Patents

Literature

55results about How to "High viscosity retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xanthan gum graft copolymer oil displacement agent as well as preparation method and application thereof

ActiveCN102051165AImprove heat stabilityImprove biostabilityFluid removalDrilling compositionSide chainHeat resistance

The invention provides a xanthan gum graft copolymer oil displacement agent as well as a preparation method and application thereof. Based on molecular design, at least two of acrylamide (AM), 2-acrylamido-2-methylpropane sulfonic acid (AMPS), N-vinylpyrrolidone (NVP) and N,N-dimethylacrylamide (DMAM) are graft-copolymerized to xanthan gum macromolecules. Since the copolymerized side chain is introduced, the viscoelasticity, heat resistance and biological stability of the xanthan gum macromolecules can be greatly enhanced; the xanthan gum graft copolymer can be used as an oil displacement agent for tertiary oil recovery simultaneously; and the solution rate of the xanthan gum graft copolymer is obviously increased, and the xanthan gum graft copolymer can not easily generate gel in brine. When the xanthan gum graft copolymer oil displacement agent is used in a high-temperature high-salinity oil reservoir, the oil displacement effect is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-soluble hyperbranched thick oil viscosity-reducing oil-displacing agent and preparation method thereof

ActiveCN110483701AStrong shear resistanceHigh viscosity retentionDrilling compositionFunctional monomerOil viscosity

The invention discloses a water-soluble hyperbranched thick oil viscosity-reducing oil-displacing agent and a preparation method thereof. The viscosity reducing oil displacing agent is prepared by copolymerizing 0.01%-1.0% of a functionalized skeleton monomer, 10%-20% of acrylamide, 10%-20% of acrylic acid, 40%-50% of a nonionic functional monomer octylphenol polyoxyethylene ether and 20%-25% of an anionic monomer 2-acrylamidotetradecyl sodium sulfonate. The viscosity-reducing oil-displacing agent is relatively strong in water-phase tackifying capacity and good in anti-shearing performance, sothat the viscosity-reducing oil-displacing agent has the functions of controlling the fluidity ratio and expanding the swept volume; meanwhile, the viscosity-reducing oil-displacing agent has stronger mixed emulsifying property with thickened oil, the emulsifying viscosity-reducing rate of common thickened oil is more than 80%, the demulsification is easy, and the effects of reducing viscosity and displacing oil are realized. The raw materials for preparing the viscosity-reducing oil-displacing agent are wide in source, the preparation process is simple and convenient, and the cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

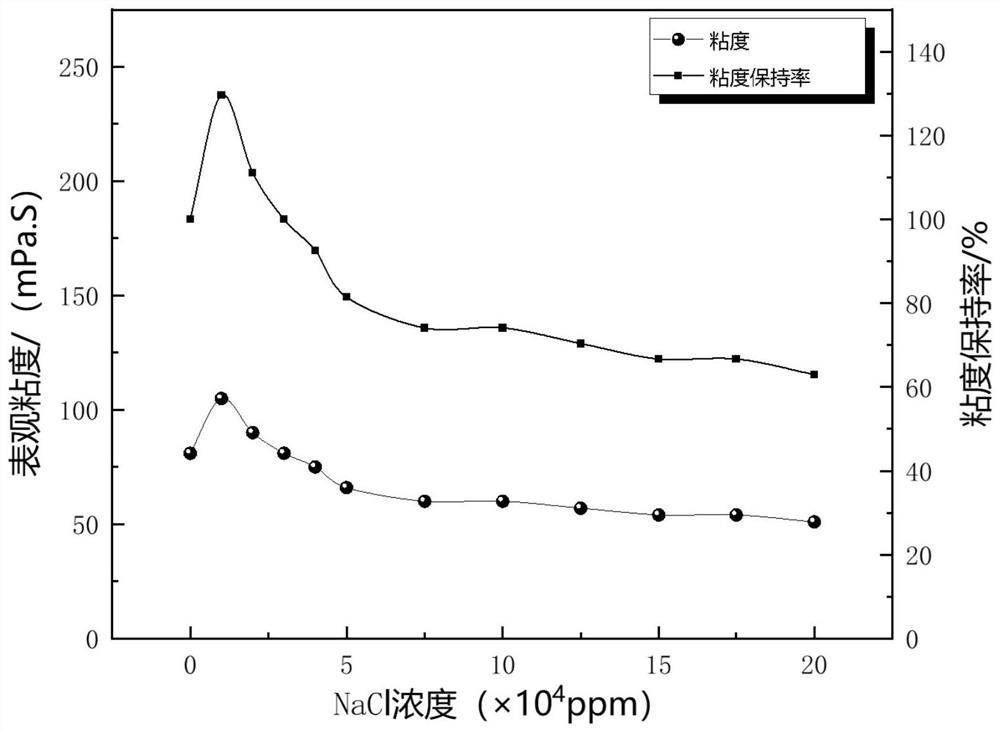

Method for synthesizing electrolyte-resistant thickener by using inverse emulsion

InactiveCN101613433AGood thickening effectStrong anti-electrolyte abilityCross-linkFunctional monomer

The invention relates to a method for synthesizing an electrolyte-resistant thickener by using an inverse emulsion. The method comprises the following steps: adding water-soluble monomer acrylamide and a cross-linking agent to neutral water-soluble unsaturated carboxylic acid to form an aqueous phase; adding a hydrophobic functional monomer and an emulsifier to the solvent to form an oil phase; mixing and emulsifying the aqueous phase and the oil phase to form a water-in-oil emulsion, adding an initiator, heating the mixture to initiate polymerization, decompressing and distilling the mixture, and adding a phase transfer agent to obtain the product. The novel thickener synthesized by the method has good thickening effect with 3 percent of white pulp viscosity up to 106000mp.s, strong electrolyte-resistant ability with viscosity retention rate up to 45.3 percent, and simple process with stable and easily controlled reaction process.

Owner:NANJING UNIV OF TECH

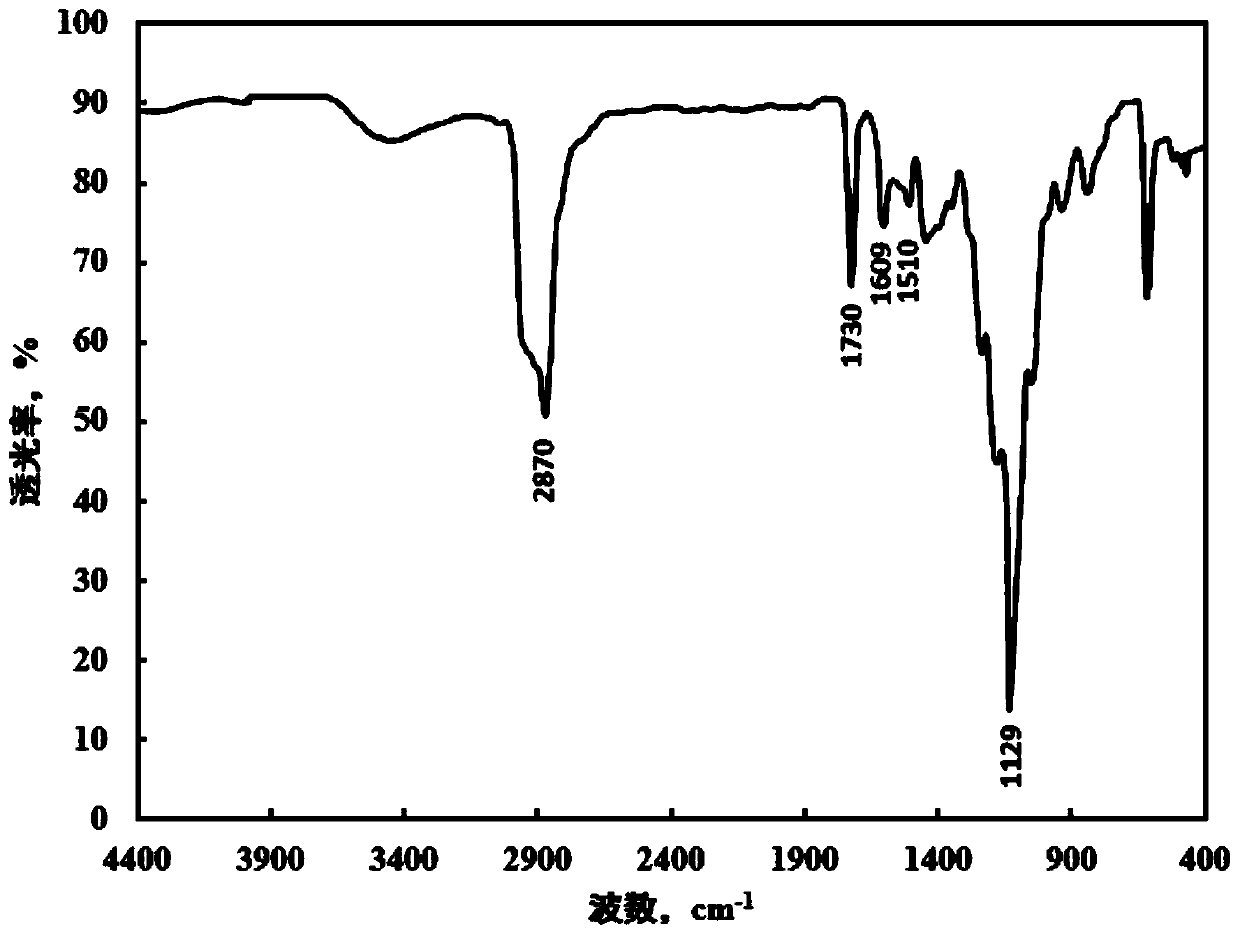

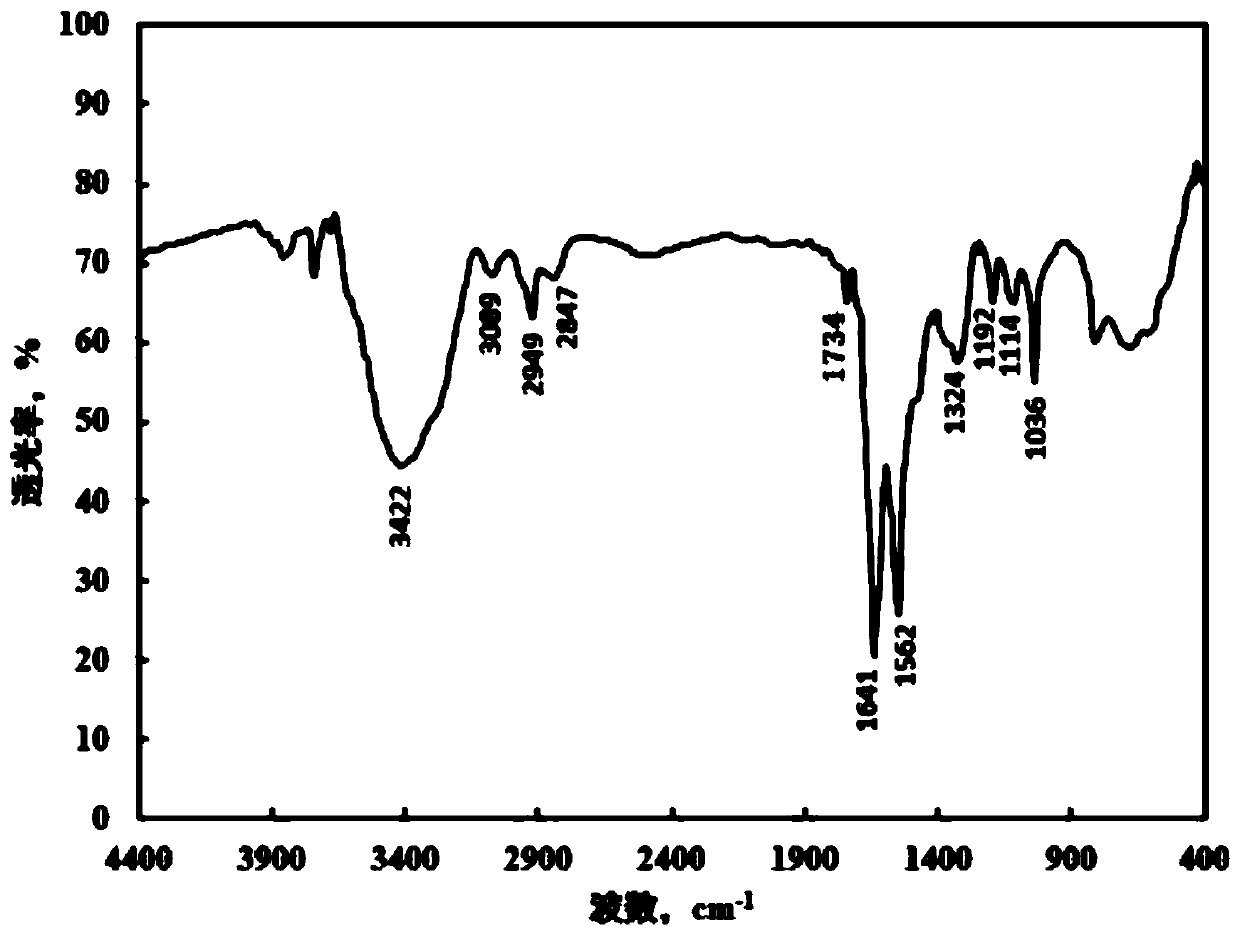

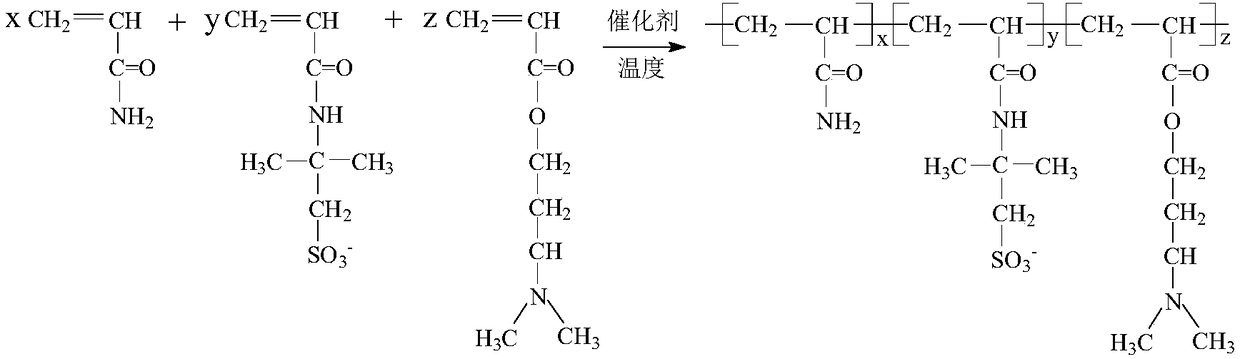

Ultra-high temperature-resistant anionic polymer fluid loss additive for drilling fluid and completion fluid and preparation method thereof

The invention relates to an ultra-high temperature-resistant anionic polymer fluid loss additive for drilling fluid and completion fluid and a preparation method thereof. The ultra-high temperature-resistant and salt-resistant polymer fluid loss additive is a terpolymer prepared by aqueous solution polymerization reaction of alkenyl monomer acrylamide, strongly hydrophilic anionic alkenyl monomer2-acrylamide-2-methylpropanesulfonic acid and alkenyl monomer 2-(dimethylamino)ethyl methacrylate. The molar ratio of anionic alkenyl monomer 2-acrylamide-2-methylpropanesulfonic acid in molecular chain units of the terpolymer is up to 35%-42.5%, and the anionic alkenyl monomer has high hydrophilicity and solubility. The molecular chain of the polymer contains 1,400 to 2,000 structural units. Theweight average molecular weight is 650,000 to 850,000, and number average molecular weight is 600,000 to 700,000. The fluid loss additive provided by the invention has good solubility in the ultra-high temperature water-based drilling fluid, and the temperature-resistant capability reaches 248 DEG C. The small amount of addition can significantly reduce the fluid loss of the water-based drilling fluid and completion fluid under ultra-high temperature conditions and can enable the drilling fluid and completion fluid to maintain good colloidal stability under ultra-high temperature conditions.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of poly-surfactant for displacement of reservoir oil

InactiveCN104231165AReduce interfacial tensionImprove temperature resistanceDrilling compositionPotassium persulfateCrude oil

The invention discloses a preparation method of a poly-surfactant for displacement of reservoir oil. The preparation method comprises the following steps: preparing an aqueous solution by using 20-40 parts of distilled water, 4-8 parts of acrylamide, 1-3 parts of 2-acrylamide sodium alkyl sulfonate, 1-3 parts of 2-acrylamide-2-sodium methallyl sulfonate and 1-3 parts of sodium acrylate, uniformly stirring at normal temperature, and then filling the solution into three flasks; introducing nitrogen into the single aqueous solution in the three flasks for 10-15 minutes, stirring, and heating to 30-40 DEG C; adding a potassium persulfate aqueous solution, stirring for 2-5 minutes, adding a sodium hydrogen sulfite aqueous solution, and stirring for 10-20 minutes; and stopping stirring, stopping introducing nitrogen, and performing constant-temperature polymerization for 6 hours. The poly-surfactant aqueous solution prepared by the method disclosed by the invention and crude oil have relatively low interfacial tension which can reach 10<-1> mN / m, and the viscosity retention rate at 95 DEG C after 7 days is over 80%.

