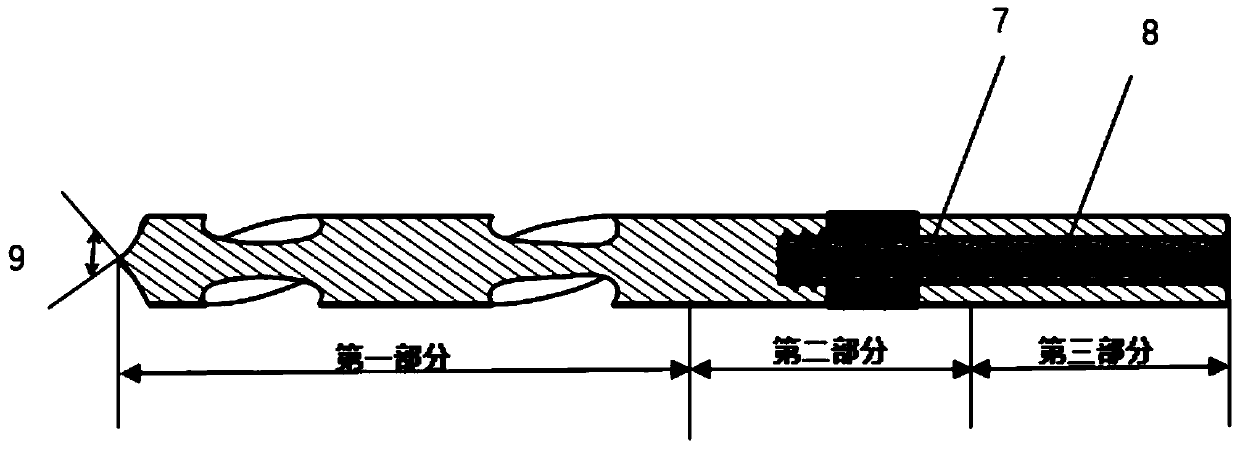

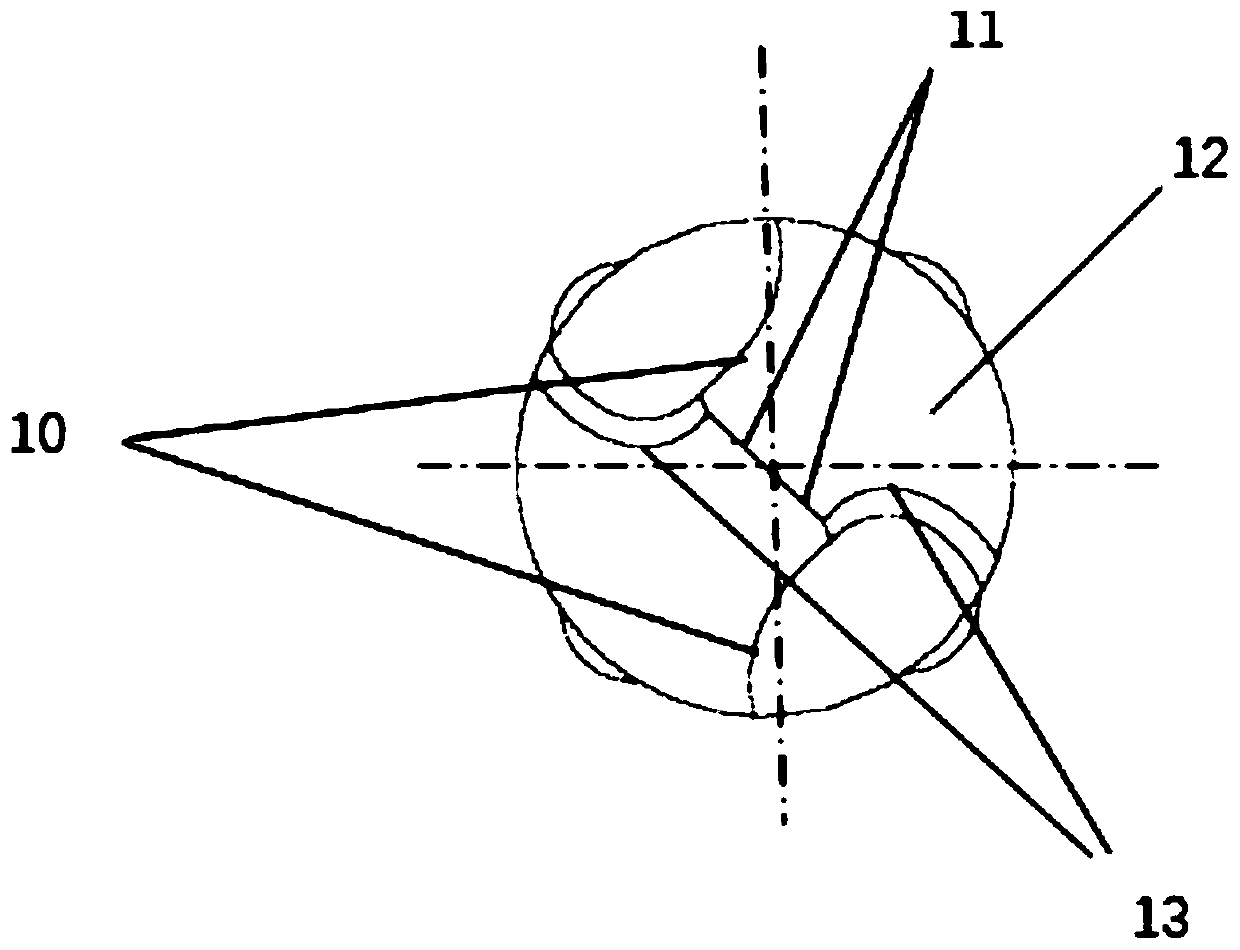

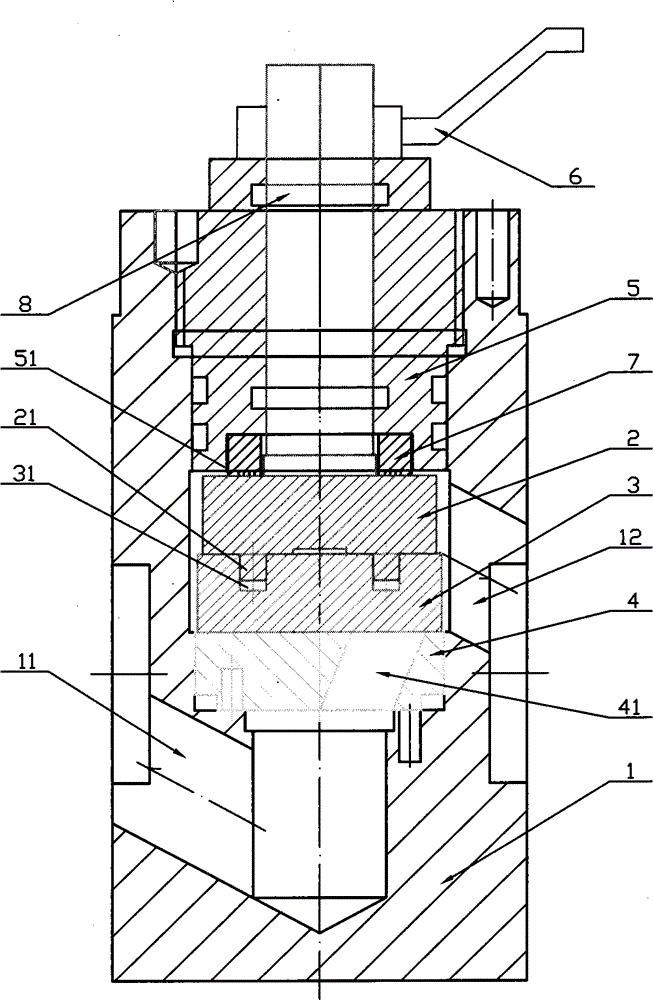

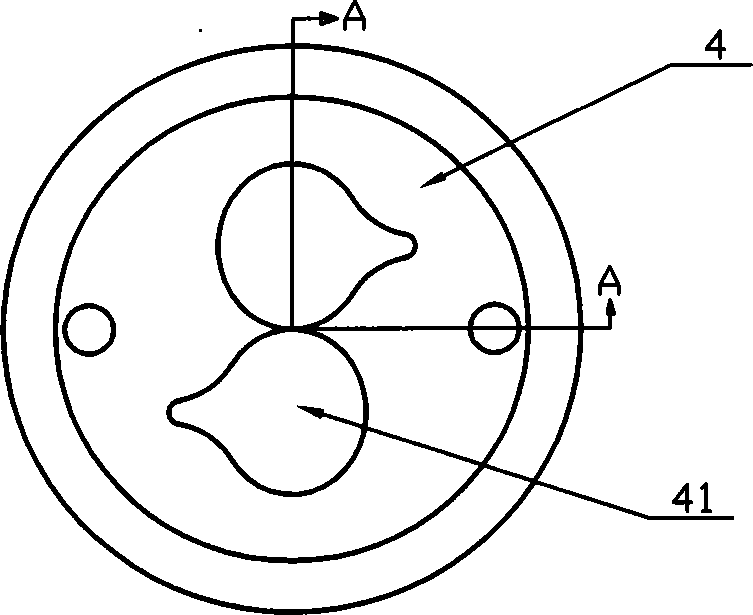

Drilling and rolling combined forming cutter

InactiveCN110560753AImprove wear resistanceEffective protectionTransportation and packagingWorkpiecesFeeding forceWave shape

The invention belongs to the field of drilling tools, and relates to a drilling and rolling combined forming cutter. The drilling and rolling combined forming cutter comprises three parts, wherein thefirst part is a drill bit, the second part is a rolling cutter, the third part is a handle, and the three parts are sequentially connected; a drill tip part of the drill bit is provided with two transverse edges; a main cutting edge of the drill tip is a wave-shaped edge, preeminent sharpness and strength are achieved, and chips are discharged more smoothly; two auxiliary cutting edges are arranged on the main rear cutter surface; and two cutting grooves with cylindrical spiral structures are formed in a drill bit body. According to the drilling and rolling combined forming cutter, drilling and rolling are simultaneously machined, so that the number of the machining procedures is reduced, the machining time is shortened, and the machining efficiency is greatly improved; through the optimized groove-shaped structure and the wave-shaped cutting edges, the preeminent sharpness and strength are achieved, and the chips are discharged more smoothly; and the top angle of 140 degrees reducesthe feeding force at the initial stage of drilling and provides excellent self-centering capability, so that the hole machining quality is improved, the hot hardness is improved, and the chip accumulation is prevented.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Novel high-speed steel

The invention relates to a novel high-speed steel. The novel high-speed steel comprises, by weight, 0.9 to 1.2% of C, 0.21 to 0.5% of Si, 0.18 to 0.3% of Mn, 9.5 to 12.0% of Cr, 4 to 4.8% of W, 0.55 to 2.2% of Mo, 0.5 to 2.2% of V, 0.05 to 0.2% of Ni, 0.25 to 4.0% of Co, 0.7 to 2% of Nb, no more than 0.01% of S and no more than 0.01% of P, with the balance being Fe. The novel high-speed steel provided by the invention has sufficient toughness and wear resistance, is applicable to preparation of a variety of cold-punching moulds, cutting elements and cutters and is low in production cost.

