Patents

Literature

126results about How to "Corrosion will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

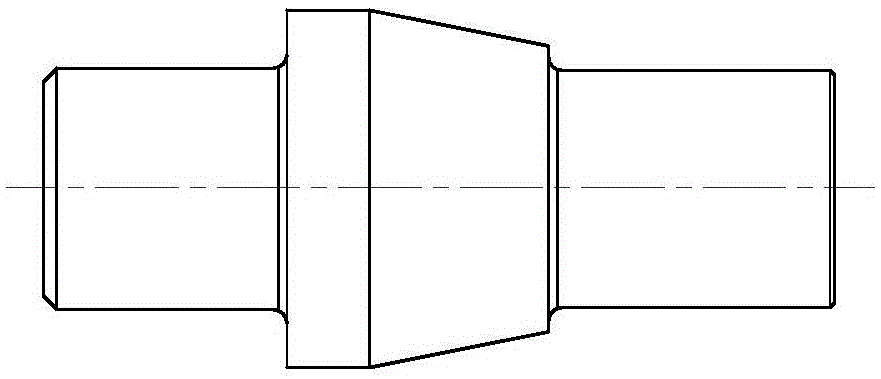

Water inlet device capable of feeding detergents

PendingCN107287839ADelivery measurement is accurateCorrosion will notOther washing machinesControl devices for washing apparatusInlet channelMain channel

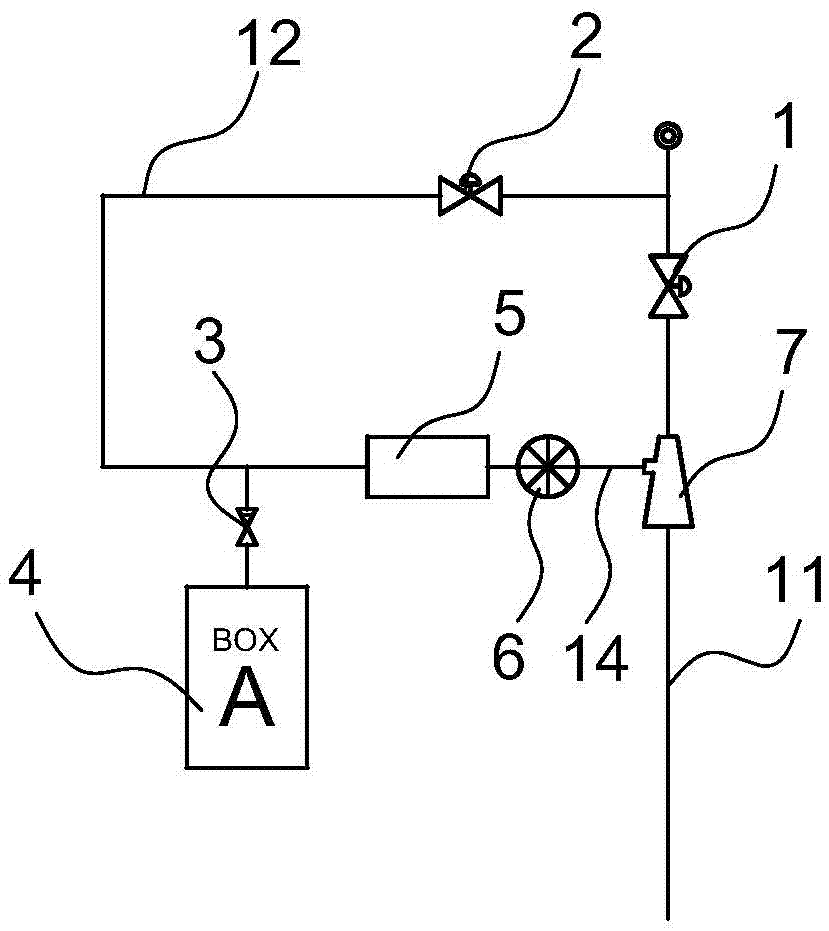

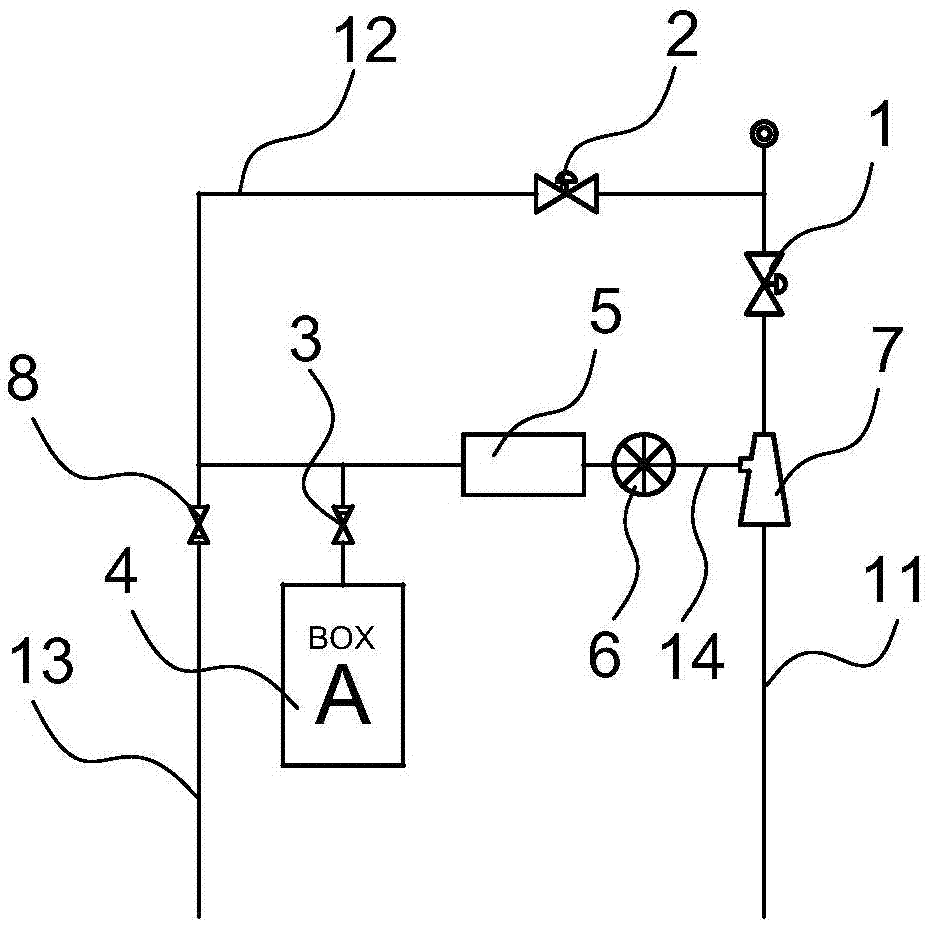

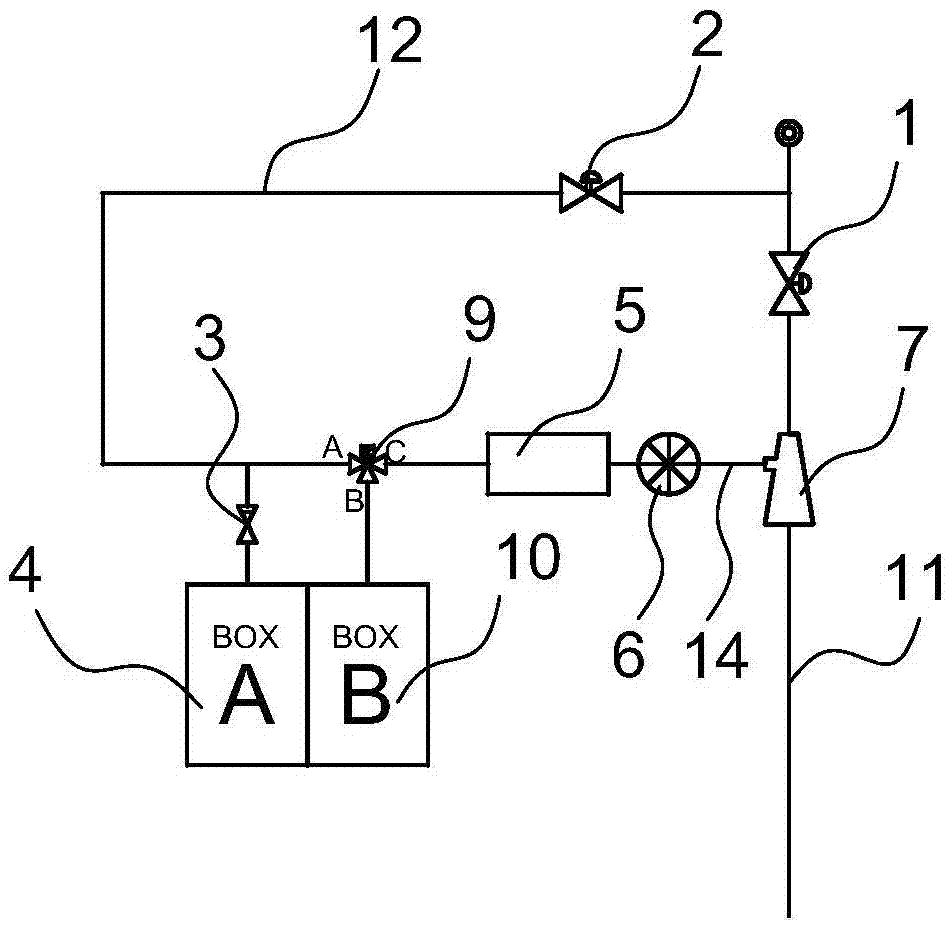

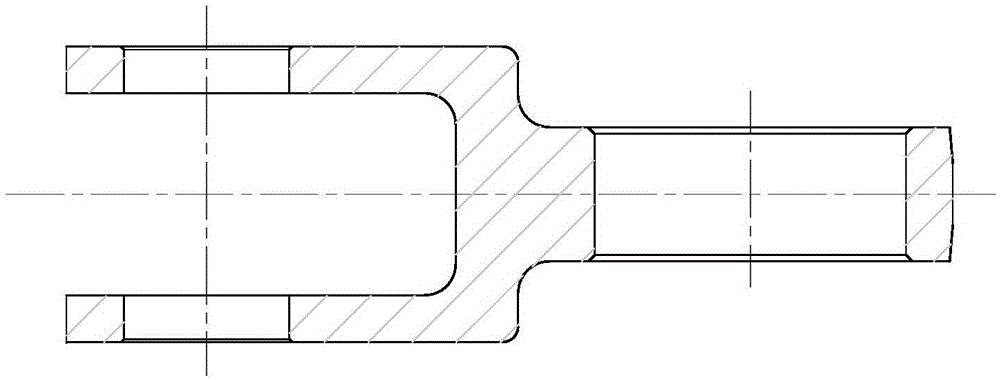

Provided is a water inlet device capable of feeding detergents. The water inlet device capable of feeding detergents can feed detergents accurately and effectively, and metal parts are not corroded. The water inlet device capable of feeding detergents comprises a main channel (11), and a Venturi tube (7) is connected to the main channel (11), wherein the main channel (11) is connected with a main electromagnetic water inlet valve (1), and a flushing and liquid inlet channel (12) is connected in parallel with a water delivery channel in the direction of the inlet of the main electromagnetic water inlet valve; the flushing and liquid inlet channel (12) is connected with an electromagnetic flushing water inlet valve (2) and a liquid collection chamber (5) located in the direction of the outlet of the electromagnetic flushing water inlet valve (2), and an one-way valve A (3) and a detergent A box (4) which is arranged in the direction of the inlet of the one-way valve A (3) are connected to the portion, between the electromagnetic flushing water inlet valve (2) and the liquid collection chamber (5), of the flushing and liquid inlet channel (12) in a branch mode; a liquid outlet passage (14) is connected to a portion between the outlet of the liquid collection chamber and the negative pressure port of the Venturi tube, the liquid outlet passage is connected with a flow sensor (6), and the outlet of the main channel is connected to a wash bucket. The water inlet device capable of feeding detergents is used as a water inlet and detergent feeding device for a washing machine.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aqueous adhesive for binding rubber and metal and preparation thereof

The invention discloses a water-based adhesive used for the bonding between rubber and metal; according to the parts by weight, the adhesive comprises 60-90 parts of soft monomer, 30-60 parts of hard monomer, 2-8 parts of functional monomer, 3-10 parts of emulsifier, 0.4-0.8 part of initiator, 0.6-1.0 part of pH buffer, 100 parts of deionized water or distilled water, 0.05-0.1 part of anticorrosive bactericide, and 1.4-1.6 parts of pH regulator. The invention also discloses a preparation method for preparing the water-based adhesive. The adhesive can replace the existing solvent-typed adhesive, effectively realizes the bonding between the rubber and the metal, has no poison, no combustion and no explosion, is safe and protects the environment. The preparation method which applies the seed latex polymerization has simple preparation process and high production efficiency and is beneficial for the industrial production.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and preparation method thereof

InactiveCN101905155AHigh catalytic activityImprove catalytic performanceCatalyst activation/preparationPreparation from organic carbonatesCoprecipitationTitanium

The invention discloses a complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and a preparation method thereof. The catalyst basically consists of a molybdenum-titanium complex oxide, wherein the weight ratio of the molybdenum to the titanium is 100:10-100; the roasting temperature is between 300 and 600 DEG C; base raw materials for preparing the catalyst are a molybdenum compound and a titanium compound; and the preparation method adopts a coprecipitation method or mechanical grinding method. The catalyst has high catalytic activity and good selectivity for the reaction of synthesizing the diphenyl carbonate by ester exchange, and particularly has the advantages of simple preparation method, easy separation and recycling, no environmental pollution, no corrosion to equipment and the like, so the catalyst can be widely applied to production of the diphenyl carbonate.

