Patents

Literature

136results about How to "With dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

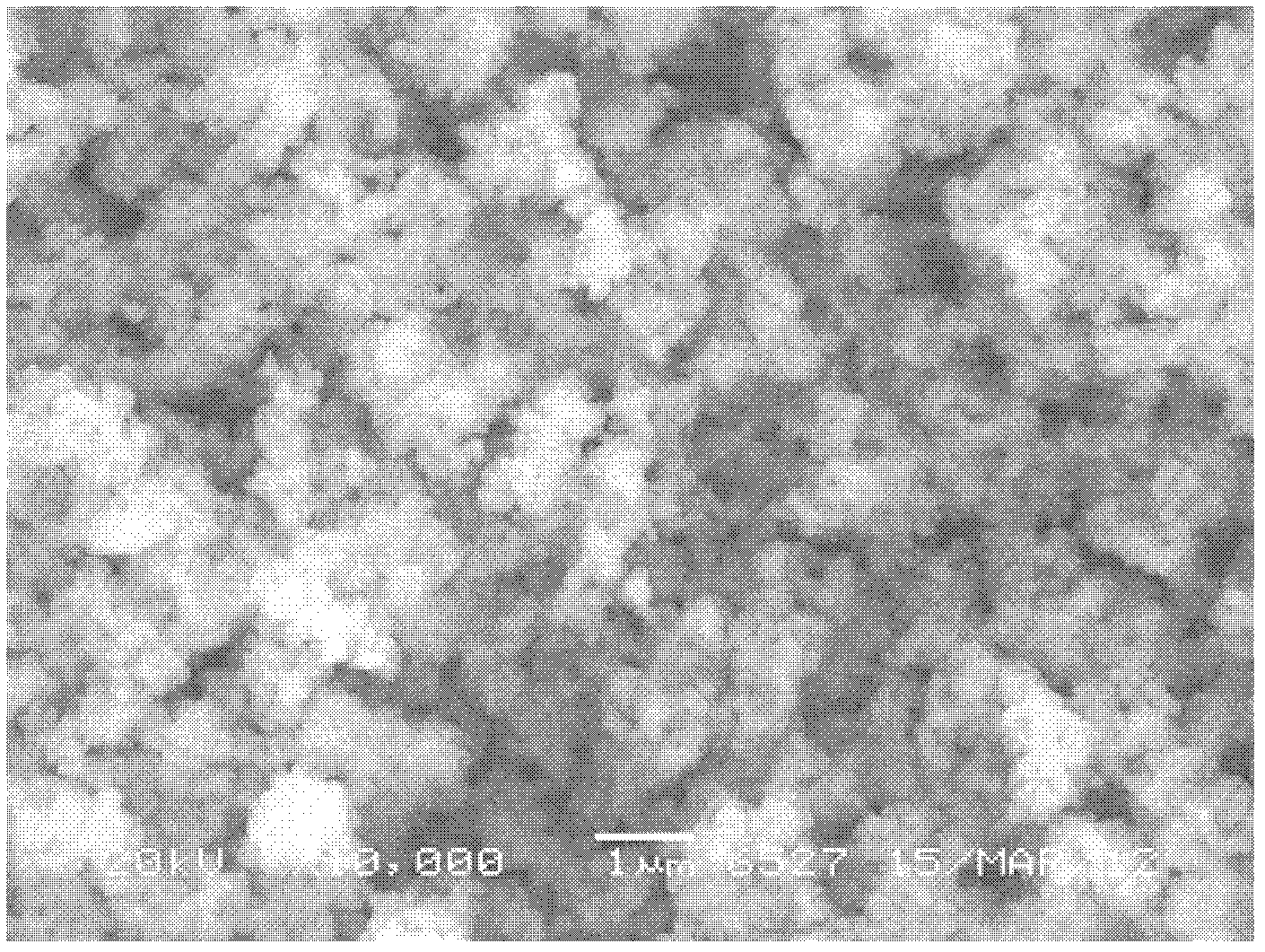

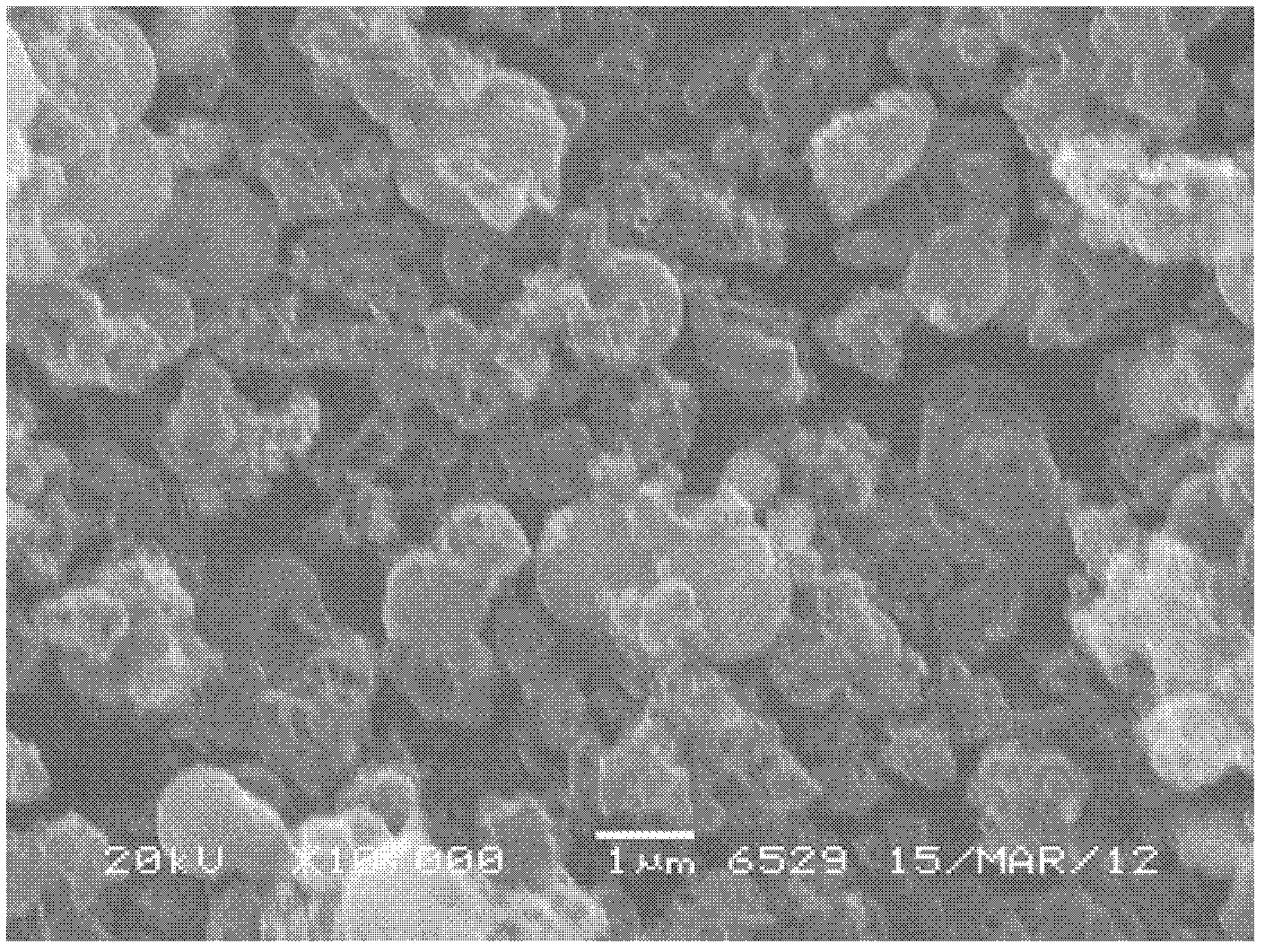

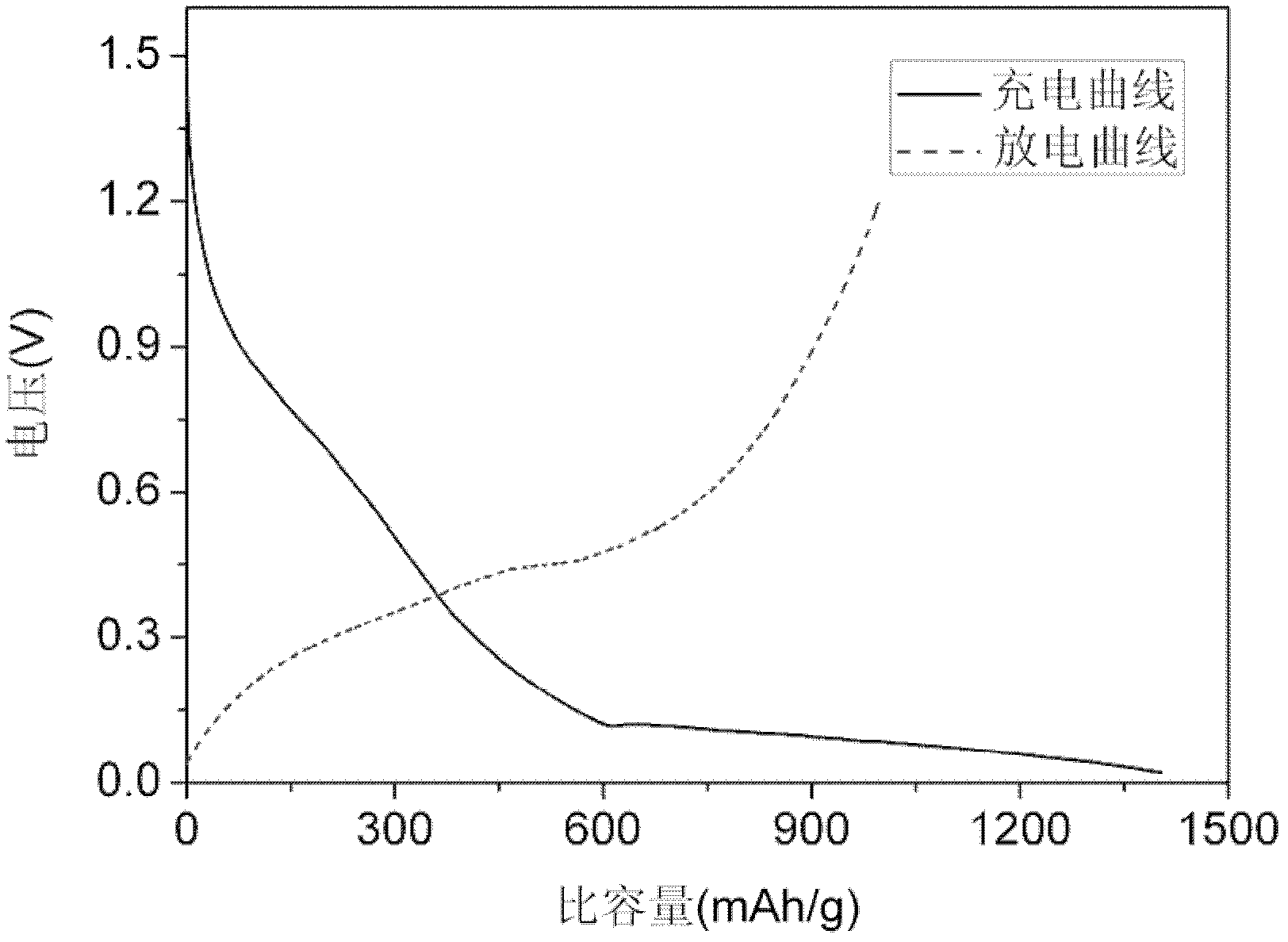

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

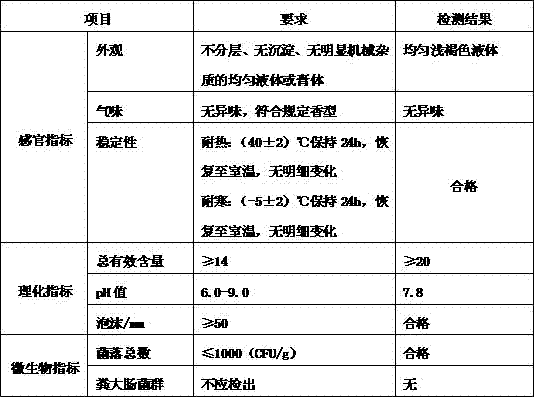

Butter inhibitor for ethylene unit alkaline washing tower

InactiveCN101838553ASuppress generationAntioxidantGaseous mixture working upTreatment apparatus corrosion/fouling inhibitionAnoxomerMaterials science

The invention relates to a butter inhibitor used for an ethylene unit alkaline washing tower. Problems of the background technology are solved, so the butter inhibitor has the performance of oxidation resistance, polymerization inhibition, cleanness, dispersion, metallic ion passivation and a better inhibition effect. The butter inhibitor is prepared from the following raw materials of: 1 to 30 percent of antioxidant, 5 to 40 percent of polymerization retarder, 2 to 30 percent of dispersant, 5 to 25 percent of metallic ion passivating agent and the balance of solvent; and the butter inhibitor is prepared by heating, uniformly mixing and cooling the materials.