Owner:重庆展申机械厂

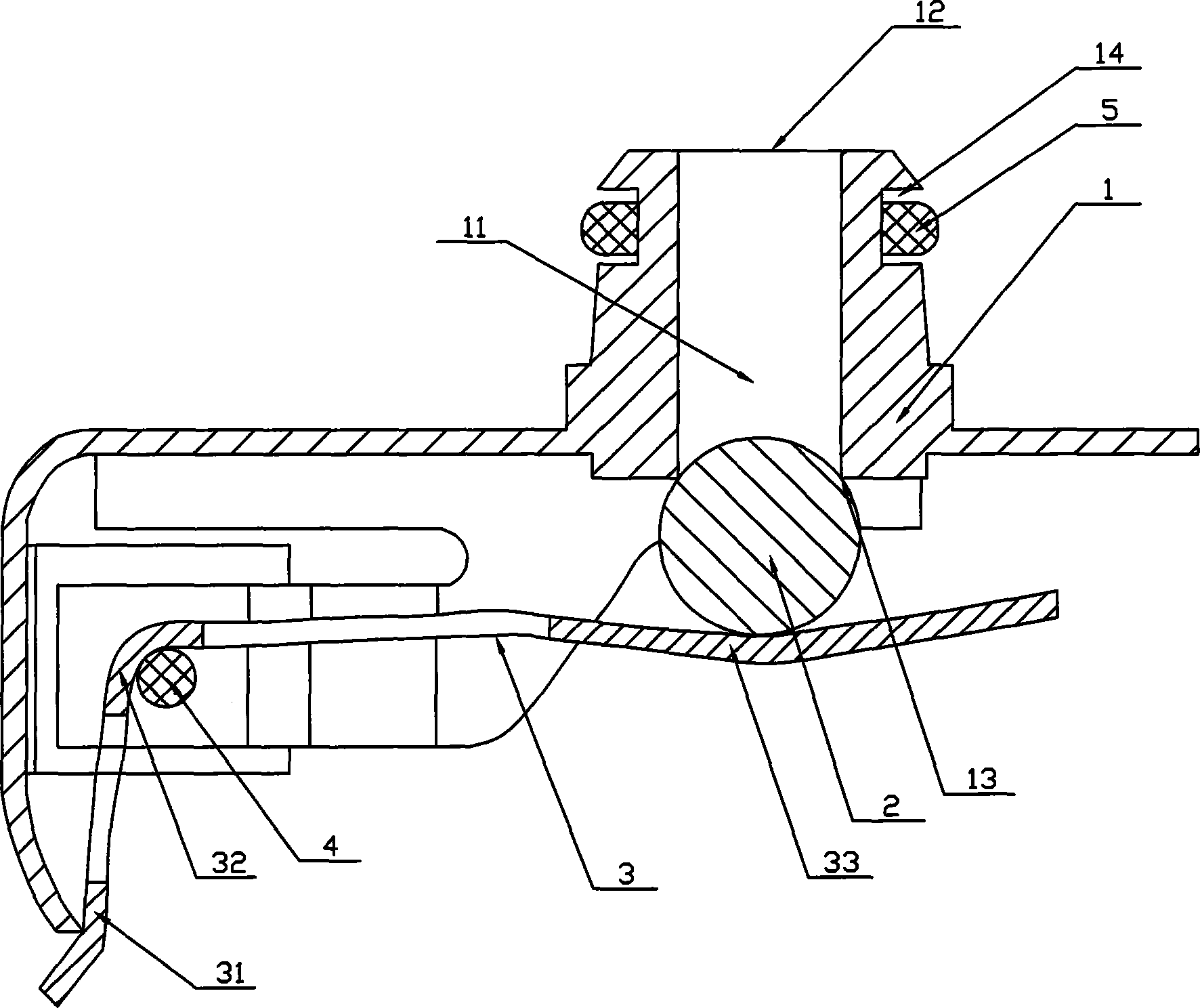

Adjusting-type plug valve

InactiveCN104154254AHigh hardnessImprove fatigue resistanceSpindle sealingsSlide valveEngineeringValve seat

The invention relates to an adjusting-type plug valve which comprises a valve body, a valve rod, a valve core, a valve seat, a valve rod screw plug and a driving handwheel. An inlet runner and an outlet runner are arranged on the valve body, the valve core is fixedly connected at the bottom end of the valve rod, the valve seat is arranged below the valve core in a clingy manner, the valve rod screw plug is arranged on the valve rod in a sleeved manner, the driving handwheel is rotatably connected on the valve rod, each of the inlet runner and the outlet runner of the valve body is arranged obliquely, position of the inlet runner is lower than that of the outlet runner, an oblique through hole capable of being communicated with the inlet runner and the outlet runner is formed in the valve seat and obliques from the middle portion of one end away from the valve core to the outer side of one end close to the valve core, and section shape of the valve core is matched with one side, close to the valve core, of the oblique through hole in the valve seat. The adjusting-type plug valve is simpler in structure and higher in sealability, and has a better flow adjusting function.

