Fe-Be-contained heat-resisting aluminum copper alloy and manufacturing method of Fe-Be-contained heat-resisting aluminum copper alloy

A heat-resistant aluminum and copper alloy technology, applied in the field of metal material engineering, can solve the problems of low high-temperature instantaneous strength and high-temperature durable strength, so as to improve grain boundary strength and creep resistance, improve heat resistance stability, strength and Effect of heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

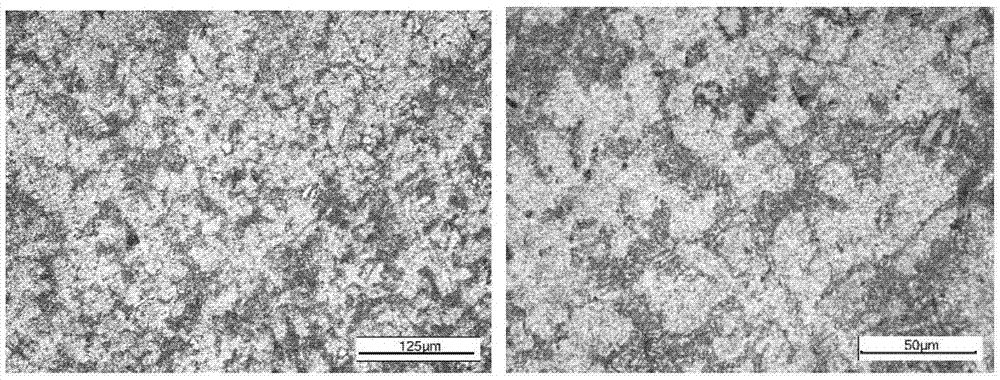

Image

Examples

Embodiment 1

[0028] The present invention contains Fe-Be heat-resistant aluminum-copper alloy, and its chemical composition is: Cu: 7%, Mn: 0.6%, Ni: 0.6%, Cr: 0.4%, Fe: 0.35%, Be: 0.4%. V: 0.3%, Ti: 0.25%, B: 0.01%, Ce: 2.8%, La: 1.8%, and the balance is Al and unavoidable impurities.

[0029] The preparation method of the present invention contains Fe-Be heat-resistant aluminum-copper alloy, comprises the steps:

[0030] Step 1, smelting:

[0031] Put the aluminum-chromium master alloy into the crucible, heat it to 920°C, and after it is completely melted, lower the furnace temperature to 790°C;

[0032] According to the set alloy composition, add aluminum copper master alloy, aluminum manganese master alloy, aluminum iron master alloy, aluminum nickel master alloy, aluminum beryllium master alloy, aluminum vanadium master alloy, aluminum titanium boron master alloy, aluminum rare earth master alloy and aluminum , after more than 2 / 3 of the charge is melted, add HZ-WYF smokeless coveri...

Embodiment 2

[0042] The present invention contains Fe-Be heat-resistant aluminum-copper alloy, and its chemical composition is as follows according to weight percentage: Cu: 6.5%, Mn: 0.65%, Ni: 0.55%, Cr: 0.35%, Fe: 0.4%, Be: 0.35%, V: 0.25%, Ti: 0.2%, B: 0.012%, Ce: 2.6%, La: 1.6%, and the balance is Al and unavoidable impurities.

[0043] The preparation method of the present invention contains Fe-Be heat-resistant aluminum-copper alloy, comprises the steps:

[0044] Step 1, smelting:

[0045] Put the aluminum-chromium master alloy into the crucible, heat it to 925°C, and after it is completely melted, lower the furnace temperature to 790°C;

[0046] According to the set alloy composition, add aluminum copper master alloy, aluminum manganese master alloy, aluminum iron master alloy, aluminum nickel master alloy, aluminum beryllium master alloy, aluminum vanadium master alloy, aluminum titanium boron master alloy, aluminum rare earth master alloy and aluminum , after more than 2 / 3 of t...

Embodiment 3

[0056] The present invention contains Fe-Be heat-resistant aluminum-copper alloy, and its chemical composition is as follows according to weight percentage: Cu: 6.0%, Mn: 0.55%, Ni: 0.65%, Cr: 0.3%, Fe: 0.35%, Be: 0.3%, V: 0.2%, Ti: 0.22%, B: 0.013%, Ce: 2.9%, La: 1.7%, and the balance is Al and unavoidable impurities.

[0057] The preparation method of the present invention contains Fe-Be heat-resistant aluminum-copper alloy, comprises the steps:

[0058] Step 1, smelting:

[0059] Put the aluminum-chromium master alloy into the crucible, heat it to 930°C, and after it is completely melted, lower the furnace temperature to 800°C;

[0060] According to the set alloy composition, add aluminum copper master alloy, aluminum manganese master alloy, aluminum iron master alloy, aluminum nickel master alloy, aluminum beryllium master alloy, aluminum vanadium master alloy, aluminum titanium boron master alloy, aluminum rare earth master alloy and aluminum , after more than 2 / 3 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com