Owner:浙江杭化科技股份有限公司

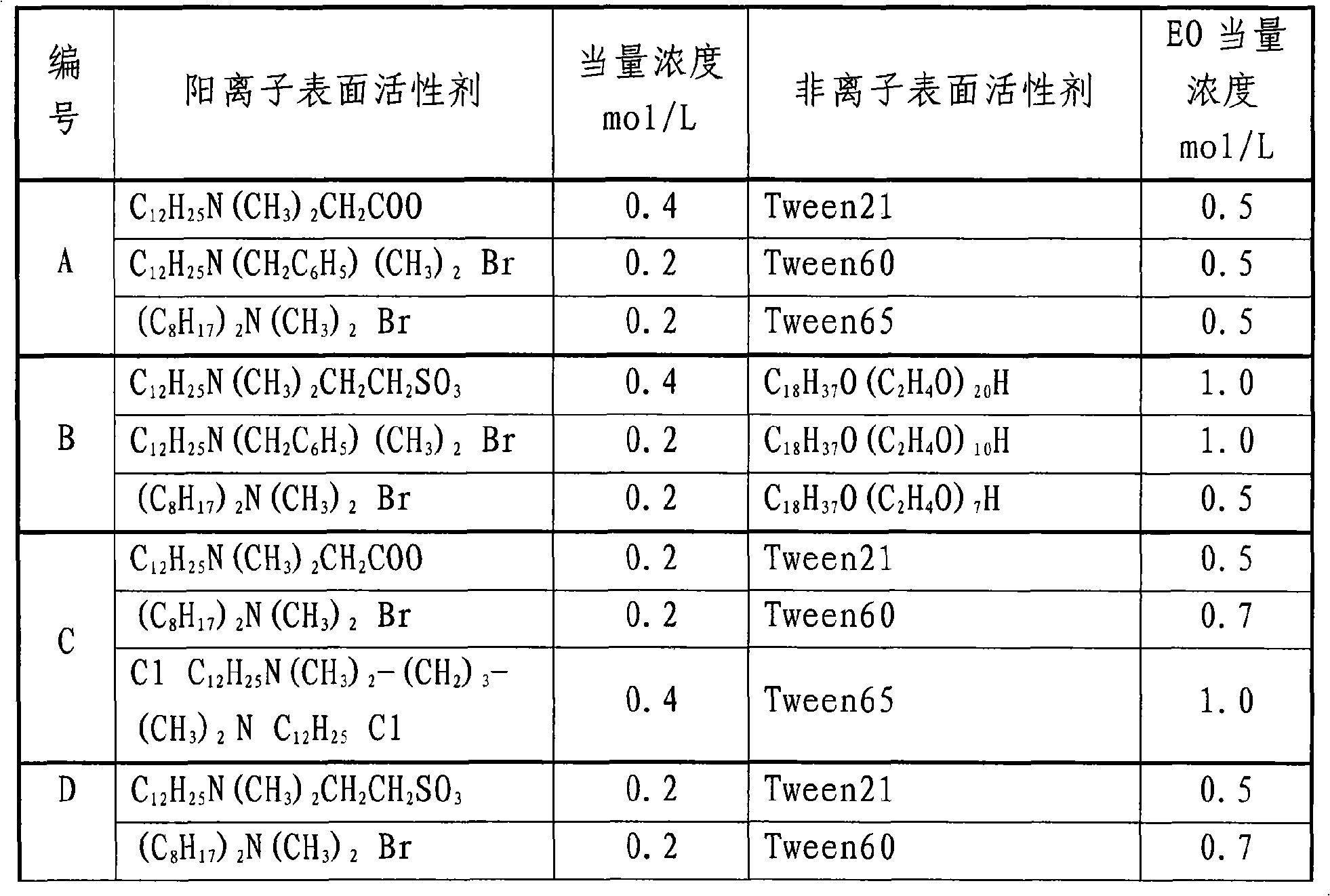

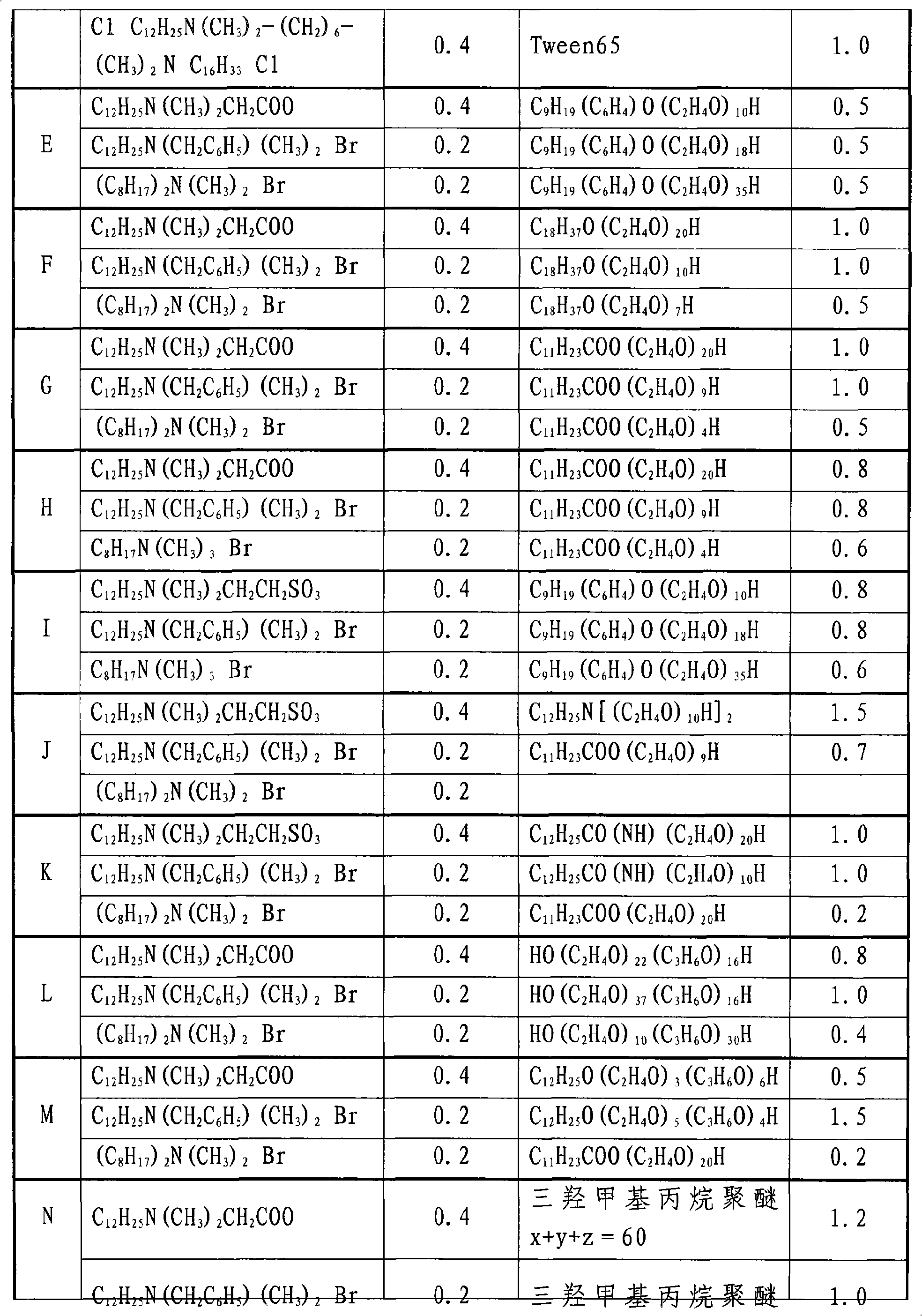

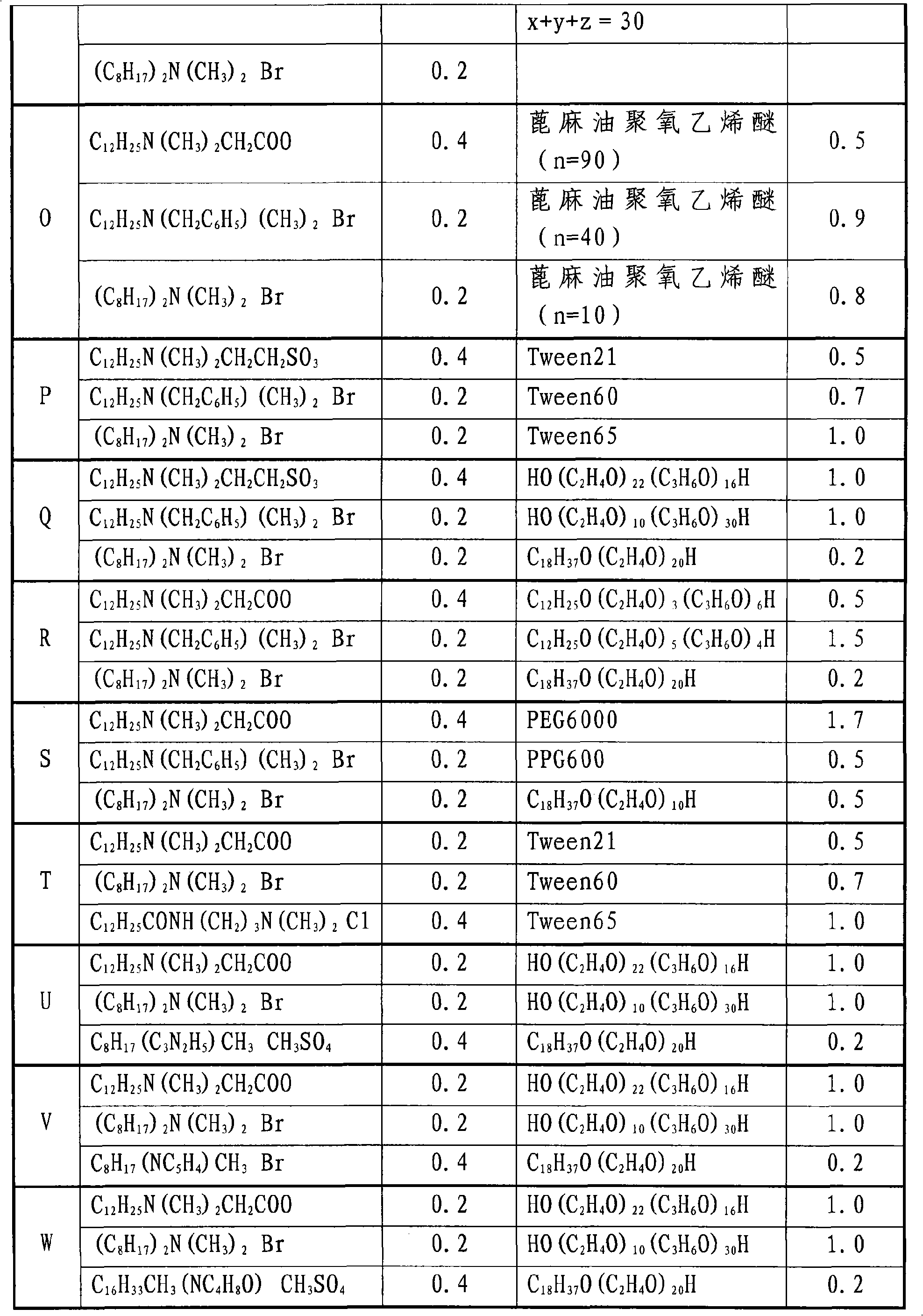

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

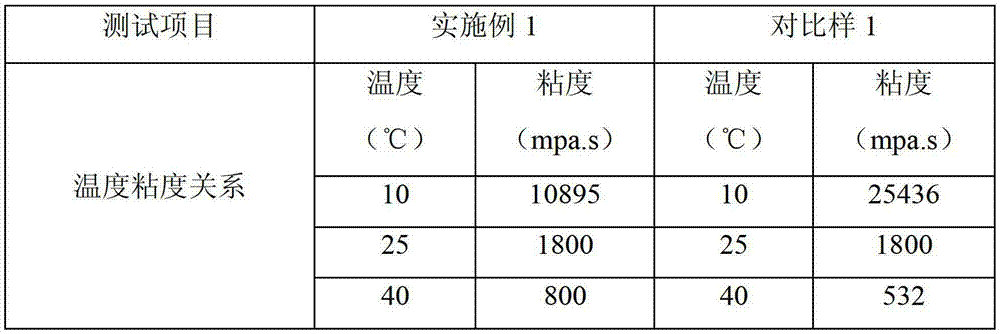

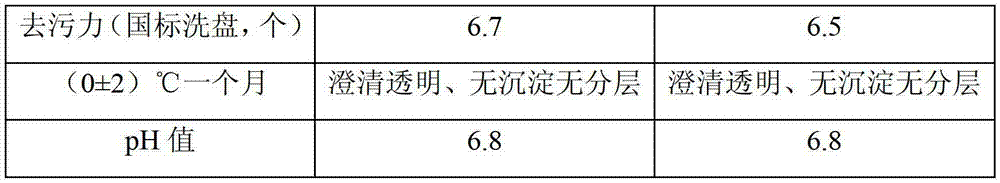

Fruit, vegetable and tableware detergent with good rheological property

ActiveCN103242974AEasy to useGood high and low temperature fluidityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsNonionic surfactantViscosity modifier

The invention discloses a fruit, vegetable and tableware detergent with a good rheological property. The detergent comprises the following raw material components in percentage by weight: 0.01-5.0% of a fluidity modifier, 5.0-40.0% of an anionic surfactant, 0.5-15.0% of a nonionic surfactant, 1.0-8.0% of an amphoteric surfactant, 0.1-8.0% of a viscosity modifier, 0.01-0.2% of an antiseptic agent, 0.01-0.5% of a chelating agent, 0.01-10% of other components, and the balance of deionized water. The invention relates to the detergent with viscosity characteristics, and the fluidity modifier is added into the detergent, so that the rheological property is improved, and the needs of consumers can be well satisfied.

Owner:GUANGZHOU LIBY

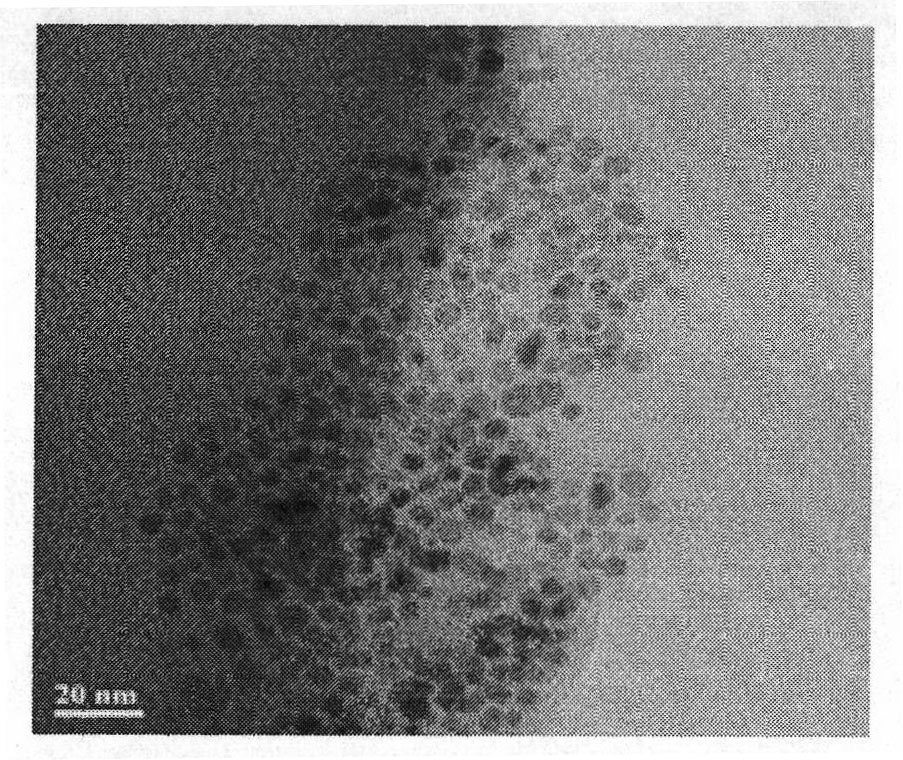

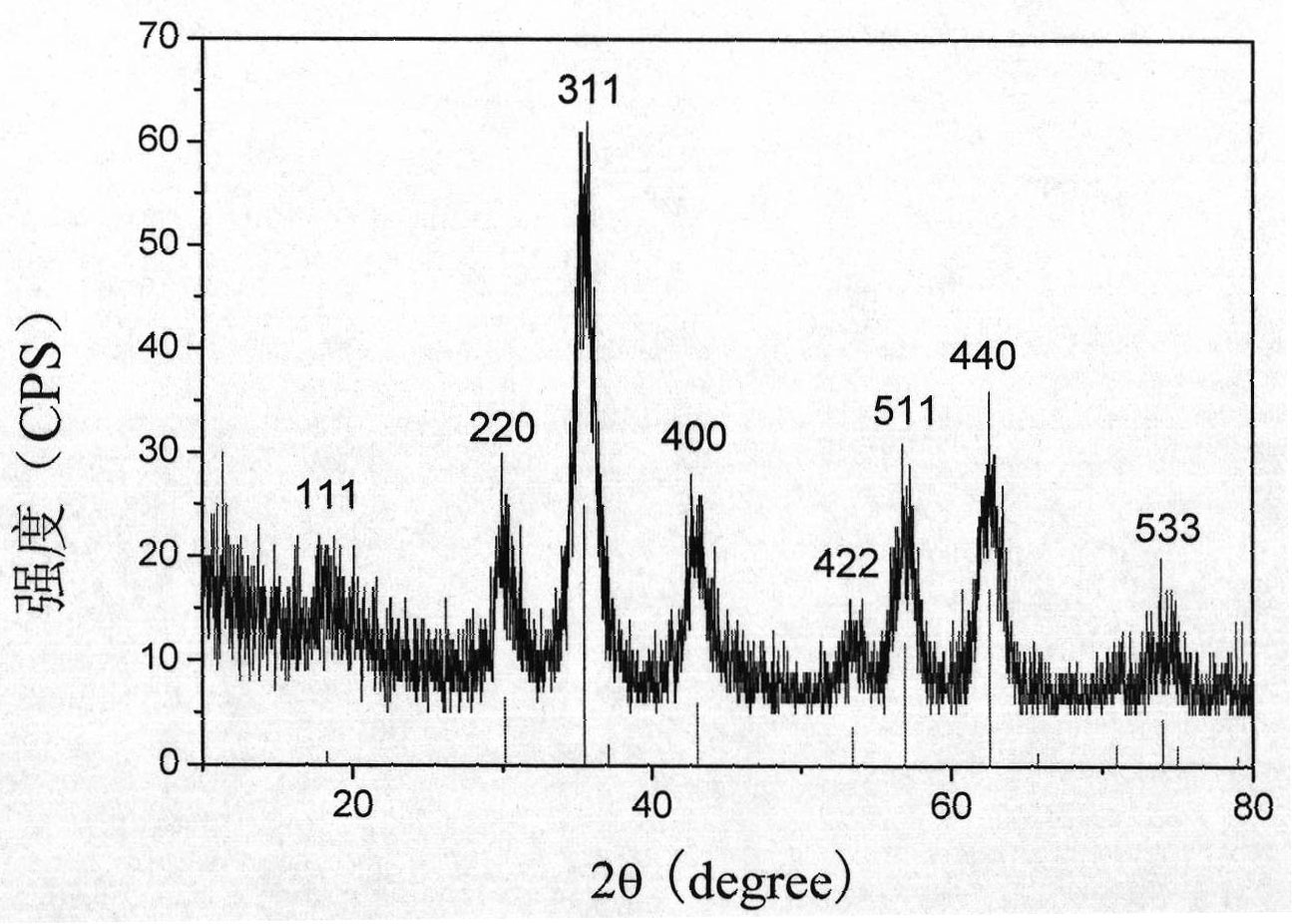