Owner:CHANGZHOU INST OF CHEM

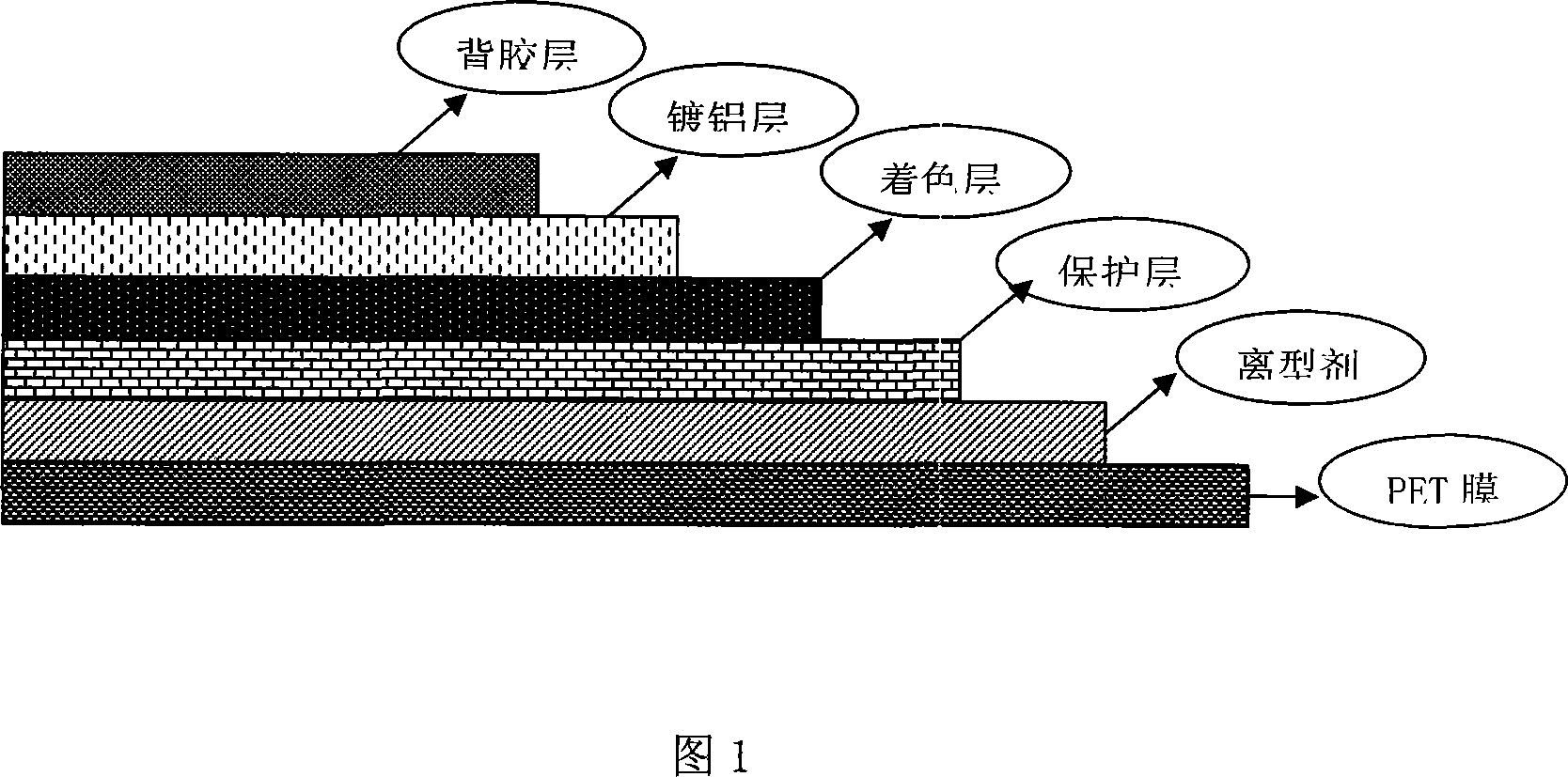

Coloring layer coating for leather full wiped film and preparation method thereof

InactiveCN101121843AImprove temperature resistanceExcellent resistance to solvent corrosionLiquid surface applicatorsDecorative surface effectsAcrylic resinAcid value

The invention discloses a coloring paint developed for a full-revolving leather film. The paint consists of the components (calculated by weight percent): host crystal (20-50), polyisocyanate resin solidifying agent (10-30), nitro cellulose resin accelerator (30-60), dye (0-10), paint assistant (1-5) and diluent (40-70). The host crystal is acrylic resin or alkyd resin or the mixture of acrylic resin and alkyd resin; the acrylic resin is hydroxyl acrylic resin, and the alkyd resin is alkyd resin with hydroxyl value and acid value. The invention has excellent temperature resisting and solvent causticity resisting performances, sound compatibility with dyes, strong bonding with the aluminum-layer, sound luster flamboyance and color fastness.

Owner:SHANXI UNIV

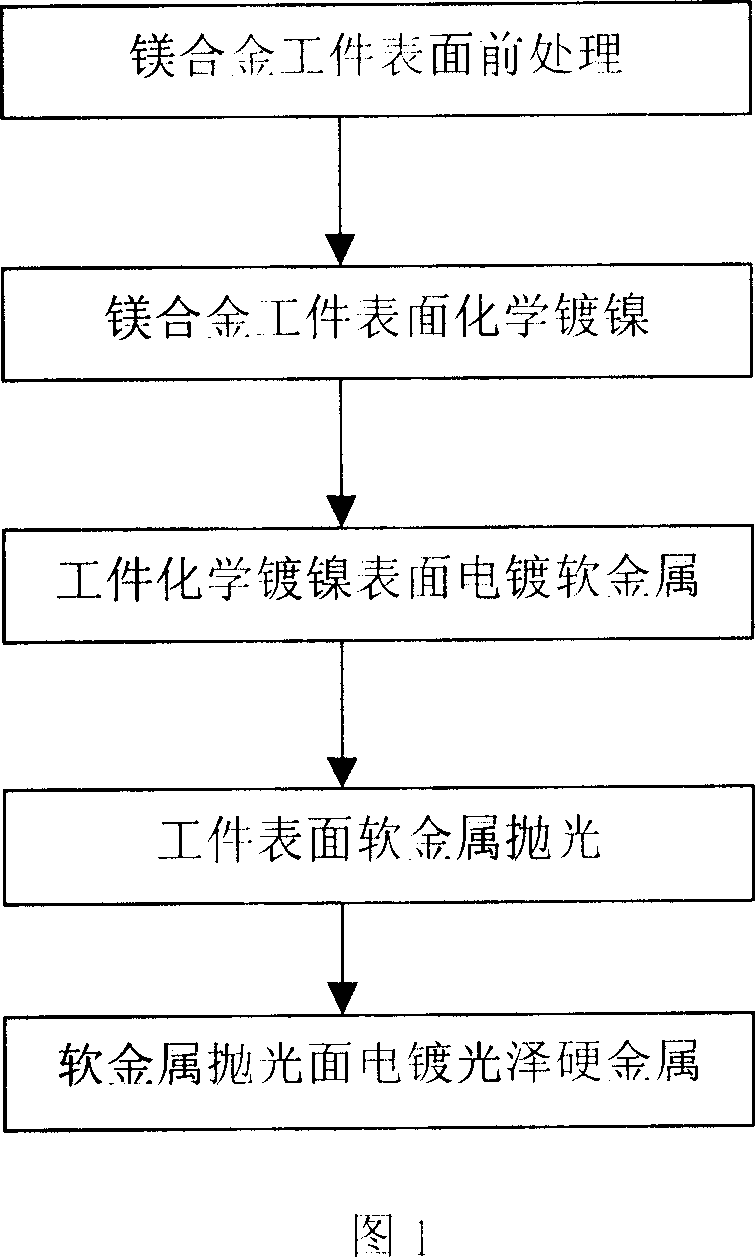

High-luster magnesium alloy surface treatment method

The invention correlates to an operation method of improving smooth glitter property after dealing with the surface of magnesium alloy. The method first does the preliminary treatment procedure to the surface of magnesium alloy workpiece, and then carries out chemical nickel plating procedure of high adhesiveness to the surface of magnesium alloy. After the procedure of electroplating soft metal to the surface of chemical nickel plating, the procedure is polishing in the surface of soft metal, and then the procedure is electroplating glitter hard metal in the surface of after polishing soft metal, so that it can reach the effect of high smooth glitter property to magnesium alloy workpiece.

Owner:何靖

Aerosol detergent for throttle valves of automobile engines

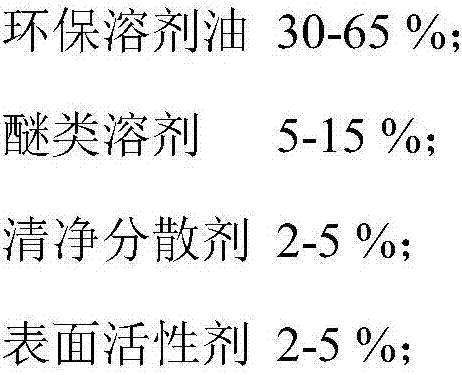

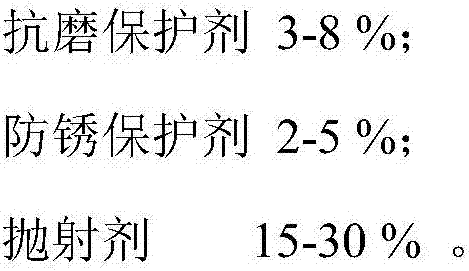

InactiveCN107057898AQuick removalCorrosion will notInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOil sludgeCarbon deposit

The invention discloses an aerosol detergent for throttle valves of automobile engines. The aerosol detergent comprises environmental-friendly solvent oil, petroleum ether solvent, ether solvent, detergent dispersant, surfactant, antiwear protective agent and liquefied petroleum gas, and particularly comprises, by mass, 30-65% of environmental-friendly solvent oil, 5-15% of ether solvent, 2-5% of detergent dispersant, 2-5% of surfactant, 3-8% of antiwear protective agent, 2-5% of rustproof protective agent and 15-30% of propellent. Compared with the prior art, the aerosol detergent for the throttle valves has the advantages of causing no corrosion to parts of electronic throttle valves, having effects of lubricating, rust preventing and abrasion preventing, being convenient to use and high in cleaning capacity, especially having rapid removal effect to stains on the throttle valves, such as oil sludge and carbon deposit, containing no water to avoid rusting the engines, and being stable in property, safe and reliable to store and use due to the fact that the aerosol detergent is made from environmental-friendly material.