Owner:PETROCHINA CO LTD

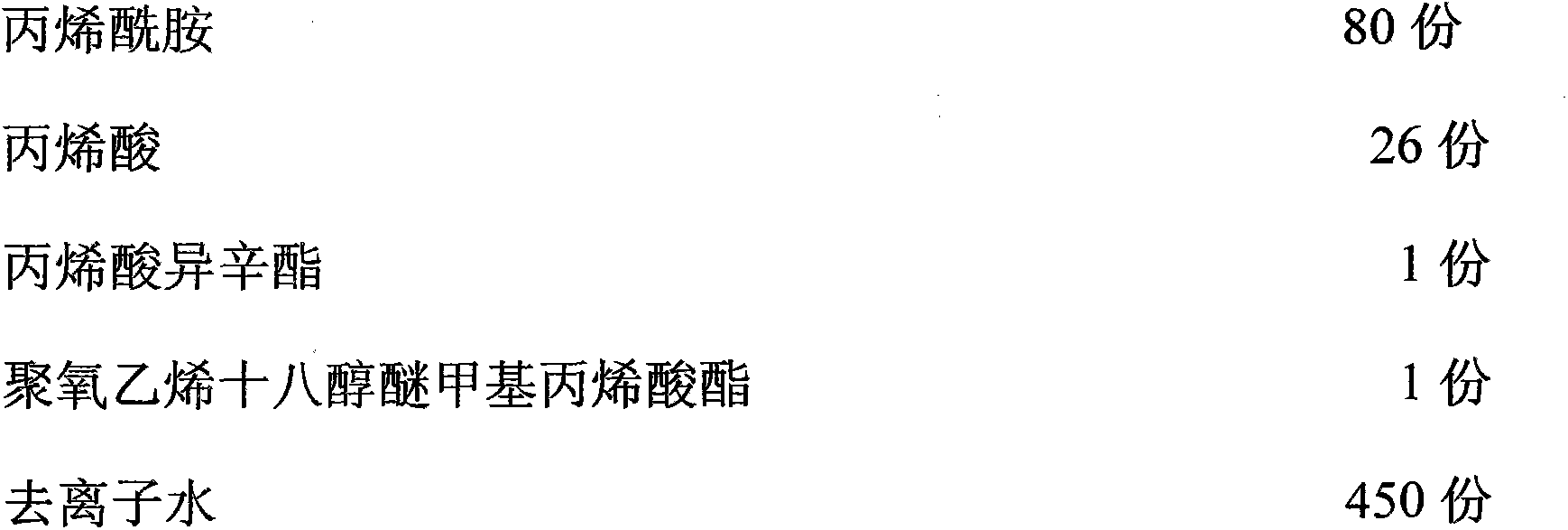

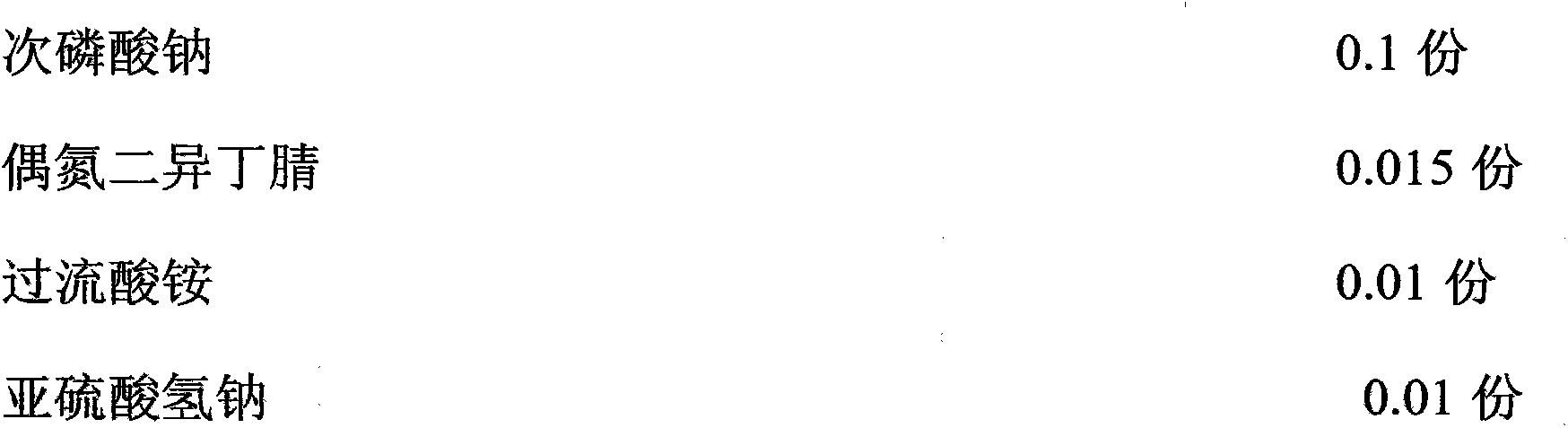

Salt-resistant polymer for oil displacement of oil field and preparation method thereof

InactiveCN104311755AImprove salt resistanceReduced post-processingDrilling compositionMethacrylatePolymer science

The invention discloses a salt-resistant polymer for oil displacement of an oil field and a preparation method thereof. The salt-resistant polymer comprises the following materials in parts by weight: 80-120 parts of acrylamide, 26-40 parts of acrylic acid, 1-5 parts of hydrophobic monomer, 1-5 parts of polyoxyethylene octadecanol ether methacrylate or polyoxyethylene hexadecanol ether methacrylate, 230-450 parts of deionized water and 0.1-0.3 part of chain transferring agent. The salt-resistant polymer and the preparation method disclosed by the invention have the advantages that in a formula of the polymer, since polyoxyethylene octadecanol ether methacrylate and the hydrophobic monomer are added for composite use, the salt resistance of the polymer is improved; in the formula of the polymer, polyoxyethylene octadecanol ether methacrylate is added, and a surface active agent does not need to be added in the synthesis process, so that the following treatment process is reduced; the viscosity retention rate of 1500ppm salt-resistant polymer solution is larger than 80% after the 1500ppm salt-resistant polymer solution is put in the solution with the degree of mineralization being 30000mg / L NaCl and 200mg / L Ca<2+> and Mg<2+>.

Owner:黑龙江吉地油田服务股份有限公司

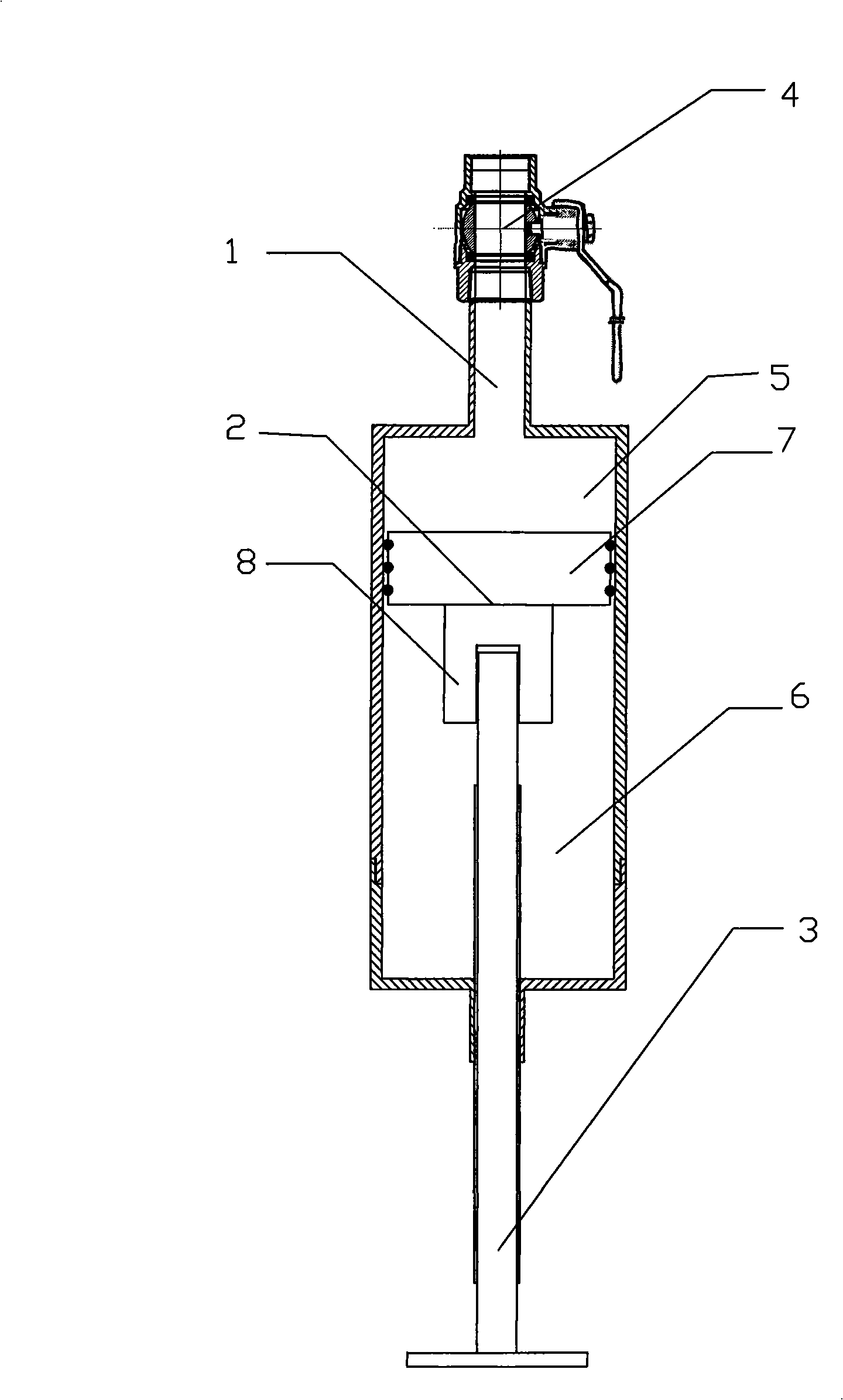

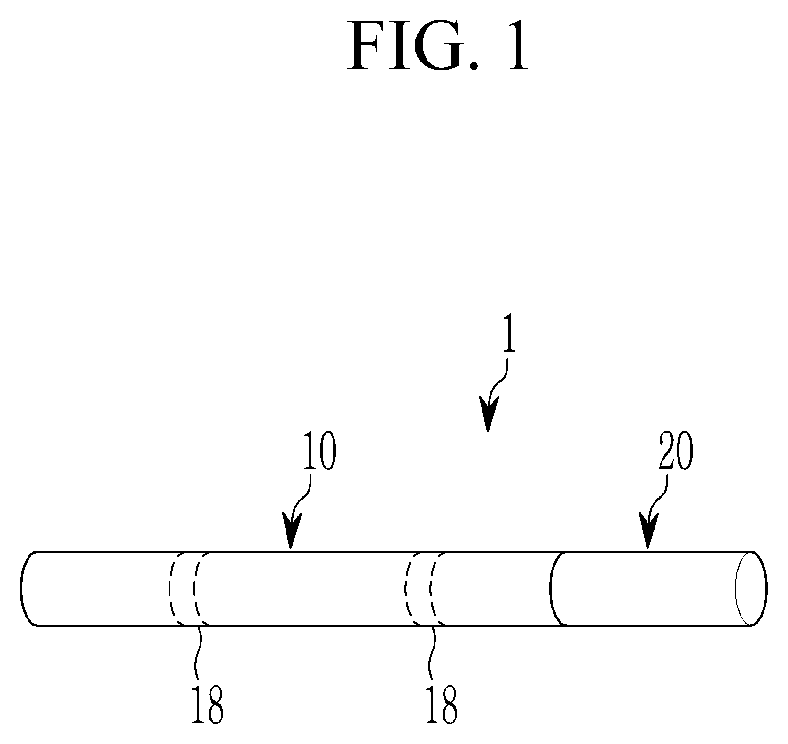

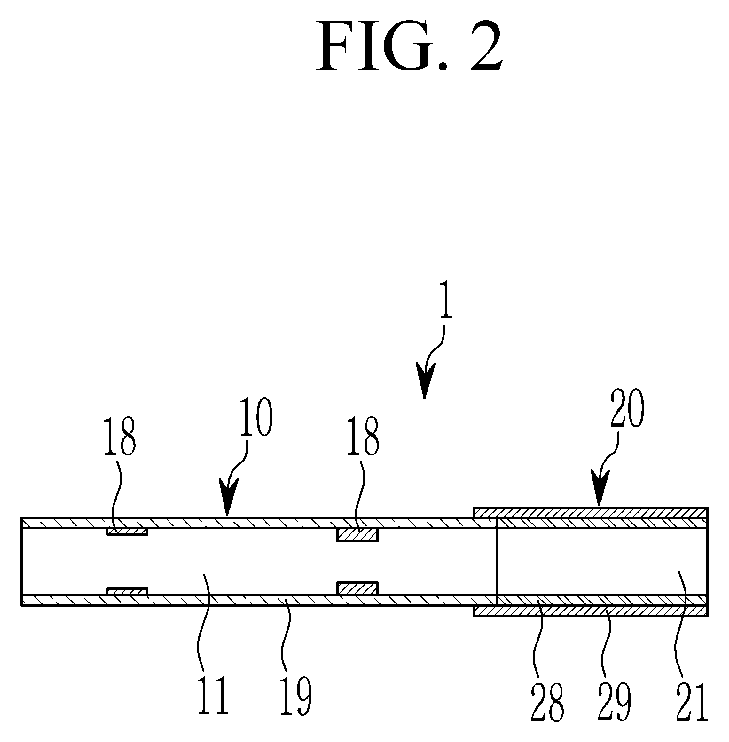

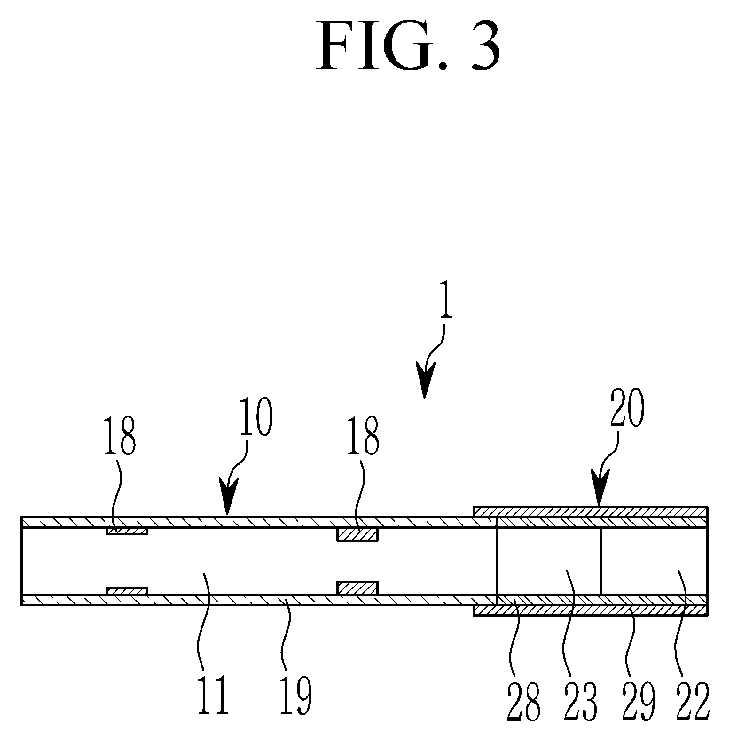

Thread-control high-pressure environment liquid sampler

InactiveCN101526445AEasy to sampleAccurate samplingWithdrawing sample devicesLiquid viscosityEngineering