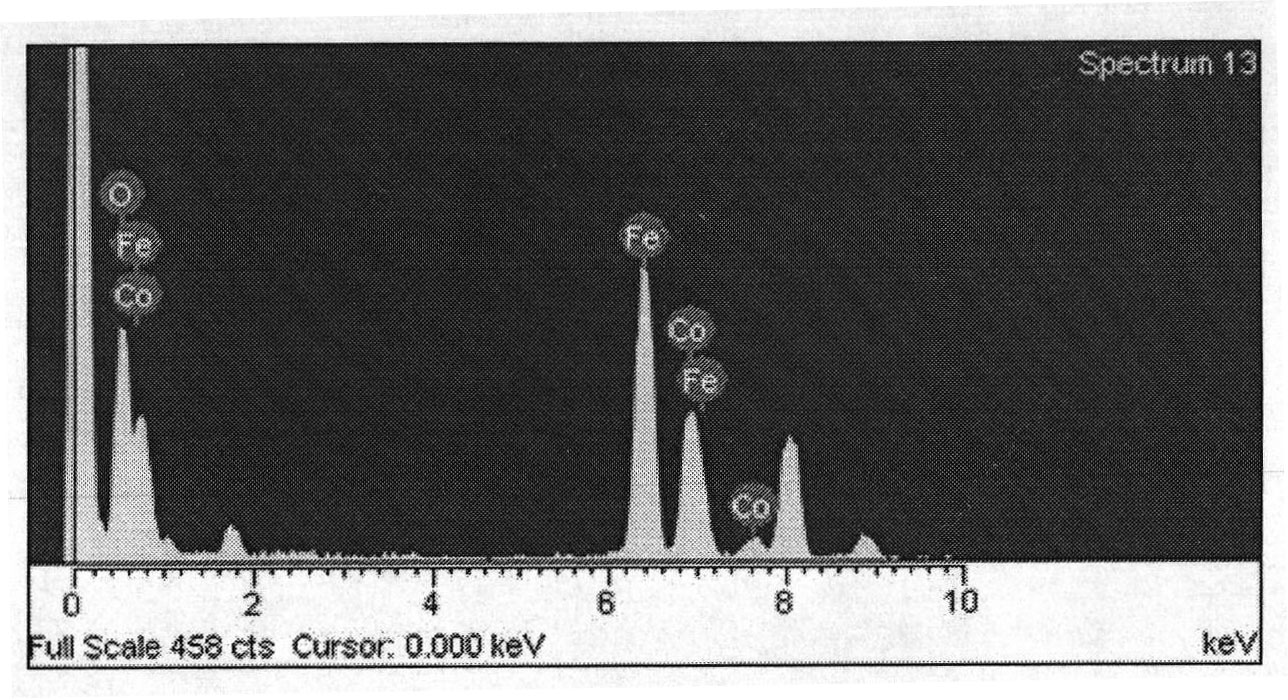

Water-soluble nuclear-shell magneto-optic dual-function nanoparticle and preparation method thereof

InactiveCN101775280AGood water solubilityGood dispersionInorganic material magnetismLuminescent compositionsSolubilityDansyl chloride

The invention relates to the technical field of the composite material, and discloses a water-soluble nuclear-shell magneto-optic dual-function nanoparticle. In the structure of the water-soluble nuclear-shell magneto-optic dual-function nanoparticle, magnetic CoFe2O4 is used as a core, amorphous SiO2 is used as a shell, the surface of the shell is connected with an organic light-emitting material dansyl chloride, and the particle size is 25-50nm. The preparation method comprises the following steps: preparing a monodisperse magnetic cobalt ferrite nanoparticle through thermal decomposition, coating silica on the surface of the nanoparticle, carrying out modification of amino on the surface of the silica, and connecting an organic light-emitting material through the amino on the peripheryof the magnetic nanoparticle. The nanoparticle of the invention has a nuclear-shell structure and a uniform particle size, and can be well dispersed in water. Moreover, the nanoparticle of the invention has good water solubility, good magnetic properties, light-emitting effect and good biocompatibility.

