Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

A technology of grafting copolymer and xanthan gum, which is applied in drilling compositions, chemical instruments and methods, and mining fluids, etc., can solve problems such as easy degradation, low XG-g-AMPS grafting rate, easy deposition, etc. problems, to achieve the effect of improving heat resistance and biological stability, improving grafting rate and grafting efficiency, and developing cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

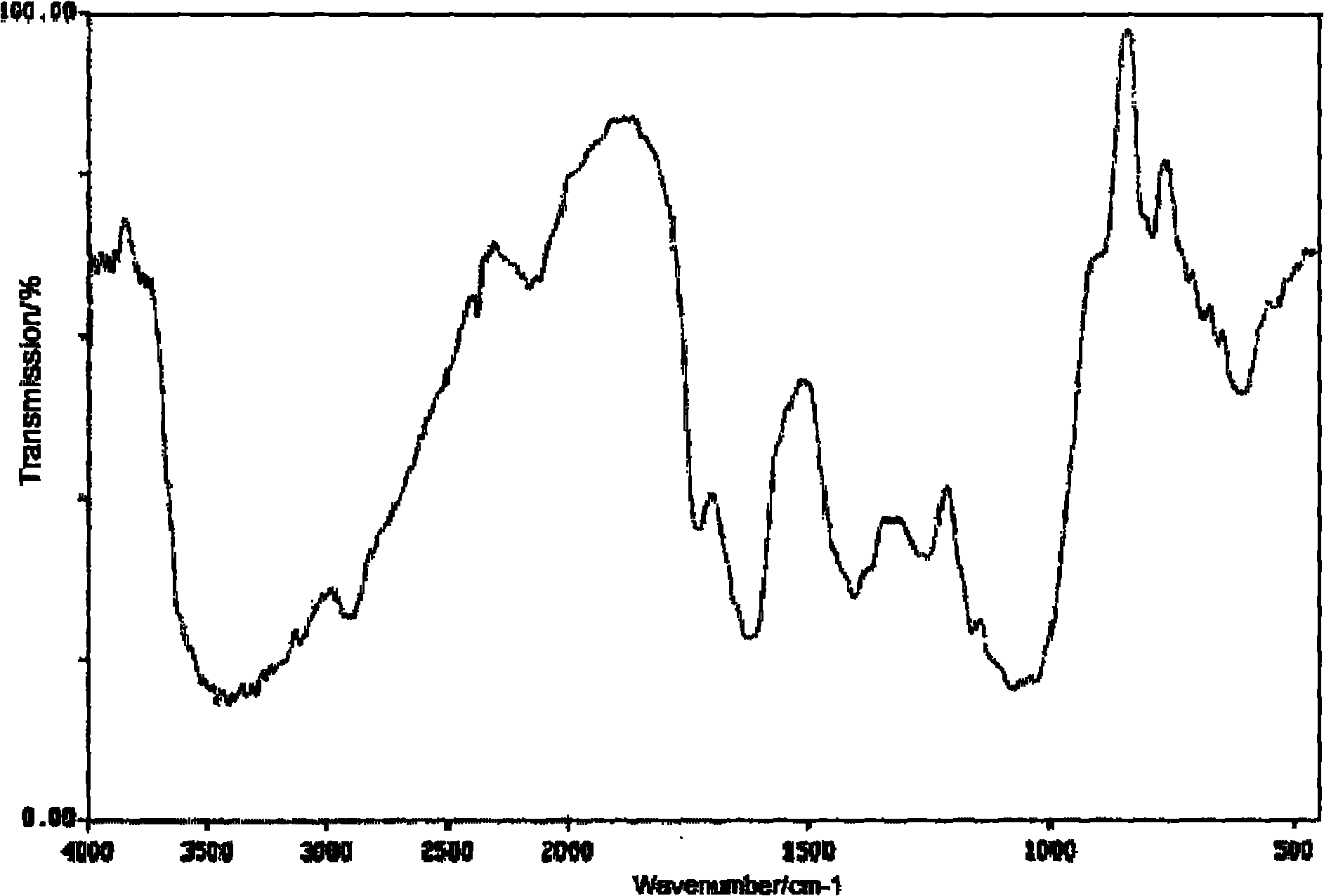

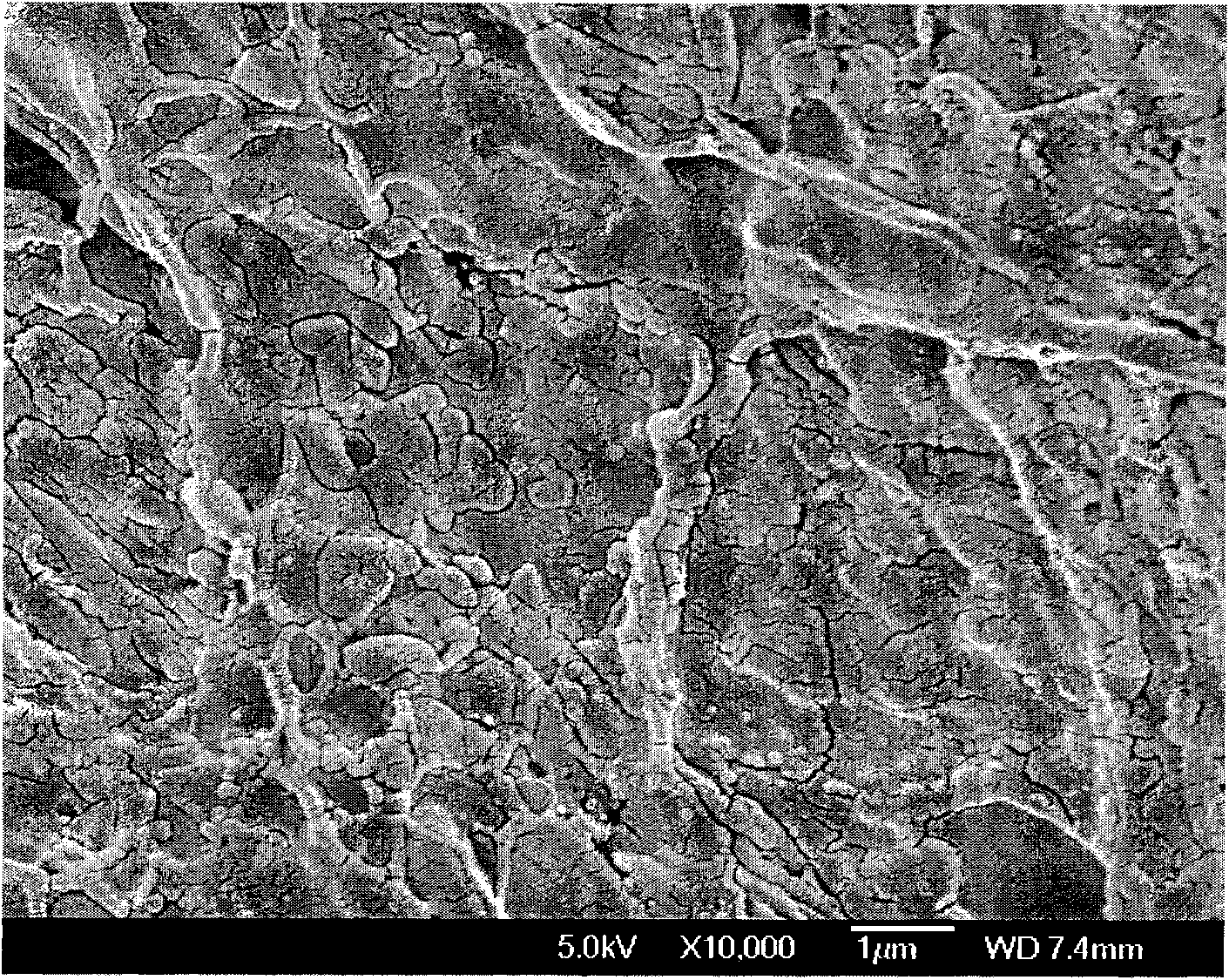

[0069] Embodiment 1 Preparation of heat-resistant and salt-resistant xanthan gum graft copolymer of the present invention

[0070] At room temperature, add 1g of xanthan gum and 100g of distilled water into a 250mL three-neck flask, stir well to completely dissolve the xanthan gum, and then blow high-purity nitrogen gas into it to remove oxygen. Add 6.43g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into the reaction vessel, stir until completely dissolved; continue to blow high-purity nitrogen into the reaction vessel to remove oxygen by bubbling for more than 20 minutes. Put the three-neck flask in a constant temperature water bath at 55°C, under nitrogen protection, add 0.02g of ammonium cerium nitrate, react at 55°C for 5 minutes, add 0.2g of ammonium persulfate, 0.6g of sodium bisulfite, and 2g of acrylamide (AM) was formulated into a 50% aqueous solution and slowly added dropwise to the reaction vessel, reacted at 55°C for 3 hours, precipitated the product with ex...