The present invention discloses a thread-control high-pressure environment liquid sampler. The thread-control high-pressure environment liquid sampler of the invention comprises the following components: a sealed barrel which is composed of a main chamber and a sampling chamber (1) communicated with the sampling chamber (1), a piston (2), a push rod (3) and a sampling valve (4). The piston is positioned in the main chamber and furthermore the outer margin of the piston is matched with the inner chamber wall of main chamber for dividing the main chamber into a liquid inlet chamber (5) and a cushion chamber (6). The base of main chamber far from the sampling chamber is provided with an opening. One end of the push rod is connected with the piston, and the other end extends out from the main chamber through an opening and is jointed with the main chamber through thread joint. The sampling chamber is installed with a sampling opening controlled by the sampling valve. The volume of liquid inlet chamber is increased through the rotation of push rod, and the polymer liquid enters through the self pressure. The flow velocity of high-pressure liquid entering into the liquid inlet chamber can be controlled through the rotation speed of push rod for reducing the shearing of high pressure to the viscosity of liquid. The volume of liquid entering the sampler can be controlled through controlling the screwing-out length of push rod. The thread-control high-pressure environment liquid sampler of the invention has the advantages of simple structure and convenient sampling. The shearing caused by the entering of liquid into the sampler in the high-pressure environment can be effectively prevented and the liquid entering into the sampler can be accurately measured.

Owner:CHINA NAT OFFSHORE OIL CORP +1

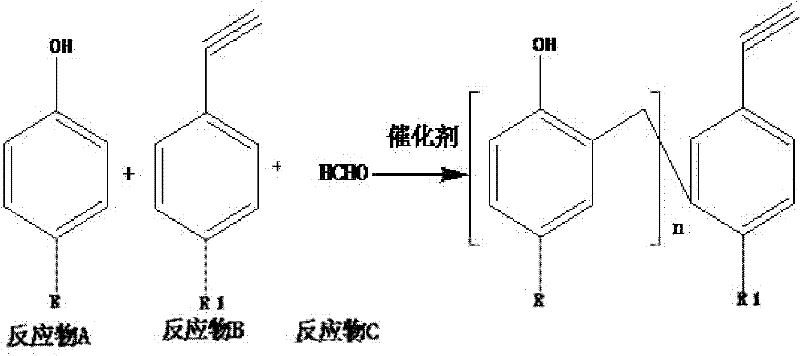

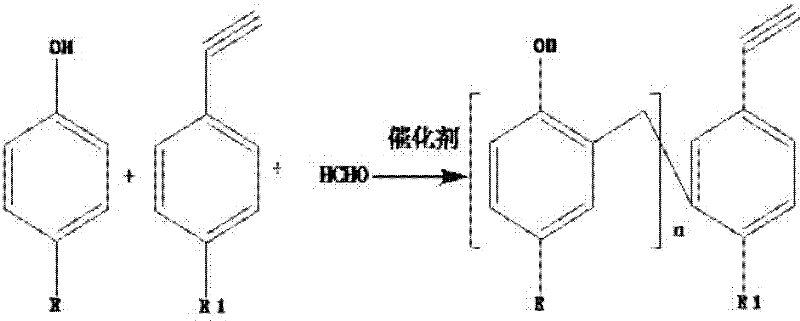

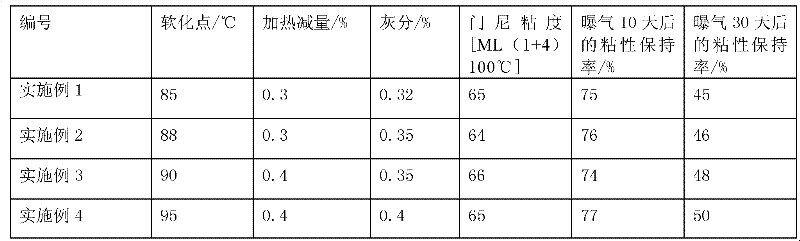

Long-acting tackifying phenolic resin and preparation method thereof

InactiveCN102241569AHigh viscosity retentionHigh long-term tackinessOrganic compound preparationAmino-hyroxy compound preparationChemical industryBenzene

The invention discloses a long-acting tackifying phenolic resin and a preparation method thereof, belonging to the technical field of chemical industry. The preparation method comprises the following steps: separately weighing a reactant A, a reactant B, a reactant C and a catalyst in a molar ratio of 1:(0.7-0.8):(0.2-0.4):(0.01-0.05), wherein the reactant A is p-tert-butyl phenol or p-tert-octyl phenol, the reactant B is phenylacetylene, p-hydroxyl phenylacetylene, p-methoxy phenylacetylene, p-amino phenylacetylene or p-chloro phenylacetylene, the reactant C is formaldehyde, and the catalyst is one or two of sulfuric acid, oxalic acid, phosphoric acid and benzene sulfonic acid; adding the reactant A into a reaction kettle, and heating for melting completely; adding the reactant C; adding the catalyst; cooling to 80 DEG C and adding the reactant B; and dewatering while depressurizing to 180 DEG C so as to obtain the product. In the preparation method, a normal-pressure production process is employed, thus overcoming potential safety hazard problems existing in foreign high-temperature and high-pressure production.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

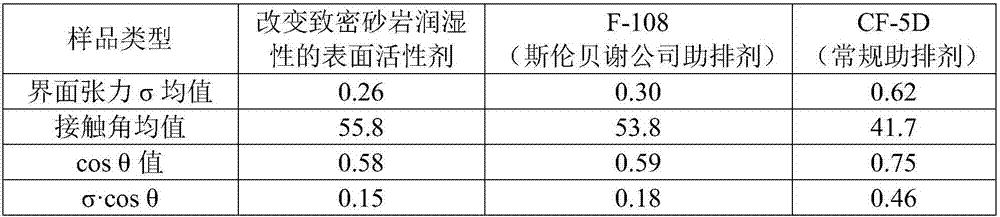

Surfactant for changing surface wettability of compact sandstone as well as preparation method and application of surfactant

InactiveCN107418546AReduce interfacial tensionReduce adhesionDrilling compositionWater wetRoom temperature

The invention relates to a surfactant for changing surface wettability of compact sandstone as well as a preparation method and an application of the surfactant. An oil phase solution is added to a water phase solution, and a dispersed and uniform phase is realized after 1-2 h under the action of an emulsifier. An initiator is added, the mixture is stirred and heated to 60-75 DEG C and reacts at the temperature for 12-18 h, and a colorless and clear liquid, namely, a high-molecular polymer, is prepared. A fluorocarbon surfactant and a biosurfactant are added at the room temperature, the mixture is stirred continuously for 4 h, and the surfactant for changing surface wettability of the compact sandstone is obtained. By the aid of the surfactant, the oil-water interface tension can be reduced, an oil wetted surface can be changed into a water wetted surface, the adhesion of oil drops on sandstone surfaces can be reduced, the flowability of crude oil in an original stratum can be improved, and the recovery percent of low-permeability oil reservoirs can be increased.

Owner:PETROCHINA CO LTD

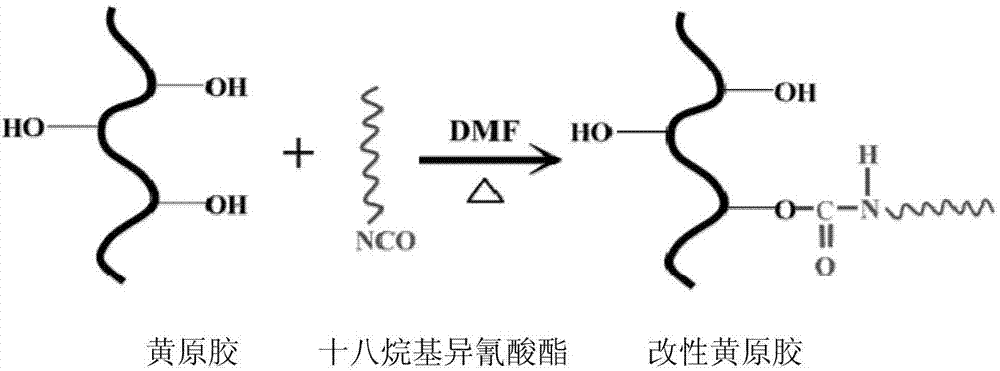

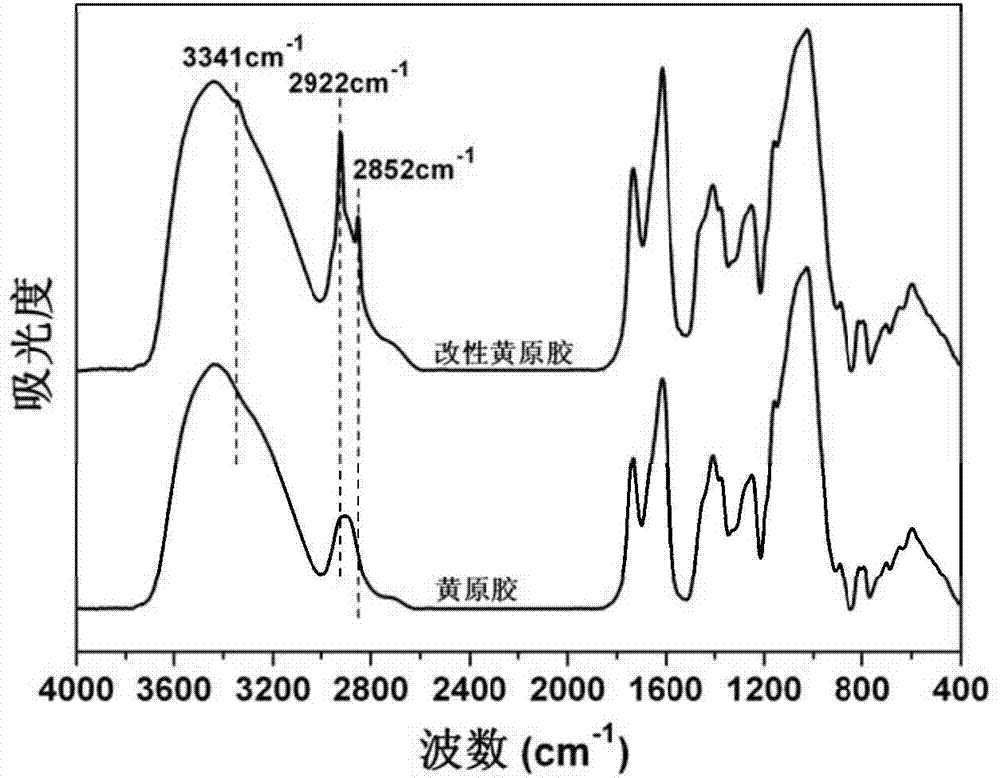

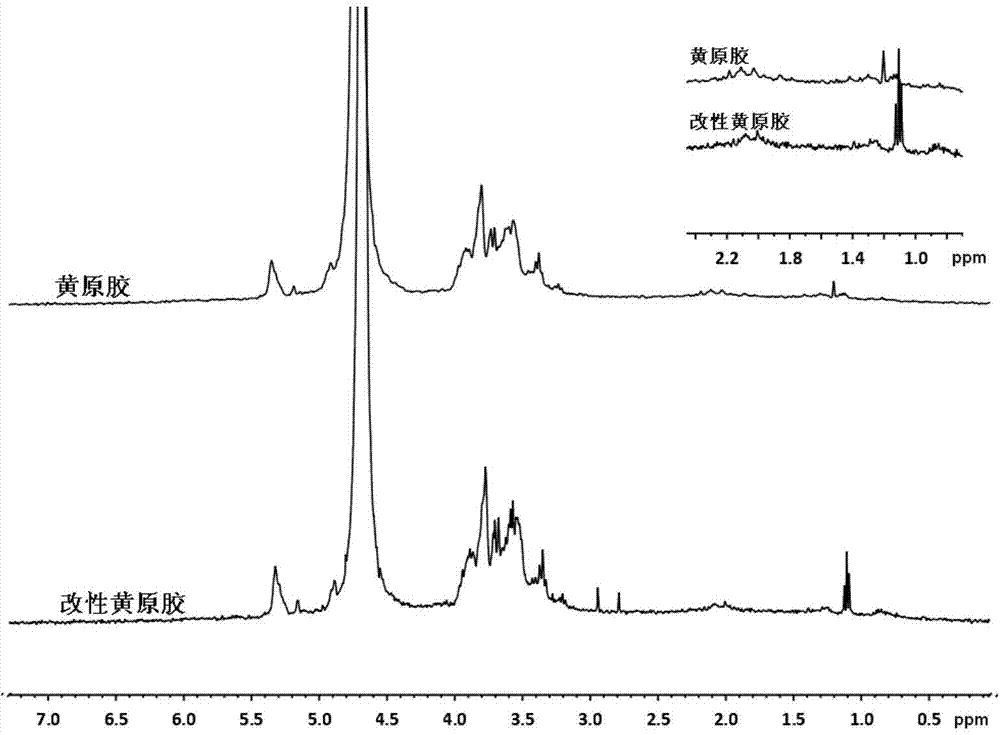

Hydrophobic association water-soluble xanthan gum and preparation method and application thereof

ActiveCN104761653AImprove temperature resistanceHigh viscosityDrilling compositionTemperature resistanceHydroxy compound

The invention discloses a hydrophobic association water-soluble xanthan gum and a preparation method and an application thereof. According to the modified xanthan gum, DMF is adopted as a reaction medium and octadecyl isocyanate is adopted as a modifier; the isocyanate group in octadecyl isocyanate reacts with the hydroxyl group (-OH) in xanthan gum molecules so that a long alkyl chain is introduced into xanthan gum molecules, thus obtaining the hydrophobic association water-soluble xanthan gum with surface activity and bactericidal property. The method has the advantages of mild reaction conditions, use of easily available raw materials, high reactant conversion rate, and convenient product post-treatment. The hydrophobic association water-soluble xanthan gum has better temperature resistance, better salt resistance, better aging resistance and lower surface tension. With the relatively low surface tension, stratum surface wettability can be changed, dispersion of crude oil in water can be enhanced, and the rheological property of crude oil is changed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