Owner:SHANGHAI NORMAL UNIVERSITY

Heavy metal-contaminated soil remediation agent and preparation method thereof

InactiveCN105567247AHigh porosityHigh adsorption valueOther chemical processesOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal-contaminated soil remediation agent. The remediation agent is prepared from, by weight, 30%-45% of quick lime, 10%-25% of biomass charcoal, 10%-15% of kieselguhr, 10%-15% of sodium bentonite, 10%-15% of activated aluminum oxide, 5%-10% of nitrilotriacetic acid, 1%-5% of sodium lignin sulfonate and 1%-5% of sodium dodecyl sulfate. A preparation method comprises the steps that the quick lime, the biomass charcoal, the kieselguhr, the sodium bentonite, activated aluminum oxide, nitrilotriacetic acid, sodium lignin sulfonate and sodium dodecyl sulfate are stirred and mixed to be uniform according to the weight ratio, and then the soil remediation agent is prepared. The prepared soil remediation agent has the good effect when cadmium-lead-zinc-mercury compound contaminated soil is remedied.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Purification method for high-purity natural graphite

The invention discloses a purification method for high-purity natural graphite. A method for purifying graphite at high temperature is adopted, and the high-purity graphite is prepared by high temperature reaction, chemical purification, washing and dehydration. An oxidizer and a complexing agent are reacted with the natural graphite, impurities in the raw material are removed, and the graphite with low content of trace element and stable properties is obtained. In the process, the graphite raw material with the carbon content of more than 60 percent is purified, and the graphite with the purity of over 99.9991 percent, ash content of less than 1PPM and the trace elements of less than 0.5PPM is obtained; and the method has the advantages that: the process is simple, and is easy to operate; the production efficiency is high; the power consumption is low; large processing equipment is not needed; and the production cost is saved.

Owner:LUOYANG GUANQI INDAL & TRADE

Low-temperature deoiling scouring agent and preparation method thereof

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

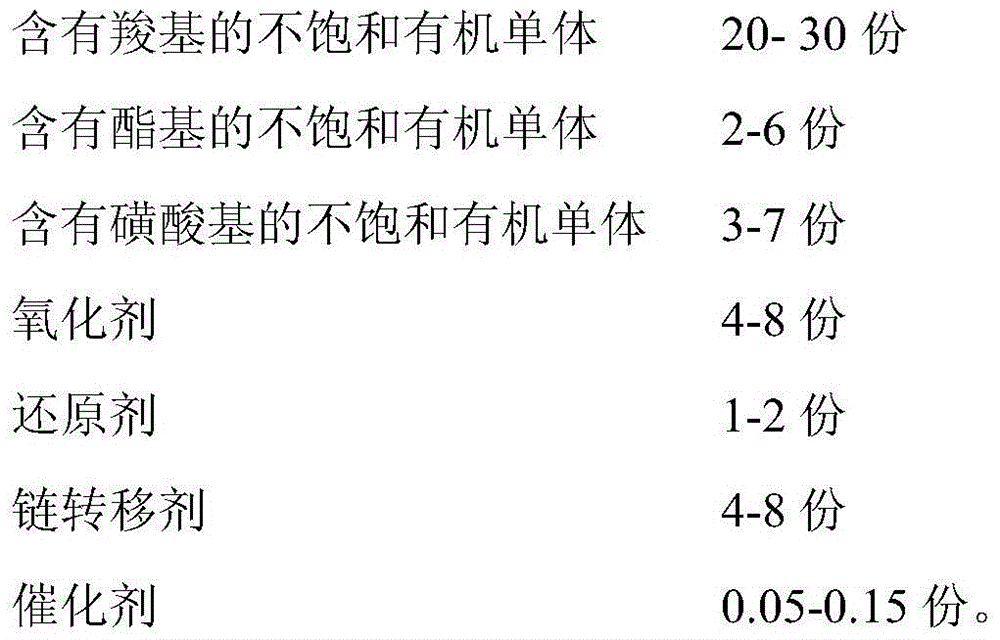

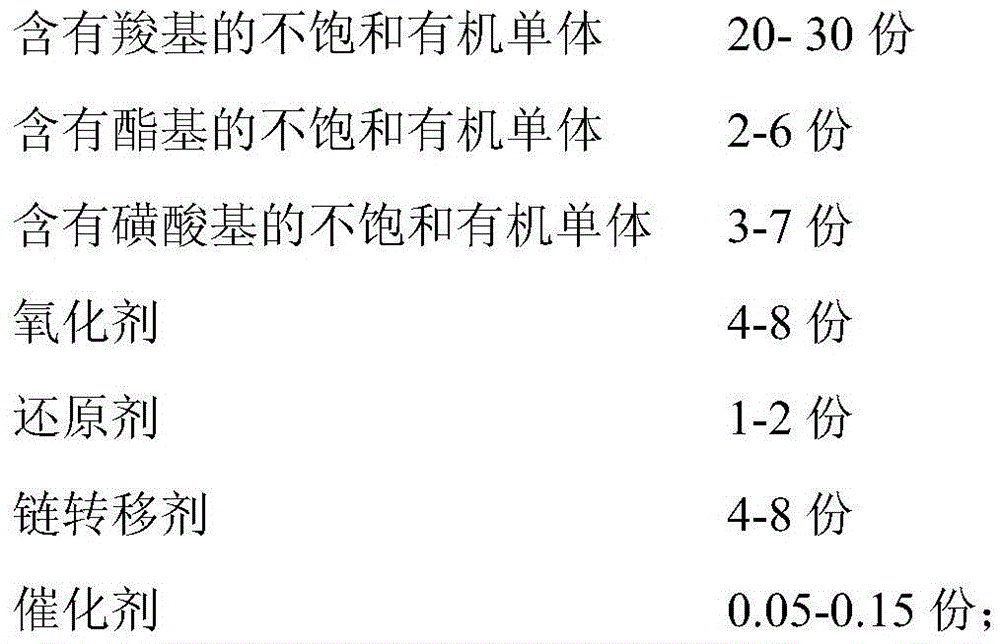

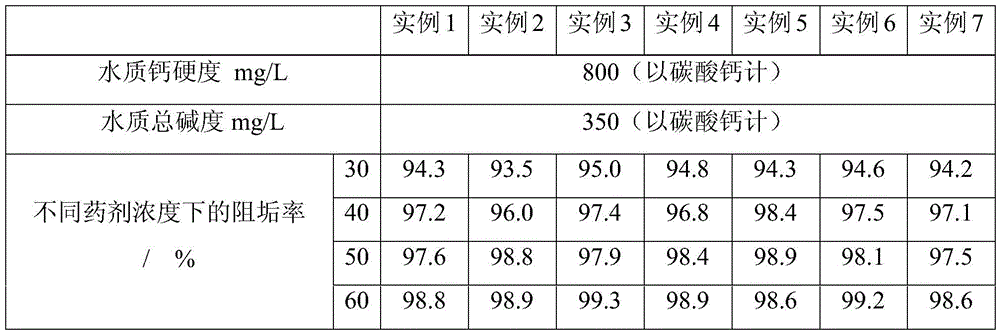

Multi-copolymer and preparation method and use thereof

ActiveCN105542055AWith anti-scalingWith dispersionWaste water treatment from quariesSeawater treatmentAcid groupCopolymer

The present invention belongs to the technical field of water treatment, relates to a multi-copolymer used for recycled water for industry and a preparation method and use thereof, particularly use as a scale and corrosion inhibitor, and especially as a low-phosphorus environmental-friendly scale and corrosion inhibitor. The multi-copolymer is obtained by copolymerization of a carboxyl-group-containing unsaturated organic monomer, an ester-group-containing unsaturated organic monomer and a sulfonic-acid group-containing unsaturated organic monomer, and the limiting viscosity number of the multi-copolymer is 0.035-0.055dL / g. The multi-copolymer has scale inhibition, dispersion, corrosion resistance, temperature resistance and other properties, can be used as a scale inhibition dispersant, especially as the low-phosphorus environmental-friendly scale and corrosion inhibitor, and can be used in circulating cooling water systems, oil field water injection systems, seawater desalination and other fields.

Owner:CHENGDU QIDA WATER TREATMENT ENG

Aqueous cleaning agent for liquid crystal display

InactiveCN1865420AEliminate residueImprove the finishOrganic detergent compounding agentsNon-ionic surface-active compoundsIonChemistry

The invention discloses a LCD water-based abluent of amine alkali and non-ion surface activator, which comprises the following parts: 20-70 percent amine alkali, 5-40 percent JFC, 5-20 percent non-ion surface activator and deionized water. The invention is beneficial to remove the surface residues, which improves the surface finishment of product.

Owner:HEBEI UNIV OF TECH

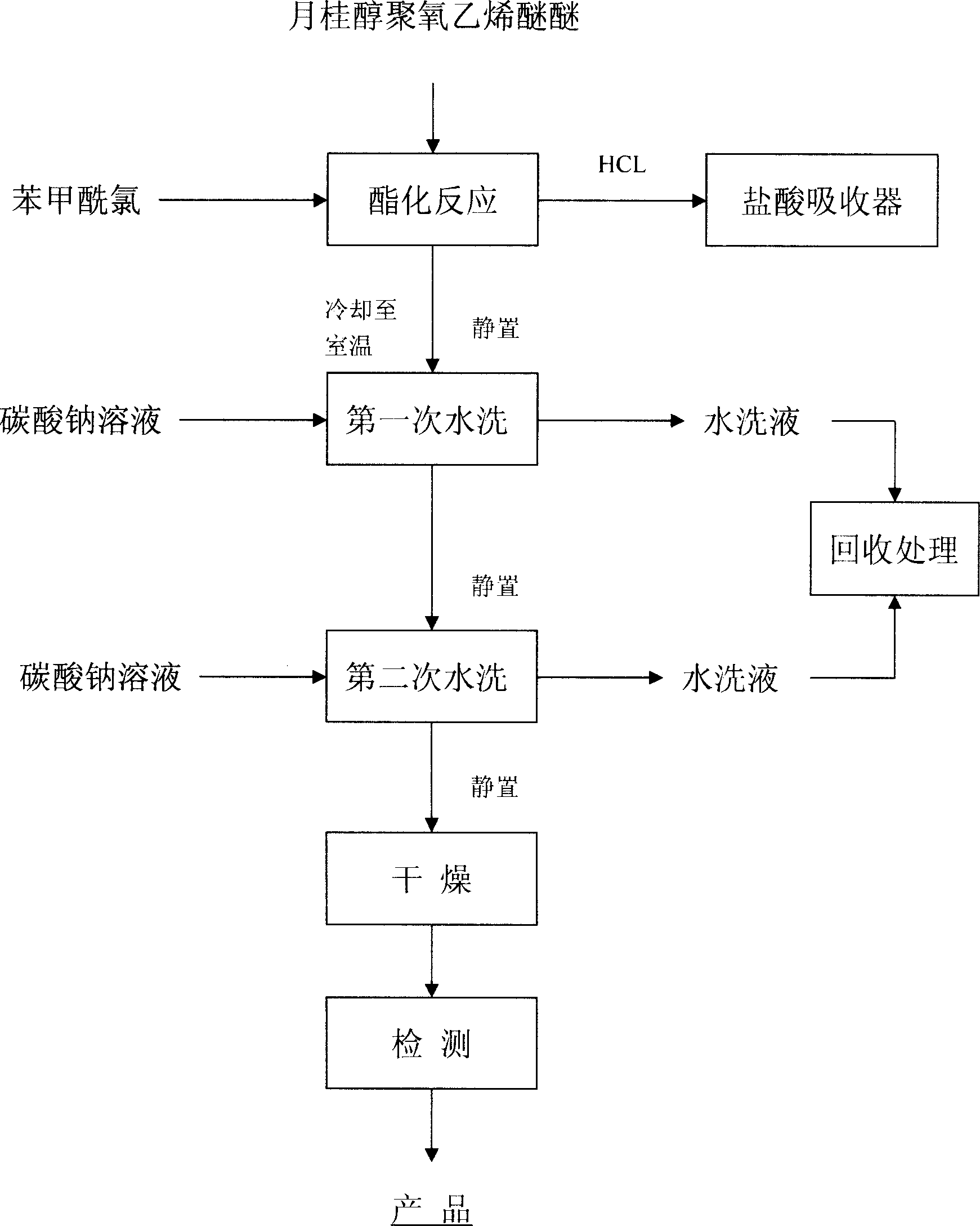

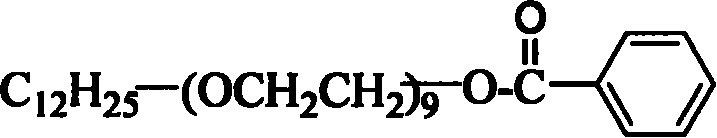

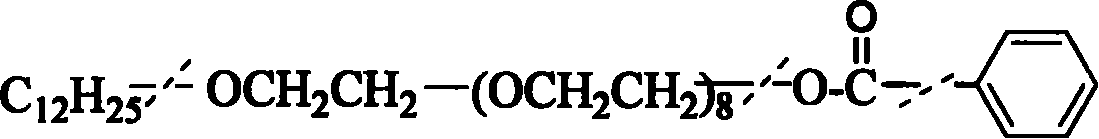

Lauryl alcohol polyethylene glycol oxide ester benzoic ether and its synthesis

InactiveCN1896046AProtectiveWith dispersionPreparation from carboxylic acid halidesPolyethylene glycolSolvent