Embodiment 2

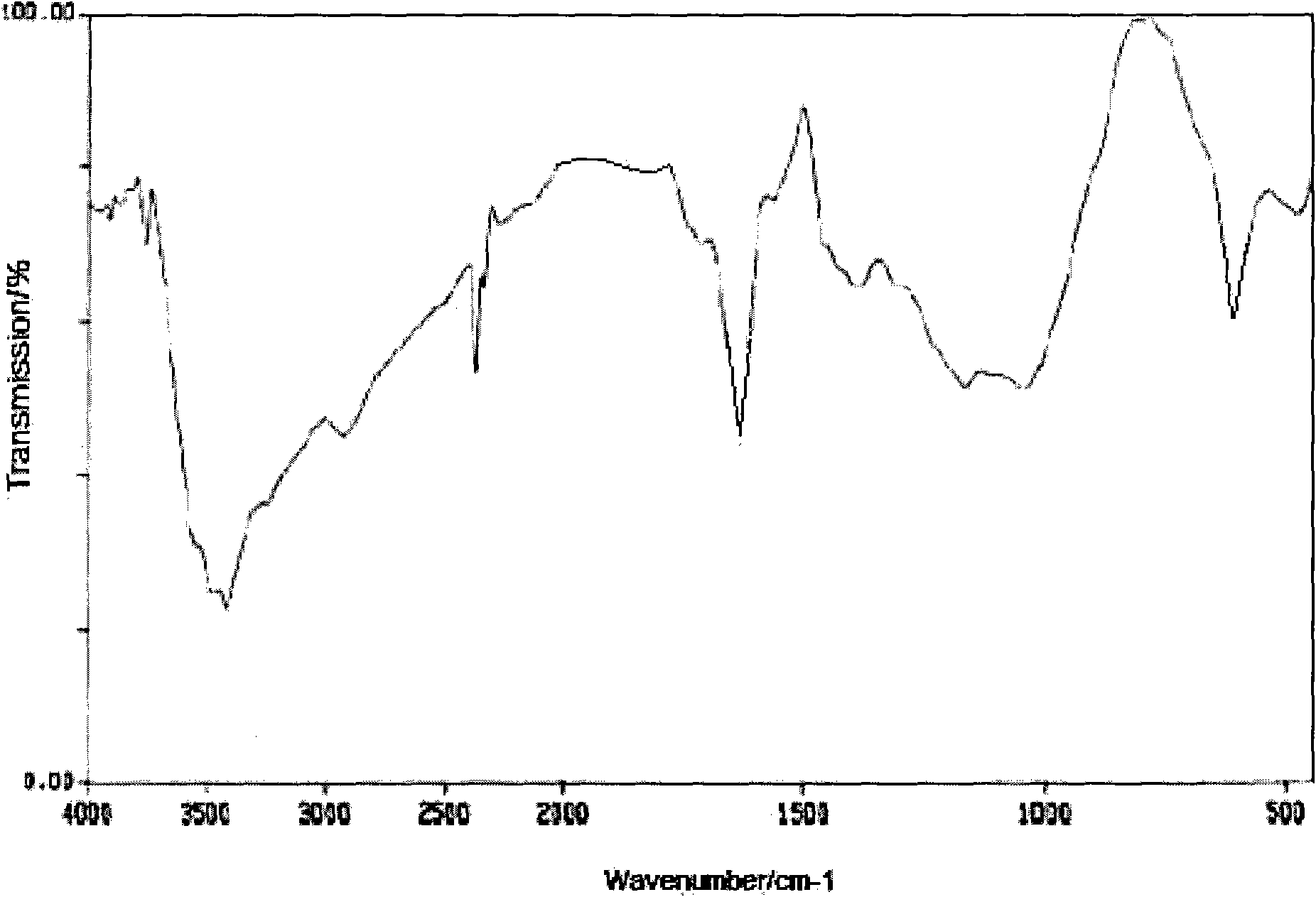

[0080] Embodiment 2 Preparation of heat-resistant and salt-resistant xanthan gum graft copolymer of the present invention

[0081]At room temperature, add 1g of xanthan gum and 100g of distilled water into a 250mL three-neck flask, stir well to completely dissolve the xanthan gum, and then blow high-purity nitrogen gas into it to remove oxygen. Add 3.44g of N-vinylpyrrolidone (NVP) into the reaction vessel, stir until completely dissolved; continue to pass high-purity nitrogen into the reaction vessel to remove oxygen by bubbling for more than 20 minutes. Put the three-neck flask in a constant temperature water bath at 55°C, under nitrogen protection, add 0.02g of ammonium cerium nitrate, react at 55°C for 5 minutes, add 0.2g of ammonium persulfate, 0.6g of sodium bisulfite, and 2g of acrylamide (AM) was formulated into a 50% aqueous solution and slowly added dropwise to the reaction vessel, reacted at 55°C for 3 hours, precipitated the product with excess acetone, and complet...

Embodiment 3

[0084] Embodiment 3 Preparation of heat-resistant and salt-resistant xanthan gum graft copolymer of the present invention

[0085] At room temperature, add 1g of xanthan gum and 100g of distilled water into a 250mL three-neck flask, stir well to completely dissolve the xanthan gum, and then blow high-purity nitrogen gas into it to remove oxygen. Add 2.79g of N,N-dimethylacrylamide into the reaction vessel and stir until completely dissolved; continue to blow high-purity nitrogen into the reaction vessel to remove oxygen by bubbling for more than 20 minutes. Put the three-neck flask in a constant temperature water bath at 55°C, under the protection of nitrogen, add 0.02g ammonium cerium nitrate, react at 55°C for 5 minutes, add 0.2g ammonium persulfate, 0.6g sodium bisulfite, and 5.83g AMPS The 50% aqueous solution was slowly added dropwise into the reaction vessel, reacted at 55°C for 3 hours, the product was precipitated with excess acetone, and completely dried at 50°C to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com