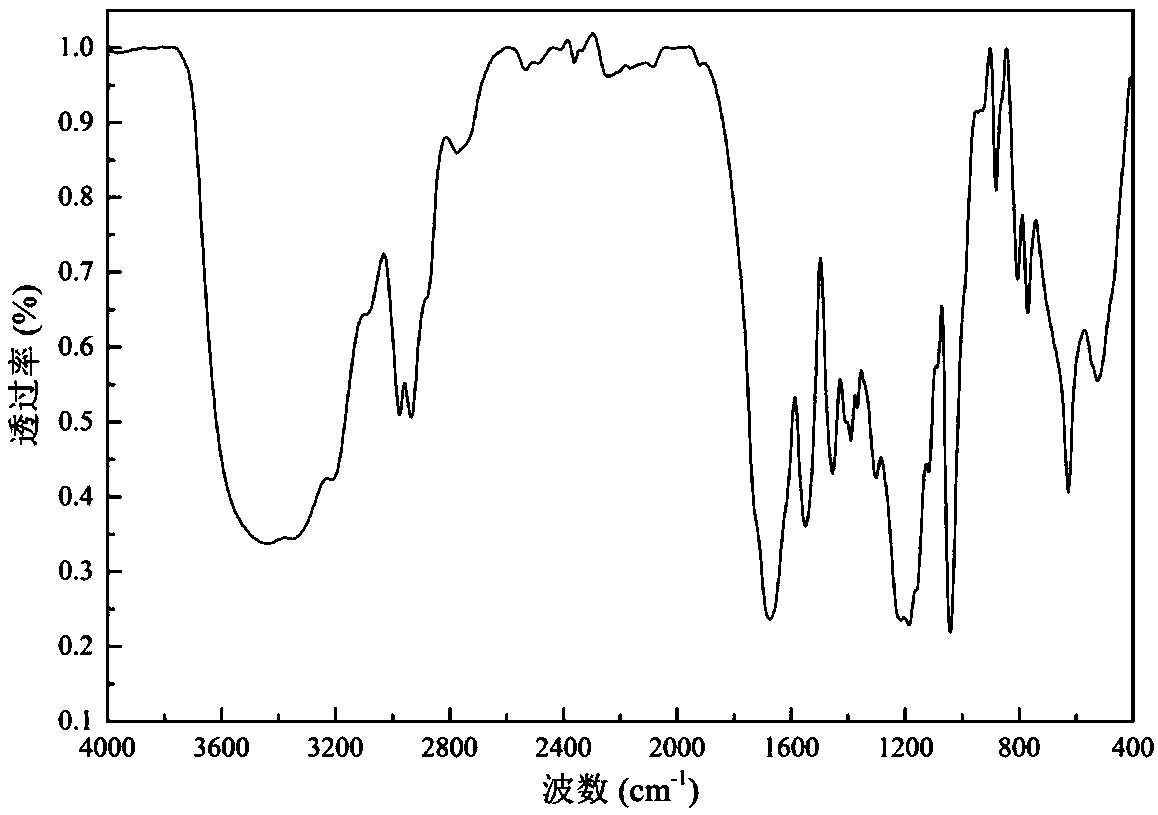

Temperature-resistant and salt-resistant copolymer and preparation method thereof

ActiveCN103772602AEnhance chain rigidityImprove hydrolytic stabilityDrilling compositionTO-18Hydrolysis

The invention relates to a temperature-resistant and salt-resistant copolymer and a preparation method thereof, and mainly solves a problem that polyacrylamide has high possibility of hydrolysis under the conditions of high temperature and high mineralization degree in a conventional technology for improving the recovery efficiency by tertiary oil recovery. According to the technical scheme, the temperature-resistant and salt-resistant copolymer NWKY-PAN has a general formula shown in the specification, wherein p is the number of -CH2- , and is 1 to 3; x, y and m are the structural unit mole numbers of acrylamide, hydrolyzed acrylamide and lactam monomers respectively, x is 95 to 15, y is 4 to 40, and m is 1 to 45; the molecular weight of the copolymer NWKY-PAN is 12,000,000 to 18,000,000; the problem in the prior art is better solved; the temperature-resistant and salt-resistant copolymer can be used for the industrial production of an oil displacement agent for oil recovery in an oilfield.

Owner:CHINA PETROLEUM & CHEM CORP +1

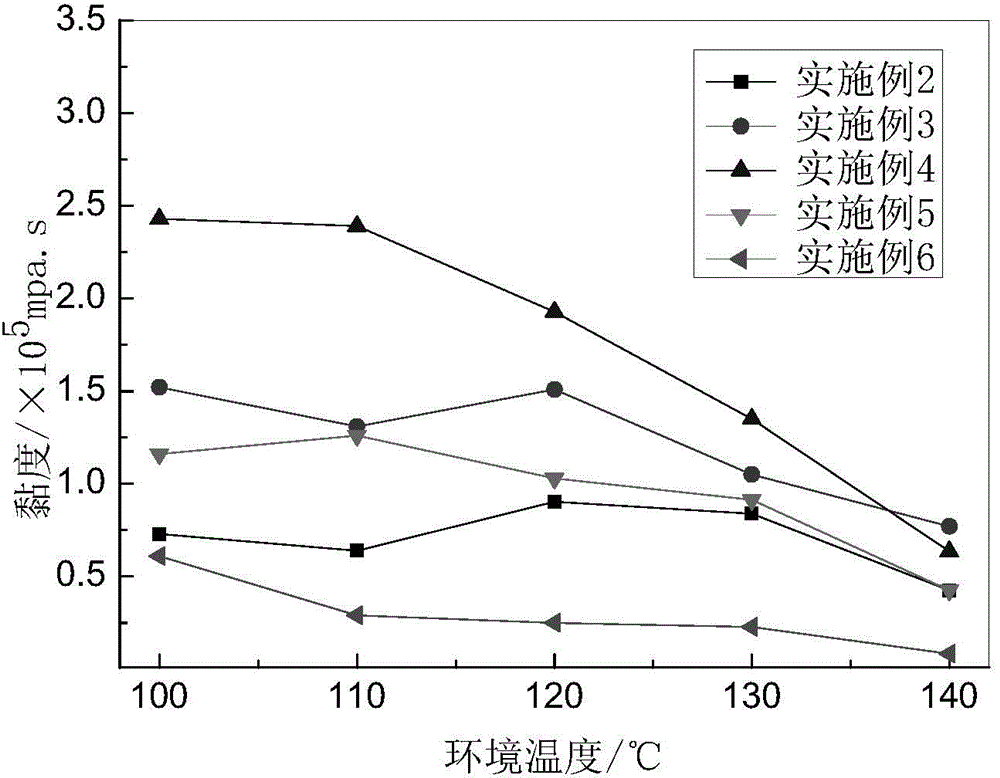

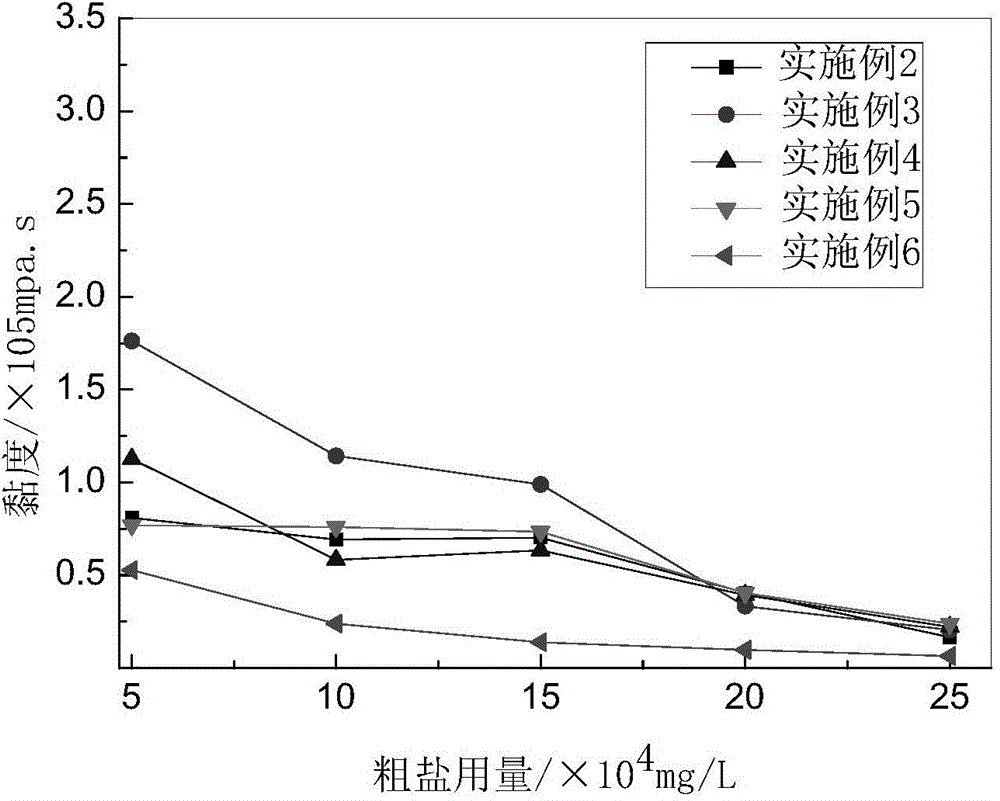

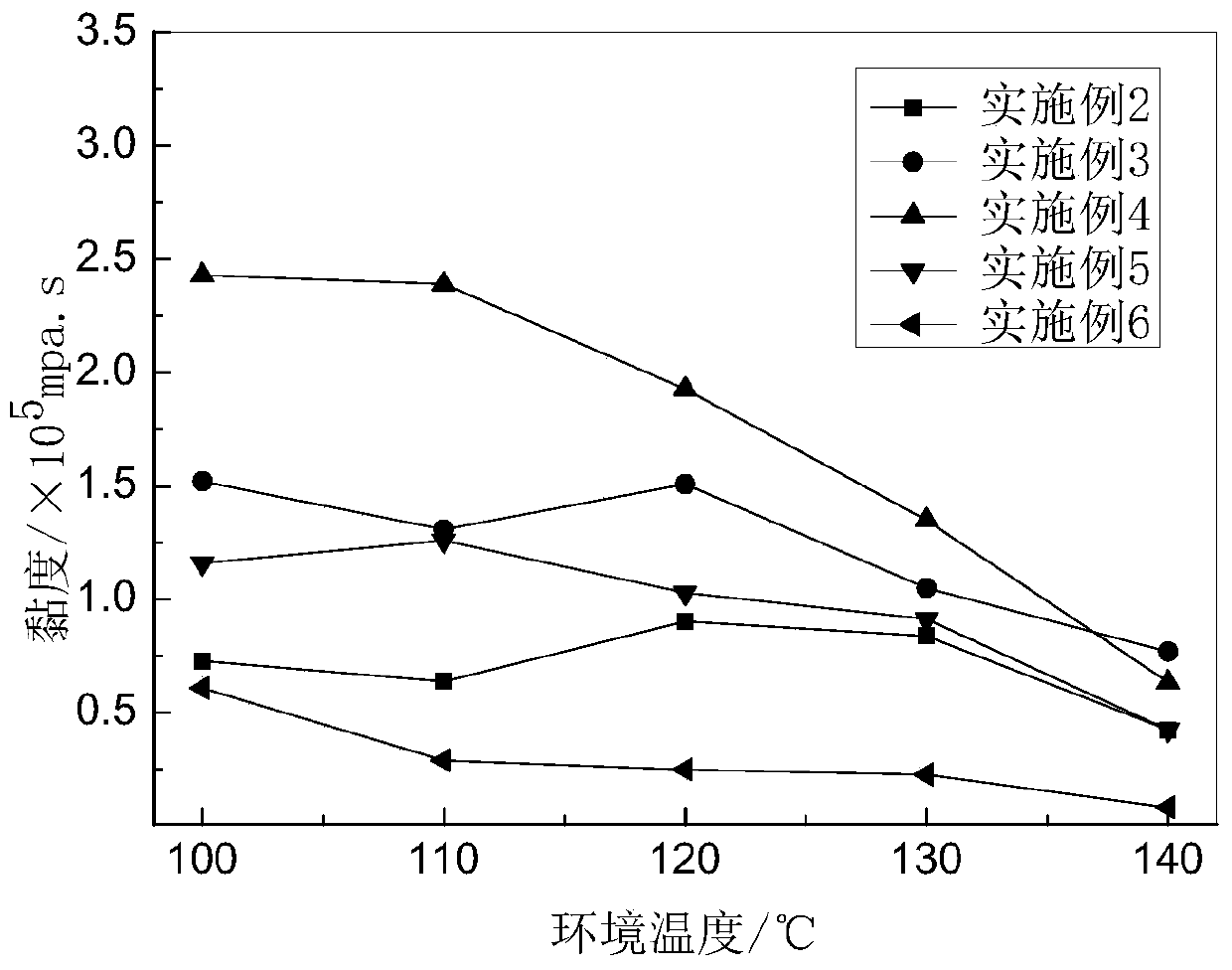

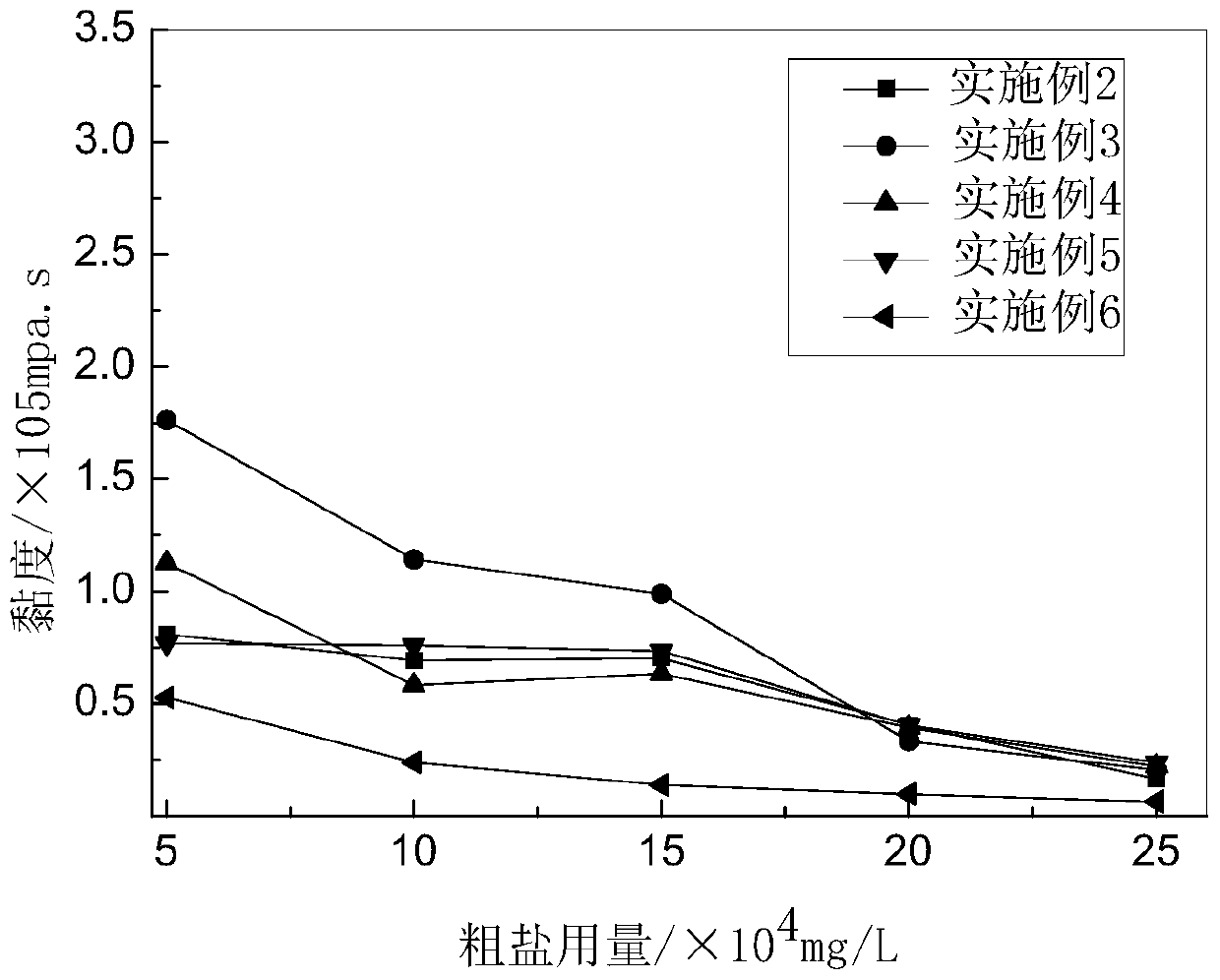

Method for preparing cross-linking acrylamide profile control agent

ActiveCN104945561ARaw materials are widely availableLow costDrilling compositionCross-linkReaction temperature