Owner:LIAOCHENG UNIV

Delicious fragrant cake with fruit flavor

The invention relates to a fruit-favor scented cake which mainly comprises ingredients by weight portions: 30 to 40 portions of glutinous rice flour, 40 to 55 portions of mashed potatoes, 0.5 to 1.6 portion of sodium cyclamate, 0.1 to 0.15 portion of fruit-favor food flavors, 1.5 to 2 portions of natural pigment, 1 to 1.8 portions of vanilla powder, 0.4 to 0.8 portion of milk tea additive and 0.2 to 0.8 portion of citric acid. The invention has the advantages of long preservation time, low production cost, and the like. The finished fruit-favor scented cake has bright color and heavy fruit favor and enables people to feel fresh. The fruit-favor scented cake tastes sweet and sour, agreeably crisp and delicious and leaves a strong aftertaste.

Owner:胡志伟

Water-soluble environment-friendly nanometer color paste and preparation method thereof

InactiveCN108676424APrevent subsidenceAvoid condensationPigment pastesWater solubleSurface-active agents

The invention discloses water-soluble environment-friendly nanometer color paste and a preparation method thereof and belongs to the technical field of color paste preparation. The water-soluble environment-friendly nanometer color paste is characterized by being prepared from the following components in parts by weight: 10 to 20 parts of dispersing agent, 10 to 30 parts of nanometer pigment, 5 to10 parts of surface active agent, 0.2 to 0.5 part of defoaming agent, 18 to 28 parts of wetting agent, 0.2 to 0.4 part of corrosion remover, 4 to 10 parts of humectant, and 15 to 30 parts of deionized water. The preparation method comprises the steps of adding 60 percent of dispersing agent, defoaming agent, corrosion remover and wetting agent and 70 percent of deionized water into a reactor; stirring at the speed of 100 to 200rpm for 15 to 20 minutes in an opening type sand mill, and then increasing by five times of stirring rate; adding 40 percent of surface active agent, nanometer pigmentand humectant into the reactor, continuously stirring for 25 to 30 minutes to obtain a mixed color paste, and coarse grinding and dispersed grinding the mixed color paste. The water-soluble nanometercolor paste prepared by the preparation method provided by the invention is small in particle size, narrow in distribution, good in stability, environmentally friendly and safe.

Owner:奥莱鑫科技股份有限公司

High efficiency and no pollution industrial cleaning agent and its application

InactiveCN102242029AImprove solubilityCorrosion will notSurface-active non-soap compounds and soap mixture detergentsCleaning using liquidsPtru catalystActive agent

The invention discloses a high efficiency and no pollution industrial cleaning agent and its application. The formula of the cleaning agent comprises 80% - 93% of mixed ester solvent, 2% - 5% of nonionic surfactant, 3% - 10% of sodium carbonate and 2% - 10% of sodium silicate. The preparation method comprises the following steps: adding the mixed ester solvent at first, simultaneously adding a nonionic surfactant, sodium carbonate and sodium silicate and then stirring by manual or a machine for 15 - 20 minutes to obtain the high efficiency and no pollution industrial cleaning agent of the present invention. The high efficiency and no pollution industrial cleaning agent of the present invention is suitable for cleaning a oil circuit system which takes an operation medium as an oil product in equipment, and especially suitable for cleaning petrochemical apparatus, as well as on-line cleaning or stopping to disassembly and clean the oil circuit system of all industrial equipments such asa compressor. The cleaning agent of the invention has no influence to the equipment system, product quality and catalyst performance.