Owner:SHENZHEN IDO TECH

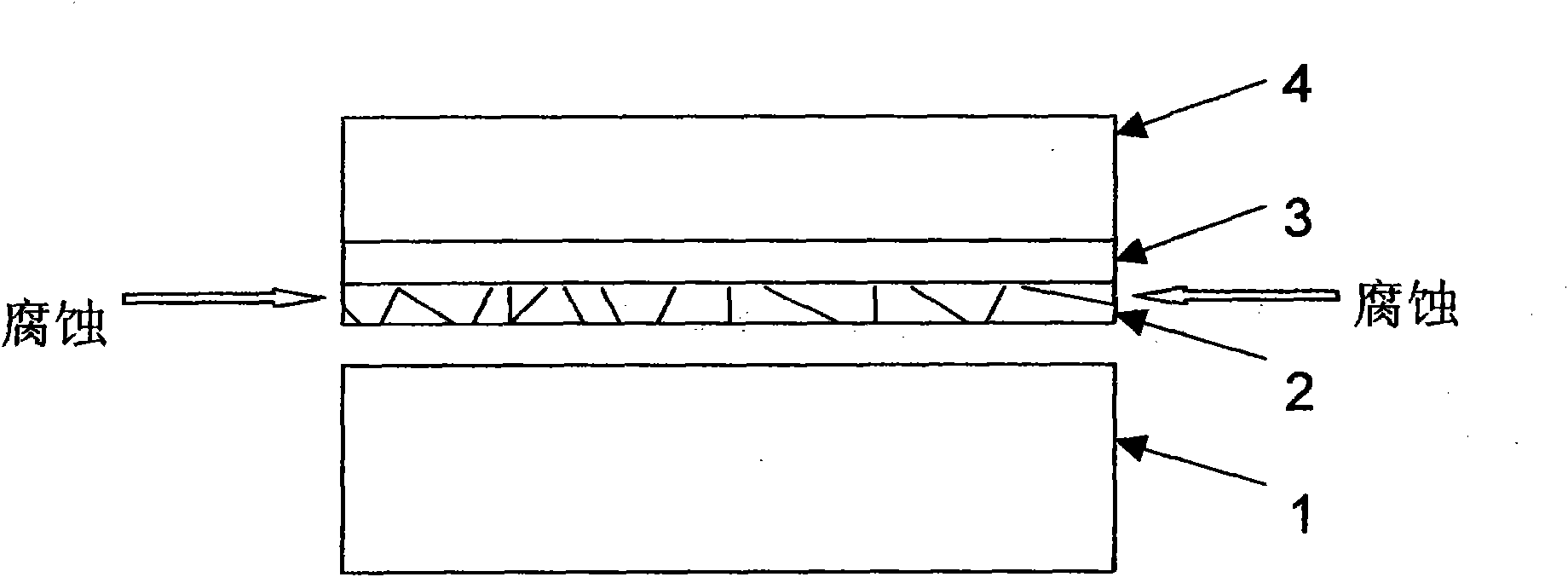

Preparation for amorphous carbon thin-film hydrophobic material with rear surface fluorating process

InactiveCN1614091ACorrosion will notAccelerated corrosionVacuum evaporation coatingSputtering coatingGas phaseElectromagnetic field

This invention relates to preparation of hydrophobic amorphous carbon film material with F-treated substrate. It comprises: depositing an amorphous 0.1-3um film on a F corrosive surface as substrate was deposited by a normal vapour deposition process; putting it into a chemical gas phase surface treatment chamber, vacuuming the chamber and filling F-C gases at 1-10000Pa, providing a electromagnetic field of 2-100W / cm2 to make gases glow discharging, F-treating the substrate at 0-500deg.C for 10-120min. No corrosion is found on the substrate in the experiment and the angle of contact was over 120deg.

Owner:BEIJING UNIV OF TECH

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN100588743CFully activatedHigh activityMetallic material coating processesGlutaric acidGluconic acid

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloricacids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

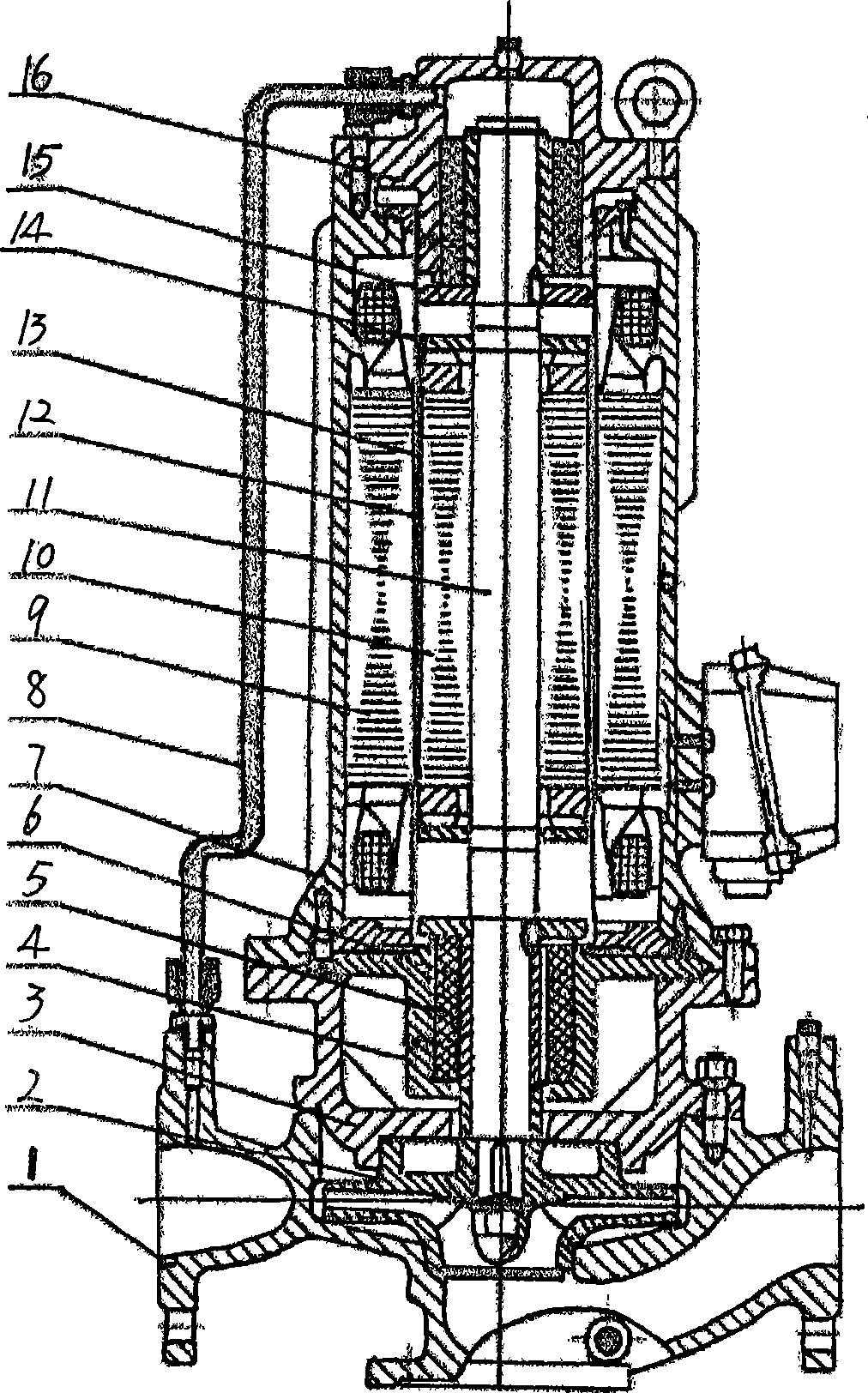

Vertical shield pump

InactiveCN101482122AAll-in-one compact structureNot easy to corrodePump componentsPump installationsImpellerWorking environment

The invention relates to the field of liquid transfer pump products, in particular to a vertical shield pump which essentially consists of a water pump and a canned motor. The water pump comprises an impeller, a pump body and a sealing ring. The canned motor comprises a stator, a rotor, shielding sleeves, a bearing support, a bearing, a cooling pipe and a deflation valve. The vertical shield pump is characterized in that the canned motor adopts an insulated winding; the rotor consists of a stainless steel shaft and a cast aluminum rotor; and the inner diameter of the stator and the surface of the rotor are respectively provided with the stainless steel shield sleeve. The vertical shield pump has the beneficial effects that a pump-motor integral structure is compact; the vertical shield pump has an external cyclic cooling system; when the vertical shield pump transfers high temperature and corrosion medium liquid containing granules, the rotor and the stator are not eroded easily, and medium can not be leaked; the vertical shield pump has the characteristics of small size, nice appearance, stable operation, convenient installation, no noise and the like; and the vertical shield pump meets the increasing requirement of the user on the stability of working environment and the environmental protection at utmost.