The invention relates to a method for preparing a cross-linking acrylamide profile control agent. The method comprises the steps of completely dissolving a cross-linking agent through acid, adding an initiator, leading in N2, adding a mixed solution of acrylamide and sulfonyl-containing monomers, performing free radical polymerization reaction in the closed atmosphere of N2 to form a product, causing the product to undergo the nucleophilic addition reaction, and obtaining polymer gel. The method has the advantages that raw materials are extensive, easy to obtain and low in cost; the cross-linking acrylamide profile control agent has good environmental friendliness compared with frequently-used chromic salt and phenolic aldehyde and the like; the viscosity of a system, gelling time and the performances of gel after gelling are controlled through the changing of the concentration or reaction temperature of the monomers, the cross-linking agent and the initiator; when the environment temperature range is 100-140 DEG C, no obvious degradation occurs, and the viscosity retention rate is high; and when the coarse salt concentration range is 0-2.5*105 mg / L, the cross-linking acrylamide profile control agent can have good stability and is not subjected to gel breaking and precipitation.

Owner:DAQING BEIHUA CHEM PLANT

Pickering emulsion for heavy oil reservoirs and preparation method thereof

InactiveCN109852359AImprove stabilityHigh viscosity retentionDrilling compositionSilica particleAdhesive

The invention discloses a Pickering emulsion for heavy oil reservoirs. The Pickering emulsion comprises nano silicon dioxide particles, water, an adhesive, and mineral oil; wherein the ratio of silicon dioxide particles to water is 1:10, and the ratio of the adhesive to mineral oil is 1:15. The production process is simple, the operation is convenient, no toxic and harmful solvent is used, moreover, the production cost is low, the product purity is high, and the preparation method is suitable for industrial production.

Owner:ZHEJIANG OCEAN UNIV

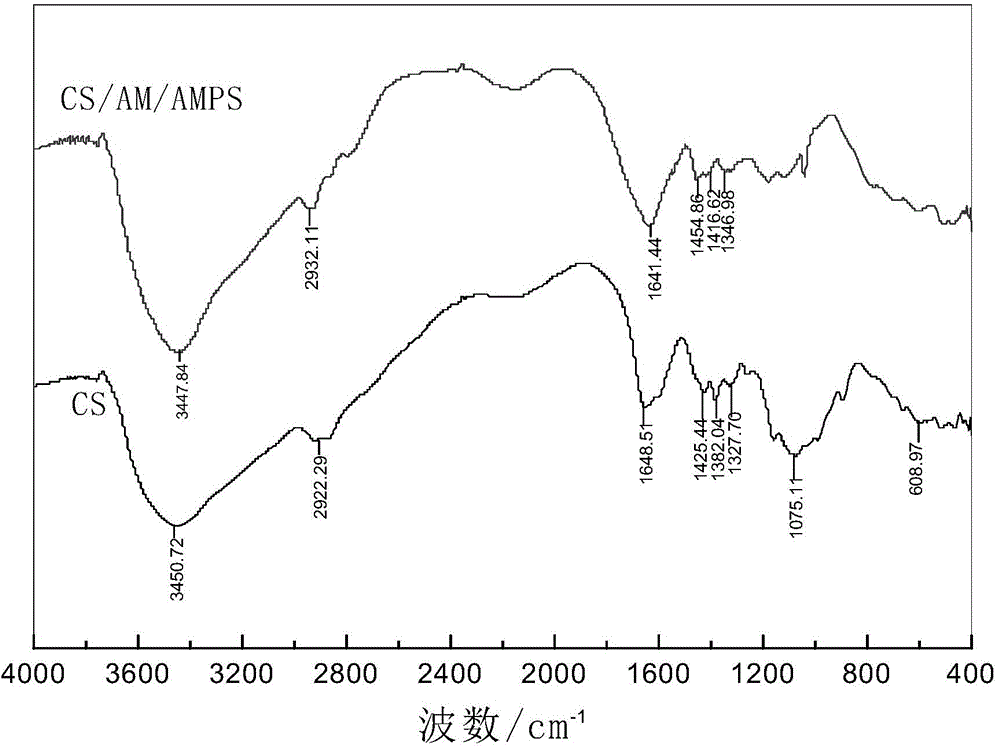

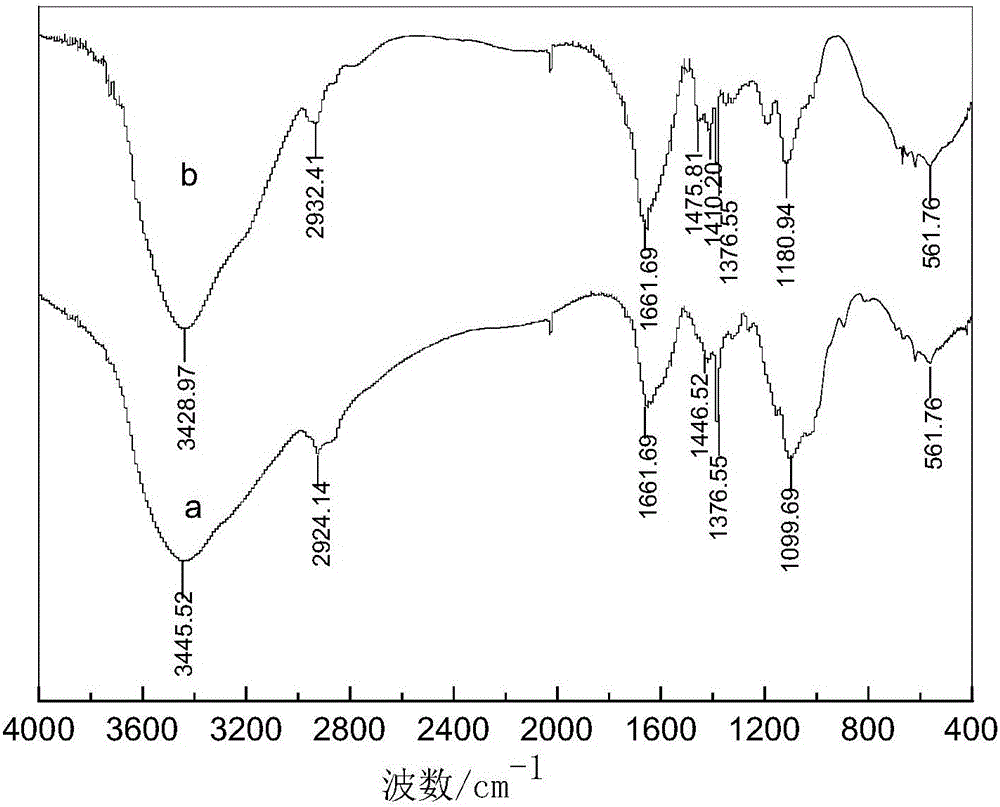

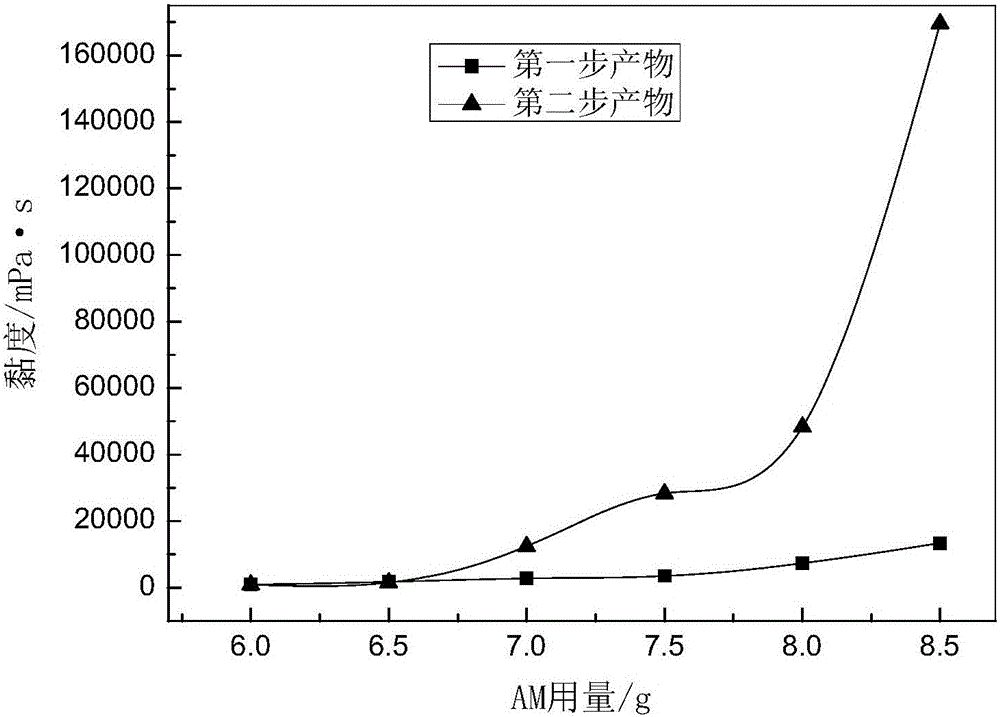

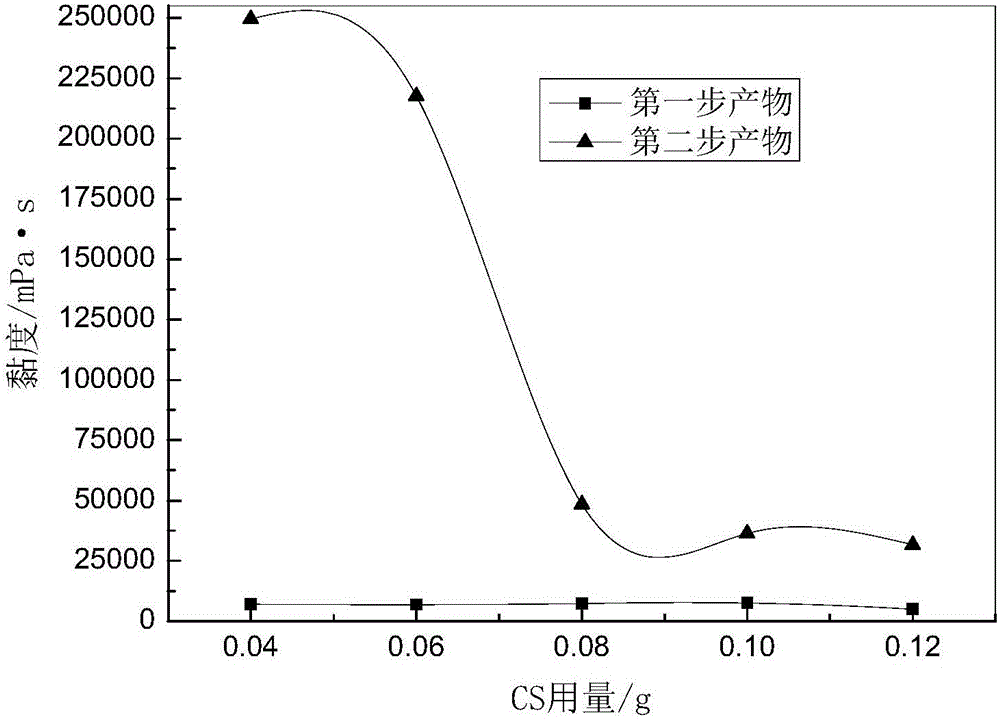

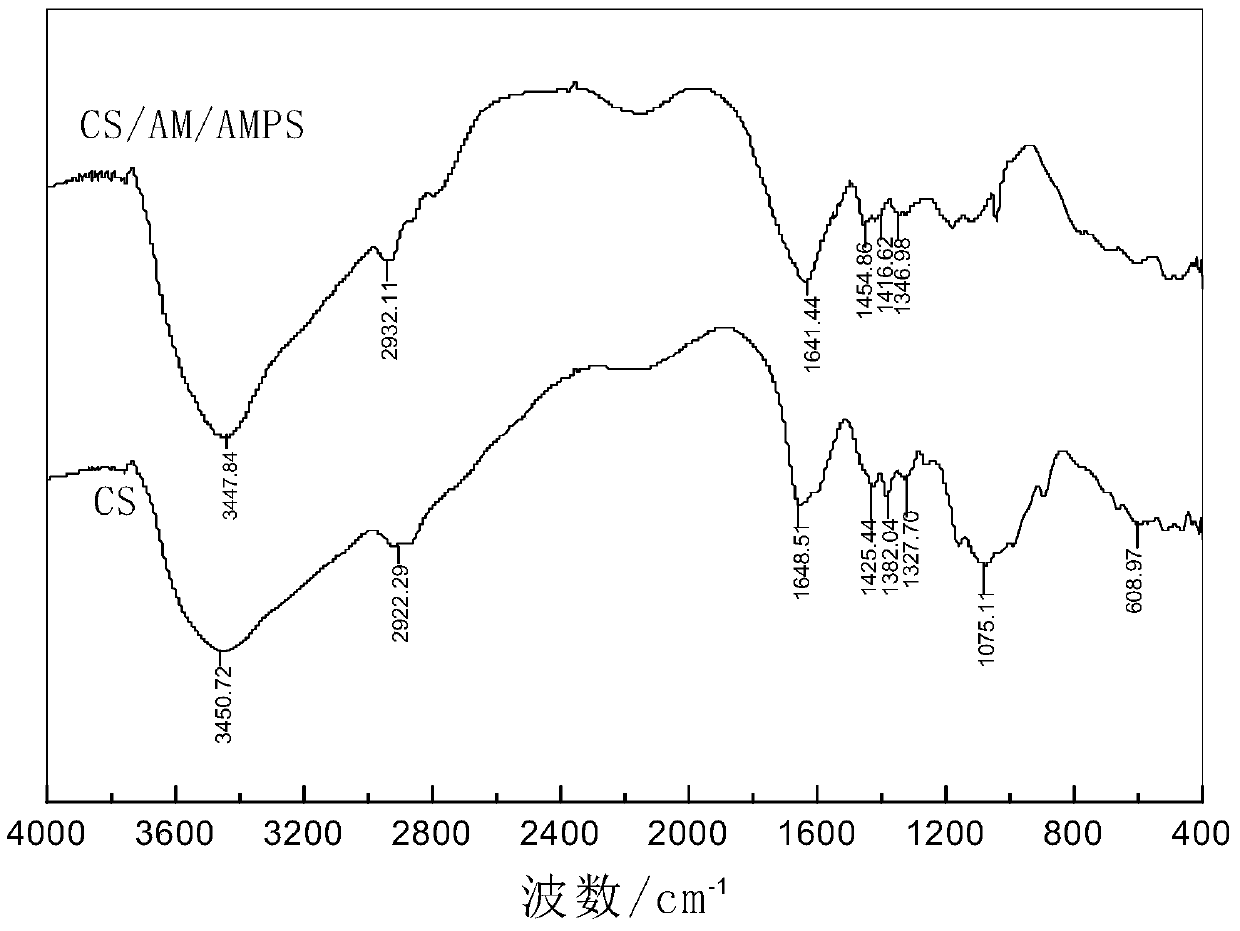

Chitosan cross-linked and modified acrylamide compound as well as preparation method thereof and application thereof