Owner:ZHEJIANG MEIDE MASCH CO LTD

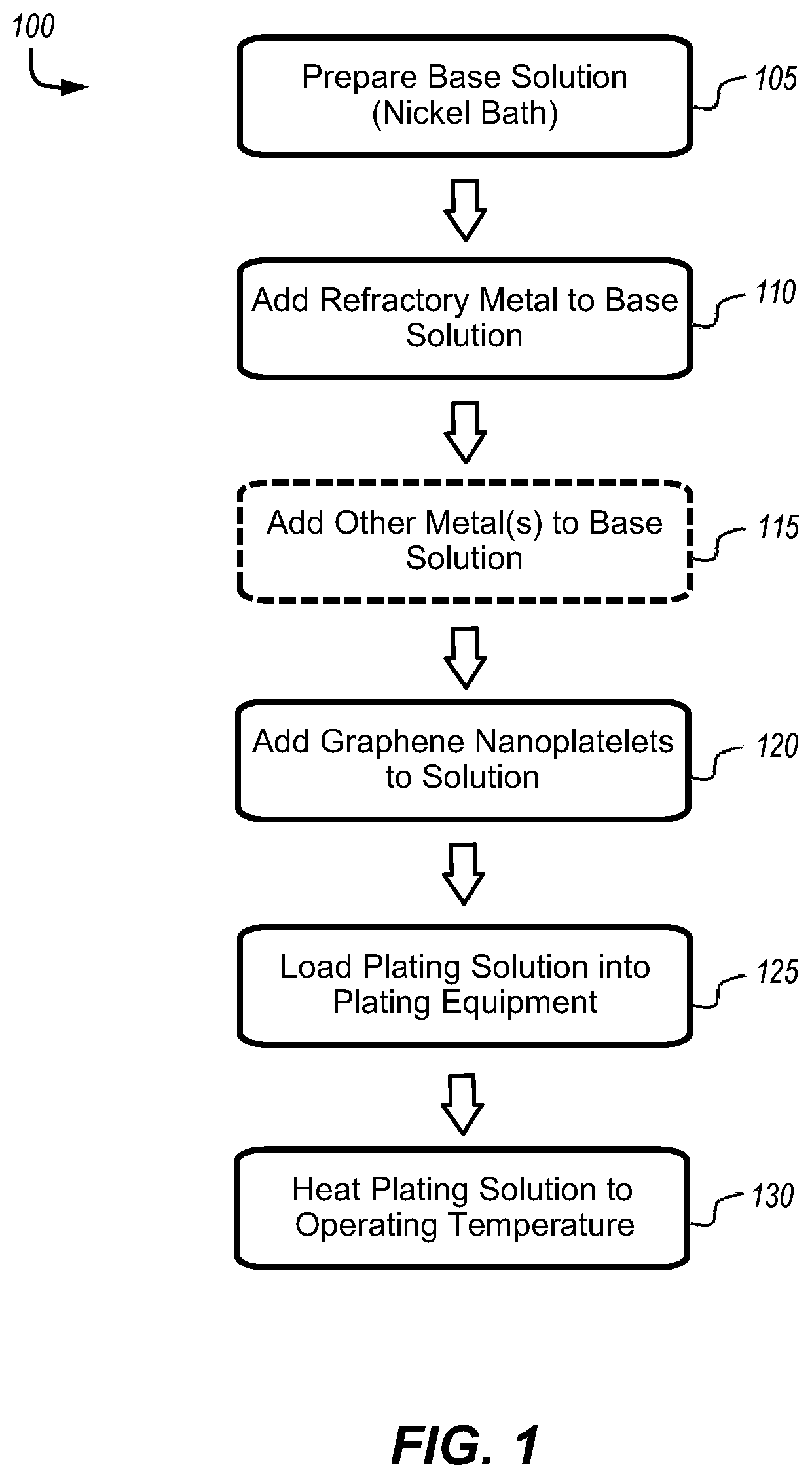

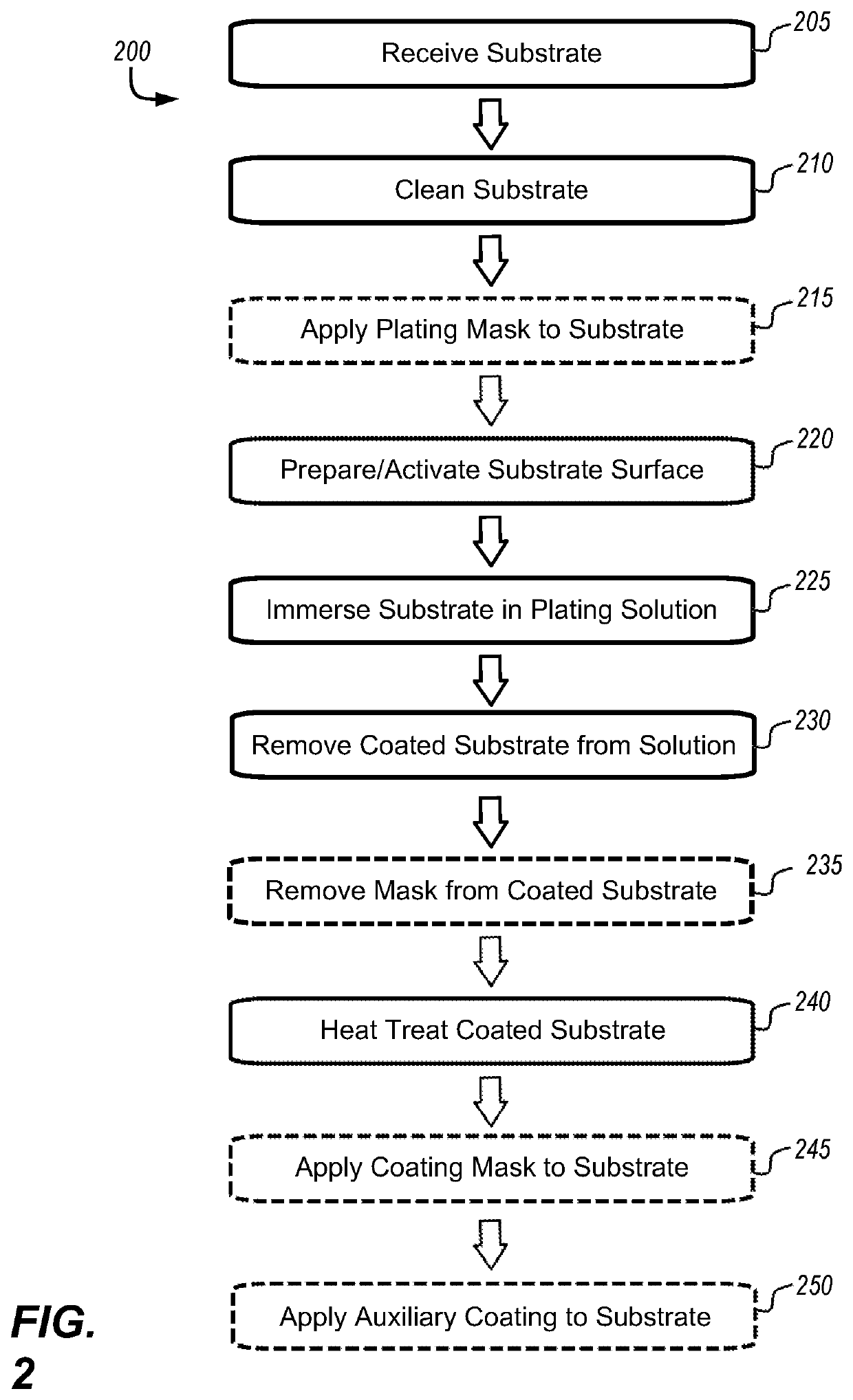

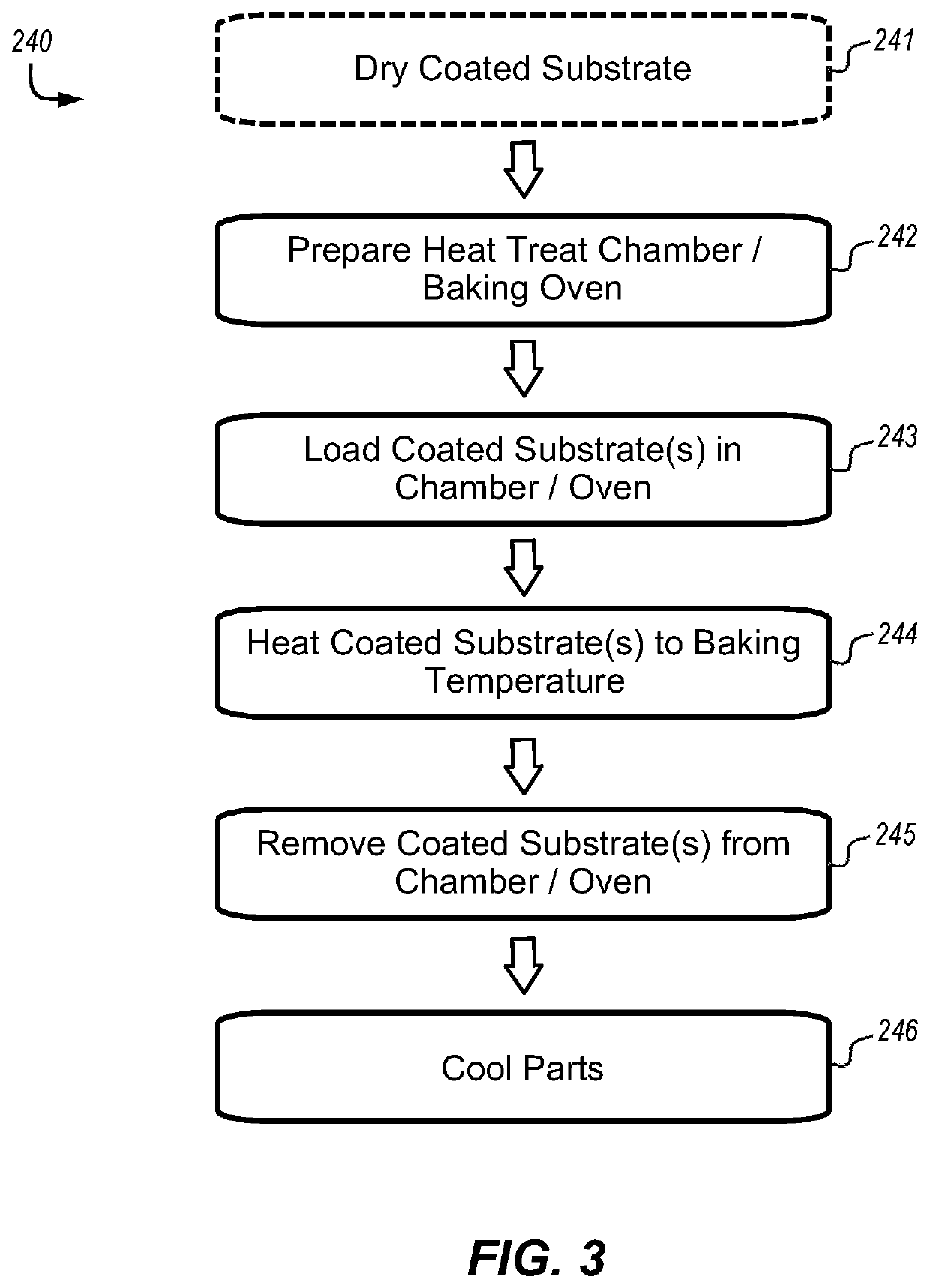

Metallic coating and method

PendingUS20210140050A1Increased microhardnessReduce coefficient of frictionElectrolytic coatingsLiquid/solution decomposition chemical coatingRheniumNiobium

The invention is a metallic coating comprising a first metal, a second metal, phosphorus, and carbon nanoparticles, wherein the carbon is in the form of graphene. In one example, the carbon nanoparticles are selected from a group consisting of graphene nanoplatelets, graphene oxide, and carbon nanotubes. The first metal may preferably be nickel and the second metal may preferably be a refractory metal. The refractory metal may be selected from a group consisting of tungsten, rhenium, molybdenum, niobium, tantalum, and mixtures thereof, and may preferably be tungsten. The metallic coating may include crystallites having a columnar structure. Crystallites comprising the columnar structure precipitate to form grain structures that improve the mechanical strength of the coating through heat treatment.

Owner:PBTT INC

Formula of welding rod coating

InactiveCN105397338ASolve the problem of easy corrosionHigh tensile strengthWelding/cutting media/materialsSoldering mediaFerrosiliconSodium silicate

The invention provides a formula of a welding rod coating. The formula consists of marbles, quartz, ferrosilicon, ferromanganese iron, calcium carbonate, potassium carbonate, sodium silicate, starch, aluminum oxide, cryolite and sodium silicate. The formula has the beneficial effects that: the problem that a welding seam is liable to corrode after a