Owner:上海成峰泵业制造有限公司

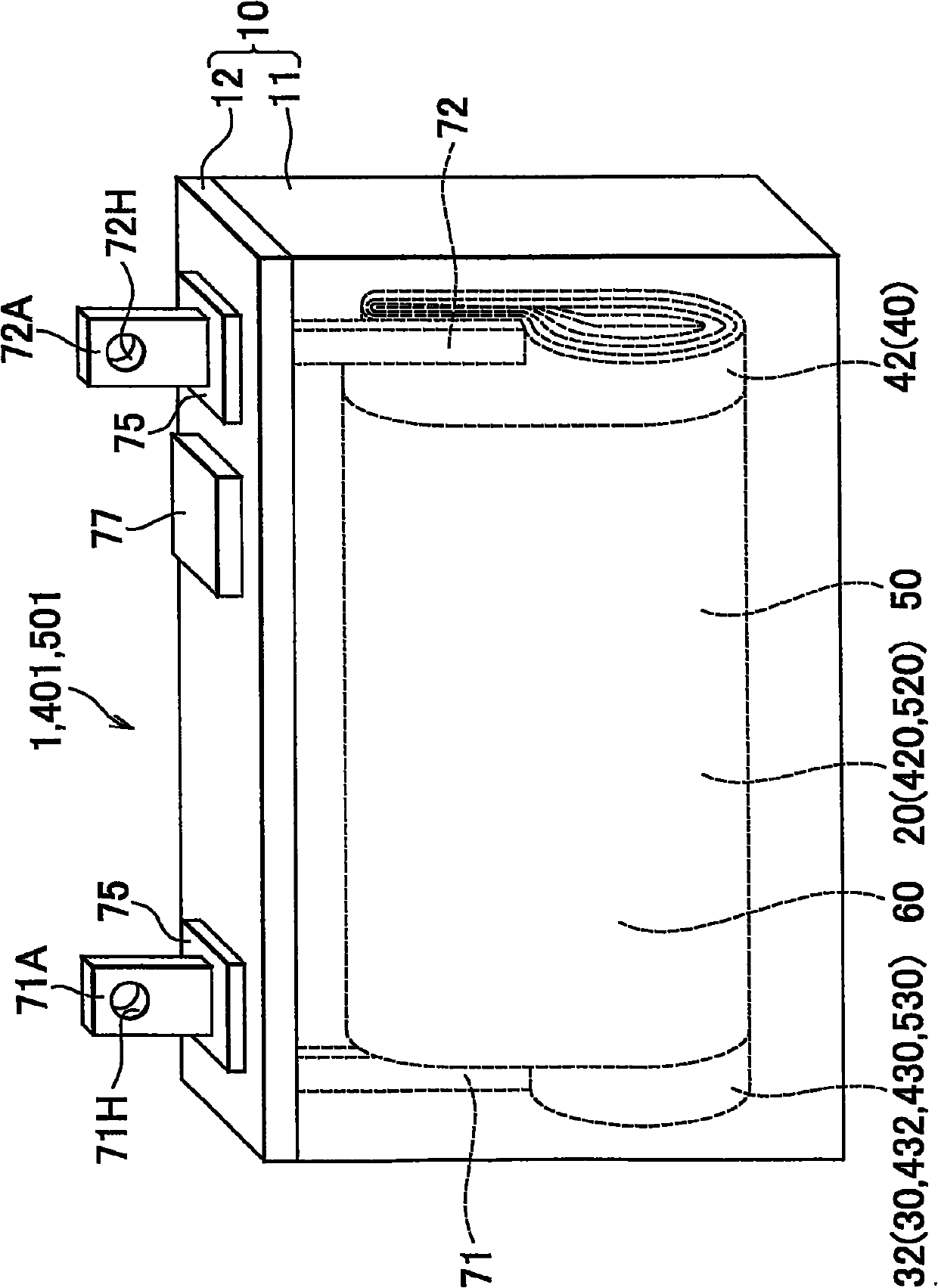

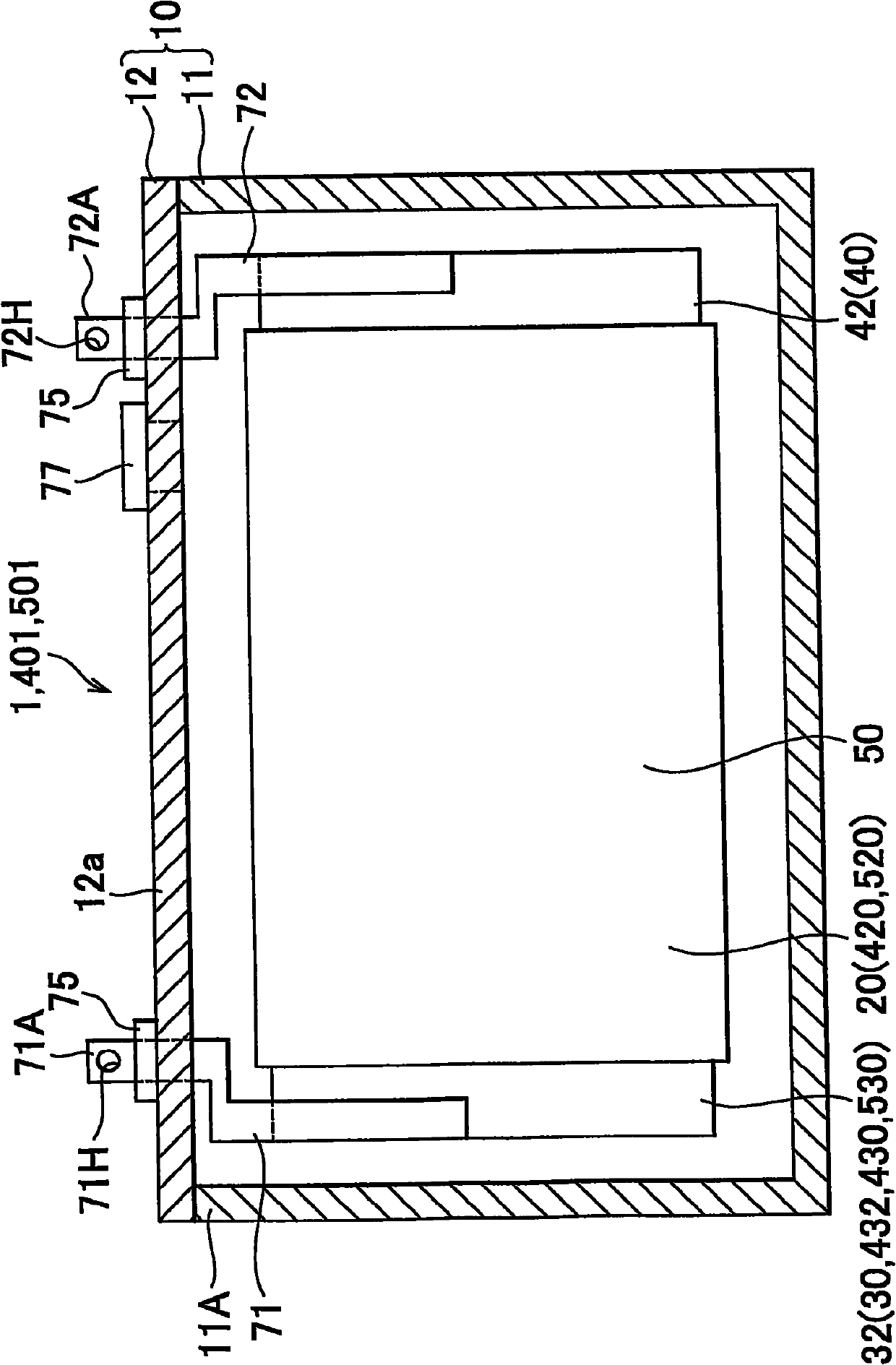

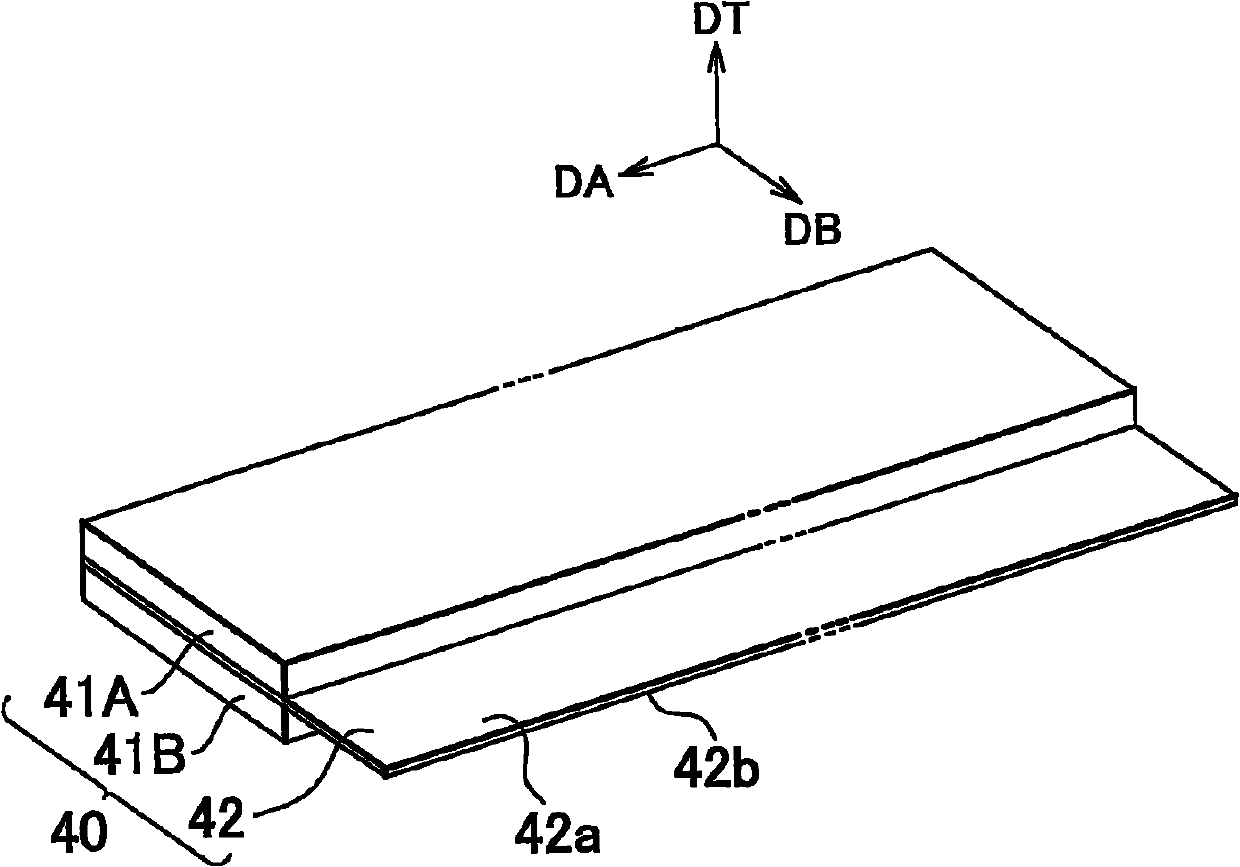

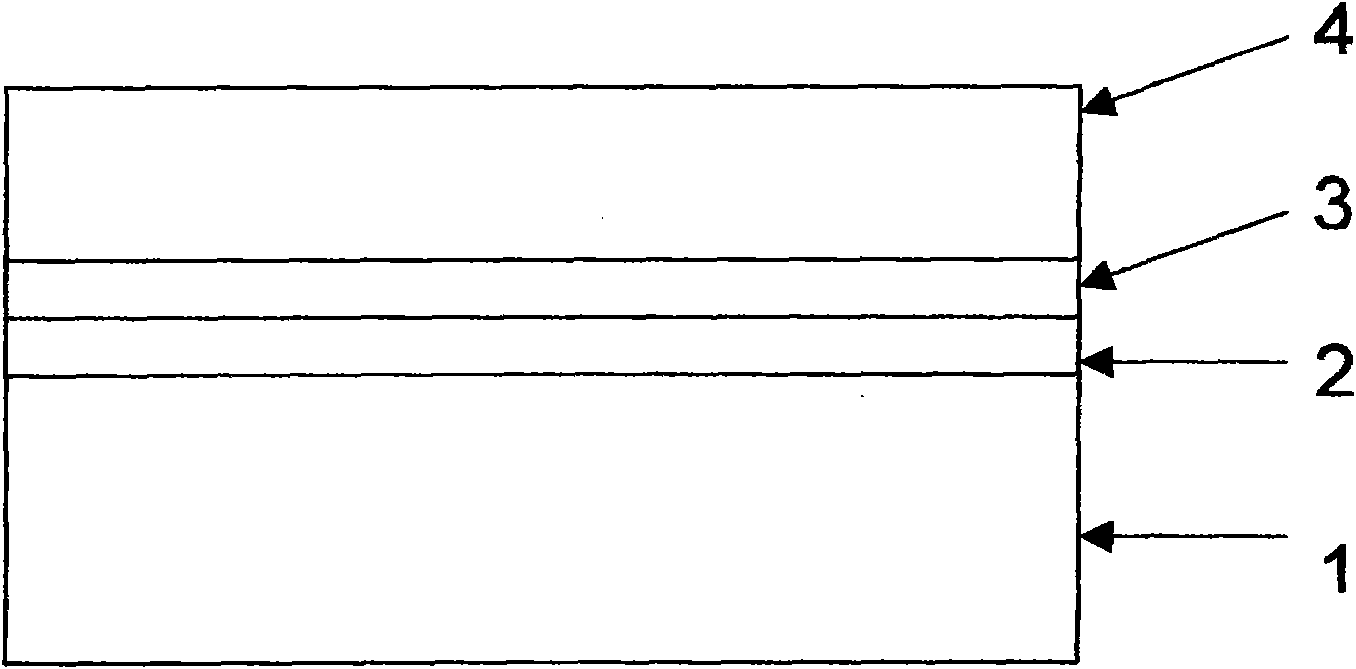

Battery-dedicated electrode foil, positive electrode plate, battery, vehicle, and battery-equipped appliance, and manufacture method for the battery-dedicated electrode foil, and manufacture method of the positive electrode plate

InactiveCN102089905ACorrosion will notElectrode manufacturing processesFinal product manufactureMetallic aluminumMechanical engineering

A battery-dedicated electrode foil (32) includes an aluminum electrode foil (33) in which metal aluminum is exposed, and corrosion-resistant layers (34A, 34B) that are formed on surfaces (33a, 33b) of the aluminum electrode foil, and that are in direct contact with the metal aluminum that forms the aluminum electrode foil, and that are made of tungsten carbide.

Owner:TOYOTA JIDOSHA KK

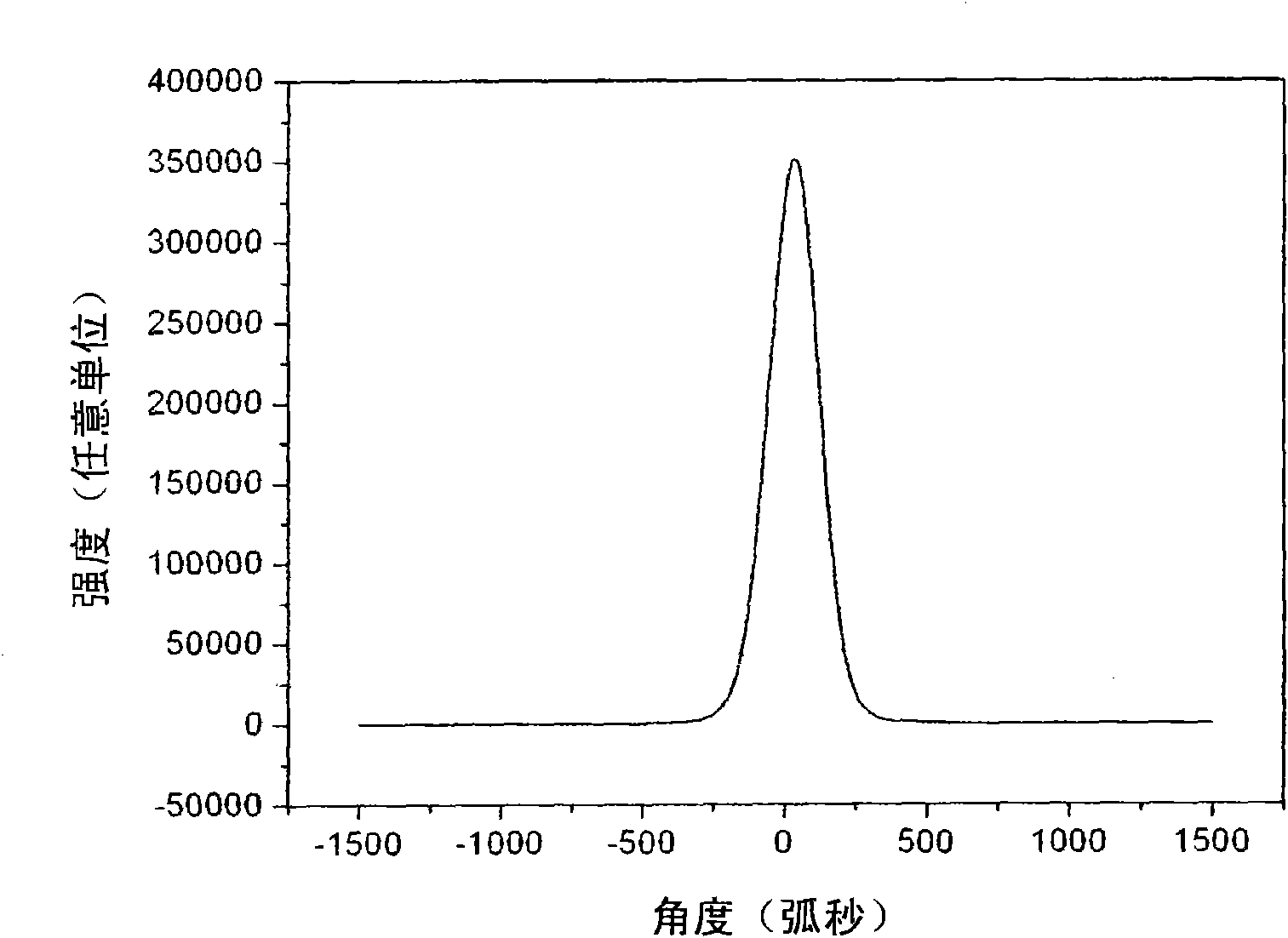

Method for preparing large-size GaN self-support substrate

InactiveCN102031560AActs as a nucleating layerAvoid destructionPolycrystalline material growthFrom chemically reactive gasesLarge sizeHydride vapour phase epitaxy

