Self-lubricating antiseiznig materials and preparing method thereof

An anti-stick coating and self-lubricating technology, applied in the direction of coating, can solve the problems of poor sintering performance, poor wear resistance of coatings, pollute the environment, etc., and achieve the effect of improving construction performance, good impact resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

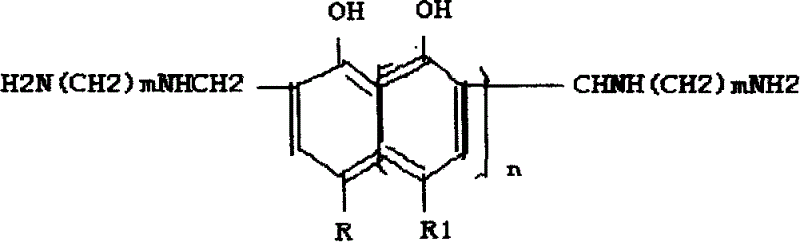

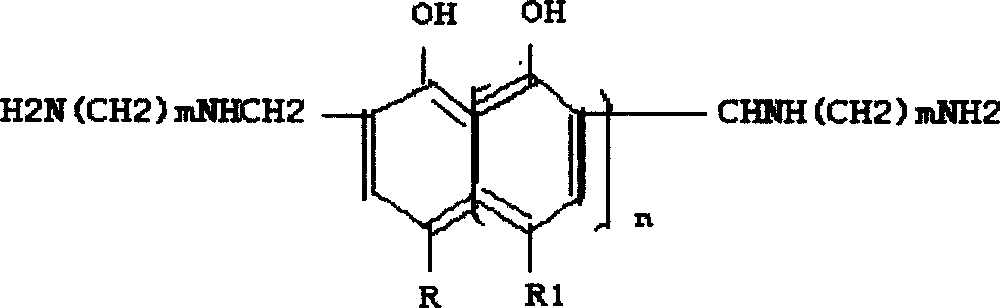

Image

Examples

Embodiment 1

[0018] The paint is prepared according to the following composition ratio: (mass ratio):

[0019] The ratio of film-forming substances is:

[0020] Cellulose Nitrate 5%, Polyacrylic acid 10%, PTFE 35%, Ca 2 Al 2 Si 3 o 10 (OH) 2 (Anorthite) 5%

[0021] Al 2 Si 4 o 10 (OH) 2 (clay) 4%, KAlSiO 4 (potassium feldspar) 3%, FeO 2%, TiO 2 5%α-Al 2 o 3 21%, SiC 10%

[0022] The preparation process is as follows: after mixing the film-forming substance and the ceramic material evenly according to the above formula components, first add ketone and ester solvents to the film-forming substance), curing agents, dispersants, wetting agents and other additives, solvents The amount of addition is 1 / 4 of the total amount of film-forming substances and ceramic fillers, and then ceramic fillers are added to mix and disperse evenly. After grinding to the required average particle size of 25 μm to 50 μm, add the rest of the solvent, sieve, and pack.

[0023] The construction proce...

Embodiment 2

[0026] The paint is prepared according to the following composition ratio: (mass ratio):

[0027] Cellulose nitrate 15%, polyacrylic acid 15%, polytetrafluoroethylene 30%, low temperature ceramic powder 15%

[0028] TiO 2 5%, α-Al 2 o 3 20%

[0029] Appropriate amount of solvent, appropriate amount of dispersant and wetting agent

[0030] The preparation process is as follows: after mixing the film-forming substance and the ceramic material in proportion to the above-mentioned substances, first add solvents and additives to the film-forming substance. The amount of solvent added is 1 / 4 of the total amount of the film-forming substance and ceramic filler. , and then add ceramic fillers to mix and disperse evenly, grind to the required average particle size (5-50μm), add the rest of the solvent, sieve, and pack.

[0031] Construction technology is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com