welding rod is used for welding is solved, tensile strength and impact toughness of a welding seam are strengthened, a brittle transition temperature of the welding seam is reduced, thermal hardness of the welding seam is improved, and surface hardness of the welding seam is strengthened. Moreover, the formula is low in production cost, simple in manufacturing process, wide in scope of application and easy to popularize.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Wear-resistant coating for stone roll surface and preparation method thereof

InactiveCN110170436AImprove wear resistanceExtended service lifeSpecial surfacesCoatingsPolyvinyl alcoholWear resistant

The invention relates to the technical field of coatings, and provides a wear-resistant coating for a stone roll surface and a preparation method thereof. The wear-resistant coating solves the problems that an existing stone roll has short service life, the surface of dewatered paper is rough, and the dehydration efficiency is low. The wear-resistant coating comprises a first coating covering theroll surface and a second coating arranged on the first coating, wherein the first coating comprises the following raw materials according to the parts by weight: 65 to 72 parts of alumina, 10 to 15 parts of titanium dioxide, 6 to 8 parts of yttrium oxide, 3 to 7 parts of cobalt, 4 to 6 parts of nickel, 2 to 4 parts of manganese, 2.4 to 3.2 parts of glass powder, 1.2 to 1. 8 parts of artificial diamond, and 1.5 to 2 parts of molybdenum disulfide; and the second coating comprises the following raw materials according to the parts by weight: 48-60 parts of organic silicon resin, 1-3 parts of coupling agent, 1.8 to 2.5 of toughening