Owner:SHANGHAI DYNAMIC TECH

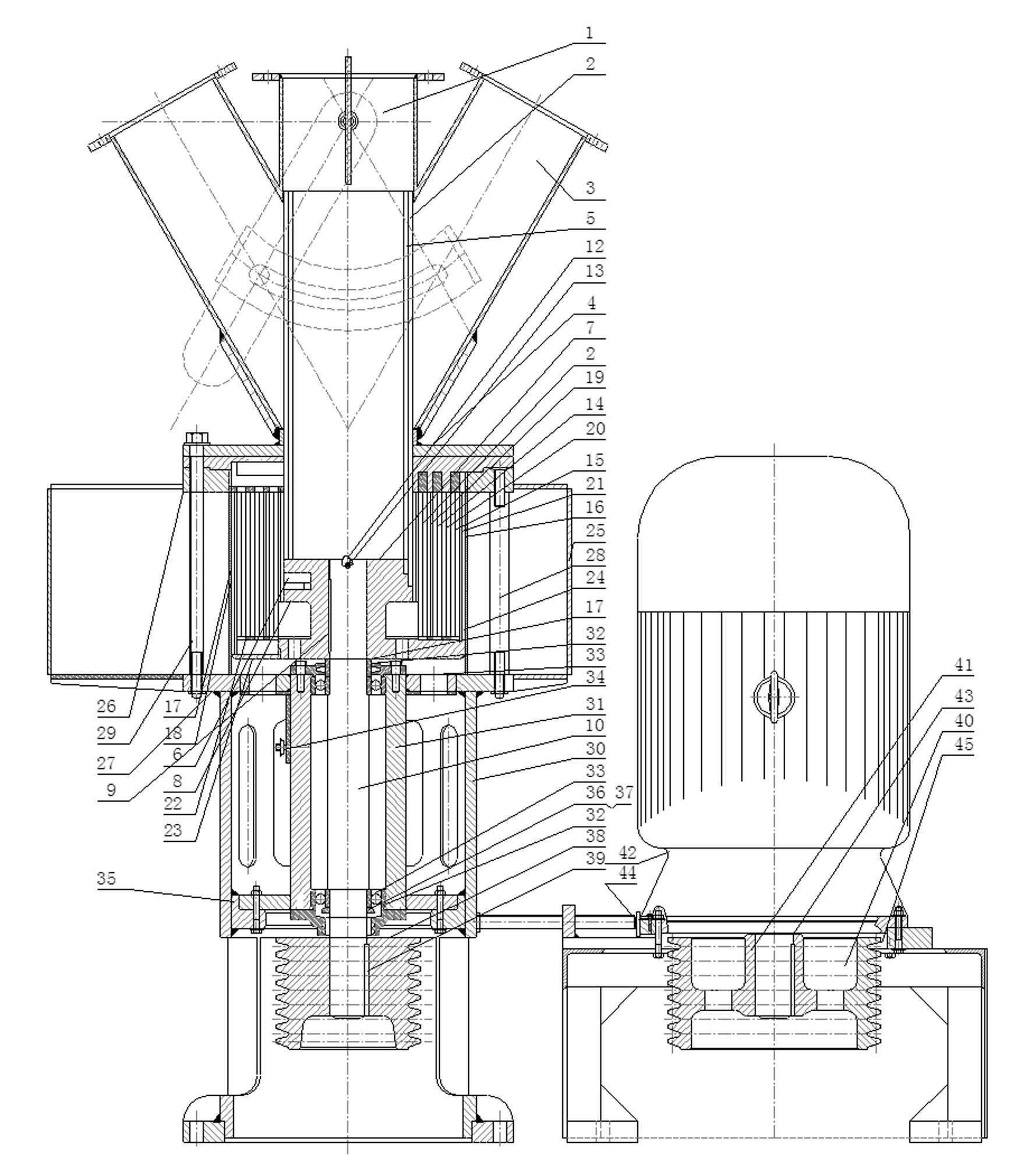

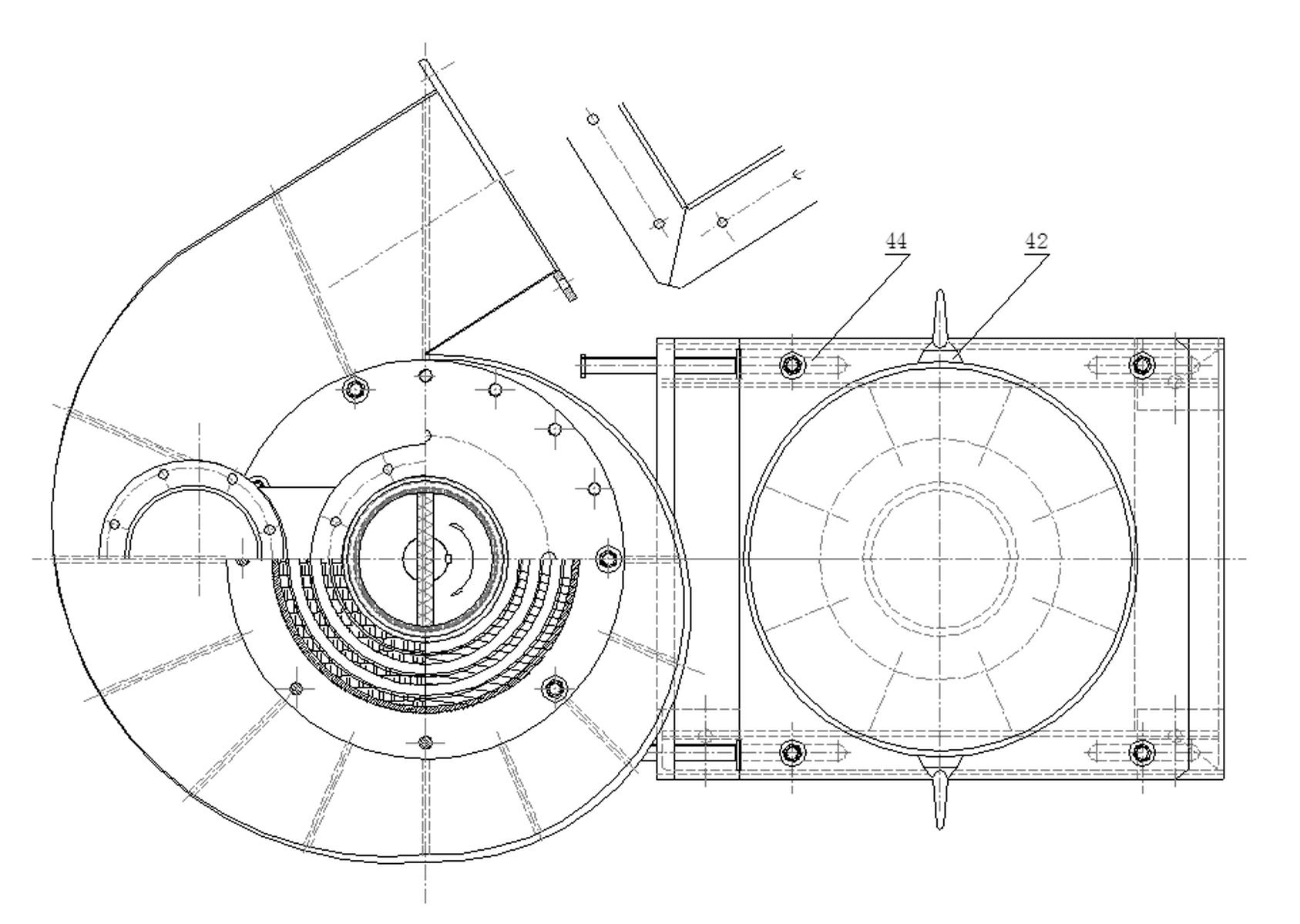

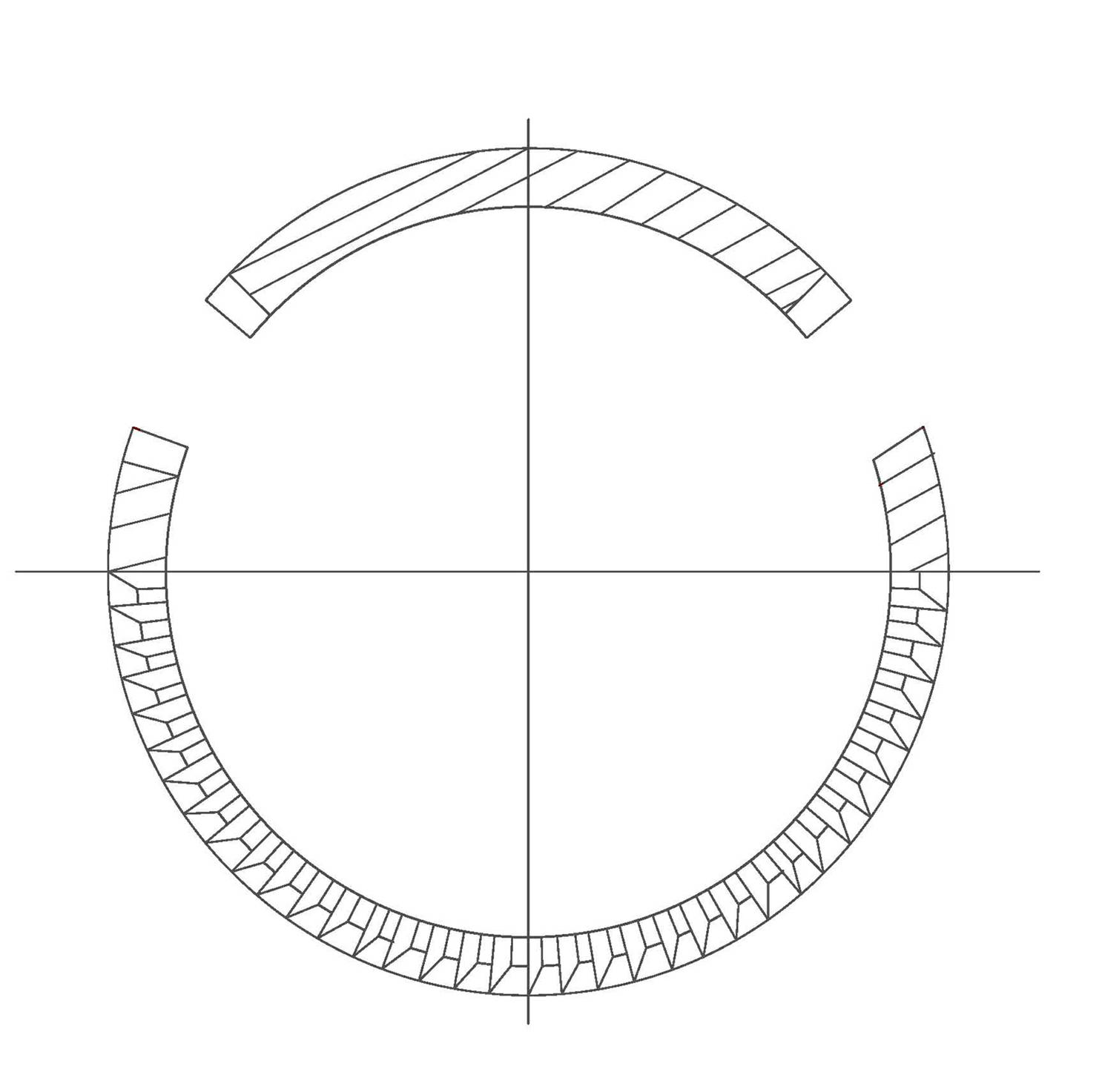

Cylinder type specific cutter grinder

The invention relates to a cylinder type specific cutter grinder, which is fence cylinder type. The cylinder type specific cutter is a grinding cutter having fixation crossing combination with an internal tooth and an outer tooth. The cylinder type specific cutter includes movable and stationary specific cutter rings (5, 2) of prepared material initial grinding, movable and stationary specific cutter rings (19, 14) of coarse grinding, movable and stationary specific cutter rings (20, 15) of micro refining, and movable and stationary specific cutter rings (21, 16) of ultramicro refining. The movable and stationary specific cutter rings in the cylinder type specific cutter grinder fully employ independent inventive fence cylinder type combination cutter. The invention provides a reasonable grinder for the exploitation and application of the grinder, especially for ultramicro refining flexible, soft, hard and plastic or the like specific material taking fiber as representative.

Owner:钟元龙 +1

Metal-contg. macrostructures of porous inorganic oxide, prepn. thereof, and use

InactiveCN1356927AWith dispersionHydrocarbon by isomerisationCatalytic crackingIon exchangeInorganic materials

There is provided a catalyst containing porous macrostructures comprised of: (a) a three-dimensional network of particles of porous inorganic material; and, (b) at least one metal. The particles of the at least one macrostructure occupy less than 75 % of the total volume of the at least one macrostructure and are jointed together to form a three-dimensional interconnected network. The three-dimensional interconnected network will usually be comprised of pores having diameters greater than about 20 ANGSTROM . The macrostructures can be made by forming an admixture containing a porous organic ion exchanger and a synthesis mixture capable of forming the porous inorganic material and the at least one metal; converting the synthesis mixture to the porous inorganic material; and removing the porous organic ion exchanger from the organic material. The metal-containing macrostructures find application in hydrocarbon conversion and in the reduction of emissions.

Owner:EXXONMOBIL CHEM PAT INC

Cleaning agent for heat cleaning of wellhole and preparation method thereof

The invention relates to a cleaning agent for heat cleaning of wellhole. The cleaning agent comprises the following components, by weight: 10-30 parts of Ninol, 1-10 parts of a penetrating agent JFC, 1-5 parts of a demulsifier AE8031, 10-30 parts of ethylene glycol monobutyl ether; 5-15 parts of HEDTA and 30-50 parts of water. The preparation method comprises the steps of: (1) dissolving HEDTA in water, and stirring until complete dissolving; and (2) adding ethylene glycol monobutyl ether into the solution from the step (1), stirring evenly, successively adding Ninol, penetrating agent JFC and demulsifier AE8031, and stirring evenly to obtain a finished product. The components of Ninol, penetrating agent JFC, demulsifier AE8031 and ethylene glycol monobutyl ether in the cleaning agent are all surfactants; HEDTA has descaling and scale inhibition function, so that the cleaning agent provided by the invention has the functions of surface activity, descaling and scale inhibition, and is suitable for cleaning of oil tubes in heavy oil heavy oil fields, and also has the function of environmental protection.

Owner:CNOOC ENERGY TECH & SERVICES +1

Plant empty capsule and manufacturing method thereof

InactiveCN104274424AReduce moisture contentWide applicabilityPharmaceutical non-active ingredientsCapsule deliveryCelluloseCarrageenan

The invention provides a plant empty capsule with a good moulding effect, high surface smoothness and good elasticity and a manufacturing method thereof. The plant empty capsule comprises 88-90wt% of complex gum, 1-3wt% of potassium chloride, 0.3-0.5wt% of humectant, 0-0.2wt% of polysaccharide, 3-5wt% of medical glycerinum, 1-3wt% of titanium dioxide and 0.2-0.3wt% of food colourant, wherein the complex gum comprises carrageenan, plant cellulose and sodium carboxymethylcellulose. The plant empty capsule is low in water content, is especially applicable to being filled with medicines which have strong hygroscopicity and are sensitive to moisture, has the advantages of wide applicability, no crosslinking reaction and high stability and is preservative-free, and microorganisms can hardly grow on the empty capsule; and meanwhile, the plant empty capsule is hardly crisp or broken at a low temperature and is still stable in capsule shell character at a high temperature.

Owner:韩字光

Temperature-sensitive starch derivative and preparation method thereof

InactiveCN101619103AImprove performanceReduce performanceTemperature responseBiocompatibility Testing

The invention relates to a temperature-sensitive starch derivative and a preparation method thereof, belonging to the functional high polymer material field. The temperature-sensitive starch derivative is the product prepared by partly replacing the hydrogen of the hydroxyl in starch with hydrophobic and hydrophilic groups. The preparation method comprises the following steps: first introducing first hydrophobic group -CH2CHOHCH2OR1 by alkoxy glycidol ether reaction between starch and C2-10, then introducing hydrophilic group -CH2COOM by reacting with chloroacetic acid, and then using the primary amine or secondary amine containing 1-6 carbon atoms to react with carboxymethyl to introduce second hydrophobic group -CH2CONR2R3. By adjusting the substituted ratio of hydrophobic and hydrophilic groups, the temperature-sensitive starch derivative of which lower critical solution temperature can change from 10 DEG C to 65 DEG C can be prepared. The temperature-sensitive starch derivative combines the advantages of starch and temperature-sensitive high molecular and is characterized in that the cost is cheap, the biocompatibility is good, the toxicity is small, the starch derivative is degradable and has temperature response property and the like. The starch derivative can be widely applied in the fields of drug carriers, sensors, biotechnology, surfactants, intelligent catalysis, separation engineering and the like.

Owner:DALIAN UNIV OF TECH

Latex abrasive base paper and preparation method and application thereof

InactiveCN107034720ALightweightWith wear resistanceInorganic fibres/flakesWater-repelling agents additionAlkali freePolyacrylamide

The invention provides latex abrasive base paper, which is prepared from the following raw materials in parts by weight: 30-50 parts of cornstalk fiber, 100 parts of high-density cotton linter pulp, 5-12 parts of polypropylene fiber, 20-40 parts of alkali-free glass fiber chopped strands and 3-8 parts of a ceramic fiber; the base paper is prepared from the following raw materials in parts by weight: 0.1-4 parts of amphoteric polyacrylamide, 0.2-0.8 part of modified starch light calcium carbonate, 0-0.2 part of polyoxyethylene with the molecular weight of 2500000 to 3000000, 0-0.2 part of an antifoaming agent and 5-10 parts of latex. The latex abrasive base paper has the characteristics of being good in abrasive resistance, good in flexibility and high in tensile strength.

Owner:杭州特种纸业有限公司

Mechanical filter oil stain cleaning agent and preparation method thereof

InactiveCN104357251AWith dispersionHigh efficiency in removing stubborn oil stainsSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsSaponification

The invention discloses a mechanical filter oil stain cleaning agent and a preparation method thereof, and belongs to the field of wastewater treatment. The mechanical filter oil stain cleaning agent disclosed by the invention comprises the following raw materials in percentage by mass: 10 to 202 percent of sodium hydroxide, 5 to 15 percent of ethanol, 0.1 to 0.5 percent of sodium dodecyl benzene sulfonate, 0.1 to 0.5 percent of sodium tripolyphosphate and the balance of desalinated water, wherein the concentration of Ca<2+> in the desalinated water is less than or equal to 2 mg / L. The preparation method comprises the following steps: weighing the raw materials; adding the ethanol into the desalinated water; adding the ethanol into the desalinated water; adding the sodium hydroxide, the sodium dodecyl benzene sulfonate and the sodium tripolyphosphate in sequence; uniformly stirring after a new material is added everytime so as to uniformly mix or dissolve the materials to obtain the mechanical filter oil stain cleaning agent. The mechanical filter oil stain cleaning agent disclosed by the invention has a saponification effect, and also has the effects of emulsifying, wetting, permeating, dispersing and dissolving, so that the mechanical filter oil stain cleaning agent disclosed by the invention has the advantages of high efficiency of removing intractable oil stain and high cleaning speed.