The invention relates to a method for preparing a large-size GaN self-support substrate, which comprises the following steps of: 1. firstly, growing a layer of ZnO membrane on a substrate; 2. growing a low-temperature buffer layer on the ZnO membrane to form a sample; 3. growing a GaN thick membrane on the low-temperature buffer layer at high temperature in a hydride vapour phase epitaxy system; and 4. after growing in the hydride vapour phase epitaxy system at high temperature, directly separating the GaN thick membrane from the substrate to form a large-size GaN self-support substrate because corrosive gases, such as HCL, NH3, and the like in the hydride vapour phase epitaxy system corrodes the ZnO membrane.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

High efficiency and no pollution industrial cleaning agent and its application

InactiveCN102242029AImprove solubilityCorrosion will notSurface-active non-soap compounds and soap mixture detergentsCleaning using liquidsPtru catalystActive agent

The invention discloses a high efficiency and no pollution industrial cleaning agent and its application. The formula of the cleaning agent comprises 80% - 93% of mixed ester solvent, 2% - 5% of nonionic surfactant, 3% - 10% of sodium carbonate and 2% - 10% of sodium silicate. The preparation method comprises the following steps: adding the mixed ester solvent at first, simultaneously adding a nonionic surfactant, sodium carbonate and sodium silicate and then stirring by manual or a machine for 15 - 20 minutes to obtain the high efficiency and no pollution industrial cleaning agent of the present invention. The high efficiency and no pollution industrial cleaning agent of the present invention is suitable for cleaning a oil circuit system which takes an operation medium as an oil product in equipment, and especially suitable for cleaning petrochemical apparatus, as well as on-line cleaning or stopping to disassembly and clean the oil circuit system of all industrial equipments such asa compressor. The cleaning agent of the invention has no influence to the equipment system, product quality and catalyst performance.

Owner:SHANGHAI DYNAMIC TECH

Liquid active carbon colloid emulsion

InactiveCN101633782AEfficient removalWill not corrodeOrganic-compounds/hydrides/coordination-complexes catalystsCoatingsVitamin CRare earth

The invention discloses a liquid active carbon colloid emulsion belonging to the technical field of construction materials. The liquid active carbon colloid emulsion is prepared from the following raw materials according to parts by weight: 15-30 parts of supramolecular poly cage shape siloxane, 3-8 parts of nano level active carbon, 3-8 parts of nano kieselguhr, 3-8 parts of nano titanium oxide, 4-9 parts of nano tourmaline, 2-5 parts of nano silicon dioxide, 3-7 parts of rare earth activator, 5-12 parts of polyethylene glycol, 5-15 parts of sodium benzoate, 5-12 parts of sodium hexametaphosphate, 0.5-1.2 parts of amino acid, 0.3-0.8 parts of vitamin C, 1-3 parts of surfactant, 10-20 parts of distilled water and 1-3 parts of carboxymethyl cellulose. The invention effectively eliminates chemical contaminants released by decoration materials after indoor decoration and also can destroy biologic contaminants, such as viruses, bacteria and the like, a product has no irritative smell and no secondary pollution, protection is not needed in the construction process, components, such as metal and the like, can not be corroded, and the construction cost can be lowered.

Owner:赵东育

Method for producing frosted glass

InactiveCN101618648AReduce cleaning processReduce cleaning costsPattern printingSurface treatment compositionsChemistryAqueous sodium hydroxide

The invention relates to a method for producing frosted glass, which comprises the following steps: firstly, selecting original white glass sheets, jointing the two sheets, and sealing four edges by tapes; putting the glass into a weak acid pool for soaking for 2 minutes; conveying the glass into a corrosion pool for frosting; clearing the frosting liquid after the glass is frosted, and drying the glass; removing the sealing tapes at the four edges of the glass; then, adopting a silk screen to print the preliminarily designed glass pattern on one surface, air-drying the glass for 2 hours, andthen, conveying the glass into a dryer for drying; pasting a protective film on the glass surface which is not printed with the pattern; scrubbing the surface which is printed with the glass pattern with weak acid liquid; soaking the glass into the corrosion liquid for 80-120 minutes; putting the glass into a sodium hydroxide solution for cleaning; and then, conveying the glass into a cleaning and drying machine for cleaning and drying to obtain a finished product. The patterned glass which is produced by the method of the invention has uniform and fine etched depth, strong aesthetic feeling of the pattern, better quality, simple processing method and environment protection, and can greatly reduce the production cost in the production process.

Owner:杜广武

Method for synthesizing active magnesium hydroxide

The invention relates to a method for synthesizing active magnesium hydroxide, which employs cheap magnesite as raw material. Obtaining caustic calcined magnesite after calcining, and then neutralizing the caustic calcined magnesite with water under the circumstance of alkali agent or high-molecular agent to synthesize magnesium hydroxide with low viscosity, high activity, lastly concentration of the magnesium hydroxide reaches 35%.

Owner:李淑荣

Method for preparing lithium ion battery anode composite material through template method

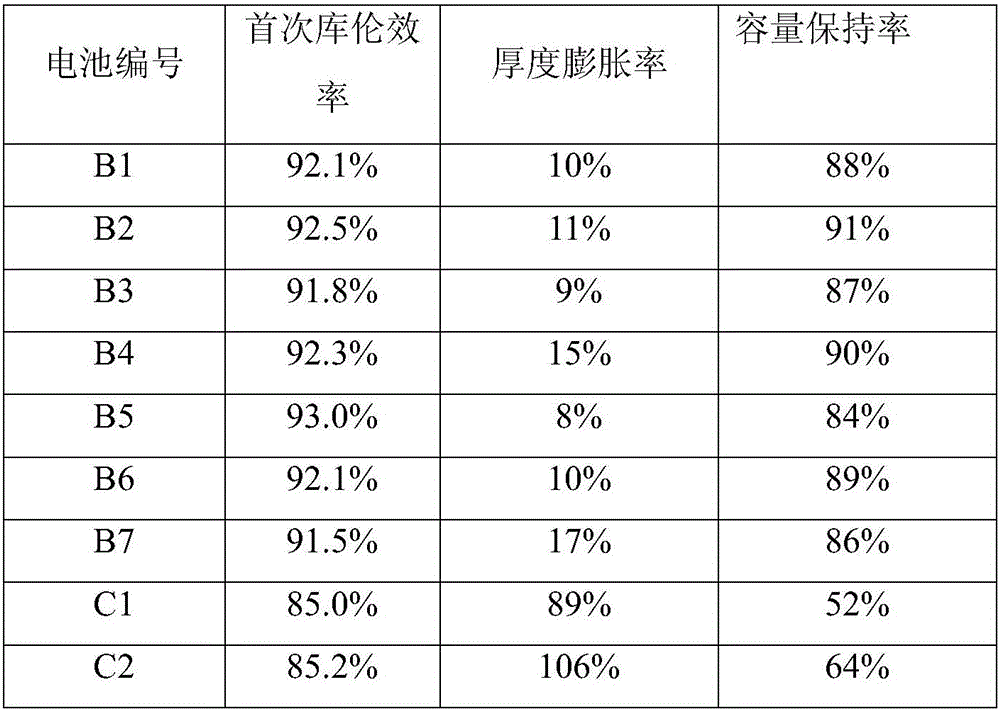

ActiveCN106328898AAlleviate volume expansionImprove cycle stabilitySecondary cellsPositive electrodesCarbonizationBattery capacity

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a method for preparing a lithium ion battery anode composite material through a template method. The method at least comprises the following steps: adding NaCl, artificial graphite, SiO particles and a carbon source into water, stirring the materials uniformly, evaporating to be dry, and then crushing and mixing to obtain a mixture; and placing the mixture into a carbonization furnace, performing carbonization treatment at 500-1200 DEG C in an inert gas protective atmosphere, then soaking the mixture with water to remove NaCl, and drying to obtain the anode composite material. The lithium ion battery anode composite material prepared by the method provided by the invention through a NaCl template method has a structure with multiple holes, and the porous composite material can well solve the problem of volume expansion of SiO during lithium embedding, so that the cycling stability of a silicon-based lithium ion battery anode material is well improved on the premise that a relatively high battery capacity is maintained, and the requirements on high-performance lithium ion battery anode materials can be met.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