agent, 3 to 5 parts of silicone oil, 4 to 8 parts of polytetrafluoroethylene, 2.5 to 3.5 parts of polyvinyl butyral, 2 to 7 parts of talcum powder, 0.9 to 1.6 ofantioxidant, 8 to 12 parts of filler, and 15 to 20 parts of trimethyl hexamethylene diamine.

Owner:晋江市兰欣新材料科技有限公司

Leaf spring type constant pressure valve

InactiveCN104373650AAvoid corrosionExtended service lifeEqualizing valvesSafety valvesSteel ballEngineering

The invention discloses a leaf spring type constant pressure valve which comprises a valve base and a steel ball. A constant pressure cavity is formed inside the valve base. The two ends of the constant pressure cavity are provided with an oil inlet and an oil outlet respectively. The steel ball is arranged at the position of an oil outlet of the valve base. A bent leaf spring is installed on the valve base. The leaf spring is composed of a connecting portion, a supporting portion and an abutting pressing portion. The connecting portion of the leaf spring is fixedly connected to the valve base. The supporting portion of the leaf spring is supported on a pin shaft installed on the valve base to form a supporting point of the leaf spring. The abutting pressing portion of the leaf spring is pressed on the steel ball in an abutting mode so that the steel ball and the oil outlet of the valve base can form a sealing state. The leaf spring type constant pressure valve is simple and reasonable in structure, interference caused by the insufficient extending space will not be caused when the size of the valve is decreased, the oil conveying stability can be well kept, the service life of an engine is prolonged, and noise generated by the valve can be greatly reduced.