Owner:NORTHEASTERN UNIV

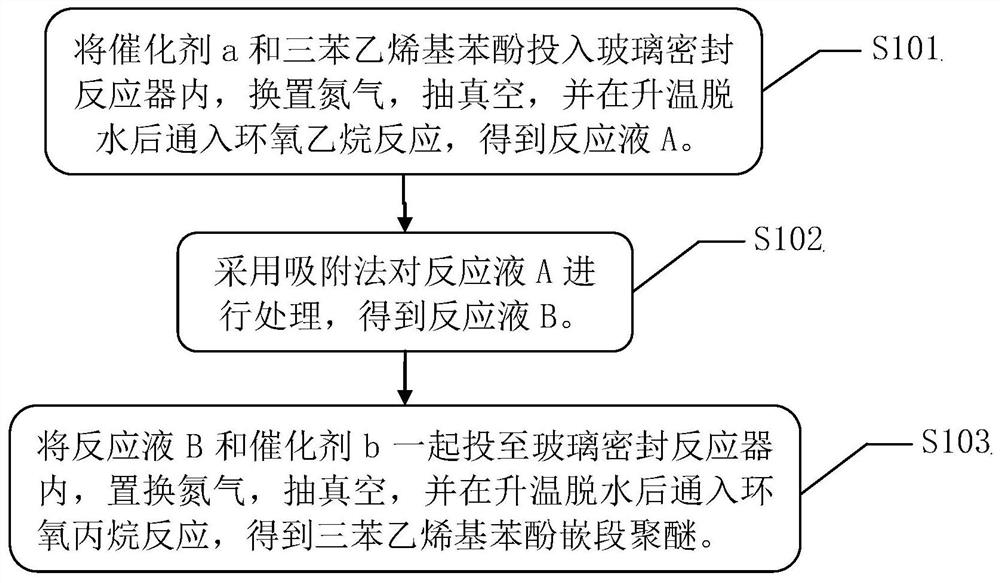

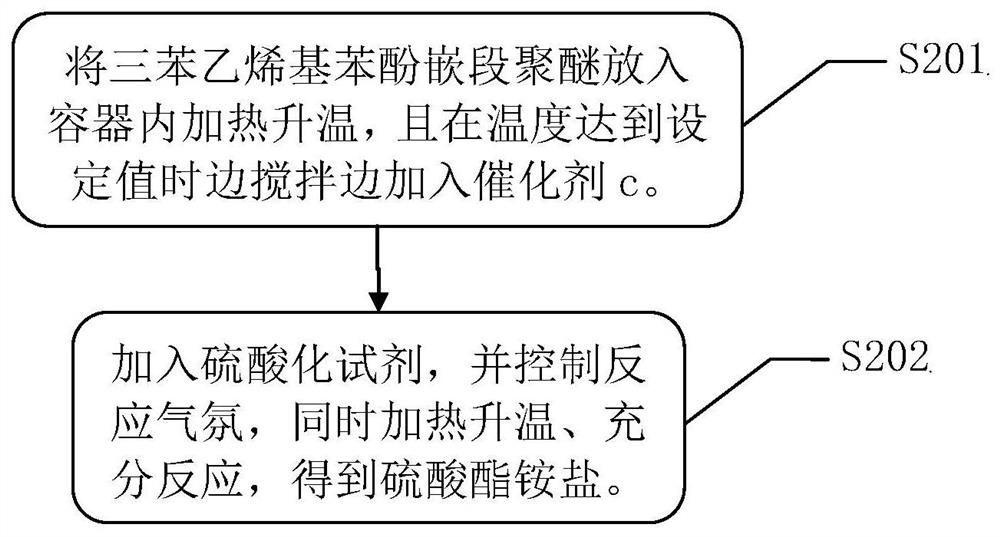

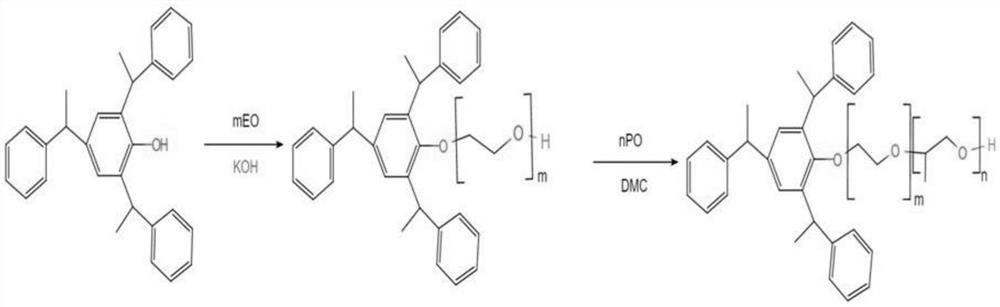

Tristyrylphenol block polyether, sulfate ammonium salt and preparation method thereof

PendingCN113214466ANarrow molecular weight distributionLow raw material residueEster sulfateSulfuric acid

TThe invention relates to tristyrylphenol block polyether, sulfate ammonium salt and a preparation method thereof. The tristyrylphenol block polyether is prepared from tristyrylphenol, ethylene oxide, propylene oxide, a catalyst a and a catalyst b, and the structural formula of the tristyrylphenol block polyether is as follows: m is 10-30, and n is 25-35. According to the present invention, the prepared sulfate ammonium salt has characteristics of narrow molecular weight distribution, low raw material residue and wide application range, and the prepared sulfate ammonium salt has characteristics of low dynamic viscosity, high active matter content, light product color and close-to-neutral pH value, can well meet the requirements of high-end users and use under harsh conditions, and further has effects of permeation, wetting, dispersion and the like.

Owner:ZHEJIANG HUANGMA TECH +3

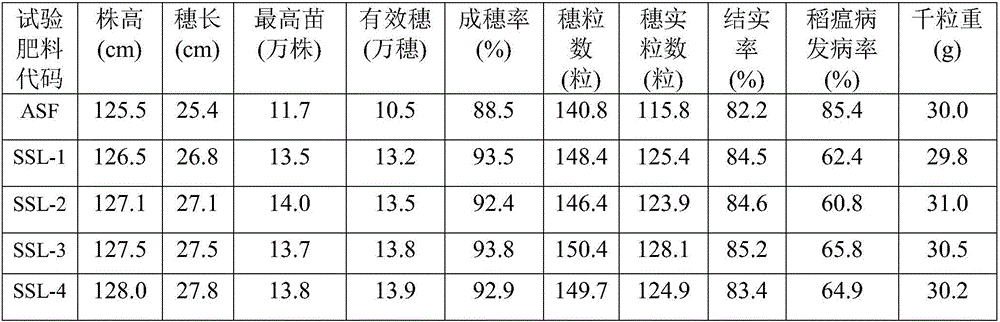

Novel special liquid fertilizer for rice capable of comprehensively controlling plant diseases and insect pests, and preparation method thereof

InactiveCN106748147ADoes not affect listing and salesReduce the amount of applicationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersRed CloverInsect pest

The invention provides a novel special liquid fertilizer for rice capable of comprehensively controlling plant diseases and insect pests, and a preparation method thereof. The novel special liquid fertilizer is prepared from the following components: 5 to 15 parts of urea-ammonium nitrate solution, 5 to 15 parts of ammonium polyphosphate solution, 5 to 10 parts of potash fertilizer, 0.1 to 2 parts of microelement, 20 to 50 parts of water, 1 to 10 parts of homemade plant pesticide extracting solution, 1 to 2 parts of soil conditioner, 1 to 5 parts of natural activity organic materials, and 1 to 5 parts of natural surfactant, wherein the homemade plant pesticide extracting solution is prepared from mixing trifolium pratense, folium artemisiae argyi, herba houttuyniae, semen persicae and black false hellebore in proportion, and extracting with water. The preparation method comprises the steps of adding the prepared urea-ammonium nitrate solution and the ammonium polyphosphate solution in proportion according to a formula into a mixing tank; then adding the other metered materials into the mixing tank; stirring, dissolving and filtering to prepare the liquid fertilizer. The liquid fertilizer provided by the invention is convenient to use and good in effect, and is a special multi-functional environment-friendly liquid fertilizer for the rice.

Owner:GUIZHOU UNIV

PH-/temperature dual-sensitive starch derivative and preparation method thereof

The invention relates to a pH- / temperature dual-sensitive starch derivative and a preparation method thereof, belonging to the field of functional polymer materials. The preparation method of the pH- / temperature dual-sensitive starch derivative comprises the following three steps of: firstly, reacting starch with alkyl polyoxyethylene ether glycidyl ether to introduce a -CH2CHOHCH2O-(CH2CH2-O)n-R1 group; next, further reacting the -CH2CHOHCH2O-(CH2CH2-O)n-R1 group with chloroacetic acid to introduce a -CH2COOM group; and then reacting the -CH2COOM group with alkyl halide containing C1-6 to introduce a -CH2COOR2 group so as to obtain the pH- / temperature dual-sensitive starch derivative. The pH- / temperature dual-sensitive starch derivative integrates the advantages of the starch and a pH- / temperature dual-sensitive polymer material and has the characteristics of low price, good biocompatibility, small toxicity, degradability, pH- / temperature dual-sensitive property, and the like.

Owner:DALIAN UNIV OF TECH

High-aluminum bearing ceramic bar beam and preparation method thereof

The invention discloses a high-aluminum bearing ceramic bar beam and a preparation method thereof. The preparation method is as follows: 64-72wt% of aluminum trioxide, 10-15%wt% of zirconia, 10-15wt% of china clay and 4-6wt% of wollastonite raw material are mixed by ball milling, then Guangdong black mud, carboxymethyl cellulose and water are added for ball milling mixing to prepare a block-shaped mud material, the block-shaped mud material is made into a blank in a stale vacuum mud refining machine, and the blank is coated with a film for nature drying, then is put in a hot air stove for not less than 15 days for drying to have a water content below 0.2%, further is put into a high-temperature shuttle kiln for heating to 600-700 DEG C, is kept warm for 8 to 10 hours, then is heated to 1400 - 1500 DEG C, and is kept warm for 4 to 5 hours for cooling to discharge. The high-aluminum bearing ceramic bar beam has high acid and alkali resistance and corrosion resistance, also has high compressive strength and flexural strength and high opening rate, is suitable for requirements of high gas velocity, reduces the use number of the bar beam, has the characteristics of stability, safety, low resistance, low consumption and uniform distribution in a strong acid medium, and can improve the acid yield by more than 12%, increase the service life by more than 3 years, and reduce the production cost by more than 30%.

Owner:JIANGXI PINGXIANG LONGFA ENTERPRISE

Biological organic fertilizer containing eucommia bark powder and preparation process of biological organic fertilizer

InactiveCN104446974AImprove use valueImprove stress resistanceMagnesium fertilisersAlkali orthophosphate fertiliserBiotechnologyCell membrane

The invention relates to biological organic fertilizer containing eucommia bark powder. Wheat straw, chicken manure and sheep manure are reutilized, Chinese herbal medicine is further added for fermentation, the utilization value of raw materials is increased, the biological organic fertilizer contains rich active organic ingredients and can activate soil, beneficial microorganisms are increased, and accordingly, the crop yield is remarkably increased. Alkaline substances and other active substances in traditional Chinese medicine can damage cell membranes and has a good inhibition function on bacteria as well as repellant and breeding inhibition functions on pests.

Owner:HENAN HENGRUIYUAN IND

Mineral oil defoaming agent for waterborne coating and preparation method of mineral oil defoaming agent

The invention discloses a mineral oil defoaming agent for a waterborne coating and a preparation method of the mineral oil defoaming agent. The mineral oil de-foaming agent for the waterborne coating comprises the following components in percentage by weight: 5-15 percent of modified organic polyether, 5-25 percent of white oil, 10-25 percent of wax, 15-40 percent of octyl alcohol, 30-55 percent of sulfonated castor oil, 2-10 percent of an emulsifying agent, 0.1-0.2 percent of a catalyst, 0.1-0.3 percent of a sterilizing agent and 0.6-0.8 percent of a dispersing agent. The mineral oil de-foaming agent for the waterborne coating is formed by refining an organic polyether ester, mineral oil and alcohol composite product through a special process. The mineral oil de-foaming agent has the performance such as self-emulsification, easy dispersion, strong universality, good de-foaming, and lasting foam inhibition; the surface defect cannot be generated or the film-forming property cannot be affected; the mineral oil de-foaming agent has a special effect on the waterborne coating.

