Ring main unit

A technology of ring main unit and cabinet body is applied in the field of ring main unit, which can solve the problems of reducing the percentage of sulfur hexafluoride gas and decreasing insulation performance, and achieve the effects of improving drying shrinkage performance, improving plasticity and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

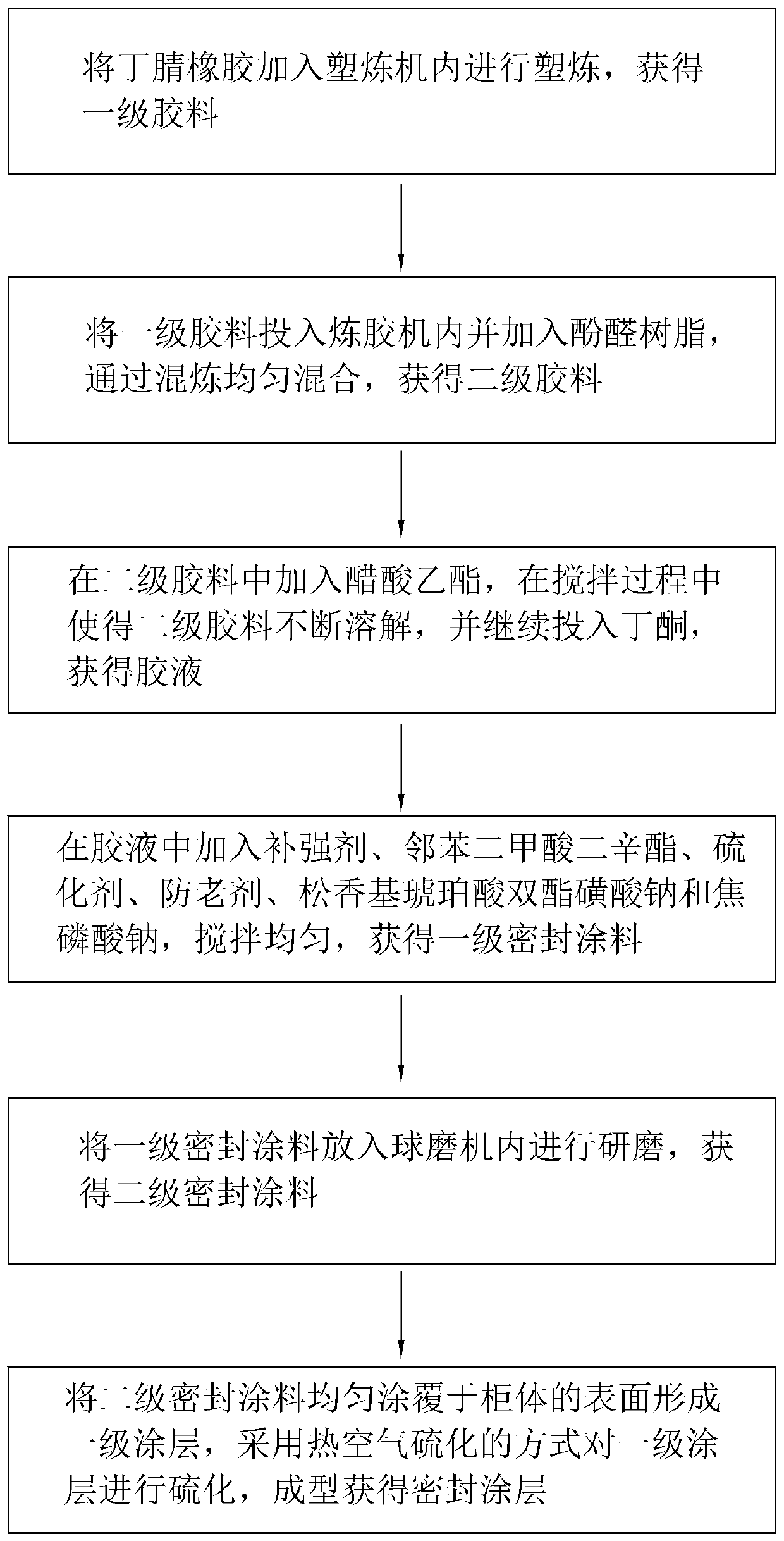

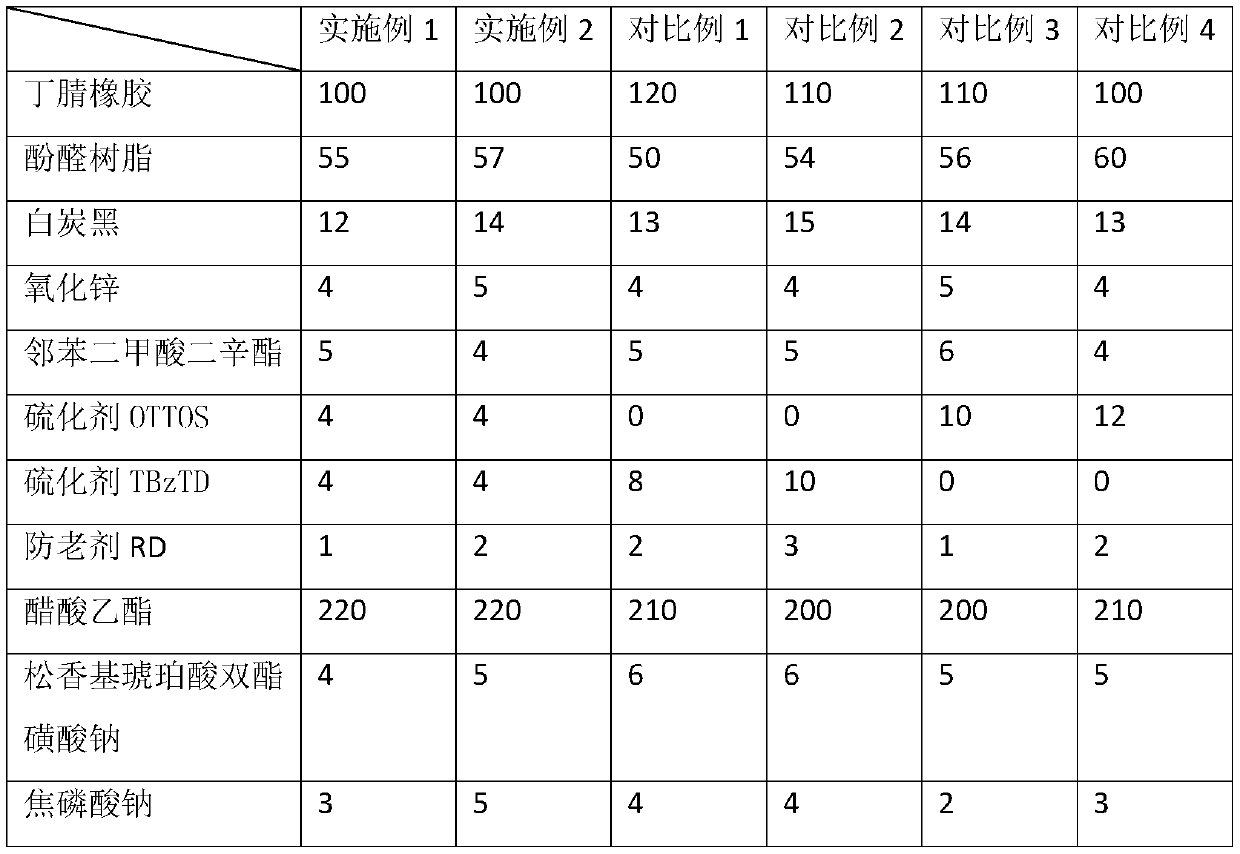

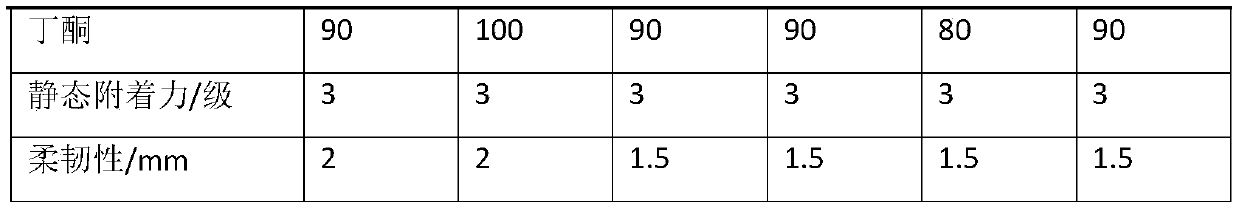

[0036] A ring network cabinet includes a cabinet body filled with sulfur hexafluoride gas, and the surface of the cabinet body is coated with sealing paint to form a sealing coating. The raw materials of the sealing coating are shown in Table 1 in parts by weight. The preparation molding method of this sealing coating comprises the following steps:

[0037] Step 1, adding nitrile rubber into the masticating machine for masticating to obtain the first-grade rubber compound;

[0038] Step 2, put the first-grade rubber material into the rubber mixer and add phenolic resin, and mix evenly through mixing to obtain the second-grade rubber material;

[0039] Step 3, adding ethyl acetate to the secondary rubber material, making the secondary rubber material continuously dissolve during the stirring process, and continuing to add methyl ethyl ketone to obtain the glue solution;

[0040] Step 4, add white carbon black, zinc oxide, dioctyl phthalate, N-oxydiethylene thiocarbamoyl-N' te...

Embodiment 2

[0044] The difference from Example 1 is that, in terms of parts by weight, the raw materials of the seal coat are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com