Owner:温州仁谦汽车油泵有限公司

Fe-Be-contained heat-resisting aluminum copper alloy and manufacturing method of Fe-Be-contained heat-resisting aluminum copper alloy

The invention provides Fe-Be-contained heat-resisting aluminum copper alloy and a manufacturing method of the Fe-Be-contained heat-resisting aluminum copper alloy, and belongs to the field of metallic material engineering. The Fe-Be-contained heat-resisting aluminum copper alloy comprises, by weight percentage, 6%-7% of Cu, 0.5%-0.7% of Mn, 0.5%-0.7% of Ni, 0.3%-0.4% of Cr, 0.3%-0.4% of Fe, 0.3-0.4% of Be, 0.2%-0.3% of V, 0.15%-0.25% of Ti, 0.01%-0.015% of B, 2.5%-3% of Ce, 1.5%-2% of La and the balance Al and inevitable impurities. The manufacturing method includes the steps of firstly, smelting, wherein an aluminum-chromium intermediate alloy is added to be molten and cooled, other alloys and aluminum are added in the form of the intermediate alloy, a covering agent is added, and an aluminum refining agent is added after the temperature is constant; secondly, casting; and thirdly, solid solution and aging treatment. According to the Fe-Be-contained heat-resisting aluminum copper alloy, the room temperature, the high-temperature strength and the high-temperature permanence performance are improved remarkably after the Fe-Be-contained heat-resisting aluminum copper alloy is subjected to multi-alloying and heat treatment; the instant tensile strength is as high as 258 MPa to 264 MPa at the temperature being 250 DEG C; and the tensile strength ranges from 213 MPa to 223 MPa after the alloy is heated for 200 hours at the temperature being 200 DEG C, and the tensile strength ranges from 185 MPa to 192 MPa after the alloy is heated for 200 hours at the temperature being 250 DEG C.

Owner:LIAONING TECHNICAL UNIVERSITY

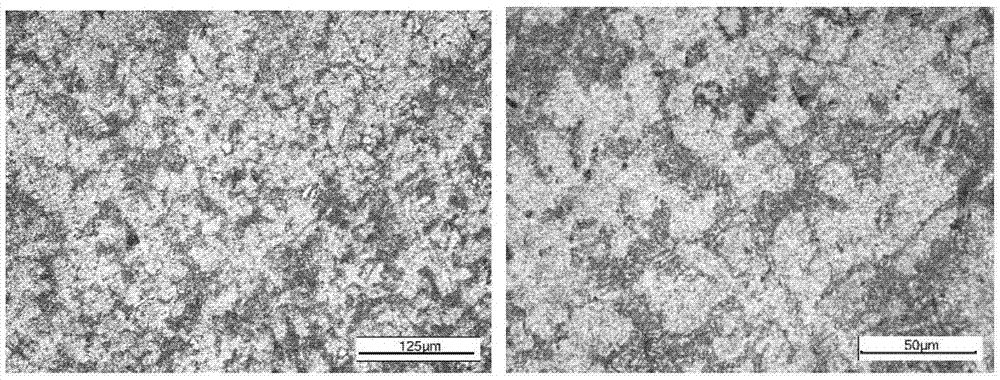

Chromium steel series high speed steel and heat treatment technique thereof

InactiveCN100510149CImprove toughnessImprove wear resistanceHeat treatment process controlManganeseAlloy

The present invention relates to an alloy high-speed steel, in particular to a chromium-steel-based high-speed steel and its heat treatment process. The high-speed steel comprises: 0.85%-1.05% carbon C, 0.2%-0.4% silicon Si, Manganese Mn0.2%~0.4%, Chromium Cr9.0%~11.0%, Tungsten W2.5%~3.5%, Molybdenum Mo0.6%~2.0%, Vanadium V0.4%~2.0%, Nickel Ni0.1% ~0.3%, cobalt Co0.2%~5.0%, niobium Nb0.8~1.2%, sulfur S≤0.015%, phosphorus P≤0.02%, and the rest is iron Fe. The chromium steel high-speed steel of the invention has sufficient toughness and wear resistance, is suitable for making various cold stamping dies, cutting tools and knives, and has low production cost. The invention also discloses the heat treatment process of the high-speed steel.

Owner:周向儒

Manufacturing method of high-precision longitudinal shearing disc cutter

The invention discloses a manufacturing method of a high-precision longitudinal shearing disc cutter, and relates to the technical field of cutter machining. The manufacturing method comprises the following steps that firstly, material selecting is conducted, and an alloy structure steel forge piece is selected as the material of the longitudinal shearing disc cutter; secondly, forge blank annealing treatment is conducted; thirdly, rough machining of the longitudinal shearing disc cutter is conducted; fourthly, heat treatment of the longitudinal shearing disc cutter is conducted; and fifthly,finish machining of the longitudinal shearing disc cutter is conducted. A grinding material used in third-time fine grinding in the fifth step is composed of green silicon carbide micro powder, kerosene and machine oil. During third-time fine grinding in the fifth step, the rotation speed of a grinding disc of a grinding machine is controlled to be 10 r / min, and the down force of the grinding discis controlled to be 980 N. According to the manufacturing method of the high-precision longitudinal shearing disc cutter, high hardness, high abrasion resistance, high heat hardness, high hardenability and enough plasticity and tenacity are achieved, and the service life of the longitudinal shearing disc cutter is greatly prolonged; and meanwhile, the grinding material composed of the green silicon carbide micro powder, the kerosene and the machine oil is adopted, smooth finish after grinding is good, and scratches can be prevented from being generated in the machining process.

