Sewage-resistant polymer for oil extraction and preparation method thereof

A polymer and sewage technology, which is used in the preparation of sewage-resistant polymers for oil production and the field of sewage-resistant polymers for oil production, can solve the problems of reduced recovery rate, increased difficulty in matching, and inability to discharge sewage, and achieve viscosity retention. high oil recovery rate, enhanced oil recovery, good solubility and viscosifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

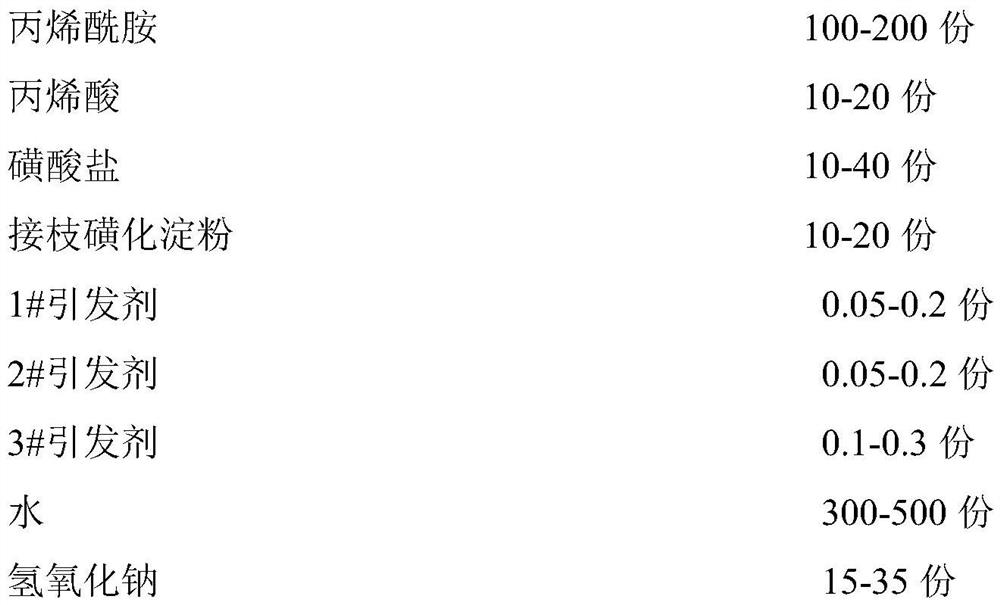

[0030] A sewage-resistant polymer for oil recovery and a preparation method thereof:

[0031] (1) 100 parts of acrylamide, 10 parts of acrylic acid, 10 parts of sulfonate, 10 parts of grafted sulfonated starch, and 300 parts of water were mixed and stirred evenly, and the pH was adjusted to 7.5 with 10% sodium hydroxide solution;

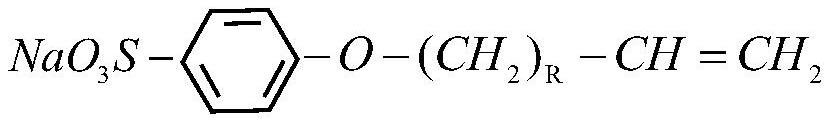

[0032] Wherein, the structure of sulfonate is as follows:

[0033]

[0034] (2) After adjusting the temperature of the solution prepared in step (1) to 8°C, transfer it to an adiabatic polymerization kettle, and then pass through nitrogen for 30 minutes to remove oxygen, then add 0.05 parts of sodium persulfate to the polymerization kettle, and then add sodium persulfate after 5 minutes. Add 0.05 part of sodium bisulfate, add 0.1 part of azobisisobutyronitrile after another 5 minutes, stop feeding nitrogen after the system in the kettle starts to heat up, and continue aging for 2 hours after the reaction is completed until the temperature is no l...