InactiveCN106046258ALow costPromote environmental protectionDrilling compositionSalt resistanceCross-link

The invention discloses a chitosan cross-linked and modified acrylamide compound as well as a preparation method thereof and application thereof, and belongs to the field of oilfield chemistry. The preparation method for the chitosan cross-linked and modified acrylamide compound comprises the following steps: 1) at a temperature being 50-70 DEG C, completely dissolving 0.04-0.12g of a biological type cross-linking agent chitosan into 50 mL of acid, adding 0.05-0.25g of an initiator, adding 50 mL of a solution with 6-8.5g of the acrylamide after certain time, and carrying out free radical polymerization reaction at certain stirring speed, thereby synthesizing a first product; and putting a product obtained in the step 1) at a temperature being 90-110 DEG C to carry out nucleophilic reaction, thereby obtaining polymer gel. The gel prepared by the preparation method is economical and environmental-friendly, has a cross-linked net-shaped structure, further has good shearing resistance, temperature and salt resistance, and can be used as a gel profile control agent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Thermal stabilizer for oilfield and preparation method thereof

InactiveCN108865099AEnhanced overall recoveryHigh viscosity retentionDrilling compositionPolyethylene glycolUltimate tensile strength

The invention discloses a thermal stabilizer for an oilfield as well as a preparation method and application thereof. The thermal stabilizer is prepared from the following components in parts by weight: 10 to 15 parts of hydrogen peroxide, 20 to 30 parts of ammonium sulfate, 2 to 3 parts of polyethylene glycol, 10 to 30 parts of urea and 900 to 1000 parts of de-ionized water. The components are uniformly mixed to obtain the thermal stabilizer; the thermal stabilizer is used for oil displacement or plugging control of an oilfield polymer. The thermal stabilizer disclosed by the invention has ahigh viscosity retention rate; the preparation method is simple and a preparation speed is rapid; the cost is relatively low, and the strength and stability of the polymer can be improved relatively well.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

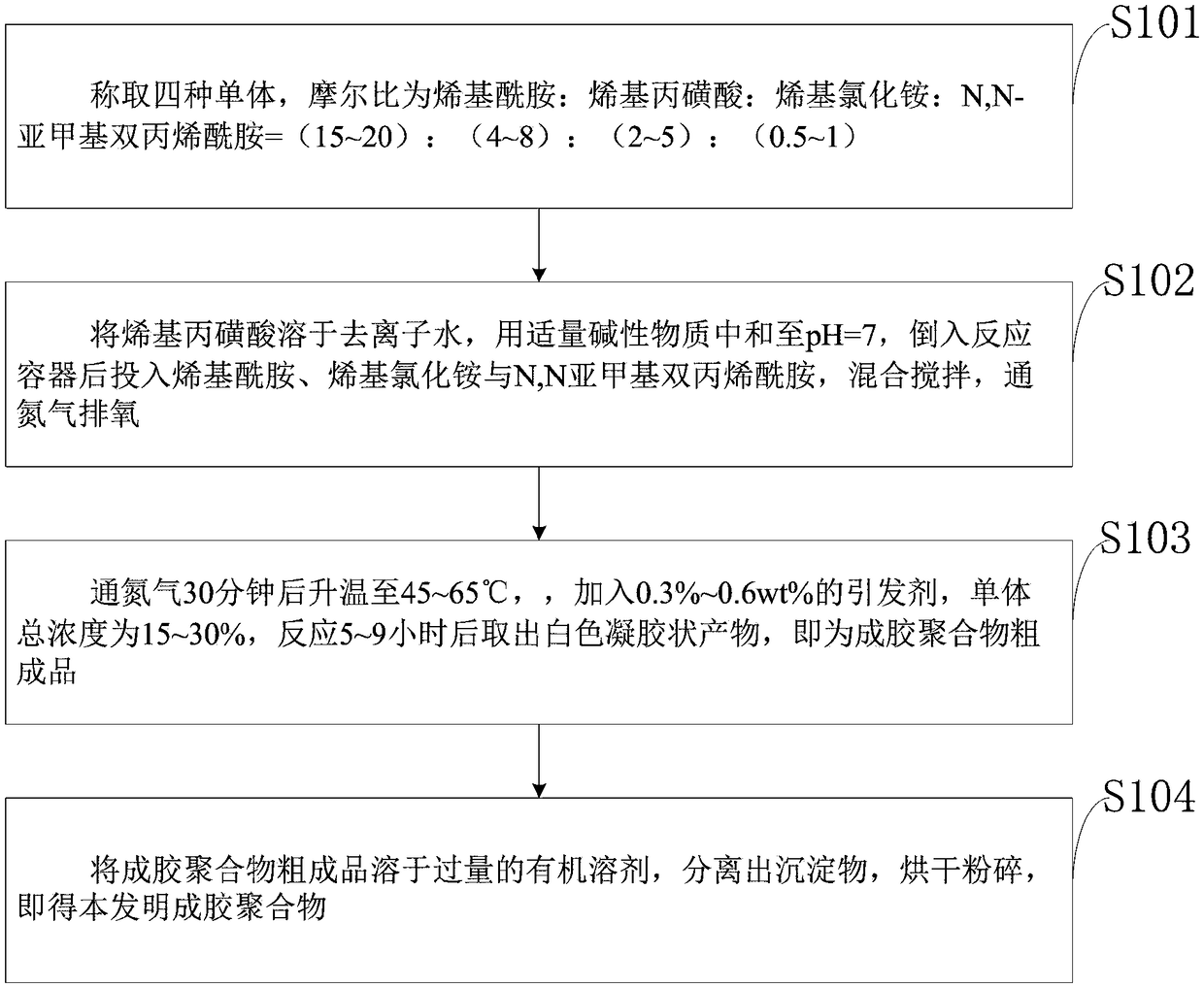

Colloidal polymer, preparation method thereof and polymer weak gel drilling fluid

InactiveCN108949124AImprove sticky effectImprove rheologyDrilling compositionWater basedPolymer science

The invention belongs to the field of polymer weak gel for a water-based drilling fluid and the preparation thereof and discloses a colloidal polymer, a preparation method thereof and a polymer weak gel drilling fluid. The colloidal polymer is formed by copolymerizing the raw materials according to a free radical solution polymerization method, wherein the raw materials include four monomers, namely alkenyl amide, allyl propyl sulfonic acid, alkenyl ammonium chloride and N,N-methylene bisacrylamide at a certain ratio. The relative molecular mass of the polymer is 20-40 ten thousands. The colloidal polymer disclosed by the invention has an excellent heat-resisting property (capable of resisting a temperature high up to 220 DEG C), is capable of maintaining strong colloidal property in an environment of high temperature and high mineralization degree and has an excellent de-filtration property; a base pulp system added with the polymer has a better rheological property, will not thickenat a high temperature and is capable of meeting the requirements of current deep drilling operations; the preparation method is simple, the condition is mild and the yield is higher.

Owner:HENGXIANG SCI & TECH KELAMAYI CITY +1

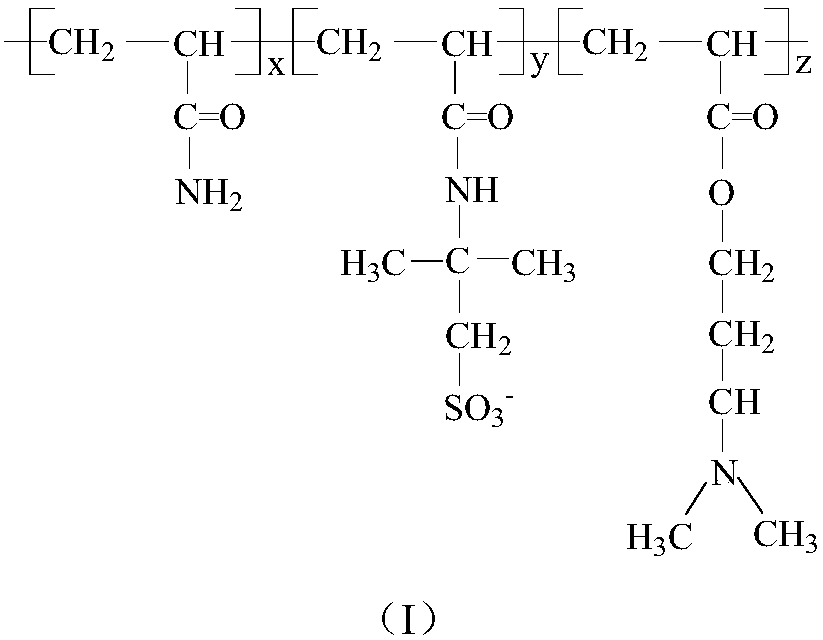

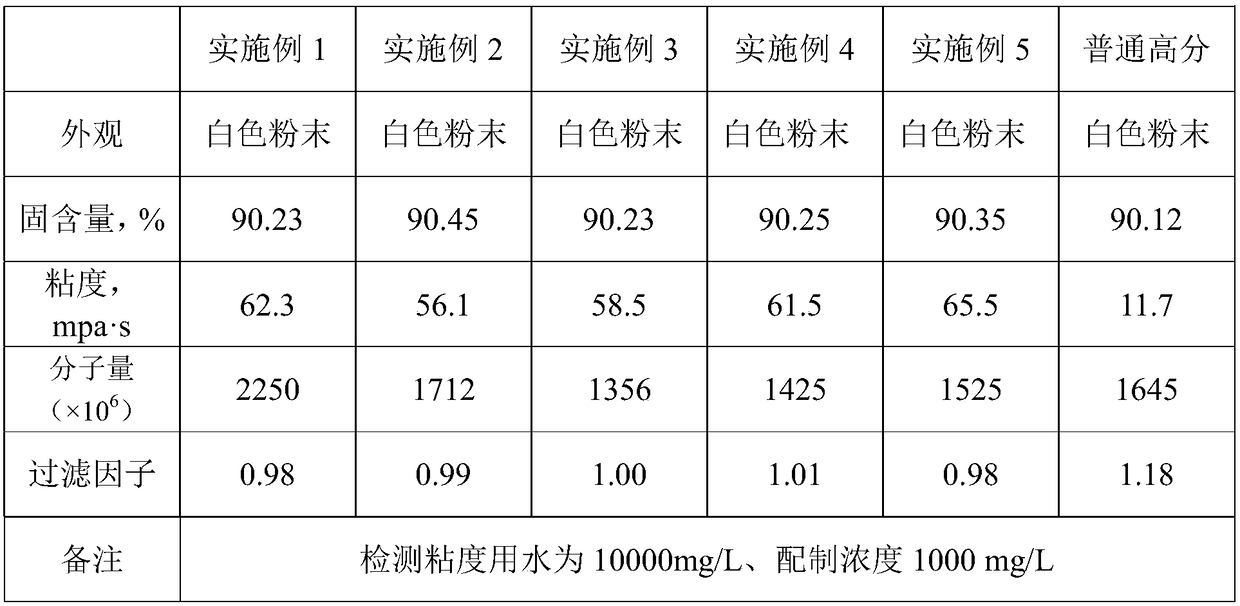

Salt-resistant polyacrylamide for oil displacement and preparation method thereof

ActiveCN109265602AHigh viscosity retentionAvoid breedingDrilling compositionSolubilityFunctional monomer

The invention relates to salt-resistant polyacrylamide for oil displacement. The salt-resistant polyacrylamide is prepared from the following components in parts by weight: 770-840 parts of deionizedwater, 150-260 parts of acrylamide, 10-30 parts of an anionic monomer and 5-40 parts of functional monomer microemulsion. The invention further relates to a preparation method for the salt-resistant polyacrylamide for oil displacement. According to the salt-resistant polyacrylamide and the preparation method thereof, the functional monomer is introduced into a polymerization formula, so that sulfate-reducing bacteria, iron bacteria, saprophytic bacteria and the like in sewage can be inhibited, the viscosity retention rate of the salt-resistant polyacrylamide for oil displacment in the sewage for 180 days is greater than 90%, and therefore the viscosity retention rate of the polyacrylamide in the sewage is greatly increased; and meanwhile, the functional monomer adopts a microemulsion preparation mode, blocks in a molecular structure of a product are more uniform, the solubility of the product is greatly improved, and therefore the problem that conventional polyacrylamide is dissolved slowly in the sewage or in high-salinity brine can be solved.

Owner:黑龙江吉地油田服务股份有限公司

Water blocking agent as well as preparation method and application thereof

ActiveCN109868126AAvoid concentrated releaseHigh strengthDrilling compositionSodium metasilicateAntioxidant

The invention provides a water blocking agent as well as a preparation method and application thereof. The water blocking agent comprises the following components: 0.5-2% of partially-hydrolyzed polyacrylamide, 0.5-1.5% of an organic crosslinking agent, 0.02-0.75% of an antioxidant, 0.02-0.75% of a stabilizing agent, 0-0.5% of anhydrous sodium metasilicate, 0-0.2% of calcium chloride, and the balance of simulation water. According to the water blocking agent provided by the invention, through a reasonable ratio of the simple components, the obtained water blocking agent has suitable gelling time, has good heat stability, high strength and good salt tolerance after gel formation, and can satisfy requirements of some high-temperature high-salt special oil reservoir conditions.