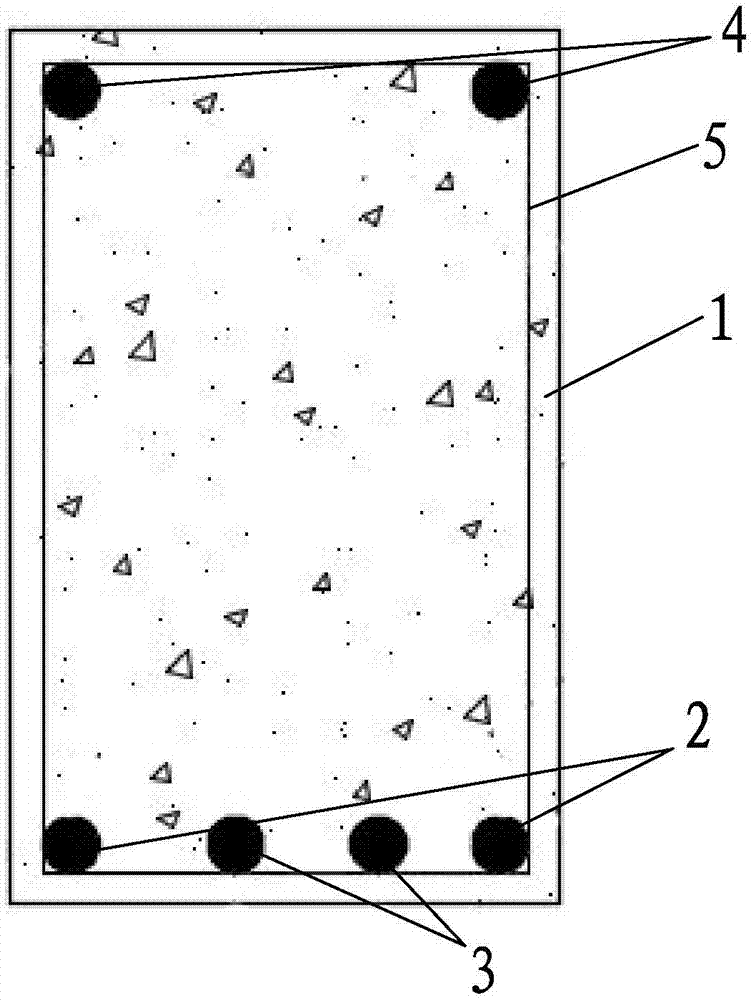

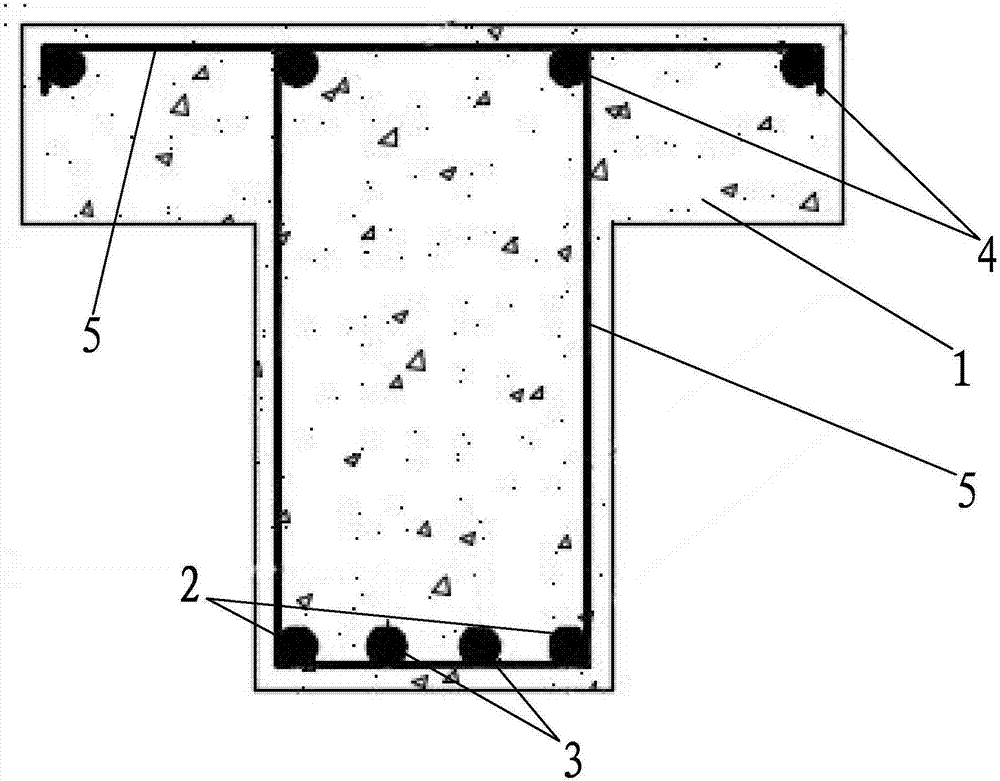

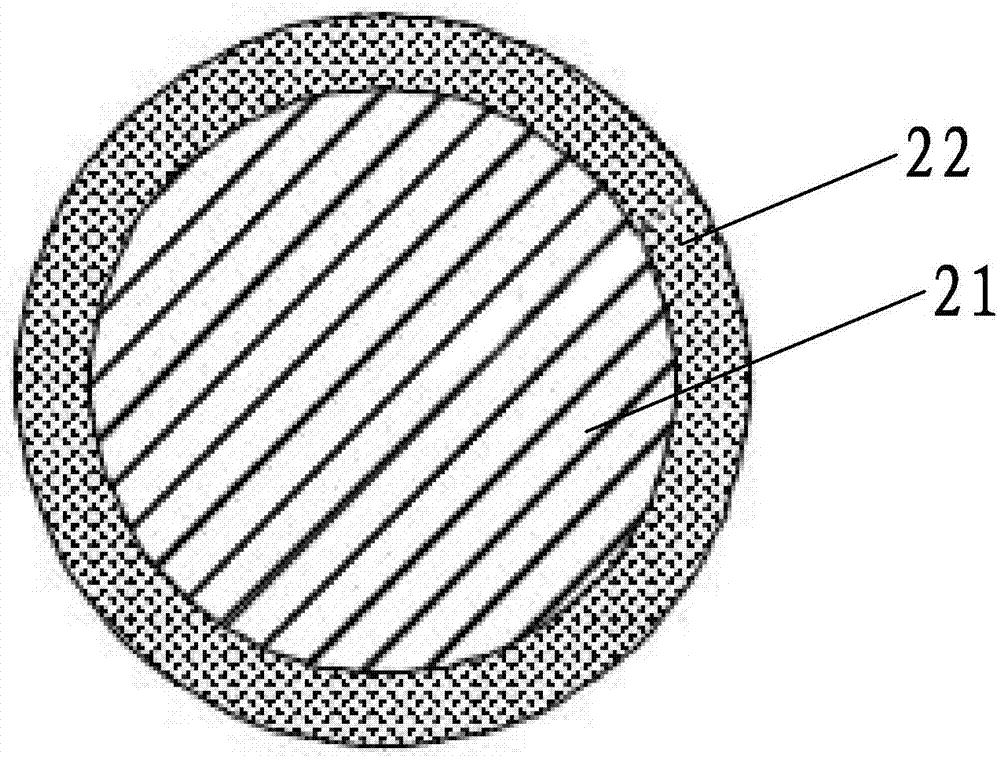

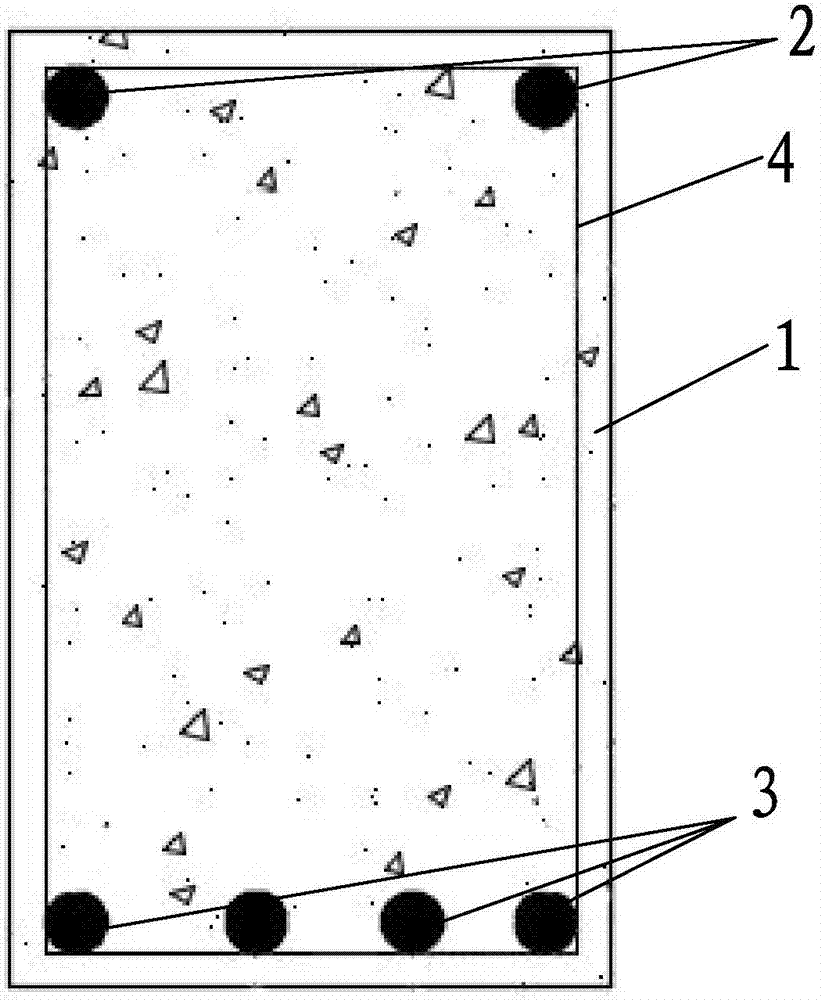

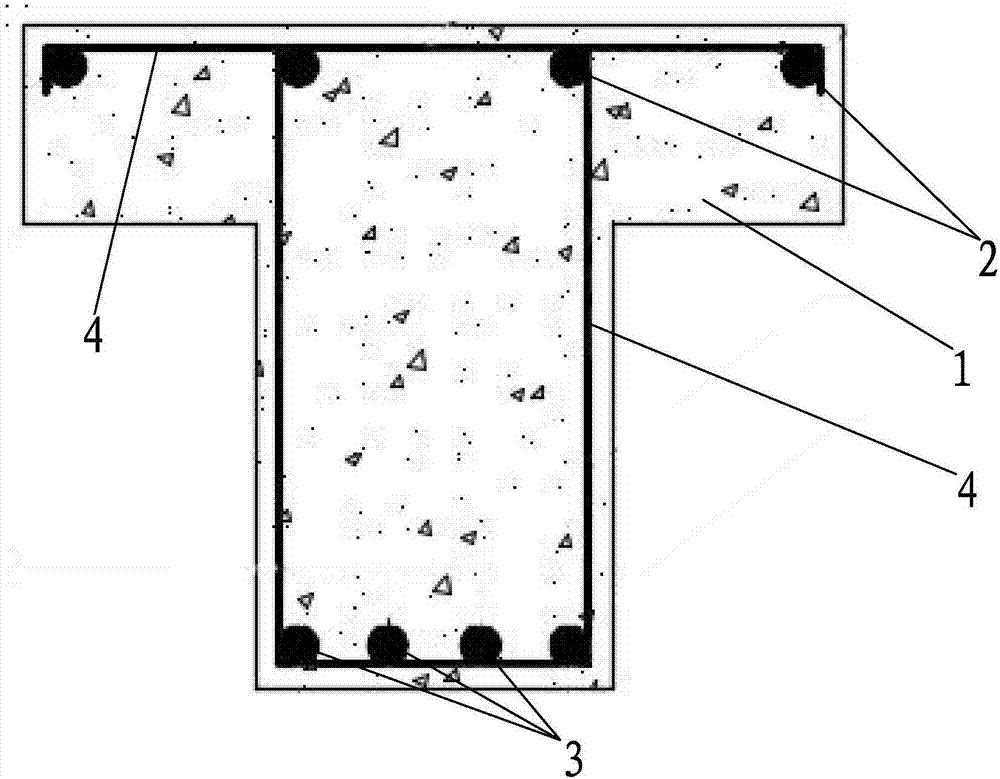

Sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars and construction method thereof

The invention discloses a sea sand concrete beam with mixed reinforcements of fiber reinforced plastics (FRP)-steel composite bars and FRP bars. The sea sand concrete beam comprises sea sand concrete, the FRP-steel composite bars, the FRP bars, erection bars and a plurality of stirrups, wherein the FRP-steel composite bars, the FRP bars, the erection bars and the stirrups are fixedly arranged in the sea sand concrete. The FRP-steel composite bars and the FRP bars are arranged at the lower end of the sea sand concrete, and the erection bars are arranged at the upper end of the sea sand concrete. The lengths of the FRP-steel composite bars and the FRP bars are arranged along the length of the sea sand concrete. The stirrups are evenly and fixedly connected to the outer surfaces of the FRP-steel composite bars, the FRP bars and the erection bars in a bound mode in the direction of the lengths of the FRP-steel composite bars and the erection bars. The FRP-steel composite bars comprise steel bars and FRP fiber cloth, wherein the outer surfaces of the steel bars are wrapped with the FRP fiber cloth. The FRP fiber cloth is bonded with the sea sand concrete. The invention further discloses a construction method of the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars. According to the sea sand concrete beam with the mixed reinforcements of the fiber reinforced plastics (FRP)-steel composite bars and the FRP bars and the construction method thereof, sea sand does not need to be subjected to desalting treatment, the strength is high, and the bearing property is good.