Owner:广东中联邦精细化工有限公司

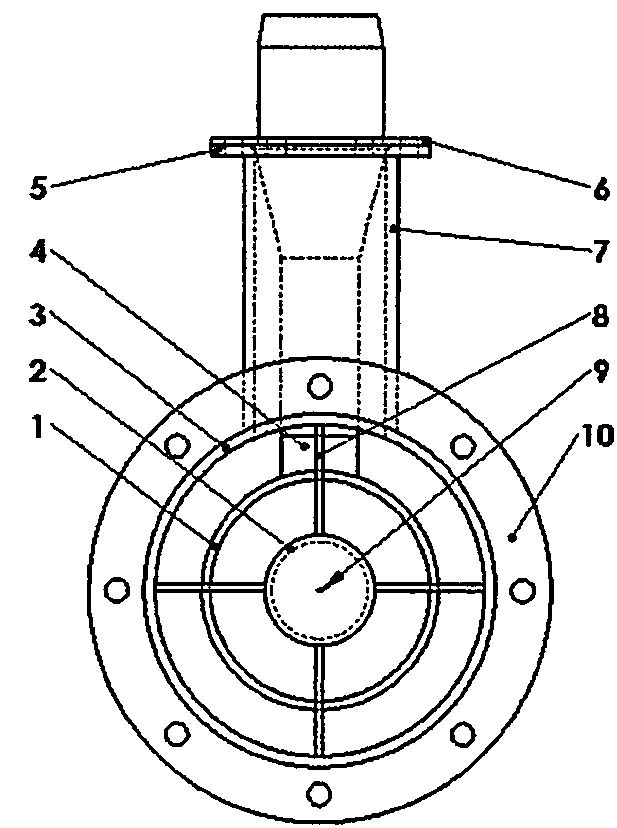

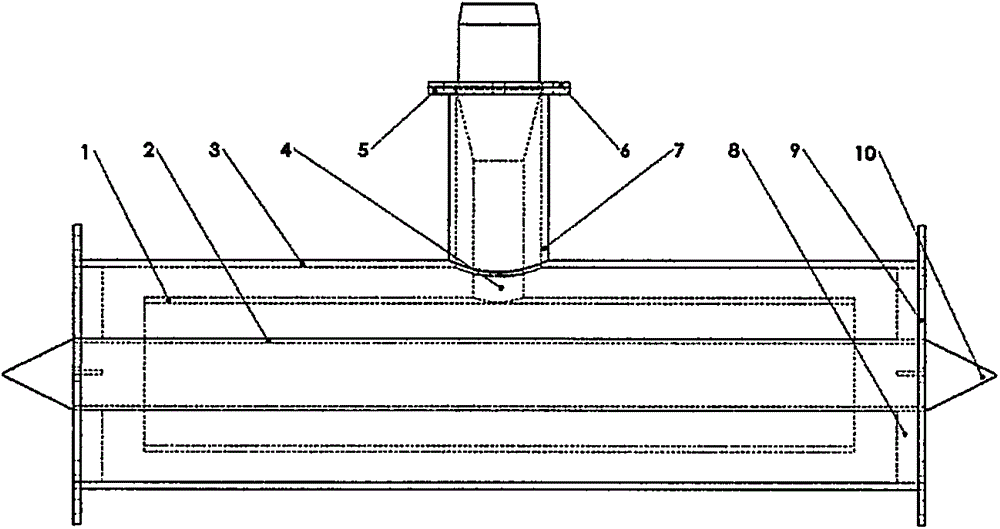

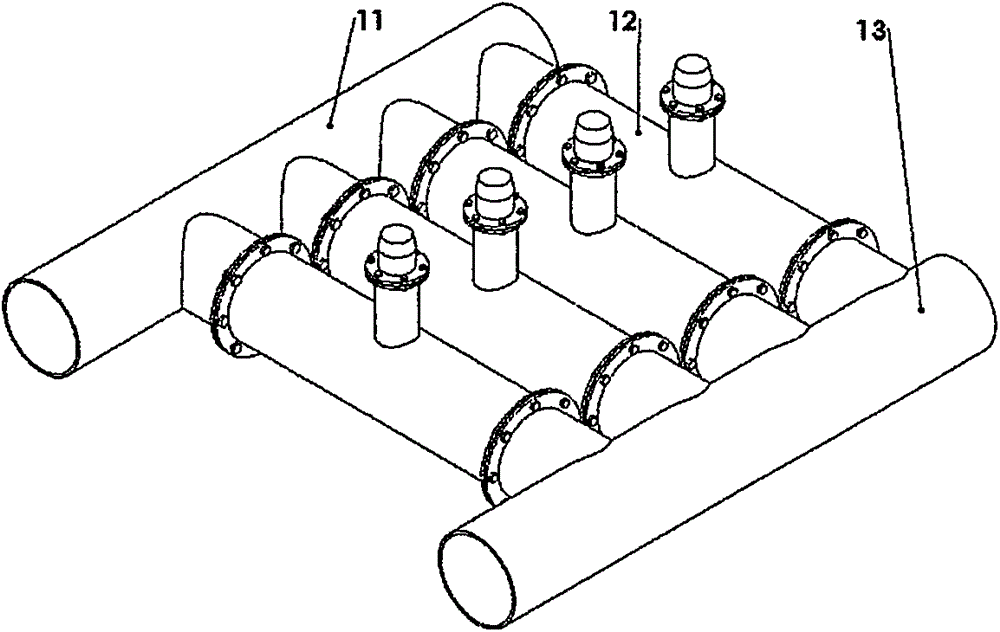

Near sound field ultrasonic reactor

ActiveCN104645916ALarge radiating surfaceUniform sound intensityEnergy based chemical/physical/physico-chemical processesEnvironmentally friendlyContinuous production

The invention relates to the technical field of generation and transfer of ultrasonic vibration and particularly relates to a near sound field ultrasonic reactor which efficiently uses ultrasonic energies. The near sound field ultrasonic reactor comprises an ultrasonic vibration tube, an ultrasonic internal reflection tube, an ultrasonic external reflection tube, an ultrasonic amplitude transformer, a flange connected with the ultrasonic amplitude transformer, an ultrasonic amplitude transformer flange, a fixed amplitude transformer sleeve, a fixed internal reflection tube rib, an internal reflection tube dividing conehead, an external reflection tube flange and the like. The ultrasonic reactor provided by the utility model is the near sound field ultrasonic reactor which is simple in structure, free from maintenance in operation, high in utilization ratio of ultrasonic energy, large in ultrasonic radiating area, uniform in ultrasonic sound intensity, low in power consumption and energy-saving and environmentally friendly and efficiently uses ultrasonic energies. The near sound field ultrasonic reactor provided by the utility model not only effectively utilizes radiating energies on the internal and external faces of the ultrasonic vibrating tube, but also effectively utilizes radiating energies reflected from inner and outer sides, so that the near sound field ultrasonic reactor is suitable for industrial flows in continuous production. A common plate type ultrasonic reactor is not as good as the near sound field ultrasonic reactor.

Owner:山东润蒙应急救援装备有限公司

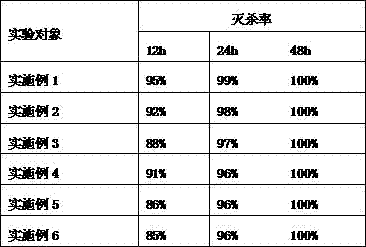

Pet nursing agent and preparation method thereof

InactiveCN107875051AGood anti-mite effectBroad-spectrum insecticidal effectCosmetic preparationsToilet preparationsMentholSURFACTANT BLEND

The invention discloses a pet nursing agent, which belongs to the technical field of a pesticide. The nursing agent comprises the following raw materials by weight percentage: 0.1-0.5% of menthol, 0.1-0.5% of thymol, 0.5-2.0% of a natural plant extract, 0.1-0.5%of natural plant essential oil, 1.0-1.5% of hydrogenated castor oil, 5.0-10.0% of an anionic surfactant, 2.0-5.0% of a nonionic surfactant, 0.2-0.5% of a corrosion-inhibition conditioning agent, 0.2-1.0% of a thickening agent, and the balance of deionized water. The nursing agent has strong-efficacy and wide-spectrum acarus-killing effect and insecticidal effect, and has strong-efficacy decontamination capability.

Owner:成都彩虹电器(集团)中南有限公司

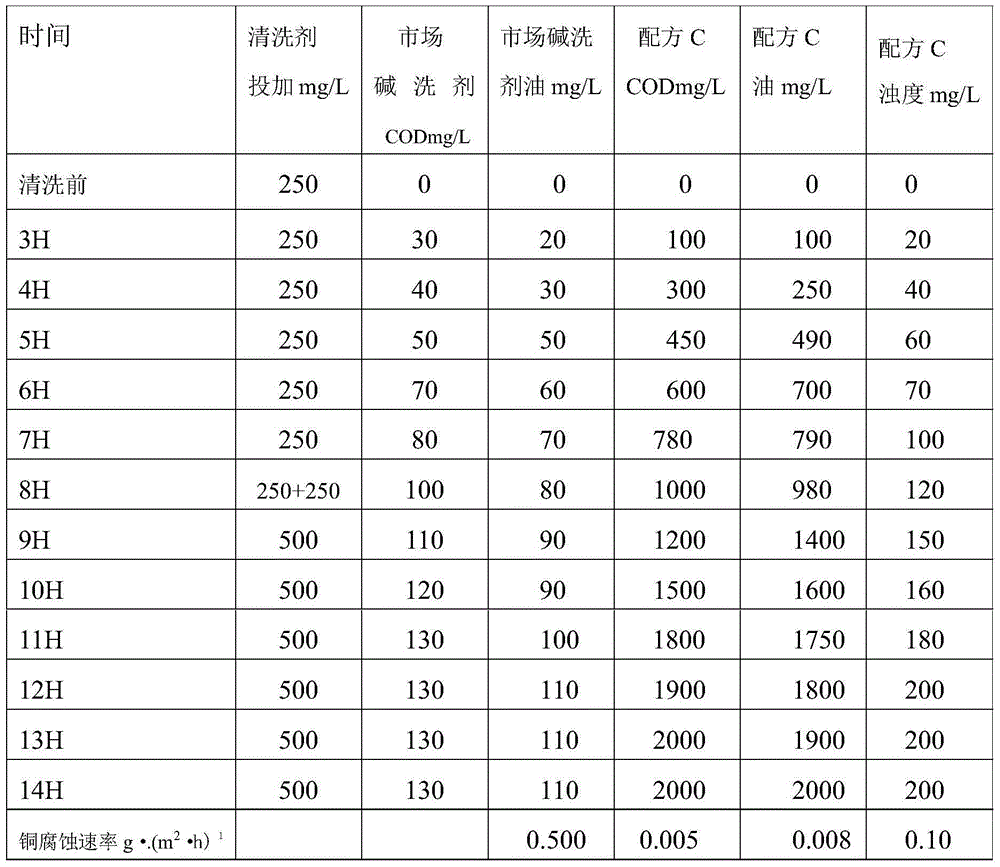

Efficient detergent used in industrial circulating water and preparation method of efficient detergent

InactiveCN104357260AWettability hasImprove decontamination abilitySurface-active non-soap compounds and soap mixture detergentsManufacturing technologyCleansing Agents

The invention belongs to the technical field of design and manufacturing of chemical products and particularly relates to an efficient detergent used in industrial circulating water and a preparation method of the efficient detergent. The detergent is prepared from the following materials in parts by weight: 5-10 parts of polyoxyethylene fatty alcohol ether, 4-6 parts of polyoxyethylene octyl phenolic ether, 5-8 parts of triethanolamine oleate soap, 15-20 parts of isopropyl alcohol, 5-10 parts of trisodium phosphate, 2-4 parts of sodium tripolyphosphate, 3-5 parts of sodium carbonate, 3-5 parts of sodium hydroxide, 10-15 parts of sodium dodecylbenzenesulfonate and 35-48 parts of tap water. The preparation method comprises the step of synthesizing the materials under a certain condition. The efficient detergent is mainly used for cleaning an oil cooler in the industrial circulating water.

Owner:新疆水处理工程技术研究中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com