Owner:PETROCHINA CO LTD

Study of novel dimeric surfactant/polymer binary compound oil-displacing agent

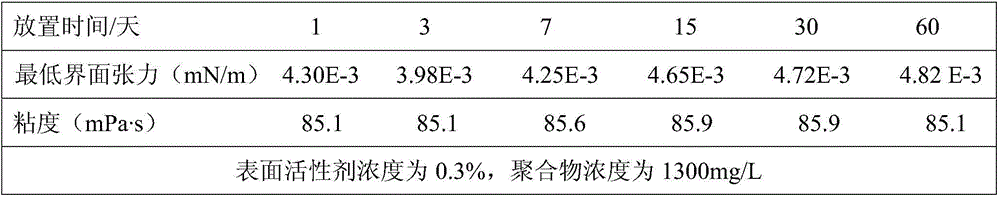

InactiveCN104673267AEnhanced overall recoveryHigh viscosity retentionDrilling compositionOil fieldBinary compound

The invention relates to a dimeric surfactant / polymer binary compound system suitable for enhancing the oil recovery in the Shengtuo area of Shengli Oil Field. The dimeric surfactant / polymer binary compound system is compounded from a polymer and a dimeric surfactant in a specific ratio; the system is capable of reducing the interfacial tension of the crude oil in the Shengtuo area of Shengli Oil Field to be ultralow; in long-term placement process, the viscosity and the interfacial activity of the system do not change much, and therefore, the binary system in the specific ratio has stable viscosity and is capable of thoroughly developing the effects of the enlarged wave and the volume, and also has stable interfacial tension and is capable of guaranteeing relatively high microcosmic oil displacement efficiency; and as a result, the purpose of enhancing the oil recovery is achieved.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Temperature-resistant polyacrylamide preparation method

InactiveCN109082058AHigh viscosity retentionImprove temperature resistanceTemperature resistanceGraphene

The invention discloses a temperature-resistant polyacrylamide preparation method. The method includes: taking acrylamide as a raw material, preparing into polyacrylamide, preparing into hydrolytic polyacrylamide, adding graphene to obtain temperature-resistant polyacrylamide, and drying and grinding to obtain a fine particle product. The viscosity keeping rate of the temperature-resistant polyacrylamide prepared according to the method is remarkably increased, temperature resistance of polyacrylamide is evidently improved, and high stability is realized.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

Low-tension hydroxyoximido emulsion oil-displacement polymer and preparation method thereof

ActiveCN105504157ASave construction investmentFast dissolutionDrilling compositionPolymer scienceHydroxylamine sulfate

The invention discloses a low-tension hydroxyoximido emulsion oil-displacement polymer and a preparation method thereof. The low-tension hydroxyoximido emulsion oil-displacement polymer is composed of acrylamide, acrylic acid, water, liquid caustic soda, 2-acrylamido-2-methylpropyl sulfonic acid, methylene-bis acrylamine, potassium bromate, sodium formate, pentasodium diethylene triamine pentaacetate, chalcanthite, hydroxylamine sulfate, white oil D110, alga oleamide, Span-80, Tween-81, an emulsifying and dispersing agent OA90, azo and isohexadecyl ethylene oxide ether. The low-tension hydroxyoximido emulsion oil-displacement polymer has high molecular-weight and high solid content, is endowed with high-polymer main chain polyfunctional groups, and is an instant-dissolution reverse-phase microemulsion product with favorable stability and low tension.

Owner:山东金智瑞新材料发展有限公司

High-temperature-resistant and high-salt-resistant heat stabilizer for polymer used for oil flooding, and preparation method and application thereof

ActiveCN105949505ALow costDegradative free radicals are activeDrilling compositionPolymer scienceField tests

The invention discloses a high-temperature-resistant and high-salt-resistant heat stabilizer for a polymer used for oil flooding, and a preparation method and application thereof. The heat stabilizer is composed of the following components in parts by weight: 3 to 5 parts of calcium peroxide, 20 to 30 parts of ammonium chloride, 2 to 3 parts of hydrogen peroxide and 900 to 1000 parts of deionized water. The heat stabilizer is prepared from the above-mentioned components by uniform mixing and used for polymer flooding in an oil field. The heat stabilizer provided by the invention has high viscosity retention rate under the conditions of high temperature and high salt; the use of the heat stabilizer greatly reduces the concentration of the polymer; and the preparation method provided by the invention is simple, has rapid preparation speed and low cost, and can well improve the strength and the stability of the polymer. Thus, the heat stabilizer can be extensively applied in a field test of polymer flooding in high-temperature and high-salt oil reservoir.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

High-temperature-resisting and high-salt-resisting thermal stabilizer of polymer for oil field as well as preparation method and application of high-temperature-resisting and high-salt-resisting thermal stabilizer

ActiveCN105802104ASave the cost of oil floodingDegradative free radicals are activeDrilling compositionPolymer scienceUltimate tensile strength

The invention discloses a high-temperature-resisting and high-salt-resisting thermal stabilizer of a polymer for an oil field as well as a preparation method and application of the high-temperature-resisting and high-salt-resisting thermal stabilizer. The thermal stabilizer is prepared from the following components in parts by weight: 3 to 5 parts of calcium peroxide, 20 to 30 parts of ammonium sulfate, 2 to 3 parts of peracetic acid and 900 to 1000 parts of de-ionized water. All the components are uniformly mixed to obtain the thermal stabilizer and the thermal stabilizer is used for oil displacement or plugging control of the polymer of the oil field. The thermal stabilizer disclosed by the invention has a high viscosity retention rate under high-temperature and high-salt conditions, and the concentration of the polymer is greatly reduced when the thermal stabilizer is utilized; the preparation method is simple and a preparation speed is rapid; the cost is relatively low, and the strength and stability of the polymer can be improved very well.

Owner:GUANGRAO LIUHE CHEM CO LTD

Coating composition for low ignition propensity cigarette paper, tobacco using same, and method for manufacturing low ignition propensity cigarette paper

PendingUS20200154759A1Extended service lifeIncrease productivitySpecial paperCigar manufactureAlcohol ethylEngineering

A coating composition for low ignition propensity cigarette paper, according to one embodiment of the present invention, comprises 10-30 wt % of gum arabic, 25-35 wt % of maltose, 15-30 wt % of ethanol and 10-40 wt % of water.

Owner:KT&G CO LTD

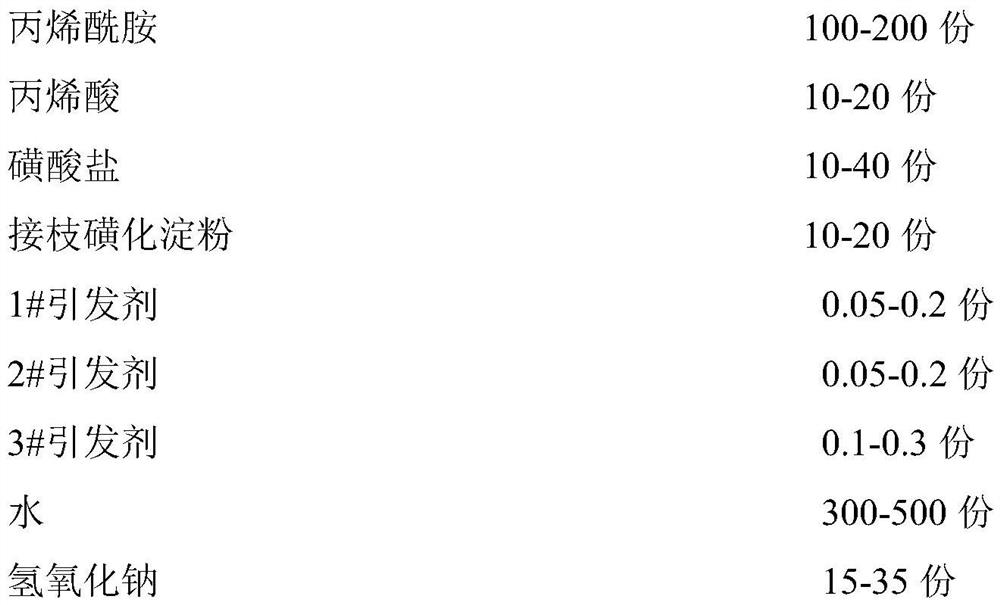

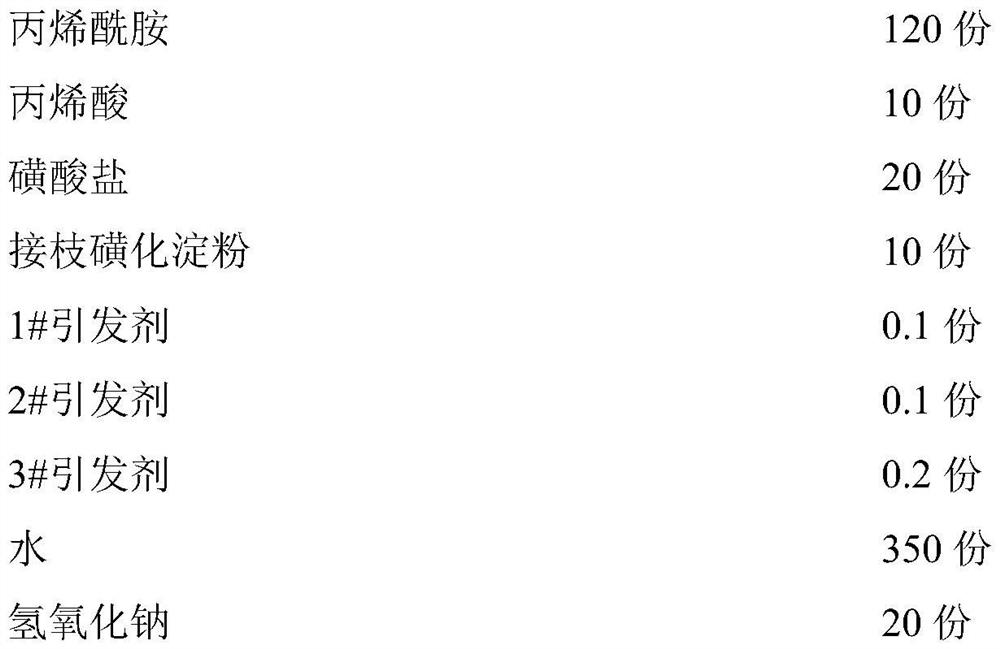

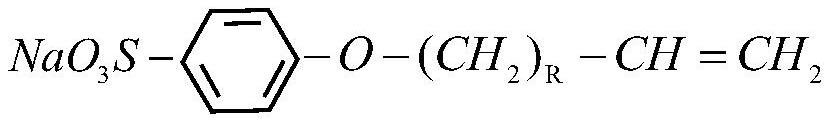

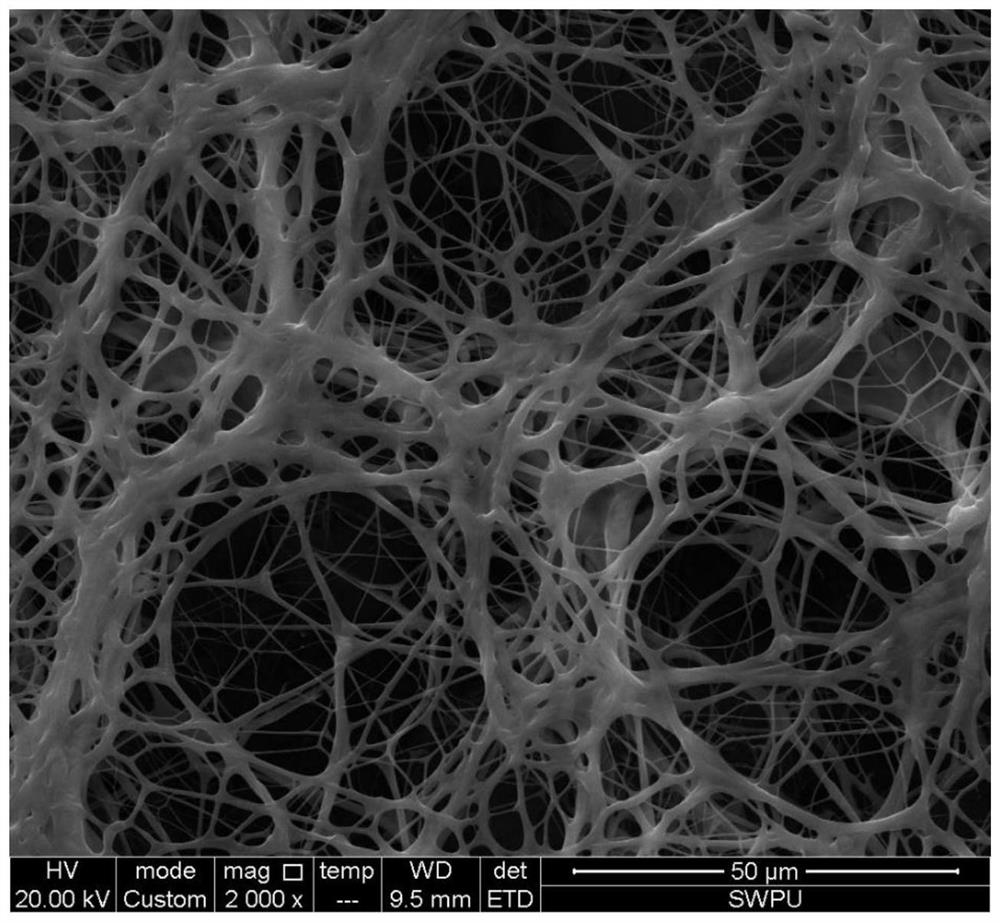

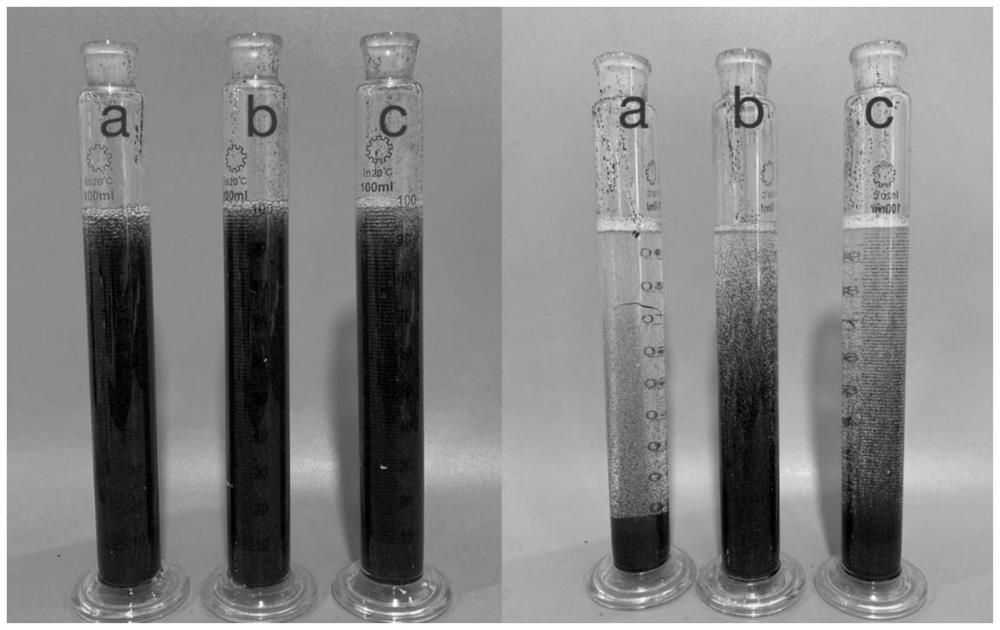

Sewage-resistant polymer for oil extraction and preparation method thereof

ActiveCN113248665ATemperature resistantSalt resistantFatty substance recoverySulfonateAnti bacterial

The invention discloses a sewage-resistant polymer for oil extraction and a preparation method thereof, and relates to the technical field of oil exploitation. The sewage-resistant polymer comprises acrylamide, acrylic acid, grafted sulfonated starch, sulfonate, an initiator and other components. The sewage-resistant polymer for oil extraction is prepared through polymerization of acrylamide, grafted sulfonated starch and sulfonate. The polymer has the characteristics of temperature resistance, salt resistance, antibiosis, high viscosity retention rate and capability of being prepared from oilfield produced sewage, can keep good solubility and tackifying effect under the sewage condition, and can improve the oil recovery rate to a relatively high extent.