Owner:GUANGDONG UNIV OF TECH

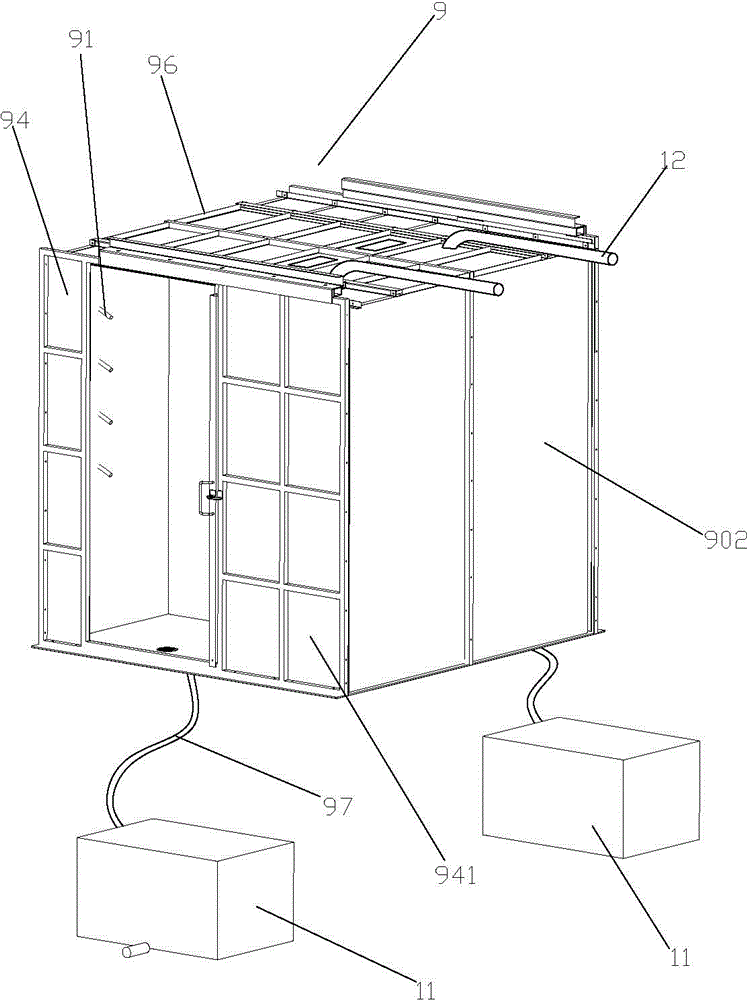

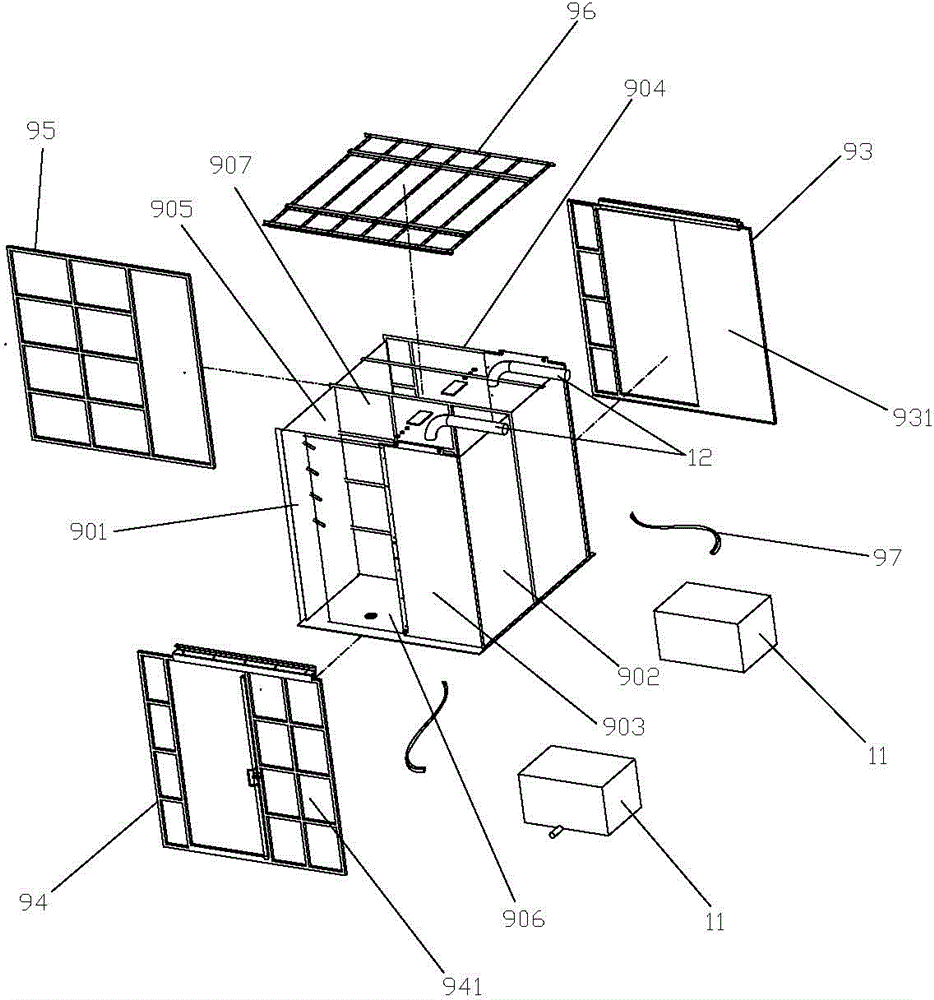

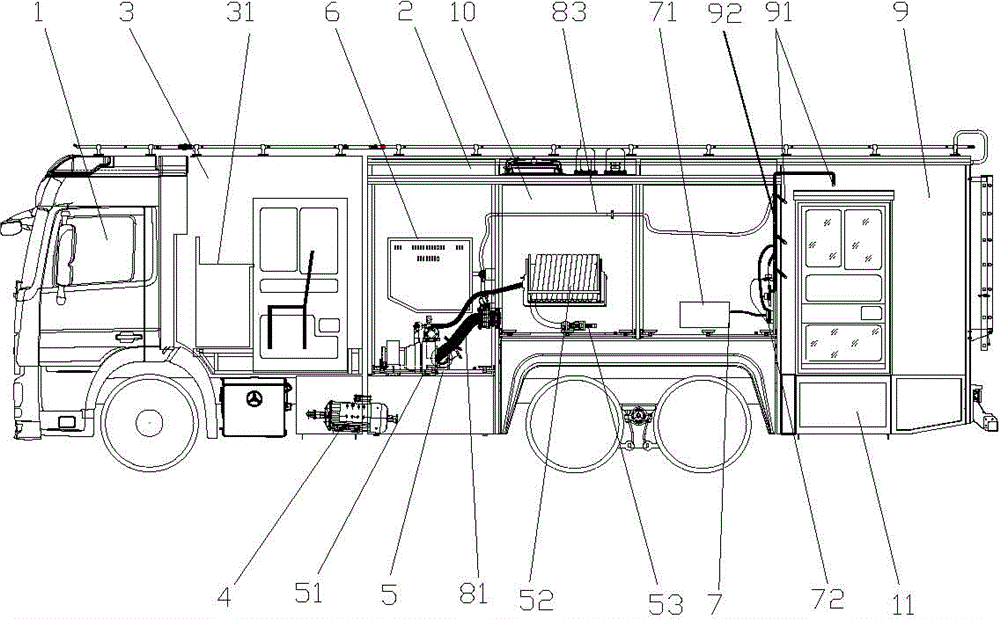

Fire-fighting truck chemical washing chamber and fire-fighting truck

InactiveCN104826258ASimple processing and assembly processReduce weightFire rescueTruckAutomotive engineering

The invention relates to the technical field of fire-fighting truck, and especially relates to a fire-fighting truck chemical washing chamber and a fire-fighting truck. The fire-fighting truck comprises a driver cab and a carriage; a power supply device, a washing device, and a chemical washing chamber are arranged in the carriage; the washing device comprises a water storage tank, a washing heating machine, a neutralizing liquid device for chemical washing, and a washing pipeline system; the washing heating machine is communicated with the water storage tank, the neutralizing liquid device and the chemical washing chamber through the washing pipeline system; the chemical washing chamber comprises a washing chamber skeleton assembly, a front sealing plate and a rear sealing plate, which are arranged oppositely, a left sealing plate and a right sealing plate, which are arranged oppositely, a top plate and a bottom plate, which are arranged oppositely, and a middle partition plate. Compared with the prior art, the provided fire-fighting truck has a plurality of functions such as indoor / outdoor washing, cold / hot water supplying, electricity supplying, and the like, and has the advantages of high washing efficiency, convenient operation, safety, and reliability.

Owner:GUANGDONG YONGQIANG ALB INT FIRE FIGHTING ENGINE

Titanium alloy and application of titanium alloy to machining of train connecting piece

The invention discloses a titanium alloy. The titanium alloy comprises the following components by weight percentage: 3.8-4.8% of Al, 2.0-3.2% of V, 0.7-1.7% of Fe, 0.2-0.3% of O and the balance of Ti. Machining steps are as follows: step (1), heating a titanium alloy ingot in a temperature range of 100-150 DEG C above a phase transformation point, controlling the final forging temperature in a range of 900 DEG C + / -20 DEG C, performing cogging forging, and controlling rolling reduction at every time within 10-25 mm; step (2), heating in a temperature range of the phase transformation point + / - 20 DEG C, performing upsetting and drawing forging, and controlling the final forging temperature in a range of 850 DEG C + / -20 DEG C and the rolling reduction not to excess 30%of the length; step (3), heating at 30-50 DEG C below the phase transformation point, performing finished-product forging, controlling deformation to be about 60%, and performing heat treatment after the finished-product forging; step (4), performing vacuum annealing as the heat treatment, controlling the annealing temperature to be in a range of about 150 DEG C within the phase transformation point, controlling the temperature changeless to be 60-90 min, and performing air cooling. The titanium alloy is applied to manufacturing of a drive pin, a connecting rod, a motor suspending lever and a fastening of a train or a motor car; weight losing and corrosion resisting effects are achieved.

Owner:沈阳泰恒通用技术有限公司

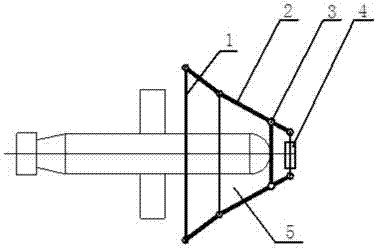

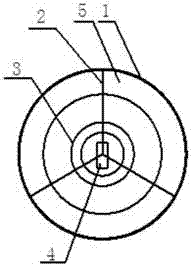

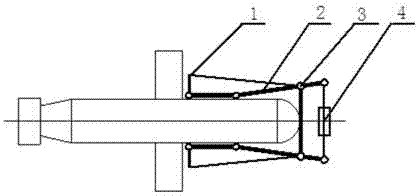

Underwater automatic catcher for light self-propulsion body

InactiveCN103496441AReduce volumeGood structural modularityVessel salvagingUnderwater equipmentSeawaterCorrosion

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Preparation process of MAME (methyl 3-methoxyacrylate)

InactiveCN107879936AHigh yieldLong-term recyclingOrganic compound preparationCarboxylic acid esters preparationIndiumDistillation

The invention provides a preparation process of MAME (methyl 3-methoxyacrylate) and belongs to the technical field of synthesis of organic compounds. According to the preparation process, methyl acrylate and excess methanol taken as starting raw materials are subjected to an addition-etherification reaction in an oxygen atmosphere under the action of a synthetic catalyst, a product is subjected tofiltration and extraction, methyl 3,3-dimethoxypropionate is obtained and subjected to a catalytic cracking reaction, MAME and methanol are generated, the target product MAME is obtained through distillation, and methanol is recovered, wherein the synthetic catalyst is cobalt oxide, indium oxide or a mixture of cobalt oxide and indium oxide in any proportion. The preparation process is simple andefficient, the yield of the product MAME is higher and reaches 78%-82.4%, the catalyst can be recycled for a long time, corrosive and toxic substances are avoided, reaction equipment cannot be corroded, industrial production can be realized, and considerable economic benefits are created.

Owner:淄博齐塑环保科技有限公司

Hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam

InactiveCN107217786AGood ductilityImprove comprehensive mechanical propertiesGirdersJoistsRebarBasalt fiber

The invention discloses a hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam, which comprises sea sand concrete, and a plurality of upper composite bars, a plurality of lower composite bars and a plurality of hoops fixedly arranged in the sea sand concrete. The hoops are uniformly fixed and tied on the outer surfaces of the upper composite bars and the lower composite bars along length directions of the upper composite bars and the lower composite bars; the upper composite bars and the lower composite bars are respectively arranged on the upper end and the lower end of the bar sand concrete, and comprise reinforcing steel bars and FRP fiber cloth coating the outer surfaces of the reinforcing steel bars; the FRP fiber cloth of each upper composite bar is made of the same material or different materials; the FRP fiber cloth of the plurality of lower composite bars adopts at least two materials; the FRP fiber cloth is adhered with the sea sand concrete; the FRP fiber cloth of the lower composite bars comprises at least two of carbon fiber cloth, glass fiber cloth, basalt fiber cloth and aramid fiber cloth. The hybrid FRP-steel composite bar sea sand concrete beam provided by the invention has no need to desalt sea sand, and has good strength and a bearing performance.