Embodiment 2

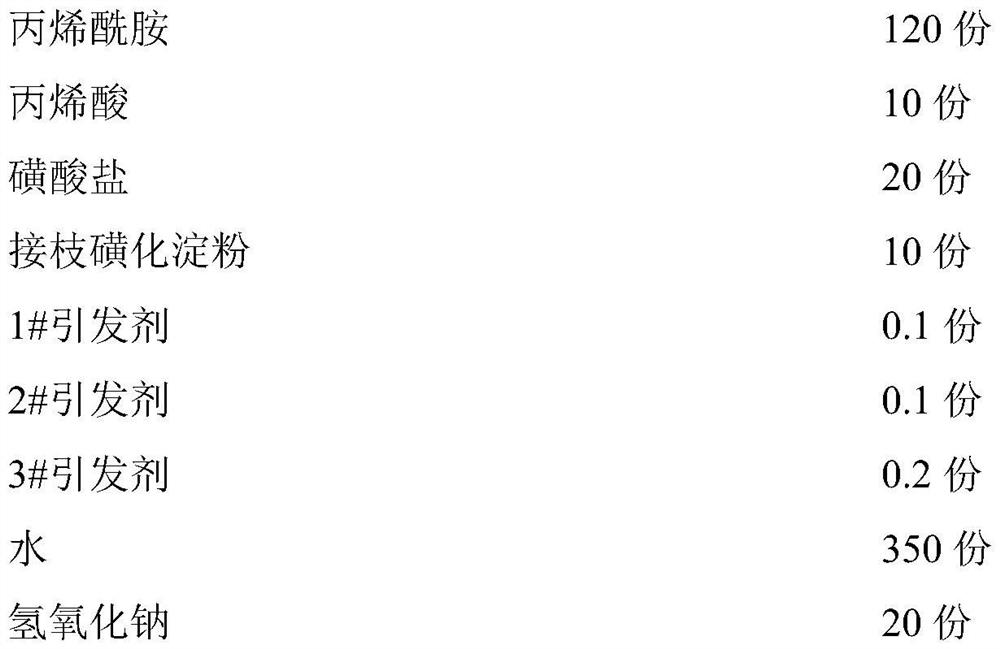

[0042] A sewage-resistant polymer for oil recovery and a preparation method thereof:

[0043](1) 120 parts of acrylamide, 10 parts of acrylic acid, 20 parts of sulfonate, 10 parts of grafted sulfonated starch, and 350 parts of water were mixed and stirred evenly, and the pH was adjusted to 7.5 with 10% sodium hydroxide solution;

[0044] Wherein, the structure of sulfonate is as follows:

[0045]

[0046] (2) After adjusting the temperature of the solution prepared in step (1) to 8°C, transfer it to an adiabatic polymerization kettle, and then pass nitrogen gas for 30 minutes to remove oxygen, then add 0.1 part of potassium persulfate to the polymerization kettle, and add three Add 0.1 part of ethanolamine, add 0.2 part of azobisisobutylamidine hydrochloride after another 5 minutes, stop feeding nitrogen after the system in the kettle starts to heat up, and continue to ripen for 2 hours after the reaction is completed until the temperature is no longer raised to obtain a po...

Embodiment 3

[0054] A sewage-resistant polymer for oil recovery and a preparation method thereof:

[0055] (1) 120 parts of acrylamide, 10 parts of acrylic acid, 20 parts of sulfonate, 20 parts of grafted sulfonated starch, and 400 parts of water were mixed and stirred evenly, and the pH was adjusted to 7.5 with 10% sodium hydroxide solution;

[0056] Wherein, the structure of sulfonate is as follows:

[0057]

[0058] (2) After adjusting the temperature of the solution prepared in step (1) to 8°C, transfer it to an adiabatic polymerization kettle, and then pass nitrogen gas for 30 minutes to remove oxygen, then add 0.1 part of potassium persulfate to the polymerization kettle, and add three Add 0.1 part of ethanolamine, add 0.2 part of azobisisobutylamidine hydrochloride after another 5 minutes, stop feeding nitrogen after the system in the kettle starts to heat up, and continue to ripen for 2 hours after the reaction is completed until the temperature is no longer raised to obtain a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com