Owner:黑龙江吉地油田服务股份有限公司

Preparation of high-salt-resistant self-elasticity-increasing type hydrophobic association polymer and application of high-salt-resistant self-elasticity-increasing type hydrophobic association polymer in fracturing fluid

The invention belongs to the technical field of oil gas yield increase, and discloses preparation of a high-salt-resistant self-elasticity-increasing type hydrophobic association polymer and application of the high-salt-resistant self-elasticity-increasing type hydrophobic association polymer in fracturing fluid. The preparation method of the polymer comprises the following steps: (1) synthesizing a hydrophobic monomer with polyether: reacting oleic acid with thionyl chloride to obtain a live intermediate oleic acid acyl chloride, and reacting the intermediate oleic acid acyl chloride with allyl polyethylene glycol to obtain a polyether monomer; and (2) synthesizing the hydrophobic associated polymer, namely polymerizing acrylamide, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, a cationic hydrophobic monomer and a polyether hydrophobic monomer APOA according to the mass ratio of (50-60): (20-30): (10-15): (3-5): (0.5-1.5) at the temperature of 1-20 DEG C for 4-8 hours, and drying and pulverizing to obtain polymer powder. The elasticity of the polymer is increased along with the increase of the mineralization degree, the polymer still has excellent elasticity and very high viscosity retention rate under the mineralization degree of 300,000, and when the polymer is applied to the fracturing fluid, the problems of low salt resistance, low sand suspending capacity and the like of the traditional fracturing fluid can be effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of preparation method of cross-linked acrylamide type profile control agent

ActiveCN104945561BRaw materials are widely availableLow costDrilling compositionCross-linkReaction temperature

The invention relates to a method for preparing a cross-linking acrylamide profile control agent. The method comprises the steps of completely dissolving a cross-linking agent through acid, adding an initiator, leading in N2, adding a mixed solution of acrylamide and sulfonyl-containing monomers, performing free radical polymerization reaction in the closed atmosphere of N2 to form a product, causing the product to undergo the nucleophilic addition reaction, and obtaining polymer gel. The method has the advantages that raw materials are extensive, easy to obtain and low in cost; the cross-linking acrylamide profile control agent has good environmental friendliness compared with frequently-used chromic salt and phenolic aldehyde and the like; the viscosity of a system, gelling time and the performances of gel after gelling are controlled through the changing of the concentration or reaction temperature of the monomers, the cross-linking agent and the initiator; when the environment temperature range is 100-140 DEG C, no obvious degradation occurs, and the viscosity retention rate is high; and when the coarse salt concentration range is 0-2.5*105 mg / L, the cross-linking acrylamide profile control agent can have good stability and is not subjected to gel breaking and precipitation.

Owner:DAQING BEIHUA CHEM PLANT

Preparation method of heat-resistant and salt-resistant polyacrylamide for oil field

The invention provides a preparing method for heat resistance and salt tolerance polyacrylamide used in an oil field. The preparing method comprises the following steps that acrylamide, 2- acrylamide-2-methyl sodium, sodium acrylate, aiding solvent and deionized water are mixed to be dissolved fully and uniformly, and alkali is used for adjusting a pH value to obtain a homopolymerisation solution; the homopolymerisation solution is pumped into a polymerizing pot after being cooled, 2,2'-azobis-(2-methylbutyronitrile) is added, nitrogen is introduced, chain extender is added at first, then solutions prepared by complexing agents, oxidizing agents, reducing agents and auxiliary reducing agents are added sequentially, after all the solutions are added, nitrogen continues to be introduced, the polymerization reaction is carried out, heat is preserved, and the aging reaction is carried out to obtain a polyacrylamide rubber block; the rubber block is taken out, cutting, pelleting, drying, smashing and screening are carried out on the rubber block to obtain high-hydrolysis-degree polyacrylamide. The polyacrylamide obtained through the method has the advantages of stable quality, high viscosity, heat resistance, salt tolerance, high dissolving speed and good solubility, the product energy consumption is low, and in the high-temperature and high-salinity environment, the viscosity is degraded slowly.

Owner:ANHUI JUCHENG FINE CHEM

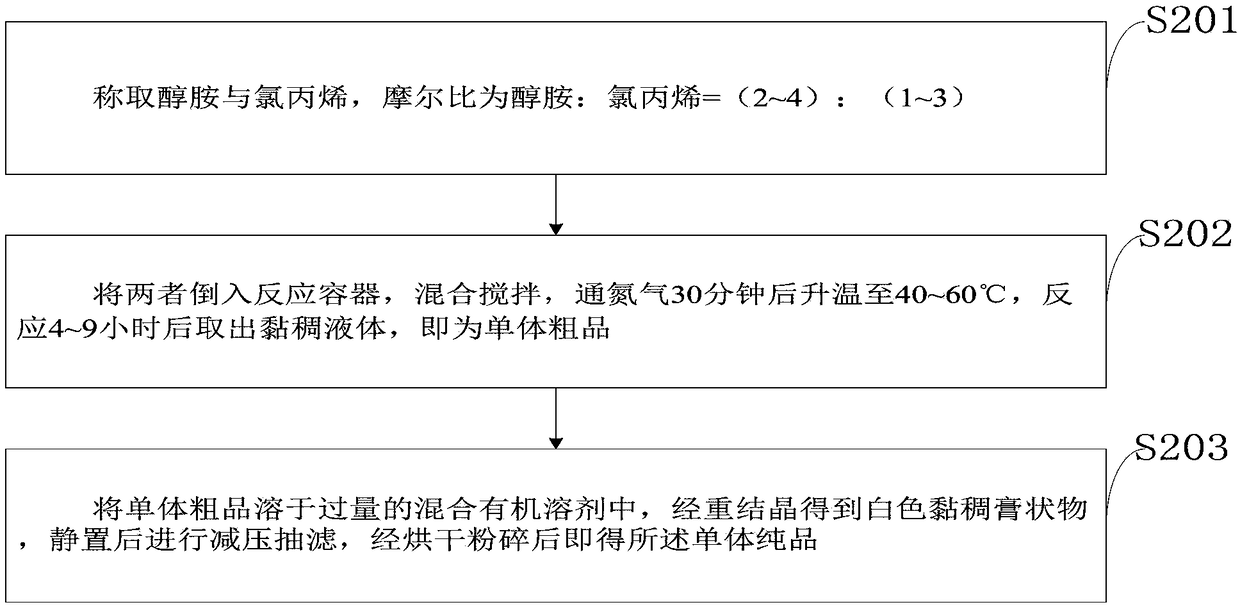

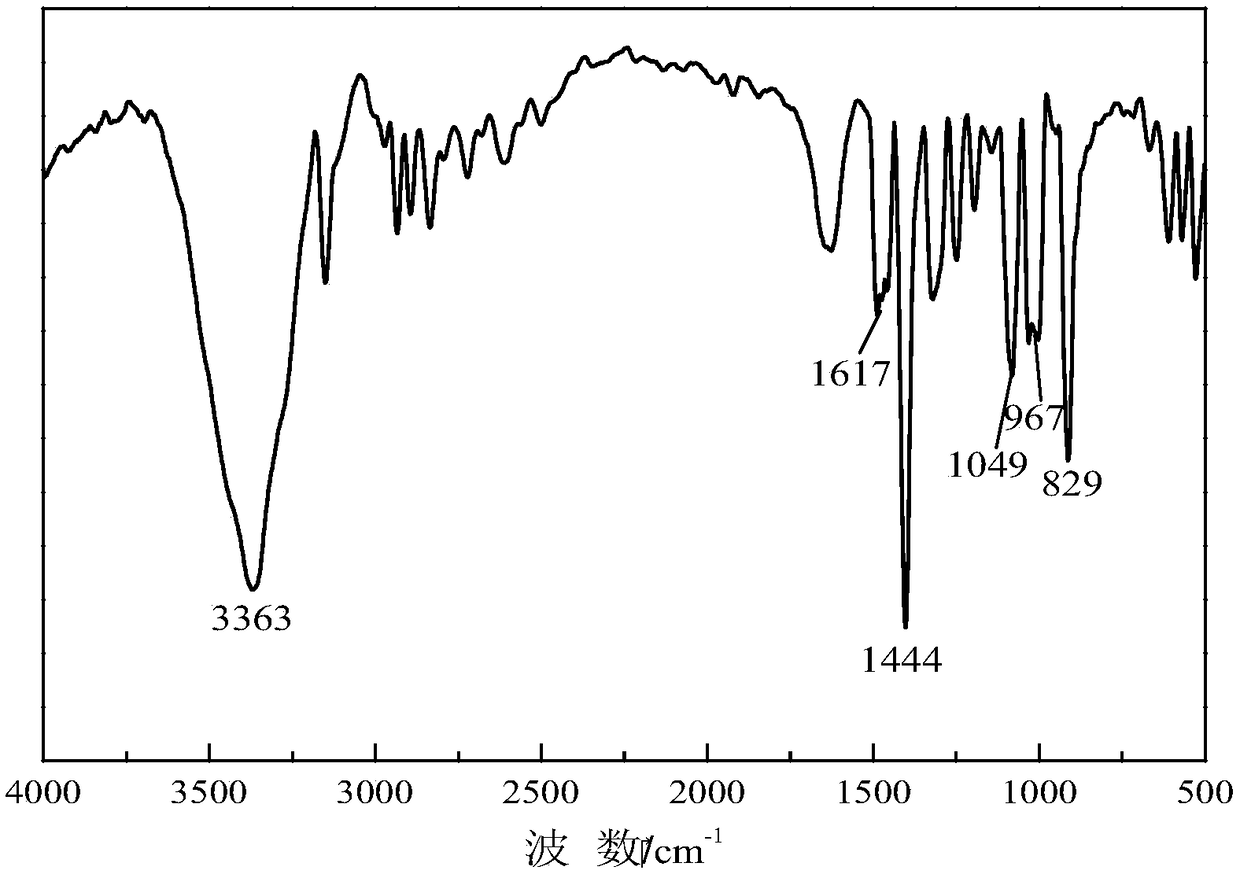

Salt-resistant monomer and preparation method thereof

The invention discloses a salt-resistant monomer and a preparation method thereof and belongs to the technical field of high-molecular polymers. The salt-resistant monomer comprises N-vinyl pyrrolidone, ring monomer with double bonds, acrylonitrile and a sulfonating agent. The salt-resistant monomer is mainly used for water-solution, segmented and random polymerization modes and is mainly used for preparing salt-resistant polymers special for oil fields.

Owner:黑龙江吉地油田服务股份有限公司

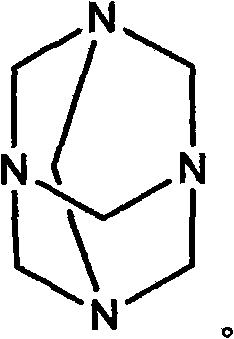

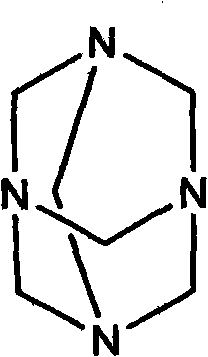

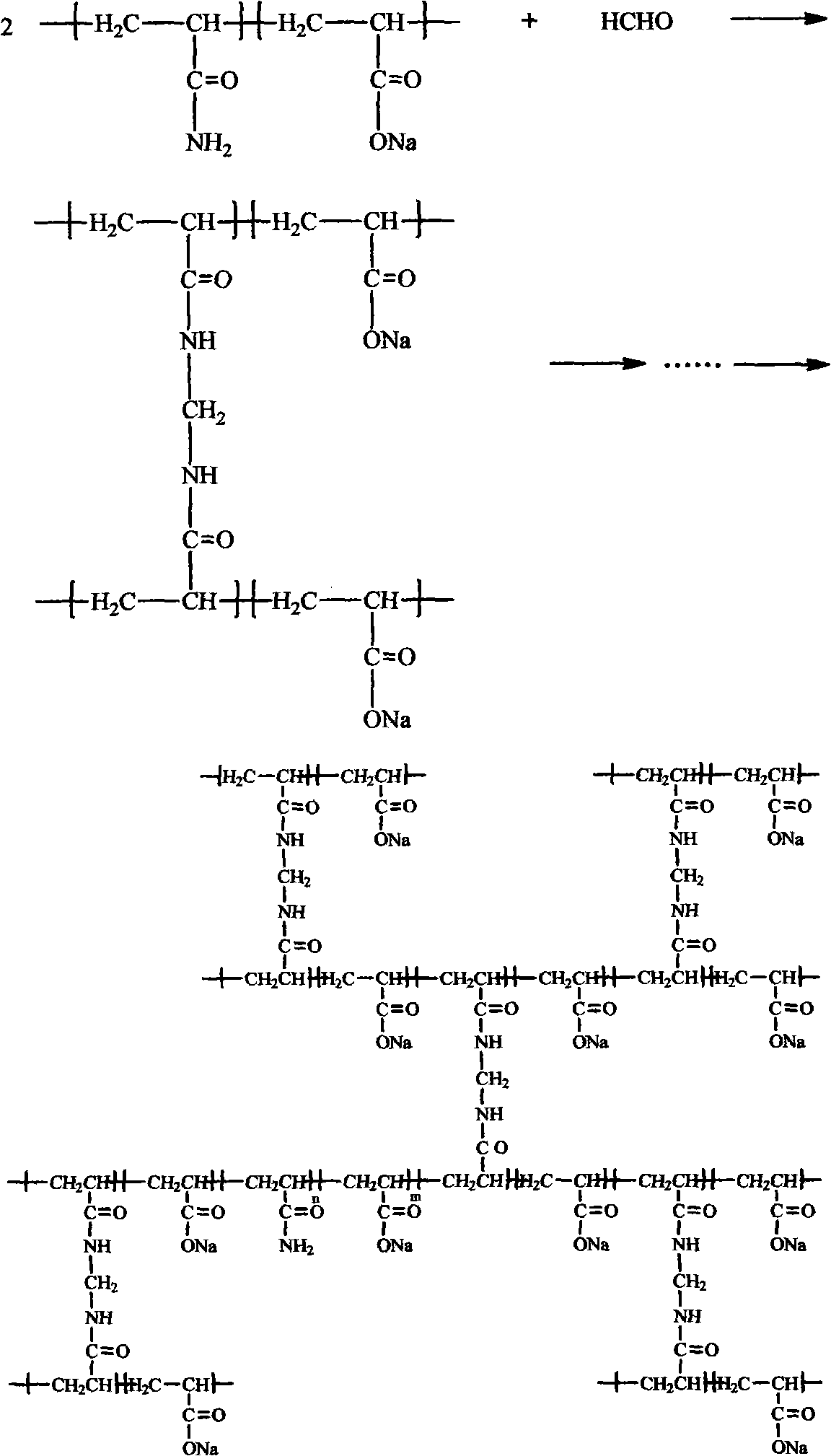

Method for stabilizing displacing fluid viscosity

ActiveCN102382636BGood viscosity stabilityImprove high temperature resistanceDrilling compositionSalt resistanceFluid viscosity

The invention discloses a method for stabilizing the displacing fluid viscosity, which comprises the following steps of: preparing polymer solution mother liquor; adding anionic polyacrylamide into water and fully dissolving the anionic polyacrylamide; adding sewage for diluting the polymer solution mother liquor; and adding hexamethylene tetramine and fully dissolving the hexamethylene tetramine. The method has the advantages that the viscosity stability of the polyacrylamide is improved, the consumption of the polyacrylamide is reduced, the cost is reduced, in addition, the addition quantity of the hexamethylene tetramine is small, the viscosity keeping effect is good, the high-temperature resistance performance and the salt resistance performance of the polyacrylamide are improved, and in addition, the viscosity stability of the displacing fluid is enhanced so that the viscosity retention rate of the displacing fluid is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com