Owner:GUANGDONG UNIV OF TECH

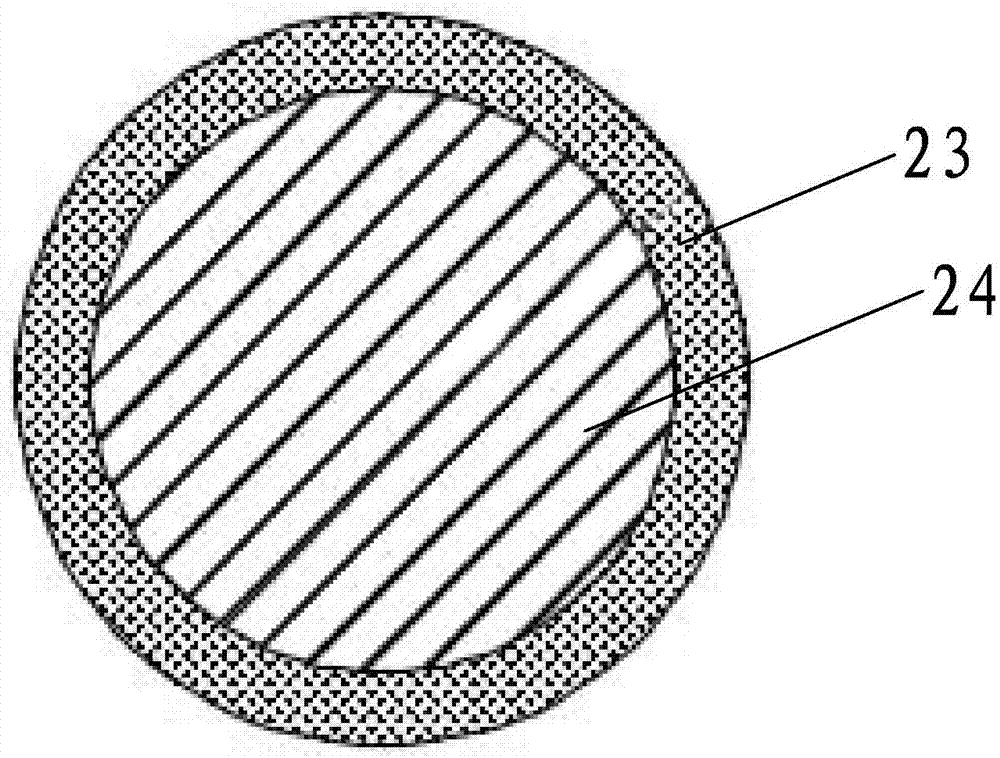

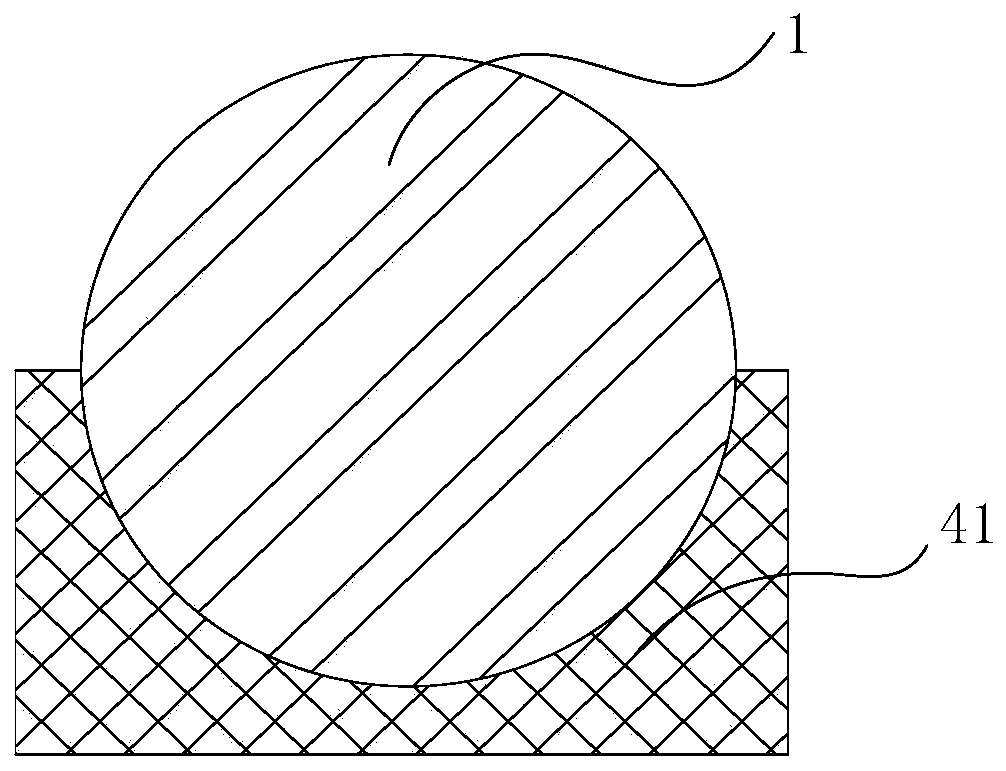

Pipe clamping device

InactiveCN109899596ACorrosion will notImprove connection strengthPipe supportsCorrosion preventionHydraulic pumpEngineering

The invention discloses a pipe clamping device. The pipe clamping device is used for fixing hydraulic pipes, and comprises a clamping ring and a support piece; the clamping ring sleeves the hydraulicpipes; the support piece is connected to a ship structure; the clamping ring is detachably connected to the support piece; an accommodating hole for enabling the hydraulic pipes to penetrate through is formed between the clamping ring and the support piece; and the clamping ring and the support piece both adopt metal materials. The pipe clamping device is used for fixing the hydraulic pipes, adopts the corrosion-resistance metal materials for main parts, achieves high connecting strength and excellent water permeability, cannot corrode the hydraulic pipes, and prolongs the service life of thehydraulic pipes.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

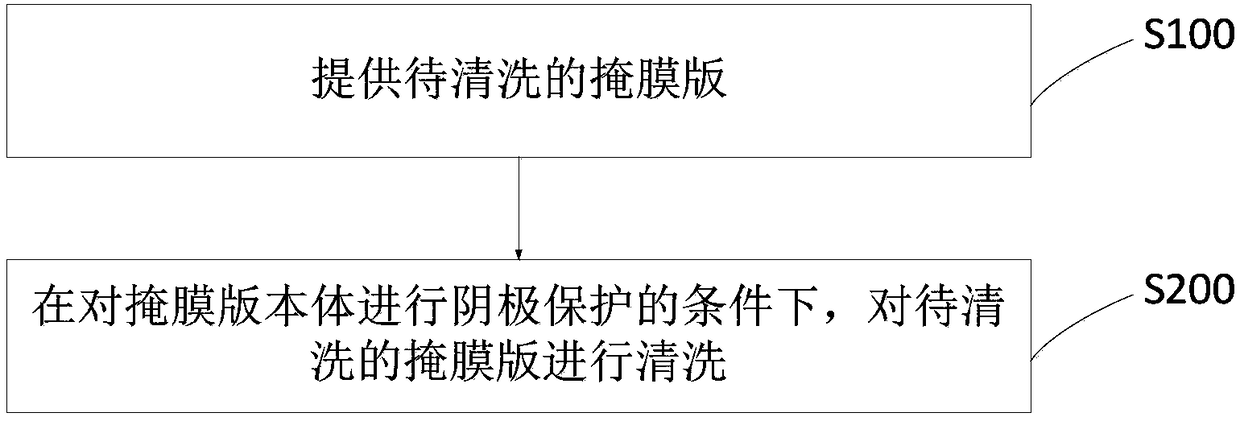

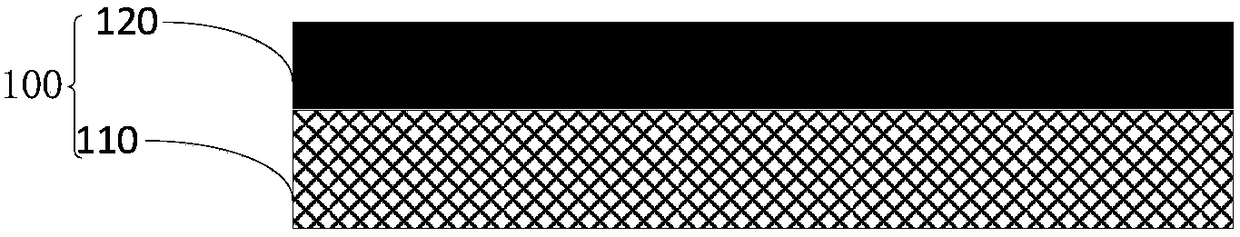

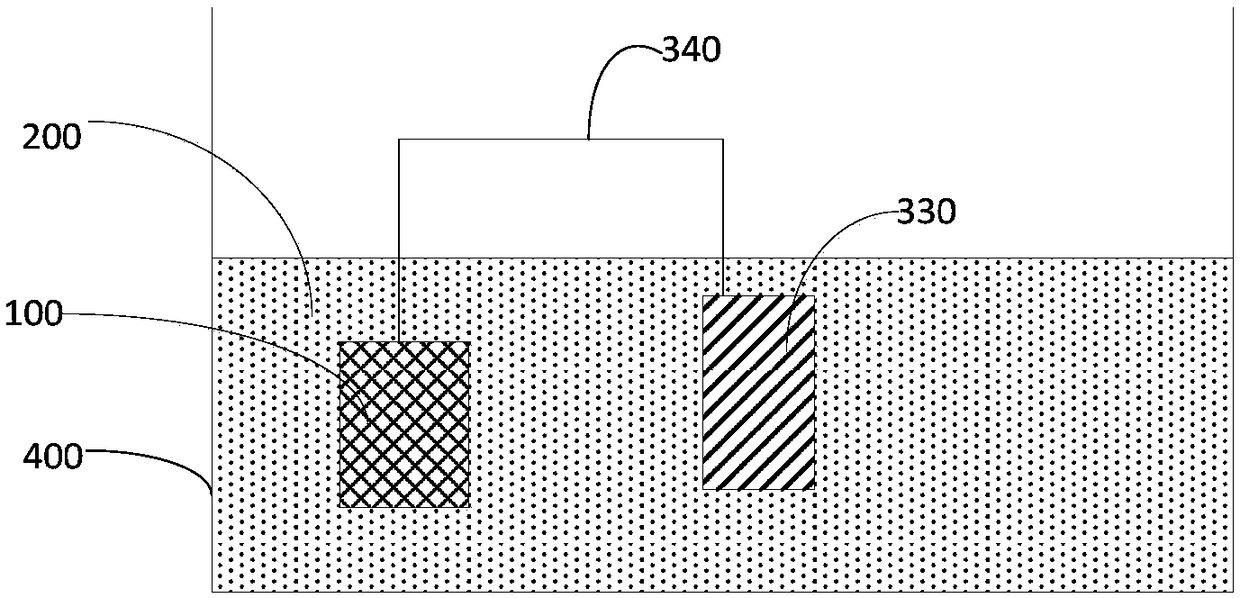

Mask cleaning method and device

ActiveCN108611599ASo as not to damageEasy to operateVacuum evaporation coatingSputtering coatingCleaning methodsEngineering

The invention provides a mask cleaning method and device, wherein the mask cleaning method comprises: providing a mask to be washed, wherein the mask to be washed includes a mask body and a metal to be washed, and the metal to be washed is formed on at least part of the surface of the mask body; cleaning the mask to be washed while the mask body is under cathode protection. It is discovered by theinventor herein that the method is simple and convenient to perform and is easy to implement; a selection range of detergents is wide, cleaning cost is low, cleaning efficiency is high, at least partof the metal to be washed is recyclable, and economic and time costs are saved.

Owner:BOE TECH GRP CO LTD +1

Grinding material for precision casting

ActiveCN1325566CHigh drop melting pointImprove heat resistanceFoundry moulding apparatusMINERAL WAXCasting mold

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of lithium ion battery anode material

InactiveCN106299327ALow costImprove electronic conductivityCell electrodesSecondary cellsHuskPhysical chemistry

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a lithium ion battery anode material. The lithium ion battery anode material comprises a core layer and a shell layer coated outside the core layer, the core layer is SiOx, and the shell layer is carbon, wherein x is more than 0.5 and less than 2. The preparation method at least includes following steps: placing rice husk in a high-temperature furnace; rising temperature to 300-1200 DEG C at a speed of 10-50 DEG C / min in an inert gas atmosphere; calcining for 10s-30min; naturally cooling; using an acid solution to clean; using a solvent to clean; air-drying to obtain the anode material. Compared with the prior art, the anode material prepared by the method has the advantages of high initial coulomb efficiency, good circulating performance and low volume expansion.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Storage method of copper artware

The invention discloses a storage method of copper artware. The storage method comprises the following steps: (I) soaking copper artware in a silver oxide solution so that a silver oxide film is attached to the surface of the copper artware; (II) wrapping the surface of the copper artware with cotton cloth; and (III) putting the cotton cloth wrapped copper artware in a dry space while keeping the humidity of the dry space below 50%. By adopting the storage method, the copper artware can be protected from the corrosion of impurities in air so as to prolong the storage time.

Owner:铜陵铜官府文化创意股份公司

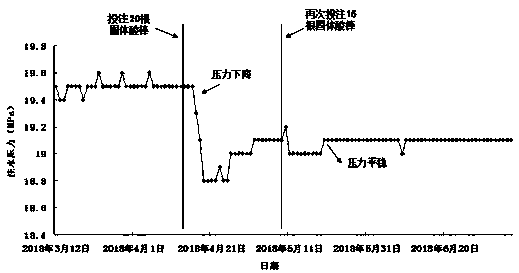

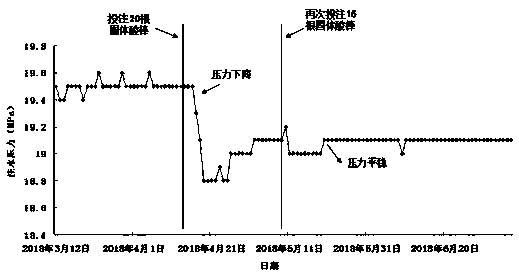

Solid acid rod for water injection well and preparation and injection methods of solid acid rod

ActiveCN110028946AGood corrosion inhibition effectImprove acidification effectFluid removalDrilling compositionSolid acidEthyl acetate

The invention discloses a solid acid rod for a water injection well as well as preparation and injection methods of the solid acid rod. The solid acid rod is prepared from 25%-35% of maleic acid-acrylic acid copolymer, 10%-20% of ethyl acetate, 10%-18% of water-soluble imidazoline oleate corrosion inhibitor, 5%-12% of sodium alpha-olefin sulfonate, 20%-30% of diethylenetriaminepentaacetic acid iron(III) diammonium and 5%-15% of polyvinyl acetate emulsion. The appearance of the solid acid rod is cylindrical.

Owner:PETROCHINA CO LTD

Copper stripping solution of permeability alloy and method for recycling permeability alloy

The invention discloses a copper stripping solution of a copper plating permeability alloy and a method for recycling the permeability alloy, and belongs to the technical field of alloy recycling. The method comprises the following steps that the copper stripping solution of the permeability alloy is prepared in proportion, the copper plating permeability alloy is soaked in the copper stripping solution, temperature control reacting is achieved, and meanwhile the content of concentrated nitric acid in the copper stripping solution is controlled; and after reacting is finished, saturated lime water is used for washing the surface of the permeability alloy, and drying and storing are achieved. According to the method, the copper plating permeability alloy is fast and effectively recycled.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com