Owner:ANHUI RISHENG MACHINERY MFG

Carbon-free high-speed steel and preparation method thereof

The invention discloses carbon-free high-speed steel and a preparation method thereof. According to the carbon-free high-speed steel provided by the invention, iron powder is introduced to replace molybdenum powder and cobalt powder, and a small amount of LaB6 is introduced to improve the tempering resistance and red hardness of the material; and through joint addition of La and B, strengthening is caused, austenite transformation is delayed, structure coarsening and desolvation of alloy elements during tempering are inhibited, so that the red hardness and the hot hardness of the Fe-Co-Mo material are improved. Meanwhile, a preparation process is simple, the cost of the raw materials is reduced, the excellent cutter material performance is shown, and a prepared cutter can keep high hardness and is not sticky under the long-time cutting action, and important application value in the industry is achieved.

Owner:XIANGTAN UNIV

Novel steel material for automobile rotation shaft

Compared with domestic steel W6Mo5Cr4V2, the steel material of the present invention replaces a large amount of molybdenum with chromium, which saves the usage of molybdenum, and also reduces the usage of vanadium and tungsten, thereby reducing the production cost of alloy steel; adding non-carbide elements Nickel improves the strength of steel through solid solution strengthening, and at the same time has high plasticity and toughness, and strongly increases the hardenability of steel, and the addition of cobalt greatly improves the hot hardness and cutting performance of alloy steel; adding The carbide forming element niobium increases the toughness of the steel and improves the processability of hot working. The content of P and S in the present invention is very low (especially P), so the purity of the steel is particularly good, and it plays a role in guaranteeing various properties of the steel. The annealed Brinell hardness of the steel reaches HB250. Therefore, the steel of the invention has high thermal hardness and cutting performance, and also has high toughness and wear resistance. However, the material cost is much lower than the domestic steel W6Mo5Cr4V2, which is suitable for making various vehicle shafts.

Owner:重庆华厦新力新能源汽车有限公司

Dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring and preparation method thereof

InactiveCN106636996AHigh strengthIncrease frictionTransportation and packagingMetal-working apparatusCobaltHeat treated

The invention discloses a dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring. The dense black-spot-free iron-based powdery metallurgical self-lubricating CNG engine valve seat ring is prepared from, by weight, 6.4-6.6 parts of chrome, 4.4-4.6 parts of cobalt, 0.7-1.2 parts of nickel, 0.3-0.5 part of neodymium, 2.3-2.6 parts of boron, 3.6-4.3 parts of polymerization iron powder, 16-18 parts of copper, 1.3-1.5 parts of nano molybdenum disulfide, 0.7-0.8 part of calcium fluoride, 1.2-1.4 parts of silicon carbide, 0.2-0.3 part of zinc chloride, 0.5-0.8 part of triethyl silane, 1-2 parts of glass fiber, 2-3 parts of high carbon ferro-chrome alloy powder and 62-65 parts of iron. The surface of the modified nano molybdenum disulfide is coated with a layer of copper film to serve as a solid lubricant which is added to a substrate material, meanwhile the silicon carbide, neodymium, boron and other ingredients are further added, metal particle phase change is changed by adopting sintering, infiltration and heat treatment processes, and the prepared product is uniform in texture, dense, stable and free of black spot and other defects.

Owner:安徽马仪科技股份有限公司

High-hardness iron-based powder metallurgy self-lubricating CNG engine valve seat ring and manufacturing method thereof

InactiveCN106636969AReduce density differenceSimilar physical and mechanical propertiesTransportation and packagingMetal-working apparatusAluminiumPolytetrafluoroethylene

The invention discloses a high-hardness iron-based powder metallurgy self-lubricating CNG engine valve seat ring. The high-hardness iron-based powder metallurgy self-lubricating CNG engine valve seat ring is made from, by weight, 6.2-6.4 parts of chrome, 4.2-4.4 parts of cobalt, 0.7-0.9 part of nickel, 0.5-0.7 part of titanium, 0.3-0.5 part of cerium, 18-19 parts of copper, 1.2-1.5 parts of nano molybdenum disulfide, 0.7-0.9 part of tungsten carbide, 1-2 parts of manganese dioxide, 0.4-0.6 part of methyl triethoxy silane, 2.1-2.4 parts of ferro boron powder, 0.2-0.4 part of aluminum dihydrogen phosphate, 2-3 parts of polytetrafluoroethylene powder and 64-68 parts of iron. According to the high-hardness iron-based powder metallurgy self-lubricating CNG engine valve seat ring, the surface of the modified nano molybdenum disulfide is covered with a layer of copper film to be added into a matrix material as a solid lubricating agent; and meanwhile, manganese dioxide, titanium, cerium and other elements are added, the sintering, melt infiltration and heat treatment process is adopted to change the phase change of metal particles, and the manufactured product has high hardness and high high-temperature stability.

Owner:安徽马仪科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com